Professional Documents

Culture Documents

PowerPoint Presentation1

PowerPoint Presentation1

Uploaded by

Feyissa EndebuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PowerPoint Presentation1

PowerPoint Presentation1

Uploaded by

Feyissa EndebuCopyright:

Available Formats

Welcome

Lisa Jerram

Director-Bus Programs and Emerging Vehicle

Technologies

APTA

Washington, DC

Staff Advisor

APTA Bus Technical Maintenance Committee

Electrical Circuit

Troubleshooting

APTA Bus Technical Maintenance Committee Webinar March 31,2020

Electrical Circuit Troubleshooting Webinar I 2

Housekeeping Moderator

• This webinar will be recorded and Obed Mejia

made available on APTA’s website Senior Bus Equipment Maintenance Instructor

LA Metro

• All attendee phone lines are muted Los Angeles, CA

• To ask a question, use the Questions

panel; questions will be answered at Vice Chair-Webinars

the end of the presentations APTA Bus Technical Maintenance Committee

Electrical Circuit Troubleshooting Webinar I 3 Electrical Circuit Troubleshooting Webinar I 4

Objectives Presenter

Attendees will learn about: Andrew Warren, Jr.

1. Performing circuit testing to identify open circuit Equipment Maintenance Instructor

2. Performing a voltage drop test to identify high resistance conditions LA Metro

3. Identifying faulty ground conditions Los Angeles, CA

Electrical Circuit Troubleshooting Webinar I 5 Electrical Circuit Troubleshooting Webinar I 6

Introduction Open Circuits

The most common electrical circuit faults you will encounter when working on bus electrical systems A circuit is said to be OPEN when a break exists in the

are: open circuits; short circuits; and high resistance. path of current flow. Although an open occurs when a

Open Circuit - any break (open) in the current path of a series circuit makes the entire circuit switch is used to de-energize a circuit, an open may

inoperative. In a parallel circuit, only the branch effected by the open is inoperative. also develop accidentally. To restore a circuit to

proper operation, the open must be located and

Short Circuit - this can be a short-to-ground or short-to-voltage. This may cause a component to repairs made.

continuously operate regardless of switch position, or a fuse to repeatedly blow, depending on the

fault. In circuits with an open check for:

Unwanted Resistance - the load device does not receive the proper voltage/current to perform work • Loose connectors, pins and terminals

and may operate sluggishly, dim, or not operate at all. • Broken grounds

• Physical damage to the harness or vehicle

Electrical Circuit Troubleshooting Webinar I 7 Electrical Circuit Troubleshooting Webinar I 8

Troubleshooting an Open Circuit Troubleshooting an Open Circuit

Find the open by measuring voltage: The best method for diagnosing an open circuit is by

measuring voltage. When that is not possible, measure

1. Measure voltage level at the fuse.

resistance following the steps below.

2. Work your way point by point toward the

circuit ground. 1. Remove the circuit fuse.

2. Measure resistance between circuit ground and a

3. Continue until you find a point where

circuit point closest to fuse; at this point you

voltage is no longer present. The open is

should measure OL or very high resistance.

between the last two measured points.

3. Work your way toward ground, point by point.

Continue until you find a point where continuity

is present. The open is between the last two

measured points. From this point you may have

to further isolate using the method above.

Electrical Circuit Troubleshooting Webinar I 9 Electrical Circuit Troubleshooting Webinar I 10

Short Circuits Short Circuits

A short circuit is a fault that creates an unwanted path between two parts of a circuit, or a short can In circuits with a short-to-ground or voltage, check for:

bridge two circuits together. • Previous repairs.

A short can be: • Physical damage to the harness or vehicle.

• An unwanted path between part of a circuit and ground (short to ground). • Equipment installed with sheet metal screws that have pierced a harness.

• An unwanted path between two separate circuits (short to power/wire to wire).

• An unwanted path between two parts of a circuit, some of the loads may be bypassed on circuit.

• An unwanted current path inside a component, internal resistance of load too low.

Most common short circuit is short to ground. This short typically blows the circuit fuse or pops the

breaker.

Note: It may not be possible to troubleshoot the circuit under its own power.

