Professional Documents

Culture Documents

Zincoseal 605 MWL PDF

Zincoseal 605 MWL PDF

Uploaded by

Prince NaswaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Zincoseal 605 MWL PDF

Zincoseal 605 MWL PDF

Uploaded by

Prince NaswaCopyright:

Available Formats

TECHNICAL DATA SHEET

ZINCOSEAL 605 MWL

ZINCOSEAL 605 MWL is major step forward in enhancing a protection of metals against corrosion. It contains

polysiloxane with wax emulsion & complex inhibitors. It is specially designed to be applied on passivated zinc

plated surface to offer higher corrosion resistance. Further to this it also influences frictional property of the

coating enabling higher tolerance towards metal- metal abrasion. This in turn helps to extend the service life

of the plated component. The product complies with ROHS regulation.

The use of ZINCOSEAL 605 MWL allows you to meet the present requirements of the car industry, which

demands a minimum 200-hour salt spray resistance, before the appearance of white rust, for parts previously

treated in an oven at 120oC during one hour.

ZINCOSEAL 605 MWL is applied, either in barrel or in rack, by means of immersion without any rinse. Parts

are dried through hot air or in a centrifuge at 70-800C after a short dripping time. In some cases, a drying at

higher temperatures may be advisable to increase corrosion resistance.

This product has been designed to give a corrosion protection compatible with the greatest versatility. It is a

coat converter. It is a liquid product supplied as concentrates, which are subsequently diluted (in accordance

with the instructions contained in this leaflet) and used for the treatment of a variety of chromatized parts in

blue and in iridescent yellow.

OPERATING INSTRUCTIONS

The following process sequence is followed :

l Zinc-plating

l Rinse

l Passivation

l Rinse - Thrice

l ZINCOSEAL 605 MWL : 7% to 40% (V/V)

Temperature : upto 70oC

Time : 1 minute

pH : 11

ZINCOSEAL 605 MWL 1 of 3

l Dripping

l Drying : 70-80oC

l Coefficient of friction : Between 0.12 - 0.18 (depends on concentration of bath solution)

If the pH varies, we suggest to use these same concentrates to adjust it. If this is not possible, please contact

GROWEL’s Technical Service.

EQUIPMENT

Steel tanks lined with PVC, polypropylene, polyethylene, plastisolders, etc. Steel alone is unadvisable.

CORROSION RESISTANCE

As an example, we can say that an iridescent yellow coating weighing 1.5 g/m2 and having been treated with

ZINCOSEAL 605 MWL for 1 hour at 120oC can protect against white corrosion for up to 200 hours in a salt

spray chamber. Regarding red corrosion of the base steel, the resistance obtained is never lower than 600

hours for a minimum thickness of 8µ of zinc.

We should emphasize that it is a conversion and protection process; therefore, the chromate layer which is

formed during passivation suffers some changes even in its apperanace. Parts treated with ZINCOSEAL 605

MWL, after an iridescent yellow passivation, get slightly discoloured. In view of this, it is not recommended to

apply this process on passivated parts whose colour is black or olive green, if we want to keep their aesthetic

characteristics.

GENRAL REMARKS

ZINCOSEAL 605 MWL can be handled immediately following the drying. However, the highest water and

salt spray resistance is reached after a 24-hour ageing.

One should see to it that the parts to be treated with ZINCOSEAL 605 MWL have been throughly cleaned

with water only.

Parts with hidden zones may have the disadvantage of forming tears during the drying. This can be solved

either through agitation or by blowing air on the when most of their surface is already dried.

Control Procedure :

Concentration of Zincoseal 605 MWL maintain by solid content as per the following procedure :

« Weigh the dry glass beaker and transfer 10 ml. of working solution of Zincoseal 605 MWL and

weigh exactly on an analytical balance. Dry the sample preferably in an oven for 2-3 hours at

110-124 ºC.

Calculation: Solid content = Weight of dry Sample X 100

Weight of Sample

Weight of dry sample = (wt. of beaker + wt. of dry sample) - weight of beaker

Weight of sample = (wt. of beaker + wt. of sample before dry) - weight of beaker

Concentration of Zincoseal 605 MWL (ml/l) = solid content X 74

Note: If any suspended particles / insolubles in Zincoseal 605 MWL bath solution, filter the solution through

Whatmen filter paper before determination of solid content.

ZINCOSEAL 605 MWL 2 of 3

CHECKING BATH CONC. BY USING REFRACTIVE INDEX

The values of Refractive Index with respect to the different concentration of Zincoseal 605 MWL are given in the

following graph.

5

4.7

4.5

4 4

Refractive Index

3.5 3.4

3

2.7

2.5

2 2

1.5

1.3

1

0.5

0

0 5 10 15 20 25 30 35 40

Bath conc. In % - Zincoseal 605 MWL

FINDING OF CONCENTRATION OF ZINCOSEAL 605 MWL IN THE WORKING BATH.

