Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

1 viewsHot Work Permit, Tyson Form 16147

Hot Work Permit, Tyson Form 16147

Uploaded by

Wan Nasrul MuhaiminCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Carpentry Canadian 3rd Edition Vogt Solutions ManualDocument11 pagesCarpentry Canadian 3rd Edition Vogt Solutions Manualalisonfernandezmerzigfkap100% (12)

- Hot Work Permit - Daily - K2C - 012Document1 pageHot Work Permit - Daily - K2C - 012wlyNo ratings yet

- Hot Work Permit FormDocument2 pagesHot Work Permit FormN.JNo ratings yet

- Hot Works PresentationDocument33 pagesHot Works Presentationpammu18100% (1)

- Sample Hot Work PermitDocument1 pageSample Hot Work PermitAndre Mars100% (2)

- Hot Work Permit WordDocument3 pagesHot Work Permit Wordmush0025No ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Ace Hot Work Permit Application Form PDFDocument3 pagesAce Hot Work Permit Application Form PDFkevin100% (1)

- Hot Work Permit: Can This Job Be Avoided? Is There A Safer Alternative?Document6 pagesHot Work Permit: Can This Job Be Avoided? Is There A Safer Alternative?Wee Soon ChaiNo ratings yet

- Hot Work Permit IMEXDocument2 pagesHot Work Permit IMEXsophia samba100% (1)

- ATT 3 Hot Works PermitDocument2 pagesATT 3 Hot Works PermitSamsu Usup SudiarsonoNo ratings yet

- Hot Work Permit Hsems Ocp 01 F 03Document2 pagesHot Work Permit Hsems Ocp 01 F 03Raju BiswasNo ratings yet

- Work Permit SystemDocument38 pagesWork Permit SystemNaveen Meena50% (2)

- Hot Work Permit TemplateDocument2 pagesHot Work Permit TemplatemullaijoeNo ratings yet

- Hot Work PermitDocument17 pagesHot Work Permituday0% (1)

- Hot Work Permit: This Permit Is Not Valid Unless All Appropriate Fields Are CompletedDocument2 pagesHot Work Permit: This Permit Is Not Valid Unless All Appropriate Fields Are CompletedEl Saleh newcapital100% (1)

- Hot Work Permit: Must Must Must Must MustDocument1 pageHot Work Permit: Must Must Must Must MustAryan DashNo ratings yet

- Hot Work PermitDocument3 pagesHot Work PermitjitheshsvNo ratings yet

- Hot Work Procedure 2021Document8 pagesHot Work Procedure 2021Wan Ahmad FaaizunNo ratings yet

- Preh W CheckDocument2 pagesPreh W CheckMd UsamaNo ratings yet

- 06 170914 TBX12 HotworksDocument2 pages06 170914 TBX12 HotworksJason LeonardNo ratings yet

- Hot Work PermitDocument2 pagesHot Work Permitkumar kannanNo ratings yet

- SF-012 Hot Works Permit - Rev 0.2Document5 pagesSF-012 Hot Works Permit - Rev 0.2Noer Amalia PuspitaNo ratings yet

- SAMPLE Winery Hot Work PermitDocument3 pagesSAMPLE Winery Hot Work PermitMohammed Ali QaziNo ratings yet

- Hot Work PermitDocument18 pagesHot Work PermitMuneeb Ur RehmanNo ratings yet

- Permit To WorkDocument3 pagesPermit To WorkPrinterHaapcolNo ratings yet

- Hot Work PermitDocument1 pageHot Work PermitExhausted bearNo ratings yet

- Hotworking Permits 2Document3 pagesHotworking Permits 2MouctarNo ratings yet

- AIG Hot Work Permit Only Rev 120618Document6 pagesAIG Hot Work Permit Only Rev 120618Herik renaldoNo ratings yet

- Hot Work Permit FormDocument3 pagesHot Work Permit FormKarthik KarunanithiNo ratings yet

- Hot Work Policy FS 15Document8 pagesHot Work Policy FS 15sunil92lNo ratings yet

- Hot Work Permit To WorkDocument3 pagesHot Work Permit To WorkMorris M.No ratings yet

