Professional Documents

Culture Documents

WPS - Is4923 Smaw

WPS - Is4923 Smaw

Uploaded by

prudvirajsriujjwalaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WPS - Is4923 Smaw

WPS - Is4923 Smaw

Uploaded by

prudvirajsriujjwalaCopyright:

Available Formats

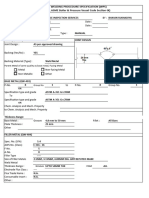

Jaybee Composites & Allied Equipments

Plot no.48 Rajeev Gandhi Nagar, Prashanti

Nagar, Balanagar, Hyderabad , Telangana

WELDING PROCEDURE SPECIFICATION (WPS)

(QW-200.1, SECTION IX, ASME BOILER AND PRESSURE VESSEL CODE)

WPS No. : JCAE/WPS-01 Date: 25-01-2023 Supporting PQR No:JCAE/SMAW/3G / IS4923 /IS4923 /WPS/01

Revision No.: 00 Date:25-01-2023 Welding Process(es) : SMAW Type(s) : Manual

JOINTS (QW-402) JOINT SKETCH

Joint Design As per Joint Sketch in drawing

Root Spacing As per Joint Sketch in drawing

Backing As Welded

Backing Material As Welded

BASE METALS (QW-403)

P.No, Group No. to P.No, Group No. IS4923 to P.No.1

As per Drawing

Spec, type and grade to All specifications classified

Spec, type and grade inIS4923 to P.No.1 Gr.No.1

Chem.Analysis and Mech.Prop to

-------------

Chem.Analysis and Mech.Prop

Groove 1.5 - 40 mm

Base Metal Thk range

Fillet All Thk

Maximum Pass thk< 1/2in.(13 mm) Not applicable

FILLER METALS (QW-404) SMAW GTAW

Spec.No (SFA) --

AWS No. (Class) TERROWELD DS4

F.No. --

A.No. --

Size of Filler Metals Ø 3.15 mm

Filler Metal Product Form Not applicable

Supplemental Filler Metal Not applicable

Weld Metal Groove 1.5 - 40 mm

Thk range Fillet All Thk

Electrode- Flux (Class) Not applicable

Flux type Not applicable

Flux trade name Not applicable

Consumable Insert Not applicable

Other Not applicable

POSITIONS(QW-405) POST WELD HEAT TREATMENT (QW-407)

Position(s) of Groove All Positions Temperature range Not Applicable

Position(s) of Fillet All Time range Not Applicable

Welding Progression Up Hill Other Not Applicable

Other Not Applicable GAS (QW-408)

PREHEAT (QW-406) Percentage Composition

Preheat Temperature, minimum 150°C Max Gas(es) Mixture

Interpass Temperature, maximum 300°C Max Shielding -- --

Preheat maintenance Not applicable Trailing -- --

Backing -- --

Other Not applicable

Other -- --

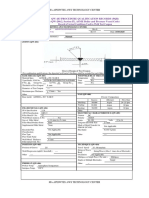

Jaybee Composites & Allied Equipments

Plot no.48 Rajeev Gandhi Nagar, Prashanti

Nagar, Balanagar, Hyderabad , Telangana

WELDING PROCEDURE SPECIFICATION (WPS)

(QW-200.1, SECTION IX, ASME BOILER AND PRESSURE VESSEL CODE)

WPS No. : JCAE/WPS-01 Date: 25-01-2023 Supporting PQR No.JCAE/SMAW/3G / IS4923 /IS4923 /WPS/01

ELECTRICAL CHARACTERISTICS (QW-409)

Filler Metal Current

Wire feed Energy or

type Amps

Weld Pass(es) Process speed Power

and (Range)

(Range) (Range)

Classification Diameter Polarity

Root run SMAW ER7018 Ø 3.15 mm DCEP 110 - 130 --- ---

2st Run SMAW ER7018 Ø 3.15 mm DCEP 110 - 130 --- ---

3nd Run SMAW ER7018 Ø 3.15 mm DCEP 110 - 130 --- ---

4rd Run SMAW ER7018 Ø 3.15 mm DCEP 110 - 130 --- ---

After Back gouging

1st Run SMAW ER7018 Ø 3.15 mm DCEP 110 - 130 --- ---

2nd Run SMAW ER7018 Ø 3.15 mm DCEP 110 - 130 --- ---

Amps and volts or power or energy range should be recorded for each electrode size,position and thickness,etc.

