Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

1 viewsSchedule Pekerjaan 5 January

Schedule Pekerjaan 5 January

Uploaded by

Alfian IkhsanCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You might also like

- CPC CascadiaDocument5 pagesCPC CascadiaLeonardo Iglesias100% (3)

- Becoming Cancer-Free ManuscriptDocument149 pagesBecoming Cancer-Free ManuscriptD100% (1)

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- Task Card A320Document8 pagesTask Card A320somendra0% (1)

- Bite Test PDFDocument3 pagesBite Test PDFbillyNo ratings yet

- Clerk of Works Project ReportDocument11 pagesClerk of Works Project ReportJoseph Mwangi WambuguNo ratings yet

- KIT Volume XX No 2 September 2008Document14 pagesKIT Volume XX No 2 September 2008KITexBruderhofCCINo ratings yet

- Schedule Pekerjaan 7 DesemberDocument5 pagesSchedule Pekerjaan 7 DesemberAlfian IkhsanNo ratings yet

- Littelfuse ProtectionRelays SE 134C ManualDocument26 pagesLittelfuse ProtectionRelays SE 134C ManualLeandro AmorimNo ratings yet

- Application Information: Reference OnlyDocument5 pagesApplication Information: Reference OnlyhumcataNo ratings yet

- Littelfuse ProtectionRelays SE 135 Manual r2Document20 pagesLittelfuse ProtectionRelays SE 135 Manual r2Bill CaiNo ratings yet

- Daily Progress Report For Nc186, Nc115 and I/R Fields El-Sharara Oil Fields Construction DepartmentDocument11 pagesDaily Progress Report For Nc186, Nc115 and I/R Fields El-Sharara Oil Fields Construction DepartmentHatem ShinkadaNo ratings yet

- 24h Look Ahead For 31-January - 19Document23 pages24h Look Ahead For 31-January - 19sami talibNo ratings yet

- Comment Control Sheet V SIE EL001 COMMON 047 - CDocument4 pagesComment Control Sheet V SIE EL001 COMMON 047 - CproteccionesNo ratings yet

- Slider I MotionDocument68 pagesSlider I Motionmirea marianNo ratings yet

- Railways Quaters PlansDocument52 pagesRailways Quaters PlansharshNo ratings yet

- NFR Maintenance Sch.Document41 pagesNFR Maintenance Sch.Ranjeet SinghNo ratings yet

- Sony - Receiver STR-De915 - Service ManualDocument56 pagesSony - Receiver STR-De915 - Service ManualEletrônica Maia Comércio e ServiçosNo ratings yet

- Costing 100MW (135) NHPCDocument3 pagesCosting 100MW (135) NHPCavanishNo ratings yet

- @A318/A319/A320/A321: Chapter 38 - Water/WasteDocument80 pages@A318/A319/A320/A321: Chapter 38 - Water/WastehengwahchungNo ratings yet

- Yellow Electric Pump: Job Card Package Title: HIM - A318/A319/A320/ A321 Tail Number - MSN - FSN ALL ContinousDocument4 pagesYellow Electric Pump: Job Card Package Title: HIM - A318/A319/A320/ A321 Tail Number - MSN - FSN ALL ContinousSuman BajracharyaNo ratings yet

- Sawamlah SS, 3 Weeks Schedule Update Till 21.01.2014Document17 pagesSawamlah SS, 3 Weeks Schedule Update Till 21.01.2014William E. NuevoNo ratings yet

- Schedule of Load: SpecificationDocument1 pageSchedule of Load: SpecificationRojim Asio DilaoNo ratings yet

- A319 - A320 - A321 - LUS - (TSM) (22-11-00-810-801-A Failure of FMGC1)Document6 pagesA319 - A320 - A321 - LUS - (TSM) (22-11-00-810-801-A Failure of FMGC1)Fredy BonillaNo ratings yet

- Communication Connectivity Diagram For 220/33 KV Pooling Substation at Muttala Village Rayala Wind Power A/C Greenko.-ExtensionDocument1 pageCommunication Connectivity Diagram For 220/33 KV Pooling Substation at Muttala Village Rayala Wind Power A/C Greenko.-ExtensionHeather CarterNo ratings yet

- A330 - TSM - 21-31-00-810-879-A - Outflow Valves Do Not Close in The Ditching ConfigurationDocument1 pageA330 - TSM - 21-31-00-810-879-A - Outflow Valves Do Not Close in The Ditching Configurationsah3liNo ratings yet

- Chapter 22Document424 pagesChapter 22Station operation KBRNo ratings yet

- rp-c4108 DMC 3Document3 pagesrp-c4108 DMC 3billyNo ratings yet

- 09 1963 CH-Electrical SystemsDocument44 pages09 1963 CH-Electrical SystemsJose LaproviteraNo ratings yet

- Planning and Cost Analysis DataDocument51 pagesPlanning and Cost Analysis DataTreasure321No ratings yet

