Professional Documents

Culture Documents

Approval Drawing-22V0250 0021,2

Approval Drawing-22V0250 0021,2

Uploaded by

Envi WorkSafeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Approval Drawing-22V0250 0021,2

Approval Drawing-22V0250 0021,2

Uploaded by

Envi WorkSafeCopyright:

Available Formats

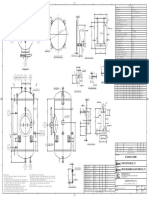

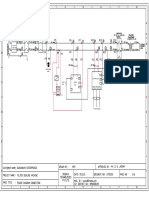

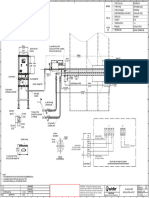

DESIGN DATA

DESIGN CODE ASME SECTION VIII DIVISION 1, EDITION 2019

0° 5 2 DESIGN PRESSURE 200 psi / 1379 kPa

7 6 DESIGN TEMPERATURE

OPERATING TEMPERATURE

100 °C

60 °C

45°

45° 2 HYDROSTATIC TEST PRESSURE 260 psi / 1793 kPa

HEAD TO SHELL : 0.65

LS1 6 Outside 6 JOINT EFFICIENCY HEAD : 0.85

SHELL : 0.70

N4 N5 Outside

WORKING MEDIUM Air

VOLUME 250L

1" 1/2" Inside WEIGHT ( EMPTY ) 135 KG ±10%

20°

WEIGHT ( HYDROTEST ) 380 KG ±10%

N8 N6 270° 90° N3 N7 Inside CORROSION ALLOWANCE 0.5 mm

1/2" 2" 1/2" 2" CERTIFICATION J.K.K.P (DOSH) MALAYSIA

NOZZLE DETAIL N3 N8 N4 MATERIAL SPECIFICATION

NOZZLE DETAIL N1 N2 SCALE: 1:5

SCALE: 1:7

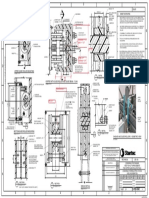

1/2" 1/2" 1" SHELL SA / A 36 or S275JR

1/4" 1/4"

240

HEAD SA / A 36 or S275JR

150 as per Figure UW-16.1(z-2)/(y-2)(Note4) SOCKET SA / A 106 Gr B

as per Figure UW-16.1(z-2)/(y-2)(Note 4) 2 SUPPORT SA / A 36 or S275JR

NOZZLE LIST

MARK QTY SIZE TYPE SERVICE

N1 1 1/4" BSPT PRESSURE GAUGE

Name plate 180° N2 1 1/4" BSPT SPARE

N3 1 1/2" BSPT SAFETY VALVE

N1 N2

2mm

Inside 3 N4 1 1" BSPT INLET

1/4" 1/4" N5 1 1/2" BSPT DRAIN

3t

N6 1 2" BSP INSPECTION HOLE

110 N7 1 2" BSP INSPECTION HOLE

ORIENTATION VIEW 80 N8 1 1/2" BSPT OUTLET

SCALE: 1:1 Outside BILL OF MATERIAL

60

ITEM QTY DESCRIPTION DIMENSION MATERIAL

6 6 9 2

1 2 SE Head Min 4.5t x OD 563 SA / A 36 or S275JR

2 1 Shell Min 5.4t x 762W x 1750L SA / A 36 or S275JR

N1 N4 N2 3 4 Leg Support Angle: L65 x 65 x 6t SA / A 36 or S275JR

90

70

60

1/4" 1" 1/4" NOZZLE DETAIL N5 Ø4 holes

4 4 Base plate 6t x 90W x 90L SA / A 36 or S275JR

5 2 Socket N1, N2 G 1/4" SA / A 106 Gr B

SCALE: 1:5 1/2"

SE Head

1 6 3 Socket N3, N5, N8 G 1/2" SA / A 106 Gr B

7 1 Socket N4 G 1" SA / A 106 Gr B

nom thk = 8mm as per Figure UW-16.1(z-2) 8 2 Socket N6, N7 G 2" SA / A 106 Gr B

NAME PLATE BRACKET DETAIL 9 1 Name plate bracket 3t x see drawing SA / A 36 or S275JR

