Professional Documents

Culture Documents

2016.8.6 Vol-II Part II Chapter 2

2016.8.6 Vol-II Part II Chapter 2

Uploaded by

Jarus YdenapCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2016.8.6 Vol-II Part II Chapter 2

2016.8.6 Vol-II Part II Chapter 2

Uploaded by

Jarus YdenapCopyright:

Available Formats

Technical Specification

SECTION-II: MATERIALS

2.0.0 Materials

All members and components listed under these specifications and specification drawings shall be

fabricated out of unused high grade materials free from any kind of defects and imperfections. The

Contractor, on the basis of the design supplied by the Employer, shall prepare and submit detail

requirement of the steel plate materials required to fabricate penstock pipe and steel liner. Such

details shall be in line with the sizes and specifications available in the Indian and/or Chinese

market. If in case the steel plate sizes proposed by the Contractor is not available in the market,

the Employer may ask the Contractor to adjust the plate sizes. However any such adjustment shall

not alter the design. Any such adjustment shall not change the price. All the materials shall

conform to the standards specified in these specifications and on the specification drawings,

however, if for any reasons the contractor desires to deviate from these standards, he shall submit

a statement stating the exact nature of deviations or substitutions along with complete and detailed

specifications and test reports of the materials which are proposed to be used as substitution or

deviation, for the approval of the Employer, prior to the fabrication work is taken up in hands. All

such materials or articles or supplies, which are not manufactured by the contractor, shall be the

product of recognized and reputed manufacturer.

The contractor shall furnish a list of names of the manufacturer(s) of the bought out complete

equipment, which are contemplated for incorporation in the work, together with their performance

characteristics and other pertinent reports along with the samples of the materials, shall be

submitted for approval of the purchaser. How the approval of purchaser shall not relieve the

manufacturer from the responsibility of supply of suitable materials. Any material or equipment

used or installed with no prior approval of the purchaser shall be at risk and cost of the contractor.

Recommended materials for some of the components of different type of gates, hoists & cranes

involved are given below :

2.1.0 Fixed Wheel Gate/Wheeled Stoplog

S. No. Component Recommended Materials Reference

1. Skin plates, Stiffeners Structural Steel IS-2062 Grade E250,

Quality B

2. Main horizontal girders, Structural Steel –––– do ––––

Vertical girders etc.

3. Seal bases, Track bases, Seal Structural Steel –––– do ––––

seat bases Seal clamps guide

shoes

4. Anchor plates, Anchorages Structural Steel –––– do ––––

etc.

5. Side guide tracks Structural Steel –––– do ––––

Bagmati Small Hydroelectric Project Page 1

Technical Specification

6. Seal seats Stainless steel, IS-1570 (Part-V)

X04Cr18Ni10

7. Wheel tracks Corrosion resistant steel IS-1570 (Part-V)

plates X30Cr13 (BHN of

wheel track should be more

by minimum 50 points than

that of wheel)

8. Wheel Cast steel/Forged Steel IS-1030/IS-2004/1875

9. Wheel pin Stainless Steel IS-1570 (Part-V)

10. Bearings in Wheels Spherical Roller SKF or

equivalent Bearing

11. Side and top Rubber Seals PTFE cladded solid bulb IS-11855, IS-15466

music note.

12. Bottom seal Wedge type rubber seal IS-11855,IS-15466

13. Steel liner Structural steel IS-2062 Grade E250,Quality

B

2.2.0 Stoplogs for Undersluice

S. No. Component Recommended Materials Reference

1. Structural members of the Structural Steel IS : 2062 (for thickness

stoplogs, such as skin plate, more than 20mm, use only

stiffeners, horizontal girders steel conforming to IS :

& vertical girders etc. 2062)

2. Lifting brackets, guide shoes Structural Steel ––– do –––

etc.

3. Track brackets, guide shoes Structural Steel ––– do –––

etc.

4. Anchor plates & anchorages Structural Steel ––– do –––

etc.

5. Track plates and seal seats Stainless steel IS : 1570 (Part-V)

6. Slide block Structural steel with bronze IS : 2062

padding

IS : 305

7. Seals Natural or synthetic rubber IS : 11855

8. Screws/Bolts for seals Stainless steel IS : 1570 (Part V)

9. CSK screws for bronze Stainless steel IS : 1570 (part V)

padding

Bagmati Small Hydroelectric Project Page 2

Technical Specification

2.3.0 Electrically Operated Rope Drum Hoist and Hoist Bridge

S. No. Component Recommended Materials Reference

1. All structural members for Structural Steel IS-2062 Grade E250,Quality

steel trestles and hoist bridge B

etc.