- Weekly Schedule: NO. Item Percentage Completion Mon. Tues. Wed. Thurs. Fri. Sat. Sun. 12 13 14 15 16 17 18Document6 pagesWeekly Schedule: NO. Item Percentage Completion Mon. Tues. Wed. Thurs. Fri. Sat. Sun. 12 13 14 15 16 17 18Colesha BarukaNo ratings yet

- Comments 1Document1 pageComments 1technojet21No ratings yet

- Kv2160wr - TV SonyDocument57 pagesKv2160wr - TV SonyapitzhappyrecordsNo ratings yet

- Tooling 2Document13 pagesTooling 2Ivo SilvaNo ratings yet

- MMO - A318 - A319 - A320 - A321 - AMM - 01-Aug-2022 - 29-12-51-000-001-A - Removal of The Electric PumpDocument4 pagesMMO - A318 - A319 - A320 - A321 - AMM - 01-Aug-2022 - 29-12-51-000-001-A - Removal of The Electric PumpBatuhan YildizNo ratings yet

- Ebro Operating Instructions Manual Modular Systeme - ENDocument55 pagesEbro Operating Instructions Manual Modular Systeme - ENErland CuariteNo ratings yet

- 12 24KV GF1 GF2 Gis Rmu R0Document2 pages12 24KV GF1 GF2 Gis Rmu R0Mohd Afifi JusohNo ratings yet

- Commissioning ActivitiesDocument19 pagesCommissioning ActivitiesDanish VodeyarNo ratings yet

- Ubstation Common SettingDocument15 pagesUbstation Common Settingaravindhana1a1100% (1)

- Philips 22dc593-62l 22dc594-62f-62l SM ColorDocument28 pagesPhilips 22dc593-62l 22dc594-62f-62l SM Colormkl.valentinNo ratings yet

- PlenumDocument9 pagesPlenumAnuna Amanullah100% (1)

- Pressurization Components TestDocument32 pagesPressurization Components TestRanjit ShawNo ratings yet

- Philips 104s Cm23 Gs IIIDocument53 pagesPhilips 104s Cm23 Gs IIIadrianrossosjNo ratings yet

- AMM - 01-Aug-2023 - 22-63-00-710-001-A - Operational Test of The Yaw Damper FunctionDocument4 pagesAMM - 01-Aug-2023 - 22-63-00-710-001-A - Operational Test of The Yaw Damper Functionayan acharjeeNo ratings yet

- Amm InstallationDocument8 pagesAmm Installationsreenathsreekumar2009No ratings yet

- IAD - A318 - A319 - A320 - A321 - AMM - 01-Aug-2021 - 29-00-00-790-001-A - Check of The External Leaks of The Hydraulic ComponentsDocument12 pagesIAD - A318 - A319 - A320 - A321 - AMM - 01-Aug-2021 - 29-00-00-790-001-A - Check of The External Leaks of The Hydraulic ComponentsMONOJ ANo ratings yet

- Relay Setting Calculation LatestDocument23 pagesRelay Setting Calculation Latestমোঃ মহসিনNo ratings yet

- @A318/A319/A320/A321: Chapter 35 - OxygenDocument50 pages@A318/A319/A320/A321: Chapter 35 - OxygenhengwahchungNo ratings yet

- Go/No Go Test: Xperia L C2104, C2105, S36hDocument8 pagesGo/No Go Test: Xperia L C2104, C2105, S36hEdixon AgurreNo ratings yet

- ATLAS-210x/215x: Installation Operation and MaintenanceDocument98 pagesATLAS-210x/215x: Installation Operation and Maintenances.gaffilunilicei.it Gaffi StefanoNo ratings yet

- 1 PM 56K HOURS (The Running Hrs Now Exceeding 9758 HRS) 2 PM 56K HOURS (The Running Hrs Now Exceeding 944 HRS) 3Document2 pages1 PM 56K HOURS (The Running Hrs Now Exceeding 9758 HRS) 2 PM 56K HOURS (The Running Hrs Now Exceeding 944 HRS) 3Zaini SarbiniNo ratings yet

- FM 2-58 - Indicator Post Valves - Turns To OpenDocument2 pagesFM 2-58 - Indicator Post Valves - Turns To OpenwastedsunsetsNo ratings yet

- 500kv 220kv, NTDC, Grid Station Gatti Faisalabad.Document56 pages500kv 220kv, NTDC, Grid Station Gatti Faisalabad.Cheap but good100% (3)

- Supervised Industrial Training Report: National Transmission and Despatch Company (NTDC) PakistanDocument56 pagesSupervised Industrial Training Report: National Transmission and Despatch Company (NTDC) PakistanMarina KhanNo ratings yet

- Mark2 Kiigroundf Fault Ctif Tre Ficat TionDocument3 pagesMark2 Kiigroundf Fault Ctif Tre Ficat TionMohamed Bin IerousNo ratings yet

- AMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Document3 pagesAMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Andre SanarNo ratings yet

- AMM A320F - Removal of Lavatory ADocument12 pagesAMM A320F - Removal of Lavatory AMugilanNo ratings yet

- Field Winding - Test: Shutdown SIS Previous ScreenDocument2 pagesField Winding - Test: Shutdown SIS Previous ScreenHector VallesNo ratings yet

