Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

2 viewsFin Irjmets1683692555

Fin Irjmets1683692555

Uploaded by

NamsangLimbooCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Theory of Structures Assignment FinalDocument21 pagesTheory of Structures Assignment FinalManasAroraNo ratings yet

- Purification of Contaminated Air From The Spinning Mill and Transformation of Microdust As Flyash For Structural FillingDocument4 pagesPurification of Contaminated Air From The Spinning Mill and Transformation of Microdust As Flyash For Structural FillingIJRASETPublicationsNo ratings yet

- Ijri Cce 02 008Document8 pagesIjri Cce 02 008ijripublishersNo ratings yet

- Studies On Stabilized Mud Block As A Construction MaterialDocument6 pagesStudies On Stabilized Mud Block As A Construction MaterialIJIRAE- International Journal of Innovative Research in Advanced Engineering100% (1)

- Research ProposalDocument3 pagesResearch ProposalMer Aily Dela CruzNo ratings yet

- ef04f4ed-2123-49c5-8d4f-eeec575b8c28Document10 pagesef04f4ed-2123-49c5-8d4f-eeec575b8c28Thiran Boy LingamNo ratings yet

- Utilization of Waste Plastic in Manufacturing of BricksDocument6 pagesUtilization of Waste Plastic in Manufacturing of BricksIJRASETPublications100% (1)

- Mycelium Brick 1Document9 pagesMycelium Brick 1Aromal psNo ratings yet

- Utilization of Non - Biodegradable Material For Repairing PotholesDocument7 pagesUtilization of Non - Biodegradable Material For Repairing PotholesIJRASETPublicationsNo ratings yet

- SYNOPSIS Bio BrickDocument5 pagesSYNOPSIS Bio BrickGopal mutkekarNo ratings yet

- Group 12Document20 pagesGroup 12Dhananjay DesaleNo ratings yet

- Polymer Fiber Reinforced Concrete PavementsDocument5 pagesPolymer Fiber Reinforced Concrete PavementsIJRASETPublicationsNo ratings yet

- An Overview Low Cost House Materials TechniquesDocument6 pagesAn Overview Low Cost House Materials TechniquesshubhamNo ratings yet

- Utilization of Coconut Shell As Greener ConcreteDocument9 pagesUtilization of Coconut Shell As Greener ConcreteIJRASETPublicationsNo ratings yet

- Papercrete Brick PDFDocument12 pagesPapercrete Brick PDFArul Vanan100% (7)

- Coir Fibre Used in Reinforced ConcreteDocument6 pagesCoir Fibre Used in Reinforced ConcreteVIVA-TECH IJRINo ratings yet

- EcoBrick A Waste Plastic Used As Construction MaterialDocument6 pagesEcoBrick A Waste Plastic Used As Construction MaterialIJRASETPublicationsNo ratings yet

- A Review On Utilization of Ppe in Construction Projects For Sustainable DevelopmentDocument7 pagesA Review On Utilization of Ppe in Construction Projects For Sustainable Developmentkushreal100No ratings yet

- Efficacy of Bacterial Concrete With Conventional ConcreteDocument10 pagesEfficacy of Bacterial Concrete With Conventional ConcreteIJRASETPublicationsNo ratings yet

- The Investigational The Effects of Waste Products Such As Wood Ash, Sugarcane Bagasse Ash, and Rice Husk Ash On The Durability of ConcreteDocument6 pagesThe Investigational The Effects of Waste Products Such As Wood Ash, Sugarcane Bagasse Ash, and Rice Husk Ash On The Durability of ConcreteIJRASETPublicationsNo ratings yet

- 12 Vol. 2, Issue 4, IJPSR, 2011, Paper 2Document4 pages12 Vol. 2, Issue 4, IJPSR, 2011, Paper 2Hilary WatsonNo ratings yet

- Bacterial ConcreteDocument6 pagesBacterial ConcreteIJRASETPublicationsNo ratings yet

- Binding Material in Pavement Block Made From Waste PlasticDocument5 pagesBinding Material in Pavement Block Made From Waste PlasticAbdelrahman AshmawyNo ratings yet

- A Survey On Design of Pavement Blocks Made From Waste of Plastic, Glass & Aluminum FoilDocument5 pagesA Survey On Design of Pavement Blocks Made From Waste of Plastic, Glass & Aluminum FoilIJRASETPublicationsNo ratings yet

- Application of Bacterial SporesDocument13 pagesApplication of Bacterial SporesasdasdasdasNo ratings yet

- Testing On Specimen - 6Document14 pagesTesting On Specimen - 6Dhruv ThakkarNo ratings yet

- Experimental Study On Influence of Bacteria in ConcreteDocument6 pagesExperimental Study On Influence of Bacteria in ConcreteIJRASETPublicationsNo ratings yet

- .Utilization of Plastic Waste and Artificial Sand in Manufacturing of Eco BricksDocument3 pages.Utilization of Plastic Waste and Artificial Sand in Manufacturing of Eco BricksSande NasNo ratings yet

- IRJET V8I-UniquenessofMudArchitectureDocument7 pagesIRJET V8I-UniquenessofMudArchitectureHarshita SaxenaNo ratings yet

- Papercrete4 PDFDocument9 pagesPapercrete4 PDFPrasad TekadeNo ratings yet

- Concrete Using Coconut Fiber - An AlternativeDocument4 pagesConcrete Using Coconut Fiber - An AlternativeSenthil KumarNo ratings yet

- Design Constructionand Performance Evaluationofa Coco Peat Block Making MachineDocument12 pagesDesign Constructionand Performance Evaluationofa Coco Peat Block Making MachinehariprasathNo ratings yet

- Utilization of Sisal Fiber in Portland Cement Concrete ElementsDocument6 pagesUtilization of Sisal Fiber in Portland Cement Concrete ElementsLucero Vasquez LopezNo ratings yet

- ProcessDocument13 pagesProcessDuy Khanh HuynhNo ratings yet

- Uniqueness of Mud Architecture: International Research Journal of Engineering and Technology (IRJET)Document6 pagesUniqueness of Mud Architecture: International Research Journal of Engineering and Technology (IRJET)Shrutie PatilNo ratings yet

- Mur Mur: StudioDocument38 pagesMur Mur: StudioMaria Fernanda Pinzon DussanNo ratings yet

- Experimental Investigation On Reinforced Concrete With Plastic FiberDocument6 pagesExperimental Investigation On Reinforced Concrete With Plastic FiberIJRASETPublicationsNo ratings yet

- A Survey On Use of Non-Recyclable Waste in ConstructionDocument9 pagesA Survey On Use of Non-Recyclable Waste in ConstructionIJRASETPublicationsNo ratings yet

- Failure Analysis of Compressed Earth Block Using Numerical PlasticDocument27 pagesFailure Analysis of Compressed Earth Block Using Numerical PlasticDaniela BaqueroNo ratings yet

- Research Article: Manufacturing of Ecofriendly Bricks Using Microdust Cotton WasteDocument10 pagesResearch Article: Manufacturing of Ecofriendly Bricks Using Microdust Cotton Wasteshinaiya StarNo ratings yet

- Application of Bio Bricks and Its BenefitsDocument10 pagesApplication of Bio Bricks and Its BenefitsSaud AfzalNo ratings yet

- Design and Fabrication of Eco-Brick Making MachineDocument5 pagesDesign and Fabrication of Eco-Brick Making MachineIJRASETPublicationsNo ratings yet

- Experimental Study of The Physical Properties of Concrete Prepared by Partial Replacement of Cement With Alccofine, Metakaolite and GGBSDocument21 pagesExperimental Study of The Physical Properties of Concrete Prepared by Partial Replacement of Cement With Alccofine, Metakaolite and GGBSIJRASETPublicationsNo ratings yet

- Sawdust Brick A Quantitative Study On Sawdust Substitute For Concrete Brick ProductionDocument21 pagesSawdust Brick A Quantitative Study On Sawdust Substitute For Concrete Brick ProductionChristian Andre FloresNo ratings yet

- 57 3 PDFDocument20 pages57 3 PDFAnonymous Qm0zbNkNo ratings yet

- Characteristics of Geopolymer Concrete Produced Using Banana Fiber and Coal AshDocument7 pagesCharacteristics of Geopolymer Concrete Produced Using Banana Fiber and Coal AshEmmanuel OgunjioforNo ratings yet

- Materials: Mechanical and Durability Performance of Coconut Fiber Reinforced Concrete: A State-of-the-Art ReviewDocument24 pagesMaterials: Mechanical and Durability Performance of Coconut Fiber Reinforced Concrete: A State-of-the-Art ReviewBenmark JabayNo ratings yet

- Use of Plastic Waste in Road Construction For SustDocument5 pagesUse of Plastic Waste in Road Construction For SustVenkateswarlu GajulaNo ratings yet

