Professional Documents

Culture Documents

T 55-00-00-220-801-Detailed Inspection of The Horizontal and Vertical

T 55-00-00-220-801-Detailed Inspection of The Horizontal and Vertical

Uploaded by

Aldo Gibran Esquivel CarmonaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

T 55-00-00-220-801-Detailed Inspection of The Horizontal and Vertical

T 55-00-00-220-801-Detailed Inspection of The Horizontal and Vertical

Uploaded by

Aldo Gibran Esquivel CarmonaCopyright:

Available Formats

Falcon 50 ● Rev.

038_005 ● FEB 01, 2024

AIRCRAFT MAINTENANCE MANUAL

DETAILED INSPECTION OF THE HORIZONTAL AND VERTICAL

STABILIZERS AND OF ENGINE 2 AIR INTAKE AND S-DUCT

1. OVERVIEW OF THE JOB

Operation code: 55-00-00-220-801-01

This procedure describes the detailed inspection of:

the horizontal and vertical stabilizers,

the engine 2 air intake and S-duct.

NOTE: The scope of the inspection to be performed, the types of damage to look for during this inspection

and the possible repairs are given in the “INSPECTIONS” description section (SDS 20-10-00).

2. LOGISTICS

A. References

Reference Designation

20-10-00 (SDS) INSPECTIONS

20-32-00-910-802 ACCEPTANCE CRITERIA FOR HYDRAULIC LEAKS

20-60-00 (SDS) PROTECTION SCHEME

20-60-00-370-813 APPLICATION OF THE PAINT SCHEME ON COMPOSITE COMPONENTS

27-00-00-910-801 FLIGHT CONTROL SYSTEM MAINTENANCE AND SAFETY PRECAUTIONS

27-40-07-220-801 REMOVAL / INSTALLATION, INSPECTION AND GREASING OF HS

REPEATER MICROMETRIC ROD

33-40-00-710-801 OPERATIONAL TEST OF THE EXTERIOR LIGHTING

51-40-04 (RPI) RIVETING

51-71-01 (RPI) REPAIR OF SKIN PANELS

51-71-04 (RPI) SMOOTHING AND BLENDING

54-42-05-900-801 REMOVAL / INSTALLATION OF THE S-DUCT SECTION S1-S2

54-42-09-900-801 REMOVAL / INSTALLATION OF THE S-DUCT SECTION S3-S5

55-10-03-900-801 REMOVAL / INSTALLATION OF THE SPRING-LOADED FAIRINGS

55-10-05 (RPI) REPAIR OF COMPOSITE HORIZONTAL STABILIZER

55-10-05-960-802 REPLACEMENT OF THE SPRING-LOADED FAIRING FRICTION STRIPS

55-30-05-960-801 REPLACEMENT OF THE FIN TIP FAIRING LIGHTNING-ARRESTER STRIP

55-30-07-900-801 REMOVAL / INSTALLATION OF THE FIN TIP FAIRING

B. Tools and Ground Support Equipment

Reference Designation Quantity

TO-20-008 TOOL BOX 1

TO-20-947 EMPENNAGE ACCESS PLATFORM 1

TO-25-952 VACUUM CLEANER 1

C. Ingredients and Consumable Products

Designation Additional designation

ADHERENCE PROMOTER FOR RTV

CLEANER MULTIPURPOSE

LUBRICATING OIL

Print Date by FIELD6: APR 11, 2024 Effectivity: ALL

Sn: 225 FIELD6 paper version not maintained Rev. Date: FEB 01, 2024

"DASSAULT AVIATION Proprietary Data" T 55-00-00-220-801

Page: 1/15

Falcon 50 ● Rev. 038_005 ● FEB 01, 2024

AIRCRAFT MAINTENANCE MANUAL

Designation Additional designation

PICKLING AGENT 6940B

SEALANT RTV106

D. Access

Reference Designation

MSD SERVICING COMPARTMENT DOOR

311A LH FIN-TO-FUSELAGE FAIRING

312D RH FIN-TO-FUSELAGE FAIRING

321A FIN MIDDLE LEADING EDGE

321BL FIN LEADING EDGE LOWER ACCESS PANEL

321BR FIN LEADING EDGE LOWER ACCESS PANEL

321C FIN UPPER LEADING EDGE

321DL FIN UPPER LEADING EDGE ACCESS DOOR

322A UPPER FIN TIP FAIRING

322B LOWER FIN TIP FAIRING

323CL FIN ACCESS DOOR

323CR FIN ACCESS DOOR

323D REAR CONE

323G FIN ACCESS DOOR

323H FIN ACCESS DOOR

323J FIN ACCESS DOOR

323K FIN ACCESS DOOR

323L FIN ACCESS DOOR

323M FIN ACCESS DOOR

323Q RUDDER DEFLECTION MEASURING FIXTURE FITTING PLUG

323R RUDDER DEFLECTION MEASURING FIXTURE FITTING PLUG

323SL FIN HOISTING FITTING BLANKING PLUG

323SR FIN HOISTING FITTING BLANKING PLUG

324A RUDDER MIDDLE HINGE LH ACCESS DOOR

324B RUDDER LOWER HINGE RH ACCESS DOOR

324C RUDDER MIDDLE HINGE RH ACCESS DOOR

324D RUDDER MIDDLE HINGE RH ACCESS DOOR

324E RUDDER UPPER HINGE RH ACCESS DOOR

325AL HORIZONTAL STABILIZER ACTUATOR LH ACCESS PANEL