Find out the Refractive Index value of the running bath using calibrated Refractometer and from the above graph

extrapolate the concentration from ‘X’ axis.

DISCLAIMER :

Our recommendations are made in good faith and are based on our skills. However, since the conditions of use of these products

are beyond our control, this information is given on the express condition and agreement that Grauer & Weil (India) Limited, will not

be liable to any person by reason thereof. Nothing herein shall be deemed to be a recommendation to use any product in violation

of any existing patent rights.

Issued on : 28.11.2013

Supersedes all earlier

ZINCOSEAL 605 MWL 3 of 3

You might also like

- The Perfect Answer Chemistry Revision Guide - Edexcel IGCSE 9-1 - 1st Edition PDFDocument34 pagesThe Perfect Answer Chemistry Revision Guide - Edexcel IGCSE 9-1 - 1st Edition PDFKevir Man100% (13)

- Alcoflood 254S - Types PDFDocument16 pagesAlcoflood 254S - Types PDFAnonymous T32l1RNo ratings yet

- Fatigue AnalysisDocument14 pagesFatigue AnalysisAndrei Ionut UtaNo ratings yet

- Phy Lib Book Jun2014Document13 pagesPhy Lib Book Jun2014Mansura Akter SusamaNo ratings yet

- Zincoseal 605 M - Data SheetDocument2 pagesZincoseal 605 M - Data SheetGANESHNo ratings yet

- Epodil 749: Reactive DiluentDocument3 pagesEpodil 749: Reactive Diluenttrường phạmNo ratings yet

- Improving The Repeatability of Aqueous Solution Analysis Performed With Capillary ColumnsDocument2 pagesImproving The Repeatability of Aqueous Solution Analysis Performed With Capillary ColumnsknbiolabsNo ratings yet

- AN5391 Determination of TKN in Water by Using KT8000 SeriesDocument7 pagesAN5391 Determination of TKN in Water by Using KT8000 SeriesJaysonAbenirCabahugNo ratings yet

- Certificado Coluna HPLC AçúcarDocument4 pagesCertificado Coluna HPLC Açúcarfernanda.cferreiraNo ratings yet

- 650pre TreatmentEDocument6 pages650pre TreatmentEAnonymous K0xGifXNo ratings yet

- Ceilcote 6650 Ceilcrete+ds+engDocument4 pagesCeilcote 6650 Ceilcrete+ds+engMohamed NouzerNo ratings yet

- 11.15 Glass ManufacturingDocument10 pages11.15 Glass ManufacturingRaulNo ratings yet

- Ecrylic KDA 790 - Die Ecronova Polymer GMBHDocument8 pagesEcrylic KDA 790 - Die Ecronova Polymer GMBHLong An ĐỗNo ratings yet

- 696044carboset® CR-717Document9 pages696044carboset® CR-717Charles Buerger Jr.No ratings yet

- Cloverdale - (Data Sheet) Clovaprimer h20-0020Document3 pagesCloverdale - (Data Sheet) Clovaprimer h20-0020PubcrawlNo ratings yet

- SurTec-650V 0922Document2 pagesSurTec-650V 0922Jihad AL-SheikhNo ratings yet

- Sanitile 120 PDSDocument3 pagesSanitile 120 PDSNguyễn PhướcNo ratings yet

- Dispersion Test For Drilling Fluids PDFDocument7 pagesDispersion Test For Drilling Fluids PDFHafiz Mudaser AhmadNo ratings yet

- Boiler ChemicalsDocument7 pagesBoiler ChemicalsTayaChandranNo ratings yet

- Chemical Engineering Laboratory III: Hardness Removal With Ion Exchange MethodDocument7 pagesChemical Engineering Laboratory III: Hardness Removal With Ion Exchange MethodVestel ÇallıNo ratings yet

- Astoline 40 V Dissolved MetalDocument3 pagesAstoline 40 V Dissolved MetalkhurshedlakhoNo ratings yet

- Cloverdale Tds 83055a eDocument2 pagesCloverdale Tds 83055a eenaron777No ratings yet

- PTssGlobal Technical Presentation OnlineTransformerDryoutSystemsDocument54 pagesPTssGlobal Technical Presentation OnlineTransformerDryoutSystemsYogesh SoodNo ratings yet

- Ozhllii!iieri': Electro-MotiveDocument3 pagesOzhllii!iieri': Electro-MotiveVladimir ArsicNo ratings yet

- Aquatensid BW 3 Ficha TecnicaDocument4 pagesAquatensid BW 3 Ficha TecnicaGerman SanchezNo ratings yet

- Transformer Oil: Bangladesh Power Management Institute (BPMI) 2019Document34 pagesTransformer Oil: Bangladesh Power Management Institute (BPMI) 2019Farhan AhmedNo ratings yet

