Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

1 viewsRoder Pump Rebuild

Roder Pump Rebuild

Uploaded by

Chris CoffinCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- MPM TroubleshootingDocument34 pagesMPM TroubleshootingMustafaNo ratings yet

- D PDFDocument49 pagesD PDFFordi100% (1)

- Bosch Diesel Injection Pump RebuildDocument26 pagesBosch Diesel Injection Pump Rebuildjoana13r100% (3)

- Service Excellence ManualDocument192 pagesService Excellence ManualAndrés Tomás Couvlaert SilvaNo ratings yet

- TM-517 AOI Piston Separator ManualDocument32 pagesTM-517 AOI Piston Separator ManualAndi Yusuf50% (2)

- Cinderella by Roald DahlDocument5 pagesCinderella by Roald DahlRaquel Gonzalez33% (3)

- List of Documents NBA PfilesDocument48 pagesList of Documents NBA PfilesDr. A. Pathanjali Sastri100% (1)

- Ati Manual Reverse Valve BodyDocument4 pagesAti Manual Reverse Valve BodyPaul OfsthunNo ratings yet

- Fuel NozzleDocument27 pagesFuel NozzleJean P. MuñozNo ratings yet

- 700R4 Manual Reverse Valve Body: Installation InstructionsDocument4 pages700R4 Manual Reverse Valve Body: Installation InstructionsAbbode HoraniNo ratings yet

- Cylinder Head: Section 12 - Base EngineDocument1 pageCylinder Head: Section 12 - Base EngineAli ZerifiNo ratings yet

- Valvula DireccionDocument8 pagesValvula DireccionVictor Manuel Lozada ObessoNo ratings yet

- 07 2984BDocument22 pages07 2984BCHARLES HUMBERTO0% (1)

- Service Manual: DaihatsuDocument7 pagesService Manual: DaihatsuMateoNo ratings yet

- 8.3 Maintenance of The Pilot ValveDocument2 pages8.3 Maintenance of The Pilot Valvealang_businessNo ratings yet

- Datex Ohmeda Modulus II W 7810 Ventilator Maintenance ProceduresDocument38 pagesDatex Ohmeda Modulus II W 7810 Ventilator Maintenance ProceduresgimenNo ratings yet

- Service Manual Trucks vn770Document16 pagesService Manual Trucks vn770Neojai jaiyuNo ratings yet

- Lab Module 01 Maintenance & Troubleshoot Centrifugal PumpDocument12 pagesLab Module 01 Maintenance & Troubleshoot Centrifugal Pumpazroy06No ratings yet

- Section 9A - Power-Assisted Steering Pump and Related ComponentsDocument14 pagesSection 9A - Power-Assisted Steering Pump and Related ComponentsJorge SoberanoNo ratings yet

- Regulating Feed Water Valve: Control Valves, Type 470/471Document28 pagesRegulating Feed Water Valve: Control Valves, Type 470/471Alexander BaziotisNo ratings yet

- KER TB16V Timing Belt Sidekick 1.6L 16 ValveDocument18 pagesKER TB16V Timing Belt Sidekick 1.6L 16 ValveMatthew BurkhalterNo ratings yet

- Tier 4 I E E A I Manual C4.4 To C 7.1 Industrial Products TPD1726E1Document29 pagesTier 4 I E E A I Manual C4.4 To C 7.1 Industrial Products TPD1726E1EduardoCastilloNo ratings yet

- MERCUR d28l - DtronicDocument8 pagesMERCUR d28l - DtronicAtakan ArıkoğluNo ratings yet

- 1001 12 PDFDocument26 pages1001 12 PDFTuấn NeoNo ratings yet

- MC99759 8b110brakeDocument18 pagesMC99759 8b110brakeANGELES NIETONo ratings yet

- Service Training Parker PV Series 42Document39 pagesService Training Parker PV Series 42Javier PeñaNo ratings yet

- 43210-0001 Jabsco PumpDocument5 pages43210-0001 Jabsco PumpRon CooperNo ratings yet

- carter-yf-manualDocument34 pagescarter-yf-manualgpavmanNo ratings yet

- Iom Biffi Morin Series A B C S en en Us 6089118Document37 pagesIom Biffi Morin Series A B C S en en Us 6089118Anonymous Wu6FDjbNo ratings yet

- Rotary Vane Service Manual Shafer en 83Document20 pagesRotary Vane Service Manual Shafer en 83pabloNo ratings yet

- SB 388Document13 pagesSB 388oscarNo ratings yet

- BB-4-18/23 Quick Guide: Warnings and Safety PrecautionsDocument4 pagesBB-4-18/23 Quick Guide: Warnings and Safety PrecautionsWalter Dario LopezNo ratings yet

- UntitledDocument44 pagesUntitledEdwinferNo ratings yet

- Vciom 06062 enDocument4 pagesVciom 06062 enJoeNo ratings yet

- Series 4280: Motor Mounted Horizontal End Suction Pump Service Work InstructionsDocument4 pagesSeries 4280: Motor Mounted Horizontal End Suction Pump Service Work InstructionsvimalmailbookNo ratings yet

- Instruction Manual For 2way & 3way Cylinder Valve: Section TitleDocument10 pagesInstruction Manual For 2way & 3way Cylinder Valve: Section TitleFlo MarineNo ratings yet

- Technical Service Manual: Installation, Start Up, Troubleshooting, Preventative Maintenance, Do'S & Don'TsDocument8 pagesTechnical Service Manual: Installation, Start Up, Troubleshooting, Preventative Maintenance, Do'S & Don'Tsroyert80No ratings yet

- 061 600seriesvalvesDocument4 pages061 600seriesvalvesnflzhang1981No ratings yet

- Z8 (CF800) Service Manual 2013 (057-211) (037-150)Document114 pagesZ8 (CF800) Service Manual 2013 (057-211) (037-150)francisco jose ramirez perezNo ratings yet

- Jabsco Marine Engine Water Cooling PumpDocument4 pagesJabsco Marine Engine Water Cooling PumpRendy Adam FarhanNo ratings yet

- Chapter 9. VAZ-21213 Vehicle Modifications, Alternative and Additional EquipmentDocument27 pagesChapter 9. VAZ-21213 Vehicle Modifications, Alternative and Additional EquipmentSergio PazNo ratings yet

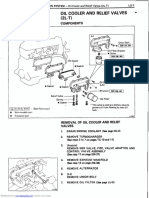

- !3imzy: Oil Cooler and Relief ValvesDocument6 pages!3imzy: Oil Cooler and Relief ValvesDavid QuispeNo ratings yet

- Enerpac P-392 Service InstructionsDocument8 pagesEnerpac P-392 Service InstructionsSergio ReyesNo ratings yet

