Professional Documents

Culture Documents

134002-Ex Equipment Repair Requirement (Ex ERR)

134002-Ex Equipment Repair Requirement (Ex ERR)

Uploaded by

Cornelius Ernest RodriguezCopyright:

Available Formats

You might also like

- Chcccs023 - Ageing Sab v3.2 TheoryDocument32 pagesChcccs023 - Ageing Sab v3.2 TheoryKanchan Adhikari38% (8)

- Case Questions - Grocery GatewayDocument4 pagesCase Questions - Grocery GatewayPankaj SharmaNo ratings yet

- Petronas Technical Standards: PETRONAS Risk-Based Inspection (PRBI)Document23 pagesPetronas Technical Standards: PETRONAS Risk-Based Inspection (PRBI)testNo ratings yet

- PTS 13.42.01 PDFDocument20 pagesPTS 13.42.01 PDFNaufal Daumi100% (1)

- Offshore Life Saving Appliances RequirementDocument31 pagesOffshore Life Saving Appliances RequirementmhabibnurNo ratings yet

- Petronas Technical Standards: Pipelines Pre-CommissioningDocument40 pagesPetronas Technical Standards: Pipelines Pre-CommissioningAsus Asri100% (4)

- Pip Pcfte100 (Inserción de Termopozos)Document8 pagesPip Pcfte100 (Inserción de Termopozos)Nilyan Berti100% (1)

- Ex Equipment Repair Requirement (Ex Err)Document13 pagesEx Equipment Repair Requirement (Ex Err)jk.jackycheokNo ratings yet

- 130004-Industrial Power Plant DesignDocument22 pages130004-Industrial Power Plant DesignCornelius Ernest RodriguezNo ratings yet

- Inspection and TestingDocument22 pagesInspection and TestingSam Low100% (2)

- 130101-Power QualityDocument22 pages130101-Power QualityCornelius Ernest RodriguezNo ratings yet

- Petronas Technical Standards: Standard Forms (Binder)Document160 pagesPetronas Technical Standards: Standard Forms (Binder)adamNo ratings yet

- Workshope Equipment and Mechanical ToolsDocument50 pagesWorkshope Equipment and Mechanical ToolsTurbo Snail RNo ratings yet

- Petronas Technical Standards: Operator Training Simulator (Ots) System Project ExecutionDocument15 pagesPetronas Technical Standards: Operator Training Simulator (Ots) System Project Executionahmadreza777100% (1)

- Low Voltage Switchgear & Controlgear AssembliesDocument49 pagesLow Voltage Switchgear & Controlgear Assembliesjk.jackycheokNo ratings yet

- Dec 98Document25 pagesDec 98c_nghia100% (1)

- Sep 09Document24 pagesSep 09c_nghia50% (2)

- Petronas Technical Standards: Operator Training Simulator (Ots) System Itb and Fds Document Technical SpecificationsDocument43 pagesPetronas Technical Standards: Operator Training Simulator (Ots) System Itb and Fds Document Technical Specificationsahmadreza777No ratings yet

- Petronas Technical StandardsDocument9 pagesPetronas Technical Standardsfaiz yatimNo ratings yet

- Petronas Technical Standards: Measurement of Viscous Properties of Completion Fluids (Endorsement of Iso 13503-1)Document7 pagesPetronas Technical Standards: Measurement of Viscous Properties of Completion Fluids (Endorsement of Iso 13503-1)ĐiệnBiênNhâmNo ratings yet

- Inspection & Functional Testing of InstrumentsDocument23 pagesInspection & Functional Testing of Instrumentsjk.jackycheokNo ratings yet

- Dec 08Document31 pagesDec 08c_nghia100% (1)

- Installation of On-Line InstrumentsDocument23 pagesInstallation of On-Line Instrumentsjk.jackycheokNo ratings yet

- Petronas Technical Standards: Specifications and Requirements For Pipeline In-Line InspectionDocument30 pagesPetronas Technical Standards: Specifications and Requirements For Pipeline In-Line InspectionAsus AsriNo ratings yet

- Dec 09Document55 pagesDec 09c_nghia100% (1)

- Power Quality PDFDocument22 pagesPower Quality PDFKhairul AshrafNo ratings yet

- Petronas Technical Standards: Power QualityDocument5 pagesPetronas Technical Standards: Power QualityjausahaslkNo ratings yet

- Petronas Technical Standards: Industrial Power Plant DesignDocument22 pagesPetronas Technical Standards: Industrial Power Plant DesignMohd Aizzuddin Md JanisNo ratings yet

- Petronas Technical Standards: Blast Resilient and Blast Resistant Control Buildings/Field Auxiliary RoomsDocument58 pagesPetronas Technical Standards: Blast Resilient and Blast Resistant Control Buildings/Field Auxiliary Roomsheriaca petersonNo ratings yet

- Petronas Technical StandardsDocument20 pagesPetronas Technical StandardsMohd Nizamuddin Mohamad NoorNo ratings yet

- Ocp - Att Open CSGR Spec-Draft 1Document15 pagesOcp - Att Open CSGR Spec-Draft 1DhirajNo ratings yet

- Structures Cabling For TelecommunicationDocument54 pagesStructures Cabling For Telecommunicationjk.jackycheokNo ratings yet

- Jan 98Document30 pagesJan 98c_nghiaNo ratings yet

- Sep 02Document19 pagesSep 02c_nghia100% (1)

- Petronas Technical Standards: Requisition (Binder)Document425 pagesPetronas Technical Standards: Requisition (Binder)adam100% (1)

- Petronas Technical Standards: Pipeline and Riser Engineering DesignDocument37 pagesPetronas Technical Standards: Pipeline and Riser Engineering DesignAzim SamiinNo ratings yet