- TDS DARVAN 811 C and R WebDocument2 pagesTDS DARVAN 811 C and R WebAhmed ElgendyNo ratings yet

- Axel Elgi 2013Document18 pagesAxel Elgi 2013Virender KumarNo ratings yet

- XIAMETER OFS 0777 TDS en PDFDocument3 pagesXIAMETER OFS 0777 TDS en PDFsriatul2006No ratings yet

- Lit Sullube Lubessull enDocument2 pagesLit Sullube Lubessull enThienNo ratings yet

- Cimcool Cimstar 585 PDFDocument2 pagesCimcool Cimstar 585 PDFtribolasNo ratings yet

- Dokumen - Tips - Registered Trademark of Basf Se Magnafloc Magnafloc 155 Is A High Molecular WeightDocument2 pagesDokumen - Tips - Registered Trademark of Basf Se Magnafloc Magnafloc 155 Is A High Molecular WeightMahmoud HakimNo ratings yet

- Alodine T-5900 TdsDocument5 pagesAlodine T-5900 TdsImeblaNo ratings yet

- DCWT PowderDocument2 pagesDCWT PowderNeeraj KumarNo ratings yet

- Epoxylite 578EB - TDS - 2008Document3 pagesEpoxylite 578EB - TDS - 2008beemer5No ratings yet

- OTC 19531 Compact Electrostatic Separation ProcessDocument6 pagesOTC 19531 Compact Electrostatic Separation Process1mmahoneyNo ratings yet

- Ginplate Ni - 426: Technical Data SheetDocument7 pagesGinplate Ni - 426: Technical Data SheetLuuThiThuyDuongNo ratings yet

- Surtec 652 Q: Protection UpgradedDocument3 pagesSurtec 652 Q: Protection UpgradedvgciasenNo ratings yet

- Ds Plastacryl 85Document1 pageDs Plastacryl 85faridNo ratings yet

- Teknobrite Az-846 Process: A High Performance Chloride Zinc ProcessDocument6 pagesTeknobrite Az-846 Process: A High Performance Chloride Zinc Processstephen dassNo ratings yet

- Redicote C-450: High Reactive Aggregates: CationicDocument1 pageRedicote C-450: High Reactive Aggregates: CationicRabin BeraNo ratings yet

- Accelguard 80Document2 pagesAccelguard 80marklohr4No ratings yet

- Sanitile 655: Selection & Specification DataDocument3 pagesSanitile 655: Selection & Specification DataIndraNo ratings yet

- NeoResin DTM Presentation 9-01Document22 pagesNeoResin DTM Presentation 9-01idreesgisNo ratings yet

- AB Card - A12-004 Samsung B-30K 24-04-12Document3 pagesAB Card - A12-004 Samsung B-30K 24-04-12wtwilightwNo ratings yet

- Data Sheet HFE-7500Document8 pagesData Sheet HFE-7500sshaffer_9No ratings yet

- Clariant Blue MagicDocument9 pagesClariant Blue MagicHrishikesh DhawadshikarNo ratings yet

- Infinity Turbine Oil 32 46 BR180104-2Document4 pagesInfinity Turbine Oil 32 46 BR180104-2Ahmad ButtNo ratings yet

- 22 - Water-Borne Road Marking Resin - Eagacryl 6050 - 2019 EditionDocument4 pages22 - Water-Borne Road Marking Resin - Eagacryl 6050 - 2019 Editionleonardo16No ratings yet

- Renolin Ac Compressor Oils: Product InformationDocument2 pagesRenolin Ac Compressor Oils: Product InformationSoporte Técnico RyRNo ratings yet

- High Productive Surfacer: Product Description FeaturesDocument7 pagesHigh Productive Surfacer: Product Description Featuresfernando machadoNo ratings yet

- TKN - VELP Application NoteDocument4 pagesTKN - VELP Application NoteAshraf MohamedNo ratings yet

- Vitrebond Tech ProfileDocument21 pagesVitrebond Tech ProfilePapun ScribdNo ratings yet

- VELP Application Note Water-Sludge E-K-001-2015 1Document3 pagesVELP Application Note Water-Sludge E-K-001-2015 1Nur Rizky InayahNo ratings yet

- Curing Behavior of Waterborne Paint Containing CatDocument15 pagesCuring Behavior of Waterborne Paint Containing CatmaNo ratings yet

- Method For The Determination of StigmastadienesDocument12 pagesMethod For The Determination of StigmastadienesSlaw Ben AissaNo ratings yet

- Scouring: 1) Kier Lining: PriorDocument4 pagesScouring: 1) Kier Lining: PriorAmirParvezNo ratings yet

- Bright Nickel ProcessDocument10 pagesBright Nickel Processshanmukha MechanicalNo ratings yet