- Edward Vacuum Pump Rebuild Guide: July 2019Document41 pagesEdward Vacuum Pump Rebuild Guide: July 2019Srikanth GedelaNo ratings yet

- BandasDocument116 pagesBandasJhon GuerraNo ratings yet

- Al Self Priming PumpDocument15 pagesAl Self Priming PumpHalley ElangovanNo ratings yet

- Maintenance and Repair of Centrifugal PumpsDocument3 pagesMaintenance and Repair of Centrifugal PumpsRohan NaikNo ratings yet

- 376000Document6 pages376000Abbode HoraniNo ratings yet

- KIKAWA Manual kp8 enDocument4 pagesKIKAWA Manual kp8 enRamesh KrishmedaNo ratings yet

- N2 Triplex Pump-MaintenanceDocument14 pagesN2 Triplex Pump-MaintenanceIbrahim Ahmed100% (1)

- SM01 010 033.00 PDFDocument4 pagesSM01 010 033.00 PDFMohamed RashedNo ratings yet

- Service Manual SM1-10-33.0: Outrigger/Steer Pump, R & IDocument4 pagesService Manual SM1-10-33.0: Outrigger/Steer Pump, R & IMohamed RashedNo ratings yet

- Exhaust Valve Actuator: S35MC DataDocument6 pagesExhaust Valve Actuator: S35MC DatalijinNo ratings yet

- P250-250S Cap 10 (A.C. GENERATOR)Document10 pagesP250-250S Cap 10 (A.C. GENERATOR)Minh ChuNo ratings yet

- PDFDocument60 pagesPDFAdolfo Moscoso100% (1)

- Log Splitter Hydraulic TroubleshootingDocument13 pagesLog Splitter Hydraulic TroubleshootingTim MckennaNo ratings yet

- Graco GM3000 Clutch Kit 308657EN-ADocument4 pagesGraco GM3000 Clutch Kit 308657EN-AjjmokieNo ratings yet

- Floating Ball Valve - 8100R21Document12 pagesFloating Ball Valve - 8100R21demblavalvesltd1989No ratings yet

- Service Buletin 07-2965DDocument29 pagesService Buletin 07-2965DAgustinus KNo ratings yet

- Manual Bomba PVX EatonDocument26 pagesManual Bomba PVX EatonLeopoldo WilleNo ratings yet

- BALEROSDocument17 pagesBALEROSjulio cesarNo ratings yet

- Manual Transmission/Transaxle - Transmission: RemovalDocument30 pagesManual Transmission/Transaxle - Transmission: RemovalJim LiebNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Index: Monthly Bulletin-Dec 2022Document46 pagesIndex: Monthly Bulletin-Dec 2022Sanif KhanNo ratings yet

- William Angelo - Week-7.AssessmentDocument2 pagesWilliam Angelo - Week-7.Assessmentsup shawtyNo ratings yet

- Belgian Carrier PigeonDocument145 pagesBelgian Carrier PigeonstepathcNo ratings yet

- Direct BriberyDocument4 pagesDirect Briberyjuillien isiderioNo ratings yet

- Group 2 Hydraulic and Mechanical SystemDocument20 pagesGroup 2 Hydraulic and Mechanical SystemMarcelino chiritoNo ratings yet

- Gravitational Force WSDocument2 pagesGravitational Force WSSatria HalimNo ratings yet

- Study of Blood Groups and Rhesus Factor in Beta Thalassemia Patients Undergoing Blood TransfusionsDocument6 pagesStudy of Blood Groups and Rhesus Factor in Beta Thalassemia Patients Undergoing Blood TransfusionsOpenaccess Research paperNo ratings yet

- R30 CFA Level 3Document19 pagesR30 CFA Level 3Ashna0188No ratings yet

- Year3 GL Style Maths Practice Paper PrintableDocument4 pagesYear3 GL Style Maths Practice Paper PrintableLolo ImgNo ratings yet

- A Biblical Philosophy of MinistryDocument11 pagesA Biblical Philosophy of MinistryDavid Salazar100% (4)

- Comprehension Toolkit 1Document3 pagesComprehension Toolkit 1api-510893209No ratings yet

- The Quiescent Benefits and Drawbacks of Coffee IntakeDocument6 pagesThe Quiescent Benefits and Drawbacks of Coffee IntakeVikram Singh ChauhanNo ratings yet

- PYF Biennial Conference Vawi 19-NaDocument1 pagePYF Biennial Conference Vawi 19-NaMizoram Presbyterian Church SynodNo ratings yet

- NT Organic FarmingDocument17 pagesNT Organic FarmingSai Punith Reddy100% (1)

- Minimal Stimulation IVF Vs Conventional IVFDocument8 pagesMinimal Stimulation IVF Vs Conventional IVFpolygoneNo ratings yet

- Teacher Learning Walk Templates - 2017 - 1Document13 pagesTeacher Learning Walk Templates - 2017 - 1Zakaria Md SaadNo ratings yet

- The Secret Book of JamesDocument17 pagesThe Secret Book of JameslaniNo ratings yet

- Emcee Script For Kindergarten Recognition (English) - 085301Document3 pagesEmcee Script For Kindergarten Recognition (English) - 085301Felinda ConopioNo ratings yet

- HABASIT 04 Guía Ingeniería HabasitLINKDocument100 pagesHABASIT 04 Guía Ingeniería HabasitLINKKyriakos MichalakiNo ratings yet

- Consultancy - Software DeveloperDocument2 pagesConsultancy - Software DeveloperImadeddinNo ratings yet

- Schedule CDocument273 pagesSchedule CAzi PaybarahNo ratings yet

- Staying in God's PresenceDocument3 pagesStaying in God's PresenceElmer Dela TorreNo ratings yet

- Birinci Pozisyon Notalar Ve IsimleriDocument3 pagesBirinci Pozisyon Notalar Ve IsimleriEmre KözNo ratings yet

- Annual Return For A Company Limited by GuaranteeDocument4 pagesAnnual Return For A Company Limited by GuaranteeAtisang Tonny SethNo ratings yet

- OutDocument318 pagesOutBet HalNo ratings yet

- Government of Karnataka: Only For Birth Verification PurposeDocument1 pageGovernment of Karnataka: Only For Birth Verification PurposeAmit VantagodiNo ratings yet

Roder Pump Rebuild

Roder Pump Rebuild

Uploaded by

Chris Coffin0 ratings0% found this document useful (0 votes)

1 views76 pagesOriginal Title

RODER PUMP REBUILD

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

1 views76 pagesRoder Pump Rebuild

Roder Pump Rebuild

Uploaded by

Chris CoffinCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 76

Vactor Rodder Pump Rebuild Guide

Maintenance

NOTICE

Follow recommended safety practices

while performing all work. Refer to the

Vactor/Guzzler Safety Manual for additional

information.