- Aug 2011Document10 pagesAug 2011c_nghia100% (2)

- Ex Management, Inspection & Maintenance (Ex Mim)Document52 pagesEx Management, Inspection & Maintenance (Ex Mim)jk.jackycheokNo ratings yet

- PTS 32.31.09.31 Instru For Package Equip PDFDocument30 pagesPTS 32.31.09.31 Instru For Package Equip PDFPilsner80No ratings yet

- 10.02.51.11 Nov 2012Document29 pages10.02.51.11 Nov 2012nur fardinaNo ratings yet

- Ni 2838Document49 pagesNi 2838marceloNo ratings yet

- 5500245X 2 ENG p02 of 2 2009-06 Cont-Tech Commander SK AdvUGDocument200 pages5500245X 2 ENG p02 of 2 2009-06 Cont-Tech Commander SK AdvUGzinebNo ratings yet

- Cathodic Protection System For Storage Tank & Pressure Vessel (Amendments Supplements To NACE and API Standards)Document7 pagesCathodic Protection System For Storage Tank & Pressure Vessel (Amendments Supplements To NACE and API Standards)Abd.Buhari Abd.GalimNo ratings yet

- 122 Norwegian Oil and Gas Recommended Guidelines For The Mangement of Life ExtensionDocument20 pages122 Norwegian Oil and Gas Recommended Guidelines For The Mangement of Life ExtensionPar MadNo ratings yet

- Ultrasonic ExaminationDocument21 pagesUltrasonic Examinationjuantamad02100% (1)

- 30401030Document12 pages30401030JohnNo ratings yet

- Electromagnetic Compatibility (Emc) RequirementDocument41 pagesElectromagnetic Compatibility (Emc) Requirementjk.jackycheokNo ratings yet

- Mar 09Document30 pagesMar 09c_nghia100% (1)

- PTS 12.01.01Document16 pagesPTS 12.01.01Aidil Fadzree MorsidinNo ratings yet

- Instrumentation For Equipment PackagesDocument14 pagesInstrumentation For Equipment Packagesjk.jackycheokNo ratings yet

- Petronas Technical Standard (PTS 50.014)Document20 pagesPetronas Technical Standard (PTS 50.014)Kellary Liaw Nyuk Chin100% (2)

- Operator Training Simulator SystemDocument24 pagesOperator Training Simulator Systemjk.jackycheokNo ratings yet

- Petronas Technical Standards: Pts Publications and Standard SpecificationsDocument38 pagesPetronas Technical Standards: Pts Publications and Standard SpecificationsadamNo ratings yet

- 00002010Document7 pages00002010minhthanhmosNo ratings yet

- 121205Document25 pages121205wdavid81No ratings yet

- MOTS-47 - Rev. 1.0 - MOG-FP-INS-STD-0047 Emergency Shutdown SystemsDocument20 pagesMOTS-47 - Rev. 1.0 - MOG-FP-INS-STD-0047 Emergency Shutdown SystemsKingston RivingtonNo ratings yet

- PTS - 202001 Safety Requirements For Mobile Offshore UnitsDocument14 pagesPTS - 202001 Safety Requirements For Mobile Offshore UnitscfkianNo ratings yet

- Petronas Technical Standards: Seismic Hazard Assessment For Onshore FacilitiesDocument24 pagesPetronas Technical Standards: Seismic Hazard Assessment For Onshore FacilitiesAsus AsriNo ratings yet

- Petronas Technical Standards: Downhole Equipment - Subsurface Safety Valves (Endorsement of Iso 10432)Document6 pagesPetronas Technical Standards: Downhole Equipment - Subsurface Safety Valves (Endorsement of Iso 10432)ĐiệnBiênNhâmNo ratings yet

- Weldable Structural SteelDocument22 pagesWeldable Structural SteelSam LowNo ratings yet

- 4.ELK20001 - Statement of WorkDocument26 pages4.ELK20001 - Statement of WorkSuneel PanditNo ratings yet

- Regulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsFrom EverandRegulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsNo ratings yet

- Impact of Christian Religious Involvement To The Stress Coping Mechanisms of Senior High Learners - Revised PaperDocument16 pagesImpact of Christian Religious Involvement To The Stress Coping Mechanisms of Senior High Learners - Revised PaperShiera Mae PuguonNo ratings yet

- Evaluation Sheets For ResearchDocument6 pagesEvaluation Sheets For ResearchMa Maudie Arah O GarciaNo ratings yet

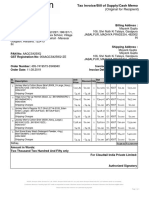

- Tax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Document2 pagesTax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)MAYANK GUPTANo ratings yet

- Mahatma Gandhi BiographyDocument5 pagesMahatma Gandhi BiographyGian LuceroNo ratings yet

- Early Christian ArchitectureDocument5 pagesEarly Christian ArchitectureDc Salvador BacsaNo ratings yet

- Hayakawa CO.,LTD.: TO: Dated: 08/01/19 Invoice No.: 190801421 1 / 1Document1 pageHayakawa CO.,LTD.: TO: Dated: 08/01/19 Invoice No.: 190801421 1 / 1Earl CharlesNo ratings yet

- MY Salary Guide 2022 - 23 - v5Document38 pagesMY Salary Guide 2022 - 23 - v5Yoong Ming JunNo ratings yet

- ItikaafDocument3 pagesItikaafmusarhadNo ratings yet

- IGCSE HISTORY Topic 5 - Who Was To Blame For The Cold WarDocument11 pagesIGCSE HISTORY Topic 5 - Who Was To Blame For The Cold WarAbby IuNo ratings yet

