Professional Documents

Culture Documents

Cyclone

Cyclone

Uploaded by

qcath001Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cyclone

Cyclone

Uploaded by

qcath001Copyright:

Available Formats

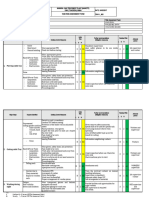

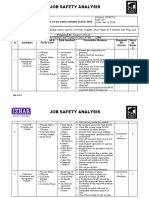

RISK ASSESSMENT FORM / GENERAL WORK PERMIT

Report No.

Location : Pre-Heater/ Cylone 5 Revision No.

Description of work : Replacement of Cylone 5 diptube and flap Date

Name of Contractor: NVH ENGINEERING AND SERVICES

With current control After additional corrective action

HOC Probabilit R A Additional control By RA

No Sequence of job Potential hazards Consequence/s Current controls Severity Severity Probability

Code y Code measures Whom Code

Preparation of Tools and

Application of proper

Equipment Such as:

positioning of body for

Installation & positioning

Manual Handling & Can cause a minor to manual handling activities.

of welding machines, Buddy 2x system/used of

Ergonomic Related serius injury to a Avoide over exertion of body S 3 2 II Con. 3 1 I

cable laying of welding mechanical techniques.

Hazard workers/ personnel movement and proper

cables & hoses and

wearing of necessary PPEs

stores tanks & pannel

Needed.

board on safe locations.

Wear appropriate hand

gloves with rubber/rubber

Cuts and Laceration

Sharp tools edges dotted to prevent hand cuts/ EL 3 2 II Con. 3 1 I

bruises

Lacerations or used leather

gloves if applicable

Proper Wearing of standard

Used of respiration if

Dust Respiratory Illness dust mask such as: KN-95/N- P 3 2 II Con. 3 1 I

needed

95

Strictly compliance at proper

wearing of skull guard with

chainstrap for head

protection on all identified low

Avulsion to medical

Low headed areas headed areas. Provide P&A 3 2 II

injury

proper illumination on site.

Provide safety signages on

all low headed areas and

familiarization of area

Risk Assessment (R A Code) Members:

Risk = Severity rate ( 1 - 5 ) Tolerable RAC No. II ( 6 - 12 ) Moderate RAC No. III ( 13 - 25 ) Intolerable Fullname Signature

1

Severity Explanation 2

5 Fatality or paralysed, property damaged more than Php 10,000,000 Exposure Category - Tick one 3

4 Permanent disability (including occupational diseases), property damaged from Php 1,000,001 1 Greater than 50 persons exposed 4

3 Temporary disablement, LTA more than 3 days, property damaged from Php 100,001 - Php 1, 2 10 to 49 persons exposed 5

2 Minor injury, LTA with up to 3 lost days, property damaged from Php 5,000 - Php 100,000 3 5 to 9 persons exposed 6

1 First aid injury, non-LTA, property damage of <Php 5,000 4 Less than 5 persons exposed 7

8

Job Specific PPE Permit Required Probability Explanation Code Hierarchy of Control 9

Mandatory PPE Othe Work at Heights 5 Almost Certain EL Elimination 10

Hotworks PPE Deviation of Isolation/Deisolation 4 Very likely S Substitution

Confined Space Commissioning (using GWP) 3 Likely EN Engineering Date Date Date

Safety Harness Lifting 2 Unlikely A Administrative Name Name Name

Hand Gloves 1 Very unlikely P PPE Safety PIC/ Teammate / Contractor

SCBA Others : ________________

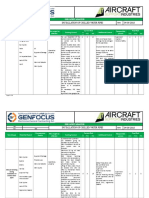

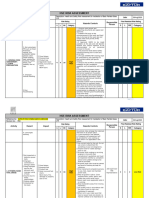

RISK ASSESSMENT FORM / GENERAL WORK PERMIT

Report No.

Location : Pre-Heater/ Cylone 5 Revision No.

Description of work : Replacement of Cylone 5 diptube and flap Date

Name of Contractor: NVH ENGINEERING AND SERVICES

With current control After additional corrective action

HOC Probabilit R A Additional control By RA

No Sequence of job Potential hazards Consequence/s Current controls Severity Severity Probability

Code y Code measures Whom Code

Weather condition/ Heavy can cause illness on

Hauling of materials/ Divert all lifting activities on

Rain occur personnel.

Provide temporary shelter on site for minimal job task that cannot

all personnel being affected of Rain. affected by the strong winds &

Temporarily heavy rain occurs. Encourage

A 4 3 II Con 4 1 I

STOP all lifting activities while the personnel to wear proper PPEs

Lifting of materials using boom Swinging of load/ Property weather condition are not applicable for the expected weather

strong winds to proceed. conditions for wet & windy

truck damage

conditions.

Proper Barricade the affected area

and Provide spotter with equiped. Of

wistle/two way radio for proper

means of communications and Safety Provide proper trainings for

Struck by, Being hit by a sinages. drivers, operators,spotter. All

Moving Vehicle moving Vehicle, Fractured, Do not allowed other EN 5 3 III mobile vehicle must have a Con 5 1 II

LTI/ Fatality contractor/personnel to enter/ interfer warning device/back horn &

with the Barricaded affected area. revolving lights.

Only used desegnated

walkways for all workers & Being

aware of all moving Vehicle

Ensure that all lifting equipment are Personnel beng assigned on the

properly inspected and updated job task are knowlegable and

Equipment failure due to over

Can cause a minor to serius inspection tags & stickers. properly trained.

load/ Lack of inspection prior A 4 2 II Con 4 1 I

injury to a person assess the weight of load being lifted Supervision of a desegnated

to used

versus on the SWL of equipment safety officer and supervisor is a

being used. must

Risk Assessment (R A Code) Members:

Risk = Severity rate ( 1 - 4 ) Tolerable RAC No. II ( 5 - 12 ) Moderate RAC No. III ( 13 - 25 ) Intolerable Fullname Signature

1

Severity Explanation 2

5 Fatality or paralysed, property damaged more than Php 10,000,000 Exposure Category - Tick one 3

4 Permanent disability (including occupational diseases), property damaged from Php 1,000,001 1 Greater than 50 persons exposed 4

3 Temporary disablement, LTA more than 3 days, property damaged from Php 100,001 - Php 1, 2 10 to 49 persons exposed 5

2 Minor injury, LTA with up to 3 lost days, property damaged from Php 5,000 - Php 100,000 3 5 to 9 persons exposed 6

1 First aid injury, non-LTA, property damage of <Php 5,000 4 Less than 5 persons exposed 7

8

Job Specific PPE Permit Required Probability Explanation Code Hierarchy of Control 9

Mandatory PPE Othe Work at Heights 5 Almost Certain EL Elimination 10

Hotworks PPE Deviation of Isolation/Deisolation 4 Very likely S Substitution

Confined Space Commissioning (using GWP) 3 Likely EN Engineering Date Date Date

Safety Harness Lifting 2 Unlikely A Administrative Name Name Name

Hand Gloves 1 Very unlikely P PPE Safety PIC/ Teammate / Contractor

SCBA Others : ________________

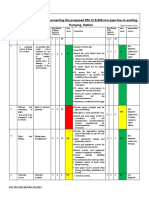

RISK ASSESSMENT FORM / GENERAL WORK PERMIT

Report No.