325BL ENGINE 2 WINCH FIN ACCESS PANEL

325BR FIN STUB ACCESS DOOR

325CL ENGINE 2 WINCH CRANK FIN ACCESS DOOR

325CR FIN STUB ACCESS DOOR

325D FIN STUB TRAILING EDGE ACCESS DOOR

325E FIN STUB LOWER FAIRING

332AB HORIZONTAL STABILIZER LH LOWER INBOARD ACCESS DOOR

332AT HORIZONTAL STABILIZER LH UPPER INBOARD ACCESS DOOR

332B ELEVATOR DEFLECTION MEASURING FIXTURE FITTING PLUG

Print Date by FIELD6: APR 11, 2024 Effectivity: ALL

Sn: 225 FIELD6 paper version not maintained Rev. Date: FEB 01, 2024

"DASSAULT AVIATION Proprietary Data" T 55-00-00-220-801

Page: 2/15

Falcon 50 ● Rev. 038_005 ● FEB 01, 2024

AIRCRAFT MAINTENANCE MANUAL

Reference Designation

332C ELEVATOR DEFLECTION MEASURING FIXTURE FITTING PLUG

335AB LH ELEVATOR MIDDLE HINGE LOWER ACCESS DOOR

335BB LH ELEVATOR OUTBOARD HINGE LOWER ACCESS DOOR

335C LH ELEVATOR INBOARD HINGE LOWER ACCESS DOOR

342AB HORIZONTAL STABILIZER RH LOWER INBOARD ACCESS DOOR

342AT HORIZONTAL STABILIZER RH UPPER INBOARD ACCESS DOOR

342B ELEVATOR DEFLECTION MEASURING FIXTURE FITTING PLUG

342C ELEVATOR DEFLECTION MEASURING FIXTURE FITTING PLUG

345AB RH ELEVATOR MIDDLE HINGE LOWER ACCESS DOOR

345BB RH ELEVATOR OUTBOARD HINGE LOWER ACCESS DOOR

345C RH ELEVATOR INBOARD HINGE UPPER ACCESS DOOR

350A S-DUCT FRONT UPPER FAIRING

350BL S-DUCT LH LATERAL FAIRING

350BR S-DUCT RH LATERAL FAIRING

350D S-DUCT REAR UPPER FAIRING

350E FIN LOWER LEADING EDGE

352AZ S-DUCT DOOR

E. Miscellaneous

LINT-FREE CLOTH

3. JOB SET-UP

A. Obey the flight control system maintenance and safety precautions (TASK 27-00-00-910-801).

B. Remove or open the following access doors and the fairings:

(311A), (312D), (321A), (321BL), (321BR), (321C), (321DL), (323CL), (323CR), (323G), (323H),

(323J), (323K), (323L), (323M), (324A), (324B), (324C), (324D), (324E), (325AL), (325BL), (325BR),

(325CL), (325CR), (325D), (325E), (332AB), (332AT), (335AB), (335BB), (335C), (342AB), (342AT),

(345AB), (345BB), (345C), (350A), (350BL), (350BR), (350D) and (350E).

C. Remove the spring-loaded fairings (TASK 55-10-03-900-801).

D. Remove the rear cone (323D).

E. Remove the upper fin tip fairing (322A) (TASK 55-30-07-900-801).

F. (A/C with SATCOM fairing) Remove the lower fin tip fairing (322B) (TASK 55-30-07-900-801).

4. STRUCTURE

Refer to fig. 2 , fig. 3 , fig. 4 , fig. 5 and fig. 6

CAUTION: DETECTION OF A CRACK ENTAILS SYSTEMATIC REPAIR.

IF A CRACK IS FOUND ON A RIVET, REPLACE THE RIVET (RPI 51-40-04).

IF A CRACK IS FOUND ON THE SKIN, CONTACT THE MANUFACTURER.

NOTE: If necessary, refer to the Structural Repair Manual (SRM) (RPI 51-71-01 - "Typical repairs for skin

panels and other sheet metal components").

A. Engine 2 air-intake and S-duct

(1) Check the air-intake leading edge, the outer skin, the lateral and upper cowlings, and the upper

inner skin of the S-duct for impact marks.

(2) Check for any damaged or missing rivets.

Print Date by FIELD6: APR 11, 2024 Effectivity: ALL

Sn: 225 FIELD6 paper version not maintained Rev. Date: FEB 01, 2024

"DASSAULT AVIATION Proprietary Data" T 55-00-00-220-801

Page: 3/15

Falcon 50 ● Rev. 038_005 ● FEB 01, 2024

AIRCRAFT MAINTENANCE MANUAL

(3) Check that the anti-icing air outlets on the cowlings (350CL) and (350CR) are not obstructed.

(4) Check that the S-duct drain is not obstructed.

(5) Open the door (352AZ).

(6) Inspect the inner and outer upper section of the S-duct, and the air-intake and S-duct anti-icing

ducts for condition.

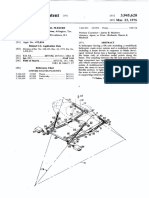

(a) Check for signs of overheating on the inner and outer surfaces of the S-duct (fig. 2 and fig.

3).

1 From inside the S-duct:

a Check for traces of overheating (brownish marks) on the inner skin at the anti-icing

manifolds located at the upper part of the S-duct.