- CH47Document26 pagesCH47Hanna HellerNo ratings yet

- PF Enomination Job AidDocument9 pagesPF Enomination Job Aidashritha prakashNo ratings yet

- 2-3 Excavation & EmbankmentDocument23 pages2-3 Excavation & Embankmentzrilek1No ratings yet

- IA 6 - Q2 - Mod6Document17 pagesIA 6 - Q2 - Mod6Elmer OdevilasNo ratings yet

- Impact of Social Media Marketing On Brand Image of Fastfood Chain in Sariaya, QuezonDocument37 pagesImpact of Social Media Marketing On Brand Image of Fastfood Chain in Sariaya, QuezonGlydel Anne C. LincalioNo ratings yet

- Mrunal Explained: Cheque Truncation System CTS-features, BenefitsDocument3 pagesMrunal Explained: Cheque Truncation System CTS-features, BenefitsPrateek BayalNo ratings yet

- McCAMISH HelpDocument39 pagesMcCAMISH HelpSrinivas BalledaNo ratings yet

- DT Ratcfull Sig 55 Sce MetaDocument3 pagesDT Ratcfull Sig 55 Sce MetaPrashant JumanalNo ratings yet

- Flight TicketDocument3 pagesFlight TicketAkshay KanyanNo ratings yet

- 14&21-Realubit v. Jaso G.R. No. 178782 September 21, 2011Document5 pages14&21-Realubit v. Jaso G.R. No. 178782 September 21, 2011Jopan SJNo ratings yet

- Form 3 Accounting June 2023Document9 pagesForm 3 Accounting June 2023Bonolo RamofoloNo ratings yet

- DEMETION-The Dispute of Philippines and Malaysia Over Sabah TerritoryDocument16 pagesDEMETION-The Dispute of Philippines and Malaysia Over Sabah TerritoryJames DemetionNo ratings yet

- The Last SupperDocument36 pagesThe Last SupperselthielNo ratings yet

- Young Kings (T.me-Riset9)Document25 pagesYoung Kings (T.me-Riset9)PRASOON PATELNo ratings yet

- God Sees The Truth But WaitsDocument2 pagesGod Sees The Truth But WaitsrowenaNo ratings yet

- Risk Management and Internal Control System - Reference Framework PDFDocument42 pagesRisk Management and Internal Control System - Reference Framework PDFChinh Lê Đình100% (1)

- FinMod 2022-2023 Tutorial Exercise + Answers Week 6Document39 pagesFinMod 2022-2023 Tutorial Exercise + Answers Week 6jjpasemperNo ratings yet

- Loan Agreement PDFDocument9 pagesLoan Agreement PDFHengki YonoNo ratings yet

- Chapter 6Document19 pagesChapter 6Naveed SultanNo ratings yet

134002-Ex Equipment Repair Requirement (Ex ERR)

134002-Ex Equipment Repair Requirement (Ex ERR)

Uploaded by

Cornelius Ernest RodriguezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

134002-Ex Equipment Repair Requirement (Ex ERR)

134002-Ex Equipment Repair Requirement (Ex ERR)

Uploaded by

Cornelius Ernest RodriguezCopyright:

Available Formats

PETRONAS TECHNICAL STANDARDS

Ex Equipment Repair Requirement (Ex ERR)

PTS 13.40.02

November 2016

© 2016 PETROLIAM NASIONAL BERHAD (PETRONAS)

All rights reserved. No part of this document may be reproduced, stored in a retrieval system or transmitted in any form

or by any means (electronic, mechanical, photocopying, recording or otherwise) without the permission of the copyright

owner. PETRONAS Technical Standards are Company’s internal standards and meant for authorized users only.

175.137.6.220 zafri@ifp.com.my 11/22/2023 01:27:25 GMT

PTS 13.40.02

Ex EQUIPMENT REPAIR REQUIREMENT (Ex ERR) November 2016

Page 2 of 13

FOREWORD

PETRONAS Technical Standards (PTS) has been developed based on the accumulated knowledge,

experience and best practices of the PETRONAS group supplementing National and International

standards where appropriate. The key objective of PTS is to ensure standard technical practice across

the PETRONAS group.

Compliance to PTS is compulsory for PETRONAS-operated facilities and Joint Ventures (JVs) where

PETRONAS has more than fifty percent (50%) shareholding and/or operational control, and includes

all phases of work activities.

Contractors/manufacturers/suppliers who use PTS are solely responsible in ensuring the quality of

work, goods and services meet the required design and engineering standards. In the case where

specific requirements are not covered in the PTS, it is the responsibility of the

Contractors/manufacturers/suppliers to propose other proven or internationally established

standards or practices of the same level of quality and integrity as reflected in the PTS.

In issuing and making the PTS available, PETRONAS is not making any warranty on the accuracy or

completeness of the information contained in PTS. The Contractors/manufacturers/suppliers shall

ensure accuracy and completeness of the PTS used for the intended design and engineering

requirement and shall inform the Owner for any conflicting requirement with other international

codes and technical standards before start of any work.

PETRONAS is the sole copyright holder of PTS. No part of this document may be reproduced, stored

in a retrieval system or transmitted in any form or by any means (electronic, mechanical, recording or

otherwise) or be disclosed by users to any company or person whomsoever, without the prior written

consent of PETRONAS.

The PTS shall be used exclusively for the authorised purpose. The users shall arrange for PTS to be

kept in safe custody and shall ensure its secrecy is maintained and provide satisfactory information to

PETRONAS that this requirement is met.