Location : Pre-Heater/ Cylone 5 Revision No.

Description of work : Replacement of Cylone 5 diptube and flap Date

Name of Contractor: NVH ENGINEERING AND SERVICES

With current control After additional corrective action

HOC Probabilit R A Additional control By RA

No Sequence of job Potential hazards Consequence/s Current controls Severity Severity Probability

Code y Code measures Whom Code

failure of lifting eqipment.

check the swing radius of the

Falling of loads. Workers can cause personal injury/

hoist and ensure that it is

Lifting of new diptube segment being crushesd by moving LTI/ fatality/ property check wind speed. Do not lift load

unobstructed by any facility and A 5 3 3 CON 4 1 2

using hoist equipment. Operator damage to equipment, when wind speed exeeds 25 knots

ensure that the hoist is

incompitence. Visual structure, person

positioned correctly.

impairment

two riggers must be assigned one

guiding at the front other at the

hoist must be third party certified

A 4 3 2 back and equipt proper means of con 4 1 1

with valid inspection certificated

communication such as two way

radio

correct capacity of lifting

accessories must be used for

lifting as per weight and shape of

load. Tag line must be used to

control the load and avoid hitting

any plant facility like pipeline,

cable trays, structure. Do not

position tha crane outriggers

near any drain line other wise

there is a chance of sinking of

these outriggers resulting crane

tipping over. barricade the

affected area, assign watchman

on all entry point to ensure no

activity under the suspension

load.

Risk Assessment (R A Code) Members:

Risk = Severity rate ( 1 - 4 ) Tolerable RAC No. II ( 5 - 12 ) ModerateRAC No. III ( 13 - 25 ) Intolerable Fullname Signature

1

Severity Explanation 2

5 Fatality or paralysed, property damaged more than Php 10,000,000 Exposure Category - Tick one 3

4 Permanent disability (including occupational diseases), property damaged from Php 1,000, 1 Greater than 50 persons exposed 4

3 Temporary disablement, LTA more than 3 days, property damaged from Php 100,001 - Php 2 10 to 49 persons exposed 5

2 Minor injury, LTA with up to 3 lost days, property damaged from Php 5,000 - Php 100,000 3 5 to 9 persons exposed 6

1 First aid injury, non-LTA, property damage of <Php 5,000 4 Less than 5 persons exposed 7

8

Job Specific PPE Permit Required Probability Explanation Code Hierarchy of Control 9

Mandatory PPE Othe Work at Heights 5 Almost Certain EL Elimination 10

Hotworks PPE Deviation of Isolation/Deisolation 4 Very likely S Substitution

Confined Space Commissioning (using GWP) 3 Likely EN Engineering Date Date Date

Safety Harness Lifting 2 Unlikely A Administrative Name Name Name

Hand Gloves 1 Very unlikely P PPE Safety PIC/ Teammate / Contractor

SCBA Others : ________________

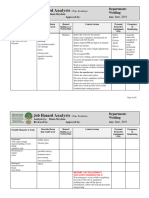

RISK ASSESSMENT FORM / GENERAL WORK PERMIT

Report No.

Location : Pre-Heater/ Cylone 5 Revision No.

Description of work : Replacement of Cylone 5 diptube and flap Date

Name of Contractor: NVH ENGINEERING AND SERVICES

With current control After additional corrective action

HOC Probabilit R A Additional control By RA

No Sequence of job Potential hazards Consequence/s Current controls Severity Severity Probability

Code y Code measures Whom Code

Proper coordination with CCR & Pressence of the issuer and the

Lototo Isolation Electrical equipment Electrocution Electrical department for the proper EL 5 3 III contractor pic & safety officer on Con. 5 1 II

Equipment isolation point site is a must

Caught between, Struck Only authorize and certified Ensure that all personnel are

Rotating Parts & Moving

by/on Equipment being personnel must be performed activity trained and knowledgable about

Equipment

isolated. Fatality regarding on electrical matters LOTOTO procedures

EL 5 3 III Con. 5 1 II

Application of LOTOTO procedure Conduct try out prior to start the

and strictly checked and provide job task to ensure that the

necessary permits needed. equipment are isolated

Ensure that all personnel involved

are attach their own podlocks on the

Eliminate all kinds of jewelries

red box and double check by the

inside the plant premises

safety officers on duty prior to start

the job task.

Provide proper means of

communication such as two way

radio and wistle for assign watch man

Conduct Safety briefing on all

personnel regarding on LOTOTO

procedure anad its importance.

Ensure that all personnel are properly

understand the sequence and safety

protocols regarding on working with

the equipment in the plant premises.

Risk Assessment (R A Code) Members:

Risk = Severity rate ( 1 - 5 ) Tolerable RAC No. II ( 6 - 12 ) Moderate RAC No. III ( 13 - 25 ) Intolerable Fullname Signature

1

Severity Explanation 2

5 Fatality or paralysed, property damaged more than Php 10,000,000 Exposure Category - Tick one 3

4 Permanent disability (including occupational diseases), property damaged from Php 1,000,001 1 Greater than 50 persons exposed 4

3 Temporary disablement, LTA more than 3 days, property damaged from Php 100,001 - Php 1, 2 10 to 49 persons exposed 5

2 Minor injury, LTA with up to 3 lost days, property damaged from Php 5,000 - Php 100,000 3 5 to 9 persons exposed 6

1 First aid injury, non-LTA, property damage of <Php 5,000 4 Less than 5 persons exposed 7

8

Job Specific PPE Permit Required Probability Explanation Code Hierarchy of Control 9

Mandatory PPE Othe Work at Heights 5 Almost Certain EL Elimination 10

Hotworks PPE Deviation of Isolation/Deisolation 4 Very likely S Substitution

Confined Space Commissioning (using GWP) 3 Likely EN Engineering Date Date Date

Safety Harness Lifting 2 Unlikely A Administrative Name Name Name

Hand Gloves 1 Very unlikely P PPE Safety PIC/ Teammate / Contractor

SCBA Others : ________________

RISK ASSESSMENT FORM / GENERAL WORK PERMIT

Report No.