This manual is available at: www.vactor.com

Effective Date February 17, 2011 1 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Contents Maintenance

Getting Started. ...................................................................................................3

Remove the Pump...................................................................................................4

Compensator Block...............................................................................................5

Truss Rods............................................................................................................8

Oil End Block......................................................................................................10

Water End Block. ............................................................................................... 11

Sensing Rod.........................................................................................................12

End Block Inspection..........................................................................................13

Remove Barrels. .................................................................................................14

Pistons.................................................................................................................18

Center Block.......................................................................................................24

Center Block.......................................................................................................25

Center Block Seal..............................................................................................26

• • • • • • • • • • • Reassembly • • • • • • • • • • • .....................................................27

Center Block.......................................................................................................27

Center Block.......................................................................................................28

Center Block.......................................................................................................29

Shaft....................................................................................................................30

Piston Heads. ......................................................................................................34

Shaft Piston End Seals......................................................................................38

Attach Piston Heads...........................................................................................40

Prepare to Attach Barrels.................................................................................51

Attach Barrels....................................................................................................53

Sensing Rod & Yoke............................................................................................58

Attach End Blocks..............................................................................................60

Attach Truss Rods..............................................................................................66

Attach Detent Block...........................................................................................70

Attach Compensator Block. ...............................................................................73

Install Check Valves...........................................................................................74

Install Check Manifolds. ....................................................................................75

Finishing Up. ........................................................................................................76

Effective Date February 17, 2011 2 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Getting Started Maintenance

A. 53592-30 seal compressor

Tools needed to rebuild the rodder pump

B. 55670-30 piston rod guide

C. 55689-30 spanner wrench

D. 86716-30 barrel remover tool

D

E. 86721-30 barrel pusher tool

All of these tools and a detailed

explanation of each can be found

E in the Vactor / Guzzler Parts and

Accessories catalog.

Effective Date February 17, 2011 3 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Remove the Pump Maintenance

Remove the bumper and hydraulic

connections.

Remember, your going to loose

hydraulic oil once you disconnect the

hydraulic lines.

Remove the pump from the Vactor.

Place on a good work bench or table.

Unbolt the high and low pressure

manifold blocks. Note the direction of

the check valves. They are different.

Remove the hydraulic hose from the

end of the pump and the detent block.

Effective Date February 17, 2011 4 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Compensator Block Maintenance

Remove the compensator block from

the detent block. Remove the detent

block and sensor.

Install an old style detent block to

support the sensing rod shaft and

piston.

Remove the locking pin from the

sensing rod and piston.

Effective Date February 17, 2011 5 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Compensator Block Maintenance

Be careful not to lose the roll pin as you

may have to reuse it.

Hold the sensing rod with a screw driver

as shown and screw the piston off of the

shaft.

You may have to clean up the threads in

order to unscrew the piston.

Effective Date February 17, 2011 6 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Compensator Block Maintenance

Remove the piston.

Once the piston has been removed

remove the detent block.

Remember to keep the old style

detent block handy. You will need it to

reassemble the pump.

Effective Date February 17, 2011 7 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Truss Rods Maintenance

Cover the check valve holes to prevent

anything from getting into the pump and

creating any more damage.

Remove the truss rod nuts from the

water end of the pump.

Always remove the water end first.

It does not matter what order you

remove the nuts.

Effective Date February 17, 2011 8 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Truss Rods Maintenance

Remove the nut plates once the nuts

have been removed. Set the nut plates

aside as they can be reused.

Be sure to clean the nut plates of any

dirt, grease or grime before reusing

them.

Remove the truss rods from the oil end.

Don’t worry about having to remove the

nuts from the oil end.

Effective Date February 17, 2011 9 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Oil End Block Maintenance

Loosen the oil end block from the end of

the pump before removing all of the truss

rods. Be aware of the oil leakage once

the end block seal is broken.

Allow the oil to drain from the oil side

barrel.

Inspect the check valve O-ring groove

in the center block and the water end

block. The o-ring groove may need to be

remachined if corrosion has eaten into the

groove surface.

Effective Date February 17, 2011 10 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Water End Block Maintenance

Remove the water end block and inspect

the o-ring groove surface. Remachine

any end block where corrosion has eaten

into the o-ring surface.

Remove the oil end block. Be careful not

to damage the sensing rod. The seal in

the end block will need to be replaced

after the pump is reassembled.

Remove the sensing rod yoke.

This can also be done using a standard

wrench.

Effective Date February 17, 2011 11 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Sensing Rod Maintenance

Inspect the sensing rod yoke for wear.

Replace any sensing rod yoke that

shows wear in the center hole for the

sensing rod.

Only the yoke on the right should

be considered for reuse. The middle

one and the one on the left should be

replaced. Failure to replace a worn or

damaged yoke can cause damage to

the sensing rod.

Check the sensing rod for any damage.

Replace any damaged sensing rod.

Effective Date February 17, 2011 12 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

End Block Inspection Maintenance

Carefully inspect the end block.

Some corrosion is normal. The key is to

insure there is no damage to the O-ring

groove.

Also inspect the check valve o-ring

groove for any damage.

Remachine any end block that shows

corrosion into the o-ring surface.

Shown is a special tool part number

86716-30 barrel remover tool. This tool

clamps onto the barrel and is used to

pull the barrel over the seals.

Effective Date February 17, 2011 13 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Remove Barrels Maintenance

Clamp the barrel remover to the barrel

Remove the barrel. Note: there will

usually be oil inside the oil barrel when

the barrel seal is broken.

Effective Date February 17, 2011 14 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Remove Barrels Maintenance

Pull the barrel all the way off or over

the piston.

Get ready to support the barrel as it

comes over the piston.

Support the barrel once it is over the

piston and seals.

Effective Date February 17, 2011 15 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Remove Barrels Maintenance

Inspect the piston and barrel for any

damage. Replace any damaged barrel

or piston.

Repeat the procedure for the water

barrel.

Get ready to support the barrel as it

comes over the piston.

Effective Date February 17, 2011 16 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Remove Barrels Maintenance

Support the barrel as it clears the

piston and seals.

Inspect the water barrel and piston for

any damage. Replace any damaged

barrel or piston.

Be sure to identify any oil barrel or

water barrel that is to be reused.

They are different and cannot be

interchanged.

Effective Date February 17, 2011 17 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Pistons Maintenance

Inspect the truss rods. Replace any

damaged truss rod.

Remove the locking screw from the

piston and shaft.

Remove the locking screw from the

other end.

Note: do not mix up the locking

set screws. The water end is

stainless steel. The oil end is

regular steel.

Effective Date February 17, 2011 18 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Pistons Maintenance

Check the o-ring groove on the center

block. Replace or remachine any center

block that has a damaged or corroded

o-ring groove.

Using the special spanner wrench part

number 55689 to remove the water

piston from the shaft.

