Professional Documents

Culture Documents

Weld Test Format3

Weld Test Format3

Uploaded by

hundred.crafts0 ratings0% found this document useful (0 votes)

0 views1 pageOriginal Title

Weld Test format3

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

0 views1 pageWeld Test Format3

Weld Test Format3

Uploaded by

hundred.craftsCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

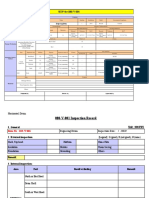

Addis Ababa University Addis Ababa University

Addis Ababa Institute of Technology Addis Ababa Institute of Technology

School of Mechanical and Industrial Engineering School of Mechanical and Industrial Engineering

Weld Test - Visual Inspection Format Weld Test - Visual Inspection Format

Node No. Node No.

Category Parameters Yes No Yes No Yes No Yes No Yes No Yes No Yes No Yes No Category Parameters Yes No Yes No Yes No Yes No Yes No Yes No Yes No Yes No

Weld surface finish Weld surface finish

Surface Surface

Slag Slag

Condition Condition

Rust/ corrosion/ erosion Rust/ corrosion/ erosion

Crack Crack

Unfilled crate, Unfilled crate,

Un-fused welds/ Lack of fusion Un-fused welds/ Lack of fusion

Weld defects Weld defects

Pin hole, blowholes, Pin hole, blowholes,

Exposed porosity, Exposed porosity,

Exposed inclusions Exposed inclusions

Burning, Burning,

Damages to the Damages to the

Overheating Overheating

parent metal parent metal

Undercut - Not exceed 1mm Undercut - Not exceed 1mm

Bead alignment Thickness Reduction Not exceed 0.6mm Bead alignment Thickness Reduction Not exceed 0.6mm

to the parent Alignment Tolerance to the parent Alignment Tolerance

material Smooth Contour Connectivity material Smooth Contour Connectivity

Excessive convexity or concavity/ Fillet

Excessive convexity or concavity/ Fillet

Overlap

Overlap

Unequal leg lengths

Unequal leg lengths

Excessive reinforcement

Profile defects Excessive reinforcement

Incompletely filled groove Profile defects

Excessive penetration bead Incompletely filled groove

Excessive root groove Excessive penetration bead

Excessive shrinkage groove Excessive root groove

ripple marks, weaving Excessive shrinkage groove

faults, chipping and peening marks ripple marks, weaving

In correct finish Spatter faults, chipping and peening marks

Under flushing(Excessive grinding) In correct finish Spatter

Uneven weld Under flushing(Excessive grinding)

Uneven weld

Addis Ababa University

Addis Ababa Institute of Technology Addis Ababa University

School of Mechanical and Industrial Engineering Addis Ababa Institute of Technology

Weld Test - Visual Inspection Format School of Mechanical and Industrial Engineering

Node No. Weld Test - Visual Inspection Format

Category Parameters Yes No Yes No Yes No Yes No Yes No Yes No Yes No Yes No Node No.

Weld surface finish Category Parameters Yes No Yes No Yes No Yes No Yes No Yes No Yes No Yes No

Surface

Slag Weld surface finish

Condition Surface

Rust/ corrosion/ erosion Slag

Condition

Crack Rust/ corrosion/ erosion

Unfilled crate, Crack

Un-fused welds/ Lack of fusion Unfilled crate,

Weld defects

Pin hole, blowholes, Un-fused welds/ Lack of fusion

Weld defects

Exposed porosity, Pin hole, blowholes,

Exposed inclusions Exposed porosity,

Burning, Exposed inclusions

Damages to the

Overheating Burning,

parent metal Damages to the

Undercut - Not exceed 1mm Overheating

parent metal

Bead alignment Thickness Reduction Not exceed 0.6mm Undercut - Not exceed 1mm

to the parent Alignment Tolerance Bead alignment Thickness Reduction Not exceed 0.6mm

material Smooth Contour Connectivity to the parent Alignment Tolerance

Excessive convexity or concavity/ Fillet material Smooth Contour Connectivity

Overlap Excessive convexity or concavity/ Fillet

Unequal leg lengths Overlap

Excessive reinforcement Unequal leg lengths

Profile defects

Incompletely filled groove Excessive reinforcement

Profile defects

Excessive penetration bead Incompletely filled groove

Excessive root groove Excessive penetration bead

Excessive shrinkage groove Excessive root groove

ripple marks, weaving Excessive shrinkage groove

faults, chipping and peening marks ripple marks, weaving

In correct finish Spatter faults, chipping and peening marks

Under flushing(Excessive grinding) In correct finish Spatter

Uneven weld Under flushing(Excessive grinding)

Uneven weld

You might also like

- 06 791 1 - Rev2 PDFDocument94 pages06 791 1 - Rev2 PDFMaria Ignacia VasquezNo ratings yet

- Main Beaaring Inspection ReportDocument3 pagesMain Beaaring Inspection Reportasanka136No ratings yet