- Service Bulletin: SUBJECT: Improve The High Voltage Electrical Charge For All Pegasus 19"Document1 pageService Bulletin: SUBJECT: Improve The High Voltage Electrical Charge For All Pegasus 19"robertoaj1No ratings yet

- Understanding Lightning and Lightning Protection: A Multimedia Teaching GuideFrom EverandUnderstanding Lightning and Lightning Protection: A Multimedia Teaching GuideNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Kinematic Wave Routing - ExampleDocument33 pagesKinematic Wave Routing - ExamplethewodrosNo ratings yet

- Distillation ColumnDocument59 pagesDistillation Columnfurqankausarhaider100% (5)

- 490806Document2 pages490806Informative InsaanNo ratings yet

- Silicio UllmanDocument29 pagesSilicio UllmanPaula OlazabalNo ratings yet

- Jawaban Bahasa InggrisDocument9 pagesJawaban Bahasa InggrisHusnul KhotimahNo ratings yet

- CCTV Technology Handbook: System Assessment and Validation For Emergency Responders (SAVER)Document33 pagesCCTV Technology Handbook: System Assessment and Validation For Emergency Responders (SAVER)vijay babuNo ratings yet

- Electronic Devices and CircuitsDocument525 pagesElectronic Devices and CircuitsSibasankar Padhy100% (4)

- SIRE Observations For 2018, 02 Jan'19Document14 pagesSIRE Observations For 2018, 02 Jan'19Romāns BogdanovsNo ratings yet

- Product Specifications 40" WXGA Color TFT-LCD Module Model Name: T400XW01 V5Document27 pagesProduct Specifications 40" WXGA Color TFT-LCD Module Model Name: T400XW01 V5marciocambruzziNo ratings yet

- Algebra Complete - 1Document120 pagesAlgebra Complete - 1kiran.suresh19No ratings yet

- Topic 2Document9 pagesTopic 2Ria AccadNo ratings yet

- 1.1 Introduction To The Particulate Nature of Matter and Chemical ChangeDocument46 pages1.1 Introduction To The Particulate Nature of Matter and Chemical ChangeCrystalNo ratings yet

- Model Paper Grade 6Document10 pagesModel Paper Grade 6mehmood aliNo ratings yet

- Do Transformers Really Perform Bad For Graph Representation?Document19 pagesDo Transformers Really Perform Bad For Graph Representation?wenwen XiaNo ratings yet

- Miniature Bioreactors Current Practices and Future Opportunities PDFDocument14 pagesMiniature Bioreactors Current Practices and Future Opportunities PDFLuisNo ratings yet

- 170 Adi 350 00Document14 pages170 Adi 350 00Gabriel ZorattiNo ratings yet

- Comcast Smart ResumeDocument8 pagesComcast Smart Resumewajhnzwhf100% (1)

- English MONTHDocument6 pagesEnglish MONTHSoliman Micaela M.No ratings yet

- Linear Regression Analysis McqsDocument2 pagesLinear Regression Analysis McqsEngr Mujahid Iqbal80% (5)

- Saa 11Document184 pagesSaa 11jcch1969No ratings yet

- Physiology Chapter 30 Renal Regulation of PotassiumDocument32 pagesPhysiology Chapter 30 Renal Regulation of PotassiumDaniel AdamsNo ratings yet

- Tubay 34.2Document33 pagesTubay 34.2gega nesywaraNo ratings yet

- Manual de Calidad de Cerveza de Barril-2019 PDFDocument122 pagesManual de Calidad de Cerveza de Barril-2019 PDFAndrey Giovanny Riveros MerchanNo ratings yet

- Unit 17 Computer Aided Manufacture CamDocument11 pagesUnit 17 Computer Aided Manufacture CamManiDeepNo ratings yet

- Hudco Trophy: Vernacular Habitats To Combat Climate ChangeDocument8 pagesHudco Trophy: Vernacular Habitats To Combat Climate ChangeUDAY PRAKASH MISHRANo ratings yet

- Codex - SeasoningDocument17 pagesCodex - SeasoningNadia KaharNo ratings yet

- Chandrayaan-2 Indias Second Lunar Exploration MisDocument16 pagesChandrayaan-2 Indias Second Lunar Exploration MisTanu SinghNo ratings yet

- Apple Airpods Max Complete Features Instructions ManualDocument7 pagesApple Airpods Max Complete Features Instructions ManualIlaria iudiceNo ratings yet

Schedule Pekerjaan 5 January

Schedule Pekerjaan 5 January

Uploaded by

Alfian Ikhsan0 ratings0% found this document useful (0 votes)

1 views5 pagesOriginal Title

SCHEDULE PEKERJAAN 5 JANUARY

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

0 ratings0% found this document useful (0 votes)

1 views5 pagesSchedule Pekerjaan 5 January

Schedule Pekerjaan 5 January

Uploaded by

Alfian IkhsanCopyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

Download as xlsx, pdf, or txt

You are on page 1of 5

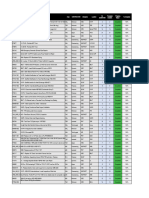

SR.

