Professional Documents

Culture Documents

7.kicker CAPA 31.5.13

7.kicker CAPA 31.5.13

Uploaded by

delightplasticsCopyright:

Available Formats

You might also like

- QRQC / 8D Form: D 1. Description of The ProblemDocument5 pagesQRQC / 8D Form: D 1. Description of The ProblemDearRed FrankNo ratings yet

- Quality Manual ISo13485Document25 pagesQuality Manual ISo13485Neha Ukale100% (2)

- 8D Report: Problem Solving TeamDocument2 pages8D Report: Problem Solving TeamAshok Kumar A100% (4)

- PPAP Approval FormDocument1 pagePPAP Approval FormNeco StanderNo ratings yet

- Auditor TesDocument19 pagesAuditor TesRinto Erwiansa PutraNo ratings yet

- Case Study On Tata SteelDocument6 pagesCase Study On Tata Steelsameerverma_78No ratings yet

- Sample Job Description QMRDocument2 pagesSample Job Description QMRamirul8686100% (1)

- Record Requirement For ISO 9001 - 2015Document2 pagesRecord Requirement For ISO 9001 - 2015NMA AppraiserNo ratings yet

- Total Quality Management On ToyotaDocument89 pagesTotal Quality Management On ToyotaChitrak Patil67% (3)

- Surface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODDocument7 pagesSurface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODBALACHANDAR SNo ratings yet

- Intervention Report (Trouble) : Page: 1/1 Review Date: 17/12/2020 Redaction Date: 22/10/2019 Reference: PS1-FORM-08Document1 pageIntervention Report (Trouble) : Page: 1/1 Review Date: 17/12/2020 Redaction Date: 22/10/2019 Reference: PS1-FORM-08Ramy Hassan EmaraNo ratings yet

- UtasTech Claim ReportDocument2 pagesUtasTech Claim ReportGalilea GalileaNo ratings yet

- Online Feedback System 1921Document2 pagesOnline Feedback System 1921santosh kumarNo ratings yet

- Supplier 8D Report: D 1. Description of The ProblemDocument7 pagesSupplier 8D Report: D 1. Description of The ProblemDearRed FrankNo ratings yet

- Capa 4500002638Document5 pagesCapa 4500002638singh.kuldeep29980No ratings yet

- Control PlanDocument2 pagesControl PlanChintamani Giramkar100% (1)

- 8D Analysis ReportDocument1 page8D Analysis ReportRupee Rudolf Lucy HaNo ratings yet

- Quality Alert - Revised 2017Document4 pagesQuality Alert - Revised 2017Faraj KhanNo ratings yet

- Online Feedback System 1738Document2 pagesOnline Feedback System 1738santosh kumarNo ratings yet

- Online Feedback System 1656Document2 pagesOnline Feedback System 1656santosh kumarNo ratings yet

- Control Plan-06Document2 pagesControl Plan-06PARI VALLALNo ratings yet

- Online Feedback System 2011Document2 pagesOnline Feedback System 2011santosh kumarNo ratings yet

- Setting Block Epdm Rev.1Document37 pagesSetting Block Epdm Rev.1Ravi Shankar KolluruNo ratings yet

- QAD Procedure - Control of Non-Conforming Products P1Document1 pageQAD Procedure - Control of Non-Conforming Products P1sumanNo ratings yet

- CP ProductionDocument7 pagesCP Productionsandeep.pantNo ratings yet

- 8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final in Charge Premkumar-CNC OperatorDocument4 pages8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final in Charge Premkumar-CNC OperatorVasanth KumarNo ratings yet

- Online Feedback System 1723Document2 pagesOnline Feedback System 1723santosh kumarNo ratings yet

- Ok Part NG: (Vendor Non-Conformance Report)Document2 pagesOk Part NG: (Vendor Non-Conformance Report)BeLlCoNtInEnT MNo ratings yet

- 8D For ID Over sizeTECUMSEHDocument4 pages8D For ID Over sizeTECUMSEHKuldeep SinghNo ratings yet

- Ipp Tag FormatDocument1 pageIpp Tag FormatSKAI AUTO100% (1)

- Quality Alert 4 - Revised 2017Document2 pagesQuality Alert 4 - Revised 2017Faraj Khan100% (1)

