Professional Documents

Culture Documents

Lecture Notes DCN4 Coffrages Verticaux

Lecture Notes DCN4 Coffrages Verticaux

Uploaded by

Rosie ChristinaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecture Notes DCN4 Coffrages Verticaux

Lecture Notes DCN4 Coffrages Verticaux

Uploaded by

Rosie ChristinaCopyright:

Available Formats

LECTURE NOTES DCN4 COFFRAGES VERTICAUX

COLUMN FORMWORK

A column form or box consists of a vertical mould that has to resist considerable horizontal

pressures in the early stages of casting. The column box should be located against a 75 mm

high plinth or kicker that has been cast monolithic with the base or floor. The kicker not only

accurately positions the formwork but also prevents loss of grout from the bottom edge of

the form. The panels forming the column sides can be strengthened by using horizontal cleats

or vertical studs, which are sometimes called soldiers. The form can be constructed to the full

storey-height of the column, with cut-outs at the top to receive the incoming beam forms.

The thickness of the sides does not generally provide sufficient bearing for the beam boxes,

and therefore the cut-outs have a margin piece fixed around the opening to provide extra

bearing (see Fig. 10.3.2). It is general practice, however, to cast the columns up to the

underside of the lowest beam soffit, and to complete the top of the column at the same time

as the beam, using make-up pieces to complete the column and receive the beam

intersections. The main advantage of casting full-height columns is the lateral restraint

provided by the beam forms; the disadvantage is the complexity of the formwork involved.

Column forms are held together with collars of timber or metal called yokes in the case of

timber and clamps when made of metal. Timber yokes are purpose made, whereas steel

column clamps are adjustable within the limits of the blades (see Fig. 10.3.3).

The spacing of the yokes and clamps should vary with the anticipated pressures, the greatest

pressure occurring at the base of the column box. The actual pressure will vary according to:

rate of placing;

type of mix being used – generally the richer the mix the greater the pressure,

method of placing – if vibrators are used, pressures can increase up to 50% over hand

placing and compacting;

air temperature – the lower the temperature the slower is the hydration process and

consequently higher pressures are encountered.

Some preliminary raking strutting is required to plumb and align the column forms in all

situations. Free-standing columns will need permanent strutting until the concrete has

hardened but with tied columns the need for permanent strutting must be considered for

each individual case.

Shaped columns will need special yoke arrangements unless they are being formed using a

patent system. Typical examples of shaped column forms are shown in Fig. 10.3.4.

The links below will demonstrate the onsite operations which you might find useful in

understanding the subject.

https://www.youtube.com/watch?v=OsIsmRdoJ8I

https://www.youtube.com/watch?v=8XFlzyrt7vU

You might also like

- Machine Learning For Cyber Security Second International Conference ML4CS 2019 Xi An China September 19 21 2019 Proceedings Xiaofeng ChenDocument54 pagesMachine Learning For Cyber Security Second International Conference ML4CS 2019 Xi An China September 19 21 2019 Proceedings Xiaofeng Chenstephen.ortiz723100% (6)

- A Primer On Rectangular TanksDocument7 pagesA Primer On Rectangular Tanksfawmer61No ratings yet

- Compressor Foundation DesignDocument12 pagesCompressor Foundation DesignSyeda Sana Naqi100% (2)

- Column SpliceDocument2 pagesColumn SpliceMdShahbazAhmedNo ratings yet

- Design of Steel TanksDocument9 pagesDesign of Steel TanksIvan Jansen Saragih0% (1)

- Rectangular Tank Engineering PracticeDocument7 pagesRectangular Tank Engineering PracticeJessicalba Lou100% (1)

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Notes CH 1 2 Revision For Mid 1Document13 pagesNotes CH 1 2 Revision For Mid 1juhanaNo ratings yet

- LECTURE NOTES DCN4 CLASS 11&12 05may2021Document12 pagesLECTURE NOTES DCN4 CLASS 11&12 05may2021Alvinio VillarsNo ratings yet

- ENG List of Entry Point ProjectsDocument11 pagesENG List of Entry Point ProjectsKhoonShihHsienNo ratings yet

- 8-IWRE 416-Formwork and FalseworkDocument41 pages8-IWRE 416-Formwork and Falseworkally IsayaNo ratings yet

- Guide To Joint Design For Welding Ship HullsDocument6 pagesGuide To Joint Design For Welding Ship HullspakzoNo ratings yet

- Pressure Vessels (Att. VIII)Document42 pagesPressure Vessels (Att. VIII)Syed M. Imran Ali100% (1)

- Some Practical Aspects of Column Base Selection: Leveling PlatesDocument9 pagesSome Practical Aspects of Column Base Selection: Leveling PlatessamehNo ratings yet

- Foundation DesignDocument12 pagesFoundation DesignLuis AparcanaNo ratings yet

- Portal Frames ConstructionDocument47 pagesPortal Frames ConstructionYashi GuptaNo ratings yet

- Reinforcement Detailing in Concrete StructuresDocument6 pagesReinforcement Detailing in Concrete StructurescherogonyaNo ratings yet

