Professional Documents

Culture Documents

Denry 2014

Denry 2014

Uploaded by

Hema SinghCopyright:

Available Formats

You might also like

- How To Bond Zirconia - The APC Concept PDFDocument9 pagesHow To Bond Zirconia - The APC Concept PDFKelly Katherine0% (1)

- How To Bond Zirconia The Apc ConceptDocument8 pagesHow To Bond Zirconia The Apc ConceptJoshua Valdez100% (1)

- Materials Science and Engineering Unit 1 PDFDocument19 pagesMaterials Science and Engineering Unit 1 PDFParis100% (1)

- Tipos Zirconia Marcas Comerciales JDR PDFDocument9 pagesTipos Zirconia Marcas Comerciales JDR PDFgerson fabian arangoNo ratings yet

- Ceramic in Dentistry 1Document14 pagesCeramic in Dentistry 1FofeNo ratings yet

- Journal of Dental Research: Resin-Composite Blocks For Dental CAD/CAM ApplicationsDocument4 pagesJournal of Dental Research: Resin-Composite Blocks For Dental CAD/CAM Applicationsgerson fabian arangoNo ratings yet

- 2007 Ceramic MaterialDocument17 pages2007 Ceramic Material이상민No ratings yet

- Evaluation of Hardness-MostafaDocument8 pagesEvaluation of Hardness-MostafaOmar PLNo ratings yet

- Novel Zirconia Materials in Dentistry: Y. Zhang and B.R. LawnDocument8 pagesNovel Zirconia Materials in Dentistry: Y. Zhang and B.R. Lawnkr7wyddmw2No ratings yet

- Biomedicines 11 03116Document18 pagesBiomedicines 11 03116Jose Manuel Quintero RomeroNo ratings yet

- Dental Research Journal: Marginal Adaptation of Spinell Inceram and Feldspathic Porcelain Laminate VeneersDocument6 pagesDental Research Journal: Marginal Adaptation of Spinell Inceram and Feldspathic Porcelain Laminate VeneersLuis Alberto Carpio MorenoNo ratings yet

- DR - Jafarian ms01759 Ghodsi - ProofDocument14 pagesDR - Jafarian ms01759 Ghodsi - ProofDaniel AtiehNo ratings yet

- All-Ceramic Restorations: A Review of The Literature: Saudi Dental JournalDocument8 pagesAll-Ceramic Restorations: A Review of The Literature: Saudi Dental JournalScribeNo ratings yet

- J Esthet Restor Dent - 2023 - Sulaiman - Zirconia Restoration Types Properties Tooth Preparation Design and Bonding ADocument7 pagesJ Esthet Restor Dent - 2023 - Sulaiman - Zirconia Restoration Types Properties Tooth Preparation Design and Bonding AAlfred OrozcoNo ratings yet

- Molecules 27 05116Document4 pagesMolecules 27 05116Odontologia HmaspNo ratings yet

- From Porcelain-fused-To-metal To Zirconia Clinical andDocument14 pagesFrom Porcelain-fused-To-metal To Zirconia Clinical andMayra Ortiz HerreraNo ratings yet

- Journal Homepage: - : IntroductionDocument7 pagesJournal Homepage: - : IntroductionIJAR JOURNALNo ratings yet

- (Tang Et Al 2021) Quantitative Analysis On The Wear of Monolithic Zirconia Crowns On Antagonist TeethDocument11 pages(Tang Et Al 2021) Quantitative Analysis On The Wear of Monolithic Zirconia Crowns On Antagonist TeethIzham KhairuNo ratings yet

- All-Ceramic Restorations - A Review of The LiteratureDocument8 pagesAll-Ceramic Restorations - A Review of The LiteratureOdonto Uninassau 4p NoiteNo ratings yet

- Clinical Success of Zirconia in Dental Applications: KeywordsDocument5 pagesClinical Success of Zirconia in Dental Applications: KeywordsJulio TorresNo ratings yet

- Zirconia Based Dental Biomaterials: Structure, Mechanical Properties, Biocompatibility, Surface Modification, and Applications As ImplantDocument7 pagesZirconia Based Dental Biomaterials: Structure, Mechanical Properties, Biocompatibility, Surface Modification, and Applications As ImplantAsyyrafNo ratings yet

- Application and Success Rates of Zirconia - A ReviewDocument9 pagesApplication and Success Rates of Zirconia - A ReviewIJAR JOURNALNo ratings yet

- 304 Review ArticleDocument4 pages304 Review ArticleDr Raj Jain100% (1)

- Cementation of Monolithic Zirconia Crown ProsthesisDocument4 pagesCementation of Monolithic Zirconia Crown ProsthesisShubham TawadeNo ratings yet

- Dental CeramicsDocument8 pagesDental Ceramicshamad_kayani_774954100% (1)

- Use of Zirconia in Dentistry: An Overview: January 2014Document10 pagesUse of Zirconia in Dentistry: An Overview: January 2014ميديكال انجنيرنج لتركيبات الأسنانNo ratings yet

- 1 s2.0 S0300571221000828 Main 2Document10 pages1 s2.0 S0300571221000828 Main 2Sandra Villalobos ArmentaNo ratings yet

- Novel Innovations in Dental Implant Biomaterials Science: Zirconia and PEEK PolymersDocument5 pagesNovel Innovations in Dental Implant Biomaterials Science: Zirconia and PEEK PolymersSatya AsatyaNo ratings yet

- Accepted Author VersionDocument65 pagesAccepted Author VersionLucianoNo ratings yet

- Recommended Cementation For Monolithic Zirconia Crowns: Drug Invention Today April 2018Document4 pagesRecommended Cementation For Monolithic Zirconia Crowns: Drug Invention Today April 2018Hector MurilloNo ratings yet

- Australian Dental Journal - 2011 - Miyazaki - CAD CAM Systems Available For The Fabrication of Crown and BridgeDocument10 pagesAustralian Dental Journal - 2011 - Miyazaki - CAD CAM Systems Available For The Fabrication of Crown and BridgeSekarSukomasajiNo ratings yet

- ContentServer Asp-2Document10 pagesContentServer Asp-2Lex Puma IdmeNo ratings yet

- Dental Ceramics: A Review of New Materials and Processing MethodsDocument15 pagesDental Ceramics: A Review of New Materials and Processing Methodsmilagros falconNo ratings yet

- ZIRCOMADocument4 pagesZIRCOMARatih CynthiaNo ratings yet

- Comparative Analysis of Transmittance For Different Types of Commercially Available Zirconia and Lithium Disilicate MaterialsDocument6 pagesComparative Analysis of Transmittance For Different Types of Commercially Available Zirconia and Lithium Disilicate MaterialsNaoki MezarinaNo ratings yet

- Zirconia As A Dental BiomaterialDocument14 pagesZirconia As A Dental BiomaterialaliNo ratings yet

- 10.1515 - Ntrev 2019 0035Document9 pages10.1515 - Ntrev 2019 0035isra suandiNo ratings yet

- 1 s2.0 S0109564124000447 MainDocument13 pages1 s2.0 S0109564124000447 MaincosadedubsNo ratings yet

- MAROTTO 2023. Partial Ceramic Veneer Technique For Challenging Esthetic Frontal Restorative ProceduresDocument11 pagesMAROTTO 2023. Partial Ceramic Veneer Technique For Challenging Esthetic Frontal Restorative ProceduresSandry marquezNo ratings yet

- IJEDe 15 03 Rocca 852 6Document23 pagesIJEDe 15 03 Rocca 852 6Danny Eduardo RomeroNo ratings yet

- ConnectionsDocument14 pagesConnectionsabraham OrtizNo ratings yet

- Medicina 59 02135Document18 pagesMedicina 59 02135sousourimeNo ratings yet

- ZirconiaDocument8 pagesZirconiaXIOMARA YASMITH REYES PALOMINONo ratings yet

- Implant Abutment Selection Criteria: Acta Scientific Dental Sciences (ISSN: 2581-4893)Document8 pagesImplant Abutment Selection Criteria: Acta Scientific Dental Sciences (ISSN: 2581-4893)priyaNo ratings yet

- Desalination and Water Treatment: Click For UpdatesDocument6 pagesDesalination and Water Treatment: Click For UpdatesMALIK ZARYABBABARNo ratings yet

- Jurnal Gigi 2019Document6 pagesJurnal Gigi 2019kinayungNo ratings yet

- Zirconia Dental Implants: A Literature Review: Journal of Oral Implantology June 2011Document11 pagesZirconia Dental Implants: A Literature Review: Journal of Oral Implantology June 2011Seno FauziNo ratings yet

- Recent Advances in Esth Tic Restorative Materials: Dental CeramicsDocument4 pagesRecent Advances in Esth Tic Restorative Materials: Dental CeramicsSMART SMARNo ratings yet

- Aboutara 2011Document4 pagesAboutara 2011Alejandra LorancaNo ratings yet

- Zirconia ArticleDocument7 pagesZirconia ArticleMichael TheofanusNo ratings yet

- Bonding To ZirconiaDocument7 pagesBonding To ZirconiavonNo ratings yet

- Effect of Surface Conditioning Techniques On The Resistance of Resin Composite Core Materiais On Titanium PostsDocument6 pagesEffect of Surface Conditioning Techniques On The Resistance of Resin Composite Core Materiais On Titanium PostsFrontiersNo ratings yet

- Use of Zirconia in Dentistry: An OverviewDocument9 pagesUse of Zirconia in Dentistry: An Overviewalfi MubarakNo ratings yet

- A Systematic Review of The Survival and Complication Rates of Zirconia-Ceramic and Metal-Ceramic Single CrownsDocument17 pagesA Systematic Review of The Survival and Complication Rates of Zirconia-Ceramic and Metal-Ceramic Single CrownsAndreea GîrleanuNo ratings yet

