Professional Documents

Culture Documents

TETC Safety Procedure - Soldering Station

TETC Safety Procedure - Soldering Station

Uploaded by

Roland von KurnatowskiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TETC Safety Procedure - Soldering Station

TETC Safety Procedure - Soldering Station

Uploaded by

Roland von KurnatowskiCopyright:

Available Formats

Safe Work Procedure

Exxon-Mobil TETC

Name of Safe Work Procedure: Soldering Station - Tool Safety Name of Safe Work Procedure #:

Original Release Date: 10 April, 2024 Revision Date:

Approval: Management Signature:

This Safe Work Procedure MUST be reviewed annually

Do NOT Operate Equipment without Prior Authorization

Personal Protective Equipment (PPE) and Precautions: ALL operators and assistants in Area MUST wear the PPE advised below and follow and

fully understand all required precautions.

Eye Protection Required Long or loose hair must be tied back

No loose fitting clothing No jewelry, watches, rings, etc.

Closed toed shoes Long sleeves and long pants made of natural fibers or a long

sleeve Lab Coat must be worn

Potential Safety Hazards: Fire Hazard, Burn Hazard, Electrocution Hazard, Toxicity Hazard,

Flying Debris Hazard

Before Operating Equipment

1.) Inspect and put on required PPE.

2.) Gather all required materials and tools and ensure a clean and safe work area.

3.) Remove all papers, notebooks, flammable & combustible materials, and excess chemicals from the area.

4.) Tie back any long hair.

5.) Inspect tool for any damage or other obvious defects. Including mechanical damage to the machine or

damage to the cord or plug. Do not use it if any are present. Notify supervisor of damage.

txrxlabs.org │6501 Navigation Blvd., Houston, TX, 77011 │ eastendmakerhub.org

While Operating Equipment

6.) Never touch the element or tip of the soldering iron. It is very hot (about 400°C) and will burn.

7.) Hold wires to be heated with tweezers, pliers or clamps to avoid receiving burns from objects that are

heated.

8.) Keep the cleaning sponge wet during use.

9.) To the extent possible, conduct soldering on a solid, level surface and always return the soldering iron to

its stand when not in use. Never put it down on your workbench. Be sure the iron is secure in its stand so

it cannot inadvertently dislodge onto the work surface.

10.)Avoid inhalation of soldering smoke/fumes. The smoke formed during soldering is mostly from the flux.

Inhalation of flux fumes during soldering may cause irritation and damage of mucous membranes and

respiratory system. Eyes may become irritated from contact with smoke from soldering. To reduce

exposure:

a.) Conduct work in a well-ventilated area.

b.) Avoid breathing fumes/smoke by keeping your head to the side of, not above, your work.

11.)Use lead free solder and components only.

12.)Keep cleaning solvents in dispensing bottles to reduce inhalation hazards.

13.) Always wash your hands with soap and water after soldering.

14.)Do not eat, drink, or allow your hands to come in contact with mucous membranes while working.

15.)Conduct work on a fire-proof or noncombustible surface that is not easily ignited.

16.) A fire extinguisher should be present in the area. Know where it is located and how to use it.

17.)Keep materials and debris clear of soldering station to limit fire risk.

After Operating Equipment

18.)Allow iron and workpieces to cool before handling.

19.)Turn the unit off or unplug the iron when not in use.

txrxlabs.org │6501 Navigation Blvd., Houston, TX, 77011 │ eastendmakerhub.org

You might also like

- Bridgeport VMC1022 PDFDocument98 pagesBridgeport VMC1022 PDFKrassi GlogovskiNo ratings yet

- Midterm Exam - Revisión Del IntentoDocument9 pagesMidterm Exam - Revisión Del IntentoGary EchavarriaNo ratings yet

- Manual HECHT 650 GB PDFDocument14 pagesManual HECHT 650 GB PDFEmaNo ratings yet

- C9370 Manual BookDocument28 pagesC9370 Manual BookJuan Norberto PerezNo ratings yet

- Engine Lathe: Operation Instruction & Parts ListDocument55 pagesEngine Lathe: Operation Instruction & Parts ListDIEGO HERNANDEZ LUNANo ratings yet

- TETC Safety Procedure - Belt and Disc SanderDocument2 pagesTETC Safety Procedure - Belt and Disc SanderRoland von KurnatowskiNo ratings yet

- TETC Safety Procedure - Hot Glue GunDocument2 pagesTETC Safety Procedure - Hot Glue GunRoland von KurnatowskiNo ratings yet