175.137.6.220 zafri@ifp.com.my 11/22/2023 01:27:25 GMT

PTS 13.40.02

Ex EQUIPMENT REPAIR REQUIREMENT (Ex ERR) November 2016

Page 3 of 13

ANNOUNCEMENT

Please be informed that the entire PTS inventory is currently undergoing transformation exercise from

2013 - 2015 which includes revision to numbering system, format and content. As part of this change,

the PTS numbering system has been revised to 6-digit numbers and drawings, forms and requisition

to 7-digit numbers. All newly revised PTS will adopt this new numbering system, and where required

make reference to other PTS in its revised numbering to ensure consistency. Users are requested to

refer to PTS 00.01.01 (Index to PTS) for mapping between old and revised PTS numbers for clarity. For

further inquiries, contact PTS administrator at ptshelpdesk@petronas.com.my

175.137.6.220 zafri@ifp.com.my 11/22/2023 01:27:25 GMT

PTS 13.40.02

Ex EQUIPMENT REPAIR REQUIREMENT (Ex ERR) November 2016

Page 4 of 13

Table of Contents

1.0 INTRODUCTION ..................................................................................................... 5

1.1 SCOPE .............................................................................................................................. 5

1.2 GLOSSARY OF TERM ........................................................................................................ 5

1.3 SUMMARY OF CHANGES ................................................................................................. 6

2.0 GENERAL REQUIREMENT ....................................................................................... 7

2.1 INSPECTION/DAMAGE ASSESSMENT .............................................................................. 7

2.2 REPAIR/REPLACEMENT OF DAMAGED COMPONENTS ................................................... 7

2.3 IN-HOUSE REPAIR ............................................................................................................ 8

2.4 REPAIR BY Ex SERVICE PROVIDER.................................................................................... 8

2.5 REPLACEMENT EQUIPEMENT – COMPLETE UNIT ........................................................... 9

2.6 ECONOMIC JUSTIFICATION ............................................................................................. 9

3.0 MARKING SYSTEM ............................................................................................... 10

3.1 SYMBOLS ....................................................................................................................... 10

4.0 BIBLIOGRAPHY .................................................................................................... 12

APPENDIX 1: Ex EQUIPMENT OVERHAUL/REPAIR FLOWCHART ....................................... 13

175.137.6.220 zafri@ifp.com.my 11/22/2023 01:27:25 GMT

PTS 13.40.02

Ex EQUIPMENT REPAIR REQUIREMENT (Ex ERR) November 2016

Page 5 of 13

1.0 INTRODUCTION

This PETRONAS Technical Standards (PTS) provides the minimum technical requirements for

repair and overhaul of Ex certified equipment by Ex Service Providers.

This PTS adopts an International Standard IEC 60079-19 and IECEx OD13, 14, 15 as a

supplement based on PETRONAS lesson learnt and best practices.

1.1 SCOPE

This PTS specify requirements for repair and overhaul of all electrical equipment certified for

use in hazardous area and specify requirement for making appropriate decision on the repair

and overhaul of Ex certified equipment.

1.2 GLOSSARY OF TERM

1.2.1 General Definition of Terms & Abbreviations

Refer to PTS 00.01.03 for PTS Requirements, General Definition Of Terms, Abbreviations &

Reading Guide.

1.2.2 Specific Definition of Terms

No Term Definition

1 Ex Service Provider An organization that has been certified by an

independent Ex Certification Body under IEC Ex

03 scheme or an OEM that has the required

service facilities including the appropriate

equipment, competent personnel and

procedures such that the repair, overhaul or

modification works complies with the relevant

Ex standards and requirements.

2 Hazardous Area An area in which an explosive gas atmosphere is

or may be expected to be present in quantities

such as to require special precautions for the

construction, installation and use of electrical

apparatus.

NOTE(S): This applies equally to hazardous dust atmospheres.

3 Modification Change to the design and construction of the

apparatus which affects material, fit, form or

function.

4 Overhaul Action to restore to a fully serviceable condition

an apparatus which has been in use or in storage

for a period of time but which is not faulty.

175.137.6.220 zafri@ifp.com.my 11/22/2023 01:27:25 GMT

PTS 13.40.02

Ex EQUIPMENT REPAIR REQUIREMENT (Ex ERR) November 2016

Page 6 of 13

No Term Definition

5 Reclamation Means of repair involving, for example, the

removal or addition of material to reclaim

component parts which have sustained damage,

in order to restore such parts to a serviceable

condition in accordance with the relevant

standard.

6 Repair Action to restore a faulty apparatus to its fully

serviceable condition and in compliance with

the relevant standard.

Table 1: Specific Definition of Terms

1.2.3 Specific Abbreviations

No Abbreviation Description

1 Ex Abbreviation which relate to equipment or

facility that is suitable to be used in hazardous

area.

2 OEM Original Equipment Manufacturer

Table 2: Specific Abbreviations

1.3 SUMMARY OF CHANGES

This PTS 13.40.02 (November 2016) replaces PTS 13.40.02 (September 2013).

175.137.6.220 zafri@ifp.com.my 11/22/2023 01:27:25 GMT

PTS 13.40.02

Ex EQUIPMENT REPAIR REQUIREMENT (Ex ERR) November 2016

Page 7 of 13

2.0 GENERAL REQUIREMENT

Three (3) options shall be considered for repair or replacement of Ex equipment, namely:

i. In-house Repair

ii. Repair by Ex Service Facility

iii. Replace Equipment (Complete Unit)

The Ex equipment overhaul/repair process flow is best depicted by the Flowchart given in

Appendix 1.

2.1 INSPECTION/DAMAGE ASSESSMENT

The condition of each Ex equipment that need to be repaired or overhauled shall be first

inspected and assessed for any damages upon delivery to the workshop.

