Professional Documents

Culture Documents

Adsorption

Adsorption

Uploaded by

Ruhyat HariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Adsorption

Adsorption

Uploaded by

Ruhyat HariCopyright:

Available Formats

M.A. Mohamed et al / Chemistry Journal (2012), Vol. 02, Issue 03, pp.

95-105 ISSN 2049-954X

Research Paper

Adsorption Studies on the Removal of Hexavalent

Chromium-Contaminated Wastewater using Activated

Carbon and Bentonite

Salah Abdel Waneesa, Abdel Monem M. Ahmedb, Mohamed S. Adamc and Mamdouh A. Mohamed*a

a

Chemistry Department, Faculty of Science, Zagazig University,44519, Sharkia, Egypt

b

Chemistry Department, Faculty of Science, Alexandria University, Alexandria, Egypt

c

Chemistry Department, Faculty of Science, Sohag University, Sohag, Egypt

Tel.: +2093 2303929; fax: +2093 2303929

*E-Mail: mamsahar2020@yahoo.com

Abstract

In this study, the adsorption potential of activated carbon and bentonite for removal of Cr(VI) ions from wastewater has

been investigated. The study involves batch type experiments to investigate the effects of initial concentration, adsorbent

dose, agitation speed, contact time, temperature and pH of solution on adsorption process and the evaluation of optimum

conditions. The adsorption process has fit pseudo-second order kinetic models. Langmuir and Freundlich adsorption

isotherm models were applied to analyze adsorption data, and both were found to be applicable to this adsorption process.

Thermodynamic parameters, e.g., ∆G◦, ∆S◦ and ∆H◦ of the on-going adsorption process have also been calculated and found

the sorption process as endothermic. Finally, it can be seen that bentonite was found to be more effective for the removal of

Cr(VI) than activated carbon, under the same experimental conditions.

Keywords: Wastewater, Chromium, Activated Carbon, Bentonite, Removal

1. Introduction

The pollution of heavy metal ions in the environment is a world mine production was estimated at a gross mass of

critical problem because of their toxicity and other adverse 13x106 metric tons in 2002 (Papp, 2003).

effects on the receiving waters and /or soils. They must be

removed from wastewater before discharging them into In nature chromium exists in two most stable oxidation

water bodies. Water pollution by chromium is due to both, states, i.e., trivalent and hexavalent forms in aqueous

natural sources and manmade activities. Chromium is systems. Although, at trace level, the trivalent form is

found in rocks, animals, plants, soils and in volcanic dusts considered as an essential nutrient (Alloway, 1995 and

and gases. Various industrial processes which involve the Rojas et al, 2005) whereas hexavalent form of chromium is

use of Cr(VI), such as steel production, electroplating, toxic, carcinogenic and mutagenic in nature (Norseth,

leather tanning, nuclear power plants, textile industries, 1981; USDHHS, 1991; Cieslak-Golonka, 1995; Myers et

wood preservation, anodizing of aluminum, water-cooling al, 2000; Zhitkovich et al, 2002 and Dupont & Guillon,

and chromate preparation. Discharge of wastes containing 2003). Kowalski (1994) revealed that the hexavalent form

chromium occurs into environment, with its varied is about 500 times more toxic than trivalent form.

concentration between 5 and 220 mg/L. Such discharge Furthermore, Cr(VI) is highly mobile in soil and aquatic

ultimately contaminates soil and water (Okuda et al, 1975; system, and also is a strong oxidant capable of being

Ouki & Neufeld, 1997 and Altundogan, 2005). Chromite adsorbed by skin (Singh, & Singh, 2002). Considering its

Available online at www.scientific-journals.co.uk 95

M.A. Mohamed et al / Chemistry Journal (2012), Vol. 02, Issue 03, pp. 95-105 ISSN 2049-954X

toxicity and carcinogenic nature, the maximum levels used to prepare synthetic chromium containing

permitted for trivalent chromium in wastewater is 5 mg/L wastewater. Powder Activated Carbon (PAC) was

and for hexavalent chromium as 0.05 mg/L (BIS, 1991 and produced by ADWIC whereas bentonite by Alexandria

Acar & Malkoc, 2004). Company for Refractories.

The most common methods of Cr(VI) ions removal from 2.2 Adsorbents Analysis

aqueous system are chemical precipitation, ion exchange,

membrane processes, electrodialysis and adsorption The surface area and particle size analyses for the two

(Patterson, 1977; George, 1985; Tiravanti et al, 1997 and adsorbents i.e. PAC and Bentonite, were checked and

Dahbi et al, 1999). Hexavalent chromium usually exists in recorded (Table 1). Elemental analysis for bentonite was

wastewater as oxyanions such as chromate CrO4-2 and evaluated using x-ray fluorescence (Philips PW 1390) as

dichromate Cr2O7-2 and does not precipitate easily using shown in (Table 2).

conventional precipitation methods. Ion exchange, reverse

osmosis and elctrodialysis are efficient for Cr(VI) ions 2.3. Apparatus and Instrumentation

removal but the cost is relatively high (George, 1985).

Magnetic hot plate stirrer was used to stir the heavy metal

Furthermore, chromium removal techniques such as co- ions solutions with adsorbents (activated carbon or

precipitation, membrane techniques and solvent extraction bentonite). A known volume of heavy metal ions solution

are challenged by the removal of lower concentrations of of a known initial ions concentration was mixed and stirred

metals from solution (Valix et al, 2006). On the other with a specific amount of adsorbent for certain period of

hand, adsorption has been proved to be one of the time at fixed temperature and agitation rate. The pH values

respective methods, which is simple, selective and of the solutions were measured by digital pH meter (Model

economical process for the removal of heavy metal ions µ pH system-361, India). The metal ion concentration was

from aqueous solution. measured using atomic-absorption spectrophotometer,

AAS, (Model, AA55; Varian Inc., USA).

In this work two different adsorbents (activated carbon and

bentonite) were used for the removal of hexavalent 2.4. Experimental Procedures

chromium (Cr+6) from wastewater. Bentonite is considered

by many authors as main candidate in the decontamination Potassium dichromate (K2Cr2O7) and redistilled water

and treatment of detrimental metal ions, because of its were used to prepare a stock solution of 1000 ppm

large specific surface area and high adsorption capacity Cr(VI) concentration, which was further diluted

(Tsai et al, 2001; Lin & Juang, 2002 and Al-Qunaibit et al, for the preparation of test solutions. Several solutions

2005). with different initial concentrations of potassium

dichromate (50, 100, 200, 300 and 400 ppm)

The objectives of the present study are: 1) to study the were prepared. The required pH was adjusted by

effect of contact time of Cr+6 metal ions adsorption on drop wise addition of 0.1N H2SO4, depending on the

activated carbon and bentonite; 2) to investigate the acidity of the sample. All experiments were

influence of pH on the adsorption of Cr+6; 3) to study the carried out at 25 oC by adding different amounts of

adsorption of Cr+6 at different temperatures and to adsorbents (0.1, 0.3, 0.5, 0.7 and 1.0 g) to different

calculate the adsorption thermodynamic parameters (i.e., concentrations of 250 ml of heavy metal ions solution. The

∆H°, ∆S° and ∆G°); 4) to find the effect of adsorbent dose agitation rate for all experiments was 200 rpm and the

and initial concentration on the adsorption of Cr+6; 5) to residence time was (0, 15, 30, 45, 60, 75, 90 and 120

describe the experimental data of adsorption isotherms minutes).

through Langmuir and Freundlich models; 6) to investigate

the adsorption properties of Cr+6 and to discuss its 1 ml of sample was taken from reaction

adsorption mechanism. solution and diluted to 10 ml by redistilled

water, adsorbents were then separated from the solution

2. Materials and Methods by using filter paper (Watman No. 40) and the

residual Cr+6 ions concentration in the solution was then

2.1. Materials and Reagents determined by atomic-absorption spectrophotometer

(AAS).

