Professional Documents

Culture Documents

Vamsadhara - Load Test Drawing

Vamsadhara - Load Test Drawing

Uploaded by

AKELLA RAMPRASADOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vamsadhara - Load Test Drawing

Vamsadhara - Load Test Drawing

Uploaded by

AKELLA RAMPRASADCopyright:

Available Formats

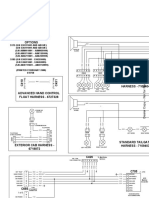

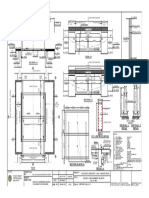

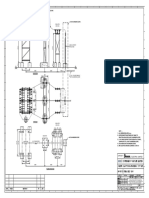

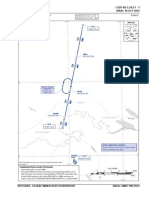

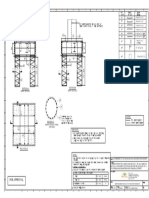

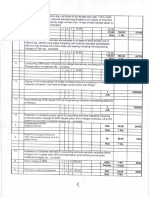

TOWARDS 32800 (C/C. OF EXP.

JOINT) TOWARDS

SARUBUJJILI KOMMANAPALLI

FRL

CL OF BEARING CL OF BEARING CL OF BEARING C

L OF BEARING

2000

PSC GIRDER

PIER

G.L.

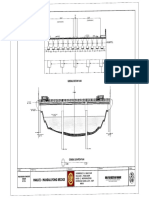

SECTIONAL ELEVATION

32800

(C/C. OF EXP. JOINT)

585 31630 585

(C/C. OF BEARING)

.OF BEARING B

5640 3165 1430 3000 3165 1430 3000 1430 3165

HAND RAIL

1475

D4

4060

D1 D7

L1 L1 L1 G1

(OVER ALL WIDTH)

2750

L2 L3 L2 L3 L3 L2 NOTES:-

2500

2135

1964

1500

1964

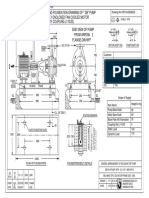

TEST VECHICLE -1 TEST VECHICLE -2 TEST VECHICLE -3 1. ALL DIMENSIONS ARE IN MM AND ALL LEVELS ARE IN METERS.

D2 L2 L3 L2 L3 L3 L2 D8 UNLESS OTHERWISE SPECIFIED.

L1 L1 L1

8450

2. DO NOT SCALE THE DRAWING. FOLLOW WRITTEN DIMENSIONS ONLY.

3. THE LOADING PLATES SHALL BE PROPERLY FIXED TO THE SURFACE OF THE DECK WITH

6950 D5 EPOXY BASED ARALDATE.

G2

2750

4. LOAD APPLICATION &TESTING:-

G3 STAGE I II III IV V A.) PRIOR TO THE START OF LOAD TEST THE CONSTRUCTION OF HAND RAIL, APPLICATION OF

D3 - DIAL GAUGE D6 D9 WEARING COAT ETC., SHALL BE COMPLETED.

LOAD SEQ. 50% 70% 80% 90% 100%

B.) PRIOR TO TESTING, WHITE PAINT SHOULD BE APPLIED AT THE CRITAICAL SECTIONS

1475

L1 1.65 2.32 2.65 2.98 3.31 FOR EASE OF OBESERVATION OF BEHAVIOR OF CRACKS. IF ANY NEW SINGNIFICANT

L2 3.31 4.63 5.30 5.96 6.62 CRACK APPEARS DURING TEST, THESE MUST BE REFERED TO THE DESIGN ENGINEER

HAND RAIL FOR APPROPRIATE FURTHER ACTION.

L3 3.31 4.63 5.30 5.96 6.62

.OF SPAN C.) FIX THE DEFLECTION GUAGES (SUPPORTED ON UNYIELDING SUPPORTS) UNDER THE STRUCTURE,

B TOTAL LOAD TRANSFER FROM EACH VEHICLE INCLUSIVE OF SELF WEIGHT = 33.1 MT JUST TOUCHING ITS SOFFIT, AT THE CRITICAL POINTS AS SHOWNIN THE DRAWING.