- Dolomite-Foamed Bioactive Silicate Scaffolds For Bone Tissue RepairDocument13 pagesDolomite-Foamed Bioactive Silicate Scaffolds For Bone Tissue RepairLuccas TeruelNo ratings yet

- Numerical Study of Two-Phase Flow in Centrifugal Dust CollectorsDocument6 pagesNumerical Study of Two-Phase Flow in Centrifugal Dust CollectorsResearch ParkNo ratings yet

- Some Aspects of The Effect of Porosity On Moisture Transfer in ConcreteDocument6 pagesSome Aspects of The Effect of Porosity On Moisture Transfer in ConcreteResearch ParkNo ratings yet

- Comparative Study of Sisal Fibre and Glass Fibre Reinforced Concrete - A ReviewDocument6 pagesComparative Study of Sisal Fibre and Glass Fibre Reinforced Concrete - A ReviewIJRASETPublicationsNo ratings yet

- Study On Experimental Behavior of Plastic Based Fiber As Secondary Reinforcement in Concrete PavementDocument13 pagesStudy On Experimental Behavior of Plastic Based Fiber As Secondary Reinforcement in Concrete PavementIJRASETPublicationsNo ratings yet

- BHANULATHADocument10 pagesBHANULATHALDavid FFelixNo ratings yet

- Sustainable Materials For Additive Manufacturing: Earth-Based ConcreteDocument11 pagesSustainable Materials For Additive Manufacturing: Earth-Based Concreteolivierm197No ratings yet

- Experimental Investigation of Waste Plastic Fiber in Reinforced Cement Concrete Using Recycled Coarse AggregateDocument12 pagesExperimental Investigation of Waste Plastic Fiber in Reinforced Cement Concrete Using Recycled Coarse AggregateInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- A Review On Utilization of Processed Inorganic Mixed Municipal Solid Waste by Mechanical Device in Manufacturing of BricksDocument6 pagesA Review On Utilization of Processed Inorganic Mixed Municipal Solid Waste by Mechanical Device in Manufacturing of BricksIJRASETPublicationsNo ratings yet

- A Brief Review of Compressed Stabilized Earth Brick CSEBDocument7 pagesA Brief Review of Compressed Stabilized Earth Brick CSEBMauricio SilesNo ratings yet

- An Experimental Study To Address The Issues of Low Durability and Low Compressive Strength of Mud PlasterDocument39 pagesAn Experimental Study To Address The Issues of Low Durability and Low Compressive Strength of Mud PlasterRafiq MirNo ratings yet

- Feasibility of Using Coconut Fibre To Improve Concrete Strength IJERTV11IS080072Document7 pagesFeasibility of Using Coconut Fibre To Improve Concrete Strength IJERTV11IS080072anunciano GuterresNo ratings yet

- CoreDocument5 pagesCoreNamsangLimbooNo ratings yet

- A Brief Review of Compressed Stabilized Earth Brick (CSEB) : Fetra Venny Riza Ismail Abdul RahmanDocument6 pagesA Brief Review of Compressed Stabilized Earth Brick (CSEB) : Fetra Venny Riza Ismail Abdul RahmanNamsangLimbooNo ratings yet

- English Sandbag ShelterDocument2 pagesEnglish Sandbag ShelterNamsangLimbooNo ratings yet

- Experimental Study of High Strength Concrete (M70) Using Manufactured SandDocument2 pagesExperimental Study of High Strength Concrete (M70) Using Manufactured SandNamsangLimbooNo ratings yet

- Janfeb 2021Document7 pagesJanfeb 2021NamsangLimbooNo ratings yet

- Lam 2019Document8 pagesLam 2019NamsangLimbooNo ratings yet

- Engineering Properties of Adobe Brick For Earth Structures: Napat SriwattanaprayoonDocument6 pagesEngineering Properties of Adobe Brick For Earth Structures: Napat SriwattanaprayoonNamsangLimbooNo ratings yet

- Activity 21 9Document34 pagesActivity 21 9NamsangLimbooNo ratings yet

- BTL2020 PrachiAiyer Track2Document8 pagesBTL2020 PrachiAiyer Track2NamsangLimbooNo ratings yet

- The Architectural Design of The ParthenoDocument35 pagesThe Architectural Design of The ParthenoNamsangLimbooNo ratings yet

- 2Document1 page2NamsangLimbooNo ratings yet

- McKean 1997LookingattheParthenonJoADocument32 pagesMcKean 1997LookingattheParthenonJoANamsangLimbooNo ratings yet

- Democracyand Design Essaysbystudentsof Mu IDKielDocument37 pagesDemocracyand Design Essaysbystudentsof Mu IDKielNamsangLimbooNo ratings yet

- 293 Standardized Coded Matrix For Secure Prepper CommunicationsDocument1 page293 Standardized Coded Matrix For Secure Prepper CommunicationsNamsangLimbooNo ratings yet

- 4Document1 page4NamsangLimbooNo ratings yet

- Transportation Lab PostersDocument8 pagesTransportation Lab PostersTushar WaleNo ratings yet

- Building SpecificationsDocument5 pagesBuilding Specificationsjologscresencia100% (1)

- Statement of The The Problem FEU Tech Building - 3Document3 pagesStatement of The The Problem FEU Tech Building - 3Matthew SumagueNo ratings yet

- ARCHITECTURAL ARTS in The PhilDocument5 pagesARCHITECTURAL ARTS in The PhilDamon KlausNo ratings yet

- How To Build A Pikler TriangleDocument24 pagesHow To Build A Pikler Trianglezopauy100% (1)

- Detailed Estimation of Building With Plan PDFDocument21 pagesDetailed Estimation of Building With Plan PDFsqqpqq1No ratings yet

- Sheets and Slates: Asbestos-CementDocument36 pagesSheets and Slates: Asbestos-CementNorfolkingNo ratings yet

- ANP Strand Anchor PDFDocument36 pagesANP Strand Anchor PDFGuoqiang LiuNo ratings yet

- Analysis of RatesDocument32 pagesAnalysis of Ratesprashantwathore100% (1)

- ADDMIX 152-v4 PDFDocument1 pageADDMIX 152-v4 PDFAnkita Baban GavadeNo ratings yet

- M. C. Abdul Malick Chartered Valuer: 54/3C Prathibimbarama Road, DehiwelaDocument3 pagesM. C. Abdul Malick Chartered Valuer: 54/3C Prathibimbarama Road, DehiwelaNaahidhNo ratings yet

- 000 Drainage Pipes, Fiitings and JointsDocument41 pages000 Drainage Pipes, Fiitings and Jointselcid agsamosamNo ratings yet

- Rock Bolting TechniqueDocument9 pagesRock Bolting TechniquesamratNo ratings yet

- Randfile 09Document32 pagesRandfile 09Sergio DiazNo ratings yet

- PSC Single SpanDocument60 pagesPSC Single Spanthanzawtun1981No ratings yet

- Whitehall Library - Case StudyDocument8 pagesWhitehall Library - Case StudyVidya SagarNo ratings yet

- Technical Data Sheet GlasGrid CGL EN 1960442Document2 pagesTechnical Data Sheet GlasGrid CGL EN 1960442vonskemaNo ratings yet

- Eco-Boards: A Green Building Material From Residues and WasteDocument26 pagesEco-Boards: A Green Building Material From Residues and WasteJaybesNo ratings yet

- CE 301-GeologyDocument1 pageCE 301-GeologychndriuhNo ratings yet

- PHILIPP Screw Anchor: Installation and Application InstructionDocument4 pagesPHILIPP Screw Anchor: Installation and Application InstructionHossein DoudiNo ratings yet

- HousekeepingDocument5 pagesHousekeepingCoca LeeNo ratings yet

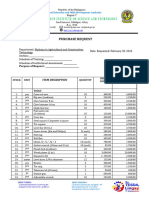

- Purchase Request CARPENTRY NC IIDocument4 pagesPurchase Request CARPENTRY NC IICatherine Mae NacionNo ratings yet

- Prismatic Beam Design: C 11 D B SDocument8 pagesPrismatic Beam Design: C 11 D B SChristian Jay GamboaNo ratings yet

- Updated 7 Point Container Inspection SheetDocument2 pagesUpdated 7 Point Container Inspection SheetMohd Shahrul Irwan Mohd Zin0% (1)

- FYP Thesis 17ME16, 12,14Document42 pagesFYP Thesis 17ME16, 12,14Sharjeel AhmedNo ratings yet

- 2.AquaArm SBS 3000XDocument3 pages2.AquaArm SBS 3000XBijaya RaulaNo ratings yet

- Farm StructuresDocument6 pagesFarm StructuresErika HonorioNo ratings yet

- Piping, Hydro QC List-InterviewDocument3 pagesPiping, Hydro QC List-InterviewAnonymous 4e7GNjzGW100% (2)

- Portal Ratol & Rates Premo: Surface Drainage RM 1500.00 1500.00Document2 pagesPortal Ratol & Rates Premo: Surface Drainage RM 1500.00 1500.00Nur Syahidah AzmiNo ratings yet

Fin Irjmets1683692555

Fin Irjmets1683692555

Uploaded by

NamsangLimboo0 ratings0% found this document useful (0 votes)

2 views15 pagesOriginal Title

fin_irjmets1683692555

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

2 views15 pagesFin Irjmets1683692555

Fin Irjmets1683692555

Uploaded by

NamsangLimbooCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 15

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:05/Issue:05/May-2023 Impact Factor- 7.868 www.irjmets.com

COMPARATIVE ANALYSIS OF CSEB, BURNT CLAY BRICK &

MYCELIUM BRICKS

Aryan Verma*1, Harsh Panchal*2, Harsh Mishra*3, Ashwin Parihar*4,

Monika Pagare*5, Anurag Tripathi*6

*1,2,3,4,5,6Medicaps Univeristy, AB Road, Pigdamber, Rau, Indore, Madhya Pradesh, India.

