Professional Documents

Culture Documents

RSI Inspection Checklist Ver 3 4

RSI Inspection Checklist Ver 3 4

Uploaded by

amasrurCopyright:

Available Formats

You might also like

- Osv Inspection Checklist PetronasDocument47 pagesOsv Inspection Checklist PetronasKunal Singh100% (6)

- FO-I-04 Report of Safety Inspection Revision 17Document8 pagesFO-I-04 Report of Safety Inspection Revision 17Jack100% (1)

- AMSA Ship Initial Inspection ChecklistDocument13 pagesAMSA Ship Initial Inspection ChecklistKEITH DESOUZA100% (1)

- ThaiREC Checklist-Barge Inspection Questionnaire GasDocument18 pagesThaiREC Checklist-Barge Inspection Questionnaire Gasเปีย วันชัย สวนทอง100% (1)

- Good Maintenance On Board ShipsDocument54 pagesGood Maintenance On Board ShipssivanandrayNo ratings yet

- Onboard MaintenanceDocument19 pagesOnboard MaintenanceViorel Andrei100% (2)

- Intro ME-GI - Dual FuelDocument37 pagesIntro ME-GI - Dual FuelamasrurNo ratings yet

- Quiz 16Document6 pagesQuiz 16Richmon SantosNo ratings yet

- 05 Voyage EstimationDocument3 pages05 Voyage Estimationburak_caglar100% (1)

- Responsible Shipping Initiative Checklist Rev3 - 3Document23 pagesResponsible Shipping Initiative Checklist Rev3 - 3Taner AkciğerNo ratings yet

- TWPST026 Ship Recycling Compliance SurveyDocument8 pagesTWPST026 Ship Recycling Compliance Surveyene oanaNo ratings yet

- ROVIQ7 Report LPG Carriers - (ECLIPSE) - 11.08.2022Document10 pagesROVIQ7 Report LPG Carriers - (ECLIPSE) - 11.08.2022TanmayNo ratings yet

- B-01 - Vessel Inspection ReportDocument20 pagesB-01 - Vessel Inspection Reportghonwa hammodNo ratings yet

- RightShip Inspections Ship Questionaire RISQ 3.0Document207 pagesRightShip Inspections Ship Questionaire RISQ 3.0Philic Rohit100% (2)

- SCV2 V2 December 2013 PDF FormatDocument30 pagesSCV2 V2 December 2013 PDF FormatNicandro PorcelliNo ratings yet

- Oil Chemical Tanker 2 5 7 FullDocument31 pagesOil Chemical Tanker 2 5 7 FullMarnie NguyenNo ratings yet

- Cheklist Fsi and GiDocument14 pagesCheklist Fsi and GiKumar AnandNo ratings yet

- Tug and Barge Part A 2014Document7 pagesTug and Barge Part A 2014lanNo ratings yet

- Bulk Carrier - General Cargo - Container Vessel Survey Report R1.3 FullDocument27 pagesBulk Carrier - General Cargo - Container Vessel Survey Report R1.3 FullKurupath SidharthanNo ratings yet

- Ship Inspection Form F P - R: 1. G I / S DDocument6 pagesShip Inspection Form F P - R: 1. G I / S DRonachai FuangfoongNo ratings yet

- Surfer Vessel Inspection Form - V2Document12 pagesSurfer Vessel Inspection Form - V2VICTORNo ratings yet

- BIQ EnglishDocument38 pagesBIQ EnglishkiyotakaayaNo ratings yet

- Bulk Carrier General Cargo Container r4 2 3 FullDocument30 pagesBulk Carrier General Cargo Container r4 2 3 FullGalih IrvandiNo ratings yet

- Chapter 1. General InformationDocument33 pagesChapter 1. General InformationaliNo ratings yet

- MLC Compliance Checlist Rev 0 30th Nov 18Document18 pagesMLC Compliance Checlist Rev 0 30th Nov 18Dini ANNo ratings yet

- ST Kitts & Nevis International Ship RegistryDocument11 pagesST Kitts & Nevis International Ship RegistrybthbidkesNo ratings yet

- Ship Risk Review: PTSC Offshore ServiceDocument35 pagesShip Risk Review: PTSC Offshore ServiceNguyễn QuânNo ratings yet

- Ism - Hongkong - MSIN 54 2015 Annex1Document12 pagesIsm - Hongkong - MSIN 54 2015 Annex1izoelgarciaNo ratings yet

- Report Part A Container Sample 1 - CompressedDocument22 pagesReport Part A Container Sample 1 - CompressedMohamed OmarNo ratings yet

- PSC Pocket Checklist MARPOL 0913 WebDocument18 pagesPSC Pocket Checklist MARPOL 0913 WebHaris Stavrou100% (4)

- P&I Condition Survey Report - Passenger-Ship-2-4-6-FullDocument28 pagesP&I Condition Survey Report - Passenger-Ship-2-4-6-FullEnrique Barajas100% (1)

- MSD252SUPPDocument3 pagesMSD252SUPPLuka ĐanovićNo ratings yet

- Cg-840 Hull Inspection BookDocument38 pagesCg-840 Hull Inspection Bookgreatenick.nbNo ratings yet

- Minimum Requirements For Seafarers To Work On A ShipDocument4 pagesMinimum Requirements For Seafarers To Work On A ShiproodbovengroenNo ratings yet

- 0 Condition Survey RPTDocument35 pages0 Condition Survey RPTKingEphrem10100% (1)

- Template Marine Contractor Office Audit QuestionnaireDocument16 pagesTemplate Marine Contractor Office Audit QuestionnairemartinusteddyNo ratings yet

- Maritime Law: Gemeinnützige Gesellschaft Trainingszentrum Ms Emsstrom MBHDocument68 pagesMaritime Law: Gemeinnützige Gesellschaft Trainingszentrum Ms Emsstrom MBHCarel Mae Cabaron100% (2)

- BP HGDK 3811 9086 6947 Observations DisclaimerDocument2 pagesBP HGDK 3811 9086 6947 Observations Disclaimersalah salaheddineNo ratings yet

- Ship Risk Review 2021 Ver 6Document37 pagesShip Risk Review 2021 Ver 6KEISHIN ISO100% (1)

- Marine Survey 1 2Document31 pagesMarine Survey 1 2Adam BanouraNo ratings yet

- Foreign Tank Vessel Exam BookDocument53 pagesForeign Tank Vessel Exam BookFernando Angulo DelgadoNo ratings yet

- MZ-5705-00 PSC Inspection Checklist Detailed Check (6 MONTHS)Document24 pagesMZ-5705-00 PSC Inspection Checklist Detailed Check (6 MONTHS)Lj NecesitoNo ratings yet

- CRW-01 - 1 (Seafarers Application Form)Document5 pagesCRW-01 - 1 (Seafarers Application Form)deniss sumilovsNo ratings yet

- HVPQ5 v1 1 09Document90 pagesHVPQ5 v1 1 09Pavel ViktorNo ratings yet

- Ships in Service Survey Report: DRB0/2012/J0251Document31 pagesShips in Service Survey Report: DRB0/2012/J0251Efthymios LouridasNo ratings yet

- Good Maintenance On Board Ships MaintenaDocument74 pagesGood Maintenance On Board Ships MaintenaVictor Hugo Valderrama ChavezNo ratings yet

- CDI - Harmonized Vessel Particulars Questionnaire (HVPQ) - 6th EditionDocument76 pagesCDI - Harmonized Vessel Particulars Questionnaire (HVPQ) - 6th EditionQuốc Tiến TrịnhNo ratings yet

- RLM 252 MODU 8 06 WDocument5 pagesRLM 252 MODU 8 06 WzaladsNo ratings yet

- PSC Pocket Checklist MARPOL Update 20180626 WebDocument18 pagesPSC Pocket Checklist MARPOL Update 20180626 WebGeorgios PapakostasNo ratings yet

- Survey Report FormDocument28 pagesSurvey Report FormJavier Rayleigh100% (2)

- Master Guide To Uk FlagDocument34 pagesMaster Guide To Uk Flag1979.alokNo ratings yet

- ANNEX - Navigational Audit QuestionnaireDocument24 pagesANNEX - Navigational Audit QuestionnaireАлексей Преподобный 1406No ratings yet

- Safety Check List - Marine SafetyDocument8 pagesSafety Check List - Marine SafetyRaphael SantosNo ratings yet

- Validity of Ship Certificates Check ListDocument5 pagesValidity of Ship Certificates Check Listadamsalum103No ratings yet

- Survey Checklist ANCODocument23 pagesSurvey Checklist ANCOkonstadine100% (1)

