Professional Documents

Culture Documents

14.electrical Continuity of Composite Hoses

14.electrical Continuity of Composite Hoses

Uploaded by

Rmz ExeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

14.electrical Continuity of Composite Hoses

14.electrical Continuity of Composite Hoses

Uploaded by

Rmz ExeCopyright:

Available Formats

Electrical Continuity of Composite Hoses

Applications

When a hose is used to convey a non-conductive fluid, electrostatic charge is transferred from the fluid

to the hose wall. To prevent the occurrence of a static discharge all metal components of the hose

assembly must be earthed.

Amnitec composite hoses consist of a hose wall of thermoplastic fabrics and films with internal and

external wire helices. The standard method of end fitting attachment is by external swaging. The end

fitting tailpiece is designed specifically for this type of hose, having a scrolled section which screws

into the hose locating positively on the inner wire. The ferrule is swaged down onto the outer wire and

tailpiece, ensuring good electrical contact.

All Amnitec hoses are checked for full electrical continuity before dispatch and are certified as such.

It is recommended that electrical continuity be checked periodically while hoses are in service, to

ensure continued safe operation. This check should be made every six months.

• Lay the hose flat on the ground. Avoid contact on metallic parts to earth.

• The electric resistance is measured from coupling to coupling.

• Use for optimal measurement an Ohm meter (picture).

• Typically, a hose assembly will have a resistance value, acc to EN13765:2010, between

the end fittings for:

< 2,5 ohm/m for sizes less than 50mm

< 1,0 ohm/m for the 50mm size and above sizes

All information in this document is without any obligation, dimensions and weight are approximate only and the specifications are subject to change without any notice.

You might also like

- Diagrama hk.t.rt2842p639Document40 pagesDiagrama hk.t.rt2842p639Miguel Esteban0% (1)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- Led TV: Service ManualDocument65 pagesLed TV: Service ManualGuilherme StarkNo ratings yet

- Led TV: Service ManualDocument100 pagesLed TV: Service ManualEgor Nazarov100% (1)

- Safety Precautions in Handling Elecrical AppliancesDocument2 pagesSafety Precautions in Handling Elecrical AppliancesKunal MehraNo ratings yet

- Asco - Iom 327 SeriesDocument4 pagesAsco - Iom 327 SeriesFabio JuniorNo ratings yet

- Electrical SafetyDocument26 pagesElectrical SafetyBolo TransportNo ratings yet

- Earthing and LpsDocument32 pagesEarthing and LpsmohamedminnaNo ratings yet

- Power System-Ii (Protection & Switchgear) : Unit-1 SubstationDocument23 pagesPower System-Ii (Protection & Switchgear) : Unit-1 SubstationVicky LakhwalNo ratings yet

- EWISDocument170 pagesEWISHollins starsNo ratings yet

- Permanent Magnet Moving Coil: Principle of WorkingDocument25 pagesPermanent Magnet Moving Coil: Principle of Workinghpss77100% (1)

- Module 3 - 9 - Precommissioning Test in Domestic InstallationsDocument13 pagesModule 3 - 9 - Precommissioning Test in Domestic InstallationsCyril ZachariasNo ratings yet

- Bonding & Earthing (Final)Document67 pagesBonding & Earthing (Final)Vardaa Impex100% (2)

- Earthing - Basics, Methods, Requirements As Per I.S.I: AdminDocument2 pagesEarthing - Basics, Methods, Requirements As Per I.S.I: Adminbrian DeckerNo ratings yet

- 07.connecting Power WiresDocument16 pages07.connecting Power WiresThoi CoNo ratings yet

- Hvf21g Viewfiner For Panasonic CameraDocument0 pagesHvf21g Viewfiner For Panasonic Camera123456789bobNo ratings yet

- IES Darshan Study MaterialDocument76 pagesIES Darshan Study MaterialPatel Neel50% (2)

- LCD TV: Service ManualDocument99 pagesLCD TV: Service Manualcongiu luciano100% (1)