- Hot WorkDocument4 pagesHot WorkMesa MesaNo ratings yet

- CAT-08 Hot Work and Safe Work-EnglishDocument23 pagesCAT-08 Hot Work and Safe Work-EnglishDanNo ratings yet

- Hot Work Permits: Corporate Environment Safety & HealthDocument17 pagesHot Work Permits: Corporate Environment Safety & HealthpraneshrshahNo ratings yet

- Hot Work TBTDocument1 pageHot Work TBTkowshickNo ratings yet

- Hot Work PermitDocument1 pageHot Work PermitMenGuitarNo ratings yet

- PTW For Hot Work: Pakistan EPCL PVC Expansion ProjectDocument1 pagePTW For Hot Work: Pakistan EPCL PVC Expansion ProjectMuhammad RafiqueNo ratings yet

- Hot Work Policy 2010Document5 pagesHot Work Policy 2010vinoz2022 regNo ratings yet

- Cis Hot Works PermitDocument3 pagesCis Hot Works PermitparhamadkNo ratings yet

- PDF - Hot Work PermitDocument2 pagesPDF - Hot Work Permitdcf67my100% (2)

- Permit To Work - Hot Works: This Permit Is Valid Only For The Job Described and The Timescales ProvidedDocument3 pagesPermit To Work - Hot Works: This Permit Is Valid Only For The Job Described and The Timescales ProvidedJohn BusherNo ratings yet

- Penn State University Hot Work PermitsDocument21 pagesPenn State University Hot Work PermitsFOZCANNo ratings yet

- Hot Work Permit SampleDocument2 pagesHot Work Permit SampleMark Roger Huberit II0% (1)

- Mukand Sumi Special Steels: Safety ChecksDocument3 pagesMukand Sumi Special Steels: Safety ChecksPrashanth JeerNo ratings yet

- Work Permit FormatDocument12 pagesWork Permit FormatAejaz Mujawar0% (1)

- Hot Work Permit: SI Tracking #Document6 pagesHot Work Permit: SI Tracking #gurvinder singhNo ratings yet

- Hot Work PermitDocument1 pageHot Work PermitAMG Co.No ratings yet

- Hot Work Permit: 1. General PrecautionsDocument3 pagesHot Work Permit: 1. General PrecautionsAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Hot Welding CuttingDocument19 pagesHot Welding Cuttingtheblues2708No ratings yet

- Permit To Hot WorkDocument2 pagesPermit To Hot WorkSaleh AlomariNo ratings yet

- PTWDocument54 pagesPTWSunil Kumar VishwakarmaNo ratings yet

- Hot Work Permit For Confined SpaceDocument3 pagesHot Work Permit For Confined SpaceDarus IshakNo ratings yet

- Safety Praktis.Document2 pagesSafety Praktis.icha Razita sabrina aliNo ratings yet

- 1 HotworkDocument1 page1 Hotworkchariot1729No ratings yet

- Hot Work Permits: Corporate Environment Safety & HealthDocument17 pagesHot Work Permits: Corporate Environment Safety & HealthMohammad AshpakNo ratings yet

- Hot Work Permit: Work On Walls or Ceilings/enclosed EquipmentDocument4 pagesHot Work Permit: Work On Walls or Ceilings/enclosed Equipmentleonel bayutasNo ratings yet

- Methodology - Hot WorksDocument5 pagesMethodology - Hot WorksPortia IbiasNo ratings yet

- Hot Work Permit Procedures: Olumbia NiversityDocument6 pagesHot Work Permit Procedures: Olumbia NiversityMairaj UddinNo ratings yet

- Hot Work PermitDocument5 pagesHot Work PermitNoel Delos ReyesNo ratings yet

- Excel CompuDocument719 pagesExcel CompuTania BenavidesNo ratings yet

- Textil Framework Documento 1Document13 pagesTextil Framework Documento 1Renato Del CidNo ratings yet

- Environmental Design of Atrium Buildings in The U.K.: F. MillsDocument9 pagesEnvironmental Design of Atrium Buildings in The U.K.: F. MillsThắm PhạmNo ratings yet