1 If traces of overheating are found, clean the affected area with cleaner to

confirm the trace of overheating; then strip the paint top coat.

b Check whether the trace of overheating affects the primer coat.

1 If it does not, apply the top coat (SDS 20-60-00).

2 If it does, strip the primer coat and check for any discoloration of the metal.

c If the metal is not discolored, apply the paint scheme (SDS 20-60-00).

NOTE: If cracks or traces of overheating are found, contact the manufacturer.

d Check the inner upper section of the S-duct for cracks (S-duct skin, anti-icing

manifold, anti-icing double skin) (fig. 2).

e Check the inner skin of the S-duct for corrosion.

1 If corrosion is found, refer to the SRM (RPI 51-71-04).

NOTE: If the inner skin of the S-duct is not painted, it is recommended to apply the

complete paint scheme:

remove the S-duct section to be painted (TASK 54-42-05-900-801) or

(TASK 54-42-09-900-801),

apply the paint scheme (SDS 20-60-00).

f Check the condition of the sealant between the different sections (between the air-

intake and section 1, and between sections 1 and 2) (fig. 2).

1 If the sealant is damaged or cracked, renew the sealant as follows:

aRemove the damaged sealant.

bClean the surface with cleaner.

cRub the surfaces with a clean lint-free cloth moistened with pickling agent

6940B.

dApply adherence promoter for RTV.

eApply sealant RTV106.

(b) From outside the S-duct:

1 Inspect the entire anti-icing double skin of the S-duct and the anti-icing ducts (check paint

for cracks, blisters, traces of overheating).

2 Check the condition of the sealant between the anti-icing manifolds and the anti-icing

double skin.

a If the sealant is damaged or cracked, renew the sealant as follows:

1 Remove the damaged sealant.

2 Clean the surface with cleaner.

3 Rub the surfaces with a clean lint-free cloth moistened with pickling agent

6940B.

Print Date by FIELD6: APR 11, 2024 Effectivity: ALL

Sn: 225 FIELD6 paper version not maintained Rev. Date: FEB 01, 2024

"DASSAULT AVIATION Proprietary Data" T 55-00-00-220-801

Page: 4/15

Falcon 50 ● Rev. 038_005 ● FEB 01, 2024

AIRCRAFT MAINTENANCE MANUAL

4 Apply adherence promoter for RTV.

5 Apply sealant RTV106.

(7) Check engine 2 air-intake and S-duct anti-icing system lines and equipment for condition and

attachment.

(8) Check the attachment of the S-duct to the rudder spar/fuselage connecting fitting.

(9) Close the door (352AZ).

B. Horizontal stabilizer

CAUTION: ON AIRCRAFT WITH A HORIZONTAL STABILIZER WITH SINGLE-PIECE CARBON

COMPOSITE SKIN PANELS:

IF DEFECTS ARE FOUND ON THE HORIZONTAL STABILIZER, REFER TO THE SRM

(RPI 55-10-05),

FOR ANY RENEWAL OF THE PAINT, IT IS IMPERATIVE TO COMPLY WITH THE

PAINT COAT THICKNESS REQUIREMENTS (TASK 20-60-00-370-813).

(1) Check for impact marks or dents on the skin panels and in particular on the leading edges.

(2) Check for any damaged or missing rivets.

(3) Check the tip fairings (334A) and (344A) for condition and attachment.

(4) Check the blanking plugs (332B)/(332C) and (342B)/(342C) of the elevator deflection measuring

fixture support fittings:

(a) Remove the blanking plugs (332B)/(332C) and (342B)/(342C).

(b) Check the blanking plugs and the tapped holes of the support fittings for:

condition,

corrosion.

(c) Lubricate the threads with lubricating oil.

(d) Install the blanking plugs (332B)/(332C) and (342B)/(342C).

(5) Check the leading edge fairings and the skin panels of each elevator for condition and attachment.

(6) Check for any interference between the elevator and the horizontal stabilizer structure.

(7) Inspect the spring-loaded fairings.

(8) Check the friction strips for condition and attachment; replace if worn or damaged (TASK 55-10-

05-960-802).

(9) Check the following attachment fittings (which are secured to or integral with the Horizontal

Stabilizer (HS) center box structure for corrosion, distortion or cracks:

the HS front attachment fitting (1-fig. 4),

the elevator servo-actuator attachment fitting on the structure (2-fig. 4),

the bellcrank upper surface support (3-fig. 4),

the spring-loaded fairing rod attachment fittings (4-fig. 4), (5-fig. 4) and (6-fig. 4),

the HS rear attachment fitting (7-fig. 4),

the front torque link/stub attachment fitting (8-fig. 4).

(10) Check the connecting pins, the actuator upper attachment fitting, and the HS rear attachment

fitting for security of attachment.

C. Vertical stabilizer - Stub

(1) Check for impact marks or dents on the skin panels and in particular on the leading edge.

(2) Check for any damaged or missing rivets.

(3) Check the blanking plugs (323SL) and (323SR) of the rudder hoisting fittings.

(a) Remove the blanking plugs (323SL) and (323SR).

