Professional Documents

Culture Documents

Ongc WS WT TBT

Ongc WS WT TBT

Uploaded by

lakshaygr8Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ongc WS WT TBT

Ongc WS WT TBT

Uploaded by

lakshaygr8Copyright:

Available Formats

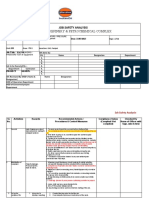

OIL AND NATURAL GAS CORPORATION LTD.

118, 1st Floor, 11-High, HWS, Well Services

Bandra- Sion link Road, Mumbai.

Tel. No.: 022-2408 8118

Toolbox Talk

Name of the Installation: Date: Time:

Toolbox talk (TBT) to be adopted for carrying out operations based on SOPs, assessment of Risks in the

operations,adhering to safe practices and also enhanced behavioural based safety.

Shift In charges/Supervisor should regularly conduct toolbox talks on following aspects with shift personnel

before start of each shift and record the same. For non-routine Jobs, Job Safety Analysis (JSA) needs to be

carried out.

S.No Points to be discussed Compliance/Remarks

1 Job / operations description 1. TCP-DST OPERATIONS.

2. HIGH PRESSURE TESTING

2 Availability & use of

appropriate & adequate PPE

3 SOPs to be followed should SEQUENCE OF OPERATIONS;

be discussed and CONTINGENCIES PLAN, RISK ASSESSMENT DISCUSSED &

deliberated. DELIBERATED.

4 Identification of associated DRIFTING OPERATIONS, LIFTING OPERATIONS, FINGER

risks/Hazards in operations PINCHING, WORKING AT HEIGHT, SLIPPING/TRIPPING,

HIGH PRESSURE OPERATIONS, HIGH NOISE, MECHANICAL

JERK FOR TCP GUNS, WATER WETTING OF TCP GUNS

WHILE CONNECTING AT RIG FLOOR.

5 Precautions/ Risk Mitigation 1. JSA & JRA WITH EACH JOB ASSOCIATED IS ENSURED.

Measure needed to do the 2. USE OF CERTIFIED EQUIPMENT.

job correctly and safely. 3. FOLLOW ALL SAFETY PRECAUTIONS AS PER SOP

CIRCULATED.

4. DST STRING DIAGRAM AT RIG FLOOR.

5. AWARENESS AND OPERATIONAL USE OF POTV,SF-TTV.

6. FOLLOW RIH PROCEDURES OF TCP-DST.

7. PROPER BARRICADING FOR HAZARDS.

8. PREVENTIVE MEASURES TO AVOID WETTING OF TCP

GUNS.

9. OBTAIN AUTHORIZATION PRIOR TO BYPASSING

‘SAFETY CRITICAL EQUIPMENT

6 Work Permit (if require for PTW TO BE ENSURED BEFORE SIMULTANEOUS

job along with electrical OPERATIONS.

isolation)

7 Any doubt/safety concern 1. Q&A CARRIED OUT DURING PJSM.

must be also be addressed. 2. PROPER HANDOVER/TAKEOVER OF SHIFTS BY ALL

INVOLVED.

3. TIME OUT FOR SAFETY IN CASE OF UNSAFE ACTS.

4. PROPER COMMUNICATION THRU PA, RADIO, PHONE.

8 Additional Risk Mitigation 1. FOLLOW ALL SOP & HSE NORMS STRICTLY.

Measure details (If require): 2. AVOID FOREIGN OBJECT FALLING IN WELL/STRING,

COVER ROTARY WHILE OPERATION TONGUE.

3. SUITABLE XOVER WITH FOSV TO KEPT READY AT RIG

ALL THE TIMES.

4. PROPER BOP SPACING OUT FOR EMERGENCY RAMS

CLOSURE.

5. AVAILABILITY OF SUFFICIENT KILL FLUID (BRINE/MUD).

6. ONLY SINGLE DRIFT OF EACH SIZE TO BE USED.

Shift In charge/Supervisor ONGC representative Captain/Installation Manager

Participants:

You might also like

- Method Statement For ExcavationDocument5 pagesMethod Statement For ExcavationNikhil RathiNo ratings yet

- Use of Hand ToolsDocument2 pagesUse of Hand Toolsvictor100% (1)

- Worksheet MerchandisingDocument6 pagesWorksheet MerchandisingLyca Mae CubangbangNo ratings yet

- Method Statement For Ultrasonic Testing: DCSM Project 2019Document5 pagesMethod Statement For Ultrasonic Testing: DCSM Project 2019Thinh NguyenNo ratings yet

- How To Write A Statement of Purpose First Visa ApplicationDocument2 pagesHow To Write A Statement of Purpose First Visa ApplicationFasih RazaNo ratings yet