- CSWIP Welding Inspection Notes and QuestionsDocument133 pagesCSWIP Welding Inspection Notes and Questionslram70100% (20)

- KE13N Upload of COPA Offline PlanningDocument6 pagesKE13N Upload of COPA Offline PlanningMOORTHYNo ratings yet

- Harddisk PCB Repairing PDFDocument18 pagesHarddisk PCB Repairing PDFmasood100% (1)

- Design and InformationDocument168 pagesDesign and InformationPinkuProtimGogoiNo ratings yet

- Weld Test Format2Document1 pageWeld Test Format2hundred.craftsNo ratings yet

- Plate Sample Cap: Welding Process MMA (SMAW)Document14 pagesPlate Sample Cap: Welding Process MMA (SMAW)Readersmo0% (1)

- Welding Defect Inspection - OptDocument25 pagesWelding Defect Inspection - Optzenmatheo100% (1)

- Welding For 2022 GATE ESE PSUs by S K MondalDocument84 pagesWelding For 2022 GATE ESE PSUs by S K MondalNabin MukherjeeNo ratings yet

- Arc Welding Length (SAWL), Submerged Arc Welding Helix (SAWH), High Frequency Welding (HFW)Document1 pageArc Welding Length (SAWL), Submerged Arc Welding Helix (SAWH), High Frequency Welding (HFW)Wojciech SpychalskiNo ratings yet

- Casting Defects: Casting Design and Simulation 2012Document3 pagesCasting Defects: Casting Design and Simulation 2012talk2sumantaNo ratings yet

- Plate Sample 6A Cap: Welding Process MMA (SMAW)Document25 pagesPlate Sample 6A Cap: Welding Process MMA (SMAW)Qaisir MehmoodNo ratings yet

- 03 Welding Imperfections & Materilal Inspection+Notes+AnsDocument42 pages03 Welding Imperfections & Materilal Inspection+Notes+AnsTakul ThongyooNo ratings yet

- Mapa Conceptual Lluvia de Ideas Doodle Creativo Scrapbook Multicolor PastelDocument1 pageMapa Conceptual Lluvia de Ideas Doodle Creativo Scrapbook Multicolor PastelMaria RocaNo ratings yet

- Fabrication MethodsDocument6 pagesFabrication MethodsSmit GandhiNo ratings yet

- Weldhelp MatrixDocument1 pageWeldhelp MatrixJoel BrasilBorgesNo ratings yet

- Weld Test Format1-2Document2 pagesWeld Test Format1-2hundred.craftsNo ratings yet

- Welding For 2023 GATE ESE PSUs by S K MondalDocument84 pagesWelding For 2023 GATE ESE PSUs by S K MondalRaj SinhaNo ratings yet

- 6a CapDocument1 page6a CapMurali D MurthyNo ratings yet

- Surface Finish Cross ReferenceDocument1 pageSurface Finish Cross ReferencemarcalpiNo ratings yet

- DC 11Document39 pagesDC 11SatSathyanNo ratings yet

- Week 1Document22 pagesWeek 1JoRdAn HaNo ratings yet

- Hard Cut End MillsDocument25 pagesHard Cut End MillsalphatoolsNo ratings yet

- 2023-04-07 Ksi Rod N' Reel - Double Angle SsDocument6 pages2023-04-07 Ksi Rod N' Reel - Double Angle SsRavi LoharNo ratings yet

- 2 Terms and Definitions SectionDocument39 pages2 Terms and Definitions SectionPraviBeetlesNo ratings yet

- Resistant Materials: Student Workbook 3aDocument24 pagesResistant Materials: Student Workbook 3a0000No ratings yet

- CPD Floors Part 4Document15 pagesCPD Floors Part 4Christo BoschNo ratings yet

- AWS A2.4 98 Standards Symbols For Welding Bracing and Nondestructive Examination Page 107Document1 pageAWS A2.4 98 Standards Symbols For Welding Bracing and Nondestructive Examination Page 107JuniorNo ratings yet

- Presentation 1Document7 pagesPresentation 1kihal zohirNo ratings yet

- Low Res Wearplates Nov 2011 v4Document3 pagesLow Res Wearplates Nov 2011 v4foo-hoat LimNo ratings yet

- WELDING ManualDocument10 pagesWELDING ManualsoftsuryaNo ratings yet

- Wire RodDocument2 pagesWire RodmljaininsulationNo ratings yet

- Press Part Nut-Spot-Mig Stud Welding Defects SheetDocument3 pagesPress Part Nut-Spot-Mig Stud Welding Defects SheetSanjayNo ratings yet

- Engine Bearing Failure Analysis GuideDocument1 pageEngine Bearing Failure Analysis GuideMahmoud AbdellatifNo ratings yet

- King Engine BearingsDocument1 pageKing Engine BearingsDanny BenderNo ratings yet

- SEIP For 080-V-001: Degassing DrumDocument6 pagesSEIP For 080-V-001: Degassing DrumThinh NguyenNo ratings yet