Print Date by FIELD6: APR 11, 2024 Effectivity: ALL

Sn: 225 FIELD6 paper version not maintained Rev. Date: FEB 01, 2024

"DASSAULT AVIATION Proprietary Data" T 55-00-00-220-801

Page: 5/15

Falcon 50 ● Rev. 038_005 ● FEB 01, 2024

AIRCRAFT MAINTENANCE MANUAL

(b) Check the blanking plugs and the tapped holes of the hoisting fittings for:

condition,

corrosion.

(c) Lubricate the threads with lubricating oil.

(d) Install the blanking plugs (323SL) and (323SR).

(4) Check the blanking plugs (323Q) and (323R) of the rudder deflection measuring fixture support

fittings

(a) Remove the blanking plugs (323Q) and (323R).

(b) Check the blanking plugs and the tapped holes of the support fittings for:

condition,

corrosion.

(c) Lubricate the threads with lubricating oil.

(d) Install the blanking plugs (323Q) and (323R).

(5) (A/C without SATCOM fairing) Inspection of the fin tip fairing:

(a) Check the upper part of rib 12 in the box structure for condition.

(b) On the fin tip fairing (322A) removed, check the fin tip fairing skin for:

impacts marks,

cracks,

erosion.

(6) (A/C with SATCOM fairing) Inspection of the fin tip fairing:

(a) On the upper fin tip fairing (322A) removed, check the following:

1 The skin of the upper fin tip fairing for:

impacts marks,

cracks,

erosion.

2 The fin tip fairing lightning-arrester strip for:

pitting,

separation,

damage of any kind.

a If damage is found, or if in doubt, replace the fin tip fairing lightning-arrester strip

(TASK 55-30-05-960-801).

(b) Check the lower fin tip fairing (322B) for condition and attachment.

(c) Check the upper part of rib 12 in the box structure for condition.

(7) Inspect the VTP external skin at rib 12 (1-fig. 6).

(8) Check the rudder leading edge and skin panels for condition and attachment.

(9) Inspect the three hinge bearings of the rudder for:

corrosion,

correct assembly of components,

tightness and safetying.

(10) Check for signs of friction between the rudder and the vertical stabilizer structure.

(11) Inside all the boxes opened for this inspection:

(a) Check for corrosion or cracks at the attachment fittings and at the equipment supports.

(b) Check that the drains holes are not obstructed.

(12) Inspect the lower end of the LH and RH spar lateral angles for corrosion cracks (DETAIL A-fig.

Print Date by FIELD6: APR 11, 2024 Effectivity: ALL

Sn: 225 FIELD6 paper version not maintained Rev. Date: FEB 01, 2024

"DASSAULT AVIATION Proprietary Data" T 55-00-00-220-801

Page: 6/15

Falcon 50 ● Rev. 038_005 ● FEB 01, 2024

AIRCRAFT MAINTENANCE MANUAL

4).

(13) Check the front and rear connection fittings of the vertical stabilizer stub for corrosion, warping

or cracks.

(14) Inspect the fittings listed in the table below for corrosion, warping or cracks. Also check these

fittings for secure attachment to the structure and to the equipment.

FITTING LOCATION ACCESS

Fixed servo-control Vertical stabilizer box structure Door (323L)

fitting between ribs 6 and 7

Neutral return fitting Vertical stabilizer box structure Door (323L)

between ribs 6 and 7

Ball-bushing holder On rib 3 and front spar Doors (323J), (323H)

fitting

Horizontal stabilizer Stub box structure Door (325AL)

actuator fitting

Engine 2 hoisting fitting Stub box structure Door (325BL)

(15) Removal of Klegecell filler block in the stub compartment

CAUTION: THE REMOVAL OF A KLEGECELL FILLER BLOCK REQUIRES USING A PLEXIGLAS

SPATULA WHICH MUST BE HANDLED WITH CARE.

DO NOT SCRATCH THE SKIN OR THE FRAMES.

(a) Through door (325AL):

1 Check for presence of the Klegecell filler block.

(b) If the Klegecell filler block is present, apply SB F50-442 (SB 442) to remove it.

D. Fuselage skin and structure around the S-Duct area

(1) Check for corrosion the following components:

the fuselage skin (1-fig. 5), stringers (2-fig. 5) and rivets under the removed S-duct lateral fairings

(350BL)/(350BR),

the front spar skin (3-fig. 5), stringers (4-fig. 5) and rivets under the removed fin fairings (321A),

(350D) and (350E).

5. COMMUNICATION SYSTEMS

A. Check the equipment supports and the equipment directly secured to the structure for condition and

efficiency of the anti-vibration mounts, and for correct installation and attachment of equipment to supports.

B. Check the bonding braids for condition and security of attachment.

C. Check the connectors and the wiring for condition, wear or twisting, in particular at the feed-through

fittings.

(1) Check clamps for attachment.

(2) Check markings.

(3) Check coaxial connectors for attachment and cleanliness.

D. Check the VHF2 antenna fairing for condition and impact marks; particularly check the leading edge for

scratches.

E. Check the equipment located under the fin tip fairing (322A)

(1) Check the ELT antenna (33RB), optional antennas, and SATCOM antenna (if A/C so equipped)

for:

correct attachment,

absence of corrosion,

traces of electrical arcing.

Print Date by FIELD6: APR 11, 2024 Effectivity: ALL

Sn: 225 FIELD6 paper version not maintained Rev. Date: FEB 01, 2024

"DASSAULT AVIATION Proprietary Data" T 55-00-00-220-801

Page: 7/15

Falcon 50 ● Rev. 038_005 ● FEB 01, 2024

AIRCRAFT MAINTENANCE MANUAL

(2) If DBS/TV (optional) is installed, check it for:

condition,

correct attachment.