2. Rope drum Structural Steel, IS-2062 Grade E250,

Quality B

Cast steel IS : 1030

3. Wire rope Improvised plough steel IS : 2266

(galvanized)

4. Hook and wire rope socket Forged steel IS : 2004

IS: 1875

5. Gears Cast steel IS : 1030

Forged steel IS : 1875

6. Pinions Forged steel IS : 2004

7. Shafts Structural Steel IS-2062 Grade E250,

Quality B

Forged steel IS : 2004

8. Sheaves/Pulleys Structural steel IS-2062 Grade E250,

Quality B

Cast steel IS : 1030

9. Bronze bushing Lead Tin Bronze IS : 318

Aluminium bronze IS : 305

10. keys and Cotters Forged steel IS : 2048/2291/2292

11. Motor Standard manufacturer IS : 325

12. Cable and conductors IS : 9968/IS : 8130

13. Conduits IS : 9537

14. Switch gear Standard manufacturer IS : 2147

IS : 4237

IS : 2516

15. Ball & roller bearings Standard manufacturer IS : 5669

IS:5692 & other applicable

standards

Bagmati Small Hydroelectric Project Page 3

Technical Specification

2.4.0 Lifting Beam

S. No. Component Recommended Materials Reference

1. Structural components of Structural Steel IS-2062 Grade E250,

lifting beam, guide bars, Quality B

diaphragms etc.

2. Axles, pins and their Corrosion resistant steel IS : 1570

retaining devises such as

nuts, bolts, washer.

3. Hooks Forged steel IS : 1875

IS-2062 Grade E250,

Structural Steel Quality B

4. Bush for hooks Self lubricating bronze IS : 305

bushes

5. Bearing for Pulleys Roller bearings Standard make

6. Sheaves & Rollers Cast steel IS : 1030

2.5.0 Monorail Crane

S. No. Component Recommended Materials Reference

1. Wire ropes 6 37 construction IS : 2266

ungalvanized improved

plough steel, with fibre core

or steel core, extra flexible

2. Wire rope sockets Forged steel IS : 2485

3. Lifting hooks Forged steel IS : 2004

4. Rope drum Cast steel IS : 1030

Structural steel IS : 2062

5. Gears Cast steel IS : 1030

IS : 3681,

IS : 4058,

IS : 4460 & others.

6. Pinion Cast steel IS : 1030

forged steel IS : 1875

C-45 Carbon Steel IS : 1570

7. Sheaves, pulleys and Cast steel IS : 1030

couplings Wrought steel IS : 1570

8. Shafts Structural Steel IS : 2062

Carbon steel IS : 1570

9. Threaded fasteners Bolt Steel IS : 1363

IS : 1364

IS : 1365

Bagmati Small Hydroelectric Project Page 4

Technical Specification

IS : 1367

IS : 2389

10. Bush Bearings Aluminium Bronze IS : 305

Phosphor Bronze IS : 28

Leaded Tin bronze IS : 318

11. Turn buckles Structural steel IS : 2062

Forged steel IS : 2004

12. Hoist supporting structure Structural plates IS : 2062

Rolled steel sections IS : 808

13. Wheels Forged steel IS : 2004

Cast steel IS : 1030

14. Keys and Cotters Forged Steel IS : 2048

IS : 2291

IS : 2292

15. Ball and Roller bearings Standard IS : 5669,

Manufacturer IS : 5692 & other applicable

standards

16. Electric Motors Standard manufacturer IS : 325

IS : 900

17. Cables and conductors Standard manufacturer IS : 9968

IS : 8130

18. Switch gear Standard manufacturer IS : 1822,

IS : 13947

IS : 5124

19. Electrical bought out items. Standard approved make

2.6.0 Penstock and It’s Accessories

S.No. Component Recommended Materials Reference

i) Penstock shells, bends, Boiler quality Steel Boiler quality steel

reducers Manholes, plates/coils conforming to

bifurcation, reducers, ASTM-537 Cl-1

stiffener rings etc.

ii) Forgings for General Forged steel IS:2004

engineering purpose

iii) Piezometer plugs Stainless steel IS:1570(Part V)

Bagmati Small Hydroelectric Project Page 5

Technical Specification

iv) Gaskets or jointing material BS:1737 or equivalent IS

specifications

v) Zinc rich primer AWWA Specifications or

equivalent IS specifications.