- Robotic - WPS Trials Summary 1Document3 pagesRobotic - WPS Trials Summary 1Prabhakaran CHNQualityNo ratings yet

- Surface Defects in Steel ProductsDocument41 pagesSurface Defects in Steel ProductsShilaj PNo ratings yet

- E Min - Wood EngineeringDocument6 pagesE Min - Wood EngineeringNiraj ShresthaNo ratings yet

- Z Welding Inspection Notes and QuestionsDocument141 pagesZ Welding Inspection Notes and Questionsattalah.djaafar19887No ratings yet

- Wire Sheave PDFDocument1 pageWire Sheave PDFBenny YacilaNo ratings yet

- SOLDADURADocument10 pagesSOLDADURAgNo ratings yet

- Product Technology: NDT Training & CertificationDocument41 pagesProduct Technology: NDT Training & CertificationSANUNo ratings yet

- Weld DesignDocument26 pagesWeld DesignRaghavendra Kilari100% (1)

- Diamond Bit Design HandoutDocument19 pagesDiamond Bit Design Handoutamin peyvand100% (1)

- CSWIP 3 1 Welding Inspection NotesDocument102 pagesCSWIP 3 1 Welding Inspection NotesPavan KallempudiNo ratings yet

- Radiographic Interpretation Radiographic Interpretation Radiographic Interpretation Radiographic InterpretationDocument49 pagesRadiographic Interpretation Radiographic Interpretation Radiographic Interpretation Radiographic InterpretationWanda LopezNo ratings yet

- 7-Welded ConnectionsDocument54 pages7-Welded ConnectionsetemNo ratings yet

- OscarII Manual PartsBook ElectricalDocument84 pagesOscarII Manual PartsBook ElectricalPablo SchinkeNo ratings yet

- Clotan Steel IBR Brochure DigitalDocument6 pagesClotan Steel IBR Brochure DigitalPieter SteenkampNo ratings yet

- Design and Testing of A 6 Inch Control Valve With A Multi-Stage Anti-Cavitation Trim PDFDocument149 pagesDesign and Testing of A 6 Inch Control Valve With A Multi-Stage Anti-Cavitation Trim PDFCarlos HilarioNo ratings yet

- 4 5792176376941381886 PDFDocument54 pages4 5792176376941381886 PDFAlex MekoNo ratings yet

- All Universities of PakistanDocument131 pagesAll Universities of PakistanziaNo ratings yet

- Dimensional ModellingDocument26 pagesDimensional Modellingrizki r nasutionNo ratings yet

- CH 6 SOC210 Powerpoint FA2020Document17 pagesCH 6 SOC210 Powerpoint FA2020janNo ratings yet

- Lecture 2 - Introduction To Game Theory PDFDocument30 pagesLecture 2 - Introduction To Game Theory PDFSenthil S. VelNo ratings yet

- Tri-Rail FinalDocument124 pagesTri-Rail FinalNone None NoneNo ratings yet

- Tahseen Ejaz: Case Study: IDocument7 pagesTahseen Ejaz: Case Study: IbabuubabNo ratings yet

- MBTI Conflict Style TypesDocument11 pagesMBTI Conflict Style TypesfbxurumelaNo ratings yet

- CMOS Op AmpsDocument17 pagesCMOS Op AmpsEshan ShailendraNo ratings yet

- KunduDocument10 pagesKunduAshwary Sheel Wali Research Scholar, Dept of Mech Engg., IIT (BHU)No ratings yet

- Romance OracleDocument108 pagesRomance Oraclericky bernadoNo ratings yet

- Info Satelit ParabolaDocument3 pagesInfo Satelit ParabolaSetya MontanaNo ratings yet

- The Deep Web and Marianas WebDocument2 pagesThe Deep Web and Marianas Webulysses araoNo ratings yet

- DTM Acrylic Pimer Finish B66W1Document4 pagesDTM Acrylic Pimer Finish B66W1Vernon Jiménez FonsecaNo ratings yet

- Project AssignmentDocument2 pagesProject Assignmentpvr123pvr0% (1)

- LNG 26-62Document37 pagesLNG 26-62mohkal1260No ratings yet

- TB 621 25 Owners ManualDocument11 pagesTB 621 25 Owners ManualIBJSC.comNo ratings yet

- Instrumentation Design EngineeringDocument4 pagesInstrumentation Design EngineeringAwneesh Kumar100% (1)

- Biomechanics of RunningDocument19 pagesBiomechanics of RunningJaviera Paz VegaNo ratings yet

- L35 MC 6Document351 pagesL35 MC 6chuminhNo ratings yet

- Mass Upload and Mass Update GuideDocument23 pagesMass Upload and Mass Update GuideGeb SopNo ratings yet

- Club and Organization Monthly Plan Sports Club (Basketball)Document2 pagesClub and Organization Monthly Plan Sports Club (Basketball)Daphne BautistaNo ratings yet

- 3.2.11-LRFD Slab Bridge DesignDocument23 pages3.2.11-LRFD Slab Bridge DesignJose La Rosa BernalNo ratings yet