- The Importance of Compressor Foundation Design Considerations Experience in Algeria by KBR Usa TRAIN ConstructionDocument4 pagesThe Importance of Compressor Foundation Design Considerations Experience in Algeria by KBR Usa TRAIN ConstructionAhmed Ben HmidaNo ratings yet

- Building Construction 8: DR Nabil El-Sawalhi Associate Professor Engineering Projects ManagementDocument31 pagesBuilding Construction 8: DR Nabil El-Sawalhi Associate Professor Engineering Projects Management54 Nayeem ur RahmanNo ratings yet

- Do's and Dont's in Civil EngineeringDocument20 pagesDo's and Dont's in Civil EngineeringRam1028100% (1)

- Precast Building Using Dovetail JointDocument17 pagesPrecast Building Using Dovetail JointcmuruganNo ratings yet

- Lift Slab 2Document8 pagesLift Slab 2mr_sunnydeiNo ratings yet

- Flat SlabsDocument11 pagesFlat SlabsSingamaneni PardhuNo ratings yet

- Antiseismic StirrupsDocument24 pagesAntiseismic StirrupsmarNo ratings yet

- What Do You Mean by Formwork?: Formwork Is The Term Given To Either Temporary or PermanentDocument7 pagesWhat Do You Mean by Formwork?: Formwork Is The Term Given To Either Temporary or PermanentJoel MathewNo ratings yet

- 24 Tips For Simplifying Braced Frame ConnectionsDocument2 pages24 Tips For Simplifying Braced Frame Connectionsgpax42100% (1)

- CE12C - Civil Drawing Concrete)Document5 pagesCE12C - Civil Drawing Concrete)Bhavish SeejoreNo ratings yet

- Joints in Structural Members: Unit IvDocument10 pagesJoints in Structural Members: Unit IvArun Akhil KunalaNo ratings yet

- Cut Out in RC SlabDocument4 pagesCut Out in RC SlabAnonymous 1HFV185Sl4No ratings yet

- Chapter 1: Introduction: 1.1 Practical Column Base Details in Steel StructuresDocument135 pagesChapter 1: Introduction: 1.1 Practical Column Base Details in Steel Structuressom_bs79100% (1)

- A Comparative Study of Conventional RC Girder Bridge and Integral BridgeDocument20 pagesA Comparative Study of Conventional RC Girder Bridge and Integral Bridgesanket panchalNo ratings yet

- Goodco Z Tech Installation Modular Joints LGDocument2 pagesGoodco Z Tech Installation Modular Joints LGligar.linNo ratings yet

- Countinous CastingDocument7 pagesCountinous Castingandreasgorga100% (1)

- Design of FoundationDocument26 pagesDesign of Foundationmessinho70% (1)

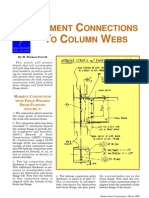

- Moment Connections To Column WebsDocument3 pagesMoment Connections To Column WebsAmro Ahmad AliNo ratings yet

- Fabrication of Steel PipeworkDocument10 pagesFabrication of Steel PipeworkjoseritoNo ratings yet

- Living Hinge DesignDocument9 pagesLiving Hinge Designom.mauryaNo ratings yet

- Base Plates and Anchor Rods - Steel Design AISCDocument3 pagesBase Plates and Anchor Rods - Steel Design AISCpenneng33% (3)

- 2000 - Novo Esquema de Design - Elimination of Flat Plate Punching Failure Mode - BromsDocument8 pages2000 - Novo Esquema de Design - Elimination of Flat Plate Punching Failure Mode - BromswhitepeteNo ratings yet

- The Design Manual For Moment and Stiff of Column PlatesDocument135 pagesThe Design Manual For Moment and Stiff of Column PlatesjdkelleyNo ratings yet

- Chevron Bracing Details - SteelwiseDocument4 pagesChevron Bracing Details - SteelwiseEugene Afable100% (1)

- Theory Application of Roll Forming (2010) - WebDocument21 pagesTheory Application of Roll Forming (2010) - WebVenugopalan Manaladikalam100% (1)

- Guidance Note Bracing and Cross Girder Connections No. 2.03: ScopeDocument5 pagesGuidance Note Bracing and Cross Girder Connections No. 2.03: ScopeRaquel CarmonaNo ratings yet

- RoofDocument31 pagesRoofsamNo ratings yet

- Design Spherical TankdocxDocument6 pagesDesign Spherical TankdocxMakhmudul FikriNo ratings yet

- Steel - Continuous CastingDocument11 pagesSteel - Continuous CastingAli AzharNo ratings yet

- Assembly of Shell Plating: By:-Jophin Joseph Noufal P.Najeeb Sachin Kumar Subhendu Kumar SinghDocument32 pagesAssembly of Shell Plating: By:-Jophin Joseph Noufal P.Najeeb Sachin Kumar Subhendu Kumar SinghGouthamVenkateshNo ratings yet

- Design and Construction FailuresDocument23 pagesDesign and Construction Failuresgokulnath.asoorNo ratings yet