Pulsating Current Not Applicable Heat Input (Max)

Tungsten Electrodes size and Not Applicable

type Mode of Metal transfer for GMAW (FCAW)

Other Not Applicable

TECHNIQUE (QW-410)

String or Weave Bead String/Weave

Multiple or single pass

Orifice,Nozzle or Gas cup size Not Applicable (Per side)

Initial & Interpass Cleaning Grinding/Wire brush Multiple or single Electrodes

Method of Back Gouging Grinding Electrode spacing

Oscillation Not Applicable Peening

Contact Tube to Work distance Not Applicable Other

Engr (W.T) HOD(W.T) Insp.Agency

You might also like

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (6)

- Non-Woven Geotextile As Per MORTH (PPGT - 150 GSM - Type-3) - TDSDocument1 pageNon-Woven Geotextile As Per MORTH (PPGT - 150 GSM - Type-3) - TDSSumit Gupta100% (2)

- Daily Machine Check List - Lathe MachineDocument6 pagesDaily Machine Check List - Lathe Machineshailendra5508110100% (3)

- WPS For Structure Mild Steel Fillet Weld PDFDocument2 pagesWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniNo ratings yet

- WPS1Document10 pagesWPS1bhavin178No ratings yet

- Smaw Wps FinalDocument3 pagesSmaw Wps FinalsheikmoinNo ratings yet

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- WPS 1310Document2 pagesWPS 1310paulNo ratings yet

- WPS & PQR of Ravindra KumarDocument4 pagesWPS & PQR of Ravindra Kumartripatipankaj023No ratings yet

- WPS-PQR Gr. WCBDocument9 pagesWPS-PQR Gr. WCBansarmulla711No ratings yet

- WPS-PQR Gr. CF8MDocument9 pagesWPS-PQR Gr. CF8Mansarmulla711No ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)mohammadNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad MunadiNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Rep WPS 02Document2 pagesRep WPS 02shaniraj BirajdarNo ratings yet

- WPS&PQR FormsDocument4 pagesWPS&PQR FormsArab WeldersNo ratings yet

- Joints (Qw-402) DetailsDocument3 pagesJoints (Qw-402) DetailsNaqqash SajidNo ratings yet

- Qw-482 Welding Procedure Specification (WPS)Document3 pagesQw-482 Welding Procedure Specification (WPS)Sagar GourNo ratings yet

- (Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Document6 pages(Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Saifulla CmpNo ratings yet

- PQRDocument2 pagesPQRafqzfieNo ratings yet

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)linaNo ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDocument5 pagesJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCmkhalil1148No ratings yet

- Final - WPS PQR 86Document4 pagesFinal - WPS PQR 86Parag WadekarNo ratings yet

- 3 BodyPart Edcb3a5f Eede 445f A423 Ea2f5809c15eDocument6 pages3 BodyPart Edcb3a5f Eede 445f A423 Ea2f5809c15emayank0738No ratings yet

- Metals Inspection Services, Inc.: QW - 482 Suggested Format For Welding Procedure Specification (WPS)Document6 pagesMetals Inspection Services, Inc.: QW - 482 Suggested Format For Welding Procedure Specification (WPS)Luis MuñozNo ratings yet

- PQWDocument3 pagesPQWcorey jacobsNo ratings yet

- WPS Vessel 1Document4 pagesWPS Vessel 1Naqqash SajidNo ratings yet

- QW-482 (WPS) GTAW 4MM FilletDocument4 pagesQW-482 (WPS) GTAW 4MM FilletBalkishan DyavanapellyNo ratings yet

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Co D E)Document2 pagesQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Co D E)Vaibhav GuptaNo ratings yet

- Sample Editable WPSDocument2 pagesSample Editable WPSf silva-No ratings yet

- Wps Magi Tig Exemple PDFDocument6 pagesWps Magi Tig Exemple PDFJaime PatrónNo ratings yet

- Qw-482 Suggested Format For Welding Procedure Specification (WPS)Document2 pagesQw-482 Suggested Format For Welding Procedure Specification (WPS)ING HARRINSON FERREBUSNo ratings yet

- PQR - 007 샘플Document2 pagesPQR - 007 샘플주용환No ratings yet

- PQR - 007 샘플Document2 pagesPQR - 007 샘플주용환No ratings yet

- Sample Editable WPSDocument2 pagesSample Editable WPSsbmmlaNo ratings yet

- Wps FormatDocument2 pagesWps FormatMeghan GhoneNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- Welding Procedure SpecificationDocument27 pagesWelding Procedure SpecificationGopakumar K100% (3)

- Wps PQR Welder Qualification Certification ConsultancyDocument2 pagesWps PQR Welder Qualification Certification ConsultancyEmam SayedNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- ASME WPS-PQR-WQT CombinedDocument6 pagesASME WPS-PQR-WQT CombinedStan HonNo ratings yet

- PQR (52a) ModelDocument1 pagePQR (52a) ModelSIDDHARTH BEHERAYNo ratings yet

- 001 WPS Cntim 2023Document10 pages001 WPS Cntim 2023shangyuan1079163.comNo ratings yet

- Welding Procedure SpecificationDocument12 pagesWelding Procedure Specificationsanjay sharmaNo ratings yet