TA SK DESCRIPTION DURATI ON Man Power START END START END UPDATE 7 ON

NO. In Days DATE DATE ACTUAL DATE DECEMBER PROGRESS

A UNIT-2 FOR MILL NO.B 150

1 Dismantling of existing Mill no.2 for Unit-2 15 2-

GANGS 16-9-19 30-9-19

100%

DRAG CHAIN FEEDER ASSEMBLY ELECTRICAL &

G INSTRUMENTATION WORKS 12 4-11-19 15-11-19

Ensure completion of civil work such as

1 foundation/fixing as per requirement/drawing. 1 4-11-19 4-11-19

100%

Installation of the electrical panel and alignment

2 of all 03 chain 1 5-11-19 5-11-19

conveyors

60%

Laying of cables as per cable schedule and cable

3 glanding at both ends for all 03 chain conveyor 3 1- GANG 6-11-19 8-11-19

40%

Cable Termination at both panel end and field

4 side for all 03 chain conveyors 3 9-11-19 11-11-19

Continuity checking of the cables for all 03 chain

5 conveyors 2 12-11-19 13-11-19

Installation of the ZSS sensor, flow sensor and

6 cable termination of the same for all 03 chain 1 14-11-19 14-11-19

conveyors.

Charging of the panel and feedback checkings

7 for all 03 chain 1 15-11-19 15-11-19

conveyors.

70%

I All Electrical & Instrumentation activities 45 10-12-19 23-1-20

1 Preliminary Activities 3 10-12-19 12-12-19 100%

2 Cable Tray Installation 14 13-12-19 26-12-19 80%

3 Cable Pulling & Laying Cable 10 21-12-19 30-12-19 80%

4 Installation of Control Pannels 6 13-12-19 18-12-19 40%

Cable Termination at both panel end and field 2- GANGS

5 side for Panel 14 31-12-19 13-1-20

Airblaster, Panel PLC & Panel Power.

40%

6 Continuity Test 5 9-1-20 13-1-20

7 Download Program PLC 1 14-1-20 14-1-20

8 IO Test Mill A 1 15-1-20 15-1-20

9 Test Integration to DCS 2 16-1-20 17-1-20

DURATI

SR. TA SK DESCRIPTION ON In Man START END START END UPDATE 7 ON

NO. Days Power DATE DATE ACTUAL DATE DECEMBER PROGRESS

Dismantling of existing Mill no.2 for 2-

1

Unit-2

15

GANGS 16-9-19 30-9-19 100%

Removing of Existing Civil foundation 2-

2 and macking of new 45 GANGS 1-10-19 14-11-19 100%

foundation as per drawing.

ERECTION & COMMISSIONING COAL

B GRINDING SYSTEM FOR 135 1-10-19 12-2-20

MILL NO.1

C AIR BLASTERS 30 10-11-19 9-12-19

Ground assembly of air blasters as per

1 drawing 4 10-11-19 13-11-19 100%

Installation of Air blasters Nozzles at 1- GANG

2 Hopper 14 14-11-19 27-11-19 100%

3 Pipe line connections of Air blasters 9 28-11-19 6-12-19 100%

4 Installation of Control Pannels 3 7-12-19 9-12-19 100%

D ROD GATE ASSEMBLY 3 1-10-19 3-10-19

Installation of Rod gate assembly as 1- GANG

1 per drawing 3 1-10-19 3-10-19 100%

E MANUAL PNEUMATIC GATE ASSEMBLY 4 4-10-19 7-10-19

Installation of Manual Pneumatic Gate 1- GANG

1 Assembly as per drawing 4 4-10-19 7-10-19 100%

F DRAG CHAIN FEEDER ASSEMBLY 30 8-10-19 6-11-19

Ensure completion of civil work such as

1 foundation, footings & insert plate 1 8-10-19 8-10-19 100%

fixing as per requirement/drawing.

Checking and marking of foundation

center lines and elevation

2

levels by piono wires as per GA

1 9-10-19 9-10-19 100%

drawing

Fixing of rod gate, slide gate, expansion

3 bellow and inlet chute to the silo as 5 10-10-19 14-10-19 100%

drawing and alignment.

Erection of the casing below inlet and

other casings along casing supports

with respective match marks in side of

the casings. Apply silicon sealents at

4 the casing joints and ensure for use of 8 15-10-19 22-10-19 100%

correct fasteners as per drawing

1- GANG

Alignment of the casings i.e.

Straightness, water level, Input &

5 Output matching with feeding 2 23-10-19 24-10-19 100%

equipments. Add shim plates wherever

necessary.

6 Installation of the conveying chain 2 25-10-19 26-10-19 100%

Installation of the drive assembly,

transmission chain and

7

alignment of the same. Electrical

4 26-10-19 30-10-19 80%

connection of the drive.

Installtion of the Zero speed and flow

8

sensor and connections

1 31-10-19 31-10-19 100%

Pre-commissioning activity - Final

9 inspection, Greasing of all bearing 2

points, Lubricants filling, baffle plate 1-11-19 2-11-19

setting, etc.