vi) Cold applied coal tar epoxy British Epilux -5 or

paint equivalent

vii) Red lead primer paint IS:102

viii) Aluminum Paint IS:2839

ix) Red oxide zinc chrome IS:2074

2.7.0 NOTES

The details covered in Para 3.1.0 to 3.6.0 shall be read in conjunction with the following notes.

i) In all the reference cited above the latest revised edition of Indian standards or equivalent

shall only be followed. In case the contractor proposes to use materials different from those

mentioned above, he should mention the same in his tender and indicate the exact extent to

which he proposes to use, furnishing necessary details for approval of the purchaser.

Materials conforming to international standards like ASTM, DIN, which are equivalent to

those mentioned above, can be used with the approval of the purchaser.

ii) The sizes, ratings, capacities, and dimensions of the various standard equipment items listed

in the contract Documents are based on currently available standard products. Reasonable

deviations will be allowed to permit supply of standard equipment. In no case the capacity

furnished shall be less than that specified, unless approved.

iii) Threaded fasteners, pipes, anti-friction bearings and gears : –

All bolts, nuts, screws, rivets, threads, pipe, ball and roller bearings, gauges and gears shall

confirm to US/BIS/DIN Standards. Screw threads for screws, bolts, nuts and other threaded

hardware shall conform to ANSI B 1.1.

iv) Asbestos: Equipment and materials such as, gaskets, packing, brake pads etc. shall contain

no asbestos products.

v) Only self lubricating bronze bushes of reputed manufacturers shall be used wherever

bronze bushes have been indicated.

2.8.0 LIST OF SOME REPUTED MANUFACTURERS OF MECHANICAL AND

ELECTRICAL EQUIPMENT TO BE USED IN HYDROMECHANICAL

Bagmati Small Hydroelectric Project Page 6

Technical Specification

INSTALLATION FOR REFERENCE

S. No. Item Make

1. Reduction Unit New Allenberry, Allen-max, Allmax, Shanti, Allroyd,

Radicon, David Brown, Elecon etc.

2. Bearings KOYA, NBC , NACHI, SKF, FAG, NSK, NTN etc.

3. Flexible coupling New Allenberry.

4. Motors Siemens, Kirloskar, NGEF, GEC, Crompton Greaves

Cotton etc.

5. Brakes Bhartia Cutler Hammer, Electromag, Strom Kraft, Elmar

AEC Sterling etc.

6. Self lubricating Lubrite, Lubron, Devaglide,Oiless,Ferroglide

bronze bearings

7. Welding electrodes Modi, Adore, D&H, L&T , Esab etc.

8. Steel wire ropes Usha Martin, Fort William, Bombay wires, Winkel GMBH

etc.

9. Hydraulic Cylinder Rexroth Hydrodyne, Hunger, Montan

10. Hydraulic Power Packs Rexroth, Vickers, Montan

11. ARMAC/Remote Allen Bradley, Rockwell, Siemens, ABB, Schneider

Control System Type : PLC Electric

12. Gasoline Engine for Portable Kohler, Honda, Yamaha

Power Pack

13. D.G. Set Caterpillar, Kirloskar, Cummins, Greaves Cotton

14. Hydraulic Oil Cleaning Unit KLAROL Oil Cleaning Systems

for Hydraulic Hoists

Bagmati Small Hydroelectric Project Page 7

You might also like

- IFI Book of Fastener Standards 2021 Edition - TOCDocument7 pagesIFI Book of Fastener Standards 2021 Edition - TOCmoises cordoba50% (2)

- Compendium of Logistics Policies Volume III PDFDocument219 pagesCompendium of Logistics Policies Volume III PDFDon-Juan Casanova92% (12)

- Australian To Indian Material Equivalent ChartDocument1 pageAustralian To Indian Material Equivalent ChartMohammad Adil100% (1)

- 051200Document11 pages051200sivaNo ratings yet

- Standard Technical Specifications For Electric WorksDocument11 pagesStandard Technical Specifications For Electric WorksnoufalNo ratings yet

- MS Pipes Technical SpecificationDocument46 pagesMS Pipes Technical SpecificationIraqui Arif Nawaz100% (1)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Gasifier Design Spreadsheet (Rice Husk) : CalculationsDocument4 pagesGasifier Design Spreadsheet (Rice Husk) : CalculationsJarus Ydenap0% (1)