Electrical Circuit Troubleshooting Webinar I 11 Electrical Circuit Troubleshooting Webinar I 12

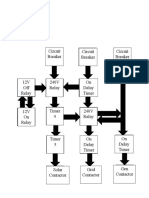

Troubleshooting a Short in Series Circuit Troubleshooting a Short in Series Circuit –

The circuit shown is shorting to ground External Load

before the load. The short can be found

in one of two ways: For some faults, using tools other than a DMM may help diagnose a fault faster. If there is a short to

ground in a series circuit, a test light may help you pinpoint the short location.

• Checking resistance

1. Remove the fuse.

• Using an external load

2. Jumper in an external load (a light works well for this).

3. Apply power to the circuit- the light will turn ON.

4. Start by disconnecting the connection point closest to the external load and work your way towards

ground.

5. The light will continue to remain lit when you disconnect the section past the short.

Electrical Circuit Troubleshooting Webinar I 13 Electrical Circuit Troubleshooting Webinar I 14

Troubleshooting a Short in Series Circuit – Troubleshooting a Short in Series Circuit –

External Load Measuring Resistance

If a circuit has a high resistance, then we could use a DMM to help locate which part of the circuit

has the fault. Set the DMM to read Ohms, and then remove all voltage from the circuit by

disconnecting the batteries or removing the fuse.

1. Disconnect the connection point closest to the power source.

2. Connect the meter to the connection point closest to the power source and ground.

Note: The measured resistance here should be close to 0Ω. Leave the meter in place.

3. Disconnect the next accessible connection point moving towards ground.

4. The point where continuity is lost is where the short is located.

Electrical Circuit Troubleshooting Webinar I 15 Electrical Circuit Troubleshooting Webinar I 16

Unwanted Resistance Circuit Faults Unwanted Resistance Circuit Fault

Unwanted resistance in a circuit can prevent it from operating normally. Unwanted Resistance Faults cause a load to

perform less work than it was intended to and

• Unwanted resistance in a circuit can be a poor connection, burned pin, corroded wire / terminal

is caused in most cases by:

or a faulty component.

• Loose or corroded connector

• Normal Resistance in a healthy circuit should be very close to 0 ohms using no voltage when the

circuit in ON. Higher resistance indicates a possible problem. A dim bulb can be an indicator of • Improper wiring repair

high resistance. • Internal wire corrosion

This unwanted resistance can best be detected when the circuit is ON by performing voltage drop • Defective Load

measurements.

Note – in a lot of cases unwanted resistance

increases as the temperature of the circuit

increases during operation.

Electrical Circuit Troubleshooting Webinar I 17 Electrical Circuit Troubleshooting Webinar I 18

Unwanted Resistance Circuit Fault Voltage Drop Measurements

The best way to diagnose unwanted resistance faults is by measuring voltage: Measuring voltage drop is one of the most useful tests you can perform. A voltage drop test checks

for loss of voltage in each portion of the circuit while the circuit is connected, powered and

Source voltage - this is the voltage measured at the beginning of the circuit.

operated.

Available voltage - this is the voltage available to the load.

Note: Voltage drop testing requires you to back probe, all components remain connected during

Load voltage drop - this is the voltage used by the load. testing.

A voltage drop test is done as follows:

1. Place the positive lead in the most positive section of the circuit you are testing.

2. Place the ground lead on the most negative section of the circuit you are testing.

3. Operate the circuit with the meter leads in place and note the reading.

Remember that voltage dropped is voltage consumed by resistance in the circuit.

Electrical Circuit Troubleshooting Webinar I 19 Electrical Circuit Troubleshooting Webinar I 20

Measuring Source Voltage Measuring Available Voltage

This measurement is done at the source of voltage

For the circuit. This could be at:

This measurement is done at the component.

1. The batteries

This is the amount of voltage available to

2. Fuse Panel

3. Control Module the component to operate. This reading

should be just under what the source

measurement is.

This test is considered voltage drop because you are

measuring the drop between the source and ground.

Circuit voltage drop should equal source voltage.