- CAD/CAM Ceramic Restorative Materials For Natural Teeth: F.A. Spitznagel, J. Boldt, and P.C. GierthmuehlenDocument10 pagesCAD/CAM Ceramic Restorative Materials For Natural Teeth: F.A. Spitznagel, J. Boldt, and P.C. GierthmuehlenlimemNo ratings yet

- Clinical Oral Implants Res - 2018 - Sailer - A Systematic Review of The Survival and Complication Rates of Zirconia CeramicDocument15 pagesClinical Oral Implants Res - 2018 - Sailer - A Systematic Review of The Survival and Complication Rates of Zirconia CeramicTao LinksNo ratings yet

- Comparison of The Load-Bearing Capacities of MonolDocument6 pagesComparison of The Load-Bearing Capacities of MonolSkAliHassanNo ratings yet

- Clinical Case Reports - 2023 - Karimi - Veneer Crowns in Anterior Endodontically Treated Teeth A Case Report With 1 YearDocument8 pagesClinical Case Reports - 2023 - Karimi - Veneer Crowns in Anterior Endodontically Treated Teeth A Case Report With 1 YearOgie WijayantoNo ratings yet

- Digitally Fabricated Dentures For Full Mouth Rehabilitation With Zirconia, Polyetheretherketone and Selective Laser Melted Ti-6Al-4V MaterialDocument9 pagesDigitally Fabricated Dentures For Full Mouth Rehabilitation With Zirconia, Polyetheretherketone and Selective Laser Melted Ti-6Al-4V MaterialWeiting LeeNo ratings yet

- Advances in Glass and Optical Materials: Proceedings of the 107th Annual Meeting of The American Ceramic Society, Baltimore, Maryland, USA 2005From EverandAdvances in Glass and Optical Materials: Proceedings of the 107th Annual Meeting of The American Ceramic Society, Baltimore, Maryland, USA 2005Shibin JiangNo ratings yet

- Advances in Photonic Materials and Devices: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004From EverandAdvances in Photonic Materials and Devices: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004Suhas BhandarkarNo ratings yet

- 1-s2.0-S0955221918306782-main-2Document27 pages1-s2.0-S0955221918306782-main-2Hema SinghNo ratings yet

- Amelogenesis ImperfectaDocument13 pagesAmelogenesis ImperfectaHema SinghNo ratings yet

- Ulrich Lohbauer, Renan Belli - Dental Ceramics - Fracture Mechanics and Engineering Design-Springer (2022)Document134 pagesUlrich Lohbauer, Renan Belli - Dental Ceramics - Fracture Mechanics and Engineering Design-Springer (2022)Hema SinghNo ratings yet

- SJ BDJ 2013 101Document1 pageSJ BDJ 2013 101Hema SinghNo ratings yet

- Dear Hema Singh, 11/01/2023 Rs. 4606/ : It's Time To Renew Your (MOTOR PRIVATE CAR PACKAGE POLICY) InsuranceDocument2 pagesDear Hema Singh, 11/01/2023 Rs. 4606/ : It's Time To Renew Your (MOTOR PRIVATE CAR PACKAGE POLICY) InsuranceHema SinghNo ratings yet

- Hickey 1991Document6 pagesHickey 1991Hema SinghNo ratings yet

- Fundamental Relation Between Phased Array Radiation and Scattering FieldsDocument13 pagesFundamental Relation Between Phased Array Radiation and Scattering FieldsHema SinghNo ratings yet

- Wjoud 2017 08 202Document5 pagesWjoud 2017 08 202Hema SinghNo ratings yet

- 37-Article Text-62-1-10-20200615Document5 pages37-Article Text-62-1-10-20200615Hema SinghNo ratings yet

- Moving From Legacy 24 GHZ To State-Of-The-Art 77 GHZ RadarDocument7 pagesMoving From Legacy 24 GHZ To State-Of-The-Art 77 GHZ RadarHema SinghNo ratings yet

- Mapex AN0320SN PDFDocument1 pageMapex AN0320SN PDFDiegoTierradentroNo ratings yet

- Oliver and Pharr - Nanoindentation History - 021511Document41 pagesOliver and Pharr - Nanoindentation History - 021511Ahmad NawazNo ratings yet

- IA Earthing Calculations BS 7430 +A1 2015 EEADocument9 pagesIA Earthing Calculations BS 7430 +A1 2015 EEAغيلان الحاشديNo ratings yet

- Ventilation in The Condor MineDocument9 pagesVentilation in The Condor MineClaudia ZicriNo ratings yet

- Elevation of Control RoomDocument1 pageElevation of Control RoomgohilnarendraNo ratings yet

- Creepof CeramicsDocument14 pagesCreepof CeramicsTejinder SinghNo ratings yet

- Ashcroft El Data SheetDocument1 pageAshcroft El Data SheetmisaelzaNo ratings yet

- Gaz 12kg and Stove-ManualDocument41 pagesGaz 12kg and Stove-ManualAlisa CampbellNo ratings yet

- Att #3-3-.Bill of MaterialsDocument4 pagesAtt #3-3-.Bill of MaterialsAnonymous Iev5ggSRNo ratings yet

- Tapcon: Storm Guard AnchorsDocument2 pagesTapcon: Storm Guard Anchorsblessed cccNo ratings yet

- Ec230 PDFDocument57 pagesEc230 PDFSOUMYA BHATTNo ratings yet

- AC Air Cycles PDFDocument18 pagesAC Air Cycles PDFJoJa JoJa100% (1)

- Rev 2Document18 pagesRev 2aun_nustNo ratings yet

- Air Conditioner Parts For Assembling and Repairing Manufacturer-Supplier ChinaDocument9 pagesAir Conditioner Parts For Assembling and Repairing Manufacturer-Supplier ChinaSiva 93No ratings yet

- Chen 801-T3Document28 pagesChen 801-T3hussainiNo ratings yet

- Gy-Roc "B": Metal Polishing Instructions - Including For Precious MetalsDocument2 pagesGy-Roc "B": Metal Polishing Instructions - Including For Precious Metalsbob100% (1)

- A New Approach of Strengthening - Spinodal DecompositionDocument9 pagesA New Approach of Strengthening - Spinodal DecompositionRolando CastilloNo ratings yet

- Katalog Griff 2021Document75 pagesKatalog Griff 2021Meita RatrianaNo ratings yet

- 3.1 Overview of Flat Plate Collectors: PrintDocument3 pages3.1 Overview of Flat Plate Collectors: Printsuseendran sNo ratings yet

- Vicinity Map: Mangaldan Public MarketDocument1 pageVicinity Map: Mangaldan Public Marketcristian gonzalesNo ratings yet

- Architectural Precast Concrete Caulking-Joint DetailDocument61 pagesArchitectural Precast Concrete Caulking-Joint DetaildedypunyaNo ratings yet

- Product Data SheetsDocument44 pagesProduct Data Sheetssalem elhajNo ratings yet

- Quote - Alain VillaDocument3 pagesQuote - Alain VillaZayed Abdul LatheefNo ratings yet

- Bathroom Shower 1accessories 2Document31 pagesBathroom Shower 1accessories 2César Fernando Gómez VelásquezNo ratings yet

- Visit To Induction HardeningDocument9 pagesVisit To Induction Hardeningdada kolekarNo ratings yet

- Foundations For Highrise BuildingsDocument54 pagesFoundations For Highrise Buildings李卓倫100% (1)

- Showertite DATASHEETSDocument2 pagesShowertite DATASHEETSsin85No ratings yet

- Base Module For Experiments in Fluid MechanicsDocument3 pagesBase Module For Experiments in Fluid MechanicsshmomenyNo ratings yet

- Causes of Failure and Repairing Options PDFDocument17 pagesCauses of Failure and Repairing Options PDFSubhash AhujaNo ratings yet

Denry 2014

Denry 2014

Uploaded by

Hema SinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Denry 2014

Denry 2014

Uploaded by

Hema SinghCopyright:

Available Formats

Journal of Dental Research

http://jdr.sagepub.com/

Emerging Ceramic-based Materials for Dentistry

I. Denry and J.R. Kelly

J DENT RES published online 1 October 2014

DOI: 10.1177/0022034514553627

The online version of this article can be found at:

http://jdr.sagepub.com/content/early/2014/10/07/0022034514553627

Published by:

http://www.sagepublications.com

On behalf of:

International and American Associations for Dental Research

Additional services and information for Journal of Dental Research can be found at:

Email Alerts: http://jdr.sagepub.com/cgi/alerts

Subscriptions: http://jdr.sagepub.com/subscriptions

Reprints: http://www.sagepub.com/journalsReprints.nav

Permissions: http://www.sagepub.com/journalsPermissions.nav

>> OnlineFirst Version of Record - Oct 8, 2014

OnlineFirst Version of Record - Oct 1, 2014

What is This?

Downloaded from jdr.sagepub.com at Uni of Southern Queensland on October 26, 2014 For personal use only. No other uses without permission.

© International & American Associations for Dental Research

research-article2014

JDR XXX10.1177/0022034514553627

CLINICAL REVIEW

I. Denry1* and J.R. Kelly2

Emerging Ceramic-based

1

The University of Iowa Department of Prosthodontics and

Materials for Dentistry

Dows Institute for Dental Research, 801 Newton Road, Iowa

City, IA 52242-1010, USA; and 2Dept. of Reconstructive

Sciences, Center for Biomaterials, University of Connecticut

Health Center, 263 Farmington Avenue, Farmington, CT

06030-1615, USA; *corresponding author, Isabelle-Denry@

uiowa.edu

J Dent Res XX(X):1-8, 2014

ABSTRACT PREAMBLE

Our goal is to give an overview of a selection of

emerging ceramics and issues for dental or bio-

medical applications, with emphasis on specific

T hree new ceramic-based materials have recently been introduced in den-

tistry: monolithic zirconia, zirconia-containing lithium silicate ceramics,

and interpenetrating phase composites. These emerging restorative materials

challenges associated with full-contour zirconia

stem from very different technological approaches that are likely to lead to

ceramics, and a brief synopsis on new machinable

further developments. At this stage, it seems appropriate to provide a focused

glass-ceramics and ceramic-based interpenetrating

update on these new materials.

phase composites. Selected fabrication techniques

relevant to dental or biomedical applications such

as microwave sintering, spark plasma sintering, FULL-CONTOUR ZIRCONIA CERAMICS

and additive manufacturing are also reviewed.