SCALE: 1:1.5

75 75 AMENDMENT

2 30-11-2021 RENEWAL DRAWING AFSHAM MARY

1 12-12-2019 RENEWAL DRAWING MIRA MARY

0 08-12-2017 FOR APPROVAL SAL MARY

REV DATE DESCRIPTION DRAWN APPROVED

CS1 W1

8

6 NOTE

100

150

N6 6

1. All dimension are in mm unless otherwise notified.

200

2. Dimension tolerance shall be as per table:-

200

2" 3 Outside

N3 Decimals Tolerance

100

N8 1/2" XX

XX.X

± 5.0mm

± 2.0mm

Name plate

1/2" Inside XX.XX ± 0.5mm

W2

Profile cut

520

3. Minimum thickness (Tmin) stated above is referring to the required thickness

762 [ SHELL LENGTH ]

NOZZLE DETAIL N6 N7 in design calculation.

4. If socket welding is fillet weld (no penetration), internal fillet weld size is

SCALE: 1:4 2" 2"

1248 [ OVERALL LENGTH ]

6mm (N1, N2, N3, N8), 8mm (N4, N6, N7).

LS1

320

OD 563.0

as per Figure UW-16.1(z-2)/(y-2)(Note 4)

512

2

Shell

6t

562

nom thk = 6mm 6 SOCKET LIST

PIPE USED

NOZZLE SIZE

SIZE OD SCH

LEG SUPPORT DETAIL N1, N2 1/4" 3/8" 17.1 80

N7 SCALE: 1:1

MANUFACTURER :

N3, N5, N8 1/2" 3/4" 26.7 160

2"

N4 1" 1-1/4" 42.2 160

100

CS2 W1

N6, N7 2" 2-1/2" 73.0 160

90 DANCOMAIR ENGINEERING SDN. BHD.

LOT 104, JALAN INDUSTRI 3/4, RAWANG INTEGRATED INDUSTRIAL PARK,

48000 RAWANG, SELANGOR DARUL EHSAN, MALAYSIA.

Ø18 hole Tel: +603 – 6093 2828 Fax: +603 – 6092 3111

W2 60°± 5° W1 60°± 5°

Email: info@dancomair.com Website: www.dancomair.com

1~2mm

320

OUTSIDE TITLE :

1~2mm

4 250 LITER VERTICAL

90

65

OUTSIDE

Shell Shell

N5

Shell Head

AIR RECEIVER TANK (A)

1/2" INSIDE INSIDE

DRAWN : SAL DATE: 08-12-2017

CHECKED : MARY DATE: 08-12-2017

BASE PLATE DETAIL 1~5gap APPROVED : MARY DATE: 08-12-2017

R 1~5gap

SCALE: 1:2 SCALE : AS SHOWN

ELEVATION VIEW

SCALE: 1:1 SHELL TO SHELL JOINT HEAD TO SHELL JOINT

DRAWING NO :

DM/ED/2017/P0749 REV

as per Table UW-12 (Type 1) as per Table UW-12 (Type 2) CAD REF NO :

DM/ED/2017/0749 2

You might also like

- Kirschen2000 - The Royal London Space Planning - Part 1Document8 pagesKirschen2000 - The Royal London Space Planning - Part 1drgeorgejose7818100% (2)

- 1.irosun OgbeDocument10 pages1.irosun OgbeOmo Awo Ifasina Aworeni91% (11)

- SG6427 Na4030 01 602 N0gad001 092Document2 pagesSG6427 Na4030 01 602 N0gad001 092umer hayatNo ratings yet

- Cost Accounting 7 8 - Solution Manual Cost Accounting 7 8 - Solution ManualDocument27 pagesCost Accounting 7 8 - Solution Manual Cost Accounting 7 8 - Solution ManualMARIA100% (1)

- MBBR FabricationDocument1 pageMBBR Fabricationvikraman_sNo ratings yet

- SHELL LONG SEAM @45° & 225°: Air Receiver Ar-001Document1 pageSHELL LONG SEAM @45° & 225°: Air Receiver Ar-001davidNo ratings yet