- TETC Safety Procedure - Strip HeaterDocument2 pagesTETC Safety Procedure - Strip HeaterRoland von KurnatowskiNo ratings yet

- VMC 56022Document99 pagesVMC 56022wirot deelamanNo ratings yet

- TETC Safety Procedure - CNC RouterDocument2 pagesTETC Safety Procedure - CNC RouterRoland von KurnatowskiNo ratings yet

- TETC Safety Procedure - CNC Laser CutterDocument2 pagesTETC Safety Procedure - CNC Laser CutterRoland von KurnatowskiNo ratings yet

- VMC 560-22 TNC 2500cmaintenance Manualsiemens 1801235 PDFDocument90 pagesVMC 560-22 TNC 2500cmaintenance Manualsiemens 1801235 PDFAmir JuttNo ratings yet

- Safety Instruction For Using Threaded MachineDocument3 pagesSafety Instruction For Using Threaded MachineKhaled AnwarNo ratings yet

- Dutchman: Tree Planter Owner's ManualDocument21 pagesDutchman: Tree Planter Owner's ManualSantiago Puyen VillegasNo ratings yet

- PONCHADORADocument9 pagesPONCHADORAJulio Cesar MendozaNo ratings yet

- AT Air Hammer-rev2-0-NoParts PDFDocument11 pagesAT Air Hammer-rev2-0-NoParts PDFHamid MojiryNo ratings yet

- Safe Operating Procedures 03 Chainsaw OperationDocument2 pagesSafe Operating Procedures 03 Chainsaw OperationVictorNo ratings yet

- Bostitch N64C Operating ManualDocument34 pagesBostitch N64C Operating Manualstephenson1975No ratings yet

- JTHB Shop Manual Sen06343-00Document112 pagesJTHB Shop Manual Sen06343-00Ser EscamNo ratings yet

- Model TB-16Document20 pagesModel TB-16xuanphuong2710No ratings yet

- New Microsoft Word DocumentDocument8 pagesNew Microsoft Word DocumentponnavasuNo ratings yet

- Page 25Document1 pagePage 25Theodor PocovnicuNo ratings yet

- ITEEA SafetyPresentation 2014 Part1Document83 pagesITEEA SafetyPresentation 2014 Part1Diana RUNo ratings yet

- Machine Shop SopDocument8 pagesMachine Shop Sophelmee kamarudinNo ratings yet

- TrioTIO6203 Screen Manual (207) Banana Doble DeckDocument39 pagesTrioTIO6203 Screen Manual (207) Banana Doble DeckPatricio Contreras100% (2)

- Concrete Cutter Procedure Rev.2Document9 pagesConcrete Cutter Procedure Rev.2Jennifer JavierNo ratings yet

- Compulsory Ppe As Needed Ppe: Safe Operating Procedures SOP 02 - Bench GrinderDocument2 pagesCompulsory Ppe As Needed Ppe: Safe Operating Procedures SOP 02 - Bench GrinderMuhammad Oji L100% (1)

- Cut-Off Machine Model CC 14SE: Handling InstructionsDocument8 pagesCut-Off Machine Model CC 14SE: Handling InstructionsseyfiNo ratings yet

- SWP For MBDocument12 pagesSWP For MBDines VijayadevarNo ratings yet

- TrioTIH5162B Screen ManualDocument32 pagesTrioTIH5162B Screen ManualAlejandro CornideNo ratings yet

- Bostitch Roofing Nailer RN46-1-ManualDocument32 pagesBostitch Roofing Nailer RN46-1-ManualRod ScottNo ratings yet

- Safety ProcedurePetropathDocument3 pagesSafety ProcedurePetropathrupa pamlNo ratings yet

- Heater - Exheat Iom ManualDocument51 pagesHeater - Exheat Iom ManualLai HuynhNo ratings yet

- Sop Drills Screwdrivers CordlessDocument1 pageSop Drills Screwdrivers CordlessSravan CholeteNo ratings yet

- PRS5000 NaDocument20 pagesPRS5000 Navincent.casenNo ratings yet

- DX50 Engine ServiceManualDocument285 pagesDX50 Engine ServiceManualjonathanrioscNo ratings yet

- Chainsaw Manual CS 310Document40 pagesChainsaw Manual CS 310digitaltextNo ratings yet

- Secoroc RotaryDocument84 pagesSecoroc RotaryElgi Zacky ZachryNo ratings yet

- Breaker Operator's and Services ManualDocument96 pagesBreaker Operator's and Services Manuallinuskotte100% (1)