- PSC Checklist: On Board Maintenance Check ListDocument15 pagesPSC Checklist: On Board Maintenance Check ListAbebè TeferiNo ratings yet

- BP Shipping SIRE Inspection Preparation DocumentDocument4 pagesBP Shipping SIRE Inspection Preparation DocumentAhmed AL BatalNo ratings yet

- Part A: Condition Survey Report FormDocument8 pagesPart A: Condition Survey Report FormBadrul 'boxer' HishamNo ratings yet

- CG-840 FV 1foreign Freight Vessel ExamDocument12 pagesCG-840 FV 1foreign Freight Vessel Exammadhan01kumarNo ratings yet

- The Rules in Practice 2021-2024: The guide to the rules of sailing around the race courseFrom EverandThe Rules in Practice 2021-2024: The guide to the rules of sailing around the race courseNo ratings yet

- Fishing Vessel Surveys and Inspections How To Prepare For Your Next MCA VisitDocument52 pagesFishing Vessel Surveys and Inspections How To Prepare For Your Next MCA VisitamasrurNo ratings yet

- Let 200727 ADocument12 pagesLet 200727 AamasrurNo ratings yet

- D13 Job Aid 21Document124 pagesD13 Job Aid 21amasrurNo ratings yet

- Maintenance Schedule DK-20 DaihatsuDocument1 pageMaintenance Schedule DK-20 Daihatsuamasrur100% (1)

- Tahfiz & Essential Practice RecordDocument18 pagesTahfiz & Essential Practice RecordamasrurNo ratings yet

- Unique Response Challenges For Senior HousingDocument10 pagesUnique Response Challenges For Senior HousingamasrurNo ratings yet

- DAFTAR PERUSAHAAN PELAYARAN - PDF Download GratisDocument17 pagesDAFTAR PERUSAHAAN PELAYARAN - PDF Download GratisamasrurNo ratings yet

- Man L23/30H MK 2 GensetDocument2 pagesMan L23/30H MK 2 GensetamasrurNo ratings yet

- Week 02 Assignment 2Document1 pageWeek 02 Assignment 2amasrurNo ratings yet

- The ELC An Early Childhood Learning Community at Work 1596036495Document169 pagesThe ELC An Early Childhood Learning Community at Work 1596036495amasrurNo ratings yet

- Foundations For Assisting in Home Care 1520419723Document349 pagesFoundations For Assisting in Home Care 1520419723amasrurNo ratings yet

- 241-Article Text-1065-1-10-20210430Document16 pages241-Article Text-1065-1-10-20210430amasrurNo ratings yet

- Implementasi Metode My Q-Map Dalam Meningkatkan Hafalan Alquran Studi Di Pondok Tahfidz Bintang Quran CirebonDocument11 pagesImplementasi Metode My Q-Map Dalam Meningkatkan Hafalan Alquran Studi Di Pondok Tahfidz Bintang Quran CirebonamasrurNo ratings yet

- Ship Planned Maintenance System Database ConceptDocument11 pagesShip Planned Maintenance System Database Conceptamasrur100% (1)

- Ship Performance & Compliancy: Yang Ingin DicapaiDocument2 pagesShip Performance & Compliancy: Yang Ingin DicapaiamasrurNo ratings yet

- SL2016 632AAB Alpha LubricatorDocument3 pagesSL2016 632AAB Alpha Lubricatorpavlo_790317697No ratings yet

- M4 Ship-Board Energy Management - IMO TTT Course Presentation Final1Document84 pagesM4 Ship-Board Energy Management - IMO TTT Course Presentation Final1amasrurNo ratings yet

- C9781316502761SM PDFDocument93 pagesC9781316502761SM PDFamasrurNo ratings yet

- Boiler Start Up ProceduresDocument8 pagesBoiler Start Up ProceduresamasrurNo ratings yet

- COPY Not Negotiable: by Maersk Brasil (Brasmar) Ltda HERNANDO F. SANTOS - CPF. 329.606.418-41Document2 pagesCOPY Not Negotiable: by Maersk Brasil (Brasmar) Ltda HERNANDO F. SANTOS - CPF. 329.606.418-41Fernando GariaNo ratings yet

- Part I: Ship Builders: Directory 2016Document91 pagesPart I: Ship Builders: Directory 2016nnadoziekenneth5No ratings yet

- The Life of Captain James Cook by Kitson, ArthurDocument169 pagesThe Life of Captain James Cook by Kitson, ArthurGutenberg.org100% (1)

- Furuno 3100 ManualDocument3 pagesFuruno 3100 Manual4tgvmfzckpNo ratings yet

- Timber Deck Cargoes: Regional Maritime UniversityDocument33 pagesTimber Deck Cargoes: Regional Maritime UniversityMahami M Prosper100% (1)

- Bulk PDFDocument5 pagesBulk PDFSlreview Hub100% (1)

- Comparison of Single and Double Hull TankersDocument9 pagesComparison of Single and Double Hull Tankersyann1982100% (2)

- Pilot Transfer Arrangements BrochureDocument5 pagesPilot Transfer Arrangements BrochureMats Karlsson100% (1)

- Билеты GOC - 2017Document10 pagesБилеты GOC - 2017Юлия АндреевнаNo ratings yet

- Oral Questions: Lower Lifeboat in Heavy Weather ConditionDocument3 pagesOral Questions: Lower Lifeboat in Heavy Weather ConditionVaratheraju SantharanNo ratings yet

- Practical Ship HandlingDocument62 pagesPractical Ship HandlingDheerajKaushal100% (14)

- SPS Vessels SiwDocument32 pagesSPS Vessels Siwpgupta71No ratings yet

- Vessel PortfolioDocument19 pagesVessel PortfolioJina DevNo ratings yet

- Question Interview - 3.O UMMS - 5Document10 pagesQuestion Interview - 3.O UMMS - 5Hoài ThanhNo ratings yet

- The Port State Control and Their Role in The Maritime SafetyDocument9 pagesThe Port State Control and Their Role in The Maritime SafetyMohamed AliNo ratings yet

- Oceanis Bunkering Co - Ltd. Receiving Vessel Name: Mt. Elise: Supply Terminals Name: EngenDocument4 pagesOceanis Bunkering Co - Ltd. Receiving Vessel Name: Mt. Elise: Supply Terminals Name: EngenAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Jensen Heavy Lift Marine Engineering BrochureDocument3 pagesJensen Heavy Lift Marine Engineering Brochuremyusuf_engineerNo ratings yet

- Contoh CVDocument1 pageContoh CVWanty Aswantie50% (2)

- Dokumen Keselamatan Pengawakan Minimum No:: Minimum Safe Manning DocumentDocument2 pagesDokumen Keselamatan Pengawakan Minimum No:: Minimum Safe Manning DocumentAlfilia KhoirunnisaNo ratings yet

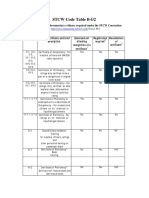

- STCW Code Table B-I/2: List of Certificates or Documentary Evidence Required Under The STCW ConventionDocument2 pagesSTCW Code Table B-I/2: List of Certificates or Documentary Evidence Required Under The STCW ConventionLita Anggraeni Verawati100% (1)

- CP Mooring Guidance 2019 OrigDocument18 pagesCP Mooring Guidance 2019 OrigJohn Mike ZstacaNo ratings yet

- Wooden Ships and Iron Men PDFDocument51 pagesWooden Ships and Iron Men PDFtrireme_899773068No ratings yet

- Voyag Charter PartyDocument14 pagesVoyag Charter Partydetrusitol100% (1)

- Jepretan Layar 2021-07-08 Pada 10.49.57Document2 pagesJepretan Layar 2021-07-08 Pada 10.49.57sulaimanNo ratings yet

- Uss Blower (Ss-325)Document4 pagesUss Blower (Ss-325)loggynety159No ratings yet

- Ship Particulars Dragonera 2023Document1 pageShip Particulars Dragonera 202322-57495No ratings yet

- Crewlist Gaba GwapoDocument14 pagesCrewlist Gaba GwapoNiñal Ramsted BNo ratings yet

- Dutch Warships of World War II PDFDocument148 pagesDutch Warships of World War II PDFMatheus Benedito100% (5)

RSI Inspection Checklist Ver 3 4

RSI Inspection Checklist Ver 3 4

Uploaded by

amasrurOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RSI Inspection Checklist Ver 3 4

RSI Inspection Checklist Ver 3 4

Uploaded by

amasrurCopyright:

Available Formats

RSI INSPECTION CHECKLIST Page 1 of 27

RSI Vessel Inspection Checklist

M/V ____________

The inspection was requested by: ___________________________________

The inspection was carried out in:

______________________, ________________ the ______ of________________ 20_____.

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 2 of 27

INDEX

CHAPTER CONTENT PAGE

1 Vessel Particulars 3

2 Port State Controls 4

3 Classification & Insurance 5

4 Index of Certificates 7

5 ISM 9

6 Working and living conditions 10

7 Bridge, Navigation and Communication Equipment 12

8 Health, Safety and Environment (HSE) 14

9 Security (ISPS) 16

10 Life Saving Appliances (LSA) 17

11 Fire Fighting Appliances (FFA) 19

12 Pollution Prevention 21

13 General Appearance 23

14 Mooring and Lifting Equipment 24

15 Construction and Stability 25

16 Machinery Space 26

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 3 of 27

1 - VESSEL PARTICULARS

Vessel Particulars

1.1 Name of Vessel

1.2 IMO number

1.3 Previous name(s)

1.4 Flag

(if the vessel has changed flag

within the past six months, report

1.5

date of change and previous flag in

‘Additional comments’)

1.6 Port of registry

1.7 Vessel owner

Company IMO number (Vessel

1.8

Owner)

Vessel Operator (if different from

1.9

vessel owner)

1.10 IMO Number (Vessel Operator)

Date current vessel operator

1.11

assumed responsibility for vessel

Manning Agent (if different from

1.12

operator)

1.13 Commercial Operator

1.14 Number of generators

Bow thruster fitted (number and

1.15

type)

1.16 Type of bunkers

Date of last owner’s/operator’s

1.17

superintendent’s visit to vessel

Date of last dry docking or in water

1.18

survey

Location of last dry docking or in

1.19

water survey

1.20 Date next dry docking due

Is the information in the

1.21

questionnaire correct, if applicable?

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 4 of 27

2 – PORT STATE CONTROLS

Port State Controls

Has the vessel been subject to a Yes No

2.1 port state inspection within the

last 24 months?

Date of last PSC:

Location of last PSC:

Inspector to comment on:

1. If a copy of the report is held onboard.

2. If there were any significant non-conformances and/or detention procedures

Have any deficiencies from the Yes No NA

2.2 port state control inspection

been addressed and closed out?

List any deficiencies from the inspection which have not been closed out.

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 5 of 27

3 – CLASSIFICATION & INSURANCE

Certification

Yes No

Is the Vessel issued with a

3.1

Certificate of Classification

Name of Classification Society:

Is the classification society a Yes No

3.2

member of IACS? DESIRED

IACS Members:

American Bureau of Shipping (ABS)

Bureau Veritas (BV), China Classification Society (CCS)

Croatian Register of Shipping (CRS), DNV-GL (DNV-GL)

Germanischer Lloyd (GL),

Indian Register of Shipping (IRS)

Korean Register of Shipping (KR)

Lloyd’s Register (LR)

Nippon Kaiji Kyokai (Class NK)

Polish Register of Shipping (PRS)

Registro Italiano Navale (RINA)

Is the vessel clear of conditions of Yes No

3.3 class and any safety related

memoranda?

Give details of conditions of class outstanding and any safety related memoranda.

Is there a Class Status Report less Yes No

3.4

than three months old onboard? DESIRED

Yes No

Is the Vessel issued with a P&I

3.5

Certificate?

Name of P&I Club:

Is the P&I club a member of Yes No

3.6

IGP&I? DESIRED

IGP&I Members:

American Steamship Owners Mutual Protection and Indemnity Association, Inc

The Britannia Steam Ship Insurance Association Limited, Gard P&I (Bermuda) Ltd,

The Japan Ship Owners' Mutual Protection & Indemnity Association

The London Steam-Ship Owners' Mutual Insurance Association Limited

The North of England Protecting & Indemnity Association Limited

The Shipowners' Mutual Protection & Indemnity Association (Luxembourg)

Assuranceforeningen Skuld

The Standard Club Ltd

The Steamship Mutual Underwriting Association (Bermuda) Limited

Sveriges Ångfartygs Assurans Förening / The Swedish Club

United Kingdom Mutual Steamship Assurance Association (Bermuda) Ltd

The West of England Ship Owners Mutual Insurance Association (Luxembourg)

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 6 of 27

Is the Vessel issued with an Yes No

3.7 Employer Liability Insurance

Certificate?

Yes No

Is the Vessel issued with a H&M

3.8

Insurance Certificate?

Is the Vessel issued with a Bunker Yes No

3.9 Oil Civil Liability Certificate

(Bunker Convention 2001 Art 7)

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 7 of 27

4 - INDEX OF CERTIFICATES

Index of Certificates

Number Certificate Notes Yes No N/A

AIS Annual Test Certificate – SOLAS

4.1

Reg V/18.9

4.2 Ballast Water Management Plan

Cargo Ship Safety Construction

4.3

Certificate (SOLAS Reg 1/12)

Cargo Ship Safety Equipment

4.4

Certificate (SOLAS Reg 1/12)

Cargo Ship Safety Radio Certificate

4.5

(SOLAS Reg 1/12)

4.6 Certificate of Registry – CLOS Art 91.

Continuous Synopsis Record (SOLAS

4.7

Reg XI-1/5)

Document of Compliance

4.8

(copy)(SOLAS/ISM Para 13)

International Air Pollution

4.9

Prevention Certificate

International Anti-fouling/TBT Free –

4.10 if applicable AFS Convention Ann

Reg 2(1)

International Energy Efficiency

4.11

Certificate - MARPOL VI Reg 6

International Load Line Certificate

4.12

(Load Line Convention)

International Oil Pollution

4.13

Prevention Certificate (MARPOL I)

International Sewage Pollution

4.14

Prevention Certificate (MARPOL IV)

International Ship Security

4.15 Certificate (SOLAS Reg XI-

2/9.1.1/ISPS Code Part A)

4.16 International Tonnage Certificate

(1969) (Tonnage Convention Art 7)

LRIT Conformance Test Report -

4.17

SOLAS Reg V/19-1

Maritime Labour Convention

Certificate / Declaration of Maritime

4.18

Labour Compliance

(DMLC) Part 1 and 2 (MLC Reg 5.1.3)

Minimum Safe Manning Document

4.19

(SOLAS Reg V/14.2)

Potable Water Quality Test

4.20

Certificate

4.21 Radio Licence (ITUC Ch.V Reg 18)

4.22 Radio Survey (Annual)

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 8 of 27

Number Certificate Notes Yes No N/A

Shipboard Marine Pollution

4.23

Emergency Plan (MARPOL I Reg 37)

Ship Sanitation Control Certificate

4.24

/Exemption Certificate (IHR 2005)

Shore Based Maintenance

4.25 Certificate (GMDSS)(SOLAS IV Reg

15)

Voyage Data Recorder Annual

4.26 Performance Test Certificate (SOLAS

Reg V/18.8)

All Certificates should be checked with respect to the expiry date and any endorsements on the

certificate. Any error in Certification or documentation will result in a NO answer, supported by

an observation. If any certificate is interim, make a note on expiry date.

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 9 of 27

5 – ISM

ISM

Yes No

Does the vessel have an ISM

5.1

Safety Management Certificate?

Review most recent internal audit. Confirm that any proposed corrective actions have been

implemented.

Yes No

5.2 Are the DPA details available?

Confirm that the correct details of designated person ashore (DPA) are displayed prominently.

Does the vessel display current Yes No

5.3 health, safety and environment

policies signed by management?

Crew should be aware of current health, safety and environmental policies.

Is there a common language Yes No

5.4

spoken onboard?

1. If there is not a common language is provision made for critical safety and security

information to be relayed internally between the crew? Note the common language.

2. Are signs and warning notices in a language(s) understood by all?

Are arrangements in place to Yes No

ensure efficient communication

5.5

between personnel on the vessel

and third parties?

Are OOW’s able to communicate in English?

Does the vessel operator have a Yes No

5.6

drug and alcohol policy? DESIRED

1. Comment on how the operation of the policy is monitored and managed.

2. Note the maximum allowed levels and frequency of drug and alcohol tests.

3. If alcohol and drugs are forbidden onboard, this is the same as alcohol level 0,0.

Is the vessel equipped with Yes No

alcohol testing equipment and is

5.7

there evidence of regular DESIRED

testing?

Is there evidence that the crew Yes No

5.8 is fully involved in the safety

management?

1. Comment by example of evidence that the crew is fully involved in safety management?

2. Is there a ship safety committee?

3. Safety meetings - note the stated frequency of the meetings and verify by reference to the

minutes.