All chemicals used in present work were either of

analytical reagent (AR) or laboratory reagent (LR) grade. The effects of several parameters, such as contact time,

K2Cr2O7 (99%) and H2SO4 (98% w/w) supplied by BDH initial concentration, adsorbent dose, pH and temperature

chemicals Ltd. Distilled water was used in all preparations. on the adsorption of Cr(VI) ions onto activated carbon and

Potassium dichromate (K2Cr2O7) and deionized water were bentonite were studied.

Available online at www.scientific-journals.co.uk 96

M.A. Mohamed et al / Chemistry Journal (2012), Vol. 02, Issue 03, pp. 95-105 ISSN 2049-954X

Table 1. Surface Area and Particle Size Analysis of Activated Carbon and Bentonite

Adsorbents Analysis Activated Carbon Bentonite

Surface Area (BET) Nova 2000 Quantachrome 931.9 m2/g 119.8 m2/g (dry)

Size (Micrometer) Wt. % Size (Micrometer) Wt. %

32-16 2.75 > 63 1

16-8 55.89 63-32 1

8-4 16.03 32-16 2

Particle size (XRD) Philips PW 1730

4-2 21.14 16-8 3

<2 4.19 8-4 2

4-2 4

<2 87

2.5. Data Analysis removal was 73% for activated carbon and 77% for

bentonite after 120 min. It is clear that, at the beginning %

The uptake of Cr(VI) ions was calculated from the Mass removal increased rapidly in few minutes, by increasing

Balance, define as the amount of solute adsorbed onto contact time, % removal increased lightly and slowly till

the solid. It equals the amount of solute removed from reach maximum value and this can be explained on the

the solution. Mathematically, it can be expressed by basis that as initially a large number of vacant surface sites

Equation 1: are available for adsorption of metal ions but with passage

of time the surface sites become exhausted (Zhan et al,

qe = (Ci Ce)/S…………………………………………...1 2000). These results indicate that the activated carbon and

bentonite have a very strong capacity for adsorption of

Where: Cr(VI) ions in solutions.

qe: The heavy metal ions concentration adsorbed by an adsorbent at

Table 2. Elemental Analysis for Bentonite was Evaluated Using X-

equilibrium (mg of metal ions/g of adsorbent)

Ray Fluorescence (Philips PW 1390)

Ci: The initial concentration of metal ions in the solution (mg/L)

Ce: The equilibrium concentration or final concentration of metal ions

in the solution (mg/L)

S: The dosage concentration.

Oxides (wt.%) Bentonite

SiO2 (%) 55.89

Dosage concentration, S, is expressed by Equation 2:

Al2O3 (%) 16.03

S = m/V………………………………………………...2 Fe2O3 (%) 4.19

CaO (%) 3.25

Where:

MgO (%) 2.75

V is the initial volume of metal ions solution used (L) and m is the K2O (%) 0.49

weight of dried used adsorbent (g)

Na2O (%) 0.34

The percentage of adsorption (%) is calculated using TiO2 (%) 0.15

Equation 3:

P2O5 (%) 0.086

% adsorption = [(Ci Ce)/Ci ] x 100………………..……3 SO3 (%) 0.23

LOI (%) 17.2

3. Results and Discussion

3.2. Effect of Adsorbent Dose

3.1. Effect of Contact Time

The percentage adsorption of Cr+6 ions onto activated

The effect of contact time on Cr(VI) adsorption on both carbon and bentonite was studied at different adsorbent

activated carbon and bentonite was investigated to study doses (0.4, 1.2, 2.0, 2.8 and 4.0 g/L), keeping pH (2.0),

the rate of Cr(VI) ions removal (Figure 1). It is easily seen temperature (25 oC), contact time (120 minutes) and initial

from Figure 1 that the percentage removal of Cr(VI) metal Cr+6 ions concentration of (400 mg/L) constant (Figure 2).

ions increased with increasing the contact time. The % The results showed that with increase in adsorbent dose,

Available online at www.scientific-journals.co.uk 97

M.A. Mohamed et al / Chemistry Journal (2012), Vol. 02, Issue 03, pp. 95-105 ISSN 2049-954X

the percentage adsorption of Cr+6 was increased. The percentage removal of Cr+6 was studied by varying

Maximum removal was observed with adsorbent dose of 4 Cr+6 concentrations from 50 to 300 mg/L with 4 g/L

mg/L for both activated carbon and bentonite. Increasing adsorbent dose of activated carbon and bentonite with the

the percentage of adsorption with adsorbent dose may be same standard conditions as illustrated in Figure 4.

due to the increase in adsorbent surface area and

availability of more adsorption sites (Namasivayam et al, activated carbon

1998 and Garg et al, 2007). Unit adsorption was, however, 600 bentonite

decreased with increasing in adsorbent dose (Figure 3).

500

This is may be due to overlapping of adsorption sites as a

Amount adsorbed (mg/g)

result of overcrowding of adsorbent particles (Garg et al, 400

2007).

300

80

200

70

100

60

+6

0

% Removal of Cr

50

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0

40 Adsorbent dose (g/L)

30

Figure 3. The Effect of Variant Activated Carbon or Bentonite

20 Adsorbent Dosage (0.4, 1.2, 2.0, 2.8, and 4.0 g/L) on the

Quantity Adsorbed for 400 mg/L Cr+6 Ions from

10 activated carbon Wastewater at Contact Time: 2 Hours; Temperature:

bentonite 25 oC; Agitation Speed: 200 rpm

0

0 20 40 60 80 100 120

t, min 90

activated carbon

+6

bentonite

Figure 1. Effect of Contact Time on Cr Ions Removal 80

(Conditions; Adsorbate Initial Concentration: 400

mg/L; pH: 2.0; Adsorbents Dose: 4 g/L; Agitation

Speed: 200 rpm; Temperature: 25 oC)

+6

% Removal of Cr

70

78

60

76

74

50

72

+6

% Removal of Cr

70

40

68 50 100 150 200 250 300

initial conc. (m g/L)

66

64

Figure 4. The Effect of Initial Concentration (Namely 50, 100, 200

62 activated carbon and 300 mg/L) on Removal of Cr+6 Ions (Conditions:

bentonite Adsorbents Dose: 4 g/L; Agitation Speed: 200 rpm;

60

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 Temperature: 25 oC)

A dsorbent dose (g/L )

The results represented in Figure 4, showed that the

percentage Cr+6 ions adsorption was decreased with

Figure 2. The Effect of Variant Activated Carbon or Bentonite increasing in initial concentration. But the actual amount

Adsorbent Dosage (0.4, 1.2, 2.0, 2.8, and 4.0 g/L) on the

Removal of 400 mg/L Cr+6 Ions from Wastewater at

of Cr+6 ions adsorbed per unit mass of the adsorbent was

Contact Time: 2 Hour; Temperature: 25 oC; Agitation increased with increasing in Cr+6 ions concentration in the

Speed: 200 rpm test solution as illustrated in Figure 5. At low

concentration the ratio of surface active sites to the total

3.3. Effect of Initial Chromium (VI) Ions Concentration metal ions in the solution is high and hence all metal ions

interact with the adsorbent and are removed quickly from

The initial heavy metal ions concentration is an important the solution. However, the amount of metal ions adsorbed

parameter in adsorption since a certain amount of per unit weight of adsorbent, q , is higher at high

adsorbent can adsorb a certain amount of heavy metal ions. concentration. According to these results, the initial Cr+6