Commissioning activity - No-load trial

10 and load trial. 1 3-11-19 3-11-19

H HP 743 BOWL MILL COMPONENTS 95 10-11-19 12-2-20

Checking and marking of foundation

center lines and elevation

1 levels by piano wires fixing 2 10-11-19 11-11-19 100%

arrangement

Preparation of packing shims for Gear

2 box base plate 3 10-11-19 12-11-19 100%

Erection and initial alignment of Gear

3 box Sole plate 2 13-11-19 14-11-19 100%

Pocket Grouting and curing of

4 foundation bolts of Gearbox ba 4 15-11-19 18-11-19 100%

5 Fianl alignment of Gearbox Sole plate 2 19-11-19 20-11-19 100%

Installation and Alignment of Existing

6 Mounting Plate with 1 21-11-19 21-11-19 100%

respective Main Gear box Sole plate.

Installation and alignment of Main

7 Gearbox 1 22-11-19 22-11-19 100%

Installation and alignment of Mill side

8 assembly with 2 23-11-19 24-11-19 100%

respective Main Gearbox

Confirmation of the seal gaps to Mill

9 side to gear box 1 25-11-19 25-11-19 100%

Installation and initial alignment of

10 main motor Sole Plate 1 26-11-19 26-11-19 100%

with respective Main Gearbox

Installation & Initial Alignemnt of Main

11

Motor with respective Main Gearbox

1 27-11-19 27-11-19 100%

12 Pocket Grouting of Motor Sole Plate. 4 28-11-19 1-12-19 100%

Final alignment of Main Motor with

13

respective Main Gearbox

2 2-12-19 3-12-19 100%

Full grouting of Mill side Mounting

14 plates, Gear Box Base 4 4-12-19 7-12-19 100%

plate and and motor base frame.

Blue Matching of Bowl hub Assembly

15 with respective Main 3 11-11-19 13-11-19 100%

Gear box out put flange

Ground assembly of Vane wheel

16 assembly. 1 10-11-19 10-11-19 100%

Installation and alignment of Bowl hub

17 assembly 2 8-12-19 9-12-19 100%

Installation and alignment of Bull ring

18 segments and clamping Ring assembly 3 10-12-19 12-12-19 100%

19 Alignment of vane wheel assembly 1 13-12-19 13-12-19 100%

20 Installation of scraper assembly 2 14-12-19 15-12-19 100%

21 Alignment of Scrapper Assembly. 2 16-12-19 17-12-19 100%

Installation of Bowl hub Air seals

22 assembly. 2 10-12-19 11-12-19 100%

Alignment of Bowl hub Air Seal

23 Assembly 1 12-12-19 12-12-19

Installation of Stuffing Rope or Gland

24 Packing. 1 13-12-19 13-12-19

2-

25 Installation of the bowl hub Insulation. 4 GANGS 14-12-19 17-12-19 100%

Installation of the Separator body

26 Assembly. 2 13-12-19 14-12-19 100%

27 Alignment of Separator body assembly 1 15-12-19 15-12-19 100%

28 Installation of Air restriction Ring 2 16-12-19 17-12-19 100%

29 Installation of Intermediate Plate 4 18-12-19 21-12-19 100%

Installation of Inner Cone assembly

30

with linning and it's support

2 22-12-19 23-12-19 100%

Installation and Alignment of Feed

31 Chute. 4 24-12-19 27-12-19 100%

Installation of Sepearator Top

32 assembly. 1 27-12-19 27-12-19 100%

Installation of Journal Heads and it'

33

Trunnion shafts.

3 28-12-19 30-12-19 100%

Installation of Journal shaft assembly

34

with Grinding Rolls.

3 31-12-19 2-1-20 100%

35 Installation of Journal Head Linners. 3 3-1-20 5-1-20 100%

36 Tilt-in the Grinding Journal Assembly. 3 6-1-20 8-1-20 100%

37 Installation of Stop bolts and O rings to 6 9-1-20 14-1-20 100%

Journal Opening Covers.

38 Installation of Journal Spring Assembly. 6 15-1-20 20-1-20 100%

Installation of Entire cover assembly to

39 the Mill. 2 21-1-20 22-1-20 100%

40 Installation of Mill Out let connections 7 27-12-19 2-1-20 80%

41 Installation of Knife Gate Valves 4 27-12-19 30-12-19 100%

Installation of Knife Gate Valves Piping

42 work 7 31-12-19 6-1-20 80%

Installation of Aspirating fitting

43 assembly 2 31-12-19 1-1-20 100%

44 Installation of Seal Air Piping 10 27-12-19 5-1-20 100%

Installation of Gearbox lubrication

45 system and it's accessories. 3 13-12-19 15-12-19 100%

Flushing of Gearbox lubrication system

46 Pipings. 2 16-12-19 17-12-19

47 Installation of Pyrites box assembly. 3 16-12-19 18-12-19 100%

Installation of Knife Gate Valves for

48 Pyrite box assembly. 2 19-12-19 20-12-19 100%

49 Installation of Mill Instrumentation and 30 11-12-19 9-1-20 90%

it's Controls.