4. Is there evidence of issues being identified and closed?

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 10 of 27

6 – WORKING AND LIVING CONDITIONS

WORKING AND LIVING CONDITIONS

Does the manning level meet or Yes No

exceed that required by the

6.1

Minimum Safe Manning

Document?

Record the required manning and the Actual manning in Comments

Yes No

Are all officer´s certificates valid

6.2

for their rank?

1. Check flag state administration acceptance.

2. Check radio licences for all deck officers.

3. If ECDIS is primary means of navigation, all deck officers must possess ECDIS certificates.

Are there more than two deck Yes No

6.3 officers including Master

onboard?

DESIRED

Are the crew’s medical Yes No

6.4

certificates valid?

1. Comment if medical certificates are out of date or not held

2. This question relates to the Medical Examination for Seafarers and not the Certificate for

Medical care providers in the crew.

Are all crew members engaged Yes No

6.5

through authorised contracts?

Contracts should be in accordance with requirements of Maritime Labour Convention 2006.

Is there a common formal hours Yes No

6.6 of rest record maintained and is

it used correctly

1. Review evidence of compliance

2. To be in accordance with STCW requirements

Are crew members covered by Yes No

6.7 an appropriate company

insurance policy?

State whether there is a copy of the insurance policy publicly displayed.

Length of contract for deck

6.8

officers FOR INFORMATION ONLY

Are there arrangements in place Yes No NA

to address the general condition,

6.9 visual appearance and

cleanliness of the

accommodation?

1. Alleyways should be free of obstructions and areas of low headroom to be properly marked.

2. All exits, including escape routes, should be clearly marked.

3. Fittings such as central radio and TV antennas, lights, emergency lighting, domestic piping

and isolation valves, should be identified and in apparent good physical condition.

4. Check for any improvised rigging of radio/TV aerials or antennas.

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 11 of 27

Are food storerooms, handling Yes No NA

and refrigerated spaces, galleys,

6.10

mess rooms and pantries clean

and tidy?

1. Are galley, fridge and storeroom decks clean, dry and free from defects?

2. Refrigerated spaces should be maintained at an appropriate temperature: frozen meat 15/

18°C, fish room 18/25°C, veg. +2/+4°C, flour <8°C, deep freeze 18°C.

3. Galley fire extinguishing systems should be available for immediate use and free of defects.

The catering workforce should be aware of locations and means of operation.

4. Food preparation areas should be tidy and clean.

5. Food storerooms and refrigerated spaces should be in a hygienic condition. Carry out random

check of food stocks to ensure stock is being rotated and is not out of date.

Is there evidence to show that Yes No NA

6.11 the vessel is free of animal or

insect infestation?

Comment on procedures in place to address the potential for animal or insect infestation?

Is the hospital clean and tidy? (If Yes No NA

6.12

applicable)

1. Hospital should be ready for immediate use.

2. First aid kits should be readily available.

3. Oxygen resuscitation equipment should be available for immediate use where fitted.

4. If a Defibrillator is carried onboard, is it in full working order?

5. Comment on how medical stores are verified and checked.

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 12 of 27

7 – BRIDGE, NAVIGATION AND COMMUNICATIONS EQUIPMENT

Bridge, Navigation and Communication Equipment

Are vessel manoeuvering Yes No

7.1

characteristics clearly displayed?

Vessel manoeuvring characteristics should be displayed on the bridge.

Are auto, manual and emergency Yes No

7.2 steering changeover procedures

displayed?

Comment on legibility, ease of access and completeness

Is the deck logbook fully Yes No

7.3 maintained in ink, both at sea

and in port?

Logbooks books should be checked to ensure that rough logs in pencil are not being maintained

and that the logbooks are up to date, with entries properly made in ink. in accordance with SOLAS

Reg II and III.

Has the Master written his/her Yes No

7.4 own standing orders and are

night orders being completed?

Have deck officers countersigned the Master’s standing orders and night orders as being read and

understood?

Has a system been established Yes No

to ensure that nautical

7.5 publications, charts and

information are both onboard

and current?

7.5.1 Date of latest Notice to Mariners:

1. Latest notices to mariners should be onboard and dated within previous two months.

2. Charts in use should be appropriate for the port.

3. If ECDIS is fitted and in use have all corrections been uploaded and recorded? (See IMO

MSC.1/Circular. 1503 dated 24 July 2015 - ECDIS - Guidance for Good Practice)

4. Comment on the system used to ensure that light lists, tide tables, pilot books, nautical

almanac, charts catalogue and ship’s routeing are the current editions.

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 13 of 27

Is a comprehensive passage plan Yes No NA

available for the previous voyage

7.6

and did it cover the full voyage

from berth to berth?

Passage Plan should include:

7.6.1 Tracks with heading notation Yes No

7.6.2 Leading lines, parallel index distances Yes No

7.6.3 Waypoints with wheel over positions, when applicable Yes No

7.6.4 Danger areas Yes No

Expected under keel clearance in shallow water areas, as well as Yes No

7.6.5

Squat

7.6.6 Identification of features to be used in position fixing Yes No

7.6.7 Air draft and overhead clearance Yes No

1. Passage plan should be prepared by an appropriate officer and verified by Master.

2. Passage plan information should be readily available for watchkeepers’ use.

3. If the vessel is equipped with ECDIS, the full passage plan must be entered in the ECDIS.

4. Note the system of passage planning in use and how the passage plan is produced, whether

this is manually or by computer.

Is gyro and magnetic compass Yes No NA

7.7 error log maintained and up to

date?

7.7.1 Date of last compass deviation:

1. SOLAS require that a magnetic compass is adjusted bi-annually.

2. Deviation curve(s) should be displayed.

Is radio and communications Yes No

7.8 equipment available for use and

free from defects?

1. Are instructions for operating the digital selective calling (DSC) and satellite communications

equipment in an emergency clearly displayed?

2. Are the vessel’s call sign and Inmarsat ship station identity clearly marked on the radio

installation?

Is a maintenance programme for Yes No

7.9 radio and electronic equipment

in place?

Outline the maintenance programme followed, e.g. onboard maintenance by competent person or

by maintenance contract, etc.

Are GMDSS logs maintained and Yes No

7.10

up to date?

Verify that the GMDSS log is being maintained.

Is all equipment, including Yes No

bridge, communication and

7.11 navigation equipment as listed in

SOLAS available for use and free

from defect?

Note any deficiencies in equipment

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 14 of 27

8 - HSE

HSE

Is there evidence of full Yes No

8.1 compliance with the company’s

HSE management system?

1. Comment on whether key personnel appear to have knowledge of the safety management

system appropriate to their duties.

2. Sufficient crew should be onboard at time of inspection trained to handle emergency

situations.

3. Check that procedures address minimum manning requirements in port.

4. All loose gear on and below deck should be safely secured.

5. Smoking regulations should be in place and complied with.

6. Safety signs and relevant safety information should be prominently displayed.

Is there evidence of full Yes No

compliance with the company’s

8.2

personal protective equipment

policy?

1. Does the company have a personal protective equipment policy?

2. Comment on evidence of compliance.

Are personnel joining the vessel Yes No

8.3 given an appropriate safety

familiarization?

Check record of familiarization and knowledge of crew.

Does the vessel have a system Yes No

for reporting and recording

8.4

incidents, accidents and near

misses?

Check reports, if no reports are available onboard mark NO.

Do vessel specific emergency Yes No

procedures exist covering, for

8.5

example, fire, explosion,

grounding, pollution?

Are emergency drills routinely Yes No

8.6

conducted with all vessel crews?

Assess familiarity of officers and crew with the procedures.

Is a permit to work (PTW) Yes No

8.7

system in use onboard?

Comment on the types of tasks covered by permits eg.

o Working at Height

o Diving

o Hot Work

o Radiation/electrical hazards

o Fuelling/bunkering

o Enclosed Space Access

o Stored energy eg. pressurised systems, tensioned lifting systems

1. How are risk assessments linked to the permit system?

2. At the time of inspection, comment on the number of tasks managed by permit.

3. The inspector should try to confirm that the relevant permit controls are in place at the

worksite.

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 15 of 27

Yes No

Are enclosed spaces and controls

8.8

for entry identified onboard?

1. Are entry permit system in use (to include testing of atmosphere for oxygen and toxic gases)

with records available for inspection.

2. Are atmosphere test conducted both before and during the access period.

Is there a calibrated oxygen Yes No

8.9

analyser onboard?

Are specific procedures used for Yes No

8.10

hot work?