DOI : https://www.doi.org/10.56726/IRJMETS38445

ABSTRACT

Earth has been utilized as a construction material for decades, first as simple brick adobe made of sun-dried

mud and straw that lacked strength and longevity. Developed into baked clay brick through bulk, quick kiln

manufacture. Compressed Stabilized Earth Brick (CSEB) gives the view of energy efficient, cost reduction, and

environmentally friendly building materials, overall contributing to the sustainable development in the rising

concern of awareness about sustainable building materials and environmental issue. This study aims to explore

mycelium as a potential composite material for construction and other applications because it has strong

binding properties and processes nutrients from sawdust, straw, grains etc. by using enzymes to convert

cellulose in the substrate into chitin, a strong compound. This proposed the improvement of a development

material with the accompanying attributes: develops, assemble, and repairs itself; changes with the season;

utilizes the powers of nature and is in agreement with its condition; favors biodiversity and regular harmony;

minimal effort and does not require impressive workforce; carbon free and waste free comes back to nature

when never again being used empowers maintainable and adjusted humanity advancement.

I. INTRODUCTION

Compressed Stabilized Earth Brick (CSEB), also known as Pressed Earth Brick, are a type of construction

material created by compressing moist earth under high pressure to form blocks. The dry inorganic subsoil,

non-expansive clay, aggregates, and Portland cement are used to make them. CSEBs are a more ecologically

friendly alternative to clay bricks, which are used in the majority of residential buildings today.

The manufacturing procedure distinguishes CSEB bricks from normal burnt bricks. CSEB brick needs

compaction, whether static, dynamic, or Vibro-static, as well as the amount of stabilizer applied to improve

strength.The quality of blocks is significantly impacted by Soil condition, compression force, curing and

proportion of stabilizer, and manufacturing quality.

Mycelium (plural mycelia) is a root-like structure of a fungus consisting of a mass of branching, thread-like

hyphae. Fungal colonies composed of mycelium are found in and on soil and many other substrates. A typical

single spore germinates into a monokaryotic mycelium, which cannot reproduce sexually; when two

compatible monokaryotic mycelia join and form a dikaryotic mycelium, that mycelium may form fruiting bodies

such as mushrooms. Through the mycelium, an organism ingests supplements from its condition. It does this in

a two- organize process. To start with, the hyphae emit catalysts onto or into the sustenance source, which

separate organic polymers into littler units, for example, monomers. These monomers are then ingested into

the mycelium by encouraged dispersion and dynamic transport.Mycelium is fundamental in earthly and

amphibian environments for their part in the deterioration of plant material.

About CSEB

With an ever-increasing environmental hazard due to the actions of man, it is vital to sustainably manage our

environment. One of such methods is the introduction of Compressed Stabilized Earth Brick (CSEB), which is an

energy efficient, affordable and ecologically friendly construction material. Soils are the primary material in

CSEB and is fairly inexpensive. It is utilized in more than Thirty nations throughout the world, amongst them

Mexico, USA, South Africa, India and Thailand. It is simple to create and a replacement for concrete, been tested

to determine its strength and the qualities utilized as a load bearing material in the construction industry. It is a

mixture of mainly three separate components which are cement, soil, sand that are combined together with

water in precise quantities. These blocks employ the same parent material Burnt Clay Red Bricks, but provide

the substantial benefit of compressive strength.

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[1721]

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:05/Issue:05/May-2023 Impact Factor- 7.868 www.irjmets.com

Figure 1. House made of CSEB brick

About Mycelium

Mycelium has body structures and methods of proliferation dissimilar to those of some other eukaryotic

creatures. The assemblages of most growths are made of structures called hyphae (solitary, hypha). Hyphae are

small strings of cytoplasm encompassed by a plasma film and secured by a phone divider. The cell dividers of

growths contrast from the cellulose cell dividers of plants. Most growths manufacture their cell dividers out of

chitin, a solid, adaptable polysaccharide that is additionally found in the outer skeletons of creepy crawlies. The

hyphae of most parasites have extra cell dividers, called cross-dividers that gap the long fibers into numerous

different end-to-end cells. This makes most organism’s multi cell. The cross-dividers of numerous growths have

pores sufficiently substantial to permit ribosome, mitochondria, and even cores to spill out of cell to cell. The

development of cytoplasm starting with one cell then onto the next enables a parasite to disseminate

supplements starting with one a player in its body then onto the next.The hyphae of a solitary growth regularly

branch as they develop, shaping a joined tangle called a mycelium (plural, mycelia).

Figure 2. Mycelium

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[1722]

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:05/Issue:05/May-2023 Impact Factor- 7.868 www.irjmets.com

II. PROCEDURE FOR MAKING OF CSEB BRICK

A. Material selection

1. Soil identification can be performed with sensitive analyses. The main points were examined as grain size

distribution to know quality of each grain size.

2. Plasticity characteristics to know the quality and properties of each of the binders.

3. Sample Details: Red Earth

4. Plastic Limit =56%

5. Liquid Limit=66%

6. Plasticity Index = 10 =Slightly plastic

7. LI= 1, hence the remolded soil is at the liquid limit and it has un-drained shear strength of about 2KPa.

B. Procedure for Making CSEB (Compressed Stabilized Earth Blocks)

1. Collected the soil sample.

2. Test for soil classification.

3. Various mixing of ingredients/stabilizers with clay soil and sand varies in percentage of mixing.

4. The various mixes are placed in the proposed brick mold.

5. The mold is compressed in a process.

6. Then it is dried for 28 days.

7. Strength determination on UTM/CTM

Figure 3. Mixing of materials

Figure 4. Hydraulic Compression Machine

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[1723]

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:05/Issue:05/May-2023 Impact Factor- 7.868 www.irjmets.com

Figure 5. Sun Drying of Bricks

Procedure for making of Mycelium Brick

1. Sterilize the Substrate i.e the agriculture waste in this case

2. Take a Plastic Bag and add sterilized agriculture waste and add formalin and fungicide.

3. Add 2-3 mushroom seeds and pack the Plastic bag and place in a dark place for 3-7 days.

4. After 3-7 days the mycelium will start growing

5. Pour this mixture in a Brick Mold

6. Add some percent of white cement to harden the Brick to be tested

7. The Brick is kept in oven at 4000 C to kill the bacteria

8. Brick is ready to be tested.

Figure 6. Brick Mould filled with Mycelium

Figure 7. Mycelium Brick

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[1724]

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:05/Issue:05/May-2023 Impact Factor- 7.868 www.irjmets.com

III. TEST PERFORMED FOR CSEB

1. Water Absorption Test

A brick is dried is weighted. It is then immersed in water for a period of 24 hours. It is weighed again and the

difference in weight indicates the amount of water absorbed by the brick. It should not, in any case, exceed 20%

of the weight of dry brick for first class.

Water absorption (%) = [(W2-W1) / W1] x 100

Were,

W1 = Dry Brick Weight (oven Dry Condition after 24 hours at temperature 110 to 150 °C)

W2 = Wet Brick Weight (After Immersion for 24 Hours)

Figure 8. Water absorption test

2. Efflorescence Test

For finding out the presence of soluble salts in brick, it is immersed in water for 24 hours. It is then taken out

and allowed to dry. If a white deposit covers about 10% surface, the efflorescence is said to be slight and it is

considered moderate when the white deposit covers about 50% of the surface. If white deposits are found on

more than 50% of the surface, the efflorescence is heavy and it is treated as serious and brick is rejected.

Figure 9. Efflorescence Test

3. Hardness

In this test, a scratch is tried to make on the brick surface with the help of a fingernail. If no impression is left on

the surface, the brick is taken as enough hard.

Figure 10. Hardness

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[1725]

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:05/Issue:05/May-2023 Impact Factor- 7.868 www.irjmets.com

4. Compression Test

Compressive strength test on bricks is carried out to determine the load carrying capacity of bricks under

compression with the help of compression testing machine.