- Aluminum Box Section 80X50X4MM THK. Ms L Angle 35X35X3Mm Thk. 50Mm WidthDocument1 pageAluminum Box Section 80X50X4MM THK. Ms L Angle 35X35X3Mm Thk. 50Mm WidthSiva RajanNo ratings yet

- Pyrocrete 341 PDSDocument6 pagesPyrocrete 341 PDSRicardo SantosNo ratings yet

- Bollard InstallationDocument3 pagesBollard InstallationBryan HermawanNo ratings yet

- ACI Egg Protection Device CompetitionDocument9 pagesACI Egg Protection Device Competitionmarcelo obandoNo ratings yet

- Istructe Ec2 (Concrete) Design Manual 11Document2 pagesIstructe Ec2 (Concrete) Design Manual 11Bertin BakariNo ratings yet

- Tugas Bahasa Inggris User ManualDocument15 pagesTugas Bahasa Inggris User ManualRandom AccountNo ratings yet

- Statement of The The Problem FEU Tech Building - 3Document3 pagesStatement of The The Problem FEU Tech Building - 3Matthew SumagueNo ratings yet

- Specification For BULL Conductor.Document4 pagesSpecification For BULL Conductor.boopelectra100% (2)

- Elite18-Master Log-CON (Pro Mag)Document123 pagesElite18-Master Log-CON (Pro Mag)muhammad75makeNo ratings yet

- BSD Short Quiz 1 2Document4 pagesBSD Short Quiz 1 2POWER_RAaaaNGERzNo ratings yet

- CE 318 Structure Analysis and Design Ii Lab: Building PlanDocument13 pagesCE 318 Structure Analysis and Design Ii Lab: Building PlanMd. Murshedul Islam 173-47-091No ratings yet

- Eco-Boards: A Green Building Material From Residues and WasteDocument26 pagesEco-Boards: A Green Building Material From Residues and WasteJaybesNo ratings yet

- Pratik Industrial TranningDocument21 pagesPratik Industrial TranningGopal mutkekarNo ratings yet

- Brooklyn - Bed B1049Q AIDocument8 pagesBrooklyn - Bed B1049Q AIBenNo ratings yet

- Floor System1Document25 pagesFloor System1DHEESHNA DILEEP 200545No ratings yet

- Durability Requirements For Civil InfrastructureDocument34 pagesDurability Requirements For Civil Infrastructure3g4342gNo ratings yet

- Home Lift - 01Document1 pageHome Lift - 01Nagarajan SNo ratings yet

- Design of Cement PlantDocument43 pagesDesign of Cement PlantSabharish Murali100% (1)

- Venetian BlindsDocument17 pagesVenetian Blindscrazy channelNo ratings yet

- 031 Steel Structure ChecklistDocument4 pages031 Steel Structure ChecklistMaria DiNo ratings yet

- Types of Grilling Materials: Submitted by - DigangganaDocument18 pagesTypes of Grilling Materials: Submitted by - DigangganaDiganggana BharadwajNo ratings yet

- Hoa ReviewerDocument3 pagesHoa ReviewerRachel Mae BahoyNo ratings yet

- ARCHITECTURAL ARTS in The PhilDocument5 pagesARCHITECTURAL ARTS in The PhilDamon KlausNo ratings yet

- Case Study: Microbial Abatement of A Moldy Hotel: T P M M RDocument9 pagesCase Study: Microbial Abatement of A Moldy Hotel: T P M M RAndrew UgohNo ratings yet

- Rock Bolting TechniqueDocument9 pagesRock Bolting TechniquesamratNo ratings yet

- Vacuum Bagging ProcessDocument11 pagesVacuum Bagging Processsyahmi sharifNo ratings yet

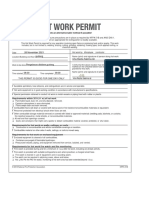

Hot Work Permit, Tyson Form 16147

Hot Work Permit, Tyson Form 16147

Uploaded by

Wan Nasrul Muhaimin0 ratings0% found this document useful (0 votes)

1 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

1 views2 pagesHot Work Permit, Tyson Form 16147

Hot Work Permit, Tyson Form 16147

Uploaded by

Wan Nasrul MuhaiminCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

Post Permit at Hot Work Location

HOT WORK PERMIT

Facility: Hot Work Work Order No. (not required):

Location:

Description of Work (material and equipment): Permit Issued (date/time): Permit Expires (date/time):

PSM Hot Work: Yes No Torch-Applied Roofing Project: Yes No

If yes, route completed permit to PSM Coordinator to file. If yes, conduct TAR Project Preconstruction Meeting with Contractor.