Where appropriate, the authors have added their

Background

opinions and guidance. Zirconia ceramics were introduced in dentistry more than a decade ago (Denry

and Kelly, 2008; Kelly and Denry, 2008). Clinical studies have demonstrated

their excellent performance despite early issues involving chipping of veneer-

KEY WORDS: zirconia, dental ceramics, glass-

ceramics, microwave sintering, spark plasma sin- ing porcelain (Sailer et al., 2006, 2007). Zirconia ceramics owe both clinical

tering, additive manufacturing. popularity and success to their outstanding mechanical properties and ease of

machining in the green stage via computer-aided design and computer-aided

manufacturing (CAD-CAM) technology. Zirconia is monoclinic at room tem-

perature and becomes tetragonal above 1,170°C. The third most common phase

is cubic, above 2,370°C (Subbarao, 1981). The reversible tetragonal-to-mono-

clinic (t-m) phase transformation is accompanied by an increase in volume upon

cooling. This transformation can be prevented by stabilizing tetragonal zirconia

at room temperature via alloying with various oxides. Zirconia ceramics for

dental applications are commonly stabilized with 3 mol% yttria. Stabilized

tetragonal zirconias exhibit excellent mechanical properties imparted by the

stress-induced t-m transformation, which is accompanied by a 4.5% volume

increase (Garvie and Nicholson, 1972; Garvie et al., 1975). This unique behav-

ior leads to development of a transformation zone, shielding the propagating

crack tip and inhibiting further crack propagation, successfully enhancing

toughness. Zirconia ceramics exhibit the highest flexural strength and fracture

toughness of all dental ceramics currently available.

Early issues with chipping of veneering porcelain appear to have been suc-

cessfully addressed with adoption of slower heating and cooling rates

reflected in laboratory practices and manufacturer recommendations, in addi-

tion to a compelling scientific explanation regarding temperature rate sensi-

DOI: 10.1177/0022034514553627 tivity (Benetti et al., 2014). However, other than one presentation (at a

General Session of the International Association for Dental Research [IADR])

Received June 13, 2014; Last revision September 9, 2014;

Accepted September 9, 2014

evaluating 702 zirconia/porcelain units for up to five years, with porcelain

failures no more prevalent than those for metal-ceramic systems (Nathanson

© International & American Associations for Dental Research et al., 2010), nothing clinical appears to have been published. In the opinion

1

Downloaded from jdr.sagepub.com at Uni of Southern Queensland on October 26, 2014 For personal use only. No other uses without permission.

© International & American Associations for Dental Research

2 Denry & Kelly J Dent Res XX(X) 2014

of the authors, most of the clinical trials reporting porcelain and microstructure. Sintering temperature and duration deter-

problems likely include a majority of prostheses predating the mine grain size, amount of cubic phase, and yttrium segregation,

now-widespread practice of slow cooling. which in turn dictate metastability, mechanical properties, and

It can be argued that the perception of porcelain issues likely resistance to LTD. It is well-established that grain size in

contributed to the development of full-contour zirconias. With 3Y-TZP ceramics increases as the sintering temperature

the elimination of veneering porcelain, only internal coloration increases from about 0.3 μm after sintering at 1,350°C for 2 hr

and stains remain to achieve adequate esthetics. However, the up to >2.0 μm after sintering at 1,650°C for the same duration

use of full-contour zirconias in dental applications, which (Fig. 1). Larger grains are more susceptible to transformation. A

include single- and multi-unit restorations, full-arch implant- larger grain size is therefore beneficial to mechanical properties

supported prostheses, abutments, implants, and orthodontic but decreases the resistance to LTD. Considering that sintering

brackets, raises a set of unique challenges stemming from shade temperatures of dental 3Y-TZPs vary from 1,350°C to 1,600°C,

production, tribological behavior, and long-term chemical sta- it is clear that these materials will behave very differently,

bility. Intricate complexities in mechanical and chemical behav- depending on sintering conditions and final grain size. The sin-

ior of partially stabilized zirconia have not yet been fully tering temperature will also determine the amount of cubic

explored. However, it is well-established that every step of the phase and yttrium distribution (Matsui et al., 2003), which have

fabrication process of zirconia ceramics has to be carefully con- been shown to directly influence resistance to LTD (Chevalier

trolled to achieve expected mechanical and chemical properties. et al., 2004).

This includes blank fabrication, green machining, sintering Although, to the authors’ knowledge, no clinical evidence of

process, and surface treatments, whether chemical, thermal, or LTD has yet been reported for dental zirconias, the combination

mechanical. of lower-grade powders, high sintering temperatures, and direct

exposure to oral fluids has the potential to trigger this slow but

Blank Fabrication autocatalytic phenomenon (Keuper et al., 2013). Indeed, look-

ing back at the performance of zirconia femoral heads in ortho-

Blank fabrication is the first step of the fabrication process, in pedics, the lack of consistency throughout clinical studies is

which powder chemical purity, granule characteristics, type of worth noticing, with some excellent in vivo performance reports

pressing, and pre-sintering treatment all play a critical role in mixed with some clearly alarming reports (Clarke et al., 2003),

final properties. One study (Stoto et al., 1991) compared two independently of process-related series of failures reported in

3Y-TZP powders of nearly identical chemical composition, 2001. This clearly indicates that in vivo use of zirconia should,

except for the amount of residual impurities (820 ppm vs. at the very least, be carefully monitored over time, and failures

360 ppm). It was shown that a glassy phase forming a continu- analyzed.

ous layer (1.5 to 2 nm) at grain boundaries and multiple junc-

tions was present in the material containing the largest amount

Tooth Color Reproduction

of impurities, together with a greater grain size. The conclusion

that larger amounts of impurities favor yttrium transport, lead- Precise tooth color reproduction presents one of the most sig-

ing to cubic phase formation, has serious implications for the nificant clinical challenges associated with full-contour zirco-

stability of 3Y-TZP: cubic grains are enriched in yttrium, leav- nia. Whether monolithic zirconia can ever match the esthetics of

ing surrounding tetragonal grains depleted, less stable, and more veneered all-ceramics is questionable, and today’s clinicians are

susceptible to transformation (Chevalier et al., 2004). left with a subjective decision often involving the position of the

Powder granulometry and compaction mode also play a key dentition in question and whether the entire esthetic zone is

role in determining the final microstructure. 3Y-TZP powders being restored (e.g., complete implant-supported denture). From

typically start with a crystallite size of 30-40 nm, from which a materials viewpoint, a traditional ceramic-engineering

spray-dried agglomerates (diameter, 20-80 μm) are then pro- approach would be to add coloring oxides to zirconia powders

duced. These agglomerates have been shown to induce a coarse prior to pressing the blanks. Another possibility is color-doping

pseudo-grain structure, more likely to occur when blanks are of powder granules by co-precipitation, leading to homogeneous

uniaxially pressed. This is due to the fact that the degree of color distribution; but many shades are needed, making both of

compaction obtained with uniaxial pressing is not as intense or these approaches financially challenging. A popular means of

homogeneous as that obtained with isostatic pressing. The pres- coloring zirconia restorations is by infiltration of various metal

ence of micropores at pseudo-grain boundaries could potentially salts at low concentrations (Suttor et al., 2004). However, the

decrease resistance to low-temperature degradation (LTD) by infiltration technique has some drawbacks, such as a non-

facilitating diffusion of water species (Swain, 2014). The pre- uniform color due to the possible presence of porosity gradients

sintering conditions of blanks directly influence machinability (Shah et al., 2008). Issues related to limited diffusion depth of

in the green stage, final sharpness, and accuracy from the sizes coloring solutions have also been reported, leading to lighter

and shapes of chippings (Filser et al., 2003). areas after grinding adjustments (Oh et al., 2012). Finally, the

sintering temperature should be carefully controlled, since it

Sintering Process may influence oxidation state and therefore color. Esthetics-

matching with monolithic zirconia also relies on achieving an

Sintering conditions are influential in determining the final acceptable degree of translucency. Mean grain size influences

properties of 3Y-TZP by acting on chemical species distribution translucency through the number of grain boundaries, with

Downloaded from jdr.sagepub.com at Uni of Southern Queensland on October 26, 2014 For personal use only. No other uses without permission.

© International & American Associations for Dental Research

J Dent Res XX(X) 2014 3

Emerging Dental Ceramics

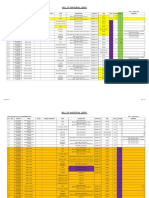

Figure 1. Scanning electron micrographs showing the effect of sintering temperature on grain size in 3Y-TZP sintered for 2 hr. (A) 1,300°C; (B)

1,350°C; (C) 1,400°C; (D) 1,450°C; (E) 1,500°C; (F) 1,550°C; (G) 1,600°C; and (H) 1,650°C.

smaller grain sizes leading to decreased translucency due to the “regeneration firing” (1,000°C/15 min) to reverse the transfor-

larger number of grain boundaries. For reasons explained earlier mation (m-t). Heat treatments as low as 650°C for 1 min were

and including greater metastability, increasing the sintering tem- shown to reverse the transformation successfully (Denry et al.,

perature to obtain a more translucent ceramic by increasing 2010). Other work revealed a significant reduction in grain size

grain size is not desirable. from 0.38 to 0.15 micrometers after diamond grinding and

annealing at 1,200°C (Kao et al., 2000). Grain refinement

occurred by recrystallization, made possible from the strain

Final Surface State and Tribological Behavior

energy associated with plastic deformation during grinding.