Location : Pre-Heater/ Cylone 5 Revision No.

Description of work : Replacement of Cylone 5 diptube and flap Date

Name of Contractor: NVH ENGINEERING AND SERVICES

With current control After additional corrective action

HOC Probabilit R A Additional control By RA

No Sequence of job Potential hazards Consequence/s Current controls Severity Severity Probability

Code y Code measures Whom Code

Ensure that all tools and

Minor to serious injury & Application of proper positioning of equipment are inspected and

opening of manhole Manual handling EL 3 2 II Con 3 1 I

body injury body for manual handling activities update stickers by RCBMI

attached

Avoid over exertion of the body

Ergonomics related injury movement and proper wearing of S 2 2 I

necessary PPE's

Wear apropriate hand gloves with

rubber/ Rubber dotted to prevent

Sharp tools/ edges Cuts and laceration EL 2 2 I

hand cuts/ Laceration or used leather

gloves if applicable

Eliminate all fabricated tools and do

not allow then to create another

fabricated tools exept if it is aproved

and aknowledge by the plant safety

Department & also documented. Provide sunctioning on those

Fabricated & Defective tools Can cause a minor to Cascade awareness and safety personel that reapetedly violate on

EL 3 2 II Con 3 1 I

and equipment serious injury to a person Reminders Regarding on fabricated using fabricated tools & Defective

toos and usage of Defective tools

Equipment on site. Strictly implement

and continues monitoring of non-

usage of fabricated and defective

tools on site.

Ensure proper illumination &

Conduct housekeeping before and

Slip & trip Fractured and Sprain EL 3 2 II cable/ hyose management on site Con 3 1 I

after proir to start

are in place

Risk Assessment (R A Code) Members:

Risk = Severity rate ( 1 - 5 ) Tolerable RAC No. II ( 6 - 12 ) Moderate RAC No. III ( 13 - 25 ) Intolerable Fullname Signature

1

Severity Explanation 2

5 Fatality or paralysed, property damaged more than Php 10,000,000 Exposure Category - Tick one 3

4 Permanent disability (including occupational diseases), property damaged from Php 1,000,001 1 Greater than 50 persons exposed 4

3 Temporary disablement, LTA more than 3 days, property damaged from Php 100,001 - Php 1, 2 10 to 49 persons exposed 5

2 Minor injury, LTA with up to 3 lost days, property damaged from Php 5,000 - Php 100,000 3 5 to 9 persons exposed 6

1 First aid injury, non-LTA, property damage of <Php 5,000 4 Less than 5 persons exposed 7

8

Job Specific PPE Permit Required Probability Explanation Code Hierarchy of Control 9

Mandatory PPE Othe Work at Heights 5 Almost Certain EL Elimination 10

Hotworks PPE Deviation of Isolation/Deisolation 4 Very likely S Substitution

Confined Space Commissioning (using GWP) 3 Likely EN Engineering Date Date Date

Safety Harness Lifting 2 Unlikely A Administrative Name Name Name

Hand Gloves 1 Very unlikely P PPE Safety PIC/ Teammate / Contractor

SCBA Others : ________________

RISK ASSESSMENT FORM / GENERAL WORK PERMIT

Report No.

Pre-Heater/ Cylone 5 Revision No.

Replacement of Cylone 5 diptube and flap Date

Name of Contractor: NVH ENGINEERING AND SERVICES

With current control After additional corrective action

HOC Probabilit R A Additional control By RA

No Sequence of job Potential hazards Consequence/s Current controls Severity Severity Probability

Code y Code measures Whom Code

advise to used fall restarint

Proper Wearing of full body

system instead of fall arrest

harness with double lanyard.

system if applicable on the activity

Fractured, sprain, LTI/ Advise to used fall restarint

Working at heights Fall from heights A 4 3 II being performed. Properly asses Con 4 1 2

Fatality system instead of fall arrest

the height of the flatform/scaffold

system if applicable on the

being access to compute the fall

activity being performed

distance.

Barricade the affected area with

provided of warning signs or

Safety sinages.Provide blinds the affected areas wth

Falling object/ parralel activity Avulsion/ head injury A 4 2 2 Con 4 1 1

watchman with equip. of wistle scaffold materials/ Net

for warning device/proper means

of communications.

Provide watchman with equip. of

wistle for warning device/proper

means of communications.

Risk Assessment (R A Code) Members:

Risk = Severity rate ( 1 - 5) Tolerable RAC No. II ( 6 - 12 ) ModerateRAC No. III ( 13 - 25 ) Intolerable Fullname Signature

1

Severity Explanation 2

5 Fatality or paralysed, property damaged more than Php 10,000,000 Exposure Category - Tick one 3

4 Permanent disability (including occupational diseases), property damaged from Php 1,000, 1 Greater than 50 persons exposed 4

3 Temporary disablement, LTA more than 3 days, property damaged from Php 100,001 - Php 2 10 to 49 persons exposed 5

2 Minor injury, LTA with up to 3 lost days, property damaged from Php 5,000 - Php 100,000 3 5 to 9 persons exposed 6

1 First aid injury, non-LTA, property damage of <Php 5,000 4 Less than 5 persons exposed 7

8

Job Specific PPE Permit Required Probability Explanation Code Hierarchy of Control 9

Mandatory PPE Othe Work at Heights 5 Almost Certain EL Elimination 10

Hotworks PPE Deviation of Isolation/Deisolation 4 Very likely S Substitution

Confined Space Commissioning (using GWP) 3 Likely EN Engineering Date Date Date

Safety Harness Lifting 2 Unlikely A Administrative Name Name Name

Hand Gloves 1 Very unlikely P PPE Safety PIC/ Teammate / Contractor

SCBA Others : ________________

RISK ASSESSMENT FORM / GENERAL WORK PERMIT

Report No.

Location : Pre-Heater/ Cylone 5 Revision No.

Description of work : Replacement of Cylone 5 diptube and flap Date

Name of Contractor: NVH ENGINEERING AND SERVICES

With current control After additional corrective action

HOC Probabilit R A Additional control By RA

No Sequence of job Potential hazards Consequence/s Current controls Severity Severity Probability

Code y Code measures Whom Code

prepared necessarily permit needed

prior to entry on confined space area

oxygen difficiency, toxic collapse, dizziness, area and compete isolation of the

working on confined space gasses, oxygen enrichment, suffocation, LTI/Fatality, confined space to be entered. A 4 3 II con 4 1 2

poor lightning slip/trip Conduct gas test on confined space

to ensure no hazardous gasses is

precent

used of GFCI on all confined spce

activity and do not allow them to

enter all the high voltage equipment

only competent person must do

on the confined space. Ensure that

electricity electric shock/ electrocution EN 5 3 3 the job task regarding on electrical con 5 1 2

the cables, extensions hoses are

matters/ activity

properly manage on site by usage of

cable post and S-hook with proper

insulation and properly.