- Quality Alert - Revised 2017Document2 pagesQuality Alert - Revised 2017Faraj KhanNo ratings yet

- URM-0819-098-MA - Cover - Warping - Condition - KDC-X7200DABEN MA12Document7 pagesURM-0819-098-MA - Cover - Warping - Condition - KDC-X7200DABEN MA12Sahid Nugroho WNo ratings yet

- Imir Pisl New (Santosh Singh Qa/qc Senior Manager)Document1 pageImir Pisl New (Santosh Singh Qa/qc Senior Manager)Santosh KumarNo ratings yet

- Pilot Lot InspectionDocument4 pagesPilot Lot Inspectiongocohov660No ratings yet

- Online Feedback System 1973Document2 pagesOnline Feedback System 1973santosh kumarNo ratings yet

- Quality Alert1 - Revised 2017Document4 pagesQuality Alert1 - Revised 2017Faraj KhanNo ratings yet

- QSP-05 Procedure - For - Non-Conforming - ProductDocument3 pagesQSP-05 Procedure - For - Non-Conforming - Productsigmaqcs02No ratings yet

- QAF-109 Supplier Corrective Action Request - GIDEP 6-1-18Document15 pagesQAF-109 Supplier Corrective Action Request - GIDEP 6-1-18AlineMeirelesNo ratings yet

- DocumentedDocument2 pagesDocumentedMahmoud KhalifaNo ratings yet

- F-PD-02 Control PlanDocument1 pageF-PD-02 Control PlanTrivesh SharmaNo ratings yet

- 8d Report New R5270Document3 pages8d Report New R5270muthuselvanNo ratings yet

- 2953 Thrad TightDocument6 pages2953 Thrad TightRohit QualityNo ratings yet

- Online Feedback System 2015Document2 pagesOnline Feedback System 2015santosh kumarNo ratings yet

- Flow Chart - Marketing Process: Start Receipt of Enquiry From The CustomerDocument3 pagesFlow Chart - Marketing Process: Start Receipt of Enquiry From The CustomerSekar Krish100% (2)

- 8d Report Ajax Fiori Stopper PinDocument4 pages8d Report Ajax Fiori Stopper PinVengadesh MNo ratings yet

- FORM 08 - Intervention Report - CRANK SHEAR - Copie - CopieDocument2 pagesFORM 08 - Intervention Report - CRANK SHEAR - Copie - CopieRamy Hassan EmaraNo ratings yet

- Online Feedback System 1665Document2 pagesOnline Feedback System 1665santosh kumarNo ratings yet

- 8D FormatDocument6 pages8D FormathemrajNo ratings yet

- Online Feedback System 1529Document2 pagesOnline Feedback System 1529santosh kumarNo ratings yet

- Non Conformity Format 01-10-2022Document1 pageNon Conformity Format 01-10-2022qc vahinipipesNo ratings yet

- Mahindra Bolt Loosening Issue 3.10.2017Document24 pagesMahindra Bolt Loosening Issue 3.10.2017Sridharan VenkatNo ratings yet

- 10-Qua-15 F01 Deviation Request Format-01.12.2019Document1 page10-Qua-15 F01 Deviation Request Format-01.12.2019Rohit SoniNo ratings yet

- 5.1.1.2 - Process Effectiveness and Efficiency - Other ExampleDocument2 pages5.1.1.2 - Process Effectiveness and Efficiency - Other Examplerc2834338No ratings yet

- Control PlanDocument9 pagesControl Planjose antonioNo ratings yet

- Material Rejection ReportDocument4 pagesMaterial Rejection ReportMunazar HussainNo ratings yet

- Supplier Problem Response Report Unpressed IssueDocument1 pageSupplier Problem Response Report Unpressed IssueKuldeep SinghNo ratings yet

- Isir - (00003)Document1 pageIsir - (00003)ducthangspktNo ratings yet

- 8D Double Punch in WW 17mmDocument2 pages8D Double Punch in WW 17mmmoonlight toolsNo ratings yet

- CAPA Escort (08.08.2023)Document1 pageCAPA Escort (08.08.2023)HOD QUALITYNo ratings yet