The quality of the final surface state in monolithic zirconia res- This also points out the complex nature of metastable zirconia

torations is particularly important, since it will condition both ceramics.

metastability and tribological behavior. It is well-established Although wear protocols vary widely, there seems to be a

that grinding or sandblasting lead to surface phase transforma- consensus on the fact that glazed zirconia is more abrasive than

tion to monoclinic, and the associated development of compres- polished or as-sintered zirconia (Figueiredo-Pina et al., 2013;

sive stresses. Meanwhile, chair-side polishing to a mirror finish Janyavula et al., 2013; Kontos et al., 2013). It is estimated that

successfully eliminates the thin layer of monoclinic phase and the glaze layer is only between 30 and 50 μm thick and worn in

compressive stresses but may not fully remove deep defects cre- 6 mo in vivo against enamel. The surface state under the glaze

ated by grinding, due to grain pullout and formation of micro- layer will therefore determine further wear characteristics

craters. In addition, via the surface stress state, polishing (Etman, 2009). One study reported 100% enamel cracks in natu-

increases the sensitivity to LTD by enhancing monoclinic phase ral teeth in contact with zirconia, possibly due to fatigue mecha-

nucleation around residual scratches (Deville et al., 2006). Heat nisms (Stawarczyk et al., 2013). It is worth noticing that

treatment following grinding, sandblasting, or aging was shown extensive formation of monoclinic phase and associated com-

to reverse the transformation and eliminate compressive stresses, pressive stresses decreases the wear resistance of 3Y-TZP. This

or surface roughening in the case of LTD (Deville et al., 2006; was attributed to microcracking, larger grain size, and weakness

Denry et al., 2010). Indeed, a few manufacturers recommend a of the m-phase (Conoci et al., 1999). Concurrently, wear of

Downloaded from jdr.sagepub.com at Uni of Southern Queensland on October 26, 2014 For personal use only. No other uses without permission.

© International & American Associations for Dental Research

4 Denry & Kelly J Dent Res XX(X) 2014

Figure 2. Scanning electron micrographs of as-received machined

dental implant abutment surfaces. Extensive microcracking can be

seen, as well as some grain refinement within deep machining Figure 3. X-ray diffraction pattern of 3Y-TZP dental implant abutment

grooves. as-received (blue) and after rough grinding (red).

3Y-TZP in self-mated conditions was shown to increase with cubic phase, characterized by x-ray diffraction (XRD) as a sig-

increasing grain size (Gahr et al., 1993). This ensures that when nificant shoulder to the left of the main reflection (011) of the

monolithic zirconia is used, surfaces should be carefully pol- tetragonal phase (Hasegawa, 1983; Hasegawa et al., 1985;

ished if grinding adjustments are necessary, since rougher sur- Kitano et al., 1988; Kondoh, 2004). Grinding also triggers fer-

faces lead to increased wear of antagonist enamel (Mitov et al., roelastic domain switching, expressed by XRD as a reversal of

2012). intensities of the t(002) and t(110) tetragonal reflections (Fig. 3).

Tribology is a “black art”. In the opinion of the authors, wear Ferroelastic domain switching has been identified as an impor-

suitability will likely be settled not by in vitro analyses but by tant additional toughening mechanism for zirconia and is not

clinical measures and observations. In our experience, many reversed by annealing (Virkar and Matsumoto, 1986; Chevalier

clinicians we know who place monolithic zirconia have yet to et al., 2009). Evidence of microstructural domain reorientation

observe untoward findings. Yet the definitive answer awaits (switching) in 3Y-TZP is shown in Fig. 4. Of clinical concern,

quantitative clinical assessment. abutment failure without screw fracture can lead to the produc-

tion of sufficient titanium debris to cause gingival tattooing

(Taylor et al., 2014).

Dental Implant Abutments (the importance of In summary, full-contour zirconias represent a class of

processing/property relationships and design) emerging ceramics that show excellent promise in terms of

Zirconia is also used in the manufacture of implant abutments. mechanical properties. Hopefully, future research in the refine-

While full-contour zirconia has been clinically successful in ment of these materials for dental applications can benefit from

single- or multi-unit cemented restorations, there have been the wealth of information and literature already available from

reports of implant abutment failures (both in vivo and in vitro) other applications of these ceramics. Emphasis should be placed

related to processing and design problems with custom CAD/ on proper control of the final surface-state to ensure reliability

CAM abutments (Aboushelib and Salameh, 2009; Sailer et al., and long-term performance.

2009). Abutment surfaces are likely to play a key role in long-

term clinical performance, with significant differences between ZIRCONIA-CONTAINING LITHIUM SILICATE

machined and as-heat-treated surfaces. Machined surfaces

exhibit extensive microcracking as well as some grain refine-

CERAMICS (ZLS)

ment within deep machining grooves (Fig. 2). Some products Lithium silicate-based glass-ceramics were recently introduced

may also exhibit surface defects such as pore clusters, together as machinable materials (Celtra™, Dentsply; Suprinity®, Vita)

with various amounts of cubic grains, easily identified from for CAD-CAM techniques, with claimed mechanical properties

their large size (Denry, 2013). The presence of significant comparable with those of lithium disilicate glass-ceramics

amounts of cubic phase at abutment surfaces is not desirable, (L2S). The technology relies on the addition of 10 wt% zirco-

since it indicates inhomogeneities in yttrium distribution nium oxide to lithium silicate glass compositions. Zirconia acts

(Chevalier et al., 1999; Chevalier, 2006). The quality of surface as nucleating agent but remains in solution in the glassy matrix,

finish and the associated stress-state is unequivocally a key issue with two main consequences: A dual microstructure consisting

when considering clinical applications of monolithic zirconia. In of very fine lithium metasilicate (Li2SiO3) and lithium disilicate

addition to the formation of the monoclinic phase, grinding of (Li2Si2O5) crystals is obtained (Fig. 5), with a glassy matrix

3Y-TZP leads to the formation of a rhombohedral or pseudo- containing zirconium oxide in solution (Kruger et al., 2013).

Downloaded from jdr.sagepub.com at Uni of Southern Queensland on October 26, 2014 For personal use only. No other uses without permission.

© International & American Associations for Dental Research

J Dent Res XX(X) 2014 5

Emerging Dental Ceramics

Figure 4. Scanning electron micrograph of a 3Y-TZP fractured surface. Figure 5. Scanning electron micrograph showing the microstructure of

Arrows indicate evidence of domain reorientation, characteristic of the lithium silicate glass-ceramic Suprinity (Vita), exhibiting platelet-

ferroelastic domain switching. shaped crystals.

The microstructure is achieved in two stages. The glass-ceramic

in the first pre-crystallized stage contains only lithium metasili-

cate crystals and is easy to machine. The final crystallization

stage, leading to the dual lithium silicate microstructure, is

obtained after a short heat treatment at 840°C for 8 min. The

main difference between ZLS and L2S glass-ceramics in their

final stage of crystallization resides in the nature of the crystal-

line phases: lithium metasilicate plus lithium disilicate for ZLS

and lithium disilicate only for L2S.

The development of zirconia-containing lithium silicate

glass-ceramics illustrates the ongoing quest for ceramic materi-

als that offer adequate translucency combined with superior

mechanical properties. These stable ceramics may offer a better

reliability than zirconia ceramics but may not represent the end-

point for this quest. Figure 6. Mean failure loads for IPS e.max CAD (Ivoclar Vivadent,

Schaan, Liechtenstein) and Enamic® (Vita) in sinusoidal loading of

adhesively bonded specimens per Kelly et al. (2010). Analysis of such

INTERPENETRATING PHASE COMPOSITES data suggests identical clinical performance against bulk fracture by

radial cracking.

Indeed, the development of a new class of interpenetrating

phase composites (IPC) further illustrates this ongoing quest.

IPCs are characterized by two phases that are each intact three- In 2013, the second IPC for dental restorations was intro-

dimensionally (intertwined) throughout the fully dense material. duced (Enamic®, Vita). This IPC is based on initial sintering of

Such composites are formed by infiltration of a porous structure porcelain powder to approximately 70% of full density, fol-

(first phase) with a liquid to form the second interpenetrating lowed by infiltration with dental monomers (He and Swain,

phase. Melt-infiltration of glasses followed by solidification and 2011). While the porous ceramic network has a strength of 135

monomer infiltration followed by thermoset polymerization are MPa and the polymer below 30 MPa, the infiltrated IPC has a

common fabrication methods (Wegner and Gibson, 2001). IPCs strength of 160 MPa (Coldea et al., 2013b). As would be

are often tougher and stronger and display a higher damage expected, many bulk and elastic properties are intermediate

tolerance (R-curve behavior) than either pure phase. between those of particle-filled resins and those of ceramics.

Due to esthetic needs, only ceramic-glass and ceramic- While not as strong as CAD/CAM ceramics, this IPC has an

polymer IPCs have been developed for dentistry. The first elastic modulus of approximately 38 GPa, slightly higher than

(In-Ceram® Alumina, Vita) is based on alumina (68%) infiltrated that of dentin (Della Bona et al., 2014), so that for any given

with a lanthanum-containing glass (Guazzato et al., 2004). load the interfacial stress causing bulk fracture by radial crack-

Fabrication of porous alumina is achieved by initial sintering char- ing is lower. In fatigue testing (500,000 cycles, water), Enamic®

acterized by surface diffusion without shrinkage. In-Ceram® performed as well as lithium disilicate [Fig. 6; testing performed

Alumina was the first fully-dense net-shape ceramic available as per Kelly et al. (2010)]. Recent study showed that this IPC

for dental restorations and performed very well (91.5-100% suc- has three additional advantages over CAD/CAM and pressable

cess) in at least eight clinical trials lasting between five and ceramics: (1) reasonable brittleness index; (2) lower hardness;

seven years (Della Bona and Kelly, 2008). It is still available, and (3) creep response similar to that of enamel (lower contact

mainly for CAD/CAM, but has never been highly marketed. stress development and good stress redistribution) (He and

Downloaded from jdr.sagepub.com at Uni of Southern Queensland on October 26, 2014 For personal use only. No other uses without permission.