Electrical Circuit Troubleshooting Webinar I 21 Electrical Circuit Troubleshooting Webinar I 22

Measuring Voltage Drop Measuring Voltage Drop

Voltage drop is the amount of voltage consumed

by the circuit. Voltage drop of individual

components, sections of circuit or connections. Voltage drop thru

• Voltage drop is voltage consumed. connections should be

• Voltage should only drop at the load in a minimal – close to 0V.

circuit.

• Voltage drop in other areas indicates high

resistance.

Voltage should only be used at the loads; voltage

used in other areas such as connectors or wiring

is unwanted resistance.

Electrical Circuit Troubleshooting Webinar I 23 Electrical Circuit Troubleshooting Webinar I 24

High Resistance on Ground Sample Avoid Open Circuit Measurements

This sample shows the light is inoperative even Before we get started, keep in mind that,

though the circuit is ON. when performing voltage measurements,

After testing the source voltage, available voltage, and the circuit must be on.

voltage drop of the light the condition was isolated to Even though you have heard it, done it,

a faulty ground wire. and seen it before, do not disconnect

As shown by the meter 25.2 volts are being used on wires to check for voltage.

the ground side of the circuit not leaving enough This is a common mistake; the readings

voltage for the light bulb to operate. will be open circuit readings. Any

resistance in the circuit unless

proportionally high in comparison to the

meter internal resistance will not be

detected.

Electrical Circuit Troubleshooting Webinar I 25 Electrical Circuit Troubleshooting Webinar I 26

Open Circuit Reading – Bad Experience Wiggle Test

Condition: No Start - Repeat Road Calls. Intermittent electrical problems are

A mechanic is working on a No Start condition on a Cummins gas engine. During the diagnosis, an active code for throttle plate common yet difficult to isolate. The

position sensor low input voltage is found. As part of the diagnostic procedure, the mechanic checks for available voltage to the throttle ‘wiggle test’ will determine if there is an

plate and measures 12.5V. Since there is full battery voltage available to the throttle, the mechanic concludes that the throttle plate is intermittent loose connection or broken

defective and needs replacement. The mechanic replaces the throttle plate, but the No Start condition does not go away.

wire. Physically move harness and

What did the mechanic do wrong? As part of the diagnostic process, the mechanic checked available voltage to the throttle plate and connectors while monitoring the DMM

found 12.5 volts. It is here where a serious mistake was made: when the mechanic made the measurement, the throttle plate connector with the circuit operating. Readings

was disconnected. As some of you may know, it is easier to disconnect this component and check it, than it is to back probe it. The

reading of 12.5 volts was actually an open circuit reading which did not reflect high resistance in the circuit.

should remain constant and should not

fluctuate. If readings fluctuate in a

When another mechanic took over the repair, the same diagnostic procedure was performed. This time however, available voltage was

certain area, inspect wiring and/or

checked with the throttle plate connected, and the measured voltage was 3V, indicating high resistance on the supply wire. Further

testing revealed a loose connector behind the fuse box. An easy replacement of the connector terminal pins took care of the problem. connectors.

So remember, when measuring voltage on any circuit, NEVER OPEN THE CIRCUIT.

Electrical Circuit Troubleshooting Webinar I 27 Electrical Circuit Troubleshooting Webinar I 28

Summary Thank You!

Proper diagnosis of electrical circuits is key to successfully repairing buses the first time. A recording of this webinar will be available on www.apta.com.

Remember! All diagnostic tests done correctly will get you to the problem.

Our preference is to perform voltage test whenever possible since the circuit in ON while

is being tested. This simulates more closely a real-world situation. Please complete the post webinar evaluation. A link to the online

evaluation will be emailed to you this afternoon.