Available online at www.scientific-journals.co.uk 98

M.A. Mohamed et al / Chemistry Journal (2012), Vol. 02, Issue 03, pp. 95-105 ISSN 2049-954X

ions concentration plays an important role in the approx.) is achieved at 40 oC in case of activated carbon.

adsorption capacities. Higher concentrations of metal ions The adsorption pro Cess does not usually operate at high

were used to study the maximum adsorption capacity of temperature (more than 40 oC) and this may be due to the

adsorbent (Mohanty et al, 2006 and Karthikeyan et al, damage of active binding sites and because of high

2005). operational cost, so experiments were performed at the

temperature range (25-40 oC). Furthermore, in the case of

activated carbon activated carbon, the enhancement in adsorption capacity

50 bentonite may be due to the chemical interaction between adsorbates

and adsorbent, creation of some new adsorption sites or

40 increased the rate of intraparticle diffusion of Cr(VI) ions

amount absorbed (mg/g)

into the pores of the adsorbent at higher temperatures (40

o

30

C). Also, it is mentioned that, the metal cations become

more faster with increasing temperature. While, in the

adsorption of Cr(IV) onto bentonite at 40 oC, probably the

20 available binding sites have been saturated and the

adsorbent no longer can bind further ions as the number of

10 sites available on the adsorbent is constant.

50 100 150 200 250 300

74 activated carbon

initial conc. (m g/L)

bentonite

72

Figure 5. The Effect Of Initial Concentration (Namely 50, 100, 200 70

and 300 mg/L) on Quantity Adsorbed of Cr+6 Ions

+6

68

% Removal of Cr

(Conditions: Adsorbents Dose: 4 g/L; Agitation Speed:

200 rpm; Temperature: 25 oC) 66

64

3.4. Effect of pH on the Uptake of Cr+6

62

The pH of the solution is an important variable which 60

controls the adsorption of the metal ions at the solid-water 58

interface. Hence, the influence of pH on the adsorption of 1.0 1.5 2.0 2.5 3.0 3.5 4.0

Cr+6 ions onto activated carbon and bentonite was pH

examined in the pH range of 1-4. These results were

represented in Figure 6, which showed that the adsorption

Figure 6. Effect of pH for the Adsorption of Cr(VI) Ions onto

capacities of Cr+6 ions onto both adsorbents increased Activated Carbon and Bentonite at 25 oC

significantly, with decreasing pH value and the maximum

removals of Cr+6 ions by both adsorbents for contact time The augmentation of the removal efficiency by stepping up

(120 min) were carried out at pH (2.0). The improved the temperature are due to: Firstly, the higher temperatures

removal of Cr(VI) at low pH is probably due to reduction activate the metal ions for enhancing adsorption at the

of hexavalent chromium to trivalent chromium ions (Anon, coordinating sites of the adsorbent, and the metal cations

1995), Equation 4 . became more faster (Babel & Kurniawan, 2003 and

Inglezakis et al, 2004). Secondly, acceleration of some

Cr2O72 + 14H+ + 6e1 → 2Cr+3 + 7H2O………………..4 originally slow step(s) and creation of some new activation

sites on the adsorbent surface (Domenico & Schwartz,

Also at low pH, there is presence of a large number of H+ 1990). Herein, the phenomenon can be observed in both

ions, which in turn neutralize the negatively charged adsorbents, but activated carbon is affected much higher

adsorbent surface, thereby reducing hindrance to the than in case bentonite Figure 7.

diffusion of dichromate ions (Sharma, & Forster, 1994).

6. Adsorption Kinetics

3.5. Effect of Temperature

Adsorption kinetics describe the solute uptake rate which

Figure 7 indicates the effect of temperature on the removal intern control the residence time and hence the size of

efficiency of Cr+6 ions from wastewater using activated adsorption equipment. The experimental results for the

carbon and bentonite. Four different temperatures were adsorption of Cr+6 ions onto activated carbon and bentonite

considered in this study (25, 30, 35 and 40o C). The figure showed rapid initial adsorption rate followed by a slower

showed that the removal efficiency increased by increasing rate. Initially, the adsorption sites are open and the metal

the temperature, where the maximum adsorption (76% ions interact easily with the sites and hence a higher rate of

Available online at www.scientific-journals.co.uk 99

M.A. Mohamed et al / Chemistry Journal (2012), Vol. 02, Issue 03, pp. 95-105 ISSN 2049-954X

adsorption is observed. Further, the driving force for model, the correlation coefficient, R2, was calculated from

adsorption (the concentration difference between the bulk these plots. The linearity of these plots indicates the

solution and the solid-liquid interface) is higher initially applicability of the two models. However, the correlation,

and this leads to a higher adsorption rate. However, after R2, showed that the pseudo-second order model, fits better

the initial period, slow adsorption may be due to slower the experimental data (R2>0.990) than the pseudo-first

diffusion of solute into the interior of the adsorbent. order model (R2 in the range of 0.888-0.964).

Several adsorption kinetics models have been developed to

understand the adsorption kinetics and rate limiting step The kinetic parameters calculated are shown in Table 3. It

(Lagergren, 1898; Ho & Mckay, 1999; Uzun & Guzel, has been found that the equilibrium sorption capacities

2000 and Ricordel, 2001). determined using second-order model were in agreement

with the experimentally determined equilibrium sorption

capacities. Also, the rate constant decreased with the

76 solution concentration increasing.

74 In general, the adsorption reaction is known to proceed

through the following three steps:

+6

% Removal of Cr

72

1) Transfer of adsorbate from bulk solution to adsorbent

70 surface, which is usually mentioned as diffusion

68 2) Migration of adsorbate into pores

a c tiv a te d c a rb o n

b e n to n ite

66

24 26 28 30 32 34 36 38 40 42 3) Interaction of adsorbate with available sites on the

T e m p e ra tu re (°C ) interior surface of pores.

3.7. Adsorption Isotherms

Figure 7. The Effect Of Temperature Between 25 and 40o C for the

Removal of Cr+6 Ions from Wastewater (Conditions: Several models have been used in the literature to describe

Adsorbate Initial Concentration: 400 mg/L; pH: 2.0;

Adsorbents Dose: 4 g/L; Agitation Speed: 200 rpm;

the experimental data of adsorption isotherm. The

Contact Time: 2 Hours) Langmuir and Freundlich models are the most frequently

employed to describe equilibrium (Zeldowitsch, 1934).

The following models have been widely used (Lagergren, The Langmuir isotherm is based on the theoretical

1898 and Ho & Mckay, 1999) Largergren pseudo-first principle that only a single adsorption layer exists on an

order model can be expressed by Equations 5 and 6: adsorbent and it represents the equilibrium distribution of

metal ions between the solid and liquid phases. The basic

dq/dt = k1(qe - q)………………………………………..5 assumption of the Langmuir adsorption process is the

formation of a monolayer of adsorbate on the outer surface

ln(qe - q) = lnqe - k1t……………………………………6 of the adsorbent and after that no further adsorption takes

place. The Langmuir-type isotherm remains to be the most

widely used for practical application. The Langmuir

Equations 7 and 8 give the pseudo-second order model as: isotherm for pure component adsorption can be obtained

from Equation 9:

dq/dt = k2(qe - q)2………………………………………7

Ce/qe = 1/(qmaxb) + (1/qmax) Ce………………………....9

t/q = t/qe + 1/k2qe2……………………………………...8

Where:

Where:

qmax is the Maximum Metal Ions uptake per unit mass of adsorbent

(mg/g), which is related to the adsorption capacity and b is Langmuir

q and qe are the amount of Cr+6 metal adsorbed per unit weight of

Constant (L/mol) which is exponentially proportional to the heat of

adsorbent (mg/g) at time t, and at equilibrium, respectively, and k1

adsorption and related to the adsorption intensity.

and k2 are the adsorption rate constants. The initial adsorption rate

(h) is equal to k1qe and k2qe2 (mgg-1min-1) for first and second order

models, respectively Therefore, a plot of Ce/qe versus Ce gives a straight line of

the slop 1/qmax and intercept 1/(qmax b) as in Figure 9.