Risk Assessment (R A Code) Members:

Risk = Severity rate ( 1 - 4 ) Tolerable RAC No. II ( 5 - 12 ) Moderate RAC No. III ( 13 - 25 ) Intolerable Fullname Signature

1

Severity Explanation 2

5 Fatality or paralysed, property damaged more than Php 10,000,000 Exposure Category - Tick one 3

4 Permanent disability (including occupational diseases), property damaged from Php 1,000,001 1 Greater than 50 persons exposed 4

3 Temporary disablement, LTA more than 3 days, property damaged from Php 100,001 - Php 1,0 2 10 to 49 persons exposed 5

2 Minor injury, LTA with up to 3 lost days, property damaged from Php 5,000 - Php 100,000 3 5 to 9 persons exposed 6

1 First aid injury, non-LTA, property damage of <Php 5,000 4 Less than 5 persons exposed 7

8

Job Specific PPE Permit Required Probability Explanation Code Hierarchy of Control 9

Mandatory PPE Othe Work at Heights 5 Almost Certain EL Elimination 10

Hotworks PPE Deviation of Isolation/Deisolation 4 Very likely S Substitution

Confined Space Commissioning (using GWP) 3 Likely EN Engineering Date Date Date

Safety Harness Lifting 2 Unlikely A Administrative Name Name Name

Hand Gloves 1 Very unlikely P PPE Safety PIC/ Teammate / Contractor

SCBA Others : ________________

RISK ASSESSMENT FORM / GENERAL WORK PERMIT

Report No.

Location : Pre-Heater/ Cylone 5 Revision No.

Description of work : Replacement of Cylone 5 diptube and flap Date

Name of Contractor: NVH ENGINEERING AND SERVICES

With current control After additional corrective action

HOC Probabilit R A Additional control By RA

No Sequence of job Potential hazards Consequence/s Current controls Severity Severity Probability

Code y Code measures Whom Code

Ensure that all tools and

cleaning of debris and Minor to serious injury & Application of proper positioning of equipment are inspected and

Manual handling EL 3 2 II Con 3 1 I

materials build-up body injury body for manual handling activities update stickers by RCBMI

attached

Avoid over exertion of the body

lossening of bolt Ergonomics related injury movement and proper wearing of S 2 2 I

necessary PPE's

Wear apropriate hand gloves with

removal of old dip tube holder rubber/ Rubber dotted to prevent

Sharp tools/ edges Cuts and laceration EL 2 2 I

and segment hand cuts/ Laceration or used leather

gloves if applicable

Eliminate all fabricated tools and do

not allow then to create another

fabricated tools exept if it is aproved

and aknowledge by the plant safety

Department & also documented. Provide sunctioning on those

Fabricated & Defective tools Can cause a minor to Cascade awareness and safety personel that reapetedly violate on

EL 3 2 II Con 3 1 I

and equipment serious injury to a person Reminders Regarding on fabricated using fabricated tools & Defective

toos and usage of Defective tools

Equipment on site. Strictly implement

and continues monitoring of non-

usage of fabricated and defective

tools on site.

Ensure proper illumination &

Conduct housekeeping before and

Slip & trip Fractured and Sprain EL 3 2 II cable/ hyose management on site Con 3 1 I

after proir to start

are in place

Risk Assessment (R A Code) Members:

Risk = Severity rate ( 1 - 5 ) Tolerable RAC No. II ( 6 - 12 ) Moderate RAC No. III ( 13 - 25 ) Intolerable Fullname Signature

1

Severity Explanation 2

5 Fatality or paralysed, property damaged more than Php 10,000,000 Exposure Category - Tick one 3

4 Permanent disability (including occupational diseases), property damaged from Php 1,000,001 1 Greater than 50 persons exposed 4

3 Temporary disablement, LTA more than 3 days, property damaged from Php 100,001 - Php 1, 2 10 to 49 persons exposed 5

2 Minor injury, LTA with up to 3 lost days, property damaged from Php 5,000 - Php 100,000 3 5 to 9 persons exposed 6

1 First aid injury, non-LTA, property damage of <Php 5,000 4 Less than 5 persons exposed 7

8

Job Specific PPE Permit Required Probability Explanation Code Hierarchy of Control 9

Mandatory PPE Othe Work at Heights 5 Almost Certain EL Elimination 10

Hotworks PPE Deviation of Isolation/Deisolation 4 Very likely S Substitution

Confined Space Commissioning (using GWP) 3 Likely EN Engineering Date Date Date

Safety Harness Lifting 2 Unlikely A Administrative Name Name Name

Hand Gloves 1 Very unlikely P PPE Safety PIC/ Teammate / Contractor

SCBA Others : ________________

RISK ASSESSMENT FORM / GENERAL WORK PERMIT

Report No.

Location : Pre-Heater/ Cylone 5 Revision No.

Description of work : Replacement of Cylone 5 diptube and flap Date

Name of Contractor: NVH ENGINEERING AND SERVICES

With current control After additional corrective action

HOC Probabilit R A Additional control By RA

No Sequence of job Potential hazards Consequence/s Current controls Severity Severity Probability

Code y Code measures Whom Code

cutting of stock up dip tube Fire, Burn, exploision

Open flame, Fluxes

holder using oxyace Property damage

fire watchers must be trained and

knowlegable on the duties and

responsibilities or a fire watch.

Proper means

of communication must be

A 4 3 II Con 4 1 I

provided. Blinds

the affected area espeacially on

those parralel job activity by the

use of fire balnkets & steel planks,

yero.

Proper wearing of eye googles & face

Spark Eye irritation/ injury P 2 2 I

shield

Proper wearing of standard dust Used of Respirators if applicable/

Toxic Gas & Fumes dust Respiratory illness P 3 2 II Con 3 1 I

mask Such as: KN-95 & N-95 needed

Risk Assessment (R A Code) Members:

Risk = Severity rate ( 1 - 5 ) Tolerable RAC No. II ( 6 - 12 ) Moderate RAC No. III ( 13 - 25 ) Intolerable Fullname Signature

1

Severity Explanation 2

5 Fatality or paralysed, property damaged more than Php 10,000,000 Exposure Category - Tick one 3

4 Permanent disability (including occupational diseases), property damaged from Php 1,000,001 1 Greater than 50 persons exposed 4

3 Temporary disablement, LTA more than 3 days, property damaged from Php 100,001 - Php 1, 2 10 to 49 persons exposed 5

2 Minor injury, LTA with up to 3 lost days, property damaged from Php 5,000 - Php 100,000 3 5 to 9 persons exposed 6

1 First aid injury, non-LTA, property damage of <Php 5,000 4 Less than 5 persons exposed 7

8

Job Specific PPE Permit Required Probability Explanation Code Hierarchy of Control 9

Mandatory PPE Othe Work at Heights 5 Almost Certain EL Elimination 10

Hotworks PPE Deviation of Isolation/Deisolation 4 Very likely S Substitution

Confined Space Commissioning (using GWP) 3 Likely EN Engineering Date Date Date

Safety Harness Lifting 2 Unlikely A Administrative Name Name Name

Hand Gloves 1 Very unlikely P PPE Safety PIC/ Teammate / Contractor

SCBA Others : ________________

RISK ASSESSMENT FORM / GENERAL WORK PERMIT

Report No.