PLAN SHOWING DIAL GAUGE LOCATIONS & TEST LOAD ON DECK TOTAL NUMBER OF TEST VEHICLES = 3 NO.S D.) EACH DIAL GAUGE SHALL BE FIXED OVER AN INDIVIDUAL STEEL TRESTLES, AND ALL STEEL

TRESTILES SHALL BE WELL PROTECTED BY CORDONING OFF THE AREA TO AVOID ANY VARYING

ALL THE LOAD VALUES ARE IN TONNES IN DEFLECTIONS READING DUE TO THE GROUND DISTURBANCE CAUSED BY MOVEMENT AROUND

THE STEEL TRESTLES. THE STEEL TRESTLE SHALL BE SUPPORTED ON WELL COMPACTED AND

UNYIELDING BED.

E.) THE DIAL GAUGE AXIS MUST BE KEPT PERFECTLY VERTICAL

F.) THE DEFLECTION GUAGES HAVING A LEAST COUNT OF 0.01MM SHALL BE USED.

G.) THE SURFACE AT THE POINT OF CONTACT BETWEEN SOFFIT OF BEAM AND THE DIAL GAUGE

IS TO BE CLEANED AND RUBBED SMOOTH WITH A CORBORUNDUM STONE.

C.

L OF BRIDGE H.) SHEET GLASS PLATES OF 50mmX50mm TO BE FIXED WITH ARALDATE AT THE SOFFIT OF

THE BEAM WHERE LECTIONS ARE TO BE OBSERVED.

8450 J.) THE TEST LOAD SHALL APPLIED BE IN FIVE EQUAL INCREMENTS (INCLUDING THE WEIGHT OF

(OVER ALL WIDTH) TEST VEHICLE IN THE FIRST INCREMENT AS PER THE TABLE GIVEN IN THE DRAWING)

SUPPORT MID SUPPORT

450 7550 450 K.) ALLOW TWO HOURS IN BETWEEN COMPLETION OF ONE LOAD INCREMENT AND COMMENCEMENT

(CARRIAGEWAY) OF THE NEXT.

4060 L.) THE DEFLECTIONS AND CRACK PATTERNS TOGEATHER WITH MAXIMUM CRACK WIDTH SHALL BE

NOTED ABOUT AN HOUR AFTER COMPLETING A LOAD INCRIMENT

M.) AFTER MEASURING THE DEFLECTIONS ETC., ONE HOUR AFTER APPLYING THE FIFTH ,I.E.,

THE FINAL LOAD INCRIMENT, KEEP THE TEST LOAD MAINTAINED FOR ABOUT 24 HOURS,

AND AGAIN MEASURE THE DEFLECTION.

VEH-1/2/3 DEFLECTION DIAGRAM FOR LOAD TESTING

N.) REMOVE THE TEST LOADS IN SIX DECREMENTS, ALLOWING TWO HOURS IN BETWEEN

COMPLETION OF ONE LOAD DECREMENT AND COMMENCEMENT OF THE NEXT.

O.) THE DELECTIONS AND CRACK WIDTHS SHALL BE NOTED ABOUT ONE HOUR AFTER THE END OF

EACH LOAD DECREMENT.

P.) 24HOURS AFTER THE REMOVAL OF THE TEST LOAD, NOTE THE FINAL DEFLECTIONS AND

225

CRACKWIDTHS (IF ANY).

5. PRECAUTIONS TO BE TAKEN DURING TESTING:-

1025

MID SPAN ROTATION AT SUPPORT

A.) THERE SHALL BE SUFFICIENT INSTRUMENTS FOR ACCURATELY MEASURING SMALL ORDER

2000

G1 12.1 MM 0.0012 Rad. DEFLECTIONS OF THE SUPER STRUCTURE .

G2 8.26 MM 0.0008 Rad. B.) STRONG SCAFFOLDING, CAPABLE OF SUPPORTING BOTH THE SUPER STRUCTURE WEIGHT

G3 4.24 MM 0.0004 Rad. AS WELL AS THE TEST LOAD, MUST BE ERECTED AND PLACED IN POSITION PRIOR TO TESTING,

LEAVING A GAP UNDER THE DECK-SOFFIT WHICH IS SUFFICIENT FOR THE DECK DEFLECTIONS.

C.) ADEQUATE PRECAUTIONS SHALL BE TAKEN TO SAFEGUARD THE PERSONNEL AT AND IN THE

G1 G2 G3 VICINITY OF THE TEST AREA.

D.) IF ANY SEVERE CRACKING / SPALLING, ETC., APPEARS AT ANY STAGE OF THE TEST,

SECTION:B-B THE TEST SHALL BE DISCONTINUED, LOAD REMOVED AND MATTER IMMEDIATELY REPORTED

TO THE DESIGNER, IN DETAIL.