- Led LCD TV: Service ManualDocument42 pagesLed LCD TV: Service ManualJm QuemadoNo ratings yet

- wELDING MAIN PowerPoint PresentationDocument159 pageswELDING MAIN PowerPoint PresentationsanjibkrjanaNo ratings yet

- Unit 4: Electricity: IHM Notes Site - Hotel EngineeringDocument25 pagesUnit 4: Electricity: IHM Notes Site - Hotel EngineeringEr Navaraj ParajuliNo ratings yet

- 37LP1D Service ManualDocument52 pages37LP1D Service ManualDenilsonAraujoNo ratings yet

- Disconnectors DesignDocument14 pagesDisconnectors DesignTravis WoodNo ratings yet

- Abbeon Cal, Inc.: Model Bd-50E High Frequency Generator Operating ManualDocument7 pagesAbbeon Cal, Inc.: Model Bd-50E High Frequency Generator Operating ManualdanielvillagrapNo ratings yet

- ZETDCDocument14 pagesZETDCElijahNo ratings yet

- Earthing: Akhila.RDocument19 pagesEarthing: Akhila.Rksm_commonNo ratings yet

- 32lg30ra TaDocument24 pages32lg30ra TaMikaela MaçkoNo ratings yet

- Protective Elements in Power SystemsDocument30 pagesProtective Elements in Power SystemsvijayamargaretNo ratings yet

- LG 32lv2500-zg 32lv250a-N-U-Zg 32lv2540-zl Chassis ld01mDocument41 pagesLG 32lv2500-zg 32lv250a-N-U-Zg 32lv2540-zl Chassis ld01mSilvina CappelloNo ratings yet

- Unit-V Electrical InstallatiosDocument34 pagesUnit-V Electrical Installatiosnaveen kumarNo ratings yet

- Unit-V Electrical InstallatiosDocument32 pagesUnit-V Electrical Installatiosltsreeram12No ratings yet

- Ingles Guía para Realizar Una Instalación EléctricaDocument7 pagesIngles Guía para Realizar Una Instalación EléctricaMauricio Criollo CarrilloNo ratings yet

- Building Services-II: Unit-I Lecture-2Document32 pagesBuilding Services-II: Unit-I Lecture-2jkNo ratings yet

- AF Prospekt Tiefenerdung eDocument6 pagesAF Prospekt Tiefenerdung eΔημητρηςΣαρακυρουNo ratings yet

- Scope of Coating Requirements FOR Field Joints From External CorrosionDocument2 pagesScope of Coating Requirements FOR Field Joints From External CorrosionImalah UgoachanumNo ratings yet

- 2014 Led LG 32lb55-A-T - Chassis Lb45bDocument58 pages2014 Led LG 32lb55-A-T - Chassis Lb45bdanielradu2760% (5)

- LG m1962d - P (W) ZL - Ld93b Chasssis LCD Monitor SMDocument38 pagesLG m1962d - P (W) ZL - Ld93b Chasssis LCD Monitor SMRoger Martínez BermúdezNo ratings yet

- LG LCD TV - 32LX-2RDocument36 pagesLG LCD TV - 32LX-2Rspunkeymonkey999No ratings yet

- LCD TV: Service ManualDocument36 pagesLCD TV: Service ManualSàenz JoséNo ratings yet

- How To Use A Megger Insulation TesterDocument3 pagesHow To Use A Megger Insulation TesterjayamolmvNo ratings yet

- Unit6 Lecture4Document25 pagesUnit6 Lecture4AdwaithNo ratings yet

- Industrial Electrical SystemDocument18 pagesIndustrial Electrical SystemH2SO4No ratings yet

- Tesing Electrical Electronics PartDocument36 pagesTesing Electrical Electronics Parthabtemariam mollaNo ratings yet

- Abstract of Is 3043Document4 pagesAbstract of Is 3043Jignesh ParmarNo ratings yet