Location : Pre-Heater/ Cylone 5 Revision No.

Description of work : Replacement of Cylone 5 diptube and flap Date

Name of Contractor: NVH ENGINEERING AND SERVICES

With current control After additional corrective action

HOC Probabilit R A Additional control By RA

No Sequence of job Potential hazards Consequence/s Current controls Severity Severity Probability

Code y Code measures Whom Code

Ensure that all tools and

removal of old dip tube holder Minor to serious injury & Application of proper positioning of equipment are inspected and

Manual handling EL 3 2 II Con 3 1 I

and segment body injury body for manual handling activities update stickers by RCBMI

attached

Avoid over exertion of the body

Ergonomics related injury movement and proper wearing of S 2 2 I

necessary PPE's

Wear apropriate hand gloves with

rubber/ Rubber dotted to prevent

Sharp tools/ edges Cuts and laceration EL 2 2 I

hand cuts/ Laceration or used leather

gloves if applicable

Eliminate all fabricated tools and do

not allow then to create another

fabricated tools exept if it is aproved

and aknowledge by the plant safety

Department & also documented. Provide sunctioning on those

Fabricated & Defective tools Can cause a minor to Cascade awareness and safety personel that reapetedly violate on

EL 3 2 II Con 3 1 I

and equipment serious injury to a person Reminders Regarding on fabricated using fabricated tools & Defective

toos and usage of Defective tools

Equipment on site. Strictly implement

and continues monitoring of non-

usage of fabricated and defective

tools on site.

Ensure proper illumination &

Conduct housekeeping before and

Slip & trip Fractured and Sprain EL 3 2 II cable/ hyose management on site Con 3 1 I

after proir to start

are in place

Risk Assessment (R A Code) Members:

Risk = Severity rate ( 1 - 5 ) Tolerable RAC No. II ( 6 - 12 ) Moderate RAC No. III ( 13 - 25 ) Intolerable Fullname Signature

1

Severity Explanation 2

5 Fatality or paralysed, property damaged more than Php 10,000,000 Exposure Category - Tick one 3

4 Permanent disability (including occupational diseases), property damaged from Php 1,000,001 1 Greater than 50 persons exposed 4

3 Temporary disablement, LTA more than 3 days, property damaged from Php 100,001 - Php 1, 2 10 to 49 persons exposed 5

2 Minor injury, LTA with up to 3 lost days, property damaged from Php 5,000 - Php 100,000 3 5 to 9 persons exposed 6

1 First aid injury, non-LTA, property damage of <Php 5,000 4 Less than 5 persons exposed 7

8

Job Specific PPE Permit Required Probability Explanation Code Hierarchy of Control 9

Mandatory PPE Othe Work at Heights 5 Almost Certain EL Elimination 10

Hotworks PPE Deviation of Isolation/Deisolation 4 Very likely S Substitution

Confined Space Commissioning (using GWP) 3 Likely EN Engineering Date Date Date

Safety Harness Lifting 2 Unlikely A Administrative Name Name Name

Hand Gloves 1 Very unlikely P PPE Safety PIC/ Teammate / Contractor

SCBA Others : ________________

RISK ASSESSMENT FORM / GENERAL WORK PERMIT

Report No.

Location : Pre-Heater/ Cylone 5 Revision No.

Description of work : Replacement of Cylone 5 diptube and flap Date

Name of Contractor: NVH ENGINEERING AND SERVICES

With current control After additional corrective action

HOC Probabilit R A Additional control By RA

No Sequence of job Potential hazards Consequence/s Current controls Severity Severity Probability

Code y Code measures Whom Code

Ensure that all tools and

installation of dip tube Minor to serious injury & Application of proper positioning of equipment are inspected and

Manual handling EL 3 2 II Con 3 1 I

segments body injury body for manual handling activities update stickers by RCBMI

attached

Avoid over exertion of the body

Ergonomics related injury movement and proper wearing of S 2 2 I

necessary PPE's

Wear apropriate hand gloves with

rubber/ Rubber dotted to prevent

Sharp tools/ edges Cuts and laceration EL 2 2 I

hand cuts/ Laceration or used leather

gloves if applicable

Eliminate all fabricated tools and do

not allow then to create another

fabricated tools exept if it is aproved

and aknowledge by the plant safety

Department & also documented. Provide sunctioning on those

Fabricated & Defective tools Can cause a minor to Cascade awareness and safety personel that reapetedly violate on

EL 3 2 II Con 3 1 I

and equipment serious injury to a person Reminders Regarding on fabricated using fabricated tools & Defective

toos and usage of Defective tools

Equipment on site. Strictly implement

and continues monitoring of non-

usage of fabricated and defective

tools on site.

Ensure proper illumination &

Conduct housekeeping before and

Slip & trip Fractured and Sprain EL 3 2 II cable/ hyose management on site Con 3 1 I

after proir to start

are in place

Risk Assessment (R A Code) Members:

Risk = Severity rate ( 1 - 5 ) Tolerable RAC No. II ( 6 - 12 ) Moderate RAC No. III ( 13 - 25 ) Intolerable Fullname Signature

1

Severity Explanation 2

5 Fatality or paralysed, property damaged more than Php 10,000,000 Exposure Category - Tick one 3

4 Permanent disability (including occupational diseases), property damaged from Php 1,000,001 1 Greater than 50 persons exposed 4

3 Temporary disablement, LTA more than 3 days, property damaged from Php 100,001 - Php 1, 2 10 to 49 persons exposed 5

2 Minor injury, LTA with up to 3 lost days, property damaged from Php 5,000 - Php 100,000 3 5 to 9 persons exposed 6

1 First aid injury, non-LTA, property damage of <Php 5,000 4 Less than 5 persons exposed 7

8

Job Specific PPE Permit Required Probability Explanation Code Hierarchy of Control 9

Mandatory PPE Othe Work at Heights 5 Almost Certain EL Elimination 10

Hotworks PPE Deviation of Isolation/Deisolation 4 Very likely S Substitution

Confined Space Commissioning (using GWP) 3 Likely EN Engineering Date Date Date

Safety Harness Lifting 2 Unlikely A Administrative Name Name Name

Hand Gloves 1 Very unlikely P PPE Safety PIC/ Teammate / Contractor

SCBA Others : ________________

RISK ASSESSMENT FORM / GENERAL WORK PERMIT

Report No.