- WPS-46 - Gtaw & Smaw Tig + SmawDocument8 pagesWPS-46 - Gtaw & Smaw Tig + SmawAvinash ShrivastavaNo ratings yet

- Rep PQR 02Document3 pagesRep PQR 02shaniraj BirajdarNo ratings yet

- Wps For Structure Mild Steel Fillet Weld - CompressDocument2 pagesWps For Structure Mild Steel Fillet Weld - CompressAhmed saberNo ratings yet

- Ejemplo Prueba 991003Document2 pagesEjemplo Prueba 991003MARIO ALBANo ratings yet

- Qw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-482 Welding Procedure Specifications (WPS) : (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)linaNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Advanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactFrom EverandAdvanced Materials for Emerging Applications Innovations, Improvements, Inclusion and ImpactNo ratings yet

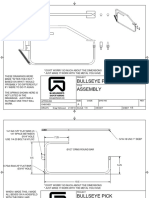

- Bullseye Pick WWW Gwellwood ComDocument5 pagesBullseye Pick WWW Gwellwood Comkick24502No ratings yet

- Laser Processing For Medical DevicesDocument8 pagesLaser Processing For Medical DevicesMIKENo ratings yet

- P1 MaterialsDocument3 pagesP1 MaterialsHarijani SoekarNo ratings yet

- SHOP Power ToolsDocument70 pagesSHOP Power ToolsBbNo ratings yet

- IH BG Ebook 2021 0628 2021Document80 pagesIH BG Ebook 2021 0628 2021dnguyen_63564No ratings yet

- Pentens T-300 Data SheetDocument2 pagesPentens T-300 Data Sheetamelinda jocelinNo ratings yet

- 027 - Drilling All ArticleDocument8 pages027 - Drilling All Articlevishnu varthanNo ratings yet

- MMT 151.1 ComminutionDocument18 pagesMMT 151.1 Comminutionvince coNo ratings yet

- L2 - Plant Layout and Process Flow PatternsDocument41 pagesL2 - Plant Layout and Process Flow PatternsBeki Computerscience studNo ratings yet

- 7T04 MP 00 Po 041 1 B 010 - Welding - Repair - Procedure - C2 - CDocument11 pages7T04 MP 00 Po 041 1 B 010 - Welding - Repair - Procedure - C2 - CRamy OmarNo ratings yet

- What Is Design For Manufacturing or DFMDocument32 pagesWhat Is Design For Manufacturing or DFMChandra HasanNo ratings yet

- Rene DatuDocument4 pagesRene DatuJoshua BitancorNo ratings yet

- 2020 Catalog Final ReducedDocument20 pages2020 Catalog Final Reduceddinhthien914No ratings yet

- Air Turbine Spindle (미국) - High Speed SpindleDocument24 pagesAir Turbine Spindle (미국) - High Speed SpindlekroczzangNo ratings yet

- Saes L 132Document26 pagesSaes L 132Reda ElsayedNo ratings yet

- Checksheet Mixing PaintDocument1 pageChecksheet Mixing PaintRizqy Fadry LazimNo ratings yet

- 03 - Partition ScheduleDocument2 pages03 - Partition ScheduleKyaw HtweNo ratings yet

- MTE Innovative Project Report Rudransh Khera 2K20 - A18 - 80Document8 pagesMTE Innovative Project Report Rudransh Khera 2K20 - A18 - 80Ayush SinghNo ratings yet

- NES 838 Part2Document42 pagesNES 838 Part2QTESNo ratings yet

- Table QW-442 Table QW-442 Table QW-432 QW-404.5: ASME BPVC - IX-2023Document1 pageTable QW-442 Table QW-442 Table QW-432 QW-404.5: ASME BPVC - IX-2023ahmadrizkiqcNo ratings yet

- Experiment 9Document6 pagesExperiment 9Mama ChoiiNo ratings yet

- Mac - Ro. System - Steelgrid™ Hr30G: High Resistance Composite Mesh SystemDocument2 pagesMac - Ro. System - Steelgrid™ Hr30G: High Resistance Composite Mesh SystemRodrigo MorgadoNo ratings yet

- 6-Heat Treatable Low-Alloy SteelsDocument17 pages6-Heat Treatable Low-Alloy SteelsMunim Dar100% (1)

- CTS Advanced CNC Machining - 1.0 - CTS - NSQF-5Document48 pagesCTS Advanced CNC Machining - 1.0 - CTS - NSQF-5Pta NahiNo ratings yet

- Exxon™ Butyl 365S: RubberDocument2 pagesExxon™ Butyl 365S: RubberMaram YasserNo ratings yet

- Koc P 003Document38 pagesKoc P 003Hari KrishnanNo ratings yet

- NEW Cataogue LineUp EnglishDocument44 pagesNEW Cataogue LineUp EnglishReginaldo AlvesNo ratings yet

- BOMDocument76 pagesBOMDurga PrasadNo ratings yet