- Saudi Aramco Inspection Checklist Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklist Saudi Aramco Inspection ChecklistNickath BanuNo ratings yet

- Online Feedback System 1563Document2 pagesOnline Feedback System 1563santosh kumarNo ratings yet

- Item Code Quantity UOM Description Stock / Non Stock Item Estimated Unit Cost ($) Total Cost ($)Document2 pagesItem Code Quantity UOM Description Stock / Non Stock Item Estimated Unit Cost ($) Total Cost ($)DILNo ratings yet

- Online Feedback System 1782Document2 pagesOnline Feedback System 1782santosh kumarNo ratings yet

- 1 OnlineDocument15 pages1 OnlineMuhaiminul Islam MubinNo ratings yet

- Time Table of MBADocument42 pagesTime Table of MBALatha JujariNo ratings yet

- Test Bank For Management 12th Edition by Schermerhorn Sample ChapterDocument26 pagesTest Bank For Management 12th Edition by Schermerhorn Sample ChapterAndrea NovillasNo ratings yet

- Quality Management ProgramDocument31 pagesQuality Management ProgramBibo RamirezNo ratings yet

- Influence of Entrepreneurial Orientation and Total Quality Management On Organizational Performance of Pharmaceutical Smes in Thailand With Moderating Role of Organizational LearningDocument11 pagesInfluence of Entrepreneurial Orientation and Total Quality Management On Organizational Performance of Pharmaceutical Smes in Thailand With Moderating Role of Organizational LearningAnkeshNo ratings yet

- Quality ManagementDocument20 pagesQuality ManagementChakshuBehl100% (1)

- WCMDocument66 pagesWCMKARLANo ratings yet

- Quality Information Systems PPT 1231Document31 pagesQuality Information Systems PPT 1231Reuben George80% (5)

- ERP Unit4Document70 pagesERP Unit4Bhuvana GanesanNo ratings yet

- Total Quality Management IN Emirates: Department of Business Management University of Central Punjab, BahawalpurDocument6 pagesTotal Quality Management IN Emirates: Department of Business Management University of Central Punjab, BahawalpurFaisal khanNo ratings yet

- Final Exam Preparation Busd 2027Document22 pagesFinal Exam Preparation Busd 2027Nyko Martin MartinNo ratings yet

- NOTADocument37 pagesNOTADuin Abd AzizNo ratings yet

- ISO 9001:2015 ISO 45001:2018: 4 Context of The Organization 4 Context of The OrganizationDocument2 pagesISO 9001:2015 ISO 45001:2018: 4 Context of The Organization 4 Context of The Organizationsohaib100% (1)

- Top Management SupportDocument5 pagesTop Management SupportMia BernardioNo ratings yet

- Ho - Basic Concepts of Qa & QCDocument13 pagesHo - Basic Concepts of Qa & QCtealyngripoNo ratings yet

- Multiple Choice Questions (MCQ) On Total Quality Management (TQM) - Set 3 - ScholarexpressDocument7 pagesMultiple Choice Questions (MCQ) On Total Quality Management (TQM) - Set 3 - ScholarexpresspramodNo ratings yet

- Lecture 6 - Project Quality ManagementDocument29 pagesLecture 6 - Project Quality ManagementZain GhummanNo ratings yet

- HMIS Project ProposalDocument17 pagesHMIS Project ProposalManal KhanNo ratings yet

- Presentation - Quality (Schedule 'Q' Requirements)Document55 pagesPresentation - Quality (Schedule 'Q' Requirements)kbldam100% (1)

- APQP ENG SiemensDocument12 pagesAPQP ENG SiemensVikash KumarNo ratings yet

- Lean Six Sigma Black Belt-Hesham Alshareef-UsaDocument1 pageLean Six Sigma Black Belt-Hesham Alshareef-UsaAbdulRahman AlhusseinNo ratings yet

- SAP PP-Production Planning: Key Steps in Production ExecutionDocument7 pagesSAP PP-Production Planning: Key Steps in Production ExecutionAhmed IhsanNo ratings yet

- Operations Management by Russell and Taylor - PRELIM-1Document119 pagesOperations Management by Russell and Taylor - PRELIM-1Bryl EfenioNo ratings yet

- Operations ManagementDocument19 pagesOperations ManagementRenzNo ratings yet

7.kicker CAPA 31.5.13

7.kicker CAPA 31.5.13

Uploaded by

delightplasticsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7.kicker CAPA 31.5.13

7.kicker CAPA 31.5.13

Uploaded by

delightplasticsCopyright:

Available Formats

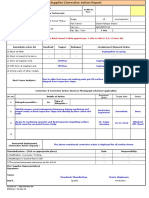

CAPA No.