Insulate the Mill Side Hot Air Entry

50 Portion. 30 17-12-19 15-1-20 90%

51 Installation of Mill Platform 15 17-12-19 31-12-19 100%

Installation of N2 Air Line connection

52 Piping 7 23-12-19 29-12-19 50%

Check all equipment, box-up the

53 pulveriser and make ready 2 23-1-20 24-1-20

for operation.

54 All Miscallaneous Jobs. 15 31-12-19 14-1-20 80%

55 No Load Trail Runs of All Equepments 3 25-1-20 27-1-20

You might also like

- CPC CascadiaDocument5 pagesCPC CascadiaLeonardo Iglesias100% (3)

- Becoming Cancer-Free ManuscriptDocument149 pagesBecoming Cancer-Free ManuscriptD100% (1)

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- Task Card A320Document8 pagesTask Card A320somendra0% (1)

- Bite Test PDFDocument3 pagesBite Test PDFbillyNo ratings yet

- Clerk of Works Project ReportDocument11 pagesClerk of Works Project ReportJoseph Mwangi WambuguNo ratings yet

- KIT Volume XX No 2 September 2008Document14 pagesKIT Volume XX No 2 September 2008KITexBruderhofCCINo ratings yet

- Schedule Pekerjaan 7 DesemberDocument5 pagesSchedule Pekerjaan 7 DesemberAlfian IkhsanNo ratings yet

- Littelfuse ProtectionRelays SE 134C ManualDocument26 pagesLittelfuse ProtectionRelays SE 134C ManualLeandro AmorimNo ratings yet

- Application Information: Reference OnlyDocument5 pagesApplication Information: Reference OnlyhumcataNo ratings yet

- Littelfuse ProtectionRelays SE 135 Manual r2Document20 pagesLittelfuse ProtectionRelays SE 135 Manual r2Bill CaiNo ratings yet

- Daily Progress Report For Nc186, Nc115 and I/R Fields El-Sharara Oil Fields Construction DepartmentDocument11 pagesDaily Progress Report For Nc186, Nc115 and I/R Fields El-Sharara Oil Fields Construction DepartmentHatem ShinkadaNo ratings yet

- 24h Look Ahead For 31-January - 19Document23 pages24h Look Ahead For 31-January - 19sami talibNo ratings yet

- Comment Control Sheet V SIE EL001 COMMON 047 - CDocument4 pagesComment Control Sheet V SIE EL001 COMMON 047 - CproteccionesNo ratings yet

- Slider I MotionDocument68 pagesSlider I Motionmirea marianNo ratings yet

- Railways Quaters PlansDocument52 pagesRailways Quaters PlansharshNo ratings yet

- NFR Maintenance Sch.Document41 pagesNFR Maintenance Sch.Ranjeet SinghNo ratings yet

- Sony - Receiver STR-De915 - Service ManualDocument56 pagesSony - Receiver STR-De915 - Service ManualEletrônica Maia Comércio e ServiçosNo ratings yet

- Costing 100MW (135) NHPCDocument3 pagesCosting 100MW (135) NHPCavanishNo ratings yet

- @A318/A319/A320/A321: Chapter 38 - Water/WasteDocument80 pages@A318/A319/A320/A321: Chapter 38 - Water/WastehengwahchungNo ratings yet

- Yellow Electric Pump: Job Card Package Title: HIM - A318/A319/A320/ A321 Tail Number - MSN - FSN ALL ContinousDocument4 pagesYellow Electric Pump: Job Card Package Title: HIM - A318/A319/A320/ A321 Tail Number - MSN - FSN ALL ContinousSuman BajracharyaNo ratings yet

- Sawamlah SS, 3 Weeks Schedule Update Till 21.01.2014Document17 pagesSawamlah SS, 3 Weeks Schedule Update Till 21.01.2014William E. NuevoNo ratings yet

- Schedule of Load: SpecificationDocument1 pageSchedule of Load: SpecificationRojim Asio DilaoNo ratings yet

- A319 - A320 - A321 - LUS - (TSM) (22-11-00-810-801-A Failure of FMGC1)Document6 pagesA319 - A320 - A321 - LUS - (TSM) (22-11-00-810-801-A Failure of FMGC1)Fredy BonillaNo ratings yet

- Communication Connectivity Diagram For 220/33 KV Pooling Substation at Muttala Village Rayala Wind Power A/C Greenko.-ExtensionDocument1 pageCommunication Connectivity Diagram For 220/33 KV Pooling Substation at Muttala Village Rayala Wind Power A/C Greenko.-ExtensionHeather CarterNo ratings yet

- A330 - TSM - 21-31-00-810-879-A - Outflow Valves Do Not Close in The Ditching ConfigurationDocument1 pageA330 - TSM - 21-31-00-810-879-A - Outflow Valves Do Not Close in The Ditching Configurationsah3liNo ratings yet