(AT MIDDLE)

6.) ACCEPTANCE CRITERIA.

THE ACCEPTANCE CRITERION FOR THE BEHAVIOUR THE STRUCTURE SHALL BE AS PER

IRC-SP:51 & IRC-SP:37.

GOVERNMENT OF ANDHRA PRADESH

ROADS & BUILDINGS DEPARTMENT

LOAD TESTING OF SUPER STRUCTURE

NOV'2021 VAMSADHARA/MJB/LOADTEST/001 R0

You might also like

- Method Statement For Concrete Blockwall ErectionDocument21 pagesMethod Statement For Concrete Blockwall ErectionGary LoNo ratings yet

- Cege0009 - PP2 10-12-2020Document3 pagesCege0009 - PP2 10-12-2020eyu HungryfishNo ratings yet

- 01.typical Details of W-Beam Crash BarrierDocument1 page01.typical Details of W-Beam Crash Barriermadhu123iitkNo ratings yet

- 7 RobDocument247 pages7 RobAKELLA RAMPRASADNo ratings yet

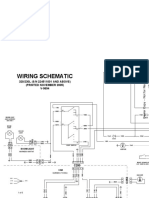

- Wiring Schematic: OptionsDocument6 pagesWiring Schematic: OptionsAlexandrNo ratings yet

- Cross Section of Metal BuildingDocument1 pageCross Section of Metal BuildingtechnopreneurvizagNo ratings yet

- SD WWTP-12Document1 pageSD WWTP-12Firmansyah RamadhanNo ratings yet

- VMC - B1 - SD-107Document1 pageVMC - B1 - SD-107Navnath GawasNo ratings yet

- CL Bridge: C7 Package High Speed Rail Launching Gantry, IndiaDocument1 pageCL Bridge: C7 Package High Speed Rail Launching Gantry, IndiaAshish BhartiNo ratings yet

- VIEW 3-3: 10900 (Carriageway) 12000 3000 5000Document1 pageVIEW 3-3: 10900 (Carriageway) 12000 3000 5000popemiNo ratings yet

- BR No 65 (Elevation)Document1 pageBR No 65 (Elevation)Sangramkeshari BejaNo ratings yet

- Wiring Schematic: 320/230L (S/N 224511001 AND ABOVE) (Printed November 2005) V-0694Document6 pagesWiring Schematic: 320/230L (S/N 224511001 AND ABOVE) (Printed November 2005) V-0694Willyas AsNo ratings yet

- Sai Const.30 TS Ib BP-1Document1 pageSai Const.30 TS Ib BP-1samj65112No ratings yet

- 864 Wiring Schematic: S/N 516811001-11999 S/N 518911001-12999Document6 pages864 Wiring Schematic: S/N 516811001-11999 S/N 518911001-12999Ataa AssaadNo ratings yet

- Load Chart Tadano Gt-550eDocument5 pagesLoad Chart Tadano Gt-550ePsdmMCCI2021 MECNo ratings yet

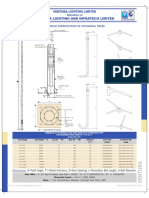

- Octagonal PoleDocument2 pagesOctagonal PoleARUN RAWATNo ratings yet

- CS Retail 2AA 1 Layout1Document1 pageCS Retail 2AA 1 Layout1SKYLERNo ratings yet

- NBS125 1Document1 pageNBS125 1April DariaNo ratings yet

- 8) Inst Layout 4942.35 Kvar 15.21 KV If Cap Bank (8 of 8)Document1 page8) Inst Layout 4942.35 Kvar 15.21 KV If Cap Bank (8 of 8)Atanu PanNo ratings yet

- SBNT - Rwy 16l 34r - 16r 34l - Vac - 20220224Document2 pagesSBNT - Rwy 16l 34r - 16r 34l - Vac - 20220224Thiago VianaNo ratings yet

- 2Document1 page2shashi rajhansNo ratings yet

- Lactation RoomDocument1 pageLactation RoomRoy Benedict BautistaNo ratings yet

- July RevampYourHome DigitalDocument8 pagesJuly RevampYourHome DigitalMlungisi SibusisoNo ratings yet

- DSG J 559 Comp Erec DWGDocument13 pagesDSG J 559 Comp Erec DWGsamir ranjan dhalNo ratings yet