Corrective & Preventive action

Component / Matl. Name (Part No.) - Kicker PPS ( SAC 752 ) Date of Problem identification - 30/05/2013

Component / Matl. Supplier Name - Sani Moulds Product Name - Timer / Thermostat / Press shop / Capillary

Actual problem details

Qty.consu

Problem facing Reason for the problem Qty.defective Remarks

med

Flash Packing person without permission

Packed ok & Hold piece . 50000 nos

Stage Qty. Immediate action / Decision for stock

At Invensys customer end

Stock status at different stages - On Invensys prodn line

In Invensys store Immidiate replace the parts at customer end .

At supplier end 100% sagrigation at our end .

Corrective action

Completion

Corrective action planned Target date Responsibility Observations Remarks / Comments

date

Immidiate replace the parts at

customer end .And 100% shorting 1/6/2013 Ram

of present stock for flash.

Preventive action

Completion

Preventive action planned Target date Responsibility Observations Remarks / Comments

date

We will be instruction given to

Packing person as flashes problem

. And do not pack any material 1/6/2013 Ram

without QC permission .

After CAPA Parts used in & dispatched to (If any identification mark - )

Customer name Model no.& Qty. Identification on product Date Observations Remarks / Comments

Signatures with Name -->Ram Yadav Supplier Quality Purchase Stores Production MR

QF/SUPP/10/07 Rev.no.-0 Rev.Date -Nil Eff.Date - 14.10.07

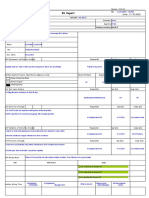

CAPA No. -

- Supplier should fill - Blank boxes Invensys should fill

QF/SUPP/10/07 Rev.no.-0 Rev.Date -Nil Eff.Date - 14.10.07

CAPA No. -

op / Capillary

s / Comments

s / Comments

s / Comments

MR

QF/SUPP/10/07 Rev.no.-0 Rev.Date -Nil Eff.Date - 14.10.07

CAPA No. -

Corrective & Preventive action

Component / Matl. Name (Part No.) - Dust Cover Yellow ( RC -751-03 ) Date of Problem identification - 31/05/2013

Component / Matl. Supplier Name - Sani Moulds Product Name - Timer / Thermostat / Press shop / Capillary

Actual problem details

Qty.consu

Problem facing Reason for the problem Qty.defective Remarks

med

Color Veriation Operator master batch not mixing properly 10000

Stage Qty. Immediate action / Decision for stock

At Invensys customer end

Stock status at different stages - On Invensys prodn line

In Invensys store

At supplier end Immediate 100% sagrigation

Corrective action

Completion

Corrective action planned Target date Responsibility Observations Remarks / Comments

date

Immediate replacements 1/6/2013 Ram

Qty 10000nos

Preventive action

Completion

Preventive action planned Target date Responsibility Observations Remarks / Comments

date

Instruction given to the operator .

How should mix the material.And 1/6/2013 Ram

also geven instruction to packing

persson to check color with master

sample before packing the material.

After CAPA Parts used in & dispatched to (If any identification mark - )

Customer name Model no.& Qty. Identification on product Date Observations Remarks / Comments

Signatures with Name -->Ram Yadav Supplier Quality Purchase Stores Production MR

QF/SUPP/10/07 Rev.no.-0 Rev.Date -Nil Eff.Date - 14.10.07

CAPA No. -

- Supplier should fill - Blank boxes Invensys should fill

QF/SUPP/10/07 Rev.no.-0 Rev.Date -Nil Eff.Date - 14.10.07

CAPA No. -

op / Capillary

s / Comments

s / Comments

s / Comments

MR

QF/SUPP/10/07 Rev.no.-0 Rev.Date -Nil Eff.Date - 14.10.07

You might also like

- QRQC / 8D Form: D 1. Description of The ProblemDocument5 pagesQRQC / 8D Form: D 1. Description of The ProblemDearRed FrankNo ratings yet