You may need to use a hammer or

mallet to loosen the piston.

Hold the spanner wrench securely while

someone hits the end of the spanner

wrench.

Keep hands and

! CAUTION fingers away from

the end of the

spanner wrench that

is to be hit.

Effective Date February 17, 2011 19 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Pistons Maintenance

Do the same thing on the other or oil

end.

Inspect the drain plug hole in the center

block for wear or corrosion. Repair any

damaged drain plug hole.

Note: This may be an opportune time

to replace the drain plug with a

remote drain system when the

reassembly is complete. See the

Retrofit Manual for the remote

drain (ball valve drain) system.

Remove the old seal(s) from the

piston(s). It’s easier to do this with the

piston still on the shaft as shown.

Effective Date February 17, 2011 20 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Pistons Maintenance

Use a screw driver or punch to get

under the seal and raise it where it can

be cut with a knife or side cutters as

shown.

Do the same with the other seal(s).

Now remove the piston from the shaft.

Effective Date February 17, 2011 21 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Pistons Maintenance

Support the piston as it comes off of

the shaft.

Carefully inspect the shaft for any

damage. Note: the multiple locking set

screw holes in the shaft. This indicates

this pump has been rebuilt at least

twice.

You may have to press or push the

shaft through the center block. In

this case we installed a lifting eye to

protect the threads.

Effective Date February 17, 2011 22 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Pistons Maintenance

Remove the shaft from the center block.

Note that is a leather mallet being used

not a sledge hammer. Be careful not to

damage the threads.

Support the shaft during the removal

process.

Remove the seal keeper from the

center block. There is one on each side.

Do not throw the bolts and washers

away. They are stainless steel and can

be reused. If new bolts and washers

are required, make sure they are

stainless steel.

Effective Date February 17, 2011 23 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Center Block Maintenance

Note the corrosion on the seal keeper.

This is not uncommon.

Also inspect the o-ring groove for

any damage or corrison. Be sure to

remachine any o-ring groove that is

damaged. Failure to do so can cause

the o-ring to leak when reassembled.

Inspect the o-ring groove on both sides

of the center block.

Check the seal keeper for any damage.

Effective Date February 17, 2011 24 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Center Block Maintenance

The seal and keeper are knocked out

using a punch or screw driver from the

opposite side of the center block.

Do the same thing to the other seal and

keeper. Inspect the seal surface in the

center block.

Check to make sure there is no groove

in the center block caused by the old

seal. If there is any kind of a groove the

center block should be sleeved.

Sleeving can be done at the factory

or any good machine shop. Failure to

sleeve the center block to remove any

groove can cause the new seal to leak

when the pump is reassembled. If after

assembly, water or oil leaks out of the

weep hole in the center block it is a

good indication the center block should

have been sleeved.

Effective Date February 17, 2011 25 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Center Block Seal Maintenance

Be sure to clean up the seal keeper

prior to assembly.

Replace any seal keeper that shows

excessive corrosion or damage.

Inspect the seal area. The seal area

must be smooth. Don’t try to sand

out any grooves. If there are grooves

machine them out and sleeve the

center block. This can be done at

Vactor if you don’t have a local facility.

Remember if it leaks out of the weep

hole, it should have been sleeved.

Effective Date February 17, 2011 26 Rodder Pump Rebuild_r0

• • • • • • • • • • • Reassembly • • • • • • • • • • •

Vactor Rodder Pump Rebuild Guide

Center Block Maintenance

Use all new seals and replace any

component that is damaged or worn.

It will save you having to rebuild the

pump prematurely.

Start with the center block.

New seals and maybe new keepers.

Remember the keepers are held in

place with stainless steel bolts and

lock washers. Don’t use standard or

non stainless steel bolts and washers.

They can rust away eventually causing

damage to the pump.

Effective Date February 17, 2011 27 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Center Block Maintenance

Double check the sealing surface.

Remachine or sleeve any center

block that shows wear. It will save you

problems later on.

Use a wooden block or hammer

handle to tap the seal into position.

Wood is less likely to damage the

center block or seal. Pay close

attention to which way your putting it

in. The lip or o-ring side of the seal

faces outward or toward you.

Tap the seal keeper into position.

Line the bolt holes up.

Effective Date February 17, 2011 28 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Center Block Maintenance

Use Loctite medium strength or

equivalent on each bolt to prevent it from

accidentally backing out once the pump

is assembled.

Insert the stainless steel bolts, lock

washers and draw up snuggly.

Remember these are 1/4 inch bolts so

don’t over torque.

NOTE: Bolts and lock washers must be

stainless steel. Do Not substitute.

Do the same thing to the other side of

the center block.

Effective Date February 17, 2011 29 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Shaft Maintenance

Next, clean and lubricate the pump

shaft, making sure the threads on both

ends are clean and well lubricated.

Clean the threads on the oil end for the

yoke.

Clean the threads for the piston.

Effective Date February 17, 2011 30 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Shaft Maintenance

Install the thread protector or bullet tool

part number 55670-30 on the water, or

solid, end of the shaft.

Now your almost ready to install the

pump shaft.

If you have a overhead crane available,

install the lifting eye on the oil end of the

piston as shown.

Effective Date February 17, 2011 31 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Shaft Maintenance

Make sure the shaft is clean and there

are no scratches or burrs on the shaft.

You don’t want to damage the new seals.

Lubricate the shaft with hydraulic oil. It

will go through the seals easier.

Lower the shaft into the center block.

Make sure you are inserting the shaft

from the oil side of the center block and

the taper side or bullet covered end is

down. The oil side is the side away from

the large check valve hole.

Effective Date February 17, 2011 32 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Shaft Maintenance

Once the shaft is through the seals

in the center block, remove the lifting

eyelet.

Turn the center block upright and push

the shaft completely through the center

block seals.

Double check the seals.

Effective Date February 17, 2011 33 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Piston Heads Maintenance

on both sides.

Install new seals on the pistons.

Make sure the o-ring side of the seal is

to the outside.

Clamp the piston to the work bench or

put it in a vise. It makes it easier to pry

the seal over the piston and into the

seal groove.

Effective Date February 17, 2011 34 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Piston Heads Maintenance

Pry the seal into position.

Tap the seal all the way around to make

sure it is properly seated in the seal

groove.

Turn the piston over and install the

other seal. Remember the o-ring side

goes to the outside.

Effective Date February 17, 2011 35 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Piston Heads Maintenance

Pry the seal into position.

Make sure it is seated properly in

the seal groove.

Start over with the other piston.

Make sure the o-ring is to the

outside.

Effective Date February 17, 2011 36 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Piston Heads Maintenance

Turn it over and install the other seal.

Use Lubriplate 630-AA or an equivalent

to lubricate the shaft threads.

Lubricate the threads on the shaft.