The applicability of the above two models can be

examined by each linear plot of ln(qe-q) vs. t, and (t/q) vs. Zeldowitsch (1934) assumed an exponentially decaying

t, respectively and are represented in Figures 8 (a,c) and 8 function of site density with respect to heat of adsorption

(b,d) respectively. To quantify the applicability of each and obtained the classical empirical isotherm, Equation 10:

Available online at www.scientific-journals.co.uk 100

M.A. Mohamed et al / Chemistry Journal (2012), Vol. 02, Issue 03, pp. 95-105 ISSN 2049-954X

lnqe = lnKf + 1/n lnCe………………………………...10 This Freundlich type of behavior is indicative of surface

heterogeneity of the adsorbents, i.e the adsorptive

This is known as Freundlich isotherm. The Freundlich sites (surface of activated carbon and bentonite) are

adsorption isotherm is an indicator of the extent of made up of small heterogeneous adsorption patches that

heterogeneity of the adsorbent surface, where the are homogeneous in themselves. The activation of

Freundlich constants Kf and n, which respectively adsorption sites takes place, leading to increased

indicating the adsorption capacity and the adsorption adsorption probably through the surface exchange

intensity, were calculated from the intercept and slope of mechanism.

the plot of lnqe versus lnCe as shown in Figure 10.

Table 3. The Adsorption Kinetics Model Rate Constants for Adsorption of Cr+6 Ions onto Activated Carbon and Bentonite at Various

Concentrations and Constant Temperature 25 oC

Lagergren First-Order Pseudo-Second-Order

Conc. qe exp.

Adsorbent

(mg/L) (mg/g) K1 q1 k2 q2

R2 R2

(min-1) (mg/g) (gmg-1min-1) (mg/g)

50 10.5 2.7x10-2 6.95 0.9276 9.7x10-3 10.7 0.9954

Activated

100 17.25 2.6x10-2 15 0.9840 1.9x10-3 20.4 0.9934

Carbon

200 29.25 2.3x10-2 27.7 0.9371 7.2x10-4 36.9 0.9597

50 10 2.8x10-2 5.6 0.8851 1.1x10-2 10.5 0.9968

Bentonite 100 18 2.7x10-2 13.2 0.9585 3.0x10-3 18.9 0.9934

200 31.75 2.5x10-2 24.5 0.9642 1.4x10-3 35.7 0.9912

3.5 (a) 50 ppm

100 ppm

10 50 ppm (b )

3.0 100 ppm

200 ppm 9

200 ppm

2.5 8

2.0 7

ln(qe-q)

6

1.5

t/q

5

1.0

4

0.5

3

0.0 2

-0.5 1

0 20 40 60 80 100 10 20 30 40 50 60 70 80 90 100 110 120 130

t, min t, m in

14

3.5 (c) 50 ppm 50 pp m (d )

100 ppm 12 100 p pm

3.0

200 ppm 200 p pm

2.5

10

2.0

8

1.5

ln(qe-q)

t/q

1.0 6

0.5

4

0.0

-0.5 2

-1.0 0

0 20 40 60 80 100 0 20 40 60 80 100 120

t, m in t, m in

Figure 8. Pseudo-First Order Kinetic Plots for the Adsorption of Cr+6 Ions onto: a) Activated Carbon and c) Bentonite; Pseudo-Second Order

Kinetic Plots for the Adsorption of Cr+6 Ions on: b) Activated Carbon and d) Bentonite. (Conditions: Concentrations: 50, 100 and

200 ppm; pH: 2.0; Adsorbents Dose: 4 g/L; Agitation Speed: 200 rpm; Temperature: 25 oC)

Available online at www.scientific-journals.co.uk 101

M.A. Mohamed et al / Chemistry Journal (2012), Vol. 02, Issue 03, pp. 95-105 ISSN 2049-954X

3.0 the bentonite is more powerful adsorbent than

activated carbon. These results indicate that both

2

2.5 R = 0.9658 adsorbents have a very strong adsorption capacity towards

Cr+6 ions.

2.0

3.8. Thermodynamic Parameters

Ce/qe

1.5

2

R = 0.9686 Thermodynamic parameters such as free energy (∆G°),

1.0 enthalpy (∆H°) and entropy (∆S°) changes of adsorption

can be evaluated from the following Equations 11 and 12:

activated carbon

0.5

bentonite

0 10 20 30 40 50 60 70 80 90

Kc = CAe/Ce…………………………………………...11

C e (m g/L)

∆G° = - RT lnKc……………………………………....12

Figure 9. Langmuir Adsorption Isotherm for Cr+6 Ions Adsorption Where:

by Activated Carbon and Bentonite at Constant

Temperature 25 oC and Contact Time 2 hours Kc is the equilibrium constant and CAe and Ce (both in mg/L) are the

equilibrium concentrations for solute on the sorbent and in the

From the calculated results of Langmuir and Freundlich solution, respectively

isotherm constants, given in Table 4, it can be shown that

the Freundlich model yields a much better fit than the The Kc values are used in Equations 11 and 12 to

Langmuir model, when the R2 values are compared in determine the ∆G°, ∆H° and ∆S°, the Kc may be expressed

Table 4. This suggests that the boundary layer thickness is in terms of the ∆H° (kj mol-1) and ∆S° (kj mol-1K-1) as a

increased. The Freundlich constant Kf indicates the function of temperature, Equation 13:

sorption capacity of the sorbent. From Table 4, the values

of Kf are 1.84 and 1.58 for activated carbon and bentonite, lnKc = - ∆H°/RT + ∆S°/R……..………………………13

respectively.

Thermodynamic parameters such as free energy of

sorption (∆G°), the heat of sorption (∆H°) and standard

1.6

2

R = 0.9956

entropy (∆S°) changes during the sorption process

1.5 were calculated using Equations 11 and 12, temperature

range of 25-40 oC , initial concentration 50 mg/L

1.4

of Cr+6 ions and dose 4 g/L for activated carbon

1.3

and bentonite. (∆H°) and (∆S°) were obtained from

ln qe

the slope and intercept of a plot of lnKc versus 1/T

1.2 (Figure 11). The values of these parameters were recorded

in Table 5.

1.1

2

R = 0.9953

activated carbon

1.0 1.6

bentonite activated carbon

bentonite

0.8 1.0 1.2 1.4 1.6 1.8 2.0

1.4

ln C e

1.2

+6

Figure 10. Freundlich Adsorption Isotherm for Cr ions

1.0

Adsorption by Activated Carbon and Bentonite at

lnKC

o

Constant Temperature 25 C and Contact Time 2 hours

0.8

Furthermore, the values of n are 2.26 and 1.78 0.6

for activated carbon and bentonite, respectively. It

is noted that the values of n are bigger than 1, 0.4

reflecting the favorable adsorption. On the other 0.00316 0 .003 18 0.00320 0.00322 0.00324 0.00326 0.00 328 0.00330 0 .003 32 0.00334 0 .003 36 0.00338

hand, the qmax and the adsorption intensity 1/T (K )

-1

values of bentonite are higher than activated carbon.