F. Check the condition of the coaxial cable between the ELT antenna (33RB) and the ELT (32RB) located

in the rear compartment ceiling (MSD).

6. ELECTRICAL SYSTEMS

A. Visually check the wiring and the attachment clamps for condition:

cleanliness,

wear,

ageing or distortion,

routing and marking.

B. Make sure that the wiring is not in contact with the structure.

C. Make sure that connectors are correctly connected.

7. FLIGHT CONTROLS

A. Check the elevator connecting mechanism for corrosion.

B. Check the rudder servo-actuator (571CC) and the elevator servo-actuator (925CW) for leaks and for

corrosion.

(1) If leaks are found (traces of hydraulic fluid on the equipment or inside the box structure), perform

a dynamic leak test (TASK 20-32-00-910-802).

C. Visually check the neutral return system (auxiliary AFU) of the servo-controls for corrosion.

D. Check the HS repeater box for corrosion.

E. Check the HS micrometric rods for corrosion and for correct greasing (TASK 27-40-07-220-801).

F. Check the condition of the HS torque link.

G. Check the connection of the horizontal stabilizer to its actuator.

H. Check the rudder ball-bushing rod located in the vertical stabilizer leading edge.

I. Check the ball-bushings for condition and attachment.

J. Check the rod sliding sections for wear or scratches.

8. HYDRAULIC SYSTEMS

A. Check the hydraulic piping for condition and attachment (correct tightening of clamps and manifolds,

signs of friction against the structure).

B. Check the hydraulic couplings and equipment for leakage (TASK 20-32-00-910-802).

9. ENGINE 2 S-DUCT ANTI-ICING SYSTEM

A. Check the air-intake and S-duct anti-icing system for condition:

attachment,

leakage at fittings,

connector markings.

B. Check the pressure switches for condition:

attachment,

connection,

connector markings.

10. LIGHTING SYSTEM

Print Date by FIELD6: APR 11, 2024 Effectivity: ALL

Sn: 225 FIELD6 paper version not maintained Rev. Date: FEB 01, 2024

"DASSAULT AVIATION Proprietary Data" T 55-00-00-220-801

Page: 8/15

Falcon 50 ● Rev. 038_005 ● FEB 01, 2024

AIRCRAFT MAINTENANCE MANUAL

A. (A/C without SATCOM fairing) on the fin tip fairing (322A) removed, check the upper anti-collision light

(17L) for cleanliness and condition of the transparency.

B. On the rear cone (323D) removed, check the rear white navigation/anti-collision light (25L) for

cleanliness and condition of the transparency.

C. Check the logo lights (if A/C so equipped) on the HS upper and lower surfaces for cleanliness and

condition.

11. CLOSE-UP

A. Before installing or closing the access doors and the fairings, check the boxes and compartments for

any foreign matter and for cleanliness.

(1) Using a vacuum cleaner (TO-25-952), remove all traces of dirt from the boxes and compartments

opened for this inspection.

B. Check the condition and efficiency of the drains in the rudder servo-actuator box, the spring-loaded

fairing box and the HS actuator box.

C. (A/C with SATCOM fairing) Install the lower fin tip fairing (322B) (TASK 55-30-07-900-801).

D. Install the upper fin tip fairing (322A) (TASK 55-30-07-900-801).

E. Install the rear cone (323D).

F. Install the spring-loaded fairings (TASK 55-10-03-900-801).

G. Install or close the following access doors and fairings:

(311A), (312D), (321A), (321BL), (321BR), (321C), (321DL), (323CL), (323CR), (323G), (323H),

(323J), (323K), (323L), (323M), (324A), (324B), (324C), (324D), (324E), (325AL), (325BL), (325BR),

(325CL), (325CR), (325D), (325E), (332AB), (332AT), (335AB), (335BB), (335C), (342AB), (342AT),

(345AB), (345BB), (345C), (350A), (350BL), (350BR), (350D) and (350E).

H. Perform a test of the anti-collision lights (TASK 33-40-00-710-801).

Print Date by FIELD6: APR 11, 2024 Effectivity: ALL

Sn: 225 FIELD6 paper version not maintained Rev. Date: FEB 01, 2024

"DASSAULT AVIATION Proprietary Data" T 55-00-00-220-801

Page: 9/15

Falcon 50 ● Rev. 038_005 ● FEB 01, 2024

AIRCRAFT MAINTENANCE MANUAL

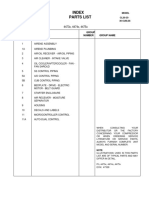

Figure 1: DETAILED INSPECTION/CHECK (AREA T1)

Print Date by FIELD6: APR 11, 2024 Effectivity: ALL

Sn: 225 FIELD6 paper version not maintained Rev. Date: FEB 01, 2024

"DASSAULT AVIATION Proprietary Data" T 55-00-00-220-801

Page: 10/15

Falcon 50 ● Rev. 038_005 ● FEB 01, 2024

AIRCRAFT MAINTENANCE MANUAL

Figure 2: INSPECTION OF ENGINE 2 S-DUCT (1/2)