Permit required for work involving open flames, heat, hot slag or sparks. Issue Permit only if no acceptable alternatives to hot work exist.

Examples of hot work include: burning, cutting, welding, brazing, soldering, grinding, thawing pipe and torch applied roofing projects.

Yes N/A General Required Precautions for all Hot Work

Sprinklers and/or fire detection systems are operating properly.

Hot work equipment is in good working condition.

Proper fire extinguisher(s) present. Check required type(s): A BC ABC CO2 Other:

Hot Work Operator(s) trained in hot work procedures and gas cylinder safety.

Fire Watch(s) trained in fire watch procedure, fire extinguisher use and sounding fire alarm system.

Yes N/A Additional Precautions Required within 35 feet of all Hot Work

Equipment and floor is clean of combustible materials and there is no hazardous atmosphere.

Combustible materials and flammable liquids have been removed or protected (using fireproof tarps, shields, etc.).

All wall and floor openings, ducts and conveyors that might carry hot slag or sparks to combustible material are covered or closed.

Team Members have been notified that hot work will occur and have been protected, if necessary, using screens, barricades, etc.

Combustible belting has been removed or protected (using fireproof tarps, shields, etc.).

Combustible floors have been wetted, covered with damp sand, metal or fireproof tarps.

Steel members, pipes, etc. that could transmit heat to combustibles are identified and protected, if necessary, using fireproof tarps, etc.

Yes N/A Additional Precautions for Hot Work on or near Walls, Ceilings or Roofs

Combustible materials have been removed from opposite side of walls, ceilings or roofs where hot work will be performed.

Identified hazards of performing hot work near walls, partitions, ceilings, roofs and protected with fireproof tarps or shields as necessary, etc.

Yes N/A Additional Precautions for Hot Work on Enclosed Equipment (tanks, containers, ducts, conveyors, etc.)

Equipment cleaned of combustibles.

Equipment purged of flammable liquids and explosive vapors.

Inlets and outlets closed and locked out as necessary.

Yes N/A Fire Watch Requirements

Perform fire watch on both sides of wall or ceiling.

Perform continuous fire watch during hot work.

After hot work is completed, perform continuous fire watch for 1 hour and then periodic checks every ½ hour for 1 hour.

After torch-applied roofing hot work is completed, perform continuous fire watch for 1 hour and then periodic checks every ½ hour for 3 hrs.

Monitor area with Thermal Infrared Camera. [Required for torch-applied roofing projects and areas difficult to visually monitor for hot spots

(examples: on or near walls, ceilings, roofs, Interlox/plastic belts, and pipes, ducts, conveyors, structures that could transfer heat or sparks].

Permit Authorization

I inspected the work area, selected the required precautions, verified the precautions were in place and authorized this permit.

___________________________________ ________________________________ ________________________

Permit Authorizer Printed Name Permit Authorizer Signature Date

___________________________________ ________________________________ ________________________

Additional Permit Authorizer Printed Name* Additional Permit Authorizer Signature* Date

* Only required for torch-applied roofing projects

PERMIT AUTHORIZER TO KEEP TOP COPY OF PERMIT UNTIL

COMPLETED BOTTOM COPY IS RECEIVED

Tyson Form 16147 Rev. 1/9/2015 Page 1 of 2

Post Permit at Hot Work Location

HOT WORK PERMIT

Facility: Hot Work Work Order No. (not required):

Location:

Description of Work (material and equipment): Permit Issued (date/time): Permit Expires (date/time):

PSM Hot Work: Yes No Torch-Applied Roofing Project: Yes No

If yes, route completed permit to PSM Coordinator to file. If yes, conduct TAR Project Preconstruction Meeting with Contractor.

Permit required for work involving open flames, heat, hot slag or sparks. Issue Permit only if no acceptable alternatives to hot work exist.