- Quality Manual ISo13485Document25 pagesQuality Manual ISo13485Neha Ukale100% (2)

- 8D Report: Problem Solving TeamDocument2 pages8D Report: Problem Solving TeamAshok Kumar A100% (4)

- PPAP Approval FormDocument1 pagePPAP Approval FormNeco StanderNo ratings yet

- Auditor TesDocument19 pagesAuditor TesRinto Erwiansa PutraNo ratings yet

- Case Study On Tata SteelDocument6 pagesCase Study On Tata Steelsameerverma_78No ratings yet

- Sample Job Description QMRDocument2 pagesSample Job Description QMRamirul8686100% (1)

- Record Requirement For ISO 9001 - 2015Document2 pagesRecord Requirement For ISO 9001 - 2015NMA AppraiserNo ratings yet

- Total Quality Management On ToyotaDocument89 pagesTotal Quality Management On ToyotaChitrak Patil67% (3)

- Surface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODDocument7 pagesSurface Finish Found 5.68ra Against Spe. 3.2ra On Ø60.0-0.3/-0.2mm ODBALACHANDAR SNo ratings yet

- Intervention Report (Trouble) : Page: 1/1 Review Date: 17/12/2020 Redaction Date: 22/10/2019 Reference: PS1-FORM-08Document1 pageIntervention Report (Trouble) : Page: 1/1 Review Date: 17/12/2020 Redaction Date: 22/10/2019 Reference: PS1-FORM-08Ramy Hassan EmaraNo ratings yet

- UtasTech Claim ReportDocument2 pagesUtasTech Claim ReportGalilea GalileaNo ratings yet

- Online Feedback System 1921Document2 pagesOnline Feedback System 1921santosh kumarNo ratings yet

- Supplier 8D Report: D 1. Description of The ProblemDocument7 pagesSupplier 8D Report: D 1. Description of The ProblemDearRed FrankNo ratings yet

- Capa 4500002638Document5 pagesCapa 4500002638singh.kuldeep29980No ratings yet

- Control PlanDocument2 pagesControl PlanChintamani Giramkar100% (1)

- 8D Analysis ReportDocument1 page8D Analysis ReportRupee Rudolf Lucy HaNo ratings yet

- Quality Alert - Revised 2017Document4 pagesQuality Alert - Revised 2017Faraj KhanNo ratings yet

- Online Feedback System 1738Document2 pagesOnline Feedback System 1738santosh kumarNo ratings yet

- Online Feedback System 1656Document2 pagesOnline Feedback System 1656santosh kumarNo ratings yet

- Control Plan-06Document2 pagesControl Plan-06PARI VALLALNo ratings yet

- Online Feedback System 2011Document2 pagesOnline Feedback System 2011santosh kumarNo ratings yet

- Setting Block Epdm Rev.1Document37 pagesSetting Block Epdm Rev.1Ravi Shankar KolluruNo ratings yet

- QAD Procedure - Control of Non-Conforming Products P1Document1 pageQAD Procedure - Control of Non-Conforming Products P1sumanNo ratings yet

- CP ProductionDocument7 pagesCP Productionsandeep.pantNo ratings yet

- 8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final in Charge Premkumar-CNC OperatorDocument4 pages8D Report: Vasanth - Production Engineer Vijaykumar - Quality Head Prabhakaran - Final in Charge Premkumar-CNC OperatorVasanth KumarNo ratings yet

- Online Feedback System 1723Document2 pagesOnline Feedback System 1723santosh kumarNo ratings yet

- Ok Part NG: (Vendor Non-Conformance Report)Document2 pagesOk Part NG: (Vendor Non-Conformance Report)BeLlCoNtInEnT MNo ratings yet

- 8D For ID Over sizeTECUMSEHDocument4 pages8D For ID Over sizeTECUMSEHKuldeep SinghNo ratings yet

- Ipp Tag FormatDocument1 pageIpp Tag FormatSKAI AUTO100% (1)

- Quality Alert 4 - Revised 2017Document2 pagesQuality Alert 4 - Revised 2017Faraj Khan100% (1)