The calculated b values indicate the interaction

Figure 11. A Plot of lnKC Versus 1/T for Cr+6 Ions Adsorption onto

forces between bentonite surface and Cr+6 ions are stronger Activated Carbon and Bentonite for 50 mg/L Initial

than in case of activated carbon, this means that Concentration at Constant Adsorbents Dose: 4 g/L

Available online at www.scientific-journals.co.uk 102

M.A. Mohamed et al / Chemistry Journal (2012), Vol. 02, Issue 03, pp. 95-105 ISSN 2049-954X

Table 4. Langmuir and Freundlich Isotherm Constants for the Adsorption of Cr+6 Ions onto Activated Carbon and Bentonite at Constant

Temperature 25 oC

Langmuir Isotherm Constants Freundlich Isotherm Constants

Adsorbent

2

qmax (mg/g) b (L/mol) R Kf (mg/g) n R2

Activated Carbon 38.17 0.0252 0.9686 1.8446 2.26 0.9953

Bentonite 48.83 0.0377 0.9658 1.5826 1.78 0.9995

Table 5. Thermodynamic Parameters for the Adsorption of Cr(VI) ions onto Activated Carbon and Bentonite

∆G° (kj mol-1)

Adsorbent ∆H° (kj mol-1) ∆S° (kj mol-1K-1)

25o C 30o C 35o C 40o C

Activated Carbon 51.45 0.1776 - 1.24 - 2.12 - 3.00 - 3.89

Bentonite 36.72 0.1268 - 1.06 - 1.70 - 2.33 - 2.71

The negative values of ∆G° indicate the spontaneous nature the sorption was feasible, spontaneous and endothermic in

of the process and more negative value with increase of nature. The positive value of the entropy change,

temperature showed that an increased in temperature suggested the increased randomness.

favours the sorption process. The positive values of ∆H°

indicated that the sorption process was endothermic in References

nature and the positive values of ∆S° showed the increased

randomness at solid/solution interfaces during the Acar, F.N., and Malkoc, E. (2004) The removal of

adsorption of metal ions onto both adsorbents and also chromium(VI) from aqueous solutions by fagus orientalis

reflected the affinity of activated carbon and bentonite L. Bioresource Technology, 94, pp. 13-15.

toward Cr+6 ions under consideration. It is also suggested

that the positive values of entropy indicated some Ajmal, M., Rao, R.A.K., Anwar, S., Ahmed, J., and

structural changes in the adsorbate and adsorbent Ahmed, R. (2003) Adsorption studies on rice husk:

(Altundogan et al, 2000; Ajmal et al, 2003 and Fuhrman et removal and recovery of Cd(II) from wastewater.

al, 2004). Bioresour. Technol., 86, pp. 147-149.

4. Conclusion Alloway, B.J. (1995) Heavy Metals in Soils. 2nd ed.

London, Blackie Academic and Professional, p. 368.

Both adsorbents can be successfully used for removing of

chromium (VI) ions from wastewater. The maximum Al-Qunaibit, M.H., Mekhemer, W.K., and Zaghloul, A.A.

adsorption percentages of Cr(VI) ions using both (2005) The adsorption of Cu(II) ions on bentonite-a kinetic

adsorbents were achieved within 120 minutes. The study. J. Colloid Interface Sci., 283, pp. 316-321.

adsorption percentages of Cr+6 ions increased sharply by

increasing adsorbent dose. As the initial concentration of Altundogan H.S., Altundogan S., Tumen F., Bildik, M.

ions increased, the percentage removal using activated (2000) Arsenic removal from aqueous solution by

carbon and bentonite decreased. The best temperature for adsorption on red mud. Waste Mange, 20, pp. 761-767.

the maximum adsorption is found to be 30-40 oC for

activated carbon, while the adsorption using bentonite is Altundogan, H.S. (2005) Arsenic removal from aqueous

less affected by increasing temperature. The maximum solution by adsorption on red mud Process Biochemistry,

removals of Cr(VI) ions by both adsorbents were carried 40, pp. 1443-1452.

out at pH 2). The pseudo-second kinetic order model is

suitable for describing the adsorption system. The obtained American Public Health Association (APHA) (1995)

experimental data has been well described by Langmuir Standard Methods for the Examination of Water and

and Freundlich isotherm models into both activated carbon Wastewater. 19th ed. Washington, APHA.

and bentonite.

Anon (1995) Standard Methods for the examination of

Different thermodynamic parameters, viz, ∆H°, ∆S° and Water and Wastewater, 19th ed. Washington USA,

∆G° have also been evaluated and it has been found that American Public Health Association. 6210 C.

Available online at www.scientific-journals.co.uk 103

M.A. Mohamed et al / Chemistry Journal (2012), Vol. 02, Issue 03, pp. 95-105 ISSN 2049-954X

Babel, S., and Kurniawan, T.A. (2003) Low- Lagergren, S. (1898) Zur theorie der sogenannten

cost adsorbents for heavy metals uptake from adsorption gelöster stoffe, Kungliga Svenska

contaminated water: a review. J. Hazard. Mater., B97, Vetenskapsakademiens, Handlingar, 24 (4), pp. 1-39.

pp. 219-243.

Lin, S.H., and Juang, R.S. (2002) Heavy metal removal

Bureau of Indian Standards (1991) Indian Standard for from water by sorption using surfactant-modified

drinking water as per BIS Specifications (IS: 10500). montmorillonite. J. Hazard. Mater., 92, pp. 315-326.

Cieslak-Golonka, M. (1995) Toxic and mutagenic effects Mohanty, K., Jha, M., Meikap, B.C., and Biwas, M.N.

of chromium(VI) a review. Polyhedron, 15, pp. 3667- (2006) Biosorption of chromium(VI) from aqueous

3689. solution by Eichhornia Crassipis. Chem. Eng. J., 117, pp.

71-77.

Dahbi, S., Azzi, M., and de la Guardia, M. (1999)

Removal of hexavalent chromium from wastewaters by Myers, C.R., Myers, J.M., Carstens, B.P., and Antholine,

bone charcoal. Fresenius Journal of Analytical W.E. (2000) Reduction of chromium(VI) by human

Chemistry, 363(4), pp. 404-407. microsomal enzymes: effects of iron and quinines. Toxic

Substance Mechanisms, 19, pp. 25-51.

Domenico, P.A., and Schwartz, F.W. (1990) Physical and

Chemical Hydrogeology. 1st ed. New York, John Wiley Namasivayam, C., Kadirvelu, K., and Kumuthu, M. (1998)

and Sons. Removal of direct red and acid brilliant blue by adsorption

onto banana pith. Bioresour. Technol., 64, pp. 77-79.

Dupont, I., and Guillon, E. (2003) Removal of hexavalent

chromium with a lignocellusic substrate extracted from Nitzsche, O., and Vereecken, H. (2002) Modelling

wheat bran. Environmental Science & Technology, 37, Sorption and Exchange Processes in Column Experiments

pp. 4235-4241. and Large Scale Field Studies. Mine Water Environ., 21,

pp. 15-23.

Fuhrman, H.G., Tjell, J.C., and Mcconchie, D. (2004)

Adsorption of arsenic from water using activated Norseth, T. (1981) Cancer hazards caused by nickel and

neutralized red mud. Environ. Sci. Technol., 38, pp. chromium exposure. Environmental Health

2428-2434. Perspectives, 40, pp. 121-130.