Bricks are generally used for construction of load bearing masonry walls, columns and footings. These load

bearing masonry structures experiences mostly the compressive loads. Thus, it is important to know the

compressive strength of bricks to check for its suitability for construction.

Figure 11. Compression test

5. Shape and Size

In this test, a brick is closely observed. It should be of standard size and its shape should be truly rectangular

with Sharp edges and corners. For this purpose, 20 bricks of standard size (190 mm x 90 mm x 90 mm) are

selected at random and they are stacked lengthwise, along with the width and along with the height.

6. Structure

A brick is broken and its structure is examined. It should be homogeneous, compact and free from any defects

such as holes, lumps etc.

IV. TEST RESULT FOR BURNT CLAY BRICKS

1. Water Absorption Test

As per IS 1077: 1992, clause 7.2, Bricks after immersion in cold water for 24 hours, water absorption shall not

be more than 20 percent by weight up to class 12.5 and for the classes above 12.5 water absorption shall be

between 12.5 and 15 percent.Water absorption for First class brick should not exceed 12-15 % of its dry

weight. For second class brick it should be between 16 - 20%.

2. Presence of soluble salt or Efflorescence

Nil- When there is not perceptible deposit of efflorescence.

Slight- Not more than 10% area of the brick covered with a thin deposit of salt.

Moderate- Covering up to 50% area of the brick.

Heavy- Covering 50% or more but unaccompanied by powdering or flacking of the brick surface.

3. Hardness

Brick should be hard enough so that it is not scratched by a finger nail.

4. Shape and Size

It should confirm in size to the specified dimensions (19 x 9 x 9 cm).

5. Structure

In this test, a brick is fractured and firmly investigated. If any flaws, holes or cracks are seen inside the broken

brick, then it is considered as poor-quality brick.

6. Compression Test

Compressive Strength of Bricks = Maximum Load at Failure (N)/Average area of bed face (mm2). Compressive

/Crushing strength of brick are very variable, and may vary from 30 kg/cm2 to 150 kg/cm2. 105 kg/cm2 for

1st class brick, 70 kg/ cm2 for 2nd class brick, 15 – 25 kg/cm2 for sun dried brick.

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[1726]

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:05/Issue:05/May-2023 Impact Factor- 7.868 www.irjmets.com

V. TEST RESULT FOR MYCELIUM BRICKS

1. Water Absorption Test

The bricks, when tested in accordance with the procedure laid down in IS 3495 (Part 2), after immersion in cold

water for 24 hours, shall have average water absorption not more than 20 percent by mass up to class 12.5 and

15 percent by mass for higher classes. The water absorption on the Mycelium bricks is about 10.46%

2. Presence of soluble salt or Efflorescence

The bricks when tested in accordance with the procedure laid down in IS 3495 (Part 3), shall have the rating of

efflorescence not more than ‘moderate’ up to Class 12.5 and ‘slight’ for higher classes. Test shows that there is

‘slight’ efflorescence in case of mycelium bricks.

Figure 12. Efflorescence test of mycelium brick

3. Hardness

Brick should be hard enough so that it is not scratched by a finger nail and Mycelium Bricks were sufficiently

hard.

4. Shape and Size

Uniform in shape and smooth in finish as the manufacturing is carried out using machinery.(22.5 x 10 x 7.5 cm)

Figure 13. Mycelium Brick

5. Structure

In this test, a brick is fractured and firmly investigated. If any flaws, holes or cracks are seen inside the broken

brick, then it is considered as poor-quality brick.

6. Compression Test

Tests show that the tile brick compressive strength test carried out as per IS 3495-1992 part 1 and following

observations are made.

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[1727]

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:05/Issue:05/May-2023 Impact Factor- 7.868 www.irjmets.com

Table 1. Compressive Strength of mycelium brick

S.No. Sample name Compressive Strength of Mycelium Bricks in N/mm^2

1 Sample 1 13.4

2 Sample 2 12.8

3 Sample 3 13.1

VI. DETAILS ABOUT CSEB AS BUILDING MATERIAL

Compressed stabilized earth blocks (CSEB) and mycelium bricks are both building materials made from

natural, sustainable materials.CSEB are made by compressing a mixture of soil, cement, and water. The mixture

is usually stabilized by the addition of a small amount of cement, which helps to bind the soil particles together

and improves the durability and strength of the blocks. CSEB is often used as an alternative to traditional fired

clay bricks and can be used to build both load-bearing and non-load-bearing walls. They are known for their

low cost, high thermal insulation properties, and environmental friendliness.

VII. DETAILS ABOUT MYCELIUM BRICK AS BUILDING MATERIAL

Mycelium bricks are made by growing mycelium (the vegetative part of a fungus) on a mixture of agricultural

waste, like straw or sawdust. The mycelium binds the waste together and forms a strong, lightweight, and

biodegradable brick. Mycelium bricks are known for their insulating properties, low carbon footprint, and the

fact that they can be grown in a relatively short period of time, meaning they can be produced more quickly

than traditional bricks. They are also known for being good at sequestering carbon. Mycelium bricks are quite

new and still developing construction material. It has not been fully adopted by the construction industry yet.

In addition, it's still in the early stages of testing and research, hence the long-term properties like durability,

fire resistance, and structural strength are still not well known. CSEB are more mature construction materials

but may not be available in all regions. They also may not match the strength of traditional bricks or concrete

blocks, so they may be less suitable for load-bearing walls or structures that need to support heavy loads.

VIII. SUSTAINABILITY AND ENVIRONMENTAL FRIENDLINESS OF CSEB AND

MYCELIUM BRICKS

A. CSEB Bricks:

Earth is a local material and the soil should preferably be extracted from the site itself or not transported

from too far away.

Labor costs for CSEB production amount to 40 to 45% of the total cost. This promotes endogenous

development.

It is a cost and energy effective material.

The embodied energy of CSEB is 10.7 times less than fired brick.

Carbon emissions of CSEB are 12.5 times less than fired brick.

Table 2. Sustainability And Environmental Friendliness of CSEB And Mycelium Bricks

Initial Embodied Energy Per M³ Carbon Emissions (Kg of Co₂) Per M³

CSEB= 572.6 MJ/m³ CSEB = 51.5 Kg/m³

Fired Brick (CFB) = 6,122.5 MJ/m³ Fired Brick (CFB) = 642.9 Kg/m³

B. Mycelium Bricks:

Mycelium bricks are made from a renewable and biodegradable resource (mycelium) and agricultural

waste, which reduces the dependence on non-renewable resources and the carbon footprint of traditional

building materials like concrete and clay bricks.

The production process of Mycelium bricks is low-energy and can be grown locally, which reduces

transportation costs and emissions.

Mycelium bricks can be grown in a matter of days, which is much faster than traditional building materials.

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[1728]

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:05/Issue:05/May-2023 Impact Factor- 7.868 www.irjmets.com

They are compostable, which makes them an environmentally friendly option for buildings that are

intended to be temporary or dismantled at the end of their useful life.

Mycelium bricks have a high insulation value and can improve energy efficiency of buildings.

They have a good soundproofing and fire-resistance property. They are a low-cost building option, which

makes them accessible to a wider range of people and communities.

Table 3.Environmental Friendliness of Mycelium

INITIAL EMBODIED ENERGY CARBON EMISSIONS (Kg of CO₂)

PER M³ PER M³

Mycelium = 2 to 7 GJ/m3 Mycelium = 20 to 50 kg CO2/m3

Fired Brick (CFB) = 6,122.5 MJ/m³ Fired Brick (CFB) = 642.9 Kg/m³

IX. SOIL SUITABILITY AND STABILIZATION FOR CSEB AND MYCELIUM BRICK

CSEB Bricks:

Not every soil is suitable for earth construction and CSEB in particular. But with some knowledge and

experience many soils can be used for producing CSEB. Topsoil and organic soils must not be used. Identifying

the properties of a soil is essential to perform, at the end, good quality products. Some simple sensitive analysis

can be performed after a short training. Cement stabilization will be better for sandy soils. Lime stabilization

will be better suited for clayey soils.

Mycelium Bricks:

Mycelium, the underground vegetative part of fungi, can grow in a wide variety of soils. However, for the

production of mycelium bricks, the soil should be rich in organic matter and have a high water-holding capacity.

The soil should also be free from heavy metals, pesticides, and other contaminants that could affect the growth

of mycelium or the safety of the final product.

To stabilize the mycelium bricks, it is often mixed with agricultural waste such as straw or sawdust. The

agricultural waste helps to provide structural support to the bricks and can also improve the insulation and

soundproofing properties of the final product. The ratio of soil to agricultural waste can vary depending on the

desired properties of the bricks.

It's important to note that the suitability of soil for mycelium brick production may vary depending on the type

of mycelium used and the specific manufacturing process. Therefore, it's recommended to conduct soil tests

and experiments before starting the production.