2.1.1 Ex Motor

Ex Motor shall be dismantled for close inspection of its rotor, stator, end shield etc. Detail

findings shall be recorded in specific check sheet based on IECEx OD 15. When assessment is

carried out, the motor’s bearing fit (shaft and housing) and shaft straightness/run out shall be

checked against tolerance limits given by OEM or relevant standards.

2.1.2 Other Equipment

Other equipment shall be assessed based on the specific check sheet adapted IECEx OD 15

report form.

2.2 REPAIR/REPLACEMENT OF DAMAGED COMPONENTS

2.2.1 The damaged components of Ex equipment may be repaired (either in-house or by external

Ex Service Provider) or replaced with new identical parts from OEM to ensure the equipment

still comply with original certification including ingress protection and temperature

classification after repair or overhaul. The component parts made from glass, plastics or any

material that is not dimensionally stable as well as fasteners should not be repaired or

reclaimed.

2.2.2 No modification shall be made to the certified apparatus unless that modification is permitted

in the certificate or is approved in writing by the manufacturer. Subsequent clauses of this

standard give detailed instructions regarding modifications in the context of different types of

protection. Particular attention is drawn to the need for care on the following activities:

i. When adding a variable speed/frequency drive to an Ex-rotating machine. It shall

be ensured that this is only done when the intended combination of the drive and

rotating machine is specified in the certificate or in the rotating machine

manufacturer’s documentation.

175.137.6.220 zafri@ifp.com.my 11/22/2023 01:27:25 GMT

PTS 13.40.02

Ex EQUIPMENT REPAIR REQUIREMENT (Ex ERR) November 2016

Page 8 of 13

ii. When adding or replacing part(s) of a panel which has been certified as 'a

complete assembly' (for example, panel built for Zone 2 hazardous area, e.g. Ex

nA) that the make and model of the replacement shall be identical with the part

being replaced even though the replacement carries the same Ex Protection, Gas

Group and Temperature Class. In addition, care shall be taken when this involves

an active device (self or externally powered), where OEM may need to be

consulted to ensure the Ex certification of the entire system remains intact.

2.2.3 For any proposed modification which would result in the apparatus not conforming to the

certification documents and the relevant type of protection standard, the Owner shall be

informed in writing that the apparatus will no longer be suitable for use in a hazardous area.

The modification shall be subject to the approval in writing from the Owner.

NOTE(S):

1. Detailed repair requirements for specific Ex protection type shall comply with IEC 60079-19.

2. The documentation and reporting for Ex equipment repair preferably be in line with IECEx OD 13, 14, and 15.

2.3 IN-HOUSE REPAIR

2.3.1 In-house repair of Ex equipment shall normally be limited to part replacement (with new

identical parts from OEM) and cleaning which will not impair the explosion-protection

integrity of the machine.

2.3.2 No modification shall be made to the certified equipment unless such modification is

permitted in the Ex certificate or in compliance with the standard. Otherwise the OEM shall

be consulted on the necessary modification.

2.4 REPAIR BY Ex SERVICE PROVIDER

2.4.1 Ex equipment which could not be fully repaired in-house (as specified in section 2.3 above) or

the validity of its Ex certificate is uncertain after the repair shall be sent to external Ex Service

Provider for necessary repair.

2.4.2 Ex Service Provider shall assess the damage, identify necessary repair work and propose work

scope for the service subject to Owner’s approval.

2.4.3 Reclamation work may result in dimensions which are different from the original stated in

relevant certification documents and affecting explosion-protection integrity of an Ex

equipment. Hence, any permitted reclamation work for all types of Ex equipment shall only

be carried out by Ex Service Provider to ensure the equipment still comply with its original

certification.

2.4.4 In case of motor, damaged stator/rotor laminations or cores normally should not be machined

or skimmed to remove surface irregularities as the maximum permissible air gap may be

exceeded. If necessary, surface skimming of stator or rotor laminations shall only be

performed by Ex Service Provider.

2.4.5 Rewinding of all Ex motors shall only be carried by Ex Service Provider to ensure that the

temperature classification of the machines are not affected.

175.137.6.220 zafri@ifp.com.my 11/22/2023 01:27:25 GMT

PTS 13.40.02

Ex EQUIPMENT REPAIR REQUIREMENT (Ex ERR) November 2016

Page 9 of 13

2.5 REPLACEMENT EQUIPEMENT – COMPLETE UNIT

2.5.1 Ex equipment which is damaged beyond economical repair or is not able to comply with

original certification after repair shall be replaced with a new unit of appropriate or equivalent

Ex certification unless appropriate repair or modification has been agreed by B-TA. The

replacement equipment should be identical with the original unit to avoid any unnecessary

retrofitting works on site.

2.5.2 In the event that the damaged equipment is obsolete and identical Ex certified replacement

equipment is no longer available from OEM, then equivalent equipment with appropriate Ex

certification may be sourced from OEM or other manufacturers/vendors for retrofitting.

Inputs from OEM may be required for sourcing the replacement equipment with the best fit

(physical dimensions, mounting/foundation requirements, electrical characteristics, etc.) and

least modification on the necessary retrofitting work.

2.6 ECONOMIC JUSTIFICATION

2.6.1 The Life Cycle Cost analysis should be performed for economic justification of any major work

required for repair of damaged Ex equipment.

2.6.2 If the total repair cost (including part replacement) is more than 50% of the cost of a new

equipment, the damaged Ex equipment should be replaced with a new unit. However, other

factors like delivery period for the new equipment, etc. should also be considered before

deciding to go for the replacement option.

175.137.6.220 zafri@ifp.com.my 11/22/2023 01:27:25 GMT

PTS 13.40.02

Ex EQUIPMENT REPAIR REQUIREMENT (Ex ERR) November 2016

Page 10 of 13

3.0 MARKING SYSTEM

Repairs not affecting the integrity of the explosion features should not be marked.