1. Are spare gas and oxygen bottles stored apart in dedicated storage lockers that are clearly

marked and in a well-ventilated position outside accommodation and engine room.

2. Comment on the system in use.

3. Comment on the system requirements for PPE and confirm that the required equipment is

available for use.

Is the vessel provided with its Yes No

8.11

own safe means of access?

1. Gangway should be available for use, free from defect and, when in use, should be properly

rigged and attended with a safety net and a life buoy with lifeline placed near the gangway

or accommodation ladder.

2. Pilot ladders should be available for use, free from defect and properly rigged. If not in use,

ladders should be properly stowed to minimise damage.

3. Pilot Boarding arrangement not to include “deck tongues” or any other equipment not in

accordance with SOLAS Ch.V Reg. 23 & IMO res. A.1045(27)

Is there evidence that safe Yes No

working practices are being

8.12

consistently applied to

machinery spaces?

1. Are safety inspections conducted that include machinery spaces?

2. Are warning signs in place indicating where hearing protection is required?

3. Do engine room machine tools have eye protection measures in place?

4. Are guards in place on exposed shafts/gears?

5. Are emergency escape routes clearly marked, unobstructed and well lit?

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 16 of 27

9 - SECURITY

SECURITY

Does the vessel have an Yes No NA

9.1 approved Ship Security Plan that

meets ISPS requirements?

1. Inspectors are not authorised to see individual ship security plans and should not request to

view them.

2. Verify a valid International Ship Security Certificate is being carried onboard.

Is there an appointed Ship Yes No NA

9.2 Security Officer and Company

Security Officer?

1. Verify there is a company appointed Security Officer. All vessels are required to have an

officially appointed Ship Security Officer.

2. Verify that the Ship Security Officer has been formally trained and certificated for ISPS Ship

Security Officer roles.

Is the ship security operating Yes No NA

9.3 level clearly indicated to all

personnel?

Verify that ship operational security level is clearly communicated to all personnel and how.

Does the vessel have specific Yes No NA

port security procedures

9.4 covering visitors, storing and

vessel gangway watchkeeping

requirements?

Give details on how the inspector was challenged when boarding.

Is a visitors’ log maintained and Yes No NA

comment on where this is

9.5

located when the vessel is in DESIRED

port?

Is the access to the vessel Yes No NA

9.6

controlled?

Access to the vessel can be controlled by gangway watch or camera.

ISPS Code 7.2.2-3

Is there signage indicating “No Yes No NA

9.7

visitors” at the gangway? DESIRED

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 17 of 27

10 – LIFE SAVING APPLIANCES

Life Saving Appliances

Are survival craft operational and Yes No NA

10.1

defect free?

1. Are lifeboats ready for immediate use?

2. Are they Internally clean, dry and tidy?

3. Are equipment suitably secured?

4. Is all equipment readily accessible, including medicines not stowed on board?

5. Are contents of lockers clearly identified?

6. Are communications equipment, where fitted, operable?

7. Is lifeboat operating instructions prominently displayed?

8. Are food and water, and pyrotechnics within their expiry date?

WARNING: Lifeboats should be secured by a fall arrestor device before any internal

inspection is carried out.

Are survival craft (including life Yes No

10.2 rafts) planned maintenance tasks

up to date?

1. Have lifeboats been lowered as appropriate for the lifeboat type?

2. Have engines and electrical equipment been tested?

3. Are lowering equipment and associated items operational and defect free?

4. Is there a maintenance and test schedule for lifeboat on-load release gear?

5. Does the life rafts have valid inspection certificate(s)

Are all life rafts available for Yes No

10.3

immediate use?

1. Are life rafts stowed as per the LSA plans?

2. Are boarding ladders in good condition (check for missing steps, rope deterioration and

lashings where required)?

3. Are hydrostatic releases, if fitted, correctly attached, in good condition and in date?

4. Are life rafts operating instructions prominently displayed?

Are muster lists posted and Yes No

10.4

correct?

Are sufficient immersion suits Yes No

10.5

available?

1. Where required, are there sufficient numbers and sizes of immersion suits for the crew?

2. Are the immersion suits maintained according to regulations?

MSC 152 (78) amendment to SOLAS Ch. III Reg. 23.3

Are sufficient life jackets Yes No

10.6

available?

1. Where required are there sufficient numbers and sizes of life jackets for the crew?

2. Are the life jackets of the appropriate type ie. automatic inflation etc.

3. Are emergency use life jackets located in remote positions for emergency use?

4. Are inflatable lifejackets inspected as required by the manufacturer?

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 18 of 27

Is the man overboard/rescue Yes No NA

10.7 boat, where fitted, operational

and defect free?

1. Have the crew received onboard training in MOB use and hazards to SOLAS requirements?

2. Is personal protective equipment provided for all crew?

3. Is launching apparatus operational and defect free?

4. Is communications equipment operable?

5. Check condition of spare fuel storage cans/tanks and suitability of storage location.

Are training manuals onboard Yes No NA

10.8 describing LSA equipment and

its correct operation?

1. Do the manuals provide equipment-specific information relevant to installed equipment?

2. Are manuals in a language understood by vessel personnel?

Are ship-specific life-saving Yes No

10.9 equipment maintenance

instructions available?

Are the manuals in a language understood by vessel personnel?

Is available LSA equipment free Yes No

10.10

from defects?

Is there a ship specific plan and Yes No NA

10.11 procedure for the recovery of

persons from the water?

1. Comment on completeness of available procedures.

2. Comment on crew's awareness of the procedures.

SOLAS Ch. III Reg. 17-I with effect from 1 July 2014.

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 19 of 27

11 – FIRE FIGHTING APPLIANCES

FIRE FIGHTING APPLIANCES

Is there a fixed fire-fighting Yes No NA

11.1 system for the cargo hold? If so,

state type of system.

Except for ro-ro and vehicle spaces, cargo spaces on cargo ships of 2,000 GRT and upwards shall

be protected by a fixed CO2 or inert gas fire extinguishing system complying with the provisions of

the FSS Code, or by a fire-extinguishing system which gives equivalent protection.

SOLAS Ch. II-2 Reg. 10 7.1.3

Is the vessel provided with fixed Yes No

fire fighting equipment in

11.2

accordance with applicable

regulations for vessel type?

1. Fire mains, pumps, hoses and nozzles should be available for use and defect free.

2. Emergency fire pump should be fully operational.

3. Starting instructions should be clearly displayed.

4. International ship/shore fire connection should be readily available and its location clearly

marked.

5. Operating instructions for fixed systems should be clearly displayed.

6. Isolating valves in fire/foam system lines should be clearly marked and operational.

7. Fixed firefighting system activation keys/controls to be available under suitable control

procedures.

Is sufficient firefighting Yes No

11.3 equipment available for use and

defect free?

1. Portable fire extinguishers should be in apparent good order with operating instructions

clearly marked.

2. Firemen's outfits including breathing apparatus should be in good condition and ready for

immediate use.

3. Breathing apparatus sets should be ready for immediate use with fully charged air bottles.

4. Sufficient fully charged spare air bottles should be available.

5. Are EEBDs available, charged and crew trained?

Are records of firefighting Yes No

11.4 equipment maintenance

available?

Inspection records and inventory lists should be maintained and kept up to date

Are fire detection system fully Yes No

11.5 operational and tested

regularly?

Establish operational condition of fire detection and alarm systems throughout vessel.

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 20 of 27

Are measures in place to Yes No

effectively isolate ventilation to

11.6 enclosed spaces, e.g. engine

room, accommodation, galley,

storerooms?

1. Vent fan stops should be operational (spot check) and clearly marked.

2. Closing devices should have maintenance and testing programmes in place.

3. Are smoke control/clearance procedures available and understood by crew?

Are vessel specific manuals and Yes No

11.7 plans for fire-fighting equipment

available and up to date?

1. Do all plans have the same revision number?

2. Are ship-specific fire training manuals available in a language understood by crew?

3. Are fire control plans exhibited within the accommodation and available outside the

accommodation?

SOLAS Ch. II-2 Reg. 15.2.3

Are a minimum of two, Yes No NA

intrinsically safe, two-way

portable radios for each fire

party for fire-fighters

11.8

communication available

onboard? (For vessels

constructed on or after 1 July

2014)

In accordance with MSC91/22Add1. Ships constructed before 1 July 2014 shall comply with the

requirements of this paragraph not later than the first survey after 1 July 2018.

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 21 of 27

12 – POLLUTION PREVENTION

Pollution Prevention

Are SOPEP/SMPEP drills held at Yes No

12.1

regular intervals?

Comment on interval of drills.