GOOD SOIL FOR CSEB AND MYCELIUM BRICK

CSEB Bricks:

The selection of a stabilizer will depend upon the soil quality and the project requirements. Cement will be

preferable for sandy soils and to achieve quickly a higher strength. Lime will be rather used for very clayey soil,

but will take a longer time to harden and to give strong blocks.

Mycelium Brick:

For mycelium brick production, the soil should be rich in organic matter and have a high water-holding

capacity. This type of soil will provide the necessary nutrients for the mycelium to grow and bind the

agricultural waste. The soil should be free from heavy metals, pesticides, and other contaminants that could

affect the growth of mycelium or the safety of the final product.

A good soil for mycelium brick production would have a high percentage of clay, silt and humus, as these

components hold water and nutrients well. Soils with high clay content tend to have good plasticity and can be

easily compacted, which is beneficial for the production of mycelium bricks.

It's important to note that the suitability of soil for mycelium brick production may vary depending on the type

of mycelium used and the specific manufacturing process. Therefore, it's recommended to conduct soil tests

and experiments before starting the production.

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[1729]

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:05/Issue:05/May-2023 Impact Factor- 7.868 www.irjmets.com

X. ENERGY EFFECTIVENESS

Table 4. Energy Effectiveness

Initial embodied energy (MJ/m³ of

Carbon emission (Kg of CO2 /m³ of materials)

materials)

CSEB are consuming 11 times less energy than CSEB are polluting 13 times less than country fired

country fired bricks bricks

CSEB produced on site with 5% cement = CSEB produced on site with 5 % cement = 49.37 Kg of

548.32 MJ/m³ CO₂ /m³

Country fired bricks = 6,122.54 MJ/m³ Country fired bricks = 642.87 Kg of CO₂ /m³

A local material

Ideally, the production is made on the site itself or in the nearby area. Thus, it will save the transportation, fuel,

time and money.

A bio-degradable material

Well-designed CSEB houses can withstand, with a minimum of maintenance, heavy rains, snowfall or frost

without being damaged. The strength and durability have been proven since half a century. But let's imagine a

building fallen down and that a jungle grows on it: the bio-chemicals contained in the humus of the topsoil will

destroy the soil cement mix in 10 or 20 years And CSEB will come back to our Mother Earth.

A Job Creation Opportunity

CSEB allow unskilled and unemployed people to learn a skill, get a job and rise in the social values. Equipment

for CSEB is available from manual to motorized tools ranging from village to semi-industry scale. The selection

of the equipment is crucial, but once done properly, it will be easy to use the most adapted equipment or each

case.

Mycelium As the demand for mycelium bricks grows, the future scope of this technology is likely to expand.

Mycelium bricks could be used in a wide range of construction projects, including residential, commercial and

industrial buildings, as well as in temporary or emergency shelters. They could also be used in the construction

of green roofs, sound barriers, and retaining walls.

It's important to note that the job and future scope of mycelium bricks will also depend on the continued

development of the technology and the acceptance of mycelium bricks as a building material by the

construction industry and building code officials.

SOCIAL ACCEPTANCE OF CSEB AND MYCELIUM BRICK

CSEB bricks:

Demonstrated, since long, CSEB can adapt itself to various needs: from poor income to well off people or

governments. Its quality, regularity and style allow a wide range of final house products. To facilitate this

acceptation, banish from your language "stabilized mud blocks", for speaking of CSEB as the latter reports R & D

done for half a century when mud blocks referred, in the mind of most people, as poor building material.

Mycelium bricks:

The social acceptance of mycelium bricks as a building material may vary depending on the location and

community. In some areas, mycelium bricks may be seen as a new and innovative technology, and therefore

may be met with interest and acceptance. In other areas, mycelium bricks may be seen as an untested or

unfamiliar technology, and may face resistance from builders, architects, and building code officials.

In general, the social acceptance of mycelium bricks may be increased by educating members of the building

industry and the general public about the environmental benefits, cost-effectiveness and structural capabilities

of the mycelium bricks.

Additionally, building with mycelium bricks can be a great way to engage with local communities and promote

sustainable and environmentally friendly building practices.

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[1730]

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:05/Issue:05/May-2023 Impact Factor- 7.868 www.irjmets.com

It's important to note that the social acceptance of mycelium bricks may also depend on the quality of the final

product and the specific application. Buildings constructed with mycelium bricks that are well-built and meet

or exceed standard building codes are more likely to be accepted by the pu

SOME LIMITATIONS OF CSEB

Proper soil identification is required or unavailability of soil.

Unawareness of the need to manage resources.

Ignorance of the basics for production & use.

Wide spans, high & long building are difficult to do.

Untrained teams producing bad quality products.

Over-stabilization through fear or ignorance, implying outrageous.

Under-stabilization resulting in low quality products.

Bad quality or un-adapted production equipment.

Low Social Expectance.

Strength and durability can vary depending on the quality of the soil used to make the blocks and the

compaction method used.

May not match the strength of traditional bricks or concrete blocks, so they may not suitable for load-

bearing walls or structures that need to support heavy loads.

Availability of soil, cement, and water required to make the blocks may not be available or accessible in

certain regions.

Depends on soil availability and quality, the production process may not be consistent in different regions.

Some regions may not have the equipment and expertise to produce CSEB blocks, and hence may not be

easily accessible.

SOME LIMITATIONS OF MYCELIUM BRICK

Are a relatively new building material and still in the early stages of research and testing, hence the long-

term properties such as durability, fire resistance and structural strength are not yet fully understood.

Not yet widely available and may not be produced in large quantities, which could limit their use in large-

scale construction projects.

Production process still in development stages, hence quality and consistency may vary between batches.

As the material is not yet widely used, there may be lack of standardized testing and building codes

available.

Not all types of agricultural waste can be used for production, limiting availability of raw materials.

XI. OPTIMIZATION OF INVESTMENT/OUTPUT / QUALITY RATIO

Light manual equipment presents the advantage of being cheap, but the disadvantage of a low durability, a low

output and not very well compressed blocks. Heavy manual equipment presents a more interesting ratio, with

more output, more durability and more strength for a subsequent increase of costs. Motorized equipment steps

into another category of cost: it will produce better quality blocks with more output, but more expensive.

Therefore, heavy manual presses are most of the time the best choice in terms of optimization for the

investment/output/quality ratio. Mobile-units are always coming far behind. Industrialization is not adapted to

the production of CSEB. Semi industrialization is the best: it offers the advantage to be more flexible and easily

adapted to a local context. It increases the quality without increasing tremendously the cost of a block. Semi

industrialization should be understood here as a centralized production, but rather with manual presses than

motorized ones.

Table 5. Physical properties of Mycelium, CSEB, Red Bricks

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[1731]

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:05/Issue:05/May-2023 Impact Factor- 7.868 www.irjmets.com

PROPERTIES MYCELIUM BRICKS CSEB BRICKS RED BRICKS

Compressed Stabilized

Earth Brick (CSEB), also

A mycelium brick is an

known as Pressed Earth A Red brick is a single unit of a

organic brick that is formed

Brick, are a type of ceramic i.e., clay material used in

Definition from organic waste and the

construction material masonry construction.

mycelium of fungus.

created by compressing

moist earth under high

pressure to form blocks.

Compressed Stabilized

Mycelium are the thin root- Earth Blocks (CSEB),

like fibers from fungi which commonly called, Pressed

Red bricks are made by mixture

run underneath the ground, Earth Blocks, are

of clay (alumina), sand, lime,

when dried it can be used as construction material made

iron oxide and magnesia. Sand

a super strong, water, mold using damp soil under high

Composition from locally available natural

and fire-resistant building amount of pressure to form

soil is used for production of

material that can be grown blocks. They are composed

bricks.

into specific forms, thus of dry inorganic subsoil,

reducing the processing non-expansive clay,

requirements. aggregates and Portland

cement.

Red bricks are strong, hard,

and durable; therefore, they

are used as a structural

Mycelium materials are CSEBs are an material in different structures

durable and naturally fire environmentally friendly such as buildings, bridges,

resistant, and they can be alternative to clay bricks foundations, arches and

Durability

easily molded to any shape. that most of the residential cornices, and pavements. Red

Moreover, they are construction in India today bricks are also used for

environmentally friendly. uses. aesthetic purposes such as

facing bricks, architectural

purposes, exposed practice

work and in landscaping.

Standard modular sizes Standard modular sizes are:

Standard modular sizes

are: 190x90x90mm

are:

Sizes 200x90x60 mm 190x90x40mm

190x90x90 mm

225x100x75 mm 230x110x70

190x90x40 mm

230x110x30

Depending upon class of the red

bricks, its compressive strength

Depending upon class of

ranges from 3.5 to 35 N/mm2.

The average compressive the CSEB bricks, its

Compressive Though IS code providing

strength of the mycelium compressive strength

Strength maximum strength of 35

brick is 13.1 N/mm2. ranges from 75 to 150

N/mm2, the maximum strength

N/mm2.

that is available in the market is

7.5 N/mm2.

Water absorption of Water absorption of fly Water absorption of brick should

Water

mycelium bricks should not CSEB bricks should not be not be more than 20% of its

Absorption

be more than 20 % of its more than 12.5 – 15% of its weight.