- EOR & Wax Preventative (THIS)Document25 pagesEOR & Wax Preventative (THIS)Lee Hunter JrNo ratings yet

- Let's Make CastablesDocument16 pagesLet's Make Castablesthaituan237No ratings yet

- 21 - Resins For Road Marking PaintsDocument4 pages21 - Resins For Road Marking Paintsraj jangid100% (1)

- Lab Catalouge - Goel Scientific - CanadaDocument36 pagesLab Catalouge - Goel Scientific - CanadaHamant GoelNo ratings yet

- Modern Glass CharacterizationFrom EverandModern Glass CharacterizationMario AffatigatoNo ratings yet

- Assignment For Sedimentation: Water Treatment (Ceng 5403)Document2 pagesAssignment For Sedimentation: Water Treatment (Ceng 5403)አድሜ ልስልሱNo ratings yet

- Hallwachs Poster A4 enDocument2 pagesHallwachs Poster A4 enanshu kushwahNo ratings yet

- InTech-Analytical Method ValidationDocument19 pagesInTech-Analytical Method ValidationIordache SorinNo ratings yet

- Copernican RevolutionDocument4 pagesCopernican RevolutionCJ PrettyNo ratings yet

- 2.1 - Historical Development of Atomic Theory - Chemistry LibreTextsDocument10 pages2.1 - Historical Development of Atomic Theory - Chemistry LibreTextsSheena Shane CantelaNo ratings yet

- Assignment IIIDocument4 pagesAssignment IIIvijay kumarNo ratings yet

- Ws Specific HeatDocument3 pagesWs Specific HeatjesudassajNo ratings yet

- Module 5: Failure Criteria of Rock and Rock Masses: 5.4.3 Hoek and Brown CriterionDocument8 pagesModule 5: Failure Criteria of Rock and Rock Masses: 5.4.3 Hoek and Brown Criterionفردوس سليمانNo ratings yet

- Lesson 47Document6 pagesLesson 47Андрій ХомишакNo ratings yet

- Practical Lab Report Typed Burning Fuels Fill inDocument6 pagesPractical Lab Report Typed Burning Fuels Fill inAh Yeong LeeNo ratings yet

- Doppler-Effect: MTI - Moving Target IndicationDocument6 pagesDoppler-Effect: MTI - Moving Target IndicationBilal ShahidNo ratings yet

- Electrowinning and Smelting BasicsDocument13 pagesElectrowinning and Smelting BasicsJohann Rene Meddrano100% (2)

- Chapter:-19 Water SafetyDocument5 pagesChapter:-19 Water Safetylolu pandeyNo ratings yet

- Xu 2019Document9 pagesXu 2019MaritaFGNo ratings yet

- Poster - The Canary in The MineshaftDocument1 pagePoster - The Canary in The MineshaftKavi SidduNo ratings yet

- Zirconia Toughened Hydroxyapatite Biocomposite Formed by A DLP 3DPDocument15 pagesZirconia Toughened Hydroxyapatite Biocomposite Formed by A DLP 3DPBattle SagaNo ratings yet

- Effect of Molecular Weight On Properties of A PolymerDocument9 pagesEffect of Molecular Weight On Properties of A PolymerSwati SharmaNo ratings yet

- Enzymes 2023Document43 pagesEnzymes 2023sanjay jaiswalNo ratings yet

- Final Simulation Paper Chem ConDocument11 pagesFinal Simulation Paper Chem ConSzidonia DeeNo ratings yet

- Danfoss 2Document10 pagesDanfoss 2Stacy WilsonNo ratings yet

- GCSE 1b6 RadioactivityDocument48 pagesGCSE 1b6 RadioactivityChahinese FahsiNo ratings yet

- MetabolomicsDocument12 pagesMetabolomicswatson191No ratings yet

- S DQPK SNyf 9 WNJHups Y4 UDocument38 pagesS DQPK SNyf 9 WNJHups Y4 UKushal DubeyNo ratings yet

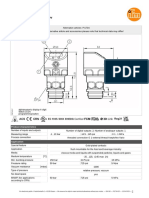

- Pi2794 02 - en GBDocument5 pagesPi2794 02 - en GBRaymond CanieteNo ratings yet

- Magnetism For JEEDocument15 pagesMagnetism For JEEJatin SonwalNo ratings yet

- Answer Key-GRX-EKYA CMR NPS-SCI-SEM1-TEE1-12.10.2020 Monday SECTION BDocument11 pagesAnswer Key-GRX-EKYA CMR NPS-SCI-SEM1-TEE1-12.10.2020 Monday SECTION BAnvi MantriNo ratings yet

- Ionpac® Cg5a Guard ColumnDocument28 pagesIonpac® Cg5a Guard ColumntayoubktirNo ratings yet