- 1 - Denah LayoutDocument1 page1 - Denah LayoutGunawan MansjurNo ratings yet

- SILICA Layout1Document1 pageSILICA Layout1ADONIS PLATINONo ratings yet

- Wiring Schematic: OptionsDocument6 pagesWiring Schematic: OptionsAlexandrNo ratings yet

- BAA WARDROBE-Layout1Document1 pageBAA WARDROBE-Layout1nishtha bhattNo ratings yet

- Wiring Schematic: (Options)Document6 pagesWiring Schematic: (Options)gluykNo ratings yet

- Karnaphuli Water Supply Project - Phase 2 (Kwsp2) PlanDocument1 pageKarnaphuli Water Supply Project - Phase 2 (Kwsp2) PlangawtomNo ratings yet

- Euro Diebold Opteva 328 177528r00Document4 pagesEuro Diebold Opteva 328 177528r00Meta UrsaNo ratings yet

- Table of Standard Executions: RE.F4 - 125 S S F WHDocument5 pagesTable of Standard Executions: RE.F4 - 125 S S F WHEko PrastyoNo ratings yet

- Gad Final 3+735Document1 pageGad Final 3+735fevahe756No ratings yet

- 10-3B Ambalema 6a DepDocument1 page10-3B Ambalema 6a Depmarroco13No ratings yet

- PILE PILE CAP & PIER - 25.10.2023-Comments-28-10-23Document5 pagesPILE PILE CAP & PIER - 25.10.2023-Comments-28-10-23Tanveer IqbalNo ratings yet

- Curtain Wall - Riya ShomeDocument1 pageCurtain Wall - Riya ShomeSam WilliamNo ratings yet

- TRU CTI ON: 4.6 DEG PITCH 1:12 Direction of Roof LayingDocument2 pagesTRU CTI ON: 4.6 DEG PITCH 1:12 Direction of Roof LayingTarun SebastianNo ratings yet

- Makati - Mandaluyong Bridge: General Section PlanDocument1 pageMakati - Mandaluyong Bridge: General Section PlangregNo ratings yet

- Ynjdc Dsco DD DWG PJW R00 Mec Acv 00344Document1 pageYnjdc Dsco DD DWG PJW R00 Mec Acv 00344Sk NgNo ratings yet

- GRD FPDocument1 pageGRD FPSahillah MahletNo ratings yet

- Gad 7+850Document1 pageGad 7+850popemiNo ratings yet

- SBFL Vor-Z-Rwy-14 Iac 20171012 PDFDocument1 pageSBFL Vor-Z-Rwy-14 Iac 20171012 PDFRômullo Furtado BeltrameNo ratings yet

- Construction of One Storey Residential BuildingDocument9 pagesConstruction of One Storey Residential Buildingwdy2ysq8d7No ratings yet

- Kolom Baja: SKALA 1:200 Layout Plan - 1St FloorDocument7 pagesKolom Baja: SKALA 1:200 Layout Plan - 1St FloorAndri MujahidinNo ratings yet

- GA-HVAC-PLUMBING PANEL-ModelDocument1 pageGA-HVAC-PLUMBING PANEL-ModelkapilNo ratings yet

- Seal Base Plate ABBASDocument3 pagesSeal Base Plate ABBASMUHAMMAD NOMANNo ratings yet

- 1220 X 900 - MRL - Auto Door - OLN0807-PlanDocument1 page1220 X 900 - MRL - Auto Door - OLN0807-PlanNagarajan SNo ratings yet

- Pav Tapr UDocument1 pagePav Tapr UTowerNo ratings yet

- Foundation DrawingsDocument5 pagesFoundation DrawingsEric PeekateNo ratings yet

- Plano Hidráulico TL1055-CDocument3 pagesPlano Hidráulico TL1055-CELKIN MAURICIO RAMIREZ PEREZNo ratings yet

- Kitchen Setail: Detailed PlanDocument1 pageKitchen Setail: Detailed PlanSha NikzNo ratings yet

- LS AD 2 LSZH 24-9-7-1 en 2012-10-18Document2 pagesLS AD 2 LSZH 24-9-7-1 en 2012-10-18Reiss SchultzNo ratings yet

- General Arrangement and Foundation Drawing of " DB" Pump Coupled With Totally Enclosed Fan Cooled Motor (With Lovejoy Coupling L110/25)Document1 pageGeneral Arrangement and Foundation Drawing of " DB" Pump Coupled With Totally Enclosed Fan Cooled Motor (With Lovejoy Coupling L110/25)Vaibhav SharmaNo ratings yet