- Chapter 22Document424 pagesChapter 22Station operation KBRNo ratings yet

- rp-c4108 DMC 3Document3 pagesrp-c4108 DMC 3billyNo ratings yet

- 09 1963 CH-Electrical SystemsDocument44 pages09 1963 CH-Electrical SystemsJose LaproviteraNo ratings yet

- Planning and Cost Analysis DataDocument51 pagesPlanning and Cost Analysis DataTreasure321No ratings yet

- Weekly Schedule: NO. Item Percentage Completion Mon. Tues. Wed. Thurs. Fri. Sat. Sun. 12 13 14 15 16 17 18Document6 pagesWeekly Schedule: NO. Item Percentage Completion Mon. Tues. Wed. Thurs. Fri. Sat. Sun. 12 13 14 15 16 17 18Colesha BarukaNo ratings yet

- Comments 1Document1 pageComments 1technojet21No ratings yet

- Kv2160wr - TV SonyDocument57 pagesKv2160wr - TV SonyapitzhappyrecordsNo ratings yet

- Tooling 2Document13 pagesTooling 2Ivo SilvaNo ratings yet

- MMO - A318 - A319 - A320 - A321 - AMM - 01-Aug-2022 - 29-12-51-000-001-A - Removal of The Electric PumpDocument4 pagesMMO - A318 - A319 - A320 - A321 - AMM - 01-Aug-2022 - 29-12-51-000-001-A - Removal of The Electric PumpBatuhan YildizNo ratings yet

- Ebro Operating Instructions Manual Modular Systeme - ENDocument55 pagesEbro Operating Instructions Manual Modular Systeme - ENErland CuariteNo ratings yet

- 12 24KV GF1 GF2 Gis Rmu R0Document2 pages12 24KV GF1 GF2 Gis Rmu R0Mohd Afifi JusohNo ratings yet

- Commissioning ActivitiesDocument19 pagesCommissioning ActivitiesDanish VodeyarNo ratings yet

- Ubstation Common SettingDocument15 pagesUbstation Common Settingaravindhana1a1100% (1)

- Philips 22dc593-62l 22dc594-62f-62l SM ColorDocument28 pagesPhilips 22dc593-62l 22dc594-62f-62l SM Colormkl.valentinNo ratings yet

- PlenumDocument9 pagesPlenumAnuna Amanullah100% (1)

- Pressurization Components TestDocument32 pagesPressurization Components TestRanjit ShawNo ratings yet

- Philips 104s Cm23 Gs IIIDocument53 pagesPhilips 104s Cm23 Gs IIIadrianrossosjNo ratings yet

- AMM - 01-Aug-2023 - 22-63-00-710-001-A - Operational Test of The Yaw Damper FunctionDocument4 pagesAMM - 01-Aug-2023 - 22-63-00-710-001-A - Operational Test of The Yaw Damper Functionayan acharjeeNo ratings yet

- Amm InstallationDocument8 pagesAmm Installationsreenathsreekumar2009No ratings yet

- IAD - A318 - A319 - A320 - A321 - AMM - 01-Aug-2021 - 29-00-00-790-001-A - Check of The External Leaks of The Hydraulic ComponentsDocument12 pagesIAD - A318 - A319 - A320 - A321 - AMM - 01-Aug-2021 - 29-00-00-790-001-A - Check of The External Leaks of The Hydraulic ComponentsMONOJ ANo ratings yet

- Relay Setting Calculation LatestDocument23 pagesRelay Setting Calculation Latestমোঃ মহসিনNo ratings yet

- @A318/A319/A320/A321: Chapter 35 - OxygenDocument50 pages@A318/A319/A320/A321: Chapter 35 - OxygenhengwahchungNo ratings yet

- Go/No Go Test: Xperia L C2104, C2105, S36hDocument8 pagesGo/No Go Test: Xperia L C2104, C2105, S36hEdixon AgurreNo ratings yet

- ATLAS-210x/215x: Installation Operation and MaintenanceDocument98 pagesATLAS-210x/215x: Installation Operation and Maintenances.gaffilunilicei.it Gaffi StefanoNo ratings yet

- 1 PM 56K HOURS (The Running Hrs Now Exceeding 9758 HRS) 2 PM 56K HOURS (The Running Hrs Now Exceeding 944 HRS) 3Document2 pages1 PM 56K HOURS (The Running Hrs Now Exceeding 9758 HRS) 2 PM 56K HOURS (The Running Hrs Now Exceeding 944 HRS) 3Zaini SarbiniNo ratings yet

- FM 2-58 - Indicator Post Valves - Turns To OpenDocument2 pagesFM 2-58 - Indicator Post Valves - Turns To OpenwastedsunsetsNo ratings yet

- 500kv 220kv, NTDC, Grid Station Gatti Faisalabad.Document56 pages500kv 220kv, NTDC, Grid Station Gatti Faisalabad.Cheap but good100% (3)

- Supervised Industrial Training Report: National Transmission and Despatch Company (NTDC) PakistanDocument56 pagesSupervised Industrial Training Report: National Transmission and Despatch Company (NTDC) PakistanMarina KhanNo ratings yet