- Canada Immigration Consultants in BangaloreDocument17 pagesCanada Immigration Consultants in Bangaloreakkam immigrationNo ratings yet

- Ongc Ws WT TBT Trident-2 B-157n-9 28072023Document3 pagesOngc Ws WT TBT Trident-2 B-157n-9 28072023lakshaygr8No ratings yet

- Ongc Ws WT TBT Trident-2 B-157n-9 23072023Document3 pagesOngc Ws WT TBT Trident-2 B-157n-9 23072023lakshaygr8No ratings yet

- JSP - Route Marker Installation & Manual BackfillingDocument3 pagesJSP - Route Marker Installation & Manual BackfillingCalman KhanNo ratings yet

- Hydro TestDocument8 pagesHydro Testmozzammil saqibNo ratings yet

- Job Safety Analysis - Doc With Penumatic TestingDocument5 pagesJob Safety Analysis - Doc With Penumatic TestingDeshbandhu Aman Pandey100% (1)

- Job Safety AnalysisDocument3 pagesJob Safety AnalysisDeshbandhu Aman PandeyNo ratings yet

- Job Hazard AnalysisDocument3 pagesJob Hazard AnalysisBrain Dee Tech LtdNo ratings yet

- SWP Air CompressorDocument2 pagesSWP Air Compressormyn maliQueNo ratings yet

- Yanbu Bulk PlantDocument6 pagesYanbu Bulk PlantDarius DsouzaNo ratings yet

- Hazard Identification Plan: Yanbu Refinery Saudi Arabian Oil Company-Saudi Aramco BI-10-00610-0001Document6 pagesHazard Identification Plan: Yanbu Refinery Saudi Arabian Oil Company-Saudi Aramco BI-10-00610-0001Darius DsouzaNo ratings yet

- Fence Installation - Method StatementDocument5 pagesFence Installation - Method StatementvelisantshuntsheNo ratings yet

- Method Statement - FOC - FYSH - 031010Document2 pagesMethod Statement - FOC - FYSH - 031010DilxazNo ratings yet

- Tuaman Engineering Limited: Job Safety Analysis (Jsa)Document6 pagesTuaman Engineering Limited: Job Safety Analysis (Jsa)abhijit janaNo ratings yet

- Plant: Work Location: Date:: Saudi Aramco PMT Saudi Aramco Project EngineerDocument6 pagesPlant: Work Location: Date:: Saudi Aramco PMT Saudi Aramco Project EngineerJoypee MacasamponNo ratings yet

- Bat (Rams)Document10 pagesBat (Rams)sodiqismail11No ratings yet

- Name Co. Number Signature: Remember Safety FirstDocument1 pageName Co. Number Signature: Remember Safety FirstgrantNo ratings yet

- Job Safety Analysis Sheet:: GOR TestDocument1 pageJob Safety Analysis Sheet:: GOR Testhp9mzbjzsfNo ratings yet

- Job Safety Analysis: Stressing WorkDocument3 pagesJob Safety Analysis: Stressing Work123shripadNo ratings yet

- INDUCTION SlideDocument10 pagesINDUCTION SlideJames JoviNo ratings yet

- Sop for Grinding-02Document4 pagesSop for Grinding-02Subhra RanjanNo ratings yet

- CLC - 9040 5.19.3 Job Safety Practices Rev 02 Radiography ActivityDocument4 pagesCLC - 9040 5.19.3 Job Safety Practices Rev 02 Radiography ActivityshafieNo ratings yet

- Job Safety Analysis (Jsa) : Fabrication Works, Welding Works Using Power Tools, Hand Tools, Welding Machine WapstechDocument3 pagesJob Safety Analysis (Jsa) : Fabrication Works, Welding Works Using Power Tools, Hand Tools, Welding Machine WapstechMohamedSaidNo ratings yet

- 008 SWMS General Onsite Activities and RepairsDocument13 pages008 SWMS General Onsite Activities and Repairssiame festusNo ratings yet

- JSA - Dismantling CM ShedDocument4 pagesJSA - Dismantling CM ShedvivekaramanaNo ratings yet

- Trimurti Fabricators PVT LTD.: Monsoon Protection PlanDocument4 pagesTrimurti Fabricators PVT LTD.: Monsoon Protection Planalla malikNo ratings yet

- Hse Management Plan: TIMIMOUN Field Development ProjectDocument37 pagesHse Management Plan: TIMIMOUN Field Development ProjectPT. Lincat Minahasa PratamaNo ratings yet

- Project ExampleDocument46 pagesProject ExampleFadzil BsbNo ratings yet

- 1-JHA - ExcavationDocument2 pages1-JHA - ExcavationAnna Marie Filipinas RajilNo ratings yet

- Hip - Qatif Aramco - FinalDocument10 pagesHip - Qatif Aramco - FinalDarius DsouzaNo ratings yet