- Inventor SoreDocument1 pageInventor SoreVINCENTIUS ADVEN BRILIANNo ratings yet

- 102-01-0313-026 Rev 1Document1 page102-01-0313-026 Rev 1JOSUE FERNANDO FERNANDEZNo ratings yet

- LS VG 003Document1 pageLS VG 003Guru MhetreNo ratings yet

- C231104 BH2 PC PID 1001 - C7 05 03 24 - GopalganjDocument10 pagesC231104 BH2 PC PID 1001 - C7 05 03 24 - GopalganjpremsukhsagarNo ratings yet

- LS VG 008Document2 pagesLS VG 008Guru MhetreNo ratings yet

- SD-9756 Rev 3Document3 pagesSD-9756 Rev 3Amresh KumarNo ratings yet

- R-01 - Ga Reactor Tank 260l - Rev.03-Ga Tank-2Document1 pageR-01 - Ga Reactor Tank 260l - Rev.03-Ga Tank-2syahib muhijarNo ratings yet

- BEL8 S (3x1.5'') 450 3MDocument1 pageBEL8 S (3x1.5'') 450 3MSergio Espinosa EscobarNo ratings yet

- Switch Room 12 X 18 M Platform 2 X 7 M: Hot Aisle Cold AisleDocument1 pageSwitch Room 12 X 18 M Platform 2 X 7 M: Hot Aisle Cold Aisleptapmc09No ratings yet

- 04443720AA Masterpact NW User ManualDocument1 page04443720AA Masterpact NW User ManualdaywalkeryNo ratings yet

- Schneider 1mva 3 Phase Oltc Distribution TransformerDocument8 pagesSchneider 1mva 3 Phase Oltc Distribution TransformerRavindra AngalNo ratings yet

- Perun 2 Mini User ManualDocument1 pagePerun 2 Mini User ManuallyndondrNo ratings yet

- Coppe R: Suction Inle T 2X 67MMDocument1 pageCoppe R: Suction Inle T 2X 67MMJitto E JoseNo ratings yet

- Item 7 - 26280-220-MTD-MTSS-01008 - 00BDocument1 pageItem 7 - 26280-220-MTD-MTSS-01008 - 00Boliver000008No ratings yet

- Staircase - WD - 043Document1 pageStaircase - WD - 043Bharani MadamanchiNo ratings yet

- 8410 SchematicsDocument19 pages8410 Schematicstolak anginNo ratings yet

- R1 Donor Cut Tower: Hexane Drum Item No. D-755Document1 pageR1 Donor Cut Tower: Hexane Drum Item No. D-755NoppolNorasriNo ratings yet

- A - MPT Rating PlateDocument1 pageA - MPT Rating PlateVishnu ShankerNo ratings yet

- Vessels 101050 - M BPV 8 1200 EpDocument1 pageVessels 101050 - M BPV 8 1200 EpHeriberto Gonzalez BritoNo ratings yet

- Utility Deck - Ahu SectionDocument1 pageUtility Deck - Ahu SectionLorenzo NakpilNo ratings yet

- Plot Details: Dubai Land Residences (L.L.C)Document1 pagePlot Details: Dubai Land Residences (L.L.C)MUQEET ahmedNo ratings yet

- R1 Dibujos Tecnicos Q24409 Enquiry E24155Document3 pagesR1 Dibujos Tecnicos Q24409 Enquiry E24155Lenin MagañaNo ratings yet

- 239 Albert Replacement Cladding PanelsDocument4 pages239 Albert Replacement Cladding PanelsmeghadurganNo ratings yet

- 2300 52 AAA BD 280 282181 01 - RevS1Document1 page2300 52 AAA BD 280 282181 01 - RevS1CosminMarianNo ratings yet

- Sea Level Sea Level: Ashrae Psychrometric Chart No.1 Ashrae Psychrometric Chart No.1Document2 pagesSea Level Sea Level: Ashrae Psychrometric Chart No.1 Ashrae Psychrometric Chart No.1KnightriderNo ratings yet

- 11 MTR Octagonal Pole-ModelDocument1 page11 MTR Octagonal Pole-Modelpankaj sharmaNo ratings yet

- Linease Actuator CAHB 22E - 17210 enDocument4 pagesLinease Actuator CAHB 22E - 17210 enAlvaro MunozNo ratings yet