- V 0732 6 PDFDocument6 pagesV 0732 6 PDFvatasaNo ratings yet

- APC100844Document1 pageAPC100844onshore purchaseNo ratings yet

- Services Site-ModelDocument1 pageServices Site-ModelPranavNo ratings yet

- Construction Issue: (SA) EF 3 (SA) EF 4Document1 pageConstruction Issue: (SA) EF 3 (SA) EF 4Хөгжилтэй ЗугаатайNo ratings yet

- Services Site ModelDocument1 pageServices Site ModelPranavNo ratings yet

- Summary: C8: A B A B C D A B A B C DDocument1 pageSummary: C8: A B A B C D A B A B C DCarl Lou BaclayonNo ratings yet

- QB20477-23 B01 - GresikDocument5 pagesQB20477-23 B01 - GresikHariz Birrul WalidNo ratings yet

- LOFT PlanDocument1 pageLOFT PlanCielo OtadoyNo ratings yet

- VXV6LPG Series1 5j WiringDocument2 pagesVXV6LPG Series1 5j WiringDanniel PizattoNo ratings yet

- Approach Ramp - Bridge-3Document3 pagesApproach Ramp - Bridge-3AKELLA RAMPRASADNo ratings yet

- Data For DrawingsDocument1 pageData For DrawingsAKELLA RAMPRASADNo ratings yet

- Approach Ramp - Bridge-5Document3 pagesApproach Ramp - Bridge-5AKELLA RAMPRASADNo ratings yet

- Approach Ramp - Bridge-2Document3 pagesApproach Ramp - Bridge-2AKELLA RAMPRASADNo ratings yet

- Bridge - DPR Estimate 2Document1 pageBridge - DPR Estimate 2AKELLA RAMPRASADNo ratings yet

- Rob-002 (Pier Rein.) - Pile-7bDocument1 pageRob-002 (Pier Rein.) - Pile-7bAKELLA RAMPRASADNo ratings yet

- TR-01&TR-02 AS PER SITE DETAILS-ModelDocument1 pageTR-01&TR-02 AS PER SITE DETAILS-ModelAKELLA RAMPRASADNo ratings yet

- Client: Project:: Rolep To Chochenpheri National Highways & Infrastructure Development Corporation LimitedDocument3 pagesClient: Project:: Rolep To Chochenpheri National Highways & Infrastructure Development Corporation LimitedAKELLA RAMPRASADNo ratings yet

- Bridge - DPR Estimate 6Document2 pagesBridge - DPR Estimate 6AKELLA RAMPRASADNo ratings yet

- Bridge - DPR Estimate 1Document1 pageBridge - DPR Estimate 1AKELLA RAMPRASADNo ratings yet

- Bridge - DPR Estimate 5Document1 pageBridge - DPR Estimate 5AKELLA RAMPRASADNo ratings yet

- Bill of QuantitiesDocument18 pagesBill of QuantitiesAKELLA RAMPRASADNo ratings yet

- Pre Bid Query (RAjauli Bhaktiyarpur)Document1 pagePre Bid Query (RAjauli Bhaktiyarpur)AKELLA RAMPRASADNo ratings yet

- Comparison-Psc&rcc Pier CapDocument3 pagesComparison-Psc&rcc Pier CapAKELLA RAMPRASADNo ratings yet

- FRL's & Service Road LevelsDocument16 pagesFRL's & Service Road LevelsAKELLA RAMPRASADNo ratings yet

- Abstract of Cost EstimateDocument1 pageAbstract of Cost EstimateAKELLA RAMPRASADNo ratings yet

- Rainfall PDFDocument1 pageRainfall PDFAKELLA RAMPRASADNo ratings yet

- NH-844 - Structures QuoteDocument1 pageNH-844 - Structures QuoteAKELLA RAMPRASADNo ratings yet

- EPC Contract: Validate Print HelpDocument6 pagesEPC Contract: Validate Print HelpAKELLA RAMPRASADNo ratings yet

- Feasible Foundation SystemDocument4 pagesFeasible Foundation SystemAKELLA RAMPRASADNo ratings yet

- Design of Staging For Underpass: Name of Work: Trichy - Karur Section of NH 52 in The State of TamilnaduDocument4 pagesDesign of Staging For Underpass: Name of Work: Trichy - Karur Section of NH 52 in The State of TamilnaduAKELLA RAMPRASADNo ratings yet