All other repaired and overhauled apparatus should be marked on the main part in a visible

place.

This marking should be legible and durable taking into account possible chemical corrosion.

The marking should include:

i. The relevant symbol (see 3.1 below);

ii. The standard number “IEC 79-19” or national equivalent;

iii. The name of the repairer or his registered trade mark;

iv. The repairer’s reference number relating to the repair;

v. The date of the overhaul/repair

The marking may be on a plate permanently attached to the repaired apparatus.

In the event of subsequent repairs, the earlier plate may be removed, a record being made of

all the markings on it.

3.1 SYMBOLS

3.1.1 Full Compliance

This mark shall be used when the apparatus is in full compliance with the standard and

certificate.

3.1.2 Compliance with the standard

This mark shall be used when apparatus is in compliance with the standard but not in

compliance with the certificate.

175.137.6.220 zafri@ifp.com.my 11/22/2023 01:27:25 GMT

PTS 13.40.02

Ex EQUIPMENT REPAIR REQUIREMENT (Ex ERR) November 2016

Page 11 of 13

3.1.3 Non-Compliance

This mark shall be used when apparatus is not in compliance with the standard and the

certificate.

175.137.6.220 zafri@ifp.com.my 11/22/2023 01:27:25 GMT

PTS 13.40.02

Ex EQUIPMENT REPAIR REQUIREMENT (Ex ERR) November 2016

Page 12 of 13

4.0 BIBLIOGRAPHY

In this PTS, reference is made to the following Standards/Publications. Unless specifically

designated by date, the latest edition of each Standards/Publications shall be used, together

with any supplements/revisions thereto:

PETRONAS TECHNICAL STANDARDS

Index to PTS PTS 00.01.01

PTS Requirements, General Definition of Terms, Abbreviations & PTS 00.01.03

Reading Guide

Index to Standard Drawings PTS 00.11.01

Field Commissioning and Maintenance of Electrical Installations PTS 13.02.01

and Equipment

SI Quantities and Units PTS 16.00.01

OTHERS STANDARDS

PETRONAS Technical Standards Management Procedure Version 3.0

INTERNATIONAL STANDARDS

Electrical Apparatus for Potentially Explosive Atmospheres. IEC 60079 – 19

IECEx Operations Manual-Assessment and Certification of IECEx OD13

Ex Repair and Overhaul Service Facilities Assessment

procedures to be followed by ExCBs for issuing and

maintaining of IECEx Certificates of Conformity for Service

Facilities conducting repair, overhaul or modifications of Ex

equipment seeking to be known as an IECEx Certified

Service Facility.

Quality Management System Requirements and IECEx OD14

Assessment of, for IECEx Service Facilities involved in repair,

overhaul and modification of Ex equipment.

IEC 60079: Electrical apparatus for explosive gas IECEx OD15

atmospheres

Part 19: Repair and overhaul for apparatus used in

explosive atmospheres (other than mines or explosives)

175.137.6.220 zafri@ifp.com.my 11/22/2023 01:27:25 GMT

PTS 13.40.02

Ex EQUIPMENT REPAIR REQUIREMENT (Ex ERR) November 2016

Page 13 of 13

APPENDIX 1: Ex EQUIPMENT OVERHAUL/REPAIR FLOWCHART

175.137.6.220 zafri@ifp.com.my 11/22/2023 01:27:25 GMT

You might also like

- Chcccs023 - Ageing Sab v3.2 TheoryDocument32 pagesChcccs023 - Ageing Sab v3.2 TheoryKanchan Adhikari38% (8)

- Case Questions - Grocery GatewayDocument4 pagesCase Questions - Grocery GatewayPankaj SharmaNo ratings yet

- Petronas Technical Standards: PETRONAS Risk-Based Inspection (PRBI)Document23 pagesPetronas Technical Standards: PETRONAS Risk-Based Inspection (PRBI)testNo ratings yet

- PTS 13.42.01 PDFDocument20 pagesPTS 13.42.01 PDFNaufal Daumi100% (1)

- Offshore Life Saving Appliances RequirementDocument31 pagesOffshore Life Saving Appliances RequirementmhabibnurNo ratings yet

- Petronas Technical Standards: Pipelines Pre-CommissioningDocument40 pagesPetronas Technical Standards: Pipelines Pre-CommissioningAsus Asri100% (4)

- Pip Pcfte100 (Inserción de Termopozos)Document8 pagesPip Pcfte100 (Inserción de Termopozos)Nilyan Berti100% (1)

- Ex Equipment Repair Requirement (Ex Err)Document13 pagesEx Equipment Repair Requirement (Ex Err)jk.jackycheokNo ratings yet

- 130004-Industrial Power Plant DesignDocument22 pages130004-Industrial Power Plant DesignCornelius Ernest RodriguezNo ratings yet

- Inspection and TestingDocument22 pagesInspection and TestingSam Low100% (2)

- 130101-Power QualityDocument22 pages130101-Power QualityCornelius Ernest RodriguezNo ratings yet

- Petronas Technical Standards: Standard Forms (Binder)Document160 pagesPetronas Technical Standards: Standard Forms (Binder)adamNo ratings yet

- Workshope Equipment and Mechanical ToolsDocument50 pagesWorkshope Equipment and Mechanical ToolsTurbo Snail RNo ratings yet

- Petronas Technical Standards: Operator Training Simulator (Ots) System Project ExecutionDocument15 pagesPetronas Technical Standards: Operator Training Simulator (Ots) System Project Executionahmadreza777100% (1)

- Low Voltage Switchgear & Controlgear AssembliesDocument49 pagesLow Voltage Switchgear & Controlgear Assembliesjk.jackycheokNo ratings yet