Examples of hot work include: burning, cutting, welding, brazing, soldering, grinding, thawing pipe and torch applied roofing projects.

Yes N/A General Required Precautions for all Hot Work

Sprinklers and/or fire detection systems are operating properly.

Hot work equipment is in good working condition.

Proper fire extinguisher(s) present. Check required type(s): A BC ABC CO2 Other:

Hot Work Operator(s) trained in hot work procedures and gas cylinder safety.

Fire Watch(s) trained in fire watch procedure, fire extinguisher use and sounding fire alarm system.

Yes N/A Additional Precautions Required within 35 feet of all Hot Work

Equipment and floor is clean of combustible materials and there is no hazardous atmosphere.

Combustible materials and flammable liquids have been removed or protected (using fireproof tarps, shields, etc.).

All wall and floor openings, ducts and conveyors that might carry hot slag or sparks to combustible material are covered or closed.

Team Members have been notified that hot work will occur and have been protected, if necessary, using screens, barricades, etc.

Combustible belting has been removed or protected (using fireproof tarps, shields, etc.).

Combustible floors have been wetted, covered with damp sand, metal or fireproof tarps.

Steel members, pipes, etc. that could transmit heat to combustibles are identified and protected, if necessary, using fireproof tarps, etc.

Yes N/A Additional Precautions for Hot Work on or near Walls, Ceilings or Roofs

Combustible materials have been removed from opposite side of walls, ceilings or roofs where hot work will be performed.

Identified hazards of performing hot work near walls, partitions, ceilings, roofs and protected with fireproof tarps or shields as necessary, etc.

Yes N/A Additional Precautions for Hot Work on Enclosed Equipment (tanks, containers, ducts, conveyors, etc.)

Equipment cleaned of combustibles.

Equipment purged of flammable liquids and explosive vapors.

Inlets and outlets closed and locked out as necessary.

Yes N/A Fire Watch Requirements

Perform fire watch on both sides of wall or ceiling.

Perform continuous fire watch during hot work.

After hot work is completed, perform continuous fire watch for 1 hour and then periodic checks every ½ hour for 1 hour.

After torch-applied roofing hot work is completed, perform continuous fire watch for 1 hour and then periodic checks every ½ hour for 3 hrs.

Monitor area with Thermal Infrared Camera. [Required for torch-applied roofing projects and areas difficult to visually monitor for hot spots

(examples: on or near walls, ceilings, roofs, Interlox/plastic belts, and pipes, ducts, conveyors, structures that could transfer heat or sparks].

Permit Authorization

I inspected the work area, selected the required precautions, verified the precautions were in place and authorized this permit.

___________________________________ ________________________________ ________________________

Permit Authorizer Printed Name Permit Authorizer Signature Date

___________________________________ ________________________________ ________________________

Additional Permit Authorizer Printed Name* Additional Permit Authorizer Signature* Date

* Only required for torch-applied roofing projects

Hot Work Operator (If more than one, the Lead Hot Work Operator must sign. Must not be the Permit Authorizer.)

Hot Work performed by: Tyson Team Member(s) Contractor Company Name (if Contractor):

I inspected the hot work area and certify the required precautions are in place and will remain in place during hot work activities.

___________________________________ ________________________________ ________________________

Hot Work Operator Printed Name Hot Work Operator Signature Date

Fire Watch (Must not be the Hot Work Operator)

Hot Work Started (date/time): Hot Work Completed (date/time):

Initial the Performed Performed Continuous Performed Periodic Fire

Extended Fire Watch Required

Completion of Continuous Fire Fire Watch after Watch After

for Torch-Applied Roofing Hot Work

each Required Watch During Hot Work Completion Hot Work Completion

Fire Watch Hot Work 1 hr. 1½ hr. 2 hr. 2½ hr. 3 hr. 3½ hr. 4 hr.

Interval:

Performed monitoring using a Thermal Infrared Camera: Yes No If yes, final thermal image taken at (date/time):

Fire Watch performed by: Team Member Contractor Company Name (if Contractor):

I performed fire watch duties as required. I certify my records are true and accurate. [Return completed form to Permit Authorizer within 24 hrs.]