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[1732]

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:05/Issue:05/May-2023 Impact Factor- 7.868 www.irjmets.com

weight. weight.

0.6 – 1.0 W/m K. The amount of

heat transfer from a specific

Thermal conductivity of

Thermal conductivity for material is called its thermal

Thermal mycelium brick is 0.078-

CSEB blocks ranges from conductivity. The thermal

Conductivity 0.081 W/m K.

0.52-0.93 W/m. conductivity of brick is high, and

hence heat transfer from brick is

more than that of AAC blocks.

Red bricks are not termite

Mycelium bricks do not

Pest CSEB bricks have excellent resistant as they are made from

spread termites and pests.

Resistance insect resistance. clay which is an organic

material.

Average 10 to 12 % or even

more breakage happens on

construction site depending

Negligible breakage. Almost Negligible breakage. Almost upon the quality of bricks. So

Breakage 100% utilization is possible. 100% utilization is 100% utilization is not possible.

possible. Even at some place, due to the

poor quality of bricks, wastage

goes up to 33%, while loading,

unloading, etc.

By using mycelium there is

a huge reduction on the

Red brick is not a green product.

reliance on fossil fuels, the

Red bricks are made from the

embodied energy required

clay which is naturally available

for fabrication and a CSEB bricks have less

material but it reduces the top

Carbon massive reduction in the carbon emission as

fertile soil cover. Hence, the land

Emission building waste which is left compared to fly ash and red

available for agriculture gets

at the end of the product’s bricks.

reduced. More amount of CO2 is

life as the mycelium product

emitted during the

is 100 percent

manufacturing of red bricks.

biodegradable and can be

used as soil.

They are cheaper as compared to

Mycelium brick are low cost CSEB blocks are costlier as other masonry units. However,

Cost and can be easily produced compared to red bricks and overall cost is more, as it

fly ash bricks. requires more mortar both for

joints and plaster.

XII. CONCLUSION

This project presented a brief overall review on CSEB bricks. In this, we have done a brief review on

Compressed Stabilized Earth Brick (CSEB). Previous researches showed that compressed earth bricks

demonstrate many advantages compare to conventional fired bricks. Compressed stabilized earth bricks are

ultimately greener, ecofriendly, comparable in strength, durability and thermal conductivity. The use of

compressive earth bricks also promotes healthier living for the building dwellers. Still, it has many possibilities

to explore more in enhancing its properties. And this project has social benefits also like energy effectiveness,

less maintenance etc. The economic benefits and contribution of CSEB bricks for sustainable development have

also been outlined. Since the CSEB brick is a whole new concept of bricks with new technology no Indian

Standards are available, so a detailed study on the chemistry behind the CSEB bricks is needed. Now a detailed

study thereafter should be needed for making of bricks cheaper and useful than that of standard brick so it can

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[1733]

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:05/Issue:05/May-2023 Impact Factor- 7.868 www.irjmets.com

be introduced into the market. Mycelium could bring a huge change in construction industry and transform the

commerce because of its maintainable design practices. The current study used oyster spawn, as it seemed

from current research that it would produce a stronger and stiffer mycelium which is also used by some

currently experimenting in this field. The making of bio-composite mycelium bricks as maintainable

construction building materials using agricultural waste. 'Mushroom materials' are a novel class of renewable

biomaterial grown from fungal mycelium and low-value non-food agricultural materials using a patented

process developed by Ecovative Design. This pure mycelium which grew at the edges and between the flat

faces of the molds was also an unexpected discovery. As there were only small pieces of this material, we could

not test its strength. These bricks are not suitable for water logging and external walls. It can be used in inner

partition walls. Mycelium bricks have excellent insulation properties, as they are made from a porous material

that can trap air and reduce heat loss.

XIII. FUTURE SCOPE

The research conducted emphasizes on the advantages of using CSEB for better living. As it promotes healthier

building material and cost reducing not only in production but also in service cost. Although economic potential

may attract more rather than ecological reasons, the full-scale production of compressed stabilized earth bricks

has demonstrated that this kind of building material have a great potential in the future for low to medium cost

housing construction and contribute on sustainable development. To date the mycelium was not so normal but

rather on future premise there is part of utilization of mycelium in numerous development materials. Like it

can supplant the thermocol that are utilized for protection and numerous different works Additionally it can

supplant wood since the mycelium can utilized to develop engineered wood and that wood is considerably

more grounded than ordinary wood and furthermore it will supplant cowhide as the calfskin we develop from

mycelium are substantially more grounded and no longer creature skin is required to develop calfskin. Many

things can be made of the mycelium. In future there is immense utilization of mycelium in development and in

different things.

XIV. SUMMARY

This project presented a brief overall review on CSEB bricks. In this, we have done a brief review on

Compressed Stabilized Earth Brick (CSEB). Previous researches showed that compressed earth bricks

demonstrate many advantages compare to conventional fired bricks. Compressed stabilized earth bricks are

ultimately greener, ecofriendly, comparable in strength, durability and thermal conductivity. The use of

compressive earth bricks also promotes healthier living for the building dwellers. Still, it has many possibilities

to explore more in enhancing its properties. And this project has social benefits also like energy effectiveness,

less maintenance etc. The economic benefits and contribution of CSEB bricks for sustainable development have

also been outlined. Since the CSEB brick is a whole new concept of bricks with new technology no Indian

Standards are available, so a detailed study on the chemistry behind the CSEB bricks is needed. Now a detailed

study thereafter should be needed for making of bricks cheaper and useful than that of standard brick so it can

be introduced into the market. Mycelium could bring a huge change in construction industry and transform the

commerce because of its maintainable design practices. The current study used oyster spawn, as it seemed

from current research that it would produce a stronger and stiffer mycelium which is also used by some

currently experimenting in this field. The making of bio-composite mycelium bricks as maintainable

construction building materials using agricultural waste. 'Mushroom materials' are a novel class of renewable

biomaterial grown from fungal mycelium and low-value non-food agricultural materials using a patented

process developed by Ecovative Design. This pure mycelium which grew at the edges and between the flat

faces of the molds was also an unexpected discovery. As there were only small pieces of this material, we could

not test its strength. These bricks are not suitable for water logging and external walls. It can be used in inner

partition walls. Mycelium bricks have excellent insulation properties, as they are made from a porous material

that can trap air and reduce heat loss.

XV. REFERENCES

[1] BS 5628: PART 1: 1992, CODE OF PRACTICE FOR USE OF MASONRY, British Standards Institute, United

Kingdom

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[1734]

e-ISSN: 2582-5208

International Research Journal of Modernization in Engineering Technology and Science

( Peer-Reviewed, Open Access, Fully Refereed International Journal )

Volume:05/Issue:05/May-2023 Impact Factor- 7.868 www.irjmets.com

[2] BAHAR R, BENAZZOUNG Mand KENAI S., Performance of compacted cement stabilized soil, Cement &

Concrete composites, 26, 811-820, 2004.

[3] Jaafar M.S., Thanoon W.A., Najm A. M. S., Abdulkadir M.R., Ali A.A.A., Strength correlation between

individual block, prism and basic wall panel for load bearing interlocking mortarless hollow block

masonry, Construction and Building Materials, 20, (2006), 492 -498.

[4] Kasthurba A.K., Santhanam M., Mathews M.S., Investigation of laterite stones for building purpose from

Malabar region, Kerela State, SW Indi a - Part I, Field studies and profile characterization, Construction

and Building Materials, 21, (2007), 73 -82

[5] WALKER P and MANJATID1S V., A review of m111111ed cart/; co11slmclio11, Natural Building

Technology group, Department of Architecture and Civil Engineering, University of Bath, United

Kingdom, 2003.

[6] HEATHCOTE K.A., Durability of earth wall buildings, Construction and Building Materials,; 9(3), 185-

189, 1995

[7] HENRY A.W., Structural Masonry, Mac million Press, London, P 284, 1990,

[8] NEW MEXICO EARTHEN BUILDING MATERIAL CODE, 2003.

[9] NZS 4297: 1998, NEW ZEALAND STANDARDS, Engineering design of earth buildings, Standard New

Zealand, Wellington, New Zealand

[10] Easton, D. (2007), The rammed earth house, Chelsea Green

[11] Faure, X. & Le Roux, N. (2012). “Time dependent flows in displacement ventilation considering the

volume envelope heat transfers”, Building and Environment, 50; 221- 230.

[12] Wagner, A., Kleber, M. and Parker, C. (2007). “Monitoring Results of a Naturally Ventilated and

Passively Cooled Office Building in Frankfurt, Germany”, International Journal of Ventilation, 6; 3-20.

