Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

2 viewsDHO-DS-200-1320-001 Mechanical Datasheet Jet A1 Fuel Storage Tank

DHO-DS-200-1320-001 Mechanical Datasheet Jet A1 Fuel Storage Tank

Uploaded by

Arif BinorikaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Thrust Boring Method StatementDocument8 pagesThrust Boring Method StatementVIGNESH100% (3)

- Vv216a-109-A-808 - 07 - 0001 - Bolt Tightening ProcedureDocument17 pagesVv216a-109-A-808 - 07 - 0001 - Bolt Tightening Proceduretonful143No ratings yet

- DHO-DS-200-1320-003 Mechanical Datasheet Fire Water TankDocument5 pagesDHO-DS-200-1320-003 Mechanical Datasheet Fire Water TankArif BinorikaNo ratings yet

- Chiyoda Malaysia Sdn. BHDDocument2 pagesChiyoda Malaysia Sdn. BHDmeeNo ratings yet

- Submersible PumpDocument105 pagesSubmersible PumpRamKS80100% (1)

- Dwg./Doc. Approval: Wha Water Co., LTDDocument47 pagesDwg./Doc. Approval: Wha Water Co., LTDธนาชัย เต็งจิรธนาภาNo ratings yet

- 1100-ME-DST-001 - Rev.1A - Data Sheet Hari Pig Launcher (1194-V-101)Document6 pages1100-ME-DST-001 - Rev.1A - Data Sheet Hari Pig Launcher (1194-V-101)Didi Hadi RiantoNo ratings yet

- YKL-APC - SDO.PKS-MII-001 - Mechanical Item Installation R1Document12 pagesYKL-APC - SDO.PKS-MII-001 - Mechanical Item Installation R1PencarianbakatNo ratings yet

- Tendernotice - 1 - 2020-09-27T221316.129 PDFDocument426 pagesTendernotice - 1 - 2020-09-27T221316.129 PDFPratik GuptaNo ratings yet

- Oxy DP Das 101 - ADocument6 pagesOxy DP Das 101 - AImthiyas MohamedNo ratings yet

- CI-G08-DP-0304 Rev 00Document23 pagesCI-G08-DP-0304 Rev 00Bashir AlamNo ratings yet

- Mucog 1910502 Mec DS 055Document12 pagesMucog 1910502 Mec DS 055vinodNo ratings yet

- Desalter DrumDocument4 pagesDesalter DrumHsein WangNo ratings yet

- TP-WMS-05969-DAS-A4-D1-K - Demulsifier DatasheetDocument9 pagesTP-WMS-05969-DAS-A4-D1-K - Demulsifier Datasheetbmanojkumar16No ratings yet

- 05020-250-090-MDS-116-01-01 Rev.2 (090TK-001,002) DCU FEED TANKSDocument5 pages05020-250-090-MDS-116-01-01 Rev.2 (090TK-001,002) DCU FEED TANKSSelim SelimNo ratings yet

- 10624-Master Index For Pipe SupportsDocument36 pages10624-Master Index For Pipe SupportsSARFRASNo ratings yet

- PPL NPL FOSL EGB PWIS INS DSH 006 - C02 - DatasheDocument7 pagesPPL NPL FOSL EGB PWIS INS DSH 006 - C02 - DatashesegunNo ratings yet

- Instrument Pressure Piping Hook-Up (N-Htr/Plant Area) : Contractor Doc. #Document82 pagesInstrument Pressure Piping Hook-Up (N-Htr/Plant Area) : Contractor Doc. #Tahir100% (1)

- Pile Foundation Design V 82510 - R1Document39 pagesPile Foundation Design V 82510 - R1Tarique MosharrufNo ratings yet

- Painampuram, Muthukurmandal, S.P.S.R. Nellore District, A.PDocument53 pagesPainampuram, Muthukurmandal, S.P.S.R. Nellore District, A.Pkkumar_717405No ratings yet

- F-94 D 25-2020 Counterforces For Anchor Chain Cable (Repeated) 18.05.2020Document1 pageF-94 D 25-2020 Counterforces For Anchor Chain Cable (Repeated) 18.05.2020Gaurav MaithilNo ratings yet

- NPT10111-PE-V-DS-621101-030 - Instrument Datasheet - Level Gauge F & B Rev-00Document6 pagesNPT10111-PE-V-DS-621101-030 - Instrument Datasheet - Level Gauge F & B Rev-00kkumar_717405No ratings yet