- CSP 20-21 App Development Planning GuideDocument7 pagesCSP 20-21 App Development Planning GuideJoel MamanNo ratings yet

- AspenTech - Compressor Modeling in Aspen HYSYS DynamicsDocument26 pagesAspenTech - Compressor Modeling in Aspen HYSYS DynamicsTaniadi SuriaNo ratings yet

- 12 Appendix 256 To 295Document40 pages12 Appendix 256 To 295subinmes413No ratings yet

- 18 - Structural Steel (Section-1900)Document39 pages18 - Structural Steel (Section-1900)Ankit MaindoliaNo ratings yet

- ICC-ES Evaluation Report ESR-2347: - (800) 423-6587 - (562) 699-0543 A Subsidiary of The International Code CouncilDocument6 pagesICC-ES Evaluation Report ESR-2347: - (800) 423-6587 - (562) 699-0543 A Subsidiary of The International Code CouncilDaniel PulgarNo ratings yet

- 19.sec.1900 (Structural Steel)Document31 pages19.sec.1900 (Structural Steel)aalignup arc & const. pvt ltdNo ratings yet

- IRON AND STEEL Standard EquivalentsDocument5 pagesIRON AND STEEL Standard Equivalentsvmls1973100% (6)

- SECTION 05 40 00 Cold-Formed Metal FramingDocument10 pagesSECTION 05 40 00 Cold-Formed Metal FramingJuanPaoloYbañezNo ratings yet

- Equivalência de Normas de AçosDocument6 pagesEquivalência de Normas de AçosCamilla GandineNo ratings yet

- Project I.D. ( - ) Structural Metal Framing (Rev. 10, April 11, 2018) 05 1000-1Document29 pagesProject I.D. ( - ) Structural Metal Framing (Rev. 10, April 11, 2018) 05 1000-1081382991318No ratings yet

- Letter To Licensee (Steel Products)Document7 pagesLetter To Licensee (Steel Products)Praveen SinghNo ratings yet

- Indian & International STDDocument8 pagesIndian & International STDMirza Sameer Ali BaigNo ratings yet

- Design Basis Report (DBR) : Proposed Steel Truss With Crane Essembly"Document18 pagesDesign Basis Report (DBR) : Proposed Steel Truss With Crane Essembly"Architects AsiaNo ratings yet

- ICC ESR-2196 For Self-Drilling and Self-Piercing Screws Approval Document ASSET DOC LOC 36Document12 pagesICC ESR-2196 For Self-Drilling and Self-Piercing Screws Approval Document ASSET DOC LOC 36javyusfNo ratings yet

- GratingsDocument3 pagesGratingssaurabhsubhuNo ratings yet

- Is Standard ListDocument5 pagesIs Standard ListbalramkinageNo ratings yet

- Is-STEEL Codes & DetailsDocument4 pagesIs-STEEL Codes & DetailssantoshcipetNo ratings yet

- King Abdullah Bin Abdulaziz Project Mataf Extension - DesignDocument14 pagesKing Abdullah Bin Abdulaziz Project Mataf Extension - DesignshoebNo ratings yet

- Production MergedDocument15 pagesProduction MergedMIHAEL CRUZNo ratings yet

- Design of Steel Structures 2Document3,379 pagesDesign of Steel Structures 2Structural SpreadsheetsNo ratings yet

- Ilovepdf Merged PDFDocument784 pagesIlovepdf Merged PDFRe DesignNo ratings yet

- Design of Steel StructuresDocument2,529 pagesDesign of Steel StructuresStructural Spreadsheets67% (9)

- G3ir 1050 65 SP 9042 - R1Document8 pagesG3ir 1050 65 SP 9042 - R1Ramu NallathambiNo ratings yet

- IRS-B1 Correction Slips Upto 11Document41 pagesIRS-B1 Correction Slips Upto 11vishal agrawal100% (1)

- AVK - Gate Valve OS&Y UL - FM - OutdoorDocument2 pagesAVK - Gate Valve OS&Y UL - FM - OutdoorVINOD PAULNo ratings yet

- FL - Ta1056Document14 pagesFL - Ta1056ery achjariNo ratings yet

- Specifications 2Document56 pagesSpecifications 2msmetalstabukNo ratings yet

- Week 1 Lecture Material - WatermarkDocument88 pagesWeek 1 Lecture Material - Watermarkchristi SNo ratings yet