- Booklet Iom enDocument88 pagesBooklet Iom enanil28xNo ratings yet

- PV275 - Components Exchange Manual Rev 2Document161 pagesPV275 - Components Exchange Manual Rev 2mantencionperfo.oxeNo ratings yet

- SOP-12-Installation and Disconnection of Live Head of Drilliing LineDocument6 pagesSOP-12-Installation and Disconnection of Live Head of Drilliing LineDQE040 HSSENo ratings yet

- Is 3 Module NotesDocument16 pagesIs 3 Module NotesRudresh HirematNo ratings yet

- Hand Power Tools PDFDocument6 pagesHand Power Tools PDFDankNo ratings yet

- SAfety Qns AnswerDocument19 pagesSAfety Qns AnswerIrfan QadriNo ratings yet

- 2 General Safety Regulations For Operation and Maintenance of Railway Transist SystemsDocument24 pages2 General Safety Regulations For Operation and Maintenance of Railway Transist SystemsFNo ratings yet

- Tools and Equipt. SafetyDocument27 pagesTools and Equipt. SafetyJericho DagamiNo ratings yet

- 18 Poeder Acuated ToolsDocument2 pages18 Poeder Acuated ToolsMohammed MinhajNo ratings yet

- Makita Ls1020 Users Manual 405647Document20 pagesMakita Ls1020 Users Manual 405647Martin HaryadiNo ratings yet

- Mach 2 Term PaperDocument9 pagesMach 2 Term PaperCj GamingNo ratings yet

- Angle Grinder SOPDocument1 pageAngle Grinder SOPNhypz Marcaida67% (3)

- Orion Safety Manual Rev 2007Document186 pagesOrion Safety Manual Rev 2007jinyuan74No ratings yet

- Manual Dustless Blasting - Db800-Instruction-manualDocument32 pagesManual Dustless Blasting - Db800-Instruction-manualJose Lin MontenegroNo ratings yet

- Engine 12V140E-3 Series: 00 Index and ForewordDocument40 pagesEngine 12V140E-3 Series: 00 Index and ForewordЕгор100% (1)

- Pha ExcavationDocument13 pagesPha ExcavationirshadNo ratings yet

- Mini Cement Mixer 1.25 Cu - Ft. Model 91907 PDFDocument13 pagesMini Cement Mixer 1.25 Cu - Ft. Model 91907 PDFAKA "Tomás de Torquemada"No ratings yet

- Hse in Drilling OperationsDocument13 pagesHse in Drilling OperationsSamad Ali Siddiqui100% (2)

- STD Template For SOPsDocument2 pagesSTD Template For SOPsHafiz HamzaNo ratings yet

- 101-101-101-0038 - COVER ASSEMBLY V2Document1 page101-101-101-0038 - COVER ASSEMBLY V2Roland von KurnatowskiNo ratings yet

- 101-101-101-0044 - PROXIMITY SWITCH BRACKETDocument1 page101-101-101-0044 - PROXIMITY SWITCH BRACKETRoland von KurnatowskiNo ratings yet

- 101-101-101-0044 - PROXIMITY SWITCH BRACKETDocument1 page101-101-101-0044 - PROXIMITY SWITCH BRACKETRoland von KurnatowskiNo ratings yet

- AN025-DC Motor Control With TMC4671Document11 pagesAN025-DC Motor Control With TMC4671Roland von KurnatowskiNo ratings yet

- TETC Safety Procedure - CNC Laser CutterDocument2 pagesTETC Safety Procedure - CNC Laser CutterRoland von KurnatowskiNo ratings yet

- 02.03 NC Liner Scale System New 2017 2Document88 pages02.03 NC Liner Scale System New 2017 2Roland von KurnatowskiNo ratings yet

- BPG - 5S-System (Fivess)Document28 pagesBPG - 5S-System (Fivess)Roland von KurnatowskiNo ratings yet

- Minas-A5-2 Manu e PDFDocument512 pagesMinas-A5-2 Manu e PDFRoland von KurnatowskiNo ratings yet

- 02.03 NC Liner Scale System New 2017 2Document88 pages02.03 NC Liner Scale System New 2017 2Roland von KurnatowskiNo ratings yet

- BPG - 5S-System (Fivess)Document28 pagesBPG - 5S-System (Fivess)Roland von KurnatowskiNo ratings yet

- Optiv Performance 443 Dual Z Fact Sheet - enDocument4 pagesOptiv Performance 443 Dual Z Fact Sheet - enRoland von KurnatowskiNo ratings yet

- Tinikling: A Philippine Folk DanceDocument8 pagesTinikling: A Philippine Folk DancetelpastorNo ratings yet