© International & American Associations for Dental Research

6 Denry & Kelly J Dent Res XX(X) 2014

Swain, 2011). Both this IPC and In-Ceram Alumina were found Many problems must be dealt with in microwave sintering.

to be more damage-tolerant than other CAD/CAM and pressed First, the least expensive and most widely available microwave

materials (Coldea et al., 2013a). Damage tolerance during applicators are low-frequency (2.45 GHz) and do not couple

machining is also better than for other CAD/CAM ceramics and power efficiently to many ceramics at room temperature, mak-

one particle-filled polymer block (as measured by brittleness ing initial heating difficult. Second, thermal instabilities may

index), as was shown to correlate linearly with less marginal arise, leading to catastrophic overheating. Third, volumetric

chipping (Tsitrou et al., 2007; He and Swain, 2011). heating can produce severe temperature gradients, leading to

It is likely that IPC materials will continue to be explored. non-uniform microstructures and properties and localized crack-

There would appear to be much engineering latitude, given all ing (Menezes et al., 2007). Researchers have addressed these

the variables available for manipulation: choice of each phase, problems by developing hybrid techniques—for example, com-

initial particle size and shape of the first phase, coupling or not bining microwave and infrared heating or using microwave-

between phases, and toughness of infiltration phase. Enamic® absorbing materials (susceptors, e.g., SiC) to provide initial

appears to be performing very well in a clinical study nearing its heating up to temperatures where most ceramic powders do

24-month completion (personal communication, Dr. Petra become absorbers of microwave radiation.

Guess, University of Freiburg, Germany). If this continues, as Currently, the dental literature on microwave sintering seems

for the alumina-glass IPC, and early commercial success contin- limited to work with zirconia (Almazdi et al., 2012; Kim et al.,

ues, this class of material will likely be added to in the future. 2013; Marinis et al., 2013). It appears that microwave sintering

In parallel with materials development, refinement of process- does not alter fracture toughness and permits the use of higher

ing techniques has actively taken place to reduce energy costs heating rates, leading to increased productivity and reduced

(microwave sintering), adapt to nanoscale particle sizes (spark energy costs (Almazdi et al., 2012; Marinis et al., 2013).

plasma sintering), or permit the realization of intricate shapes Zirconias processed by microwave sintering can have smaller

(additive manufacturing). These emerging techniques certainly grain sizes and increased translucency compared with those

have the potential to be used for dental applications in the future. from conventional firing (Kim et al., 2013).

MICROWAVE SINTERING

SPARK PLASMA SINTERING (KINETIC

On the electromagnetic spectrum, microwave radiation falls just

ENGINEERING)

above radio waves and just below visible light, with wave-

lengths between 1 mm and 1 m corresponding to frequencies of Precise control of sintering kinetics is becoming of special

about 1 to 300 GHz. Regarding microwave-material interac- interest in the development of nano-ceramics and multifunc-

tions, three basic conditions exist. Materials having very low tional composite-ceramics where “kinetic windows” can be

loss-tangents allow microwave radiation to pass through with very narrow for the retention of fine grain microstructures

little or no absorption. Materials having very high loss-tangents and the prevention of unwanted side reactions (Shen and

(e.g., metals) reflect this radiation and are considered to be Nygren, 2005). As with microwave sintering, the main aim of

opaque. Materials that efficiently absorb microwaves have inter- spark plasma sintering is to enhance surface diffusion (lead-

mediate loss-tangents. Loss-tangents of ceramic powders are a ing to densification) while limiting grain boundary diffusion

strong function of temperature, often increasing linearly. Thus, leading to coarsening and side reactions. Grain boundary

powders that do not absorb at room temperature can be efficient diffusion is activated at higher temperatures than surface dif-

absorbers at 500°C to 600°C. Direct dielectric heating can fusion. Precursor powders are loaded into an electrically

become very efficient, as high as 80% to 90%, in dramatic con- conductive die that provides uniaxial pressure as well during

trast to conventional heating (Katz, 1992). sintering. Strong direct current (DC) is applied through the

Sintering consists of at least two heat-activated processes, die, and possibly the powders, providing heat from the out-

densification and grain growth. Densification involves atomic side as well as the inside. Under such conditions, rapid con-

diffusion (surface and lattice) in polycrystalline ceramics and solidation is driven at relatively low temperatures, enhancing

viscous flow in glassy materials. Grain growth involves grain mass transport in a relatively short time period (Shen and

boundary diffusion and is usually thought to be deleterious, Nygren, 2005). Although implied by the commonly used

especially if leading to the emergence of non-uniform grains, term, it appears that a plasma is not created.

i.e., via Ostwald ripening. Microwave energy not only provides Since this process requires that sintering be done within

volume heating vs. surface heating, but also lowers the activa- the confines of a die, complex shapes such as those required

tion energy for atomic diffusion, reducing sintering times by up for dental restorations are not possible. Therefore, the empha-

to 10 times. It provides for sintering at lower temperatures and sis is on developing special microstructures, such as carbon

avoids the prolonged heating that would encourage grain growth nano-tube-reinforced hydroxyapatite (Kim et al., 2014).

(Oghbaei and Mirzaee, 2010). These processes have been col- Apatite powders can be sintered to high density in approxi-

lectively termed the “microwave effect.” Therefore, in many mately 5 min at < 300°C to retain non-stoichiometric compo-

cases, microwave sintering leads to materials having a more sitions and preserve surface hydration (Grossin et al., 2010).

uniform grain size and higher density. In one dental porcelain, This process has also been applied to calcium phosphate

microwave sintering led to higher density and flexural strength ceramics and glass compositions (Champion, 2013; López-

than seen with conventional sintering (Menezes et al., 2007). Esteban et al., 2014; Porwal et al., 2014).

Downloaded from jdr.sagepub.com at Uni of Southern Queensland on October 26, 2014 For personal use only. No other uses without permission.

© International & American Associations for Dental Research

J Dent Res XX(X) 2014 7

Emerging Dental Ceramics

ADDITIVE MANUFACTURING (ROBOCASTING, 3D phase composites show great promise as excellent attempts at

reproducing tooth structure. Remarkable progress has been

PRINTING, SELECTIVE LASER SINTERING)

made in ceramic processing and development over the past few

Solid freeform fabrication of complex ceramic parts is mainly years. It is likely that further breakthroughs will occur in the

being explored by slurry additive manufacturing (“robocast- near future.

ing”), which consists of extrusion of continuous filaments or

rods to additively build complex porous scaffolds, mainly for

ACKNOWLEDGMENTS

bone tissue engineering. While slurry additive manufacturing

has been investigated for fabrication of zirconia/alumina pros- This work was supported by National Institutes of Health

theses cores, the process is still too crude where fine control (NIH)-National Institute of Dental and Craniofacial Research

over final dimensions is required (Silva et al., 2011). More com- (NIDCR) Grant R01DE019972 (PI: Denry, Isabelle). J. Robert

monly, various combinations of bioactive calcium phosphate Kelly acknowledges research support from Vita Zahnfabrik

ceramic powders are processed into scaffolds for orthopedic (Bad Säckingen, Germany). The authors declare no potential

applications (Miranda et al., 2006). conflicts of interest with respect to the authorship and/or publi-

Such additive manufacturing is essentially a complex exam- cation of this article.

ple of ceramics powder processing in which water-based “inks”

are developed with specific properties. First, these inks must

have well-controlled viscoelastic properties such that they can REFERENCES

flow through a deposition nozzle and then “set” to facilitate both Aboushelib MN, Salameh Z (2009). Zirconia implant abutment fracture:

shape retention and bridging of small gaps (i.e., be pseudoplas- clinical case reports and precautions for use. Int J Prosthodont 22:616-

tic). Second, they need to contain high volume fractions of col- 619.

Almazdi AA, Khajah HM, Monaco EA Jr, Kim H (2012). Applying microwave

loidal particles to reduce drying shrinkage and resist compressive technology to sintering dental zirconia. J Prosthet Dent 108:304-309.

stresses from capillary tension (Smay et al., 2002). These inks Benetti P, Kelly JR, Sanchez M, Della Bona A (2014). Influence of thermal

are often specific to the powders being processed, depending on gradients on stress state of veneered restorations. Dent Mater 30:554-563.

particle size and distribution, and zeta potentials. Although com- Champion E (2013). Sintering of calcium phosphate bioceramics. Acta

Biomater 9:5855-5875.

puters control build-up of the assemblies, all steps of colloidal

Chevalier J (2006). What future for zirconia as a biomaterial? Biomaterials

processing of ceramics are utilized: (1) powder synthesis, (2) 27:535-543.

powder dispersion (or suspension), (3) powder consolidation, Chevalier J, Calès B, Drouin JM (1999). Low-temperature aging of Y-TZP

(4) removal of solvent and organic processing components, and ceramics. J Am Ceram Soc 82:2150-2154.

(5) densification (Lewis, 2000). While one of the benefits of Chevalier J, Deville S, Münch E, Jullian R, Lair F (2004). Critical effect of

cubic phase on aging in 3mol% yttria-stabilized zirconia ceramics for

robocasting is the ability to fabricate complex shapes, limita- hip replacement prosthesis. Biomaterials 25:5539-5545.

tions for broad dental use include low packing density and a lack Chevalier J, Grémillard L, Virkar AV, Clarke DR (2009). The tetragonal-

of uniformity of the greenwares fabricated, which limits control monoclinic transformation in zirconia: lessons learned and future

over final dimensional tolerances. trends. J Am Ceram Soc 92:1901-1920.

Ink production for robocasting involves controlling colloidal Clarke IC, Manaka M, Green DD, Williams P, Pezzotti G, Kim YH, et al.

(2003). Current status of zirconia used in total hip implants. J Bone

stability, i.e., control over interparticle potential energy—both Joint Surg Am 85-A(Suppl 4):73-84.

attractive and repulsive using organic additives (and inorganic) Coldea A, Swain MV, Thiel N (2013a). In-vitro strength degradation of

for pH adjustments. For an excellent example of robocasting ink dental ceramics and novel PICN material by sharp indentation. J Mech

development, see Smay et al. (2002). Behav Biomed Mater 26:34-42.