Electrical Circuit Troubleshooting Webinar I 29 Electrical Circuit Troubleshooting Webinar I 30

You might also like

- Elevator Troubleshooting & Repair: A Technician's Certification Study GuideFrom EverandElevator Troubleshooting & Repair: A Technician's Certification Study GuideRating: 4 out of 5 stars4/5 (9)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 4 out of 5 stars4/5 (2)

- 2318-RA 18.03.2023-REV 0A Cutting The Leg Bracing - RIG Rig LovansingDocument9 pages2318-RA 18.03.2023-REV 0A Cutting The Leg Bracing - RIG Rig LovansingHafeez AliNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- Automated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsFrom EverandAutomated Broad and Narrow Band Impedance Matching for RF and Microwave CircuitsNo ratings yet

- InternshipDocument26 pagesInternshipfawwaz sazalliNo ratings yet

- QEG Opensourced Build Manual 25-Mar-15Document76 pagesQEG Opensourced Build Manual 25-Mar-15Naicheval RobitaiNo ratings yet

- Servicing The GE AMX4/4+ Portable X-Ray System: Course OutlineDocument1 pageServicing The GE AMX4/4+ Portable X-Ray System: Course OutlineMai Thanh SơnNo ratings yet

- 1309 5457Document6 pages1309 5457ElafanNo ratings yet

- Analysis and Optimization of 132KV Grid Using ETAP PDFDocument6 pagesAnalysis and Optimization of 132KV Grid Using ETAP PDFAlejandro PalaciosNo ratings yet

- Partial Discharge Testing For Cables: Electrical Reliability ServicesDocument4 pagesPartial Discharge Testing For Cables: Electrical Reliability ServicesTommy SiddiqNo ratings yet

- Conference 101719 PDFDocument5 pagesConference 101719 PDFUtkarsh LavateNo ratings yet

- 4su18ee400 SeminarDocument12 pages4su18ee400 SeminarAkshay NaikNo ratings yet

- APTA Presentation Basic Electrical Circuit Diagnosis Final DraftDocument30 pagesAPTA Presentation Basic Electrical Circuit Diagnosis Final DraftMaulidani RakhmadNo ratings yet

- Reliability & Failure AnalysisDocument31 pagesReliability & Failure AnalysisAshraf YusofNo ratings yet

- Core 1 EimDocument108 pagesCore 1 Eimkentcarlopaye08No ratings yet

- Update - Field Testing Capacitor Bank With M4000 Test Instrument Long Pong, Doble Engineering Company Daryl Wheat, Big River Electric CorporationDocument6 pagesUpdate - Field Testing Capacitor Bank With M4000 Test Instrument Long Pong, Doble Engineering Company Daryl Wheat, Big River Electric Corporationupt vadodaraNo ratings yet

- Cable Fault Location MethodsDocument10 pagesCable Fault Location MethodsPaulo Cardoso0% (1)

- Diagnosing Voltage Drops Electrical Automotive Troubleshooting - FlukeDocument1 pageDiagnosing Voltage Drops Electrical Automotive Troubleshooting - Flukemecanidec La MotteNo ratings yet

- General Troubleshooting CANDocument8 pagesGeneral Troubleshooting CANjonNo ratings yet

- Substation Design ApplicationDocument405 pagesSubstation Design Applicationwasimwalayat100% (1)

- Substation Design Application GuideDocument405 pagesSubstation Design Application GuideHana Ben JaballahNo ratings yet

- Current Transformer Basics - Understanding Ratio, Polarity, and ClassDocument25 pagesCurrent Transformer Basics - Understanding Ratio, Polarity, and ClassSàazón KasulaNo ratings yet

- Chapter 4Document7 pagesChapter 4MaxwellNo ratings yet

- Breaker Timing - ZensolDocument20 pagesBreaker Timing - ZensolIsmail Azad100% (1)

- Circuit Analysis and Troubleshooting PowerpointDocument6 pagesCircuit Analysis and Troubleshooting PowerpointAzmeer ReemzaNo ratings yet

- Fault Diagnosis of Three-Phase PWM Inverters Using Wavelet and SVMDocument9 pagesFault Diagnosis of Three-Phase PWM Inverters Using Wavelet and SVMbensumbbNo ratings yet

- A Novel Online Technique To Detect Power Transformer Winding FaultsDocument9 pagesA Novel Online Technique To Detect Power Transformer Winding FaultsV S B Chaitanya DuvvuryNo ratings yet

- Technical Training Safety Training: Eaton's Electrical Services & SystemsDocument12 pagesTechnical Training Safety Training: Eaton's Electrical Services & Systemsjunior_jazzzNo ratings yet

