Professional Documents

Culture Documents

American Institute of Steel CoAnchor Rods (2004) 2nd Edition 20

American Institute of Steel CoAnchor Rods (2004) 2nd Edition 20

Uploaded by

behnam fallah0 ratings0% found this document useful (0 votes)

0 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

0 views1 pageAmerican Institute of Steel CoAnchor Rods (2004) 2nd Edition 20

American Institute of Steel CoAnchor Rods (2004) 2nd Edition 20

Uploaded by

behnam fallahCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

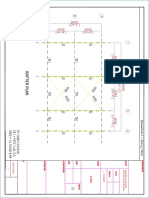

izontal X-bracing system comprises axially loaded mem- Solution:

bers arranged as shown in Figure 5.3.1, the bracing can be

Because the diagonal bracing layout as shown in Figure

designed for 0.6 percent of the truss chord axial load. Since

5.3.2 forms an angle of 45 degrees with the trusses, the

two truss chord sections are being braced at each bracing

solution used in the paper by Nair, (1988b) is suitable. The

strut location the strut connections to the trusses must be

bracing force thus equals 0.6 percent of the chord axial

designed for 1.2 percent of the average chord axial load for

load. Member forces are summarized above.

the two adjacent chords. In the reference it is pointed out

that the bracing forces do not accumulate along the length

5.4 Erection Bracing

of the truss; however, the brace force requirements do accu-

mulate based on the number of trusses considered braced by The engineer of record is not responsible for the design of

the bracing system. erection bracing unless specific contract arrangements

In addition to stability bracing, top and bottom chord incorporate this responsibility into the work. However,

bracing may also be required to transfer wind or seismic lat- designers must be familiar with OSHA erection require-

eral loads to the main lateral stability system. The force ments (OSHA, 2001) relative to their designs.

requirements for the lateral loads must be added to the sta- Even though the designer of trusses is not responsible for

bility force requirements. Lateral load bracing is placed in the erection bracing, the designer should consider sequence

either the plane of the top chord or the plane of the bottom and bracing requirements in the design of large trusses in

chord, but generally not in both planes. Stability require- order to provide the most cost effective system. Large

ments for the unbraced plane can be transferred to the later- trusses require significant erection bracing not only to resist

ally braced plane by using vertical sway braces. wind and construction loads but also to provide stability

until all of the gravity load bracing is installed. Significant

EXAMPLE 5.3.1 cost savings can be achieved if the required erection brac-

ing is incorporated into the permanent bracing system.

Roof Truss Stability Bracing

Erection is generally accomplished by first connecting

For the truss system shown in Figure 5.3.2 determine the two trusses together with strut braces and any additional

brace forces in the horizontal bracing system. Use the pro- erection braces to form a stable box system. Additional

cedure discussed by (Nair, 1988b). trusses are held in place by the crane or cranes until they

can be “tied off” with strut braces to the already erected sta-

ble system. Providing the necessary components to facili-

tate this type of erection sequence is essential for a cost

1 2 3 4 5 6 7

effective project.

A

Additional considerations are as follows:

1. Columns are usually erected first with the lateral brac-

B

ing system (see Figure 5.4.1). If top chord seats are

Web

Diagonals

C

Horizontal

Truss Bracing installed

45°

D while crane holds

Chord

Bearing trusses.

Seats

E Column

Bracing Truss

Struts

F

Bracing

Framing Plan installed

prior to

(600k) (800k) (1000k)

truss

erection.