- ASM E B16.34 Valve Body W All Thickness ASM E B16.10 Api 6D Design & M AnufacturingDocument1 pageASM E B16.34 Valve Body W All Thickness ASM E B16.10 Api 6D Design & M AnufacturingANILNo ratings yet

- Me02 DR Vincent Tanyag Doctrs Alley Medical DiagnosticDocument1 pageMe02 DR Vincent Tanyag Doctrs Alley Medical Diagnostickeijohn62No ratings yet

- Cgs - Sv-17 Alipurduar - Ga: Provision For Check MeteringDocument3 pagesCgs - Sv-17 Alipurduar - Ga: Provision For Check MeteringpremsukhsagarNo ratings yet

- Ashrae Psychrometric Chart No 1 Normal TDocument2 pagesAshrae Psychrometric Chart No 1 Normal TJEREMIAH Nepomuceno BAÑARESNo ratings yet

- Client: Drawing Number Scale Dimensions 'MM' NTS SES 1062/16 Sheet Title 100A Ats Panel Project DetailsDocument7 pagesClient: Drawing Number Scale Dimensions 'MM' NTS SES 1062/16 Sheet Title 100A Ats Panel Project DetailsDinesh GowdNo ratings yet

- Chamber Detail Drill Site B-Reva-1Document1 pageChamber Detail Drill Site B-Reva-1ahmed saadNo ratings yet

- PFD Group 11-ModelDocument1 pagePFD Group 11-ModelJiawen ChongNo ratings yet

- Phe - 1 3957 KWDocument1 pagePhe - 1 3957 KWNam ĐặngNo ratings yet

- GA DRG AIR RECEIVER 5m3 WPR 9.2 KG 100mm SR 500 CADocument1 pageGA DRG AIR RECEIVER 5m3 WPR 9.2 KG 100mm SR 500 CArmsh301No ratings yet

- 5 POWER DIAGRAM OFFLINE-ModelDocument1 page5 POWER DIAGRAM OFFLINE-ModelJitNo ratings yet

- 07 522213 4800000612 WSP SLT DRG 210002 - CDocument1 page07 522213 4800000612 WSP SLT DRG 210002 - CMOHD NAZEEF KHANNo ratings yet

- Lighting TK SITE-010923Document6 pagesLighting TK SITE-010923Sela SinNo ratings yet

- To Be DownloadDocument1 pageTo Be DownloadEasy WriteNo ratings yet

- Hopper Guide Plate DWG - RDDocument1 pageHopper Guide Plate DWG - RDRaj KumarNo ratings yet

- Mack Reducing ValvesDocument11 pagesMack Reducing ValvesJOHNNo ratings yet

- 1197 - Tipical CFB POWER PLANT OIL GUN & HESI UNIT PROJECT (SO#771) - Rev BDocument1 page1197 - Tipical CFB POWER PLANT OIL GUN & HESI UNIT PROJECT (SO#771) - Rev BEyuNo ratings yet

- 00 Drawing Cnt2 PDFDocument135 pages00 Drawing Cnt2 PDFImam MohamedNo ratings yet

- False Ceiling Plan For Parent'S BedroomDocument1 pageFalse Ceiling Plan For Parent'S BedroomfrosterapNo ratings yet

- Cable M12-Picospox 0.5MDocument1 pageCable M12-Picospox 0.5MBoxerpower GasNo ratings yet

- Balance de AireDocument1 pageBalance de AireJesús VelázquezNo ratings yet

- 962g Hyd PDFDocument4 pages962g Hyd PDFRonald Yucra CadenaNo ratings yet

- STORAGESDocument1 pageSTORAGESmukul1saxena6364No ratings yet

- Consultation 1Document1 pageConsultation 1Leri GuevarraNo ratings yet

- Balcont DetailsDocument1 pageBalcont DetailsBharani MadamanchiNo ratings yet

- Led Ceiling With SensorDocument1 pageLed Ceiling With Sensormaja mitrovic-jovanoskaNo ratings yet

- 4bedroom Maisonette - Monopitch - Sheet - A100 - Plan Layout & ViewsDocument15 pages4bedroom Maisonette - Monopitch - Sheet - A100 - Plan Layout & ViewsGusta OkoyeNo ratings yet