- Dec 98Document25 pagesDec 98c_nghia100% (1)

- Sep 09Document24 pagesSep 09c_nghia50% (2)

- Petronas Technical Standards: Operator Training Simulator (Ots) System Itb and Fds Document Technical SpecificationsDocument43 pagesPetronas Technical Standards: Operator Training Simulator (Ots) System Itb and Fds Document Technical Specificationsahmadreza777No ratings yet

- Petronas Technical StandardsDocument9 pagesPetronas Technical Standardsfaiz yatimNo ratings yet

- Petronas Technical Standards: Measurement of Viscous Properties of Completion Fluids (Endorsement of Iso 13503-1)Document7 pagesPetronas Technical Standards: Measurement of Viscous Properties of Completion Fluids (Endorsement of Iso 13503-1)ĐiệnBiênNhâmNo ratings yet

- Inspection & Functional Testing of InstrumentsDocument23 pagesInspection & Functional Testing of Instrumentsjk.jackycheokNo ratings yet

- Dec 08Document31 pagesDec 08c_nghia100% (1)

- Installation of On-Line InstrumentsDocument23 pagesInstallation of On-Line Instrumentsjk.jackycheokNo ratings yet

- Petronas Technical Standards: Specifications and Requirements For Pipeline In-Line InspectionDocument30 pagesPetronas Technical Standards: Specifications and Requirements For Pipeline In-Line InspectionAsus AsriNo ratings yet

- Dec 09Document55 pagesDec 09c_nghia100% (1)

- Power Quality PDFDocument22 pagesPower Quality PDFKhairul AshrafNo ratings yet

- Petronas Technical Standards: Power QualityDocument5 pagesPetronas Technical Standards: Power QualityjausahaslkNo ratings yet

- Petronas Technical Standards: Industrial Power Plant DesignDocument22 pagesPetronas Technical Standards: Industrial Power Plant DesignMohd Aizzuddin Md JanisNo ratings yet

- Petronas Technical Standards: Blast Resilient and Blast Resistant Control Buildings/Field Auxiliary RoomsDocument58 pagesPetronas Technical Standards: Blast Resilient and Blast Resistant Control Buildings/Field Auxiliary Roomsheriaca petersonNo ratings yet

- Petronas Technical StandardsDocument20 pagesPetronas Technical StandardsMohd Nizamuddin Mohamad NoorNo ratings yet

- Ocp - Att Open CSGR Spec-Draft 1Document15 pagesOcp - Att Open CSGR Spec-Draft 1DhirajNo ratings yet

- Structures Cabling For TelecommunicationDocument54 pagesStructures Cabling For Telecommunicationjk.jackycheokNo ratings yet

- Jan 98Document30 pagesJan 98c_nghiaNo ratings yet

- Sep 02Document19 pagesSep 02c_nghia100% (1)

- Petronas Technical Standards: Requisition (Binder)Document425 pagesPetronas Technical Standards: Requisition (Binder)adam100% (1)

- Petronas Technical Standards: Pipeline and Riser Engineering DesignDocument37 pagesPetronas Technical Standards: Pipeline and Riser Engineering DesignAzim SamiinNo ratings yet

- Aug 2011Document10 pagesAug 2011c_nghia100% (2)

- Ex Management, Inspection & Maintenance (Ex Mim)Document52 pagesEx Management, Inspection & Maintenance (Ex Mim)jk.jackycheokNo ratings yet

- PTS 32.31.09.31 Instru For Package Equip PDFDocument30 pagesPTS 32.31.09.31 Instru For Package Equip PDFPilsner80No ratings yet

- 10.02.51.11 Nov 2012Document29 pages10.02.51.11 Nov 2012nur fardinaNo ratings yet

- Ni 2838Document49 pagesNi 2838marceloNo ratings yet

- 5500245X 2 ENG p02 of 2 2009-06 Cont-Tech Commander SK AdvUGDocument200 pages5500245X 2 ENG p02 of 2 2009-06 Cont-Tech Commander SK AdvUGzinebNo ratings yet

- Cathodic Protection System For Storage Tank & Pressure Vessel (Amendments Supplements To NACE and API Standards)Document7 pagesCathodic Protection System For Storage Tank & Pressure Vessel (Amendments Supplements To NACE and API Standards)Abd.Buhari Abd.GalimNo ratings yet

- 122 Norwegian Oil and Gas Recommended Guidelines For The Mangement of Life ExtensionDocument20 pages122 Norwegian Oil and Gas Recommended Guidelines For The Mangement of Life ExtensionPar MadNo ratings yet

- Ultrasonic ExaminationDocument21 pagesUltrasonic Examinationjuantamad02100% (1)

- 30401030Document12 pages30401030JohnNo ratings yet

- Electromagnetic Compatibility (Emc) RequirementDocument41 pagesElectromagnetic Compatibility (Emc) Requirementjk.jackycheokNo ratings yet

- Mar 09Document30 pagesMar 09c_nghia100% (1)

- PTS 12.01.01Document16 pagesPTS 12.01.01Aidil Fadzree MorsidinNo ratings yet

- Instrumentation For Equipment PackagesDocument14 pagesInstrumentation For Equipment Packagesjk.jackycheokNo ratings yet

- Petronas Technical Standard (PTS 50.014)Document20 pagesPetronas Technical Standard (PTS 50.014)Kellary Liaw Nyuk Chin100% (2)

- Operator Training Simulator SystemDocument24 pagesOperator Training Simulator Systemjk.jackycheokNo ratings yet

- Petronas Technical Standards: Pts Publications and Standard SpecificationsDocument38 pagesPetronas Technical Standards: Pts Publications and Standard SpecificationsadamNo ratings yet