- 44AC9100-000-V.02-0124-A4 - Rev B - STANDARD FOR ANCHOR BOLTSDocument16 pages44AC9100-000-V.02-0124-A4 - Rev B - STANDARD FOR ANCHOR BOLTSAvinash ShuklaNo ratings yet

- Metal FabricationsDocument6 pagesMetal FabricationskangchinNo ratings yet

- Indian Standard Radial GateDocument8 pagesIndian Standard Radial GateMirza Fadlulah100% (1)

- S-AAA-CIV-METAL (Rev.0-2015)Document13 pagesS-AAA-CIV-METAL (Rev.0-2015)Sam AzzNo ratings yet

- Properties of Structure Steel As Per Limit State Method IS 800:2007, Mechanical Properties of SteelDocument19 pagesProperties of Structure Steel As Per Limit State Method IS 800:2007, Mechanical Properties of SteelRaju Sharma75% (4)

- DBRDocument3 pagesDBRkeerthivasan_mrvNo ratings yet

- Cold-Formed Steel in ConstructionDocument33 pagesCold-Formed Steel in ConstructionVijender JainNo ratings yet

- IW - High Torque Duty: Keeping The World FlowingDocument4 pagesIW - High Torque Duty: Keeping The World FlowingElinton SarmientoNo ratings yet

- AISIS240 15 (1stprinting)Document204 pagesAISIS240 15 (1stprinting)Roberto Pérez LeónNo ratings yet

- Hardware SpecificationDocument62 pagesHardware Specificationritesh.tavNo ratings yet

- Is For Swing Check Type RefluxDocument8 pagesIs For Swing Check Type RefluxRahul GandhiNo ratings yet

- Iron and Steel ProductsDocument4 pagesIron and Steel ProductssskamalakannanNo ratings yet

- Cost & Specifications - 05Document11 pagesCost & Specifications - 05REEM MOEMENNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 05120-1 Structural SteelDocument6 pagesITCC in Riyadh Residential Complex J10-13300 05120-1 Structural SteeluddinnadeemNo ratings yet

- Hidrante Seco Mod F0733Document1 pageHidrante Seco Mod F0733Julio FloresNo ratings yet

- Avk Metal Seated Gate Valve, Pn10/16 54/3132-007: ISO F14 Actuator Flange, DN350-600Document3 pagesAvk Metal Seated Gate Valve, Pn10/16 54/3132-007: ISO F14 Actuator Flange, DN350-600Sakir ZakNo ratings yet

- 1 01 026 18Document5 pages1 01 026 18esskaydhakarNo ratings yet

- Spec's For Steel StructureDocument11 pagesSpec's For Steel StructureAburvarajNo ratings yet

- Steel Stairs, Ladders and Platforms - MSTDocument13 pagesSteel Stairs, Ladders and Platforms - MSTwafikmh4No ratings yet

- Sheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkFrom EverandSheet Metalwork on the Farm - Containing Information on Materials, Soldering, Tools and Methods of Sheet MetalworkNo ratings yet

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesFrom EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- American Blacksmithing, Toolsmiths' and Steelworkers' Manual - It Comprises Particulars and Details Regarding:: the Anvil, Tool Table, Sledge, Tongs, Hammers, How to use Them, Correct Position at an Anvil, Welding, Tube Expanding, the Horse, Anatomy of the Foot, Horseshoes, Horseshoeing, Hardening a Plowshare and BabbitingFrom EverandAmerican Blacksmithing, Toolsmiths' and Steelworkers' Manual - It Comprises Particulars and Details Regarding:: the Anvil, Tool Table, Sledge, Tongs, Hammers, How to use Them, Correct Position at an Anvil, Welding, Tube Expanding, the Horse, Anatomy of the Foot, Horseshoes, Horseshoeing, Hardening a Plowshare and BabbitingNo ratings yet

- Worm Gear Screw Jack - ClassicDocument6 pagesWorm Gear Screw Jack - ClassicJarus YdenapNo ratings yet

- Sample NP Chart of Accounts With Func Exp Cat - 5F00Document6 pagesSample NP Chart of Accounts With Func Exp Cat - 5F00Jarus YdenapNo ratings yet

- Ghimire 2012 Renewable-EnergyDocument5 pagesGhimire 2012 Renewable-EnergyJarus YdenapNo ratings yet

- This Is A Great StuffDocument121 pagesThis Is A Great StuffJarus YdenapNo ratings yet

- Memo CiDocument2 pagesMemo CiJarus YdenapNo ratings yet

- Diesel Stock Report 2074.75Document10 pagesDiesel Stock Report 2074.75Jarus YdenapNo ratings yet