- Mark2 Kiigroundf Fault Ctif Tre Ficat TionDocument3 pagesMark2 Kiigroundf Fault Ctif Tre Ficat TionMohamed Bin IerousNo ratings yet

- AMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Document3 pagesAMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Andre SanarNo ratings yet

- AMM A320F - Removal of Lavatory ADocument12 pagesAMM A320F - Removal of Lavatory AMugilanNo ratings yet

- Field Winding - Test: Shutdown SIS Previous ScreenDocument2 pagesField Winding - Test: Shutdown SIS Previous ScreenHector VallesNo ratings yet

- Service Bulletin: SUBJECT: Improve The High Voltage Electrical Charge For All Pegasus 19"Document1 pageService Bulletin: SUBJECT: Improve The High Voltage Electrical Charge For All Pegasus 19"robertoaj1No ratings yet

- Understanding Lightning and Lightning Protection: A Multimedia Teaching GuideFrom EverandUnderstanding Lightning and Lightning Protection: A Multimedia Teaching GuideNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Kinematic Wave Routing - ExampleDocument33 pagesKinematic Wave Routing - ExamplethewodrosNo ratings yet

- Distillation ColumnDocument59 pagesDistillation Columnfurqankausarhaider100% (5)

- 490806Document2 pages490806Informative InsaanNo ratings yet

- Silicio UllmanDocument29 pagesSilicio UllmanPaula OlazabalNo ratings yet

- Jawaban Bahasa InggrisDocument9 pagesJawaban Bahasa InggrisHusnul KhotimahNo ratings yet

- CCTV Technology Handbook: System Assessment and Validation For Emergency Responders (SAVER)Document33 pagesCCTV Technology Handbook: System Assessment and Validation For Emergency Responders (SAVER)vijay babuNo ratings yet

- Electronic Devices and CircuitsDocument525 pagesElectronic Devices and CircuitsSibasankar Padhy100% (4)

- SIRE Observations For 2018, 02 Jan'19Document14 pagesSIRE Observations For 2018, 02 Jan'19Romāns BogdanovsNo ratings yet

- Product Specifications 40" WXGA Color TFT-LCD Module Model Name: T400XW01 V5Document27 pagesProduct Specifications 40" WXGA Color TFT-LCD Module Model Name: T400XW01 V5marciocambruzziNo ratings yet

- Algebra Complete - 1Document120 pagesAlgebra Complete - 1kiran.suresh19No ratings yet

- Topic 2Document9 pagesTopic 2Ria AccadNo ratings yet

- 1.1 Introduction To The Particulate Nature of Matter and Chemical ChangeDocument46 pages1.1 Introduction To The Particulate Nature of Matter and Chemical ChangeCrystalNo ratings yet

- Model Paper Grade 6Document10 pagesModel Paper Grade 6mehmood aliNo ratings yet

- Do Transformers Really Perform Bad For Graph Representation?Document19 pagesDo Transformers Really Perform Bad For Graph Representation?wenwen XiaNo ratings yet

- Miniature Bioreactors Current Practices and Future Opportunities PDFDocument14 pagesMiniature Bioreactors Current Practices and Future Opportunities PDFLuisNo ratings yet

- 170 Adi 350 00Document14 pages170 Adi 350 00Gabriel ZorattiNo ratings yet

- Comcast Smart ResumeDocument8 pagesComcast Smart Resumewajhnzwhf100% (1)

- English MONTHDocument6 pagesEnglish MONTHSoliman Micaela M.No ratings yet

- Linear Regression Analysis McqsDocument2 pagesLinear Regression Analysis McqsEngr Mujahid Iqbal80% (5)

- Saa 11Document184 pagesSaa 11jcch1969No ratings yet

- Physiology Chapter 30 Renal Regulation of PotassiumDocument32 pagesPhysiology Chapter 30 Renal Regulation of PotassiumDaniel AdamsNo ratings yet

- Tubay 34.2Document33 pagesTubay 34.2gega nesywaraNo ratings yet

- Manual de Calidad de Cerveza de Barril-2019 PDFDocument122 pagesManual de Calidad de Cerveza de Barril-2019 PDFAndrey Giovanny Riveros MerchanNo ratings yet

- Unit 17 Computer Aided Manufacture CamDocument11 pagesUnit 17 Computer Aided Manufacture CamManiDeepNo ratings yet

- Hudco Trophy: Vernacular Habitats To Combat Climate ChangeDocument8 pagesHudco Trophy: Vernacular Habitats To Combat Climate ChangeUDAY PRAKASH MISHRANo ratings yet

- Codex - SeasoningDocument17 pagesCodex - SeasoningNadia KaharNo ratings yet

- Chandrayaan-2 Indias Second Lunar Exploration MisDocument16 pagesChandrayaan-2 Indias Second Lunar Exploration MisTanu SinghNo ratings yet

- Apple Airpods Max Complete Features Instructions ManualDocument7 pagesApple Airpods Max Complete Features Instructions ManualIlaria iudiceNo ratings yet