Are arrangements in place to Yes No

12.2 prevent any spillage entering the

water?

1. Anti-pollution warning notices should be posted.

2. Unused bunker pipeline connections, drains and vents and unused gauge stems should be

suitably blanked or capped.

3. Suitable containment should be fitted around hydraulic deck machinery.

4. During fuel transfer operations, scuppers should be plugged or dammed

5. Are there arrangements in place to prevent spillages from tank vents?

6. Emergency bilge suction valves should be suitably marked and specific warning notices

posted to safeguard against the accidental opening. They can also be fitted with a visible tag

which does not prevent the operation of the valve.

7. Comment on evidence of any leaks noticed during inspection.

8. What pollution prevention equipment is available for immediate use?

Is the bilge oily water separator Yes No NA

12.3 (OWS)/filtering system in good

working order?

1. Confirm that the OWS is functional.

2. Comment on last test and any OWS planned maintenance outstanding.

3. Are notices posted to warn of the dangers of the accidental opening of the overboard

discharge valve?

4. Has the OWS been fitted with an automatic stopping device?

Does the vessel have a waste/ Yes No NA

12.4

garbage management plan?

1. Does the plan contain procedures for the collecting, storage, processing and disposing of

garbage?

2. Are the garbage disposal records complete and up to date?

3. The GMP does not need to be approved/stamped by Classification Surveyor

Does the vessel have a ballast Yes No NA

12.5

water management plan?

Is the plan approved by the relevant flag state or classification society?

Are oil record book(s) correctly Yes No NA

12.6

completed and up to date?

1. Do the sludge and bilge tanks designated in Form B of the IOPP Certificate and those listed in

the Oil Record Book Part I, agree?

2. Comment on the evidence that oil transfer activities are signed off by the person performing

the task and is each completed page endorsed by the Master?

3. If any pollution incidents have occurred in the last twelve months, note how they were closed

out and any preventative measures that were put in place.

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 22 of 27

Is a fuel changeover procedure Yes No NA

for entering Sulphur Emission

12.7 Control Area (SECA) available

and are records kept that this is

being implemented?

1. Is there evidence that if required the procedure is controlled adequately?

2. If vessel is only using MGO/MDO, question to be answered N/A.

Is a Shipboard Energy Efficiency Yes No NA

Management Plan available

12.8

onboard and is it implemented

and maintained?

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 23 of 27

13 – GENERAL APPEARANCE

General Appearance

Are there arrangements in place Yes No

to address the general condition,

13.1

visual appearance and cleanliness

of the hull?

1. Are all hull markings, namely vessel name, load lines, draft marks and warning signs,

correctly placed and legible?

2. Comment on whether hull is visibly free of extensive coating breakdown.

3. Hull should be free of fractures or indentations which may significantly weaken the structure

or affect the watertight integrity.

Are there arrangements in place Yes No

to address the general condition,

13.2

visual appearance and cleanliness

of the weather decks?

1. The deck should be well lit.

2. Chain locker doors should be firmly battened down.

3. Forecastle space, lockers and holds should be free of water.

4. Ladders and walkways should be in good condition.

5. Inspection of weather decks should include checking for any evidence of wastage, structural

problems, collision contact or distortion from heavy weather on fore end of accommodation.

6. Check condition of wood sheathing and T-bars.

Are all deck openings, including Yes No

watertight doors and portholes,

13.3

defect free and capable of being

properly secured?

1. Bridge windows should be effectively sealed and, where vulnerable to wave action, provided

with shutters.

2. Are vents and air pipes on freeboard deck in good condition and fitted with closing devices to

prevent ingress of water?

3. Closing devices, packing material and locking arrangements should be complete and free of

defects.

4. Securing arrangements of ends of vessel's own anchor chains, when visually accessible, are

unobstructed.

5. Chain locker doors should firmly battened down.

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 24 of 27

14 – MOORING AND LIFTING EQUIPMENT

MOORING AND LIFTING EQUIPMENT

Are mooring practices Yes No

14.1

appropriate for the size of vessel?

1. Are mooring lines secured to bitts and not to drum ends?

2. Is the vessel securely moored at berth with moorings arranged to take into account

anticipated conditions?

Yes No

Is all mooring equipment

14.2

available for use and defect free?

1. Deadmen and roller fairleads should be well greased and free to turn with little evidence of

grooving.

2. Winch seatings and connections to deck should be sound.

3. Comment on the conditions of all mooring equipment, brakes, wires and lines.

Are anchors, cables and securing Yes No

14.3 arrangements available for use

and defect free?

1. Anchor chain stoppers should be available for use and defect free;

2. Anchors should be cleared and ready for immediate use during port entry.

3. Chain locker spurling pipe cover(s) should be in place at sea to prevent chain locker flooding.

4. Comment on general state of anchor(s) and cable(s).

Does the company have a lifting Yes No NA

14.4 equipment management system

in place?

1. Comment on system in use and include procedure for quarantining defective equipment.

2. Check that it is being adhered to, i.e. no evidence of wrong colour/non-coded equipment in

use, that non-coded/wrong colour equipment is segregated and access to same denied.

3. Items such as cranes, derricks and pad eyes must be clearly marked with their SWL

4. Test certificates should be onboard for all items of lifting equipment including chain blocks,

strops, ropes, shackles (NB: may have a batch certificate for small shackles).

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 25 of 27

15 – CONSTRUCTION AND STABILITY

CONSTRUCTION AND STABILITY

Is there an approved stability Yes No

15.1

book?

Approved stability book should be available including damage stability.

Are procedures in place to govern Yes No

15.2 vessel stability through all stages

of the operation?

1. Are records kept of previous loading conditions and stability calculations?

2. Note how the officer in charge can establish stability conditions without extensive

calculations.

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 26 of 27

16 – MACHINERY SPACE

Machinery Space

Are main, auxiliary and Yes No NA

16.1 emergency plant reported to be

fully operational?

1. All fluid transfer and storage systems, e.g. hydraulic oil, oil fuel, cooling water and water

supplied for domestic purposes, should be leak-free.

2. Record those items of machinery not operational, and why.

Yes No NA

Is there a planned maintenance

16.2

system in use?

1. Note type of system in use.

2. Comment on number of routines outstanding

3. Is an inventory of spare parts being maintained?

Is the engine logbook fully Yes No NA

16.3 maintained in ink, both at sea

and in port?

Compare entries in the main logbook with entries in the rough log.

Is there a set of chief engineer's Yes No NA

16.4 standing orders posted and

countersigned?

1. Comment on whether machinery space PPE requirements are specified and complied with;

2. Does the chief engineer maintain a night order book? If so, this should be checked as

providing instruction for situations likely to be encountered;

3. Has the chief engineer written his own standing orders and are night orders being

completed? Have the watch engineers countersigned the chief engineer's standing and night

orders as read and understood?

4. Watertight doors should be in full working order and operating/warning notices posted.

5. N/A if only one Engine Room Crew onboard

Are hot surfaces and exposed Yes No NA

16.5 lagging free of any evidence of

fuel, hydraulic or lubricating oil?

1. All lagging should be free from oil, grease or other flammable contaminants and maintained

without exposed hot surfaces.

2. Check that there are no potential sources of ignition in the vicinity of fuel, hydraulic and

lubricating oil pipes.

3. Check that there are no unlagged/exposed hot surfaces above 220 degrees C in the vicinity of

fuel, hydraulic and lubricating oil pipes. All machinery insulation and shielding should be

properly fitted and fit for purpose.

Are main switchboard, Yes No NA

generators and critical electrical

16.6

equipment protected against

water spray?

Risk due to water spray in the event of failure of sea water pipes including fire mains and hydrants

should be assessed. If main switchboard is not located in engine control room or other protective

location, note in 'comments'.

Revision 3.4 – 2022-03-21

RSI INSPECTION CHECKLIST Page 27 of 27

Are emergency electrical power Yes No NA

16.7

supplies fully operational?

1. Emergency starting arrangements should be regularly tested and proved to be operational.

2. Instructions should be available to maintain/ restore main plant in the event of emergency.

3. There should be records of equipment being regularly tested.

4. Emergency generator fuel tank should be fully charged.

5. Concise starting instructions for emergency generator should be clearly displayed.

Yes No NA

16.8 Is the bilge system operational?

1. Are the engine room bilge oily water pumping and disposal arrangements available for use?

2. Bilge system normal discharge should be via OWS without bypass and not directly overboard.

3. Are emergency bilge pumping arrangements ready for immediate use; is the emergency bilge

suction clearly identified and, where fitted, is the emergency overboard discharge valve

provided with a notice warning against accidental opening?