- Inspection and Maintenance of Steel Girders-5Document10 pagesInspection and Maintenance of Steel Girders-5vpmohammedNo ratings yet

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- A Little Book of Making Tools and Equipment for the Studio: Includes Instructions for Making a Printing Press, Line Printing Blocks, Rubber Stamp Making, Stencil Cutting and StencillingFrom EverandA Little Book of Making Tools and Equipment for the Studio: Includes Instructions for Making a Printing Press, Line Printing Blocks, Rubber Stamp Making, Stencil Cutting and StencillingNo ratings yet

- Transactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173From EverandTransactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173No ratings yet

- Metalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsFrom EverandMetalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsNo ratings yet

- Грузовзвес Ds EuroDocument12 pagesГрузовзвес Ds EuroВлад ТелеNo ratings yet

- Intel Logo: Trademark and Logo Usage Guidelines - 3rd PartyDocument10 pagesIntel Logo: Trademark and Logo Usage Guidelines - 3rd PartyНикита ЖевлаковNo ratings yet

- Aplast Rp2640: Retarding Water Reducing AdmixtureDocument4 pagesAplast Rp2640: Retarding Water Reducing Admixturemazen jamalNo ratings yet

- Future of The Media Business: WLH' Nsrntly Looks Forwatd, and Even Teinvents HistoryDocument14 pagesFuture of The Media Business: WLH' Nsrntly Looks Forwatd, and Even Teinvents HistoryMariia G.No ratings yet

- FRM Annual Report 2021Document14 pagesFRM Annual Report 2021l rockyNo ratings yet

- Unit 6 HCE Textbook CHE110Document34 pagesUnit 6 HCE Textbook CHE110Bhanu OhriNo ratings yet

- CodexxDocument3 pagesCodexxLuis DiazNo ratings yet

- Geofill LD Abandonment SpecDocument3 pagesGeofill LD Abandonment SpecMerluza, Ullys M.No ratings yet

- Next Gen Ia MethodologyDocument11 pagesNext Gen Ia MethodologyAlexchandar AnbalaganNo ratings yet

- VLD 6000 AIS Airborne Transponder PDFDocument2 pagesVLD 6000 AIS Airborne Transponder PDFShin Ami IgamiNo ratings yet

- HydraulicscDocument15 pagesHydraulicscAaron Tom VilaNo ratings yet

- 01.01 TPB SubscriptionsDocument15 pages01.01 TPB SubscriptionsaNo ratings yet

- Lab1 Week7Document30 pagesLab1 Week7NUR SYAFIQAH BINTI BAIDROL AZMEE / UPMNo ratings yet

- Handbook On Indian Railway Standard Drawings & Specifications For SignallingDocument48 pagesHandbook On Indian Railway Standard Drawings & Specifications For SignallingsreelukkyNo ratings yet

- Full Ebook of Think Like A Software Engineering Manager Meap V05 Akanksha Gupta Online PDF All ChapterDocument69 pagesFull Ebook of Think Like A Software Engineering Manager Meap V05 Akanksha Gupta Online PDF All Chapterteachasahari100% (12)

- Chapter 5 - JAVA IODocument38 pagesChapter 5 - JAVA IOTheHqDevNo ratings yet

- Ascensor Gearles Con CintasDocument6 pagesAscensor Gearles Con CintasLuis ChavarryNo ratings yet

- Statement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing BalanceDocument2 pagesStatement of Account: Date Narration Chq./Ref - No. Value DT Withdrawal Amt. Deposit Amt. Closing Balancechandan kumarNo ratings yet

- U3 PIC 18F Microcontroller InterruptsDocument59 pagesU3 PIC 18F Microcontroller Interruptsmadhukar v nimbalkarNo ratings yet

- Datasheet Modulo Inversor Alto 20kVADocument2 pagesDatasheet Modulo Inversor Alto 20kVALuis CanepaNo ratings yet

- Course Outline: - Computer SecurityDocument21 pagesCourse Outline: - Computer Securityابتهاج عبدالسلامNo ratings yet

- IFS Engine MRODocument8 pagesIFS Engine MROCarlos CastNo ratings yet

- Rocky Linux Focus GuideDocument24 pagesRocky Linux Focus GuideJudson BorgesNo ratings yet

- Condition Monitoring PresentationDocument101 pagesCondition Monitoring PresentationKostasNo ratings yet

- Acr 5000 Ram Plain Ends NormalDocument2 pagesAcr 5000 Ram Plain Ends NormalFernando Sanchez Feris100% (1)

- OOSD RecordDocument53 pagesOOSD RecordKevin JasonNo ratings yet

- Microsoft Excel 2016 Step-By-Step GuideDocument84 pagesMicrosoft Excel 2016 Step-By-Step GuideMelvin DipasupilNo ratings yet

- Power Plant and Calculations - Why Does Load Hunting Occur in Steam TurbinesDocument7 pagesPower Plant and Calculations - Why Does Load Hunting Occur in Steam TurbinesRajeshNo ratings yet