One modification of this method, using an inkjet printer, has Coldea A, Swain MV, Thiel N (2013b). Mechanical properties of polymer-

infiltrated-ceramic-network materials. Dent Mater 29:419-426.

been explored to fabricate crude prostheses, but the total process Conoci S, Melandri C, De Portu G (1999). Wear of 3Y–TZP containing

remains cumbersome, and significant defect introduction has compressive residual stresses at the surface. J Mater Sci 34:1009-1015.

been reported (Ebert et al., 2009). Layer-by-layer greenware Della Bona A, Kelly JR (2008). The clinical success of all-ceramic restora-

build-up of a bioactive ceramic was demonstrated where part tions. J Am Dent Assoc 139(Suppl):8S-13S.

Della Bona A, Corazza PH, Zhang Y (2014). Characterization of a polymer-

definition occurs by laser sintering of a binder included in the

infiltrated ceramic-network material. Dent Mater 30:564-569.

ceramic powder bed (Goodridge et al., 2006). In the opinion of Denry I (2013). How and when does fabrication damage adversely affect the

the authors, other than for porous scaffold fabrication, ceramic clinical performance of ceramic restorations? Dent Mater 29:85-96.

additive manufacturing remains exploratory. Denry I, Kelly JR (2008). State of the art of zirconia for dental applications.

Dent Mater 24:299-307.

Denry IL, Peacock JJ, Holloway JA (2010). Effect of heat treatment after

CONCLUDING REMARKS accelerated aging on phase transformation in 3Y-TZP. J Biomed Mater

Res B Appl Biomater 93:236-243.

The evolution of dental ceramics over the past 30 years has been Deville S, Chevalier J, Grémillard L (2006). Influence of surface finish and

most interesting from a biomedical engineering point of view. residual stresses on the ageing sensitivity of biomedical grade zirconia.

Introduction of zirconia ceramics has opened a wide range of Biomaterials 27:2186-2192.

all-ceramic applications unthinkable 30 years ago. The consen- Ebert J, Ozkol E, Zeichner A, Uibel K, Weiss O, Koops U, et al. (2009).

Direct inkjet printing of dental prostheses made of zirconia. J Dent Res

sus, however, is on caution in selecting highest product quality 88:673-676.

and strict respect of manufacturers’ recommendations, with Etman MK (2009). Confocal examination of subsurface cracking in ceramic

special attention on sintering temperature. Interpenetrating materials. J Prosthodont 18:550-559.

Downloaded from jdr.sagepub.com at Uni of Southern Queensland on October 26, 2014 For personal use only. No other uses without permission.

© International & American Associations for Dental Research

8 Denry & Kelly J Dent Res XX(X) 2014

Figueiredo-Pina CG, Monteiro A, Guedes M, Mauricio A, Serro AP, Matsui K, Horikoshi H, Ohmichi N, Ohgai M, Yoshida H, Ikuhara Y (2003).

Ramalho A, et al. (2013). Effect of feldspar porcelain coating upon the Cubic-formation and grain-growth mechanisms in tetragonal zirconia

wear behavior of zirconia dental crowns. Wear 297:872-877. polycrystal. J Am Ceram Soc 86:1401-1408.

Filser F, Kocher P, Gauckler LJ (2003). Net-shaping of ceramic components Menezes RR, Souto PM, Kiminami RH (2007). Microwave hybrid fast

by direct ceramic machining. Assembly Autom 23:382-390. sintering of porcelain bodies. J Mater Process Tech 190:223-229.

Gahr KH, Bundschuh W, Zimmerlin B (1993). Effect of grain size on fric- Miranda P, Saiz E, Gryn K, Tomsia AP (2006). Sintering and robocasting of

tion and sliding wear of oxide ceramics. Wear 162-164A:269-279. beta-tricalcium phosphate scaffolds for orthopaedic applications. Acta

Garvie RC, Nicholson PS (1972). Phase analysis in zirconia systems. J Am Biomater 2:457-466.

Ceram Soc 55:303-305. Mitov G, Heintze SD, Walz S, Woll K, Muecklich F, Pospiech P (2012).

Garvie RC, Hannink RH, Pascoe RT (1975). Ceramic steel? Nature 258:703- Wear behavior of dental Y-TZP ceramic against natural enamel after

704. different finishing procedures. Dent Mater 28:909-918.

Goodridge RD, Dalgarno KW, Wood DJ (2006). Indirect selective laser Nathanson D, Chu S, Yamamoto H, Stappert CF (2010). Performance of

sintering of an apatite-mullite glass-ceramic for potential use in bone zirconia based crowns and FPDs in prosthodontic practice. J Dent Res

replacement applications. Proc Inst Mech Eng H 220:57-68. 89(Spec Iss B):Abstract #2115 (https://iadr.confex.com/iadr/2010barce/

Grossin D, Rollin-Martinet S, Estournes C, Rossignol F, Champion E, webprogram/Paper140795.html).

Combes C, et al. (2010). Biomimetic apatite sintered at very low tem- Oghbaei M, Mirzaee O (2010). Microwave versus conventional sintering: a

perature by spark plasma sintering: physico-chemistry and microstruc- review of fundamentals, advantages and applications. J Alloys Comp

ture aspects. Acta Biomater 6:577-585. 494:175-189.

Guazzato M, Albakry M, Ringer SP, Swain MV (2004). Strength, fracture Oh GJ, Lee K, Lee DJ, Lim HP, Yun KD, Ban JS, et al. (2012). Effect of

toughness and microstructure of a selection of all-ceramic materials. metal chloride solutions on coloration and biaxial flexural strength of

Part I. Pressable and alumina glass-infiltrated ceramics. Dent Mater yttria-stabilized zirconia. Met Mater Int 18:805-812.

20:441-448. Porwal H, Grasso S, Cordero-Arias L, Li C, Boccaccini A, Reece M (2014).

Hasegawa H (1983). Rhombohedral phase produces in abraded surfaces of Processing and bioactivity of 45S5 Bioglass®-graphene nanoplatelets

partially stabilized zirconia (PSZ). J Mater Sci Lett 2:91-93. composites. J Mater Sci: Mater Med 25:1403-1413.

Hasegawa H, Hioki T, Kamigaito O (1985). Cubic-to-rhombohedral phase- Sailer I, Feher A, Filser F, Lüthy H, Gauckler LJ, Scharer P, et al. (2006).

transformation in zirconia by ion-implantation. J Mater Sci Lett 4:1092- Prospective clinical study of zirconia posterior fixed partial dentures:

1094. 3-year follow-up. Quintessence Int 37:685-693.

He LH, Swain M (2011). A novel polymer infiltrated ceramic dental mate- Sailer I, Feher A, Filser F, Gauckler LJ, Lüthy H, Hämmerle CH (2007).

rial. Dent Mater 27:527-534. Five-year clinical results of zirconia frameworks for posterior fixed

Janyavula S, Lawson N, Cakir D, Beck P, Ramp LC, Burgess JO (2013). The partial dentures. Int J Prosthodont 20:383-388.

wear of polished and glazed zirconia against enamel. J Prosthet Dent Sailer I, Philipp A, Zembic A, Pjetursson BE, Hämmerle CH, Zwahlen M

109:22-29. (2009). A systematic review of the performance of ceramic and metal

Kao HC, Ho FY, Yang CC, Wei WJ (2000). Surface machining of fine-grain implant abutments supporting fixed implant reconstructions. Clin Oral

Y-TZP. J Eur Ceram Soc 20:2447-2455. Implants Res 20(Suppl 4):4-31.

Katz JD (1992). Microwave sintering of ceramics. Ann Rev Mater Sci Shah K, Holloway JA, Denry IL (2008). Effect of coloring with various

22:153-170. metal oxides on the microstructure, color, and flexural strength of

Kelly JR, Denry I (2008). Stabilized zirconia as a structural material. Dent 3Y-TZP. J Biomed Mater Res B Appl Biomater 87:329-337.

Mater 24:289-298. Shen Z, Nygren M (2005). Microstructural prototyping of ceramics by

Kelly JR, Rungruanganunt P, Hunter B, Vailati F (2010). Development of a kinetic engineering: applications of spark plasma sintering. Chem Rec

clinically validated bulk failure test for ceramic crowns. J Prosthet Dent 5:173-184.

104:228-238. Silva NR, Witek L, Coelho PG, Thompson VP, Rekow ED, Smay J (2011).

Keuper M, Eder K, Berthold C, Nickel KG (2013). Direct evidence for Additive CAD/CAM process for dental prostheses. J Prosthodont

continuous linear kinetics in the low-temperature degradation of Y-TZP. 20:93-96.

Acta Biomater 9:4826-4835. Smay JE, Cesarano J, Lewis JA (2002). Colloidal inks for directed assembly

Kim DY, Han YH, Lee JH, Kang IK, Jang BK, Kim S (2014). Characterization of 3-D periodic structures. Langmuir 18:5429-5437.

of multiwalled carbon nanotube-reinforced hydroxyapatite composites Stawarczyk B, Özcan M, Schmutz F, Trottmann A, Roos M, Hämmerle CH

consolidated by spark plasma sintering. Biomed Res Int 2014:768254. (2013). Two-body wear of monolithic, veneered and glazed zirconia

Kim MJ, Ahn JS, Kim JH, Kim HY, Kim WC (2013). Effects of the sintering and their corresponding enamel antagonists. Acta Odontol Scand

conditions of dental zirconia ceramics on the grain size and translu- 71:102-112.

cency. J Adv Prosthodont 5:161-166. Stoto T, Nauer M, Carry C (1991). Influence of residual impurities on phase

Kitano Y, Mori Y, Ishitani A, Masaki T (1988). Rhombohedral phase in partitioning and grain-growth processes of Y-TZP materials. J Am

Y2O3-partially-stabilized ZrO2. J Am Ceram Soc 71:C34-C36. Ceram Soc 74:2615-2621.