- North Hydro Company Profile-2015Document13 pagesNorth Hydro Company Profile-2015Jarus YdenapNo ratings yet

- Research and Writing SkillsDocument141 pagesResearch and Writing Skillsapi-19731241No ratings yet

- Technical and Field Experience of Downdraft Gasifier ForDocument18 pagesTechnical and Field Experience of Downdraft Gasifier ForJarus YdenapNo ratings yet

- Libro de Gasógeno de La FAODocument139 pagesLibro de Gasógeno de La FAOpobrecitogasificadorNo ratings yet

- Superficial VelocityDocument8 pagesSuperficial VelocitybatazivoNo ratings yet

- Gasifier Engine Calculation SpreadsheetDocument12 pagesGasifier Engine Calculation SpreadsheetJarus Ydenap100% (1)

- Effective Viral Clearance in Mab PurificationTOYOPEARL® ResinDocument1 pageEffective Viral Clearance in Mab PurificationTOYOPEARL® ResinBruno AndreNo ratings yet

- Module 1 - Computer EthicsDocument19 pagesModule 1 - Computer EthicsJay BagayasNo ratings yet

- FSC International StandardDocument15 pagesFSC International StandardEMINANo ratings yet

- Writing Covered Calls: The Ultimate Guide ToDocument36 pagesWriting Covered Calls: The Ultimate Guide ToRamus PerssonNo ratings yet

- Q2-COT-LP-Health7 - Wk4 (Malnutrition and Micronutrients Deficiency)Document4 pagesQ2-COT-LP-Health7 - Wk4 (Malnutrition and Micronutrients Deficiency)ivonneNo ratings yet

- Đề cũ 4Document30 pagesĐề cũ 4Lê Hồng ThịnhNo ratings yet

- Métodos de Violín y ViolaDocument10 pagesMétodos de Violín y ViolaMaria de los Ángeles50% (2)

- Module 7Document5 pagesModule 7marleteNo ratings yet

- 11-SuperCritical Fluid ChromatographyDocument6 pages11-SuperCritical Fluid ChromatographyGopiNo ratings yet

- When Caring Hurts: The Silence Burnout of SonographersDocument5 pagesWhen Caring Hurts: The Silence Burnout of SonographersCarlos BarradasNo ratings yet

- Neo FuturismDocument16 pagesNeo Futurismboddutilak100% (1)

- Laser AttenuationDocument8 pagesLaser AttenuationMARTIN TIRKEYNo ratings yet

- Kingfisher CalendarDocument54 pagesKingfisher CalendarMalay K GhoshNo ratings yet

- PowerDB Uninstall Guide PDFDocument4 pagesPowerDB Uninstall Guide PDFMarco C. PumaNo ratings yet

- RMS Titanic Was A British Passenger: Olympic - Class Ocean LinersDocument1 pageRMS Titanic Was A British Passenger: Olympic - Class Ocean Linersandreea uNo ratings yet

- Sustainability AccountingDocument14 pagesSustainability AccountingAbba ShallomNo ratings yet

- Cleanroom Design GOODDocument135 pagesCleanroom Design GOODtony manyookNo ratings yet

- Torque Spiral Wound GSKT TableDocument2 pagesTorque Spiral Wound GSKT TableCarlos Roberto Tamariz100% (1)

- ELMS Project ReportDocument42 pagesELMS Project ReportLuckinsi Samuel100% (1)

- ProposalDocument15 pagesProposalCourage JuwawoNo ratings yet

- Big Picture B: Unit 3Document4 pagesBig Picture B: Unit 3vworldpeace yanibNo ratings yet

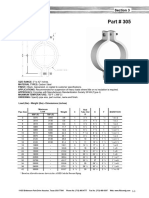

- Part 305 Heavy Pipe ClampDocument1 pagePart 305 Heavy Pipe ClampezhiljananiNo ratings yet

- Angel Baby LyricsDocument1 pageAngel Baby LyricsBianca Mongaya100% (1)

- KPI FormulaDocument3 pagesKPI FormulaSrikant GuptaNo ratings yet

- History G4 Report FinalDocument14 pagesHistory G4 Report FinalElvira MirajulNo ratings yet

- Airbus Family Figures BookletDocument17 pagesAirbus Family Figures BookletCoffardNo ratings yet

- Ultrasonic TestingDocument153 pagesUltrasonic Testinglucky kakanNo ratings yet