Column

Top Chord Seats Bottom Bearing

Truss Elevation

Fig. 5.3.2 Horizontal Bracing Systen Fig. 5.4.1 Wall Bracing Erection Sequence

DESIGN GUIDE 7 / INDUSTRIAL BUILDINGS—ROOFS TO ANCHOR RODS, 2ND EDITION / 13

You might also like

- Sweeper (54 - ) (60 - ) (72 - ) - (S - N 782600101 & Above, 714400101 & Above, 783700101 & Above) - SweeperDocument8 pagesSweeper (54 - ) (60 - ) (72 - ) - (S - N 782600101 & Above, 714400101 & Above, 783700101 & Above) - SweeperCristian SchildNo ratings yet

- Logan Standard Releasing Spear ManualDocument37 pagesLogan Standard Releasing Spear ManualSamuel Arévalo GNo ratings yet

- Design For Rigging and Transportation of Large Process columns-HP Article PDFDocument3 pagesDesign For Rigging and Transportation of Large Process columns-HP Article PDFManish542No ratings yet

- AISC - Design Guide 10 - Errata - Erection Bracing of Low - Rise Structural Steel Buildings PDFDocument2 pagesAISC - Design Guide 10 - Errata - Erection Bracing of Low - Rise Structural Steel Buildings PDFapuhapuh_153349No ratings yet

- Steel ConnectionsDocument6 pagesSteel ConnectionsABEGAIL LARONNo ratings yet

- Effective Span Length: 139 Concrete Deck SlabsDocument5 pagesEffective Span Length: 139 Concrete Deck SlabsJohn Royer Araúz Fuentes100% (1)

- Tension Field Design of Tapered WebsDocument7 pagesTension Field Design of Tapered WebsTigredesudafricaNo ratings yet

- Effective Lengthsof Uniformand Stepped Crane ColumnsDocument9 pagesEffective Lengthsof Uniformand Stepped Crane ColumnspruebaNo ratings yet

- IMG - 0095 PSME Code 2008 86Document1 pageIMG - 0095 PSME Code 2008 86Arwyn BermasNo ratings yet

- TYPICALLY' TORSION Has An Effect: ForceDocument6 pagesTYPICALLY' TORSION Has An Effect: ForceLaura PascuazaNo ratings yet

- MSC 2005-04 THoltermann EfficientlyDocument5 pagesMSC 2005-04 THoltermann EfficientlyJuan HernanNo ratings yet

- التصميم الزلزالي للديافرامات البيتونية المسلحةDocument56 pagesالتصميم الزلزالي للديافرامات البيتونية المسلحةmsdNo ratings yet

- 800-4 ExtractDocument17 pages800-4 Extractsai vivekNo ratings yet

- 10 1016@j JCSR 2017 07 022Document17 pages10 1016@j JCSR 2017 07 022Siti Aisyah NurjannahNo ratings yet

- EJ Fisher BracingwithJoistsDocument6 pagesEJ Fisher BracingwithJoistsGabby KenNo ratings yet

- Bracing RulesDocument3 pagesBracing RulesSelahattinNo ratings yet

- Journal of Constructional Steel ResearchDocument17 pagesJournal of Constructional Steel ResearchNaomi PratiwiNo ratings yet

- Bridge Design - Grillage Analysis Tutorial For Bridge Decks To British StandardsDocument10 pagesBridge Design - Grillage Analysis Tutorial For Bridge Decks To British StandardsvinodNo ratings yet

- Punching Shear ReinforcementDocument12 pagesPunching Shear ReinforcementMạnh ThànhNo ratings yet

- 8 Braces and Ties (Compatibility Mode)Document16 pages8 Braces and Ties (Compatibility Mode)susan870% (1)

- Depth I Ys: Will Volve ElowDocument26 pagesDepth I Ys: Will Volve ElowPaulNo ratings yet

- Punching Shear Reinforcement: For The Construction IndustryDocument12 pagesPunching Shear Reinforcement: For The Construction IndustrySuhail AhamedNo ratings yet

- PurlinDocument19 pagesPurlinLia Ame100% (2)

- Grillage Analysis SampleDocument6 pagesGrillage Analysis SamplerenandNo ratings yet

- Chevron Effect AISC PublicationDocument40 pagesChevron Effect AISC Publicationamanpreet_ahujaNo ratings yet

- CFR 2011 Title29 Vol8 Sec1926 704Document1 pageCFR 2011 Title29 Vol8 Sec1926 704Arnold GarciaNo ratings yet