Put some grease on the o-ring groove

on the shaft. It will help hold the seal in

place while installing the piston.

Effective Date February 17, 2011 37 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Shaft Piston End Seals Maintenance

Do the same to the other end of the

shaft.

Install the o-ring on the shaft.

Make sure the o-ring is properly seated

in the groove.

Effective Date February 17, 2011 38 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Shaft Piston End Seals Maintenance

Do the same to the other end of the

shaft.

Make sure the o-ring is properly seated

in the groove.

Install the piston on the shaft. Be aware

of which is the oil end and which is the

water end. You don’t want to mix them

up. The oil piston is steel and the water

piston is bronze. The side of the piston

with the two (2) holes in it goes to the

outside. In this case we are starting with

the oil side piston.

Effective Date February 17, 2011 39 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach Piston Heads Maintenance

Screw it on as far as it will go.

Make sure it is all the way on the

shaft.

Now do the same with the water

piston.

Effective Date February 17, 2011 40 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach Piston Heads Maintenance

Screw it on all the way.

Be sure it is all the way on the shaft.

Install the spanner wrench part number

55689-30 into the two holes on the

piston

Effective Date February 17, 2011 41 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach Piston Heads Maintenance

Do the same with the spanner wrench

on the other piston.

Hit the spanner wrench a dead blow

with a hammer to ensure the piston is

tight on the shaft. There is no set torque

on the piston to the shaft. It is simply

as tight as it can get. The piston will

be locked to the shaft with a set screw

later.

Make sure each piston is flush with the

end of the shaft. If the shaft is not flush

with the end of the piston damage to

the shaft can occur once the pump is

fully assembled.

Effective Date February 17, 2011 42 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach Piston Heads Maintenance

This shows a properly positioned piston

on the shaft. Notice how the shaft and

piston are flush.

Drill a new set screw hole. DO NOT try

to reuse the old set screw hole. If the

piston is properly installed on the shaft

the old hole will not line up properly due

to the threads stretching. Start with a

small diameter drill. Suggest using a 1/8

drill to start.

Then use a letter I drill to enlarge the

hole. The letter I drill is the proper size

for a 5/16 set screw.

Effective Date February 17, 2011 43 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach Piston Heads Maintenance

Tap the hole using a 5/16 - 24 NF tap.

Be sure to lubricate the tap to prevent it

sticking.

The threads must be at least 1/2 inch

deep for the set screw to be properly

seated.

Use Loctite medium strength thread

blocker or equivalent on the set screw

before installing it.

NOTE: The set screws are different

between the oil end and the

water end. The water end must

have a stainless steel set screw.

The oil end does not require a

stainless steel set screw. Failure

to use a stainless steel set screw

on the water end can cause the

set screw to rust away causing

damage to the piston, shaft and

pump.

Effective Date February 17, 2011 44 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach Piston Heads Maintenance

Install the set screw.

Make sure the set screw is below the

surface of the piston and shaft.

Now dimple the piston over the set

screw. This prevents the set screw from

backing out accidentally.

Effective Date February 17, 2011 45 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach Piston Heads Maintenance

Do the same to the other piston.

Start with the 1/8 diameter drill.

Be sure the hole is over 1/2 inch

deep.

Now use the letter I drill to enlarge the

hole to the proper size.

Effective Date February 17, 2011 46 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach Piston Heads Maintenance

Tap the hole using a 5/16 - 24 NF tap.

Make sure the threads are over 1/2

inch deep.

Be sure to clean out the set screw

hole after tapping the threads. Any

pieces of metal left in the hole can

get caught in the threads between

the piston and the shaft causing the

piston to lock to the shaft making

disassembly difficult.

Effective Date February 17, 2011 47 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach Piston Heads Maintenance

Use Loctite medium strength thread

blocker or equivalent on the set screw

before installing it.

Install the set screw. Remember the set

screws are different. Do not mix them

up. Stainless steel on the water end and

regular steel on the oil end.

Be sure the set screw is below the

surface of the piston and shaft.

Effective Date February 17, 2011 48 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach Piston Heads Maintenance

This shows a piston of a pump that has

been rebuilt 3 times. Note that 3 of the

holes don’t line up properly.

The arrow shows the set screw installed

properly below the surface of the piston

and shaft.

Dimple the edge of the piston over the

set screw with a center punch to hold it

in place. Failure to lock the set screw in

place can allow it to back out causing

damage to the pump.

This shows the set screw having been

properly dimpled to prevent it from

backing out.

Effective Date February 17, 2011 49 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach Piston Heads Maintenance

Now we are ready to install the

barrels.

Make sure both sides are properly

dimpled.

Now were ready to start installing

the barrels. Note the steel block in

place preventing any movement of

the pump during the barrel installation

procedure.

Effective Date February 17, 2011 50 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Prepare to Attach Barrels Maintenance

Lubricate the o-ring groove on the center

block. This will help hold the o-ring in

position during the barrel installation.

Install the o-ring part # 29663.

Lubricate the seals with hydraulic oil.

This will ease the installation of the

barrel.

Effective Date February 17, 2011 51 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Prepare to Attach Barrels Maintenance

Install the seal compressor part number

53592. This compresses the seals

making the barrel installation easier.

Position the barrel pusher tool part

number 86721-30.

Be sure the barrel is clean and there is

no damage to it. A damaged barrel will

only damage the seals creating the need

to have to rebuild the pump prematurely.

Inspect the edge of the barrel for

chamfer. The chamfered edge is the

leading edge.

Note: New barrels will not have a

chamfered edge.

Effective Date February 17, 2011 52 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach Barrels Maintenance

Note the difference between the two

barrels. The red or green stripe and the

letter H in the serial number of the barrel

indicate that this is a WATER barrel.

DO NOT MIX UP THE BARRELS. THE

WATER BARREL AND OIL BARREL

ARE DIFFERENT. If you are unsure

which barrel is which or the barrel is

painted, take a file to the outside of the

barrel. The water barrel is hardened

steel, a file WILL NOT score it. The oil

barrel is not hardened steel, a file will

score it.

Use the barrel pusher tool to push the

barrel over the piston and seals.

Note how the barrel is pushing the seal

keeper off of the piston and seals. Also

note the ” steel rod supporting the barrel.

This is important to keep the barrel

properly aligned.

Effective Date February 17, 2011 53 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach Barrels Maintenance

We are almost over the piston.

Remove the seal keeper once it is

completely off of the piston and seals.

Install it on the other piston.

Double check the o-ring to be sure it is

not out of position.

Effective Date February 17, 2011 54 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach Barrels Maintenance

Push the barrel all the way into position.

Note the steel rod keeping the barrel

up off of the work bench and in proper

position.

Turn the pump around and install a

block of wood or something similar

to prevent the piston and shaft from

moving during the installation of the

second barrel.