4. Bilge level alarms should be regularly tested and records maintained.

5. Check that the Oil Record Book is correctly completed for bilge pumping operations

Is the steering gear/steering Yes No NA

16.9

compartment free from defects?

1. Emergency steering gear should have been tested quarterly and tests recorded - last test

date?

2. Instructions for the changeover of steering gear from remote to local operation should be

clearly displayed in steering flat.

3. Access to steering gear should be unobstructed.

4. The steering gear save-all should be free of spilled oil.

Are all machinery spaces clean Yes No NA

16.10

and free from obvious leaks?

Comment on general condition of machinery spaces.

Revision 3.4 – 2022-03-21

You might also like

- Osv Inspection Checklist PetronasDocument47 pagesOsv Inspection Checklist PetronasKunal Singh100% (6)

- FO-I-04 Report of Safety Inspection Revision 17Document8 pagesFO-I-04 Report of Safety Inspection Revision 17Jack100% (1)

- AMSA Ship Initial Inspection ChecklistDocument13 pagesAMSA Ship Initial Inspection ChecklistKEITH DESOUZA100% (1)

- ThaiREC Checklist-Barge Inspection Questionnaire GasDocument18 pagesThaiREC Checklist-Barge Inspection Questionnaire Gasเปีย วันชัย สวนทอง100% (1)

- Good Maintenance On Board ShipsDocument54 pagesGood Maintenance On Board ShipssivanandrayNo ratings yet

- Onboard MaintenanceDocument19 pagesOnboard MaintenanceViorel Andrei100% (2)

- Intro ME-GI - Dual FuelDocument37 pagesIntro ME-GI - Dual FuelamasrurNo ratings yet

- Quiz 16Document6 pagesQuiz 16Richmon SantosNo ratings yet

- 05 Voyage EstimationDocument3 pages05 Voyage Estimationburak_caglar100% (1)

- Responsible Shipping Initiative Checklist Rev3 - 3Document23 pagesResponsible Shipping Initiative Checklist Rev3 - 3Taner AkciğerNo ratings yet

- TWPST026 Ship Recycling Compliance SurveyDocument8 pagesTWPST026 Ship Recycling Compliance Surveyene oanaNo ratings yet

- ROVIQ7 Report LPG Carriers - (ECLIPSE) - 11.08.2022Document10 pagesROVIQ7 Report LPG Carriers - (ECLIPSE) - 11.08.2022TanmayNo ratings yet

- B-01 - Vessel Inspection ReportDocument20 pagesB-01 - Vessel Inspection Reportghonwa hammodNo ratings yet

- RightShip Inspections Ship Questionaire RISQ 3.0Document207 pagesRightShip Inspections Ship Questionaire RISQ 3.0Philic Rohit100% (2)

- SCV2 V2 December 2013 PDF FormatDocument30 pagesSCV2 V2 December 2013 PDF FormatNicandro PorcelliNo ratings yet

- Oil Chemical Tanker 2 5 7 FullDocument31 pagesOil Chemical Tanker 2 5 7 FullMarnie NguyenNo ratings yet

- Cheklist Fsi and GiDocument14 pagesCheklist Fsi and GiKumar AnandNo ratings yet

- Tug and Barge Part A 2014Document7 pagesTug and Barge Part A 2014lanNo ratings yet

- Bulk Carrier - General Cargo - Container Vessel Survey Report R1.3 FullDocument27 pagesBulk Carrier - General Cargo - Container Vessel Survey Report R1.3 FullKurupath SidharthanNo ratings yet

- Ship Inspection Form F P - R: 1. G I / S DDocument6 pagesShip Inspection Form F P - R: 1. G I / S DRonachai FuangfoongNo ratings yet

- Surfer Vessel Inspection Form - V2Document12 pagesSurfer Vessel Inspection Form - V2VICTORNo ratings yet

- BIQ EnglishDocument38 pagesBIQ EnglishkiyotakaayaNo ratings yet

- Bulk Carrier General Cargo Container r4 2 3 FullDocument30 pagesBulk Carrier General Cargo Container r4 2 3 FullGalih IrvandiNo ratings yet

- Chapter 1. General InformationDocument33 pagesChapter 1. General InformationaliNo ratings yet

- MLC Compliance Checlist Rev 0 30th Nov 18Document18 pagesMLC Compliance Checlist Rev 0 30th Nov 18Dini ANNo ratings yet

- ST Kitts & Nevis International Ship RegistryDocument11 pagesST Kitts & Nevis International Ship RegistrybthbidkesNo ratings yet

- Ship Risk Review: PTSC Offshore ServiceDocument35 pagesShip Risk Review: PTSC Offshore ServiceNguyễn QuânNo ratings yet

- Ism - Hongkong - MSIN 54 2015 Annex1Document12 pagesIsm - Hongkong - MSIN 54 2015 Annex1izoelgarciaNo ratings yet

- Report Part A Container Sample 1 - CompressedDocument22 pagesReport Part A Container Sample 1 - CompressedMohamed OmarNo ratings yet

- PSC Pocket Checklist MARPOL 0913 WebDocument18 pagesPSC Pocket Checklist MARPOL 0913 WebHaris Stavrou100% (4)

- P&I Condition Survey Report - Passenger-Ship-2-4-6-FullDocument28 pagesP&I Condition Survey Report - Passenger-Ship-2-4-6-FullEnrique Barajas100% (1)

- MSD252SUPPDocument3 pagesMSD252SUPPLuka ĐanovićNo ratings yet

- Cg-840 Hull Inspection BookDocument38 pagesCg-840 Hull Inspection Bookgreatenick.nbNo ratings yet

- Minimum Requirements For Seafarers To Work On A ShipDocument4 pagesMinimum Requirements For Seafarers To Work On A ShiproodbovengroenNo ratings yet

- 0 Condition Survey RPTDocument35 pages0 Condition Survey RPTKingEphrem10100% (1)

- Template Marine Contractor Office Audit QuestionnaireDocument16 pagesTemplate Marine Contractor Office Audit QuestionnairemartinusteddyNo ratings yet

- Maritime Law: Gemeinnützige Gesellschaft Trainingszentrum Ms Emsstrom MBHDocument68 pagesMaritime Law: Gemeinnützige Gesellschaft Trainingszentrum Ms Emsstrom MBHCarel Mae Cabaron100% (2)

- BP HGDK 3811 9086 6947 Observations DisclaimerDocument2 pagesBP HGDK 3811 9086 6947 Observations Disclaimersalah salaheddineNo ratings yet

- Ship Risk Review 2021 Ver 6Document37 pagesShip Risk Review 2021 Ver 6KEISHIN ISO100% (1)

- Marine Survey 1 2Document31 pagesMarine Survey 1 2Adam BanouraNo ratings yet

- Foreign Tank Vessel Exam BookDocument53 pagesForeign Tank Vessel Exam BookFernando Angulo DelgadoNo ratings yet

- MZ-5705-00 PSC Inspection Checklist Detailed Check (6 MONTHS)Document24 pagesMZ-5705-00 PSC Inspection Checklist Detailed Check (6 MONTHS)Lj NecesitoNo ratings yet

- CRW-01 - 1 (Seafarers Application Form)Document5 pagesCRW-01 - 1 (Seafarers Application Form)deniss sumilovsNo ratings yet

- HVPQ5 v1 1 09Document90 pagesHVPQ5 v1 1 09Pavel ViktorNo ratings yet

- Ships in Service Survey Report: DRB0/2012/J0251Document31 pagesShips in Service Survey Report: DRB0/2012/J0251Efthymios LouridasNo ratings yet

- Good Maintenance On Board Ships MaintenaDocument74 pagesGood Maintenance On Board Ships MaintenaVictor Hugo Valderrama ChavezNo ratings yet

- CDI - Harmonized Vessel Particulars Questionnaire (HVPQ) - 6th EditionDocument76 pagesCDI - Harmonized Vessel Particulars Questionnaire (HVPQ) - 6th EditionQuốc Tiến TrịnhNo ratings yet

- RLM 252 MODU 8 06 WDocument5 pagesRLM 252 MODU 8 06 WzaladsNo ratings yet

- PSC Pocket Checklist MARPOL Update 20180626 WebDocument18 pagesPSC Pocket Checklist MARPOL Update 20180626 WebGeorgios PapakostasNo ratings yet

- Survey Report FormDocument28 pagesSurvey Report FormJavier Rayleigh100% (2)

- Master Guide To Uk FlagDocument34 pagesMaster Guide To Uk Flag1979.alokNo ratings yet