- GrillageDocument6 pagesGrillagevasanthk81No ratings yet

- 2.3.2 Establishing Equivalent Static Fatigue Loads For Noncantilevered Support StructuresDocument1 page2.3.2 Establishing Equivalent Static Fatigue Loads For Noncantilevered Support Structuresanwarali1975No ratings yet

- SB CatalogueDocument48 pagesSB CatalogueShamik BiswasNo ratings yet

- Lifting Design ConsiderationsDocument3 pagesLifting Design ConsiderationsNed VasicNo ratings yet

- 4.1 - Lifting OverviewDocument47 pages4.1 - Lifting OverviewNguyễnThànhThépNo ratings yet

- F Truss Bracing1 PDFDocument4 pagesF Truss Bracing1 PDFpallavi guptaNo ratings yet

- Steel BracingsDocument6 pagesSteel BracingsLleiLlei100% (1)

- PT Foundations-4Document5 pagesPT Foundations-4YNNo ratings yet

- Unified Shear DesignDocument6 pagesUnified Shear DesignKemz JancordaNo ratings yet

- Journal of Constructional Steel ResearchDocument16 pagesJournal of Constructional Steel ResearchfankenstainNo ratings yet

- Alston Ladder Bar InstallDocument5 pagesAlston Ladder Bar InstalldanescoNo ratings yet

- One Engineer's Opinion - Bolted SplicesDocument2 pagesOne Engineer's Opinion - Bolted SplicesDoctoreNo ratings yet

- (Sabelli Et Al. 2013) : Page - 1Document36 pages(Sabelli Et Al. 2013) : Page - 1Harshit NagarNo ratings yet

- American Institute of Steel CoAnchor Rods (2004) 2nd Edition 18Document1 pageAmerican Institute of Steel CoAnchor Rods (2004) 2nd Edition 18behnam fallahNo ratings yet

- Bulletin No 2018 12Document13 pagesBulletin No 2018 12pkh25739No ratings yet

- Steelwise PDFDocument3 pagesSteelwise PDFFourHorsemenNo ratings yet

- GN Guideline 197Document1 pageGN Guideline 197Zac Francis DaymondNo ratings yet

- Kippap-Handout-SEC (40 RCD - Footings)Document10 pagesKippap-Handout-SEC (40 RCD - Footings)top1echolocoNo ratings yet

- Application of AISC Design Provisions For Tapered Members PDFDocument13 pagesApplication of AISC Design Provisions For Tapered Members PDFclam2014No ratings yet

- S B RCC V T C: Eismic Ehavior of Olumns With Arious IE Onfigurations by Y. L. Mo, Member, ASCE, and S. J. WangDocument9 pagesS B RCC V T C: Eismic Ehavior of Olumns With Arious IE Onfigurations by Y. L. Mo, Member, ASCE, and S. J. Wangdexter238No ratings yet

- Local Buckling: C RveDocument1 pageLocal Buckling: C RveprateekmuleNo ratings yet

- CRSI Manual To Design RC Diaphragms - Part12Document4 pagesCRSI Manual To Design RC Diaphragms - Part12Adam Michael GreenNo ratings yet

- ViewPoint March 2021Document7 pagesViewPoint March 2021Premnath YadavNo ratings yet

- FHWA-Steel Bridge Design - 2022Document1 pageFHWA-Steel Bridge Design - 2022Tam CaptainNo ratings yet

- Demountable Flares DatasheetDocument2 pagesDemountable Flares Datasheetmanojeil1No ratings yet

- American Institute of Steel CoAnchor Rods (2004) 2nd Edition 31Document1 pageAmerican Institute of Steel CoAnchor Rods (2004) 2nd Edition 31behnam fallahNo ratings yet

- 3 Ieg 3260 3-LRFD Aashto 4-56-61Document6 pages3 Ieg 3260 3-LRFD Aashto 4-56-61Francisco CarrascoNo ratings yet