Clean and inspect the other barrel to be

installed. Check for the chamfer on the

leading edge.

Effective Date February 17, 2011 55 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach Barrels Maintenance

Note this one has a blue stripe indicating

it is a oil barrel. Again if you are unsure

that this is the correct barrel, use a file

to the OUTSIDE of the barrel. If the file

scores the barrel it is a oil barrel. If a

file cannot score the barrel, it is a water

barrel.

Push the barrel into position. Note the

steel rod supporting the barrel.

Push the barrel over the piston.

Effective Date February 17, 2011 56 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach Barrels Maintenance

Continue pushing the barrel until the seal

keeper is all the way off of the piston and

seals. Remove the seal keeper.

Push the barrel all of the way into the

center block.

Remove the barrel pusher. Clean and

inspect the sensing rod prior to installing

it in the oil end shaft.

Effective Date February 17, 2011 57 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Sensing Rod & Yoke Maintenance

Put Loctite medium strength thread

blocker on the sensing rod yoke prior to

installation.

Note: Inspect the yoke for wear.

Replace any yoke showing any kind

of wear. NO NOT reuse a worn yoke.

Damage to the pump can occur if a

worn yoke is used.

Install the yoke and tighten.

This shows the sensing rod and yoke in

position.

Effective Date February 17, 2011 58 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Sensing Rod & Yoke Maintenance

This shows the tool used to install the

yoke. We simply welded a steel tube to

a socket making it easier to tighten the

yoke.

Tighten the yoke. There is no set torque

to the yoke and shaft. Simply make sure

it is a tight as possible.

Now we are ready to install the end

blocks.

Effective Date February 17, 2011 59 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach End Blocks Maintenance

Lubricate the o-ring groove.

Install the o-ring part # 29663 in the

end block

Do the same to the other end block.

Effective Date February 17, 2011 60 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach End Blocks Maintenance

Slide the sensing rod through the oil

end block. Pay close attention to the

positioning (timing) of each end block.

Make sure it is positioned correctly.

Be careful in positioning the sensing rod.

Carefully slide the end block on to the

barrel. The barrel must fit into the o-ring

groove to be properly sealed.

Effective Date February 17, 2011 61 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach End Blocks Maintenance

Measure the barrel length to be sure it is

properly seated in the center block and

end block o-ring grooves.

The inside length of the oil side is 19

inches

Install the water end block. Again, make

sure of the positioning (timing) of the end

block. Be sure the check valve holes are

aligned.

Be sure it seats properly against the

water barrel.

Effective Date February 17, 2011 62 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach End Blocks Maintenance

The end block and barrel appear properly

positioned. Measure the length of the

assembly like you did the other side. The

water side should be 19 inches inside

length.

Slide the sensing rod seal over the

sensing rod shaft.

Be sure the o-ring side of the seal goes

toward the pump.

Effective Date February 17, 2011 63 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach End Blocks Maintenance

The o-ring side of the seal goes toward

the pump. Lubricate the seal to ease the

installation. Install the hat bushing.

Install the sensing rod piston on the

sensing rod.

Lubricate the seal cavity prior to

installing the seal.

Effective Date February 17, 2011 64 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach End Blocks Maintenance

Use the piston and hat bushing to

install the seal in the end block. It

works much like a slide hammer.

Seal and hat bushing in place.

Now were ready for the truss rods.

Effective Date February 17, 2011 65 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach Truss Rods Maintenance

Install the nuts on one end of the truss

rod. This will be the oil end of the truss

rod.

In stall the truss rod through the end

blocks.

Do this with all four (4) truss rods.

Effective Date February 17, 2011 66 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach Truss Rods Maintenance

Carefully slide the truss rods through

the water end block.

Lubricate the bolting plates. Only the

side that meets the nuts needs to be

lubricated.

Install the bolting plates on the water

end of the pump.

Note: only the water end gets the

bolting plates. Lubricate the truss

rod threads before installing the

nuts.

Effective Date February 17, 2011 67 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach Truss Rods Maintenance

Install the nuts on the water end of the

truss rods.

On pumps used on units built in the

70’s and 80’s it will be necessary to

index the flat of the nut so that it does

not stick above the end block. This only

needs to be done on the oil end.

One person will need to hold the nut

on the oil end of the truss rod while

another person tightens the water end.

Effective Date February 17, 2011 68 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach Truss Rods Maintenance

Tighten the nuts on the water end in an

X pattern.

Torque the nuts on the water end to

1200 foot pounds. Torque in an X pattern

increasing the torque in 200 foot pound

increments until 1200 foot pounds

is reached. If you are using a torque

multiplier, increase the torque to 1400

foot pounds.

Install the drain plug, or ball valve fitting,

in the center block and the water end

block.

Effective Date February 17, 2011 69 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach Detent Block Maintenance

Install an old style detent block on

the oil end block. This will support the

piston and shaft during the installation

of the roll pin.

Align the roll pin hole between the

sensing rod piston and shaft.

Install the roll pin to lock the piston and

shaft together.

Effective Date February 17, 2011 70 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach Detent Block Maintenance

Put Loctite on the end cap prior to

installing it on the sensing rod.

Install the end cap on the sensing rod.

End cap and piston are assembled.

Now remove the old style detent block.

NOTE: The old style detent block will

be left in place if the pump is

used on a unit built in the 80’s.

It will be removed and replaced

with a different detent block for

pumps used on 2100 series units.

Effective Date February 17, 2011 71 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach Detent Block Maintenance

Install the breather plugs in the detent

block prior to installing the detent block

on the pump. Tape over the breather

plugs if the pump is to be painted after

assembly.

Install the detent block.

Install the sensor.

NOTE: Prior to installing the sensor

make sure the sensing rod piston

is properly positioned under the

sensor. Failure to properly position

the piston under the sensor can

cause the sensor to be improperly

set causing damage to the sensor

and pump.

Screw the sensor down until it touches

the piston and back it off a minimum of

2 turns but no more than 3 turns. This

allows the LED on the sensor to be

positioned where it can easily be seen

when the pump

Effective Date February 17, 2011 72 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Attach Compensator Block Maintenance

Install the compensator block.

Install the hydraulic hose between the

oil end block and the compensator

block.

Clean and lubricate the check valve

o-ring grooves on the water end of the

pump.

Effective Date February 17, 2011 73 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Install Check Valves Maintenance

Install the o-rings.

There are 4 o-rings that need to be

installed. 2 intake and 2 exhaust.

Install the check valves.

Effective Date February 17, 2011 74 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Install Check Manifolds Maintenance

Note the intake and exhaust check

valves are installed opposite of each

other. The intake check valves have the

springs out. The exhaust check valves

have the springs inside the pump.