- Job Hazard Analysis Template SampleDocument2 pagesJob Hazard Analysis Template SampleRobin JohnNo ratings yet

- Part-B Risk Assessment ActivityDocument3 pagesPart-B Risk Assessment ActivitySupritha HegdeNo ratings yet

- JSA For Errection of Batching PlantDocument4 pagesJSA For Errection of Batching Plantasamrat582No ratings yet

- HIRA - Night Work Hazard ControlDocument3 pagesHIRA - Night Work Hazard ControlHiralal Pattanayak100% (2)

- Hse Management Plan: TIMIMOUN Field Development ProjectDocument37 pagesHse Management Plan: TIMIMOUN Field Development ProjectNaba majeadNo ratings yet

- Siddhivinayak Jsa-004-Work in ShaftDocument5 pagesSiddhivinayak Jsa-004-Work in Shaftyogeshraut1910No ratings yet

- JSA-009a Drilling and Mon Well Construction-Sonic - 2Document4 pagesJSA-009a Drilling and Mon Well Construction-Sonic - 2sudarmanNo ratings yet

- 18 - Maintenance of Skip HoistDocument5 pages18 - Maintenance of Skip Hoistgiet11aei010No ratings yet

- Concreting and ShutteringDocument3 pagesConcreting and ShutteringAnuj Kjoy0% (1)

- Element 6 - Safe Operation Job Safety Analysis (JSA) SMS 6.17.3 JSA Record SheetDocument14 pagesElement 6 - Safe Operation Job Safety Analysis (JSA) SMS 6.17.3 JSA Record SheetGurumoorthy Rajavijayan100% (2)

- Job Safety Analysis and Risk AssessmentDocument1 pageJob Safety Analysis and Risk Assessmentghada gattouchNo ratings yet

- 630-Lubrication of CSR#3Document7 pages630-Lubrication of CSR#3Buddy HartNo ratings yet

- JSA For Childrens RoomDocument3 pagesJSA For Childrens Roomkalai selvanNo ratings yet

- SWMS FOR INSTALLATION OF 5x500 KVA GENERATORS AND TOTALIZING PANEL 25.01.23Document8 pagesSWMS FOR INSTALLATION OF 5x500 KVA GENERATORS AND TOTALIZING PANEL 25.01.23Md Shahbaz AlamNo ratings yet

- 712-Lubrcation Pipe Checking and Changing of CSR#2Document5 pages712-Lubrcation Pipe Checking and Changing of CSR#2Buddy HartNo ratings yet

- Action To Be Done Potential Hazards Location ActivitiesDocument28 pagesAction To Be Done Potential Hazards Location ActivitiesReda MashalNo ratings yet

- JHA RCBC Plaza SignedDocument8 pagesJHA RCBC Plaza SignedledromechjohnNo ratings yet

- HIPhazard Id PlanDocument27 pagesHIPhazard Id PlanAhmed Raza KhanNo ratings yet

- Hazard Identification Plan: Turaif Bulk Plant Saudi Arabian Oil Company-Saudi Aramco BI-10-00610-0001Document7 pagesHazard Identification Plan: Turaif Bulk Plant Saudi Arabian Oil Company-Saudi Aramco BI-10-00610-0001Darius DsouzaNo ratings yet

- Suroj Buildcon Pvt. LTD.: Job Safety AnalysisDocument6 pagesSuroj Buildcon Pvt. LTD.: Job Safety AnalysisKiran ChenchalaNo ratings yet

- SWMS For Installation of Package Substation 25.01.23Document5 pagesSWMS For Installation of Package Substation 25.01.23Md Shahbaz AlamNo ratings yet

- Safe Work Method Statement: Excavation, Trenching and Underground ServicesDocument5 pagesSafe Work Method Statement: Excavation, Trenching and Underground ServicesMorhne RufinNo ratings yet

- Job Safety Procedure - TSEILDocument13 pagesJob Safety Procedure - TSEILRavi thokalNo ratings yet

- Inter Tank Transfers - SWPDocument5 pagesInter Tank Transfers - SWPPriince MogomotsiNo ratings yet

- Method Statement For Internal Rotary Inspection System: Document No: D-P5-BV-MS-011Document4 pagesMethod Statement For Internal Rotary Inspection System: Document No: D-P5-BV-MS-011Thinh NguyenNo ratings yet

- Job Safety Analysis Work Sheet: Date Prepared D / M / YDocument4 pagesJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

- Del 861117751920793Document9 pagesDel 861117751920793Varahi VigneshNo ratings yet

- Hazard Identification Plan: Al Jouf Bulk Plant Saudi Arabian Oil Company-Saudi Aramco BI-10-00610-0001Document7 pagesHazard Identification Plan: Al Jouf Bulk Plant Saudi Arabian Oil Company-Saudi Aramco BI-10-00610-0001Darius DsouzaNo ratings yet