Location : Pre-Heater/ Cylone 5 Revision No.

Description of work : Replacement of Cylone 5 diptube and flap Date

Name of Contractor: NVH ENGINEERING AND SERVICES

With current control After additional corrective action

HOC Probabilit R A Additional control By RA

No Sequence of job Potential hazards Consequence/s Current controls Severity Severity Probability

Code y Code measures Whom Code

Electricity and defective

Welding works for repair power tools & cables, Electrocution/ Electric shock Ensure that all power tool and

Extensions Strictly checking of all power tools

cables/ extension being used on

and cables, extension proir to used

site are with approved and update

on site. Returened and put a tag of all EL 5 3 II Con. 5 1 II

inspection stickers by the RCBMI

defective tools subject for repair by a

plant. Only competent person

competent person/ Electricians

must do the job task.

Comsumable/ Flamable materials to

be secured/ Removed from the hot

works activity. Vallid fire Extnguisher Proper means of communacation

Property damage EL 3 2 II Con. 3 1 I

and fire watcher should be provided must be provided

and contenues monitoring of hot

works activity

Blinds the affected area especially on Fire watchers must be trained and

Welding/ Fluxes Fire, Burn those parralel job activity by the use EL 4 3 II knowlegable on the duties and Con. 4 1 I

of fire blanket & steel planks, yero responsibilities or a fire watc

Proper wearing of eye protection &

Spark Eye irritation/ injury P 2 2 I

face shield

Proper wearing of standard dust Use of Resperatory if aplicable/

Fumes & Dust Respiratory illnes P 3 2 II Con. 3 1 I

musk such as KN-95& N95 needed

Risk Assessment (R A Code) Members:

Risk = Severity rate ( 1 - 4 ) Tolerable RAC No. II ( 5 - 12 ) Moderate RAC No. III ( 13 - 25 ) Intolerable Fullname Signature

1

Severity Explanation 2

5 Fatality or paralysed, property damaged more than Php 10,000,000 Exposure Category - Tick one 3

4 Permanent disability (including occupational diseases), property damaged from Php 1,000,001 1 Greater than 50 persons exposed 4

3 Temporary disablement, LTA more than 3 days, property damaged from Php 100,001 - Php 1, 2 10 to 49 persons exposed 5

2 Minor injury, LTA with up to 3 lost days, property damaged from Php 5,000 - Php 100,000 3 5 to 9 persons exposed 6

1 First aid injury, non-LTA, property damage of <Php 5,000 4 Less than 5 persons exposed 7

8

Job Specific PPE Permit Required Probability Explanation Code Hierarchy of Control 9

Mandatory PPE Othe Work at Heights 5 Almost Certain EL Elimination 10

Hotworks PPE Deviation of Isolation/Deisolation 4 Very likely S Substitution

Confined Space Commissioning (using GWP) 3 Likely EN Engineering Date Date Date

Safety Harness Lifting 2 Unlikely A Administrative Name Name Name

Hand Gloves 1 Very unlikely P PPE Safety PIC/ Teammate / Contractor

SCBA Others : ________________

RISK ASSESSMENT FORM / GENERAL WORK PERMIT

Report No.

Pre-Heater/ Cylone 5 Revision No.

Replacement of Cylone 5 diptube and flap Date

Name of Contractor: NVH ENGINEERING AND SERVICES

With current control After additional corrective action

Application of propper HOC Probabilit R A Additional control By RA

No Sequence of job Potential hazards Consequence/s Current controls Severity Severity Probability

positioning of body for Code y Code measures Whom Code

manual handling activities.

Manual Handling & Can Cause a minor to

Buddy 2x system/ used of

House keeping Ergonomic Related serious injury to a EL 3 2 II Con. 3 1 I

mechanical techniques.

Harzard workers/personnel

Properly coordinated with

the area owner & safety

Avoid department on removal of

over Exertion of body machine guardings

movement and proper

wearing of Necessary PPEs

needed.

Proper wearing of standard

Used of respirators if

Dust Respiratory illness dust mask such as:KN95/n- EL 3 2 II Con. 3 1 I

needed

95

Strictly Compliance at proper

wearing of skull guard with

Low headed areas Avulsion chainstrap for head EL 3 2 II

protection on all identified low

headed areas.

Slip/Trip Fractured and Sprain EL 2 2 II Ensure that all cables and Con. 2 1 I

Provide proper illumination on hoses are not serve as

site. Provide safety signages stripping hazard. Eliminate

on all low headed areas and all obstruction on site and

familiarization of area proper storage of tools and

materials.

proper wearing of Hand

Grease Skin allergy/irritation gloves and appropiate and P 2 2 II

PPEs

Risk Assessment (R A Code) Members:

Risk = Severity rate ( 1 - 5 ) Tolerable RAC No. II ( 6 - 12 ) Moderate RAC No. III ( 13 - 25 ) Intolerable Fullname Signature

1

Severity Explanation 2

5 Fatality or paralysed, property damaged more than Php 10,000,000 Exposure Category - Tick one 3

4 Permanent disability (including occupational diseases), property damaged from Php 1,000,001 1 Greater than 50 persons exposed 4

3 Temporary disablement, LTA more than 3 days, property damaged from Php 100,001 - Php 1, 2 10 to 49 persons exposed 5

2 Minor injury, LTA with up to 3 lost days, property damaged from Php 5,000 - Php 100,000 3 5 to 9 persons exposed 6

1 First aid injury, non-LTA, property damage of <Php 5,000 4 Less than 5 persons exposed 7

8

Job Specific PPE Permit Required Probability Explanation Code Hierarchy of Control 9

Mandatory PPE Othe Work at Heights 5 Almost Certain EL Elimination 10

Hotworks PPE Deviation of Isolation/Deisolation 4 Very likely S Substitution

Confined Space Commissioning (using GWP) 3 Likely EN Engineering Date Date Date

Safety Harness Lifting 2 Unlikely A Administrative Name Name Name

Hand Gloves 1 Very unlikely P PPE Safety PIC/ Teammate / Contractor

SCBA Others : ________________

You might also like

- RA For Hvac Duct InstallationDocument10 pagesRA For Hvac Duct InstallationAnandu Ashokan88% (8)

- Risk Assessment MicrotunnelingDocument7 pagesRisk Assessment Microtunnelingmohamed ghalyNo ratings yet