- 00002010Document7 pages00002010minhthanhmosNo ratings yet

- 121205Document25 pages121205wdavid81No ratings yet

- MOTS-47 - Rev. 1.0 - MOG-FP-INS-STD-0047 Emergency Shutdown SystemsDocument20 pagesMOTS-47 - Rev. 1.0 - MOG-FP-INS-STD-0047 Emergency Shutdown SystemsKingston RivingtonNo ratings yet

- PTS - 202001 Safety Requirements For Mobile Offshore UnitsDocument14 pagesPTS - 202001 Safety Requirements For Mobile Offshore UnitscfkianNo ratings yet

- Petronas Technical Standards: Seismic Hazard Assessment For Onshore FacilitiesDocument24 pagesPetronas Technical Standards: Seismic Hazard Assessment For Onshore FacilitiesAsus AsriNo ratings yet

- Petronas Technical Standards: Downhole Equipment - Subsurface Safety Valves (Endorsement of Iso 10432)Document6 pagesPetronas Technical Standards: Downhole Equipment - Subsurface Safety Valves (Endorsement of Iso 10432)ĐiệnBiênNhâmNo ratings yet

- Weldable Structural SteelDocument22 pagesWeldable Structural SteelSam LowNo ratings yet

- 4.ELK20001 - Statement of WorkDocument26 pages4.ELK20001 - Statement of WorkSuneel PanditNo ratings yet

- Regulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsFrom EverandRegulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsNo ratings yet

- Impact of Christian Religious Involvement To The Stress Coping Mechanisms of Senior High Learners - Revised PaperDocument16 pagesImpact of Christian Religious Involvement To The Stress Coping Mechanisms of Senior High Learners - Revised PaperShiera Mae PuguonNo ratings yet

- Evaluation Sheets For ResearchDocument6 pagesEvaluation Sheets For ResearchMa Maudie Arah O GarciaNo ratings yet

- Tax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Document2 pagesTax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)MAYANK GUPTANo ratings yet

- Mahatma Gandhi BiographyDocument5 pagesMahatma Gandhi BiographyGian LuceroNo ratings yet

- Early Christian ArchitectureDocument5 pagesEarly Christian ArchitectureDc Salvador BacsaNo ratings yet

- Hayakawa CO.,LTD.: TO: Dated: 08/01/19 Invoice No.: 190801421 1 / 1Document1 pageHayakawa CO.,LTD.: TO: Dated: 08/01/19 Invoice No.: 190801421 1 / 1Earl CharlesNo ratings yet

- MY Salary Guide 2022 - 23 - v5Document38 pagesMY Salary Guide 2022 - 23 - v5Yoong Ming JunNo ratings yet

- ItikaafDocument3 pagesItikaafmusarhadNo ratings yet

- IGCSE HISTORY Topic 5 - Who Was To Blame For The Cold WarDocument11 pagesIGCSE HISTORY Topic 5 - Who Was To Blame For The Cold WarAbby IuNo ratings yet

- CH47Document26 pagesCH47Hanna HellerNo ratings yet

- PF Enomination Job AidDocument9 pagesPF Enomination Job Aidashritha prakashNo ratings yet

- 2-3 Excavation & EmbankmentDocument23 pages2-3 Excavation & Embankmentzrilek1No ratings yet

- IA 6 - Q2 - Mod6Document17 pagesIA 6 - Q2 - Mod6Elmer OdevilasNo ratings yet

- Impact of Social Media Marketing On Brand Image of Fastfood Chain in Sariaya, QuezonDocument37 pagesImpact of Social Media Marketing On Brand Image of Fastfood Chain in Sariaya, QuezonGlydel Anne C. LincalioNo ratings yet

- Mrunal Explained: Cheque Truncation System CTS-features, BenefitsDocument3 pagesMrunal Explained: Cheque Truncation System CTS-features, BenefitsPrateek BayalNo ratings yet

- McCAMISH HelpDocument39 pagesMcCAMISH HelpSrinivas BalledaNo ratings yet

- DT Ratcfull Sig 55 Sce MetaDocument3 pagesDT Ratcfull Sig 55 Sce MetaPrashant JumanalNo ratings yet

- Flight TicketDocument3 pagesFlight TicketAkshay KanyanNo ratings yet

- 14&21-Realubit v. Jaso G.R. No. 178782 September 21, 2011Document5 pages14&21-Realubit v. Jaso G.R. No. 178782 September 21, 2011Jopan SJNo ratings yet

- Form 3 Accounting June 2023Document9 pagesForm 3 Accounting June 2023Bonolo RamofoloNo ratings yet

- DEMETION-The Dispute of Philippines and Malaysia Over Sabah TerritoryDocument16 pagesDEMETION-The Dispute of Philippines and Malaysia Over Sabah TerritoryJames DemetionNo ratings yet

- The Last SupperDocument36 pagesThe Last SupperselthielNo ratings yet

- Young Kings (T.me-Riset9)Document25 pagesYoung Kings (T.me-Riset9)PRASOON PATELNo ratings yet

- God Sees The Truth But WaitsDocument2 pagesGod Sees The Truth But WaitsrowenaNo ratings yet

- Risk Management and Internal Control System - Reference Framework PDFDocument42 pagesRisk Management and Internal Control System - Reference Framework PDFChinh Lê Đình100% (1)

- FinMod 2022-2023 Tutorial Exercise + Answers Week 6Document39 pagesFinMod 2022-2023 Tutorial Exercise + Answers Week 6jjpasemperNo ratings yet

- Loan Agreement PDFDocument9 pagesLoan Agreement PDFHengki YonoNo ratings yet

- Chapter 6Document19 pagesChapter 6Naveed SultanNo ratings yet