- Ethiopia Maritime Training Institute CirDocument48 pagesEthiopia Maritime Training Institute CirADDIS JOHNNo ratings yet

- Protective Relay TestingDocument9 pagesProtective Relay TestingluhusapaNo ratings yet

- WRK PDFDocument5 pagesWRK PDFRaghul RamasamyNo ratings yet

- PSP 11Document7 pagesPSP 11Muhammad AnsNo ratings yet

- Teaching in Circuit Test Ict Techniques in Electrical Engineering TechnologyDocument5 pagesTeaching in Circuit Test Ict Techniques in Electrical Engineering TechnologySanjay ParelkarNo ratings yet

- Agenda of 2 Days TrainingDocument1 pageAgenda of 2 Days TrainingMD ShaejNo ratings yet

- Electricalnotes Wordpress Com 2011 06 07 Low Voltage and High Voltage Cable TestingDocument13 pagesElectricalnotes Wordpress Com 2011 06 07 Low Voltage and High Voltage Cable TestingArie Amri MartaNo ratings yet

- 1 46Document5 pages1 46Dedit Gunarso PutroNo ratings yet

- Ijet V3i2p17Document6 pagesIjet V3i2p17International Journal of Engineering and TechniquesNo ratings yet

- Mv-105 Cable - Field Acceptance Testing - A Cable Manufacturer'S PerspectiveDocument7 pagesMv-105 Cable - Field Acceptance Testing - A Cable Manufacturer'S PerspectiveMarcelo Gomes PlanteirNo ratings yet

- IEEE PQ Case-1Document33 pagesIEEE PQ Case-1TienRienNo ratings yet

- Analysis of Three Phase Transmission Line Fault Using Matlab SimulinkDocument8 pagesAnalysis of Three Phase Transmission Line Fault Using Matlab SimulinkEEE 01 AATHI KESAVAN G 2021No ratings yet

- Root-Cause Analysis of Transformer Failure Scenario at Power Sub-StationDocument6 pagesRoot-Cause Analysis of Transformer Failure Scenario at Power Sub-StationShashank ChawdharyNo ratings yet

- Technical Submittal - Electrical ModificationDocument8 pagesTechnical Submittal - Electrical ModificationsaravananNo ratings yet

- Grounding Equipment: Catalog 3000 March 2020Document32 pagesGrounding Equipment: Catalog 3000 March 2020destro57No ratings yet

- PSP 11Document7 pagesPSP 11Muhammad AnsNo ratings yet

- Design of 400-220kV SubstationDocument62 pagesDesign of 400-220kV SubstationboopelectraNo ratings yet

- VLF TestingDocument28 pagesVLF TestingEngr Irfan Akhtar100% (3)

- Practical Work Book LcaDocument93 pagesPractical Work Book LcaFaheem Raza100% (2)

- Ieee Guide For Making High-Direct-Voltage Tests Power Cable Systems The FieldDocument10 pagesIeee Guide For Making High-Direct-Voltage Tests Power Cable Systems The FieldIsrael JosueNo ratings yet

- Automotive Technology: A Systems ApproachDocument124 pagesAutomotive Technology: A Systems Approachgo to slip100% (1)

- WIRINGDocument3 pagesWIRINGNorhasmawi HassanNo ratings yet

- Electrical System TestingDocument10 pagesElectrical System TestingoritasNo ratings yet

- SGP Lab Manual PDFDocument17 pagesSGP Lab Manual PDFdanish fareedNo ratings yet

- SGP Lab ManualDocument17 pagesSGP Lab Manualshreemanti75% (4)

- It Is Quite Another Electricity: Transmitting by One Wire and Without GroundingFrom EverandIt Is Quite Another Electricity: Transmitting by One Wire and Without GroundingNo ratings yet

- Analog Dialogue Volume 46, Number 1: Analog Dialogue, #5From EverandAnalog Dialogue Volume 46, Number 1: Analog Dialogue, #5Rating: 5 out of 5 stars5/5 (1)

- Unit 14 Design of Slender ColumnsDocument32 pagesUnit 14 Design of Slender ColumnsSh Jvon Sh JvonNo ratings yet