- Sensor Probe Monitoring Unit: Not in Our Scope of Supply. Front View Without Cover Front View With CoverDocument1 pageSensor Probe Monitoring Unit: Not in Our Scope of Supply. Front View Without Cover Front View With CoverAlexander SolomonNo ratings yet

- 5Document1 page519jclatozaNo ratings yet

- Colorful Chalkboard Classroom Labels and OrganizersFrom EverandColorful Chalkboard Classroom Labels and OrganizersNo ratings yet

- 3m ReportDocument22 pages3m Reportapi-321324040No ratings yet

- Aqa 2420 W TRB Psa11Document6 pagesAqa 2420 W TRB Psa11Chan Kah KeatNo ratings yet

- Patient ManagementDocument101 pagesPatient ManagementRhutvi ViraniNo ratings yet

- CuttackDocument6 pagesCuttackbaivabi priyadarshiniNo ratings yet

- Zamil Product Brochure PDFDocument30 pagesZamil Product Brochure PDFZameer KhanNo ratings yet

- Technical Data Sheet: Hanson Construction AggregatesDocument9 pagesTechnical Data Sheet: Hanson Construction AggregatesShaiful ZamriNo ratings yet

- Reflective Journaling2Document3 pagesReflective Journaling2api-313631358No ratings yet

- P3-F Grammar Revision For MidyearDocument10 pagesP3-F Grammar Revision For MidyearnewtonelifNo ratings yet

- Biology Laboratory ManualDocument314 pagesBiology Laboratory ManualLeroyJones91% (11)

- Study Plan - Imam HidayatDocument3 pagesStudy Plan - Imam HidayatchiwankdebakNo ratings yet

- Out 10Document12 pagesOut 10restu anindityaNo ratings yet

- Fallo Flujo de VentiladoresDocument4 pagesFallo Flujo de Ventiladores3GSERONo ratings yet

- Methods of Injection Delivery: MDSC 3203 Department of Child & Adolescent HealthDocument16 pagesMethods of Injection Delivery: MDSC 3203 Department of Child & Adolescent HealthMeko All Real EdwardsNo ratings yet

- Day 1 Exam 1Document3 pagesDay 1 Exam 1Cheng PasionNo ratings yet

- OM-UHT Plant PDFDocument138 pagesOM-UHT Plant PDFToni0% (1)

- SDS Biplas PL 4 MMDocument3 pagesSDS Biplas PL 4 MMAkhilNo ratings yet

- Safety Data Sheet: Section 1: Identification of The Substance and SupplierDocument9 pagesSafety Data Sheet: Section 1: Identification of The Substance and Supplier12030440No ratings yet

- Ramadan PresentationDocument20 pagesRamadan Presentationsajid_cdNo ratings yet

- MCQ Practice Test - Anatomy - 18 - 10 - 2020Document36 pagesMCQ Practice Test - Anatomy - 18 - 10 - 2020KhanNo ratings yet

- Vader Jakob Father James: Children's SongDocument7 pagesVader Jakob Father James: Children's SongnightclownNo ratings yet

- 11.utilization of Demolished Concrete Waste For New ConstructionDocument6 pages11.utilization of Demolished Concrete Waste For New Constructionhasnath kpNo ratings yet

- Philo Worksheet 8Document8 pagesPhilo Worksheet 8JANNA MATILLANO100% (1)

- General Description: Plug Fan ER..C With Standard MotorDocument7 pagesGeneral Description: Plug Fan ER..C With Standard MotorwildanNo ratings yet

- 30-Article Text-59-1-10-20201115Document9 pages30-Article Text-59-1-10-20201115Regita cahyani achmadNo ratings yet

- GMCO FOR INDUSTRIAL SERVICES - Welding Procedure SpecificationsDocument2 pagesGMCO FOR INDUSTRIAL SERVICES - Welding Procedure SpecificationsMohamedNo ratings yet

- INTRODUCING YOU-WPS OfficeDocument2 pagesINTRODUCING YOU-WPS OfficeNkey Obiwulu ChibuzorNo ratings yet

- BVBRC GenomeDocument7 pagesBVBRC GenomefsjhfjkhfNo ratings yet