- Goldstar 26lx1r-ZeDocument36 pagesGoldstar 26lx1r-Zef17439No ratings yet

- LG 37lp1r-TeDocument39 pagesLG 37lp1r-TevideosonNo ratings yet

- LG Ml051a Chassis 26lx2r-Ze LCD TV SMDocument24 pagesLG Ml051a Chassis 26lx2r-Ze LCD TV SMtavitaraNo ratings yet

- Led LCD TV: Service ManualDocument60 pagesLed LCD TV: Service ManualFrank VillaNo ratings yet

- LG 32ld450-460-461c Chassis lb01bDocument45 pagesLG 32ld450-460-461c Chassis lb01bDan Alexandru Floricica100% (1)

- Mos - Earthing System - Thales ProjectDocument16 pagesMos - Earthing System - Thales ProjectMohamed shabeebNo ratings yet

- 500 KV Substation Grounding PresentationDocument66 pages500 KV Substation Grounding Presentationmnotcool100% (4)

- LG 20LS5R Chassis LP68A PDFDocument30 pagesLG 20LS5R Chassis LP68A PDFPaulo SimõesNo ratings yet

- Samsung Ps43d450a2wxxn Chassis F82aDocument69 pagesSamsung Ps43d450a2wxxn Chassis F82asunil beedasseeNo ratings yet

- Electrical Earthling: Construction, Faults & ProtectionDocument24 pagesElectrical Earthling: Construction, Faults & ProtectionsitanshumnitNo ratings yet

- 42LM6300 SMDocument89 pages42LM6300 SMmarcokersulrodriguesNo ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- A Guide to the Home Electric System: Home Guide Basics Series, #2From EverandA Guide to the Home Electric System: Home Guide Basics Series, #2No ratings yet

- Risk Engineering Position Paper PROCESS SAFETY PERFORMANCEDocument20 pagesRisk Engineering Position Paper PROCESS SAFETY PERFORMANCERmz ExeNo ratings yet

- Hazards 26 Paper 54 What Are Intelligent Procedures and How Can They Be DevelopedDocument8 pagesHazards 26 Paper 54 What Are Intelligent Procedures and How Can They Be DevelopedRmz ExeNo ratings yet

- BOWtie HSE UKDocument92 pagesBOWtie HSE UKRmz Exe100% (1)

- 056 PDFDocument6 pages056 PDFRmz ExeNo ratings yet

- Probability Bow-Ties A Transparent Risk Management ToolDocument10 pagesProbability Bow-Ties A Transparent Risk Management ToolRmz ExeNo ratings yet

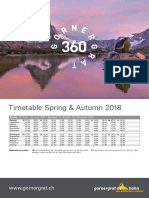

- GGB Fahrplan Spring-Autumn EN PDFDocument1 pageGGB Fahrplan Spring-Autumn EN PDFRmz ExeNo ratings yet

- ChemicalReactivityHazards (Compatibility Mode)Document101 pagesChemicalReactivityHazards (Compatibility Mode)Rmz ExeNo ratings yet

- Interactions and Incompatibilities in Pharmaceutical PreparationsDocument38 pagesInteractions and Incompatibilities in Pharmaceutical PreparationsRmz ExeNo ratings yet

- Form 1243i Your Personal Identifying InformationDocument4 pagesForm 1243i Your Personal Identifying InformationRmz ExeNo ratings yet

- Feature Matrix 2013Document3 pagesFeature Matrix 2013Rmz ExeNo ratings yet

- Implementation of Chemical Management Plan, Challenges and Lessons Learnt Sri LankaDocument26 pagesImplementation of Chemical Management Plan, Challenges and Lessons Learnt Sri LankaRmz ExeNo ratings yet

- Purified Terephthalic Acid Wastewater Biodegradation and ToxicityDocument8 pagesPurified Terephthalic Acid Wastewater Biodegradation and ToxicityRmz ExeNo ratings yet