[13] Orosa, J. A. and Oliveira, A. C. (2012). “A field study on building inertia and its effects on indoor thermal

environment”, Renewable Energy, 37; 89-96.

www.irjmets.com @International Research Journal of Modernization in Engineering, Technology and Science

[1735]

You might also like

- Theory of Structures Assignment FinalDocument21 pagesTheory of Structures Assignment FinalManasAroraNo ratings yet

- Purification of Contaminated Air From The Spinning Mill and Transformation of Microdust As Flyash For Structural FillingDocument4 pagesPurification of Contaminated Air From The Spinning Mill and Transformation of Microdust As Flyash For Structural FillingIJRASETPublicationsNo ratings yet

- Ijri Cce 02 008Document8 pagesIjri Cce 02 008ijripublishersNo ratings yet

- Studies On Stabilized Mud Block As A Construction MaterialDocument6 pagesStudies On Stabilized Mud Block As A Construction MaterialIJIRAE- International Journal of Innovative Research in Advanced Engineering100% (1)

- Research ProposalDocument3 pagesResearch ProposalMer Aily Dela CruzNo ratings yet

- ef04f4ed-2123-49c5-8d4f-eeec575b8c28Document10 pagesef04f4ed-2123-49c5-8d4f-eeec575b8c28Thiran Boy LingamNo ratings yet

- Utilization of Waste Plastic in Manufacturing of BricksDocument6 pagesUtilization of Waste Plastic in Manufacturing of BricksIJRASETPublications100% (1)

- Mycelium Brick 1Document9 pagesMycelium Brick 1Aromal psNo ratings yet

- Utilization of Non - Biodegradable Material For Repairing PotholesDocument7 pagesUtilization of Non - Biodegradable Material For Repairing PotholesIJRASETPublicationsNo ratings yet

- SYNOPSIS Bio BrickDocument5 pagesSYNOPSIS Bio BrickGopal mutkekarNo ratings yet

- Group 12Document20 pagesGroup 12Dhananjay DesaleNo ratings yet

- Polymer Fiber Reinforced Concrete PavementsDocument5 pagesPolymer Fiber Reinforced Concrete PavementsIJRASETPublicationsNo ratings yet

- An Overview Low Cost House Materials TechniquesDocument6 pagesAn Overview Low Cost House Materials TechniquesshubhamNo ratings yet

- Utilization of Coconut Shell As Greener ConcreteDocument9 pagesUtilization of Coconut Shell As Greener ConcreteIJRASETPublicationsNo ratings yet

- Papercrete Brick PDFDocument12 pagesPapercrete Brick PDFArul Vanan100% (7)

- Coir Fibre Used in Reinforced ConcreteDocument6 pagesCoir Fibre Used in Reinforced ConcreteVIVA-TECH IJRINo ratings yet

- EcoBrick A Waste Plastic Used As Construction MaterialDocument6 pagesEcoBrick A Waste Plastic Used As Construction MaterialIJRASETPublicationsNo ratings yet

- A Review On Utilization of Ppe in Construction Projects For Sustainable DevelopmentDocument7 pagesA Review On Utilization of Ppe in Construction Projects For Sustainable Developmentkushreal100No ratings yet

- Efficacy of Bacterial Concrete With Conventional ConcreteDocument10 pagesEfficacy of Bacterial Concrete With Conventional ConcreteIJRASETPublicationsNo ratings yet

- The Investigational The Effects of Waste Products Such As Wood Ash, Sugarcane Bagasse Ash, and Rice Husk Ash On The Durability of ConcreteDocument6 pagesThe Investigational The Effects of Waste Products Such As Wood Ash, Sugarcane Bagasse Ash, and Rice Husk Ash On The Durability of ConcreteIJRASETPublicationsNo ratings yet

- 12 Vol. 2, Issue 4, IJPSR, 2011, Paper 2Document4 pages12 Vol. 2, Issue 4, IJPSR, 2011, Paper 2Hilary WatsonNo ratings yet

- Bacterial ConcreteDocument6 pagesBacterial ConcreteIJRASETPublicationsNo ratings yet

- Binding Material in Pavement Block Made From Waste PlasticDocument5 pagesBinding Material in Pavement Block Made From Waste PlasticAbdelrahman AshmawyNo ratings yet

- A Survey On Design of Pavement Blocks Made From Waste of Plastic, Glass & Aluminum FoilDocument5 pagesA Survey On Design of Pavement Blocks Made From Waste of Plastic, Glass & Aluminum FoilIJRASETPublicationsNo ratings yet

- Application of Bacterial SporesDocument13 pagesApplication of Bacterial SporesasdasdasdasNo ratings yet

- Testing On Specimen - 6Document14 pagesTesting On Specimen - 6Dhruv ThakkarNo ratings yet

- Experimental Study On Influence of Bacteria in ConcreteDocument6 pagesExperimental Study On Influence of Bacteria in ConcreteIJRASETPublicationsNo ratings yet

- .Utilization of Plastic Waste and Artificial Sand in Manufacturing of Eco BricksDocument3 pages.Utilization of Plastic Waste and Artificial Sand in Manufacturing of Eco BricksSande NasNo ratings yet

- IRJET V8I-UniquenessofMudArchitectureDocument7 pagesIRJET V8I-UniquenessofMudArchitectureHarshita SaxenaNo ratings yet

- Papercrete4 PDFDocument9 pagesPapercrete4 PDFPrasad TekadeNo ratings yet

- Concrete Using Coconut Fiber - An AlternativeDocument4 pagesConcrete Using Coconut Fiber - An AlternativeSenthil KumarNo ratings yet

- Design Constructionand Performance Evaluationofa Coco Peat Block Making MachineDocument12 pagesDesign Constructionand Performance Evaluationofa Coco Peat Block Making MachinehariprasathNo ratings yet

- Utilization of Sisal Fiber in Portland Cement Concrete ElementsDocument6 pagesUtilization of Sisal Fiber in Portland Cement Concrete ElementsLucero Vasquez LopezNo ratings yet

- ProcessDocument13 pagesProcessDuy Khanh HuynhNo ratings yet

- Uniqueness of Mud Architecture: International Research Journal of Engineering and Technology (IRJET)Document6 pagesUniqueness of Mud Architecture: International Research Journal of Engineering and Technology (IRJET)Shrutie PatilNo ratings yet

- Mur Mur: StudioDocument38 pagesMur Mur: StudioMaria Fernanda Pinzon DussanNo ratings yet

- Experimental Investigation On Reinforced Concrete With Plastic FiberDocument6 pagesExperimental Investigation On Reinforced Concrete With Plastic FiberIJRASETPublicationsNo ratings yet

- A Survey On Use of Non-Recyclable Waste in ConstructionDocument9 pagesA Survey On Use of Non-Recyclable Waste in ConstructionIJRASETPublicationsNo ratings yet

- Failure Analysis of Compressed Earth Block Using Numerical PlasticDocument27 pagesFailure Analysis of Compressed Earth Block Using Numerical PlasticDaniela BaqueroNo ratings yet

- Research Article: Manufacturing of Ecofriendly Bricks Using Microdust Cotton WasteDocument10 pagesResearch Article: Manufacturing of Ecofriendly Bricks Using Microdust Cotton Wasteshinaiya StarNo ratings yet

- Application of Bio Bricks and Its BenefitsDocument10 pagesApplication of Bio Bricks and Its BenefitsSaud AfzalNo ratings yet

- Design and Fabrication of Eco-Brick Making MachineDocument5 pagesDesign and Fabrication of Eco-Brick Making MachineIJRASETPublicationsNo ratings yet

- Experimental Study of The Physical Properties of Concrete Prepared by Partial Replacement of Cement With Alccofine, Metakaolite and GGBSDocument21 pagesExperimental Study of The Physical Properties of Concrete Prepared by Partial Replacement of Cement With Alccofine, Metakaolite and GGBSIJRASETPublicationsNo ratings yet

- Sawdust Brick A Quantitative Study On Sawdust Substitute For Concrete Brick ProductionDocument21 pagesSawdust Brick A Quantitative Study On Sawdust Substitute For Concrete Brick ProductionChristian Andre FloresNo ratings yet

- 57 3 PDFDocument20 pages57 3 PDFAnonymous Qm0zbNkNo ratings yet

- Characteristics of Geopolymer Concrete Produced Using Banana Fiber and Coal AshDocument7 pagesCharacteristics of Geopolymer Concrete Produced Using Banana Fiber and Coal AshEmmanuel OgunjioforNo ratings yet

- Materials: Mechanical and Durability Performance of Coconut Fiber Reinforced Concrete: A State-of-the-Art ReviewDocument24 pagesMaterials: Mechanical and Durability Performance of Coconut Fiber Reinforced Concrete: A State-of-the-Art ReviewBenmark JabayNo ratings yet

- Use of Plastic Waste in Road Construction For SustDocument5 pagesUse of Plastic Waste in Road Construction For SustVenkateswarlu GajulaNo ratings yet