- Machine Learning EbookDocument63 pagesMachine Learning EbookGhost Rider100% (1)

- 5 XerophtalmiaDocument36 pages5 XerophtalmiaMarshet GeteNo ratings yet

- Conduction Power Loss in MOSFET Synchronous Rectifier With Parallel-Connected Schottky Barrier DiodeDocument7 pagesConduction Power Loss in MOSFET Synchronous Rectifier With Parallel-Connected Schottky Barrier DiodeMuhammad Saqib AliNo ratings yet

- Workmanship Standard For Crimping, Interconnecting Cables, Harnesses, and WiringDocument101 pagesWorkmanship Standard For Crimping, Interconnecting Cables, Harnesses, and WiringCemy IraclyNo ratings yet

- Dot Point Txtbook ChemDocument24 pagesDot Point Txtbook ChemDavid ChinNo ratings yet

- Shapeshell - Steel Structure Painting Technical Specification 2020-02-10 PDFDocument4 pagesShapeshell - Steel Structure Painting Technical Specification 2020-02-10 PDFmorisNo ratings yet

- Indian Childhood CirrhosisDocument20 pagesIndian Childhood Cirrhosissubinj_3100% (4)

- Cell Division: Mitosis & MeiosisDocument50 pagesCell Division: Mitosis & MeiosisLyca GunayNo ratings yet

- Design and Performance Analysis of 2Document24 pagesDesign and Performance Analysis of 2Dilip Kumar100% (1)

- Starbucks Business Report ManagementDocument21 pagesStarbucks Business Report ManagementParidhi LapalikarNo ratings yet

- Cross Reference Odpowiedniki - DanfossDocument29 pagesCross Reference Odpowiedniki - DanfossDanielEscobarMontecinosNo ratings yet

- Blue Land Concept NoteDocument2 pagesBlue Land Concept Notenayan83No ratings yet

- Asthma Action PlanDocument1 pageAsthma Action PlanAkosNo ratings yet

- Planetary Motion Online Simulations KEYDocument4 pagesPlanetary Motion Online Simulations KEYiubyvtcrxewzertyhNo ratings yet

- Astm A781 2020 PDFDocument11 pagesAstm A781 2020 PDFCristhian Camilo Quiroga Walteros100% (1)

- EarthDayMathActivities 1Document5 pagesEarthDayMathActivities 1Anonymous PersonNo ratings yet

- Fertilizacion Nitrogenada en Maiz Basada en Materia Organica (Sanchez Roldan)Document33 pagesFertilizacion Nitrogenada en Maiz Basada en Materia Organica (Sanchez Roldan)Brian RamosNo ratings yet

- BCC - 1,2 H SPLN 41-4Document1 pageBCC - 1,2 H SPLN 41-4TPNo ratings yet

- An Epistle of JeremiahDocument3 pagesAn Epistle of JeremiahBenson MuimiNo ratings yet

- Consolidation (2) - 4th SEMDocument3 pagesConsolidation (2) - 4th SEMDipankar NathNo ratings yet

- VDS 2095 Guidelines For Automatic Fire Detection and Fire Alarm Systems - Planning and InstallationDocument76 pagesVDS 2095 Guidelines For Automatic Fire Detection and Fire Alarm Systems - Planning and Installationjavikimi7901No ratings yet

- CBSE Class 10 Mathematics SA1 RevisionDocument3 pagesCBSE Class 10 Mathematics SA1 Revisionaryan bhanssaliNo ratings yet

- Adrenaline (Epinephrine) Nebulised 2016: AlertDocument2 pagesAdrenaline (Epinephrine) Nebulised 2016: AlertnurfitriaNo ratings yet

- Seminar Report On Smart Note TakerDocument22 pagesSeminar Report On Smart Note TakerSritejNo ratings yet

- High Voltage Engineering Assignment No 2: Ma'Am DR Sidra MumtazDocument7 pagesHigh Voltage Engineering Assignment No 2: Ma'Am DR Sidra MumtazZabeehullahmiakhailNo ratings yet

- PDMS Smartplant PDS (Coordinator Administrator)Document10 pagesPDMS Smartplant PDS (Coordinator Administrator)sconvens100% (1)