Garg, U.K., Kaur, M.P., Garg, V.K., and Sud, D. (2007) Okuda, T., Sugano, I., and Tsuji, T. (1975) Removal of

Removal of hexavalent chromium from aqueous solution heavy metals from wastewater by ferrite co-precipitation.

by agricultural waste biomass. Hazard. Mater., 140, pp. Filtration and Separation, 12, pp. 475-476.

60-68.

Ouki, S.K., and Neufeld, R.D. (1997) Use of activated

George, C.C. (1985) Electroplating Wastewater carbon for the recovery of chromium from industrial

Pollution Control Technology. Park Ridge, Noyes wastewaters. Journal of Chemical Technology and

Publications, pp. 30-39. Biotechnology, 70, pp. 3-8.

Ho, Y.S., and Mckay, G. (1999) Pseudo-second order Papp, J.F. (2003) US Geological survey (USGS) mineral

model for sorption processes. Process Biochem., 34, pp. commodity summaries. In: Guertin, et al, ed.

451-465. Chromium(VI) Handbook, CRC Press, p. 2005.

Inglezakis, V.J., Loizidou, M.D., and Grigoropoulou, H.P. Patterson, J.W. (1977) Wastewater Treatment

(2004) Ion exchange studies on natural and modified Technology. New York, Ann Arbor Science Publishers,

zeolites and the concept of exchange site accessibility. J. Inc.

Colloid Interface Sci., 275, pp. 570-576.

Reddi, L.N., and Inyang, H.I. (2001) Geo-Environmental

Karthikeyan, T., Rajgopal, S., and Miranda, L.R. (2005) Engineering Principles and Applications. New York,

Chromium adsorption from aqueous solution by Hevea Marcel Decker Inc.

Brasilinesis sawdust activated carbon. J. Hazard. Mater.,

B124, pp. 192-199. Ricordel, S., Taha, S., Cisse, I., and Dorange, G. (2001)

Heavy metals removal by adsorption onto peanut husks

Kowalski, Z. (1994) Treatment of chromic tannery wastes. carbon: characterization, kinetic study and modelling. Sep.

Journal of Hazardous Material., 37, pp. 137-144. Purif. Technol., 24(3), pp. 389-401.

Available online at www.scientific-journals.co.uk 104

M.A. Mohamed et al / Chemistry Journal (2012), Vol. 02, Issue 03, pp. 95-105 ISSN 2049-954X

Rojas, G., Silva, J., Flores, J.A., Rodriguez, A., and

L’Maldonado, M. (2005) Adsorption of chromium onto

cross-linked chitosan. Separation and Purification

Technology, 44, pp. 31-36.

Lagergren, S. (1898) Zur theorie der sogenannten

adsorption gelöster stoffe. Kungliga Svenska

Vetenskapsakademiens. Handlingar, 24(4), pp. 1-39.

Sharma, D.C., and Forster, C.F. (1994) The treatment of

chromium wastewaters using the sorptive potential of leaf

mould. Biores. Technol., 49, pp. 31-40.

Singh, I.B., and Singh, D.R. (2002) Cr(VI) removal in

acidic aqueous solution using iron-bearing industrial solid

wastes and their stabilization with cement. Environmental

Technology, 23, pp. 85-95.

Tiravanti, G., Petrluzzelli, D., and Passino, R. (1997)

Pretreatment of tannery wastewaters by an ion exchange

process for Cr(III) removal and recovery. Water Science

& Technology, 36, pp. 197-207.

Tsai, S.C., Ouyang, S., and Hsu, C.N. (2001) Sorption and

diffusion behavior of Cs and Sr on Jih-Hsing bentonite.

Appl. Radiat. Isot., 54, pp. 209-215.

US Department of Health and Human Services (USDHHS)

(1991) Toxicological Profile for Chromium, Public

Health Services Agency for Toxic Substances and

Diseases Registry. Washington, USDHHS.

Uzun, I., and Guzel, F. (2000) Adsorption of some heavy

metal ions from aqueous solution by activated carbon and

comparison of percent adsorption results of activated

carbon with those of some other adsorbents. Turk. J.

Chem., 24, pp. 291-297.

Valix, M., Cheung, W.H., and Zhang, K. (2006) Role of

heteroatoms in activated carbon for removal of hexavalent

chromium from wastewaters. Journal of Hazardous

Materials, B135, pp. 395-405.

Zeldowitsch, J. (1934) Űber den Mechanismus der

Katalytischen Oxydation von CO an MnO2. Acta

Physiochim. URSS, 1, pp. 364-449.

Zhan, Y.B., Shukla, A., Shukla, S., and Dorris, K.L.

(2000) The removal of heavy metal from aqueous

solutions by sawdust adsorption-removal of Copper. J.

Hazard. Mater., 80, pp. 33-42.

Zhitkovich, A., Quievryn, G., Messer, J., and Motylevich,

Z. (2002) Reductive activation with cysteine represents a

chromium(III)-dependent pathway in the induction of

genotoxicity by carcinogenic chromium(VI). Environ.

Health Persp., 110(S9), pp. 729-731.

Available online at www.scientific-journals.co.uk 105

You might also like

- Apprenticeship Sample Test Fauji Fertilizer Bin Qasim Limited FFBLDocument12 pagesApprenticeship Sample Test Fauji Fertilizer Bin Qasim Limited FFBLOsamaIsmail86% (36)

- Questions For Chem Lab 4Document4 pagesQuestions For Chem Lab 4Md IjazNo ratings yet

- Ion Exchange Resins and Adsorbents in Chemical Processing: Second EditionFrom EverandIon Exchange Resins and Adsorbents in Chemical Processing: Second EditionRating: 5 out of 5 stars5/5 (1)

- Acronal LA 471 SDocument2 pagesAcronal LA 471 SrallemNo ratings yet

- Obaid - 2019 - J. - Phys. - Conf. - Ser. - 1234 - 012032Document14 pagesObaid - 2019 - J. - Phys. - Conf. - Ser. - 1234 - 012032MUDIN JEMALNo ratings yet

- s13201 018 0674 1Document8 pagess13201 018 0674 1Angel Vegoline Cuevas FerrerasNo ratings yet

- 2.ISCA IRJEvS 2014 31Document8 pages2.ISCA IRJEvS 2014 31Xia KhanNo ratings yet

- Adsorption of Chromium VI On Activated CDocument6 pagesAdsorption of Chromium VI On Activated CTahani MoncerNo ratings yet

- Removal of Heavy Metals by Cement Kiln Dust: M. H. El-Awady, T. M. SamiDocument2 pagesRemoval of Heavy Metals by Cement Kiln Dust: M. H. El-Awady, T. M. SamiMargabrielNo ratings yet

- Cangkang TelurDocument8 pagesCangkang TelurDinda JuwitaNo ratings yet

- (664-673) V10N5CT-Hydro Dynamics PaperDocument10 pages(664-673) V10N5CT-Hydro Dynamics Paperleelabhanu12No ratings yet

- 44 PDF 22.7.23Document14 pages44 PDF 22.7.23toslim jahidNo ratings yet

- Equilibrium Uptake, Isotherm and Kinetic Studies of CD (II) Adsorption Onto Iron Oxide Activated Red Mud From Aqueous SolutionDocument11 pagesEquilibrium Uptake, Isotherm and Kinetic Studies of CD (II) Adsorption Onto Iron Oxide Activated Red Mud From Aqueous SolutionĐỗ Quang TháiNo ratings yet

- Food and Chemical Toxicology: Mustafa Soylak, Ayse AydinDocument7 pagesFood and Chemical Toxicology: Mustafa Soylak, Ayse Aydinlox agencyNo ratings yet

- Food and Chemical Toxicology: Mustafa Soylak, Ayse AydinDocument7 pagesFood and Chemical Toxicology: Mustafa Soylak, Ayse Aydinlox agencyNo ratings yet