Print Date by FIELD6: APR 11, 2024 Effectivity: ALL

Sn: 225 FIELD6 paper version not maintained Rev. Date: FEB 01, 2024

"DASSAULT AVIATION Proprietary Data" T 55-00-00-220-801

Page: 11/15

Falcon 50 ● Rev. 038_005 ● FEB 01, 2024

AIRCRAFT MAINTENANCE MANUAL

Figure 3: INSPECTION OF ENGINE 2 S-DUCT (2/2)

Print Date by FIELD6: APR 11, 2024 Effectivity: ALL

Sn: 225 FIELD6 paper version not maintained Rev. Date: FEB 01, 2024

"DASSAULT AVIATION Proprietary Data" T 55-00-00-220-801

Page: 12/15

Falcon 50 ● Rev. 038_005 ● FEB 01, 2024

AIRCRAFT MAINTENANCE MANUAL

Figure 4: INSPECTION OF THE HS CENTER BOX STRUCTURE

Print Date by FIELD6: APR 11, 2024 Effectivity: ALL

Sn: 225 FIELD6 paper version not maintained Rev. Date: FEB 01, 2024

"DASSAULT AVIATION Proprietary Data" T 55-00-00-220-801

Page: 13/15

Falcon 50 ● Rev. 038_005 ● FEB 01, 2024

AIRCRAFT MAINTENANCE MANUAL

Figure 5: INSPECTION OF SKIN AND STRUCTURE UNDER S-DUCT

Print Date by FIELD6: APR 11, 2024 Effectivity: ALL

Sn: 225 FIELD6 paper version not maintained Rev. Date: FEB 01, 2024

"DASSAULT AVIATION Proprietary Data" T 55-00-00-220-801

Page: 14/15

Falcon 50 ● Rev. 038_005 ● FEB 01, 2024

AIRCRAFT MAINTENANCE MANUAL

322A

322A

RIB12

VTP SKIN 1

RIB12

VTP SKIN

A/C WITH SMALL FIN TIP

322A

322B

322B

RIB12

1

VTP SKIN RIB12

VTP SKIN

A/C WITH SATCOM FIN TIP

Figure 6: FIN TIP FAIRING LOCATION

Print Date by FIELD6: APR 11, 2024 Effectivity: ALL

Sn: 225 FIELD6 paper version not maintained Rev. Date: FEB 01, 2024

"DASSAULT AVIATION Proprietary Data" T 55-00-00-220-801

Page: 15/15

You might also like

- 2082 S.R.M. Airbus A320Document1,415 pages2082 S.R.M. Airbus A320Jose Miguel Peña Palafox56% (16)

- Filtros Por EquiposDocument342 pagesFiltros Por EquiposJorge Galarce100% (1)

- SM-601 A2Document112 pagesSM-601 A2bob smith50% (2)

- Piper IPCDocument549 pagesPiper IPCmidun100% (1)

- Falcon - 2000 - PTM - V2r2 - MCD Description Des Systemes PDFDocument387 pagesFalcon - 2000 - PTM - V2r2 - MCD Description Des Systemes PDFRodrigo Alvarenga100% (2)

- 495bi ErbDocument408 pages495bi ErbWalisson100% (1)

- Service Parts List: R33425-5 4266886 Tamrock TransmissionDocument46 pagesService Parts List: R33425-5 4266886 Tamrock TransmissionXG W100% (1)

- Horizon Parts Manual (New Model) - Ilovepdf-CompressedDocument251 pagesHorizon Parts Manual (New Model) - Ilovepdf-CompressedS Sathish Kumar63% (8)

- CL20-30Cub SS4473x 4474x 4475xPLDocument59 pagesCL20-30Cub SS4473x 4474x 4475xPLDiana Zar100% (1)

- ALTIMETRDocument527 pagesALTIMETREleazar0% (1)

- Lockheed Field Service Digest FSD Vol.3 No.6 Intro L1649 Starliner Part 2 of 3Document32 pagesLockheed Field Service Digest FSD Vol.3 No.6 Intro L1649 Starliner Part 2 of 3arizonaflyer100% (1)

- A318/A319/A320/A321 (CFM56) : StructureDocument211 pagesA318/A319/A320/A321 (CFM56) : StructureRaby Abidi100% (1)

- Detailed Inspection of The Fuselage Lower Section Areas and of The Compartments Above The Feeder TanksDocument5 pagesDetailed Inspection of The Fuselage Lower Section Areas and of The Compartments Above The Feeder TanksAldo Gibran Esquivel CarmonaNo ratings yet

- T 55-10-31-220-801-Dimensional Check of Horizontal Stabilizer Rear HiDocument19 pagesT 55-10-31-220-801-Dimensional Check of Horizontal Stabilizer Rear HiAldo Gibran Esquivel CarmonaNo ratings yet

- T 53-80-09-710-801-Operational Test of The 'Circle Seal' Automatic DRDocument4 pagesT 53-80-09-710-801-Operational Test of The 'Circle Seal' Automatic DRAldo Gibran Esquivel CarmonaNo ratings yet

- Detailed Inspection of The Fuselage Structural Fuel Tanks: Aircraft Maintenance ManualDocument24 pagesDetailed Inspection of The Fuselage Structural Fuel Tanks: Aircraft Maintenance ManualAldo Gibran Esquivel CarmonaNo ratings yet

- Rack de Tuberia Rack de Tuberia: 3400-15R-701 0T 240K-C2-1:250Document1 pageRack de Tuberia Rack de Tuberia: 3400-15R-701 0T 240K-C2-1:250Jose Kylle Unocc YauriNo ratings yet