- ANNEX - Navigational Audit QuestionnaireDocument24 pagesANNEX - Navigational Audit QuestionnaireАлексей Преподобный 1406No ratings yet

- Safety Check List - Marine SafetyDocument8 pagesSafety Check List - Marine SafetyRaphael SantosNo ratings yet

- Validity of Ship Certificates Check ListDocument5 pagesValidity of Ship Certificates Check Listadamsalum103No ratings yet

- Survey Checklist ANCODocument23 pagesSurvey Checklist ANCOkonstadine100% (1)

- PSC Checklist: On Board Maintenance Check ListDocument15 pagesPSC Checklist: On Board Maintenance Check ListAbebè TeferiNo ratings yet

- BP Shipping SIRE Inspection Preparation DocumentDocument4 pagesBP Shipping SIRE Inspection Preparation DocumentAhmed AL BatalNo ratings yet

- Part A: Condition Survey Report FormDocument8 pagesPart A: Condition Survey Report FormBadrul 'boxer' HishamNo ratings yet

- CG-840 FV 1foreign Freight Vessel ExamDocument12 pagesCG-840 FV 1foreign Freight Vessel Exammadhan01kumarNo ratings yet

- The Rules in Practice 2021-2024: The guide to the rules of sailing around the race courseFrom EverandThe Rules in Practice 2021-2024: The guide to the rules of sailing around the race courseNo ratings yet

- Fishing Vessel Surveys and Inspections How To Prepare For Your Next MCA VisitDocument52 pagesFishing Vessel Surveys and Inspections How To Prepare For Your Next MCA VisitamasrurNo ratings yet

- Let 200727 ADocument12 pagesLet 200727 AamasrurNo ratings yet

- D13 Job Aid 21Document124 pagesD13 Job Aid 21amasrurNo ratings yet

- Maintenance Schedule DK-20 DaihatsuDocument1 pageMaintenance Schedule DK-20 Daihatsuamasrur100% (1)

- Tahfiz & Essential Practice RecordDocument18 pagesTahfiz & Essential Practice RecordamasrurNo ratings yet

- Unique Response Challenges For Senior HousingDocument10 pagesUnique Response Challenges For Senior HousingamasrurNo ratings yet

- DAFTAR PERUSAHAAN PELAYARAN - PDF Download GratisDocument17 pagesDAFTAR PERUSAHAAN PELAYARAN - PDF Download GratisamasrurNo ratings yet

- Man L23/30H MK 2 GensetDocument2 pagesMan L23/30H MK 2 GensetamasrurNo ratings yet

- Week 02 Assignment 2Document1 pageWeek 02 Assignment 2amasrurNo ratings yet

- The ELC An Early Childhood Learning Community at Work 1596036495Document169 pagesThe ELC An Early Childhood Learning Community at Work 1596036495amasrurNo ratings yet

- Foundations For Assisting in Home Care 1520419723Document349 pagesFoundations For Assisting in Home Care 1520419723amasrurNo ratings yet

- 241-Article Text-1065-1-10-20210430Document16 pages241-Article Text-1065-1-10-20210430amasrurNo ratings yet

- Implementasi Metode My Q-Map Dalam Meningkatkan Hafalan Alquran Studi Di Pondok Tahfidz Bintang Quran CirebonDocument11 pagesImplementasi Metode My Q-Map Dalam Meningkatkan Hafalan Alquran Studi Di Pondok Tahfidz Bintang Quran CirebonamasrurNo ratings yet

- Ship Planned Maintenance System Database ConceptDocument11 pagesShip Planned Maintenance System Database Conceptamasrur100% (1)

- Ship Performance & Compliancy: Yang Ingin DicapaiDocument2 pagesShip Performance & Compliancy: Yang Ingin DicapaiamasrurNo ratings yet

- SL2016 632AAB Alpha LubricatorDocument3 pagesSL2016 632AAB Alpha Lubricatorpavlo_790317697No ratings yet

- M4 Ship-Board Energy Management - IMO TTT Course Presentation Final1Document84 pagesM4 Ship-Board Energy Management - IMO TTT Course Presentation Final1amasrurNo ratings yet

- C9781316502761SM PDFDocument93 pagesC9781316502761SM PDFamasrurNo ratings yet

- Boiler Start Up ProceduresDocument8 pagesBoiler Start Up ProceduresamasrurNo ratings yet

- COPY Not Negotiable: by Maersk Brasil (Brasmar) Ltda HERNANDO F. SANTOS - CPF. 329.606.418-41Document2 pagesCOPY Not Negotiable: by Maersk Brasil (Brasmar) Ltda HERNANDO F. SANTOS - CPF. 329.606.418-41Fernando GariaNo ratings yet

- Part I: Ship Builders: Directory 2016Document91 pagesPart I: Ship Builders: Directory 2016nnadoziekenneth5No ratings yet

- The Life of Captain James Cook by Kitson, ArthurDocument169 pagesThe Life of Captain James Cook by Kitson, ArthurGutenberg.org100% (1)

- Furuno 3100 ManualDocument3 pagesFuruno 3100 Manual4tgvmfzckpNo ratings yet

- Timber Deck Cargoes: Regional Maritime UniversityDocument33 pagesTimber Deck Cargoes: Regional Maritime UniversityMahami M Prosper100% (1)

- Bulk PDFDocument5 pagesBulk PDFSlreview Hub100% (1)

- Comparison of Single and Double Hull TankersDocument9 pagesComparison of Single and Double Hull Tankersyann1982100% (2)

- Pilot Transfer Arrangements BrochureDocument5 pagesPilot Transfer Arrangements BrochureMats Karlsson100% (1)

- Билеты GOC - 2017Document10 pagesБилеты GOC - 2017Юлия АндреевнаNo ratings yet

- Oral Questions: Lower Lifeboat in Heavy Weather ConditionDocument3 pagesOral Questions: Lower Lifeboat in Heavy Weather ConditionVaratheraju SantharanNo ratings yet

- Practical Ship HandlingDocument62 pagesPractical Ship HandlingDheerajKaushal100% (14)

- SPS Vessels SiwDocument32 pagesSPS Vessels Siwpgupta71No ratings yet

- Vessel PortfolioDocument19 pagesVessel PortfolioJina DevNo ratings yet

- Question Interview - 3.O UMMS - 5Document10 pagesQuestion Interview - 3.O UMMS - 5Hoài ThanhNo ratings yet

- The Port State Control and Their Role in The Maritime SafetyDocument9 pagesThe Port State Control and Their Role in The Maritime SafetyMohamed AliNo ratings yet

- Oceanis Bunkering Co - Ltd. Receiving Vessel Name: Mt. Elise: Supply Terminals Name: EngenDocument4 pagesOceanis Bunkering Co - Ltd. Receiving Vessel Name: Mt. Elise: Supply Terminals Name: EngenAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Jensen Heavy Lift Marine Engineering BrochureDocument3 pagesJensen Heavy Lift Marine Engineering Brochuremyusuf_engineerNo ratings yet

- Contoh CVDocument1 pageContoh CVWanty Aswantie50% (2)

- Dokumen Keselamatan Pengawakan Minimum No:: Minimum Safe Manning DocumentDocument2 pagesDokumen Keselamatan Pengawakan Minimum No:: Minimum Safe Manning DocumentAlfilia KhoirunnisaNo ratings yet

- STCW Code Table B-I/2: List of Certificates or Documentary Evidence Required Under The STCW ConventionDocument2 pagesSTCW Code Table B-I/2: List of Certificates or Documentary Evidence Required Under The STCW ConventionLita Anggraeni Verawati100% (1)

- CP Mooring Guidance 2019 OrigDocument18 pagesCP Mooring Guidance 2019 OrigJohn Mike ZstacaNo ratings yet

- Wooden Ships and Iron Men PDFDocument51 pagesWooden Ships and Iron Men PDFtrireme_899773068No ratings yet

- Voyag Charter PartyDocument14 pagesVoyag Charter Partydetrusitol100% (1)

- Jepretan Layar 2021-07-08 Pada 10.49.57Document2 pagesJepretan Layar 2021-07-08 Pada 10.49.57sulaimanNo ratings yet

- Uss Blower (Ss-325)Document4 pagesUss Blower (Ss-325)loggynety159No ratings yet

- Ship Particulars Dragonera 2023Document1 pageShip Particulars Dragonera 202322-57495No ratings yet

- Crewlist Gaba GwapoDocument14 pagesCrewlist Gaba GwapoNiñal Ramsted BNo ratings yet

- Dutch Warships of World War II PDFDocument148 pagesDutch Warships of World War II PDFMatheus Benedito100% (5)