- 1 s2.0 S0304389407017001 MainDocument7 pages1 s2.0 S0304389407017001 Mainhenrique ferreiraNo ratings yet

- LogamDocument9 pagesLogamSabina AzharNo ratings yet

- Adsorption Characteristics of Spent Co As An Alternative Adsorbent For Cadmium in SolutionDocument12 pagesAdsorption Characteristics of Spent Co As An Alternative Adsorbent For Cadmium in Solutionhaneen radNo ratings yet

- Cromocarbon Activado TelasDocument16 pagesCromocarbon Activado TelasMishel BautistaNo ratings yet

- Removal of Cadmium Using Mno Loaded D301 Resin: Zhu Zhi-Liang, Ma Hong-Mei, Zhang Rong-Hua, Ge Yuan-Xin, Zhao Jian-FuDocument5 pagesRemoval of Cadmium Using Mno Loaded D301 Resin: Zhu Zhi-Liang, Ma Hong-Mei, Zhang Rong-Hua, Ge Yuan-Xin, Zhao Jian-FuSabiho GinoNo ratings yet

- 2017, kumar-ZnCl2-YADocument42 pages2017, kumar-ZnCl2-YAElvis BoniNo ratings yet

- Ijetr021101 PDFDocument5 pagesIjetr021101 PDFerpublicationNo ratings yet

- Comparative Adsorption Affinities of Nano-Metal Oxides Towards CR (VI) : Synthesis, Characterization, Kinetics, Isotherms, Thermodynamic and Techno-Economics StudyDocument27 pagesComparative Adsorption Affinities of Nano-Metal Oxides Towards CR (VI) : Synthesis, Characterization, Kinetics, Isotherms, Thermodynamic and Techno-Economics StudyHany HeibaNo ratings yet

- Adsorption of Hexavalent CR From Aq Soln Using Chemically Activated C Prepared From Waste of BambooDocument23 pagesAdsorption of Hexavalent CR From Aq Soln Using Chemically Activated C Prepared From Waste of BambooChern YuanNo ratings yet

- Removal of Phosphate From Aqueous Solutions Using Calcined Metal Hydroxides Sludge Waste Generated From ElectrocoagulationDocument8 pagesRemoval of Phosphate From Aqueous Solutions Using Calcined Metal Hydroxides Sludge Waste Generated From ElectrocoagulationLamine tech & scienceNo ratings yet

- Polyvinylсhloride Based Anion Exchanger for Efficient RemovalDocument10 pagesPolyvinylсhloride Based Anion Exchanger for Efficient Removalilhom4995898No ratings yet

- Copper and Cadmium Removal by Bagasse Fly Ash: Kinetic and Isotherm StudyDocument25 pagesCopper and Cadmium Removal by Bagasse Fly Ash: Kinetic and Isotherm StudySatyamGuptaNo ratings yet

- Potential of Nano Crystalline Calcium Hydroxyapatite For T - 2017 - Arabian JourDocument11 pagesPotential of Nano Crystalline Calcium Hydroxyapatite For T - 2017 - Arabian Jourlucian_lovNo ratings yet

- Effectiveness of Sunflower Seed Husk Biochar For Removing Cu 2+ in Waste WaterDocument11 pagesEffectiveness of Sunflower Seed Husk Biochar For Removing Cu 2+ in Waste WaterMuhamad SuharNo ratings yet

- Dried Activated Sludge As An Appropriate Biosorbent For Removal of Copper (II) IonsDocument7 pagesDried Activated Sludge As An Appropriate Biosorbent For Removal of Copper (II) IonsNataliakusumaDewiNo ratings yet

- Selvi 2001 PDFDocument3 pagesSelvi 2001 PDFFredy Colpas CastilloNo ratings yet

- 1 s2.0 S0043135400003067 MainDocument8 pages1 s2.0 S0043135400003067 MainZIZU79No ratings yet

- HU 2016 Calcopirita Con Liquidos Ionicos...Document8 pagesHU 2016 Calcopirita Con Liquidos Ionicos...Juan Ignacio Gonzalez CabreraNo ratings yet

- CR (VI) Ions Removal From Aqueous Solutions Using Natural Adsorbents-FTIR StudiesDocument7 pagesCR (VI) Ions Removal From Aqueous Solutions Using Natural Adsorbents-FTIR StudiesVaibhav JaiswalNo ratings yet

- REMOVAL OF REACTIVE RED 120 IN AQUEOUS SOLUTION USING Mg-HYDROTALCITESDocument11 pagesREMOVAL OF REACTIVE RED 120 IN AQUEOUS SOLUTION USING Mg-HYDROTALCITESAlexa RiveraNo ratings yet

- Reprint in JASR 233-239 2013-Libre PDFDocument7 pagesReprint in JASR 233-239 2013-Libre PDFWali YudinNo ratings yet

- Research ArticleDocument10 pagesResearch ArticleFeb OktafihartoNo ratings yet

- Gupta 2011Document6 pagesGupta 2011Rega DesramadhaniNo ratings yet

- Photocatalytic Degradation of Chromium (Vi) From Wastewater Using Nanomaterials Like Tio, Zno, and CdsDocument9 pagesPhotocatalytic Degradation of Chromium (Vi) From Wastewater Using Nanomaterials Like Tio, Zno, and Cdsahmet yavaşNo ratings yet

- Separation and Purification Technology: Jin-Wei Zhang, Sarah Mariska, Sabolc Pap, Hai Nguyen Tran, Huan-Ping ChaoDocument11 pagesSeparation and Purification Technology: Jin-Wei Zhang, Sarah Mariska, Sabolc Pap, Hai Nguyen Tran, Huan-Ping ChaoLoc TonNo ratings yet

- A Novel Modified Cellulose Nanomaterials (CNMS) For Remediation of Chromium (Vi) Ions From WastewaterDocument16 pagesA Novel Modified Cellulose Nanomaterials (CNMS) For Remediation of Chromium (Vi) Ions From WastewaterArturo CervantesNo ratings yet

- 111biosorption of Chromium by Termitomyces ClypeatusDocument9 pages111biosorption of Chromium by Termitomyces Clypeatuskarima majdouliNo ratings yet

- 1 s2.0 S1876107017305618 MainDocument15 pages1 s2.0 S1876107017305618 MainAly MohamedNo ratings yet

- Removal of Cadmium From Aqueous Solution Using Marine Green Algae, Ulva LactucaDocument8 pagesRemoval of Cadmium From Aqueous Solution Using Marine Green Algae, Ulva LactucaCrisss 18No ratings yet

- 10 1016@j Jwpe 2017 08 007Document10 pages10 1016@j Jwpe 2017 08 007saeedsshNo ratings yet

- 1 s2.0 S1878535211002632 MainDocument12 pages1 s2.0 S1878535211002632 MainAbeer El ShahawyNo ratings yet

- 12 - Chapter 3 PDFDocument122 pages12 - Chapter 3 PDFsushant kadamNo ratings yet

- A15.... HGFDGGSZDocument8 pagesA15.... HGFDGGSZanand sagarNo ratings yet

- (652-663) V10N5CT-Comparison Studies PaperDocument12 pages(652-663) V10N5CT-Comparison Studies Paperleelabhanu12No ratings yet

- Synthitic Biopolymer PDFDocument4 pagesSynthitic Biopolymer PDFKarthik Kalasipalya Vinod KumarNo ratings yet

- 6 - Acb 1211 001Document14 pages6 - Acb 1211 001Khalid SirajNo ratings yet

- Artigo Cadmio e BiocharDocument7 pagesArtigo Cadmio e Biocharnayaraprado22No ratings yet