- Risk Assessment HVAC DuctingDocument5 pagesRisk Assessment HVAC DuctingAsad Zakria100% (6)

- Labor Relations and NegotiationsDocument12 pagesLabor Relations and NegotiationsElia Na100% (3)

- JSA OF Fabrication and Installation Work ApproviedDocument3 pagesJSA OF Fabrication and Installation Work Approviedsakthi venkatNo ratings yet

- JHA ConcretingDocument3 pagesJHA Concretingfatimah beluhi75% (4)

- HSE Certificate in Process Safety Management Leaflet - A5 - AW2 - Web222017221413Document2 pagesHSE Certificate in Process Safety Management Leaflet - A5 - AW2 - Web222017221413midozoty100% (1)

- HVAC Risk AssessmentDocument6 pagesHVAC Risk AssessmentpragyaadanaNo ratings yet

- Risk Assessment For Braket Scaffolding: Construction of Lubricating Oil Blending Plant (LOBP)Document3 pagesRisk Assessment For Braket Scaffolding: Construction of Lubricating Oil Blending Plant (LOBP)AmeerHamzaWarraichNo ratings yet

- Cable Dray ATRDocument3 pagesCable Dray ATRferielvpkNo ratings yet

- IM-08-B HSE Wall Grinding For Finishing WorkDocument2 pagesIM-08-B HSE Wall Grinding For Finishing WorkAnsari HarisNo ratings yet

- Ra For Hot Work (Welding & Cutting Works)Document3 pagesRa For Hot Work (Welding & Cutting Works)Abrar AhmedNo ratings yet

- HSE-F-NEOM-014 - General Risk AssessmentDocument32 pagesHSE-F-NEOM-014 - General Risk AssessmentAhmed Mohamed100% (1)

- Installation of Chilled Water PipesDocument6 pagesInstallation of Chilled Water PipesAnandu Ashokan0% (1)

- JSA Format NEW Equipment ErectionDocument5 pagesJSA Format NEW Equipment Erectionsakthi venkatNo ratings yet

- HIRA Cage Ladder & Life Line Installation01Document3 pagesHIRA Cage Ladder & Life Line Installation01R. Ayyanuperumal Ayyanuperumal100% (1)

- HIRA 013 Working Over Water.Document2 pagesHIRA 013 Working Over Water.srinibas mohapatra100% (1)

- Equipment Repairs RA 2012Document2 pagesEquipment Repairs RA 2012Shannon MooreNo ratings yet

- Jsa For Pipe Fabrication ErrectionDocument8 pagesJsa For Pipe Fabrication Errectiondeepakkumaryadav841441No ratings yet

- DrillingDocument22 pagesDrillingMandhatt KyleNo ratings yet

- Risk Assessment - Elie SabDocument8 pagesRisk Assessment - Elie SabMuhammad FaizalNo ratings yet

- 14 - Method Statements For Erection of Steel PDFDocument1 page14 - Method Statements For Erection of Steel PDFAbdul RahmanNo ratings yet

- Risk Assessment. Unit III P Station.Document8 pagesRisk Assessment. Unit III P Station.Saad MuzaffarNo ratings yet

- Wiac - Info PDF Jsa For Using Jack Hammer PRDocument3 pagesWiac - Info PDF Jsa For Using Jack Hammer PRmaiman.mzakiNo ratings yet

- JSA - Non-Destructive Testing (NDT) - Liquid Penetrant TestDocument5 pagesJSA - Non-Destructive Testing (NDT) - Liquid Penetrant TestRajuNo ratings yet

- Hse Risk Assessment For Civil Works, Isolators and Duct InstallationDocument6 pagesHse Risk Assessment For Civil Works, Isolators and Duct Installationvenkatesh snkNo ratings yet

- Cutting & Welding Job JSADocument1 pageCutting & Welding Job JSADeepak PatelNo ratings yet

- Risk assessmentRA08Document2 pagesRisk assessmentRA08Munaku TafadzwaNo ratings yet

- Jsa For Pipe Fabrication ErrectionDocument8 pagesJsa For Pipe Fabrication Errectionjithin shankarNo ratings yet

- Sheikh Jaber Causeway Subcontract No.: KUSC-SC-S-0600: Activity/Task: Installation of Cable TrayDocument7 pagesSheikh Jaber Causeway Subcontract No.: KUSC-SC-S-0600: Activity/Task: Installation of Cable Traywaseem kausarNo ratings yet

- Waterproofing Risk AssessmentDocument8 pagesWaterproofing Risk AssessmentEnahs ZedlaumorNo ratings yet

- ELEC/RA-001 Risk Assessment CCPP, MBPL: Pipe Rack and Bottom Ash AreaDocument12 pagesELEC/RA-001 Risk Assessment CCPP, MBPL: Pipe Rack and Bottom Ash AreaYuva samaj sewa TrustNo ratings yet

- TRA - For Air Condition Prefab BuildingDocument8 pagesTRA - For Air Condition Prefab Buildingabdulhanan86457No ratings yet

- Risk Assesment For Connecting The Existing Pipe To Pump StationDocument4 pagesRisk Assesment For Connecting The Existing Pipe To Pump StationSasi Kumar100% (2)

- General Maintenance Risk Assessment 2011Document9 pagesGeneral Maintenance Risk Assessment 2011Shannon MooreNo ratings yet

- Job Safety Analysis For Hydro Test: Indmax Prime-G, Ighds Unit, Iocl, BGRDocument5 pagesJob Safety Analysis For Hydro Test: Indmax Prime-G, Ighds Unit, Iocl, BGRAkash ShuklaNo ratings yet

- Risk Assesment For KerbstonesDocument11 pagesRisk Assesment For KerbstonesZain butt67% (3)

- JSA For Hand Tool Painting BM 1 TADocument2 pagesJSA For Hand Tool Painting BM 1 TATaufiq AhamedNo ratings yet

- 4066-To Perform Hot Work Activities (Welding, Oxy Cutting, Grinding, Cutting, Heat Gun andDocument3 pages4066-To Perform Hot Work Activities (Welding, Oxy Cutting, Grinding, Cutting, Heat Gun andEric TingNo ratings yet

- Ra - MC 9 Kiln RepairDocument4 pagesRa - MC 9 Kiln RepairalbinkhanNo ratings yet

- Risk Assessment SheetDocument4 pagesRisk Assessment Sheetfuturecolor7No ratings yet

- Job Safety Analysis (JSA) : Electronics (Cleaning + Servicing)Document2 pagesJob Safety Analysis (JSA) : Electronics (Cleaning + Servicing)Nishad MuhammedNo ratings yet

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisDocument4 pagesProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisJohn100% (1)