- Dolomite-Foamed Bioactive Silicate Scaffolds For Bone Tissue RepairDocument13 pagesDolomite-Foamed Bioactive Silicate Scaffolds For Bone Tissue RepairLuccas TeruelNo ratings yet

- Numerical Study of Two-Phase Flow in Centrifugal Dust CollectorsDocument6 pagesNumerical Study of Two-Phase Flow in Centrifugal Dust CollectorsResearch ParkNo ratings yet

- Some Aspects of The Effect of Porosity On Moisture Transfer in ConcreteDocument6 pagesSome Aspects of The Effect of Porosity On Moisture Transfer in ConcreteResearch ParkNo ratings yet

- Comparative Study of Sisal Fibre and Glass Fibre Reinforced Concrete - A ReviewDocument6 pagesComparative Study of Sisal Fibre and Glass Fibre Reinforced Concrete - A ReviewIJRASETPublicationsNo ratings yet

- Study On Experimental Behavior of Plastic Based Fiber As Secondary Reinforcement in Concrete PavementDocument13 pagesStudy On Experimental Behavior of Plastic Based Fiber As Secondary Reinforcement in Concrete PavementIJRASETPublicationsNo ratings yet

- BHANULATHADocument10 pagesBHANULATHALDavid FFelixNo ratings yet

- Sustainable Materials For Additive Manufacturing: Earth-Based ConcreteDocument11 pagesSustainable Materials For Additive Manufacturing: Earth-Based Concreteolivierm197No ratings yet

- Experimental Investigation of Waste Plastic Fiber in Reinforced Cement Concrete Using Recycled Coarse AggregateDocument12 pagesExperimental Investigation of Waste Plastic Fiber in Reinforced Cement Concrete Using Recycled Coarse AggregateInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- A Review On Utilization of Processed Inorganic Mixed Municipal Solid Waste by Mechanical Device in Manufacturing of BricksDocument6 pagesA Review On Utilization of Processed Inorganic Mixed Municipal Solid Waste by Mechanical Device in Manufacturing of BricksIJRASETPublicationsNo ratings yet

- A Brief Review of Compressed Stabilized Earth Brick CSEBDocument7 pagesA Brief Review of Compressed Stabilized Earth Brick CSEBMauricio SilesNo ratings yet

- An Experimental Study To Address The Issues of Low Durability and Low Compressive Strength of Mud PlasterDocument39 pagesAn Experimental Study To Address The Issues of Low Durability and Low Compressive Strength of Mud PlasterRafiq MirNo ratings yet

- Feasibility of Using Coconut Fibre To Improve Concrete Strength IJERTV11IS080072Document7 pagesFeasibility of Using Coconut Fibre To Improve Concrete Strength IJERTV11IS080072anunciano GuterresNo ratings yet

- CoreDocument5 pagesCoreNamsangLimbooNo ratings yet

- A Brief Review of Compressed Stabilized Earth Brick (CSEB) : Fetra Venny Riza Ismail Abdul RahmanDocument6 pagesA Brief Review of Compressed Stabilized Earth Brick (CSEB) : Fetra Venny Riza Ismail Abdul RahmanNamsangLimbooNo ratings yet

- English Sandbag ShelterDocument2 pagesEnglish Sandbag ShelterNamsangLimbooNo ratings yet

- Experimental Study of High Strength Concrete (M70) Using Manufactured SandDocument2 pagesExperimental Study of High Strength Concrete (M70) Using Manufactured SandNamsangLimbooNo ratings yet

- Janfeb 2021Document7 pagesJanfeb 2021NamsangLimbooNo ratings yet

- Lam 2019Document8 pagesLam 2019NamsangLimbooNo ratings yet

- Engineering Properties of Adobe Brick For Earth Structures: Napat SriwattanaprayoonDocument6 pagesEngineering Properties of Adobe Brick For Earth Structures: Napat SriwattanaprayoonNamsangLimbooNo ratings yet

- Activity 21 9Document34 pagesActivity 21 9NamsangLimbooNo ratings yet

- BTL2020 PrachiAiyer Track2Document8 pagesBTL2020 PrachiAiyer Track2NamsangLimbooNo ratings yet

- The Architectural Design of The ParthenoDocument35 pagesThe Architectural Design of The ParthenoNamsangLimbooNo ratings yet

- 2Document1 page2NamsangLimbooNo ratings yet

- McKean 1997LookingattheParthenonJoADocument32 pagesMcKean 1997LookingattheParthenonJoANamsangLimbooNo ratings yet

- Democracyand Design Essaysbystudentsof Mu IDKielDocument37 pagesDemocracyand Design Essaysbystudentsof Mu IDKielNamsangLimbooNo ratings yet

- 293 Standardized Coded Matrix For Secure Prepper CommunicationsDocument1 page293 Standardized Coded Matrix For Secure Prepper CommunicationsNamsangLimbooNo ratings yet

- 4Document1 page4NamsangLimbooNo ratings yet

- Transportation Lab PostersDocument8 pagesTransportation Lab PostersTushar WaleNo ratings yet

- Building SpecificationsDocument5 pagesBuilding Specificationsjologscresencia100% (1)

- Statement of The The Problem FEU Tech Building - 3Document3 pagesStatement of The The Problem FEU Tech Building - 3Matthew SumagueNo ratings yet

- ARCHITECTURAL ARTS in The PhilDocument5 pagesARCHITECTURAL ARTS in The PhilDamon KlausNo ratings yet

- How To Build A Pikler TriangleDocument24 pagesHow To Build A Pikler Trianglezopauy100% (1)

- Detailed Estimation of Building With Plan PDFDocument21 pagesDetailed Estimation of Building With Plan PDFsqqpqq1No ratings yet

- Sheets and Slates: Asbestos-CementDocument36 pagesSheets and Slates: Asbestos-CementNorfolkingNo ratings yet

- ANP Strand Anchor PDFDocument36 pagesANP Strand Anchor PDFGuoqiang LiuNo ratings yet

- Analysis of RatesDocument32 pagesAnalysis of Ratesprashantwathore100% (1)

- ADDMIX 152-v4 PDFDocument1 pageADDMIX 152-v4 PDFAnkita Baban GavadeNo ratings yet

- M. C. Abdul Malick Chartered Valuer: 54/3C Prathibimbarama Road, DehiwelaDocument3 pagesM. C. Abdul Malick Chartered Valuer: 54/3C Prathibimbarama Road, DehiwelaNaahidhNo ratings yet

- 000 Drainage Pipes, Fiitings and JointsDocument41 pages000 Drainage Pipes, Fiitings and Jointselcid agsamosamNo ratings yet

- Rock Bolting TechniqueDocument9 pagesRock Bolting TechniquesamratNo ratings yet

- Randfile 09Document32 pagesRandfile 09Sergio DiazNo ratings yet

- PSC Single SpanDocument60 pagesPSC Single Spanthanzawtun1981No ratings yet

- Whitehall Library - Case StudyDocument8 pagesWhitehall Library - Case StudyVidya SagarNo ratings yet

- Technical Data Sheet GlasGrid CGL EN 1960442Document2 pagesTechnical Data Sheet GlasGrid CGL EN 1960442vonskemaNo ratings yet

- Eco-Boards: A Green Building Material From Residues and WasteDocument26 pagesEco-Boards: A Green Building Material From Residues and WasteJaybesNo ratings yet

- CE 301-GeologyDocument1 pageCE 301-GeologychndriuhNo ratings yet

- PHILIPP Screw Anchor: Installation and Application InstructionDocument4 pagesPHILIPP Screw Anchor: Installation and Application InstructionHossein DoudiNo ratings yet

- HousekeepingDocument5 pagesHousekeepingCoca LeeNo ratings yet

- Purchase Request CARPENTRY NC IIDocument4 pagesPurchase Request CARPENTRY NC IICatherine Mae NacionNo ratings yet

- Prismatic Beam Design: C 11 D B SDocument8 pagesPrismatic Beam Design: C 11 D B SChristian Jay GamboaNo ratings yet

- Updated 7 Point Container Inspection SheetDocument2 pagesUpdated 7 Point Container Inspection SheetMohd Shahrul Irwan Mohd Zin0% (1)

- FYP Thesis 17ME16, 12,14Document42 pagesFYP Thesis 17ME16, 12,14Sharjeel AhmedNo ratings yet

- 2.AquaArm SBS 3000XDocument3 pages2.AquaArm SBS 3000XBijaya RaulaNo ratings yet

- Farm StructuresDocument6 pagesFarm StructuresErika HonorioNo ratings yet

- Piping, Hydro QC List-InterviewDocument3 pagesPiping, Hydro QC List-InterviewAnonymous 4e7GNjzGW100% (2)

- Portal Ratol & Rates Premo: Surface Drainage RM 1500.00 1500.00Document2 pagesPortal Ratol & Rates Premo: Surface Drainage RM 1500.00 1500.00Nur Syahidah AzmiNo ratings yet