Install the intake manifold blocks.

Note there are different size blocks for

different pumps. Be sure you install

the correct one. Install new o-rings

in the manifold blocks prior to

installing them on the pump.

Install the hose and center block elbow

manifold. Be sure to tighten the hose

clamps.

Effective Date February 17, 2011 75 Rodder Pump Rebuild_r0

Vactor Rodder Pump Rebuild Guide

Finishing Up Maintenance

Install the exhaust check valve blocks.

If the unit has a debris body wash out

system, the outside valve block will have

a ball valve installed in it. Install new

o-rings in the manifold blocks prior to

installation.

Install the hose between the two valve

blocks. This hose is only installed on

units with a debris body washout system.

Paint the pump if necessary. We are now

ready to install it back on the unit.

Effective Date February 17, 2011 76 Rodder Pump Rebuild_r0

You might also like

- MPM TroubleshootingDocument34 pagesMPM TroubleshootingMustafaNo ratings yet

- D PDFDocument49 pagesD PDFFordi100% (1)

- Bosch Diesel Injection Pump RebuildDocument26 pagesBosch Diesel Injection Pump Rebuildjoana13r100% (3)

- Service Excellence ManualDocument192 pagesService Excellence ManualAndrés Tomás Couvlaert SilvaNo ratings yet

- TM-517 AOI Piston Separator ManualDocument32 pagesTM-517 AOI Piston Separator ManualAndi Yusuf50% (2)

- Cinderella by Roald DahlDocument5 pagesCinderella by Roald DahlRaquel Gonzalez33% (3)

- List of Documents NBA PfilesDocument48 pagesList of Documents NBA PfilesDr. A. Pathanjali Sastri100% (1)

- Ati Manual Reverse Valve BodyDocument4 pagesAti Manual Reverse Valve BodyPaul OfsthunNo ratings yet

- Fuel NozzleDocument27 pagesFuel NozzleJean P. MuñozNo ratings yet

- 700R4 Manual Reverse Valve Body: Installation InstructionsDocument4 pages700R4 Manual Reverse Valve Body: Installation InstructionsAbbode HoraniNo ratings yet

- Cylinder Head: Section 12 - Base EngineDocument1 pageCylinder Head: Section 12 - Base EngineAli ZerifiNo ratings yet

- Valvula DireccionDocument8 pagesValvula DireccionVictor Manuel Lozada ObessoNo ratings yet

- 07 2984BDocument22 pages07 2984BCHARLES HUMBERTO0% (1)

- Service Manual: DaihatsuDocument7 pagesService Manual: DaihatsuMateoNo ratings yet

- 8.3 Maintenance of The Pilot ValveDocument2 pages8.3 Maintenance of The Pilot Valvealang_businessNo ratings yet

- Datex Ohmeda Modulus II W 7810 Ventilator Maintenance ProceduresDocument38 pagesDatex Ohmeda Modulus II W 7810 Ventilator Maintenance ProceduresgimenNo ratings yet

- Service Manual Trucks vn770Document16 pagesService Manual Trucks vn770Neojai jaiyuNo ratings yet

- Lab Module 01 Maintenance & Troubleshoot Centrifugal PumpDocument12 pagesLab Module 01 Maintenance & Troubleshoot Centrifugal Pumpazroy06No ratings yet

- Section 9A - Power-Assisted Steering Pump and Related ComponentsDocument14 pagesSection 9A - Power-Assisted Steering Pump and Related ComponentsJorge SoberanoNo ratings yet

- Regulating Feed Water Valve: Control Valves, Type 470/471Document28 pagesRegulating Feed Water Valve: Control Valves, Type 470/471Alexander BaziotisNo ratings yet

- KER TB16V Timing Belt Sidekick 1.6L 16 ValveDocument18 pagesKER TB16V Timing Belt Sidekick 1.6L 16 ValveMatthew BurkhalterNo ratings yet

- Tier 4 I E E A I Manual C4.4 To C 7.1 Industrial Products TPD1726E1Document29 pagesTier 4 I E E A I Manual C4.4 To C 7.1 Industrial Products TPD1726E1EduardoCastilloNo ratings yet

- MERCUR d28l - DtronicDocument8 pagesMERCUR d28l - DtronicAtakan ArıkoğluNo ratings yet

- 1001 12 PDFDocument26 pages1001 12 PDFTuấn NeoNo ratings yet

- MC99759 8b110brakeDocument18 pagesMC99759 8b110brakeANGELES NIETONo ratings yet

- Service Training Parker PV Series 42Document39 pagesService Training Parker PV Series 42Javier PeñaNo ratings yet

- 43210-0001 Jabsco PumpDocument5 pages43210-0001 Jabsco PumpRon CooperNo ratings yet

- carter-yf-manualDocument34 pagescarter-yf-manualgpavmanNo ratings yet

- Iom Biffi Morin Series A B C S en en Us 6089118Document37 pagesIom Biffi Morin Series A B C S en en Us 6089118Anonymous Wu6FDjbNo ratings yet

- Rotary Vane Service Manual Shafer en 83Document20 pagesRotary Vane Service Manual Shafer en 83pabloNo ratings yet

- SB 388Document13 pagesSB 388oscarNo ratings yet

- BB-4-18/23 Quick Guide: Warnings and Safety PrecautionsDocument4 pagesBB-4-18/23 Quick Guide: Warnings and Safety PrecautionsWalter Dario LopezNo ratings yet

- UntitledDocument44 pagesUntitledEdwinferNo ratings yet

- Vciom 06062 enDocument4 pagesVciom 06062 enJoeNo ratings yet

- Series 4280: Motor Mounted Horizontal End Suction Pump Service Work InstructionsDocument4 pagesSeries 4280: Motor Mounted Horizontal End Suction Pump Service Work InstructionsvimalmailbookNo ratings yet

- Instruction Manual For 2way & 3way Cylinder Valve: Section TitleDocument10 pagesInstruction Manual For 2way & 3way Cylinder Valve: Section TitleFlo MarineNo ratings yet

- Technical Service Manual: Installation, Start Up, Troubleshooting, Preventative Maintenance, Do'S & Don'TsDocument8 pagesTechnical Service Manual: Installation, Start Up, Troubleshooting, Preventative Maintenance, Do'S & Don'Tsroyert80No ratings yet

- 061 600seriesvalvesDocument4 pages061 600seriesvalvesnflzhang1981No ratings yet

- Z8 (CF800) Service Manual 2013 (057-211) (037-150)Document114 pagesZ8 (CF800) Service Manual 2013 (057-211) (037-150)francisco jose ramirez perezNo ratings yet

- Jabsco Marine Engine Water Cooling PumpDocument4 pagesJabsco Marine Engine Water Cooling PumpRendy Adam FarhanNo ratings yet