___________________________________ ________________________________ ________________________

Fire Watch Printed Name Fire Watch Signature Date

Permit Review and Closure

Following Hot Work and Fire Watch, I reviewed this Permit for completeness. Corrective actions, if required, were addressed as necessary

[File non PSM-related Hot Work Permits for 3 months. If PSM-related, route to the PSM Coordinator to file per PSM Record Retention requirements.]

___________________________________ ________________________________ ________________________

Permit Authorizer Printed Name Permit Authorizer Signature Date

Tyson Form 16147 Rev. 1/9/2015 Page 2 of 2

You might also like

- Carpentry Canadian 3rd Edition Vogt Solutions ManualDocument11 pagesCarpentry Canadian 3rd Edition Vogt Solutions Manualalisonfernandezmerzigfkap100% (12)

- Hot Work Permit - Daily - K2C - 012Document1 pageHot Work Permit - Daily - K2C - 012wlyNo ratings yet

- Hot Work Permit FormDocument2 pagesHot Work Permit FormN.JNo ratings yet

- Hot Works PresentationDocument33 pagesHot Works Presentationpammu18100% (1)

- Sample Hot Work PermitDocument1 pageSample Hot Work PermitAndre Mars100% (2)

- Hot Work Permit WordDocument3 pagesHot Work Permit Wordmush0025No ratings yet

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionFrom EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionRating: 4.5 out of 5 stars4.5/5 (3)

- Ace Hot Work Permit Application Form PDFDocument3 pagesAce Hot Work Permit Application Form PDFkevin100% (1)

- Hot Work Permit: Can This Job Be Avoided? Is There A Safer Alternative?Document6 pagesHot Work Permit: Can This Job Be Avoided? Is There A Safer Alternative?Wee Soon ChaiNo ratings yet

- Hot Work Permit IMEXDocument2 pagesHot Work Permit IMEXsophia samba100% (1)

- ATT 3 Hot Works PermitDocument2 pagesATT 3 Hot Works PermitSamsu Usup SudiarsonoNo ratings yet

- Hot Work Permit Hsems Ocp 01 F 03Document2 pagesHot Work Permit Hsems Ocp 01 F 03Raju BiswasNo ratings yet

- Work Permit SystemDocument38 pagesWork Permit SystemNaveen Meena50% (2)

- Hot Work Permit TemplateDocument2 pagesHot Work Permit TemplatemullaijoeNo ratings yet

- Hot Work PermitDocument17 pagesHot Work Permituday0% (1)

- Hot Work Permit: This Permit Is Not Valid Unless All Appropriate Fields Are CompletedDocument2 pagesHot Work Permit: This Permit Is Not Valid Unless All Appropriate Fields Are CompletedEl Saleh newcapital100% (1)

- Hot Work Permit: Must Must Must Must MustDocument1 pageHot Work Permit: Must Must Must Must MustAryan DashNo ratings yet

- Hot Work PermitDocument3 pagesHot Work PermitjitheshsvNo ratings yet

- Hot Work Procedure 2021Document8 pagesHot Work Procedure 2021Wan Ahmad FaaizunNo ratings yet

- Preh W CheckDocument2 pagesPreh W CheckMd UsamaNo ratings yet

- 06 170914 TBX12 HotworksDocument2 pages06 170914 TBX12 HotworksJason LeonardNo ratings yet

- Hot Work PermitDocument2 pagesHot Work Permitkumar kannanNo ratings yet

- SF-012 Hot Works Permit - Rev 0.2Document5 pagesSF-012 Hot Works Permit - Rev 0.2Noer Amalia PuspitaNo ratings yet

- SAMPLE Winery Hot Work PermitDocument3 pagesSAMPLE Winery Hot Work PermitMohammed Ali QaziNo ratings yet

- Hot Work PermitDocument18 pagesHot Work PermitMuneeb Ur RehmanNo ratings yet

- Permit To WorkDocument3 pagesPermit To WorkPrinterHaapcolNo ratings yet

- Hot Work PermitDocument1 pageHot Work PermitExhausted bearNo ratings yet

- Hotworking Permits 2Document3 pagesHotworking Permits 2MouctarNo ratings yet

- AIG Hot Work Permit Only Rev 120618Document6 pagesAIG Hot Work Permit Only Rev 120618Herik renaldoNo ratings yet