- Quality Alert - Revised 2017Document2 pagesQuality Alert - Revised 2017Faraj KhanNo ratings yet

- URM-0819-098-MA - Cover - Warping - Condition - KDC-X7200DABEN MA12Document7 pagesURM-0819-098-MA - Cover - Warping - Condition - KDC-X7200DABEN MA12Sahid Nugroho WNo ratings yet

- Imir Pisl New (Santosh Singh Qa/qc Senior Manager)Document1 pageImir Pisl New (Santosh Singh Qa/qc Senior Manager)Santosh KumarNo ratings yet

- Pilot Lot InspectionDocument4 pagesPilot Lot Inspectiongocohov660No ratings yet

- Online Feedback System 1973Document2 pagesOnline Feedback System 1973santosh kumarNo ratings yet

- Quality Alert1 - Revised 2017Document4 pagesQuality Alert1 - Revised 2017Faraj KhanNo ratings yet

- QSP-05 Procedure - For - Non-Conforming - ProductDocument3 pagesQSP-05 Procedure - For - Non-Conforming - Productsigmaqcs02No ratings yet

- QAF-109 Supplier Corrective Action Request - GIDEP 6-1-18Document15 pagesQAF-109 Supplier Corrective Action Request - GIDEP 6-1-18AlineMeirelesNo ratings yet

- DocumentedDocument2 pagesDocumentedMahmoud KhalifaNo ratings yet

- F-PD-02 Control PlanDocument1 pageF-PD-02 Control PlanTrivesh SharmaNo ratings yet

- 8d Report New R5270Document3 pages8d Report New R5270muthuselvanNo ratings yet

- 2953 Thrad TightDocument6 pages2953 Thrad TightRohit QualityNo ratings yet

- Online Feedback System 2015Document2 pagesOnline Feedback System 2015santosh kumarNo ratings yet

- Flow Chart - Marketing Process: Start Receipt of Enquiry From The CustomerDocument3 pagesFlow Chart - Marketing Process: Start Receipt of Enquiry From The CustomerSekar Krish100% (2)

- 8d Report Ajax Fiori Stopper PinDocument4 pages8d Report Ajax Fiori Stopper PinVengadesh MNo ratings yet

- FORM 08 - Intervention Report - CRANK SHEAR - Copie - CopieDocument2 pagesFORM 08 - Intervention Report - CRANK SHEAR - Copie - CopieRamy Hassan EmaraNo ratings yet

- Online Feedback System 1665Document2 pagesOnline Feedback System 1665santosh kumarNo ratings yet

- 8D FormatDocument6 pages8D FormathemrajNo ratings yet

- Online Feedback System 1529Document2 pagesOnline Feedback System 1529santosh kumarNo ratings yet

- Non Conformity Format 01-10-2022Document1 pageNon Conformity Format 01-10-2022qc vahinipipesNo ratings yet

- Mahindra Bolt Loosening Issue 3.10.2017Document24 pagesMahindra Bolt Loosening Issue 3.10.2017Sridharan VenkatNo ratings yet

- 10-Qua-15 F01 Deviation Request Format-01.12.2019Document1 page10-Qua-15 F01 Deviation Request Format-01.12.2019Rohit SoniNo ratings yet

- 5.1.1.2 - Process Effectiveness and Efficiency - Other ExampleDocument2 pages5.1.1.2 - Process Effectiveness and Efficiency - Other Examplerc2834338No ratings yet

- Control PlanDocument9 pagesControl Planjose antonioNo ratings yet

- Material Rejection ReportDocument4 pagesMaterial Rejection ReportMunazar HussainNo ratings yet

- Supplier Problem Response Report Unpressed IssueDocument1 pageSupplier Problem Response Report Unpressed IssueKuldeep SinghNo ratings yet

- Isir - (00003)Document1 pageIsir - (00003)ducthangspktNo ratings yet

- 8D Double Punch in WW 17mmDocument2 pages8D Double Punch in WW 17mmmoonlight toolsNo ratings yet

- CAPA Escort (08.08.2023)Document1 pageCAPA Escort (08.08.2023)HOD QUALITYNo ratings yet

- Saudi Aramco Inspection Checklist Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection Checklist Saudi Aramco Inspection ChecklistNickath BanuNo ratings yet