- JHA Welding Pipe BenderDocument2 pagesJHA Welding Pipe Bendermohammad arshadNo ratings yet

- Risk Assessment - GROUNDINGDocument5 pagesRisk Assessment - GROUNDINGkarla.adamesNo ratings yet

- HIRA - Pier ConstructionDocument8 pagesHIRA - Pier ConstructionMMRDACA07 SAFETYNo ratings yet

- Cathodic 2 ProtectionDocument2 pagesCathodic 2 ProtectionferielvpkNo ratings yet

- Pdfslide - Us Jsa For Using Jack HammerDocument3 pagesPdfslide - Us Jsa For Using Jack HammerWidya BungaNo ratings yet

- JSA Trunks InstallationDocument9 pagesJSA Trunks InstallationWeru MorrisNo ratings yet

- Risk Assessment/Management FormDocument4 pagesRisk Assessment/Management FormNazriNo ratings yet

- JSA CABLE TaggingDocument5 pagesJSA CABLE TaggingthennarasuNo ratings yet

- HSE Risk Assessment For Reinstatement Work: ContractDocument2 pagesHSE Risk Assessment For Reinstatement Work: ContractSasi KumarNo ratings yet

- RA-Installation of GRP Pipe CulvertsDocument6 pagesRA-Installation of GRP Pipe CulvertsArsh NazarNo ratings yet

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- JHA - Gas Cutting For ReferenceDocument2 pagesJHA - Gas Cutting For ReferenceNarayanKavitakeNo ratings yet

- Risk Assessment - Installation of Back Painted GlassDocument7 pagesRisk Assessment - Installation of Back Painted GlassMuhammad NadeemNo ratings yet

- Reinforcement Cutting Bending JSA HSE ProfessionalsDocument1 pageReinforcement Cutting Bending JSA HSE ProfessionalsNoval FebriNo ratings yet

- HIRA 038 Cleaning of Cranes .Document4 pagesHIRA 038 Cleaning of Cranes .srinibas mohapatraNo ratings yet

- F.03-09 Job Safety Analysis - EMV MaintenanceDocument3 pagesF.03-09 Job Safety Analysis - EMV Maintenanceaqeel ahmedNo ratings yet

- HIRA WORK SHEET Blasting and Painting.Document10 pagesHIRA WORK SHEET Blasting and Painting.Madhu Electricals & Engineering100% (3)

- Jha Lighting ArrestorDocument3 pagesJha Lighting ArrestorRavi thokalNo ratings yet

- Soi FormDocument3 pagesSoi FormFunboy100% (1)

- Accident Investigation Report Form 1 PDFDocument2 pagesAccident Investigation Report Form 1 PDFMinhDũngNo ratings yet

- AHP15 Confined SpacesDocument9 pagesAHP15 Confined SpacesBayu Adi PratamaNo ratings yet

- EHS321 Health Safety and Environment FinalDocument104 pagesEHS321 Health Safety and Environment FinalFiona AtimNo ratings yet

- Safety Data Sheet OCG™1000MDocument8 pagesSafety Data Sheet OCG™1000MNur Cholis HadiNo ratings yet

- Safety Data Sheet Polymer Additive: Classification of The ChemicalDocument7 pagesSafety Data Sheet Polymer Additive: Classification of The ChemicalRinaldi SatriaNo ratings yet

- Risk Assessment For The Installation of Mobile CrusherDocument6 pagesRisk Assessment For The Installation of Mobile CrusherArsh NazarNo ratings yet

- SOP BTI HR 03 Absensi Karyawan Rev.03Document10 pagesSOP BTI HR 03 Absensi Karyawan Rev.03Asga LaksaNo ratings yet

- Dismantling WorksDocument1 pageDismantling WorksKoneti JanardhanaraoNo ratings yet

- Et47003 - SP Arlamol Ps15e Mbal-Lq - (Ap) - UsensdsDocument9 pagesEt47003 - SP Arlamol Ps15e Mbal-Lq - (Ap) - UsensdsMohammad BhatNo ratings yet

- Melanie M. Reyes Bsied - Iiia Apply Appropriate Safety Measures While Working in The FarmDocument2 pagesMelanie M. Reyes Bsied - Iiia Apply Appropriate Safety Measures While Working in The FarmMelanie Delgado Magsino ReyesNo ratings yet

- JSA (Job Safety Analysis)Document3 pagesJSA (Job Safety Analysis)Meysam DoskiNo ratings yet

- Rada Vs NLRCDocument1 pageRada Vs NLRCDanica Irish RevillaNo ratings yet

- CPE615 Tutorial 1Document3 pagesCPE615 Tutorial 1Alif Aikal Che HatNo ratings yet

- Compensation and BenefitsDocument4 pagesCompensation and BenefitsNiño Sismoan BenigayNo ratings yet

- Risk Assess Gasket RemovalDocument1 pageRisk Assess Gasket RemovalMAB AliNo ratings yet

- Lockout TagoutDocument34 pagesLockout TagoutBahadir Can GENCER100% (1)

- Sds Epdm RubberDocument6 pagesSds Epdm RubberPramana BudimanNo ratings yet

- Meteq 2Document30 pagesMeteq 2Josman Pineda HernandezNo ratings yet

- JTKSWK20Document4 pagesJTKSWK20rosmainyNo ratings yet

- WCF NushadaDocument2 pagesWCF NushadaAkiks GamingNo ratings yet

- C&D MSDSDocument10 pagesC&D MSDSDhiraj KapoorNo ratings yet

- Material Safety Data Sheet: Burdick & Jackson Burdick & JacksonDocument7 pagesMaterial Safety Data Sheet: Burdick & Jackson Burdick & JacksonFahad AhmedNo ratings yet

- QHSE Training Plan and RegisterDocument3 pagesQHSE Training Plan and RegisterTito SamomaNo ratings yet

- Hmis IntroductionDocument10 pagesHmis IntroductionSantiago GaceloNo ratings yet

- Guidance On The Preparation of An Annex XV Dossier For The Identification of Substances of Very High ConcernDocument10 pagesGuidance On The Preparation of An Annex XV Dossier For The Identification of Substances of Very High ConcerntiknoNo ratings yet

- SRL-SDS-8006-28!8!38119-Soda Lime With Indicator Extrapure ARDocument3 pagesSRL-SDS-8006-28!8!38119-Soda Lime With Indicator Extrapure AREVAST FOR CHEMICALSNo ratings yet

- BSTC Batam Course Schedule 2019: Code Course Title Duration (Days) Course Validity (Years) Schedule Min/Max (PAX)Document1 pageBSTC Batam Course Schedule 2019: Code Course Title Duration (Days) Course Validity (Years) Schedule Min/Max (PAX)Bayu SudarsonoNo ratings yet