Kondoh J (2004). Origin of the hump on the left shoulder of the x-ray dif- Subbarao EC (1981). Zirconia – an overview. In: Science and technology of

fraction peaks observed in Y2O3-fully and partially stabilized ZrO2. zirconia. Heuer AH, Hobbs LW, editors. Columbus, OH: The American

J Alloy Compd 375:270-282. Ceramic Society, pp 1-24.

Kontos L, Schille C, Schweizer E, Geis-Gerstörfer J (2013). Influence of Suttor D, Hauptmann H, Schnagl R, Frank S, inventors (2004). 3M Espe AG

surface treatment on the wear of solid zirconia. Acta Odontol Scand assignee. Coloring ceramics by way of ionic or complex-containing

71:482-487. solutions. United States Patent #6,709,694.

Kruger S, Deubener J, Ritzberger C, Holand W (2013). Nucleation kinetics Swain MV (2014). Impact of oral fluids on dental ceramics: What is the

of lithium metasilicate in ZrO2-bearing lithium disilicate glasses for clinical relevance? Dent Mater 30:33-42.

dental application. Int J Appl Glass Sci 4:9-19. Taylor TD, Klotz MW, Lawton RA (2014). Titanium tattooing associated

Lewis JA (2000). Colloidal processing of ceramics. J Am Ceram Soc with zirconia implant abutments: a clinical report of two cases. Int J

83:2341-2359. Oral Maxillofac Implants 29:958-960.

López-Esteban S, Bartolomé JF, Díaz LA, Esteban-Tejeda L, Prado C, Tsitrou EA, Northeast SE, van Noort R (2007). Brittleness index of machin-

López-Piriz R, et al. (2014). Mechanical performance of a biocompat- able dental materials and its relation to the marginal chipping factor.

ible biocide soda-lime glass-ceramic. J Mech Behav Biomed Mater J Dent 35:897-902.

34:302-312. Virkar AV, Matsumoto RL (1986). Ferroelastic domain switching as a tough-

Marinis A, Aquilino SA, Lund PS, Gratton DG, Stanford CM, Diaz-Arnold AM, ening mechnism in tetragonal zirconia. J Am Ceram Soc 69:C224-C226.

et al. (2013). Fracture toughness of yttria-stabilized zirconia sintered in Wegner LD, Gibson LJ (2001). The fracture toughness behaviour of inter-

conventional and microwave ovens. J Prosthet Dent 109:165-171. penetrating phase composites. Int J Mech Sci 43:1771-1791.

Downloaded from jdr.sagepub.com at Uni of Southern Queensland on October 26, 2014 For personal use only. No other uses without permission.

© International & American Associations for Dental Research

You might also like

- How To Bond Zirconia - The APC Concept PDFDocument9 pagesHow To Bond Zirconia - The APC Concept PDFKelly Katherine0% (1)

- How To Bond Zirconia The Apc ConceptDocument8 pagesHow To Bond Zirconia The Apc ConceptJoshua Valdez100% (1)

- Materials Science and Engineering Unit 1 PDFDocument19 pagesMaterials Science and Engineering Unit 1 PDFParis100% (1)

- Tipos Zirconia Marcas Comerciales JDR PDFDocument9 pagesTipos Zirconia Marcas Comerciales JDR PDFgerson fabian arangoNo ratings yet

- Ceramic in Dentistry 1Document14 pagesCeramic in Dentistry 1FofeNo ratings yet

- Journal of Dental Research: Resin-Composite Blocks For Dental CAD/CAM ApplicationsDocument4 pagesJournal of Dental Research: Resin-Composite Blocks For Dental CAD/CAM Applicationsgerson fabian arangoNo ratings yet

- 2007 Ceramic MaterialDocument17 pages2007 Ceramic Material이상민No ratings yet

- Evaluation of Hardness-MostafaDocument8 pagesEvaluation of Hardness-MostafaOmar PLNo ratings yet

- Novel Zirconia Materials in Dentistry: Y. Zhang and B.R. LawnDocument8 pagesNovel Zirconia Materials in Dentistry: Y. Zhang and B.R. Lawnkr7wyddmw2No ratings yet

- Biomedicines 11 03116Document18 pagesBiomedicines 11 03116Jose Manuel Quintero RomeroNo ratings yet

- Dental Research Journal: Marginal Adaptation of Spinell Inceram and Feldspathic Porcelain Laminate VeneersDocument6 pagesDental Research Journal: Marginal Adaptation of Spinell Inceram and Feldspathic Porcelain Laminate VeneersLuis Alberto Carpio MorenoNo ratings yet

- DR - Jafarian ms01759 Ghodsi - ProofDocument14 pagesDR - Jafarian ms01759 Ghodsi - ProofDaniel AtiehNo ratings yet

- All-Ceramic Restorations: A Review of The Literature: Saudi Dental JournalDocument8 pagesAll-Ceramic Restorations: A Review of The Literature: Saudi Dental JournalScribeNo ratings yet

- J Esthet Restor Dent - 2023 - Sulaiman - Zirconia Restoration Types Properties Tooth Preparation Design and Bonding ADocument7 pagesJ Esthet Restor Dent - 2023 - Sulaiman - Zirconia Restoration Types Properties Tooth Preparation Design and Bonding AAlfred OrozcoNo ratings yet

- Molecules 27 05116Document4 pagesMolecules 27 05116Odontologia HmaspNo ratings yet

- From Porcelain-fused-To-metal To Zirconia Clinical andDocument14 pagesFrom Porcelain-fused-To-metal To Zirconia Clinical andMayra Ortiz HerreraNo ratings yet

- Journal Homepage: - : IntroductionDocument7 pagesJournal Homepage: - : IntroductionIJAR JOURNALNo ratings yet

- (Tang Et Al 2021) Quantitative Analysis On The Wear of Monolithic Zirconia Crowns On Antagonist TeethDocument11 pages(Tang Et Al 2021) Quantitative Analysis On The Wear of Monolithic Zirconia Crowns On Antagonist TeethIzham KhairuNo ratings yet

- All-Ceramic Restorations - A Review of The LiteratureDocument8 pagesAll-Ceramic Restorations - A Review of The LiteratureOdonto Uninassau 4p NoiteNo ratings yet

- Clinical Success of Zirconia in Dental Applications: KeywordsDocument5 pagesClinical Success of Zirconia in Dental Applications: KeywordsJulio TorresNo ratings yet

- Zirconia Based Dental Biomaterials: Structure, Mechanical Properties, Biocompatibility, Surface Modification, and Applications As ImplantDocument7 pagesZirconia Based Dental Biomaterials: Structure, Mechanical Properties, Biocompatibility, Surface Modification, and Applications As ImplantAsyyrafNo ratings yet

- Application and Success Rates of Zirconia - A ReviewDocument9 pagesApplication and Success Rates of Zirconia - A ReviewIJAR JOURNALNo ratings yet

- 304 Review ArticleDocument4 pages304 Review ArticleDr Raj Jain100% (1)

- Cementation of Monolithic Zirconia Crown ProsthesisDocument4 pagesCementation of Monolithic Zirconia Crown ProsthesisShubham TawadeNo ratings yet

- Dental CeramicsDocument8 pagesDental Ceramicshamad_kayani_774954100% (1)

- Use of Zirconia in Dentistry: An Overview: January 2014Document10 pagesUse of Zirconia in Dentistry: An Overview: January 2014ميديكال انجنيرنج لتركيبات الأسنانNo ratings yet

- 1 s2.0 S0300571221000828 Main 2Document10 pages1 s2.0 S0300571221000828 Main 2Sandra Villalobos ArmentaNo ratings yet

- Novel Innovations in Dental Implant Biomaterials Science: Zirconia and PEEK PolymersDocument5 pagesNovel Innovations in Dental Implant Biomaterials Science: Zirconia and PEEK PolymersSatya AsatyaNo ratings yet

- Accepted Author VersionDocument65 pagesAccepted Author VersionLucianoNo ratings yet

- Recommended Cementation For Monolithic Zirconia Crowns: Drug Invention Today April 2018Document4 pagesRecommended Cementation For Monolithic Zirconia Crowns: Drug Invention Today April 2018Hector MurilloNo ratings yet

- Australian Dental Journal - 2011 - Miyazaki - CAD CAM Systems Available For The Fabrication of Crown and BridgeDocument10 pagesAustralian Dental Journal - 2011 - Miyazaki - CAD CAM Systems Available For The Fabrication of Crown and BridgeSekarSukomasajiNo ratings yet

- ContentServer Asp-2Document10 pagesContentServer Asp-2Lex Puma IdmeNo ratings yet

- Dental Ceramics: A Review of New Materials and Processing MethodsDocument15 pagesDental Ceramics: A Review of New Materials and Processing Methodsmilagros falconNo ratings yet

- ZIRCOMADocument4 pagesZIRCOMARatih CynthiaNo ratings yet

- Comparative Analysis of Transmittance For Different Types of Commercially Available Zirconia and Lithium Disilicate MaterialsDocument6 pagesComparative Analysis of Transmittance For Different Types of Commercially Available Zirconia and Lithium Disilicate MaterialsNaoki MezarinaNo ratings yet

- Zirconia As A Dental BiomaterialDocument14 pagesZirconia As A Dental BiomaterialaliNo ratings yet

- 10.1515 - Ntrev 2019 0035Document9 pages10.1515 - Ntrev 2019 0035isra suandiNo ratings yet

- 1 s2.0 S0109564124000447 MainDocument13 pages1 s2.0 S0109564124000447 MaincosadedubsNo ratings yet

- MAROTTO 2023. Partial Ceramic Veneer Technique For Challenging Esthetic Frontal Restorative ProceduresDocument11 pagesMAROTTO 2023. Partial Ceramic Veneer Technique For Challenging Esthetic Frontal Restorative ProceduresSandry marquezNo ratings yet