- Chapter 9. VAZ-21213 Vehicle Modifications, Alternative and Additional EquipmentDocument27 pagesChapter 9. VAZ-21213 Vehicle Modifications, Alternative and Additional EquipmentSergio PazNo ratings yet

- !3imzy: Oil Cooler and Relief ValvesDocument6 pages!3imzy: Oil Cooler and Relief ValvesDavid QuispeNo ratings yet

- Enerpac P-392 Service InstructionsDocument8 pagesEnerpac P-392 Service InstructionsSergio ReyesNo ratings yet

- Edward Vacuum Pump Rebuild Guide: July 2019Document41 pagesEdward Vacuum Pump Rebuild Guide: July 2019Srikanth GedelaNo ratings yet

- BandasDocument116 pagesBandasJhon GuerraNo ratings yet

- Al Self Priming PumpDocument15 pagesAl Self Priming PumpHalley ElangovanNo ratings yet

- Maintenance and Repair of Centrifugal PumpsDocument3 pagesMaintenance and Repair of Centrifugal PumpsRohan NaikNo ratings yet

- 376000Document6 pages376000Abbode HoraniNo ratings yet

- KIKAWA Manual kp8 enDocument4 pagesKIKAWA Manual kp8 enRamesh KrishmedaNo ratings yet

- N2 Triplex Pump-MaintenanceDocument14 pagesN2 Triplex Pump-MaintenanceIbrahim Ahmed100% (1)

- SM01 010 033.00 PDFDocument4 pagesSM01 010 033.00 PDFMohamed RashedNo ratings yet

- Service Manual SM1-10-33.0: Outrigger/Steer Pump, R & IDocument4 pagesService Manual SM1-10-33.0: Outrigger/Steer Pump, R & IMohamed RashedNo ratings yet

- Exhaust Valve Actuator: S35MC DataDocument6 pagesExhaust Valve Actuator: S35MC DatalijinNo ratings yet

- P250-250S Cap 10 (A.C. GENERATOR)Document10 pagesP250-250S Cap 10 (A.C. GENERATOR)Minh ChuNo ratings yet

- PDFDocument60 pagesPDFAdolfo Moscoso100% (1)

- Log Splitter Hydraulic TroubleshootingDocument13 pagesLog Splitter Hydraulic TroubleshootingTim MckennaNo ratings yet

- Graco GM3000 Clutch Kit 308657EN-ADocument4 pagesGraco GM3000 Clutch Kit 308657EN-AjjmokieNo ratings yet

- Floating Ball Valve - 8100R21Document12 pagesFloating Ball Valve - 8100R21demblavalvesltd1989No ratings yet

- Service Buletin 07-2965DDocument29 pagesService Buletin 07-2965DAgustinus KNo ratings yet

- Manual Bomba PVX EatonDocument26 pagesManual Bomba PVX EatonLeopoldo WilleNo ratings yet

- BALEROSDocument17 pagesBALEROSjulio cesarNo ratings yet

- Manual Transmission/Transaxle - Transmission: RemovalDocument30 pagesManual Transmission/Transaxle - Transmission: RemovalJim LiebNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Index: Monthly Bulletin-Dec 2022Document46 pagesIndex: Monthly Bulletin-Dec 2022Sanif KhanNo ratings yet

- William Angelo - Week-7.AssessmentDocument2 pagesWilliam Angelo - Week-7.Assessmentsup shawtyNo ratings yet

- Belgian Carrier PigeonDocument145 pagesBelgian Carrier PigeonstepathcNo ratings yet

- Direct BriberyDocument4 pagesDirect Briberyjuillien isiderioNo ratings yet

- Group 2 Hydraulic and Mechanical SystemDocument20 pagesGroup 2 Hydraulic and Mechanical SystemMarcelino chiritoNo ratings yet

- Gravitational Force WSDocument2 pagesGravitational Force WSSatria HalimNo ratings yet

- Study of Blood Groups and Rhesus Factor in Beta Thalassemia Patients Undergoing Blood TransfusionsDocument6 pagesStudy of Blood Groups and Rhesus Factor in Beta Thalassemia Patients Undergoing Blood TransfusionsOpenaccess Research paperNo ratings yet

- R30 CFA Level 3Document19 pagesR30 CFA Level 3Ashna0188No ratings yet

- Year3 GL Style Maths Practice Paper PrintableDocument4 pagesYear3 GL Style Maths Practice Paper PrintableLolo ImgNo ratings yet

- A Biblical Philosophy of MinistryDocument11 pagesA Biblical Philosophy of MinistryDavid Salazar100% (4)

- Comprehension Toolkit 1Document3 pagesComprehension Toolkit 1api-510893209No ratings yet

- The Quiescent Benefits and Drawbacks of Coffee IntakeDocument6 pagesThe Quiescent Benefits and Drawbacks of Coffee IntakeVikram Singh ChauhanNo ratings yet

- PYF Biennial Conference Vawi 19-NaDocument1 pagePYF Biennial Conference Vawi 19-NaMizoram Presbyterian Church SynodNo ratings yet

- NT Organic FarmingDocument17 pagesNT Organic FarmingSai Punith Reddy100% (1)

- Minimal Stimulation IVF Vs Conventional IVFDocument8 pagesMinimal Stimulation IVF Vs Conventional IVFpolygoneNo ratings yet

- Teacher Learning Walk Templates - 2017 - 1Document13 pagesTeacher Learning Walk Templates - 2017 - 1Zakaria Md SaadNo ratings yet

- The Secret Book of JamesDocument17 pagesThe Secret Book of JameslaniNo ratings yet

- Emcee Script For Kindergarten Recognition (English) - 085301Document3 pagesEmcee Script For Kindergarten Recognition (English) - 085301Felinda ConopioNo ratings yet

- HABASIT 04 Guía Ingeniería HabasitLINKDocument100 pagesHABASIT 04 Guía Ingeniería HabasitLINKKyriakos MichalakiNo ratings yet

- Consultancy - Software DeveloperDocument2 pagesConsultancy - Software DeveloperImadeddinNo ratings yet

- Schedule CDocument273 pagesSchedule CAzi PaybarahNo ratings yet

- Staying in God's PresenceDocument3 pagesStaying in God's PresenceElmer Dela TorreNo ratings yet

- Birinci Pozisyon Notalar Ve IsimleriDocument3 pagesBirinci Pozisyon Notalar Ve IsimleriEmre KözNo ratings yet

- Annual Return For A Company Limited by GuaranteeDocument4 pagesAnnual Return For A Company Limited by GuaranteeAtisang Tonny SethNo ratings yet

- OutDocument318 pagesOutBet HalNo ratings yet

- Government of Karnataka: Only For Birth Verification PurposeDocument1 pageGovernment of Karnataka: Only For Birth Verification PurposeAmit VantagodiNo ratings yet