- ERSS-Lecture 6 (ChiewSP 6mar20)Document51 pagesERSS-Lecture 6 (ChiewSP 6mar20)sunilarunaNo ratings yet

- Additional Class Materials BES322748 Breaking Down Steelto Concrete Connection Designand Workflow Limitations Mario FitzDocument10 pagesAdditional Class Materials BES322748 Breaking Down Steelto Concrete Connection Designand Workflow Limitations Mario FitzEDDYVECENo ratings yet

- Module-3 1Document20 pagesModule-3 1Prince Gerald VargasNo ratings yet

- Evaluation of Load Transfer and Strut Strength of Deep BeamDocument12 pagesEvaluation of Load Transfer and Strut Strength of Deep BeamProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNo ratings yet

- Chapter 5 Post-Tensioned SlabDocument19 pagesChapter 5 Post-Tensioned SlabSharan BvpNo ratings yet

- ASCE 7-05 Section13.5Document8 pagesASCE 7-05 Section13.5Emre EgribozNo ratings yet

- DSS PDF 2Document1 pageDSS PDF 2Antharya N shettyNo ratings yet

- American Institute of Steel CoAnchor Rods (2004) 2nd Edition 70Document1 pageAmerican Institute of Steel CoAnchor Rods (2004) 2nd Edition 70behnam fallahNo ratings yet

- CAEPIPE - Code - Compliance - Manual 164Document1 pageCAEPIPE - Code - Compliance - Manual 164behnam fallahNo ratings yet

- American Institute of Steel CoAnchor Rods (2004) 2nd Edition 32Document1 pageAmerican Institute of Steel CoAnchor Rods (2004) 2nd Edition 32behnam fallahNo ratings yet

- American Institute of Steel CoAnchor Rods (2004) 2nd Edition 26Document1 pageAmerican Institute of Steel CoAnchor Rods (2004) 2nd Edition 26behnam fallahNo ratings yet

- 336146044-XXX-XXXX-XXX-Details-Structural-Calculation-Report 9Document1 page336146044-XXX-XXXX-XXX-Details-Structural-Calculation-Report 9behnam fallahNo ratings yet

- Limit - States - of - Steel - Supporting - Structure - For - Bri 8Document1 pageLimit - States - of - Steel - Supporting - Structure - For - Bri 8behnam fallahNo ratings yet

- CAEPIPE - Code - Compliance - Manual 100Document1 pageCAEPIPE - Code - Compliance - Manual 100behnam fallahNo ratings yet

- Apa-Zhd-Pr-Cal-026 19Document1 pageApa-Zhd-Pr-Cal-026 19behnam fallahNo ratings yet

- Apa-Zhd-Pr-Cal-026 15Document1 pageApa-Zhd-Pr-Cal-026 15behnam fallahNo ratings yet

- Binder1 1Document1 pageBinder1 1behnam fallahNo ratings yet

- Apa-Zhd-Pr-Cal-026 13Document1 pageApa-Zhd-Pr-Cal-026 13behnam fallahNo ratings yet

- Operating and Installation Instructions: Pressure Reducing Station Ari-Presys (Type PRS)Document13 pagesOperating and Installation Instructions: Pressure Reducing Station Ari-Presys (Type PRS)behnam fallahNo ratings yet

- Druckminderstation 300 200 eDocument35 pagesDruckminderstation 300 200 ebehnam fallahNo ratings yet

- AJEAT Vol.7 No.S1 April 2018 Pp. 7 10Document5 pagesAJEAT Vol.7 No.S1 April 2018 Pp. 7 10behnam fallahNo ratings yet

- Safety Shut Off Valve DatasheetDocument3 pagesSafety Shut Off Valve Datasheetbehnam fallahNo ratings yet

- 1100-ME-DST-001 - Rev.1A - Data Sheet Hari Pig Launcher (1194-V-101)Document6 pages1100-ME-DST-001 - Rev.1A - Data Sheet Hari Pig Launcher (1194-V-101)Didi Hadi RiantoNo ratings yet