- Hot Work Permit FormDocument3 pagesHot Work Permit FormKarthik KarunanithiNo ratings yet

- Hot Work Policy FS 15Document8 pagesHot Work Policy FS 15sunil92lNo ratings yet

- Hot Work Permit To WorkDocument3 pagesHot Work Permit To WorkMorris M.No ratings yet

- Hot WorkDocument4 pagesHot WorkMesa MesaNo ratings yet

- CAT-08 Hot Work and Safe Work-EnglishDocument23 pagesCAT-08 Hot Work and Safe Work-EnglishDanNo ratings yet

- Hot Work Permits: Corporate Environment Safety & HealthDocument17 pagesHot Work Permits: Corporate Environment Safety & HealthpraneshrshahNo ratings yet

- Hot Work TBTDocument1 pageHot Work TBTkowshickNo ratings yet

- Hot Work PermitDocument1 pageHot Work PermitMenGuitarNo ratings yet

- PTW For Hot Work: Pakistan EPCL PVC Expansion ProjectDocument1 pagePTW For Hot Work: Pakistan EPCL PVC Expansion ProjectMuhammad RafiqueNo ratings yet

- Hot Work Policy 2010Document5 pagesHot Work Policy 2010vinoz2022 regNo ratings yet

- Cis Hot Works PermitDocument3 pagesCis Hot Works PermitparhamadkNo ratings yet

- PDF - Hot Work PermitDocument2 pagesPDF - Hot Work Permitdcf67my100% (2)

- Permit To Work - Hot Works: This Permit Is Valid Only For The Job Described and The Timescales ProvidedDocument3 pagesPermit To Work - Hot Works: This Permit Is Valid Only For The Job Described and The Timescales ProvidedJohn BusherNo ratings yet

- Penn State University Hot Work PermitsDocument21 pagesPenn State University Hot Work PermitsFOZCANNo ratings yet

- Hot Work Permit SampleDocument2 pagesHot Work Permit SampleMark Roger Huberit II0% (1)

- Mukand Sumi Special Steels: Safety ChecksDocument3 pagesMukand Sumi Special Steels: Safety ChecksPrashanth JeerNo ratings yet

- Work Permit FormatDocument12 pagesWork Permit FormatAejaz Mujawar0% (1)

- Hot Work Permit: SI Tracking #Document6 pagesHot Work Permit: SI Tracking #gurvinder singhNo ratings yet

- Hot Work PermitDocument1 pageHot Work PermitAMG Co.No ratings yet

- Hot Work Permit: 1. General PrecautionsDocument3 pagesHot Work Permit: 1. General PrecautionsAbu Syeed Md. Aurangzeb Al MasumNo ratings yet

- Hot Welding CuttingDocument19 pagesHot Welding Cuttingtheblues2708No ratings yet

- Permit To Hot WorkDocument2 pagesPermit To Hot WorkSaleh AlomariNo ratings yet

- PTWDocument54 pagesPTWSunil Kumar VishwakarmaNo ratings yet

- Hot Work Permit For Confined SpaceDocument3 pagesHot Work Permit For Confined SpaceDarus IshakNo ratings yet

- Safety Praktis.Document2 pagesSafety Praktis.icha Razita sabrina aliNo ratings yet

- 1 HotworkDocument1 page1 Hotworkchariot1729No ratings yet

- Hot Work Permits: Corporate Environment Safety & HealthDocument17 pagesHot Work Permits: Corporate Environment Safety & HealthMohammad AshpakNo ratings yet

- Hot Work Permit: Work On Walls or Ceilings/enclosed EquipmentDocument4 pagesHot Work Permit: Work On Walls or Ceilings/enclosed Equipmentleonel bayutasNo ratings yet

- Methodology - Hot WorksDocument5 pagesMethodology - Hot WorksPortia IbiasNo ratings yet

- Hot Work Permit Procedures: Olumbia NiversityDocument6 pagesHot Work Permit Procedures: Olumbia NiversityMairaj UddinNo ratings yet