- Trial SheetDocument7 pagesTrial SheetGauranka MoranNo ratings yet

- List of Qa Equiptment For CalibrationDocument26 pagesList of Qa Equiptment For CalibrationVincent EbdaniNo ratings yet

- T 55-00-00-270-801-Ultrasonic Inspection For Stress Corrosion in StabDocument29 pagesT 55-00-00-270-801-Ultrasonic Inspection For Stress Corrosion in StabAldo Gibran Esquivel CarmonaNo ratings yet

- cfm56-7 CAPDocument12 pagescfm56-7 CAPMohsen PeykaranNo ratings yet

- 1 15 C050 SpecificationsDocument335 pages1 15 C050 SpecificationsPhạm Thanh PhươngNo ratings yet

- 26071-100-V2a-H701-04002 - R02 - Datasheet For MFDDocument54 pages26071-100-V2a-H701-04002 - R02 - Datasheet For MFDogyriskyNo ratings yet

- A. For Structural Identification See .: Learjet 20/30 Series Structural Repair ManualDocument29 pagesA. For Structural Identification See .: Learjet 20/30 Series Structural Repair ManualMartin RicciutiNo ratings yet

- Water Cleaning and Blasting Catalogue 2021 V1 1Document36 pagesWater Cleaning and Blasting Catalogue 2021 V1 1Nikola AngjelkovskiNo ratings yet

- Avionics Circuit Breaker Panel - 17280001 Thru 17280003 REF Nomenclature Effectivity DES Number 1 2 3 4 5 6 7 From TO Units PER AssyDocument2 pagesAvionics Circuit Breaker Panel - 17280001 Thru 17280003 REF Nomenclature Effectivity DES Number 1 2 3 4 5 6 7 From TO Units PER AssybnolascoNo ratings yet

- 221 VS 218 VS 215Document76 pages221 VS 218 VS 215Juan Jose MurilloNo ratings yet

- AMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Document38 pagesAMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Andre SanarNo ratings yet

- TM 5-5420-209-12 Ribbon BridgeDocument609 pagesTM 5-5420-209-12 Ribbon BridgeAdvocateNo ratings yet

- Cause and Effect DiagramDocument18 pagesCause and Effect Diagramwado11100% (3)

- 3.500 Heavy Duty Tubing SwivelDocument2 pages3.500 Heavy Duty Tubing SwivelJack Foster100% (1)

- 00.00.00184 (Part Departing From Aircraft (Pda) )Document5 pages00.00.00184 (Part Departing From Aircraft (Pda) )Manish ShAhNo ratings yet

- Still Forklift Spares List PM-159015ENDocument2,052 pagesStill Forklift Spares List PM-159015ENI hartNo ratings yet

- 3016FHR24321 110 - TPL 3501 - 2019 11 18Document52 pages3016FHR24321 110 - TPL 3501 - 2019 11 18Павел ПосканныйNo ratings yet

- Only Reference 2023Document32 pagesOnly Reference 2023Luis miguel SanchezNo ratings yet

- KTA - TB-PAC03-M07-005.Rev0 - GLYCOL REBOILER & STILL COLUMN PIDDocument2 pagesKTA - TB-PAC03-M07-005.Rev0 - GLYCOL REBOILER & STILL COLUMN PIDlamNo ratings yet

- DPR - 18-06-2023Document1 pageDPR - 18-06-2023Muhammad AftabNo ratings yet

- Vdocuments - MX - JCB Seal Kit PDFDocument20 pagesVdocuments - MX - JCB Seal Kit PDFKo NgelayNo ratings yet

- 24-21-00-210-811-A - Check Torque of IDG Quick-Attach-Detach Tension BoltDocument7 pages24-21-00-210-811-A - Check Torque of IDG Quick-Attach-Detach Tension BoltHarold Boya AncichoNo ratings yet

- Condensador York YD180Document6 pagesCondensador York YD180Arturo SinecioNo ratings yet

- DF410 - JCB PowerunitDocument2 pagesDF410 - JCB PowerunitBenjamin MurphyNo ratings yet

- Tools and Materials List F 040 GL 5000Document548 pagesTools and Materials List F 040 GL 5000leonid765890No ratings yet

- Service Bulletin: Piper Considers Compliance MandatoryDocument5 pagesService Bulletin: Piper Considers Compliance MandatoryАндрей ОлейникNo ratings yet

- Ilovepdf MergedDocument816 pagesIlovepdf MergedLytmerAcuña100% (1)

- Appendix A-2 Service BulletinDocument3 pagesAppendix A-2 Service BulletinquyNo ratings yet

- AMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Document15 pagesAMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Andre SanarNo ratings yet

- Service Publications: Number SubjectDocument5 pagesService Publications: Number Subjectpiyush agrawalNo ratings yet

- 4295 Spare Parts Front Page DD210Document42 pages4295 Spare Parts Front Page DD210Mep RoleroNo ratings yet

- Section III - Details: Aisd Project Development ManualDocument136 pagesSection III - Details: Aisd Project Development ManualAhmed LabibNo ratings yet

- Motor Load List - VRMDocument21 pagesMotor Load List - VRMmanohar1005No ratings yet