- Online Feedback System 1563Document2 pagesOnline Feedback System 1563santosh kumarNo ratings yet

- Item Code Quantity UOM Description Stock / Non Stock Item Estimated Unit Cost ($) Total Cost ($)Document2 pagesItem Code Quantity UOM Description Stock / Non Stock Item Estimated Unit Cost ($) Total Cost ($)DILNo ratings yet

- Online Feedback System 1782Document2 pagesOnline Feedback System 1782santosh kumarNo ratings yet

- 1 OnlineDocument15 pages1 OnlineMuhaiminul Islam MubinNo ratings yet

- Time Table of MBADocument42 pagesTime Table of MBALatha JujariNo ratings yet

- Test Bank For Management 12th Edition by Schermerhorn Sample ChapterDocument26 pagesTest Bank For Management 12th Edition by Schermerhorn Sample ChapterAndrea NovillasNo ratings yet

- Quality Management ProgramDocument31 pagesQuality Management ProgramBibo RamirezNo ratings yet

- Influence of Entrepreneurial Orientation and Total Quality Management On Organizational Performance of Pharmaceutical Smes in Thailand With Moderating Role of Organizational LearningDocument11 pagesInfluence of Entrepreneurial Orientation and Total Quality Management On Organizational Performance of Pharmaceutical Smes in Thailand With Moderating Role of Organizational LearningAnkeshNo ratings yet

- Quality ManagementDocument20 pagesQuality ManagementChakshuBehl100% (1)

- WCMDocument66 pagesWCMKARLANo ratings yet

- Quality Information Systems PPT 1231Document31 pagesQuality Information Systems PPT 1231Reuben George80% (5)

- ERP Unit4Document70 pagesERP Unit4Bhuvana GanesanNo ratings yet

- Total Quality Management IN Emirates: Department of Business Management University of Central Punjab, BahawalpurDocument6 pagesTotal Quality Management IN Emirates: Department of Business Management University of Central Punjab, BahawalpurFaisal khanNo ratings yet

- Final Exam Preparation Busd 2027Document22 pagesFinal Exam Preparation Busd 2027Nyko Martin MartinNo ratings yet

- NOTADocument37 pagesNOTADuin Abd AzizNo ratings yet

- ISO 9001:2015 ISO 45001:2018: 4 Context of The Organization 4 Context of The OrganizationDocument2 pagesISO 9001:2015 ISO 45001:2018: 4 Context of The Organization 4 Context of The Organizationsohaib100% (1)

- Top Management SupportDocument5 pagesTop Management SupportMia BernardioNo ratings yet

- Ho - Basic Concepts of Qa & QCDocument13 pagesHo - Basic Concepts of Qa & QCtealyngripoNo ratings yet

- Multiple Choice Questions (MCQ) On Total Quality Management (TQM) - Set 3 - ScholarexpressDocument7 pagesMultiple Choice Questions (MCQ) On Total Quality Management (TQM) - Set 3 - ScholarexpresspramodNo ratings yet

- Lecture 6 - Project Quality ManagementDocument29 pagesLecture 6 - Project Quality ManagementZain GhummanNo ratings yet

- HMIS Project ProposalDocument17 pagesHMIS Project ProposalManal KhanNo ratings yet

- Presentation - Quality (Schedule 'Q' Requirements)Document55 pagesPresentation - Quality (Schedule 'Q' Requirements)kbldam100% (1)

- APQP ENG SiemensDocument12 pagesAPQP ENG SiemensVikash KumarNo ratings yet

- Lean Six Sigma Black Belt-Hesham Alshareef-UsaDocument1 pageLean Six Sigma Black Belt-Hesham Alshareef-UsaAbdulRahman AlhusseinNo ratings yet

- SAP PP-Production Planning: Key Steps in Production ExecutionDocument7 pagesSAP PP-Production Planning: Key Steps in Production ExecutionAhmed IhsanNo ratings yet

- Operations Management by Russell and Taylor - PRELIM-1Document119 pagesOperations Management by Russell and Taylor - PRELIM-1Bryl EfenioNo ratings yet

- Operations ManagementDocument19 pagesOperations ManagementRenzNo ratings yet