- Quick Build 3D PanelDocument4 pagesQuick Build 3D Paneldivyanshu33No ratings yet

- Concealedhinges Ep Dok Bus $sus $aof $v14Document110 pagesConcealedhinges Ep Dok Bus $sus $aof $v14john smithNo ratings yet

- Fisher YD and YS 3 Way Valves: Scope of ManualDocument32 pagesFisher YD and YS 3 Way Valves: Scope of ManualbondsivamaniNo ratings yet

- A Practical Course in Mechanical Drawing PDFDocument168 pagesA Practical Course in Mechanical Drawing PDFДмитрий Бойко100% (1)

- Sap ReportDocument42 pagesSap Reportnaqibullah.ib165No ratings yet

- Structural Steel International StandardsDocument4 pagesStructural Steel International StandardsnguyenquanghiepNo ratings yet

- Personal DataDocument2 pagesPersonal DataAnsol - Cold ChainNo ratings yet

- Viking Xtreme: Extreme EnvironmentsDocument17 pagesViking Xtreme: Extreme EnvironmentsAnibal Jose Cruz LarezNo ratings yet

- Marine Railway Site InstallationDocument14 pagesMarine Railway Site Installationtapumonisha.navalNo ratings yet

- Pract 02Document3 pagesPract 02Timothy CNo ratings yet

- Milling CNCDocument1 pageMilling CNCAlteknologi Bahtera PrayataNo ratings yet

- Company Profile - VerlindeDocument8 pagesCompany Profile - Verlindesaddam4everNo ratings yet

- 14Document1 page14ျမတ္ သူ ေအာင္No ratings yet

- AD-9 Air Dryer (SD-08-2412)Document20 pagesAD-9 Air Dryer (SD-08-2412)Jefe nacional De flotaNo ratings yet

- Installation and Maintenance Manual: Centrifugal Fans At-As-Ash-Rsh-Adh-RdhDocument31 pagesInstallation and Maintenance Manual: Centrifugal Fans At-As-Ash-Rsh-Adh-Rdhshahzad32552372No ratings yet

- Tyre Coupling CatalogDocument9 pagesTyre Coupling CatalogKariem R NoweerNo ratings yet

- Gearbox AT2612F - FACT SHEET AT2612FDocument4 pagesGearbox AT2612F - FACT SHEET AT2612FlushnuNo ratings yet

- Spare Parts Catalogue: Type Gear Reduction UnitsDocument19 pagesSpare Parts Catalogue: Type Gear Reduction UnitsAio JumaNo ratings yet

- Bermudian Articles - Draught of Water and FreeboardDocument1 pageBermudian Articles - Draught of Water and Freeboardadel belkacemNo ratings yet

- Consumer Reports Buying Guide 2012 - Vacuum CleanersDocument7 pagesConsumer Reports Buying Guide 2012 - Vacuum Cleanersdesijnk100% (1)

- Design Calculation Sheet: Project No: Date: Sheet No.:1 1 Computed By: SubjectDocument1 pageDesign Calculation Sheet: Project No: Date: Sheet No.:1 1 Computed By: SubjectfebousNo ratings yet

- Toyota 7FG 7FD 7FGK 7FDK Forklift Trucks Repair ManualDocument111 pagesToyota 7FG 7FD 7FGK 7FDK Forklift Trucks Repair ManualPedro Filipe CerqueiraNo ratings yet

- ClassNK PSCMDocument36 pagesClassNK PSCMBudi SetiawanNo ratings yet

- 6.1 Chamber R1Document2 pages6.1 Chamber R1unnicyriacNo ratings yet

- 04 Power TransmissionDocument66 pages04 Power TransmissionAbdul Hani MohammedNo ratings yet

- Overhaul Tangki-5t-25Document7 pagesOverhaul Tangki-5t-25prasetyo bbiNo ratings yet

- Lecture 8 - MDPE - Design of Nozzles & FlangeDocument26 pagesLecture 8 - MDPE - Design of Nozzles & FlangePatel DhruvilNo ratings yet