- Biosorption of Heavy Metals From Synthetic Wastewater by Using Macro Algae Collected From Iraqi MarshlandsDocument5 pagesBiosorption of Heavy Metals From Synthetic Wastewater by Using Macro Algae Collected From Iraqi Marshlandsreem.s. AbdNo ratings yet

- A Simple Rapid and Sensitive Method Based On Modified Multi 2019 Arabian JoDocument7 pagesA Simple Rapid and Sensitive Method Based On Modified Multi 2019 Arabian Jo95w8ngzjbmNo ratings yet

- Adsorption of Nickel (Ii) Ions From Aqueous Solution Using Banana Peel and Coconut ShellDocument12 pagesAdsorption of Nickel (Ii) Ions From Aqueous Solution Using Banana Peel and Coconut ShellDevita AmeliaNo ratings yet

- 36 T 41Document6 pages36 T 41Bhuvana Sundar BagavathiNo ratings yet

- Álvarez-Ayuso, García-Sánchez, Querol - 2007 - Adsorption of CR (VI) From Synthetic Solutions and Electroplating Wastewaters On AmorphousDocument8 pagesÁlvarez-Ayuso, García-Sánchez, Querol - 2007 - Adsorption of CR (VI) From Synthetic Solutions and Electroplating Wastewaters On AmorphousBFCNo ratings yet

- Removal of Cadmium and Hexavalent Chromium From Electroplating Waste Water Using Thiocarbamoyl ChitosanDocument6 pagesRemoval of Cadmium and Hexavalent Chromium From Electroplating Waste Water Using Thiocarbamoyl ChitosanSabiho GinoNo ratings yet

- Chromium Removal From Solution by Five PhotosyntheticDocument13 pagesChromium Removal From Solution by Five Photosyntheticdaniela.aparecidaNo ratings yet

- A Comparative Isothermal and Kinetic Study of The Removal of Lead (II) From Aqueous Solution Using Different SorbentsDocument21 pagesA Comparative Isothermal and Kinetic Study of The Removal of Lead (II) From Aqueous Solution Using Different Sorbentssagar dasguptaNo ratings yet

- Adsorption Study of Heavy Metal Ions From Aqueous Solution by Activated Carbon in Single and Mixed SystemDocument10 pagesAdsorption Study of Heavy Metal Ions From Aqueous Solution by Activated Carbon in Single and Mixed SystemArega GenetieNo ratings yet

- Isotherm, Kinetic and Thermodynamic Studies For The Sorption of Mercury (II) Onto Activated Carbon From RosmarinusDocument11 pagesIsotherm, Kinetic and Thermodynamic Studies For The Sorption of Mercury (II) Onto Activated Carbon From Rosmarinusazizah.irwansyah27No ratings yet

- 1 s2.0 S030147970400146X MainDocument8 pages1 s2.0 S030147970400146X MainAnas YusufNo ratings yet

- Titration 2Document3 pagesTitration 2Mushfiqur RahmanNo ratings yet

- Chemistry QuestionsDocument2 pagesChemistry QuestionsCarlo BangayanNo ratings yet

- Effective and Sustainable Adsorbent Materials For Oil Spill Cleanup Based On A Multistage Desalination ProcessDocument12 pagesEffective and Sustainable Adsorbent Materials For Oil Spill Cleanup Based On A Multistage Desalination Processحيدر عبدالمجيد كاظمNo ratings yet

- Properties of Matter Key Term ReviewDocument1 pageProperties of Matter Key Term ReviewRishikesh HooliNo ratings yet

- PPO SlideDocument29 pagesPPO SlideRadhashyam GiriNo ratings yet

- Confocal Scanning MicrosDocument3 pagesConfocal Scanning MicrosJuvvilyynGraceMahomatNo ratings yet

- PHY 462-Atomic PhysicsDocument3 pagesPHY 462-Atomic PhysicsAnil karela100% (1)

- Atkins - PhysicalChemistry F6 Chemical EquilibriumDocument42 pagesAtkins - PhysicalChemistry F6 Chemical EquilibriumJavier Palomino GarateNo ratings yet

- Articol Stiintific Tradus Din EnglezaDocument5 pagesArticol Stiintific Tradus Din EnglezaDiane DianaNo ratings yet

- 04compositional Simulation Study of Gas Flood and Water Alternating Gas Wag Injection Impacts of Injection ParametersDocument13 pages04compositional Simulation Study of Gas Flood and Water Alternating Gas Wag Injection Impacts of Injection ParametersHerry SuhartomoNo ratings yet

- 2 - The Chemical Basis of LifeDocument6 pages2 - The Chemical Basis of LifeGel Austin PascuaNo ratings yet

- Catalase (CAT) : From Bovine LiverDocument4 pagesCatalase (CAT) : From Bovine Liver幸福No ratings yet

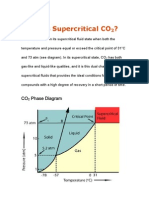

- What Is Super Critical CO2Document42 pagesWhat Is Super Critical CO2kesaco100% (2)

- Mass Transfer 02: Instructor: Zafar ShakoorDocument29 pagesMass Transfer 02: Instructor: Zafar ShakoorSkaye RichesNo ratings yet

- Identification of AlcoholsDocument26 pagesIdentification of Alcoholspupu_wowNo ratings yet

- Cambridge IGCSE Chemistry Topic 9: The Periodic TableDocument3 pagesCambridge IGCSE Chemistry Topic 9: The Periodic TableKalaiarasu SelvarajanNo ratings yet

- BRHS Chap3 Hydrogen Ignition Version 0 9 0Document17 pagesBRHS Chap3 Hydrogen Ignition Version 0 9 0Adel SukerNo ratings yet

- Cambridge Secondary Checkpoint - Science (1113) October 2018 Paper 2 Mark SchemeDocument11 pagesCambridge Secondary Checkpoint - Science (1113) October 2018 Paper 2 Mark SchemeMilcah Tesfaye100% (2)

- Physics of SuperconductivityDocument106 pagesPhysics of SuperconductivityRaj JanaNo ratings yet

- Spectrochemical Analysis by Atomic Absorption and Emission - Lajunen 2nd Edition 2004Document360 pagesSpectrochemical Analysis by Atomic Absorption and Emission - Lajunen 2nd Edition 2004Goretti Arvizu100% (1)

- Lesson Plan in Nov. 15 Electronic Structure Grade 9Document8 pagesLesson Plan in Nov. 15 Electronic Structure Grade 9Edessa MasinasNo ratings yet

- Periodic Table and Periodicity of PropertiesDocument6 pagesPeriodic Table and Periodicity of Propertieswama ojhaNo ratings yet

- Flame Retardant and Fire Resistance Test - A Brief Story of Construction Project PDFDocument6 pagesFlame Retardant and Fire Resistance Test - A Brief Story of Construction Project PDFwidiNo ratings yet

- Cambridge O Level: CHEMISTRY 5070/21Document20 pagesCambridge O Level: CHEMISTRY 5070/21Fasih RazaNo ratings yet

- Review of Corrosion Protection and Control Techniques For Metallic PipelinesDocument22 pagesReview of Corrosion Protection and Control Techniques For Metallic Pipelinescarlos gomezNo ratings yet

- Calculadora de Tanque de Cilindro Vertical - Spirax SarcoDocument1 pageCalculadora de Tanque de Cilindro Vertical - Spirax SarcoJuan MendozaNo ratings yet

- MCQ For NANO T HighlightDocument12 pagesMCQ For NANO T HighlightsindhujaNo ratings yet