- Sherman Motor Compant Case Analysis Sherman Motor Compant Case AnalysisDocument5 pagesSherman Motor Compant Case Analysis Sherman Motor Compant Case AnalysisChristian CabariqueNo ratings yet

- Deloitte: Telecommunications Predictions 2010Document27 pagesDeloitte: Telecommunications Predictions 2010gasibuteaNo ratings yet

- Special Laws - Midterms (Leave, BMBE)Document3 pagesSpecial Laws - Midterms (Leave, BMBE)josiah9_5No ratings yet

- Problems in Calculating National IncomeDocument2 pagesProblems in Calculating National IncomesmilesamNo ratings yet

- Importance of Human Resource ManagementDocument2 pagesImportance of Human Resource ManagementFred OchiengNo ratings yet

- 6th Sem Syllabus - Hospitalty and TourismDocument10 pages6th Sem Syllabus - Hospitalty and Tourismanil gondNo ratings yet

- Universidad Nacional de Colombia Intensive English Ii - Statement of Purpose VALENTINA RONCANCIO NIÑO C.C:1026.598.972 Europa Universitat ViadrinaDocument1 pageUniversidad Nacional de Colombia Intensive English Ii - Statement of Purpose VALENTINA RONCANCIO NIÑO C.C:1026.598.972 Europa Universitat ViadrinaValentina RoncancioNo ratings yet

- PZOPSQ0001 Ambush in AbsalomDocument7 pagesPZOPSQ0001 Ambush in AbsalomOmer Torem100% (1)

- Sample Practice Questions - Module-01 To Module-09Document30 pagesSample Practice Questions - Module-01 To Module-09المائدہNo ratings yet

- New Jersey Motor Vehicle CommissionDocument2 pagesNew Jersey Motor Vehicle CommissionWen' George BeyNo ratings yet

- Yahoo Consumer Direct Marries Purchase Metrics ToDocument16 pagesYahoo Consumer Direct Marries Purchase Metrics ToStupendous Sourabh100% (1)

- Magnolia State BankDocument5 pagesMagnolia State BankMd. Rakibul Hasan RonyNo ratings yet

- Cover Letter DW Indonesia Reporter M Syahrul KhairahDocument1 pageCover Letter DW Indonesia Reporter M Syahrul Khairahmuhammad ArollNo ratings yet

- Consumer Buying Behavior: The Multicultural Influence in The PhilippinesDocument5 pagesConsumer Buying Behavior: The Multicultural Influence in The PhilippinesThe IjbmtNo ratings yet

- Grand Jury Report On Internal Audit DivisionDocument7 pagesGrand Jury Report On Internal Audit DivisionThe Press-Enterprise / pressenterprise.comNo ratings yet

- Terex Genie Rl4000 Parts ManualDocument5 pagesTerex Genie Rl4000 Parts Manualwesley100% (36)

- HNN Vo. 4 No. 6 Full PublicationDocument124 pagesHNN Vo. 4 No. 6 Full PublicationBrigette RiversNo ratings yet

- Dap An Tham Khao - VNU-EPT Speaking Part 2 & Writing Essay - Dot Thi 21.09.19Document3 pagesDap An Tham Khao - VNU-EPT Speaking Part 2 & Writing Essay - Dot Thi 21.09.19Thúy Ngọc Lê TrầnNo ratings yet

- The Declaration-Cum-Undertaking Under Sec 10 (5), Chapter III of FEMA, 1999 Is Enclosed As UnderDocument1 pageThe Declaration-Cum-Undertaking Under Sec 10 (5), Chapter III of FEMA, 1999 Is Enclosed As UnderarvinfoNo ratings yet

- Integer ProgrammingDocument10 pagesInteger ProgrammingIsza Marie N. SocorinNo ratings yet

- 06 Plastic Model KitsDocument1 page06 Plastic Model KitsLeonidas MianoNo ratings yet

- Press KitDocument36 pagesPress KitHerson Mata100% (2)

- Excerpt From "When Wall Street Met Main Street" by Julia C. OttDocument2 pagesExcerpt From "When Wall Street Met Main Street" by Julia C. OttOnPointRadioNo ratings yet

- CAFE Pindot PresentationDocument33 pagesCAFE Pindot PresentationAirah MondonedoNo ratings yet

- Logistics Execution in The SAP Business SuiteDocument26 pagesLogistics Execution in The SAP Business SuitemayurNo ratings yet

- Chapter 6-Cost Concepts and Measurement: Multiple ChoiceDocument29 pagesChapter 6-Cost Concepts and Measurement: Multiple Choiceakash deepNo ratings yet