- Hot Work PermitDocument5 pagesHot Work PermitNoel Delos ReyesNo ratings yet

- Excel CompuDocument719 pagesExcel CompuTania BenavidesNo ratings yet

- Textil Framework Documento 1Document13 pagesTextil Framework Documento 1Renato Del CidNo ratings yet

- Environmental Design of Atrium Buildings in The U.K.: F. MillsDocument9 pagesEnvironmental Design of Atrium Buildings in The U.K.: F. MillsThắm PhạmNo ratings yet

- Aluminum Box Section 80X50X4MM THK. Ms L Angle 35X35X3Mm Thk. 50Mm WidthDocument1 pageAluminum Box Section 80X50X4MM THK. Ms L Angle 35X35X3Mm Thk. 50Mm WidthSiva RajanNo ratings yet

- Pyrocrete 341 PDSDocument6 pagesPyrocrete 341 PDSRicardo SantosNo ratings yet

- Bollard InstallationDocument3 pagesBollard InstallationBryan HermawanNo ratings yet

- ACI Egg Protection Device CompetitionDocument9 pagesACI Egg Protection Device Competitionmarcelo obandoNo ratings yet

- Istructe Ec2 (Concrete) Design Manual 11Document2 pagesIstructe Ec2 (Concrete) Design Manual 11Bertin BakariNo ratings yet

- Tugas Bahasa Inggris User ManualDocument15 pagesTugas Bahasa Inggris User ManualRandom AccountNo ratings yet

- Statement of The The Problem FEU Tech Building - 3Document3 pagesStatement of The The Problem FEU Tech Building - 3Matthew SumagueNo ratings yet

- Specification For BULL Conductor.Document4 pagesSpecification For BULL Conductor.boopelectra100% (2)

- Elite18-Master Log-CON (Pro Mag)Document123 pagesElite18-Master Log-CON (Pro Mag)muhammad75makeNo ratings yet

- BSD Short Quiz 1 2Document4 pagesBSD Short Quiz 1 2POWER_RAaaaNGERzNo ratings yet

- CE 318 Structure Analysis and Design Ii Lab: Building PlanDocument13 pagesCE 318 Structure Analysis and Design Ii Lab: Building PlanMd. Murshedul Islam 173-47-091No ratings yet

- Eco-Boards: A Green Building Material From Residues and WasteDocument26 pagesEco-Boards: A Green Building Material From Residues and WasteJaybesNo ratings yet

- Pratik Industrial TranningDocument21 pagesPratik Industrial TranningGopal mutkekarNo ratings yet

- Brooklyn - Bed B1049Q AIDocument8 pagesBrooklyn - Bed B1049Q AIBenNo ratings yet

- Floor System1Document25 pagesFloor System1DHEESHNA DILEEP 200545No ratings yet

- Durability Requirements For Civil InfrastructureDocument34 pagesDurability Requirements For Civil Infrastructure3g4342gNo ratings yet

- Home Lift - 01Document1 pageHome Lift - 01Nagarajan SNo ratings yet

- Design of Cement PlantDocument43 pagesDesign of Cement PlantSabharish Murali100% (1)

- Venetian BlindsDocument17 pagesVenetian Blindscrazy channelNo ratings yet

- 031 Steel Structure ChecklistDocument4 pages031 Steel Structure ChecklistMaria DiNo ratings yet

- Types of Grilling Materials: Submitted by - DigangganaDocument18 pagesTypes of Grilling Materials: Submitted by - DigangganaDiganggana BharadwajNo ratings yet

- Hoa ReviewerDocument3 pagesHoa ReviewerRachel Mae BahoyNo ratings yet

- ARCHITECTURAL ARTS in The PhilDocument5 pagesARCHITECTURAL ARTS in The PhilDamon KlausNo ratings yet

- Case Study: Microbial Abatement of A Moldy Hotel: T P M M RDocument9 pagesCase Study: Microbial Abatement of A Moldy Hotel: T P M M RAndrew UgohNo ratings yet

- Rock Bolting TechniqueDocument9 pagesRock Bolting TechniquesamratNo ratings yet

- Vacuum Bagging ProcessDocument11 pagesVacuum Bagging Processsyahmi sharifNo ratings yet