- IJEDe 15 03 Rocca 852 6Document23 pagesIJEDe 15 03 Rocca 852 6Danny Eduardo RomeroNo ratings yet

- ConnectionsDocument14 pagesConnectionsabraham OrtizNo ratings yet

- Medicina 59 02135Document18 pagesMedicina 59 02135sousourimeNo ratings yet

- ZirconiaDocument8 pagesZirconiaXIOMARA YASMITH REYES PALOMINONo ratings yet

- Implant Abutment Selection Criteria: Acta Scientific Dental Sciences (ISSN: 2581-4893)Document8 pagesImplant Abutment Selection Criteria: Acta Scientific Dental Sciences (ISSN: 2581-4893)priyaNo ratings yet

- Desalination and Water Treatment: Click For UpdatesDocument6 pagesDesalination and Water Treatment: Click For UpdatesMALIK ZARYABBABARNo ratings yet

- Jurnal Gigi 2019Document6 pagesJurnal Gigi 2019kinayungNo ratings yet

- Zirconia Dental Implants: A Literature Review: Journal of Oral Implantology June 2011Document11 pagesZirconia Dental Implants: A Literature Review: Journal of Oral Implantology June 2011Seno FauziNo ratings yet

- Recent Advances in Esth Tic Restorative Materials: Dental CeramicsDocument4 pagesRecent Advances in Esth Tic Restorative Materials: Dental CeramicsSMART SMARNo ratings yet

- Aboutara 2011Document4 pagesAboutara 2011Alejandra LorancaNo ratings yet

- Zirconia ArticleDocument7 pagesZirconia ArticleMichael TheofanusNo ratings yet

- Bonding To ZirconiaDocument7 pagesBonding To ZirconiavonNo ratings yet

- Effect of Surface Conditioning Techniques On The Resistance of Resin Composite Core Materiais On Titanium PostsDocument6 pagesEffect of Surface Conditioning Techniques On The Resistance of Resin Composite Core Materiais On Titanium PostsFrontiersNo ratings yet

- Use of Zirconia in Dentistry: An OverviewDocument9 pagesUse of Zirconia in Dentistry: An Overviewalfi MubarakNo ratings yet

- A Systematic Review of The Survival and Complication Rates of Zirconia-Ceramic and Metal-Ceramic Single CrownsDocument17 pagesA Systematic Review of The Survival and Complication Rates of Zirconia-Ceramic and Metal-Ceramic Single CrownsAndreea GîrleanuNo ratings yet

- CAD/CAM Ceramic Restorative Materials For Natural Teeth: F.A. Spitznagel, J. Boldt, and P.C. GierthmuehlenDocument10 pagesCAD/CAM Ceramic Restorative Materials For Natural Teeth: F.A. Spitznagel, J. Boldt, and P.C. GierthmuehlenlimemNo ratings yet

- Clinical Oral Implants Res - 2018 - Sailer - A Systematic Review of The Survival and Complication Rates of Zirconia CeramicDocument15 pagesClinical Oral Implants Res - 2018 - Sailer - A Systematic Review of The Survival and Complication Rates of Zirconia CeramicTao LinksNo ratings yet

- Comparison of The Load-Bearing Capacities of MonolDocument6 pagesComparison of The Load-Bearing Capacities of MonolSkAliHassanNo ratings yet

- Clinical Case Reports - 2023 - Karimi - Veneer Crowns in Anterior Endodontically Treated Teeth A Case Report With 1 YearDocument8 pagesClinical Case Reports - 2023 - Karimi - Veneer Crowns in Anterior Endodontically Treated Teeth A Case Report With 1 YearOgie WijayantoNo ratings yet

- Digitally Fabricated Dentures For Full Mouth Rehabilitation With Zirconia, Polyetheretherketone and Selective Laser Melted Ti-6Al-4V MaterialDocument9 pagesDigitally Fabricated Dentures For Full Mouth Rehabilitation With Zirconia, Polyetheretherketone and Selective Laser Melted Ti-6Al-4V MaterialWeiting LeeNo ratings yet

- Advances in Glass and Optical Materials: Proceedings of the 107th Annual Meeting of The American Ceramic Society, Baltimore, Maryland, USA 2005From EverandAdvances in Glass and Optical Materials: Proceedings of the 107th Annual Meeting of The American Ceramic Society, Baltimore, Maryland, USA 2005Shibin JiangNo ratings yet

- Advances in Photonic Materials and Devices: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004From EverandAdvances in Photonic Materials and Devices: Proceedings of the 106th Annual Meeting of The American Ceramic Society, Indianapolis, Indiana, USA 2004Suhas BhandarkarNo ratings yet

- 1-s2.0-S0955221918306782-main-2Document27 pages1-s2.0-S0955221918306782-main-2Hema SinghNo ratings yet

- Amelogenesis ImperfectaDocument13 pagesAmelogenesis ImperfectaHema SinghNo ratings yet

- Ulrich Lohbauer, Renan Belli - Dental Ceramics - Fracture Mechanics and Engineering Design-Springer (2022)Document134 pagesUlrich Lohbauer, Renan Belli - Dental Ceramics - Fracture Mechanics and Engineering Design-Springer (2022)Hema SinghNo ratings yet

- SJ BDJ 2013 101Document1 pageSJ BDJ 2013 101Hema SinghNo ratings yet

- Dear Hema Singh, 11/01/2023 Rs. 4606/ : It's Time To Renew Your (MOTOR PRIVATE CAR PACKAGE POLICY) InsuranceDocument2 pagesDear Hema Singh, 11/01/2023 Rs. 4606/ : It's Time To Renew Your (MOTOR PRIVATE CAR PACKAGE POLICY) InsuranceHema SinghNo ratings yet

- Hickey 1991Document6 pagesHickey 1991Hema SinghNo ratings yet

- Fundamental Relation Between Phased Array Radiation and Scattering FieldsDocument13 pagesFundamental Relation Between Phased Array Radiation and Scattering FieldsHema SinghNo ratings yet

- Wjoud 2017 08 202Document5 pagesWjoud 2017 08 202Hema SinghNo ratings yet

- 37-Article Text-62-1-10-20200615Document5 pages37-Article Text-62-1-10-20200615Hema SinghNo ratings yet

- Moving From Legacy 24 GHZ To State-Of-The-Art 77 GHZ RadarDocument7 pagesMoving From Legacy 24 GHZ To State-Of-The-Art 77 GHZ RadarHema SinghNo ratings yet

- Mapex AN0320SN PDFDocument1 pageMapex AN0320SN PDFDiegoTierradentroNo ratings yet

- Oliver and Pharr - Nanoindentation History - 021511Document41 pagesOliver and Pharr - Nanoindentation History - 021511Ahmad NawazNo ratings yet

- IA Earthing Calculations BS 7430 +A1 2015 EEADocument9 pagesIA Earthing Calculations BS 7430 +A1 2015 EEAغيلان الحاشديNo ratings yet

- Ventilation in The Condor MineDocument9 pagesVentilation in The Condor MineClaudia ZicriNo ratings yet

- Elevation of Control RoomDocument1 pageElevation of Control RoomgohilnarendraNo ratings yet

- Creepof CeramicsDocument14 pagesCreepof CeramicsTejinder SinghNo ratings yet

- Ashcroft El Data SheetDocument1 pageAshcroft El Data SheetmisaelzaNo ratings yet

- Gaz 12kg and Stove-ManualDocument41 pagesGaz 12kg and Stove-ManualAlisa CampbellNo ratings yet

- Att #3-3-.Bill of MaterialsDocument4 pagesAtt #3-3-.Bill of MaterialsAnonymous Iev5ggSRNo ratings yet

- Tapcon: Storm Guard AnchorsDocument2 pagesTapcon: Storm Guard Anchorsblessed cccNo ratings yet

- Ec230 PDFDocument57 pagesEc230 PDFSOUMYA BHATTNo ratings yet

- AC Air Cycles PDFDocument18 pagesAC Air Cycles PDFJoJa JoJa100% (1)

- Rev 2Document18 pagesRev 2aun_nustNo ratings yet

- Air Conditioner Parts For Assembling and Repairing Manufacturer-Supplier ChinaDocument9 pagesAir Conditioner Parts For Assembling and Repairing Manufacturer-Supplier ChinaSiva 93No ratings yet

- Chen 801-T3Document28 pagesChen 801-T3hussainiNo ratings yet

- Gy-Roc "B": Metal Polishing Instructions - Including For Precious MetalsDocument2 pagesGy-Roc "B": Metal Polishing Instructions - Including For Precious Metalsbob100% (1)

- A New Approach of Strengthening - Spinodal DecompositionDocument9 pagesA New Approach of Strengthening - Spinodal DecompositionRolando CastilloNo ratings yet

- Katalog Griff 2021Document75 pagesKatalog Griff 2021Meita RatrianaNo ratings yet

- 3.1 Overview of Flat Plate Collectors: PrintDocument3 pages3.1 Overview of Flat Plate Collectors: Printsuseendran sNo ratings yet

- Vicinity Map: Mangaldan Public MarketDocument1 pageVicinity Map: Mangaldan Public Marketcristian gonzalesNo ratings yet

- Architectural Precast Concrete Caulking-Joint DetailDocument61 pagesArchitectural Precast Concrete Caulking-Joint DetaildedypunyaNo ratings yet

- Product Data SheetsDocument44 pagesProduct Data Sheetssalem elhajNo ratings yet

- Quote - Alain VillaDocument3 pagesQuote - Alain VillaZayed Abdul LatheefNo ratings yet

- Bathroom Shower 1accessories 2Document31 pagesBathroom Shower 1accessories 2César Fernando Gómez VelásquezNo ratings yet

- Visit To Induction HardeningDocument9 pagesVisit To Induction Hardeningdada kolekarNo ratings yet

- Foundations For Highrise BuildingsDocument54 pagesFoundations For Highrise Buildings李卓倫100% (1)

- Showertite DATASHEETSDocument2 pagesShowertite DATASHEETSsin85No ratings yet