- 5307 Spare Parts Front Page DD210L-VDocument42 pages5307 Spare Parts Front Page DD210L-VrolandNo ratings yet

- cfm56-7 CAPDocument12 pagescfm56-7 CAPgarsi2346No ratings yet

- LS1000 Series Leroy Somer AlternatorDocument7 pagesLS1000 Series Leroy Somer AlternatorHavijaniNo ratings yet

- Air Leak Test Machine Lynx.6Document1 pageAir Leak Test Machine Lynx.6Tinu SebastianNo ratings yet

- Clesta Chair Parts ListDocument20 pagesClesta Chair Parts ListTalal Sindi-AlNo ratings yet

- 05 - Sistema de Saida de Ar e ExaustaoDocument14 pages05 - Sistema de Saida de Ar e ExaustaoFabio MacielNo ratings yet

- Technical Data Sheet and Ga of Packaged Ac & Split Ac Units: 00 14.12.2020 For Information S.Saravanan RBK RBKDocument7 pagesTechnical Data Sheet and Ga of Packaged Ac & Split Ac Units: 00 14.12.2020 For Information S.Saravanan RBK RBKAshok reddyNo ratings yet

- Super m2 New Offshore RigDocument50 pagesSuper m2 New Offshore RigcatullusNo ratings yet

- Maintanence Check ListDocument225 pagesMaintanence Check Listsuraj rawatNo ratings yet

- Pressurization of The Hydraulic Reservoirs Through The Ground ConnectorDocument5 pagesPressurization of The Hydraulic Reservoirs Through The Ground ConnectorAdrianGilRojanoNo ratings yet

- 2518TM BsiiiDocument707 pages2518TM Bsiiipadmanabank_1100% (1)

- Air Blower Haya Water VerfDocument9 pagesAir Blower Haya Water Verfgharsallah mounaNo ratings yet

- DAIHATSU SERVICE INFORMATION (Read-Only) PDFDocument96 pagesDAIHATSU SERVICE INFORMATION (Read-Only) PDFSajeev NerurkarNo ratings yet

- Alarm Codes List-ND051R00EHEDocument5 pagesAlarm Codes List-ND051R00EHEAbu FatihNo ratings yet

- AMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Document5 pagesAMM - JAT - A318/A319/A320/A321 REV DATE: May 01/2022 Tail Number - MSN - FSN: CC-AWK - 09328 - 102Andre SanarNo ratings yet

- Index: Aircraft Design Project - IIDocument56 pagesIndex: Aircraft Design Project - IIRohit MunaNo ratings yet

- FAA 2019 0710 0005 - Attachment - 1Document48 pagesFAA 2019 0710 0005 - Attachment - 1burakNo ratings yet

- РЛЭ l410uvp e20 h80 EnDocument478 pagesРЛЭ l410uvp e20 h80 EnСергей БагрецовNo ratings yet

- Modern Aircraft Design Techniques (William H. Mason)Document24 pagesModern Aircraft Design Techniques (William H. Mason)aeroacademicNo ratings yet

- Piper J-3 CubDocument15 pagesPiper J-3 CubAviation/Space History Library100% (8)

- M11 Past PaperDocument25 pagesM11 Past PaperMuhammad ShoaibNo ratings yet

- Detailed Structural LayoutsDocument8 pagesDetailed Structural LayoutsVenkatNo ratings yet

- Ch2 Conceptual Design ConfigurationDocument31 pagesCh2 Conceptual Design ConfigurationkwangsooNo ratings yet

- Aircraft Structure.Document6 pagesAircraft Structure.Сајам СудибиоNo ratings yet

- Training Manual: EASA Part-66 57 Level 3Document40 pagesTraining Manual: EASA Part-66 57 Level 3Luis Enrique La Font FrancoNo ratings yet

- Detailed Design of 120 Seater Passenger Aircraft - Aircraft Design Project-IIDocument71 pagesDetailed Design of 120 Seater Passenger Aircraft - Aircraft Design Project-IIShàñkâr À SháñzNo ratings yet

- Aviation Structural Mechanic (H& S) 3 & 2Document700 pagesAviation Structural Mechanic (H& S) 3 & 2Bob KowalskiNo ratings yet

- PA-18 150 SuperCub Parts Catalog Complete)Document164 pagesPA-18 150 SuperCub Parts Catalog Complete)martinhocandido8448No ratings yet

- FLEX BEAM Bell 206Document7 pagesFLEX BEAM Bell 206Lewis MarcvsNo ratings yet

- Corsair InstructionmanualDocument45 pagesCorsair InstructionmanualJorge José Figueiredo SiqueiraNo ratings yet

- Aircraft Design 30Document23 pagesAircraft Design 30Paul GernahNo ratings yet

- Manual Luscombe PDFDocument85 pagesManual Luscombe PDFSantiago AlthabeNo ratings yet

- PC 761638Document392 pagesPC 761638Clyde Bonnie100% (1)

- Equipment & FurnishingDocument96 pagesEquipment & FurnishingAl Iskandari Avfan HudaNo ratings yet

- HPC Airbus A350 XWBDocument4 pagesHPC Airbus A350 XWBMohammad NorouzzadehNo ratings yet

- Dgca Module 11 Part 02 PDFDocument21 pagesDgca Module 11 Part 02 PDFBhaskerNegiNo ratings yet

- Fuselage StructureDocument3 pagesFuselage StructureKabilan SiranjiviNo ratings yet