- Base Pressure Redistribution - TengDocument11 pagesBase Pressure Redistribution - TengAKELLA RAMPRASAD100% (1)

- Aavarna 2Document13 pagesAavarna 2SNEHA DEVARAJU100% (1)

- Space For Electrical and Machanical Services in BuildingsDocument31 pagesSpace For Electrical and Machanical Services in BuildingsAkshat Dev Singh100% (1)

- Section 4 - Masonry Works PDFDocument5 pagesSection 4 - Masonry Works PDFادزسر بانديكو هادولهNo ratings yet

- Aurora: WWW - Atlasleisurehomes.co - Uk Telephone: 01482 562101Document2 pagesAurora: WWW - Atlasleisurehomes.co - Uk Telephone: 01482 562101Федя ФедяNo ratings yet

- Hasil Uji Beton SarawarnaDocument1 pageHasil Uji Beton SarawarnaTrianaNo ratings yet

- Norhouse - Constructions LGSDocument18 pagesNorhouse - Constructions LGSPinkNo ratings yet

- On Brick Construction: Technical NotesDocument10 pagesOn Brick Construction: Technical NotesCassamo SucáNo ratings yet

- MasonryDocument40 pagesMasonryJames Daniel GarciaNo ratings yet

- KSA Standard Components: 1br-Ba-20-K 1 Bed Room - Bariatric, 20 MDocument1 pageKSA Standard Components: 1br-Ba-20-K 1 Bed Room - Bariatric, 20 MAbdulaziz AlphaNo ratings yet

- C JustFAQs CFS Mar121Document1 pageC JustFAQs CFS Mar121Vengatesh HariNo ratings yet

- Sika Bro - E - Sikadur-Combiflex SG System - High Performance Joint - Crack Waterproofing System (09.2010)Document8 pagesSika Bro - E - Sikadur-Combiflex SG System - High Performance Joint - Crack Waterproofing System (09.2010)Joh SongthamNo ratings yet

- Caravan SpecificationDocument5 pagesCaravan SpecificationVimala PonnusamyNo ratings yet

- DRGS 0401 0201Document1 pageDRGS 0401 0201AJAY SHINDENo ratings yet

- Durakore BrochureDocument20 pagesDurakore BrochureisoemardjanNo ratings yet

- Wood Structural SystemsDocument54 pagesWood Structural SystemsRene BermudezNo ratings yet

- Tds. Technical Data Sheet Tds. Technical Data Sheet: Polyurethane Waterproofing MembraneDocument9 pagesTds. Technical Data Sheet Tds. Technical Data Sheet: Polyurethane Waterproofing Membranesantosh mhetreNo ratings yet

- Scaffold 2005-CDocument28 pagesScaffold 2005-CDennis SeparaNo ratings yet

- 5491R 93Document30 pages5491R 93Rene Coronado VacaflorNo ratings yet

- 08 - SOP - APPROVAL FOR MOS MATERIAL AND SHOP DRAWING - DraftDocument9 pages08 - SOP - APPROVAL FOR MOS MATERIAL AND SHOP DRAWING - DraftYit WanNo ratings yet

- Sikawrap - 600 C WVDocument4 pagesSikawrap - 600 C WVIndra KusumaNo ratings yet

- Pre Cast ConstructionDocument44 pagesPre Cast ConstructionSneha Dasari100% (1)

- Cba 7 Updated Sliding Door ScheduleDocument8 pagesCba 7 Updated Sliding Door ScheduleJohn Carl SalasNo ratings yet

- Mehewara Piyasa ProjectDocument33 pagesMehewara Piyasa ProjectTharindu Dilshan Niwunhella100% (2)

- Ref. SiloDocument8 pagesRef. Siloahmed aboyosefNo ratings yet

- By Ben Uyeda: A. CushionsDocument3 pagesBy Ben Uyeda: A. Cushionsfopoku2k2No ratings yet

- LKM Door Program BrochureDocument4 pagesLKM Door Program BrochureEgyptian ItalianNo ratings yet

- Method Statement-Building Raised FloorDocument7 pagesMethod Statement-Building Raised Floorharun yucelNo ratings yet

- Looking at Heritage BuildingsDocument15 pagesLooking at Heritage BuildingsAbyan Fakhri JamaluddinNo ratings yet