- English HL - Transforming Moments NotesDocument14 pagesEnglish HL - Transforming Moments NotesABULELA NAMANo ratings yet

- The Watchful Wife Chapter SamplerDocument23 pagesThe Watchful Wife Chapter SamplerAllen & UnwinNo ratings yet

- Virtual Dressing Room Application: April 2019Document6 pagesVirtual Dressing Room Application: April 2019Bharath BallalNo ratings yet

- Get CockroachDB The Definitive Guide: Distributed Data at Scale Guy Harrison PDF Full ChapterDocument24 pagesGet CockroachDB The Definitive Guide: Distributed Data at Scale Guy Harrison PDF Full Chapterhatianavu100% (7)

- 7-Architectural Design and Allied ArtsDocument46 pages7-Architectural Design and Allied ArtsAngeline CuriosoNo ratings yet

- Review Article: Sales Forecasting For Fashion Retailing Service Industry: A ReviewDocument10 pagesReview Article: Sales Forecasting For Fashion Retailing Service Industry: A ReviewJaytraNo ratings yet

- GP Information ReportDocument1 pageGP Information ReportAvanntika GurungNo ratings yet

- Fabric and Garments Designing Techniques 1: Btvted - GFD 2ADocument40 pagesFabric and Garments Designing Techniques 1: Btvted - GFD 2Amaria divina bitagoNo ratings yet

- Undisclosed DesiresDocument31 pagesUndisclosed DesiresallendraNo ratings yet

- SeesawDocument25 pagesSeesawJeminah PauneNo ratings yet

- Blowin Up A Murder Kenni Lowry Mystery Book 8 Tonya Kappes Full ChapterDocument51 pagesBlowin Up A Murder Kenni Lowry Mystery Book 8 Tonya Kappes Full Chapterrichard.corella434100% (7)

- Gustavo Giovannoni - New Design in Old CitiesDocument23 pagesGustavo Giovannoni - New Design in Old CitieskonstantiouantoniaNo ratings yet

- COL - TRB1 - Vocabulary - Standard - Unit 5Document1 pageCOL - TRB1 - Vocabulary - Standard - Unit 5American Class100% (1)

- Implementing Project-Based Learning (PBL) in Final Collection To Improve The Quality of Fashion Design StudentDocument9 pagesImplementing Project-Based Learning (PBL) in Final Collection To Improve The Quality of Fashion Design StudentIrmaniar PutriNo ratings yet

- Unit 5 Grammar ActivitiesDocument3 pagesUnit 5 Grammar ActivitiesLidia Pop Bloander100% (2)

- L.G.Alexander: For and Against: An Oral Practice Book For Advanced Students of English (1975) - Longman: London 1Document30 pagesL.G.Alexander: For and Against: An Oral Practice Book For Advanced Students of English (1975) - Longman: London 1c3po_meNo ratings yet

- Museum Replicas Weapons and Armor Catalog Number 107Document78 pagesMuseum Replicas Weapons and Armor Catalog Number 107buckonbeach100% (3)

- Tarea de Ingles 3 y 4Document3 pagesTarea de Ingles 3 y 4genesisNo ratings yet

- EthicsDocument2 pagesEthicsmskumar_meNo ratings yet

- 1000 Poses in Fashion PDFDocument321 pages1000 Poses in Fashion PDFangela castilloNo ratings yet

- Simplicity Complete Measurement Guide PDFDocument9 pagesSimplicity Complete Measurement Guide PDFAhmed Rami Nasri100% (3)

- Effect of Balloon Breaker in Winding - Textile LearnerDocument8 pagesEffect of Balloon Breaker in Winding - Textile Learnermasum_austNo ratings yet

- Uni of AucklandDocument1 pageUni of AucklandN Afiqah RazakNo ratings yet

- Types of Sewing NeedlesDocument21 pagesTypes of Sewing Needlesaanchal jainNo ratings yet

- Safety Material ChecklistDocument2 pagesSafety Material ChecklistSafety Dept100% (1)

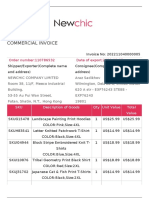

- Order InvoiceDocument2 pagesOrder InvoiceAraz SadikhovNo ratings yet

- Zara Case PPT 1Document28 pagesZara Case PPT 1estuputriwirasNo ratings yet

- 28 Nov 2019 Rekap Kaos NatalDocument18 pages28 Nov 2019 Rekap Kaos NatalSam KurniaNo ratings yet