- 11 86 Me DTS 00008Document3 pages11 86 Me DTS 00008Erdal CanNo ratings yet

- Itp Piping Rev 0Document2 pagesItp Piping Rev 0Angel Rebollo100% (1)

- LPP-30-W4-DS-202-R Rev.4 Instrument Air Dryer Package Unit Data SheetDocument4 pagesLPP-30-W4-DS-202-R Rev.4 Instrument Air Dryer Package Unit Data SheetNyssaMaurillaNo ratings yet

- Alarm Trip SettingsDocument6 pagesAlarm Trip Settingsavenir334No ratings yet

- J-DMS: Issued For InformationDocument2 pagesJ-DMS: Issued For InformationNerubian AssasinNo ratings yet

- Civil Ga of Cct r0-Model-model 240115 132341Document1 pageCivil Ga of Cct r0-Model-model 240115 132341Shimendi GebreslassieNo ratings yet

- Civil Ga of Cct r0-Model-modelDocument1 pageCivil Ga of Cct r0-Model-modelShimendi GebreslassieNo ratings yet

- V-3111-002-A-712 - 2 Method Statement For Shallow Drilling WorkDocument5 pagesV-3111-002-A-712 - 2 Method Statement For Shallow Drilling WorkWidya PrasetyaNo ratings yet

- E1881-DS-2210-M-0001-RA1Document11 pagesE1881-DS-2210-M-0001-RA1Anonymous bySKOTNo ratings yet

- Saka Indonesia Pangkah Limited Contract No. 4600012838: Piping Test Package W3-0103-01 Production HeaderDocument19 pagesSaka Indonesia Pangkah Limited Contract No. 4600012838: Piping Test Package W3-0103-01 Production HeaderriandiNo ratings yet

- Q3710 U Int Ge DSH 6111 2116Document2 pagesQ3710 U Int Ge DSH 6111 2116Rachid El KinanyNo ratings yet

- V-3111-002-A-713 - 2 Method Statement For Lifting PlanDocument135 pagesV-3111-002-A-713 - 2 Method Statement For Lifting PlanWidya PrasetyaNo ratings yet

- RT Request: Hail Surface Facilities Eps ProjectDocument4 pagesRT Request: Hail Surface Facilities Eps ProjectAnonymous AdofXEYAgENo ratings yet

- Subsea Basis of DesignDocument29 pagesSubsea Basis of DesignShah Alam100% (1)

- KG98 2 ONT OMF in 7861 DS 152 R4 Differential Pressure Transmitter Datasheet (Code 1)Document7 pagesKG98 2 ONT OMF in 7861 DS 152 R4 Differential Pressure Transmitter Datasheet (Code 1)Madheswaran DharmapuriNo ratings yet

- KG982-ONT-PR-OGT-DS-00001 - Process Datasheet For Gas Separators - Rev.ADocument5 pagesKG982-ONT-PR-OGT-DS-00001 - Process Datasheet For Gas Separators - Rev.Asumit kumarNo ratings yet

- Indra: KSB Pumps LimitedDocument2 pagesIndra: KSB Pumps Limitedvsv mnaNo ratings yet

- Oxy DP Das 001 - ADocument6 pagesOxy DP Das 001 - AImthiyas MohamedNo ratings yet

- 2.3.1 PSV DatasheetDocument3 pages2.3.1 PSV Datasheetph0inixNo ratings yet

- SA - L LYX - RIS - GA#3 - Shining Mark - 051022Document1 pageSA - L LYX - RIS - GA#3 - Shining Mark - 051022Hafizuddin SuhaimanNo ratings yet

- Guara B.V.: Seawater Electrolyzer Data Sheet - E-UE-5121502Document2 pagesGuara B.V.: Seawater Electrolyzer Data Sheet - E-UE-5121502Adalton BritoNo ratings yet

- 501abcde 016Document30 pages501abcde 016husen123 alhusadaNo ratings yet

- Zi Gam02 U4839 Dts en 001 WiproDocument4 pagesZi Gam02 U4839 Dts en 001 Wiprosantoshkumarnavik264No ratings yet

- Centrifugal Pump Data Sheet: Doc. No.Document6 pagesCentrifugal Pump Data Sheet: Doc. No.Mahdi KazemiNo ratings yet

- RT Request: Hail Surface Facilities Eps ProjectDocument4 pagesRT Request: Hail Surface Facilities Eps ProjectAnonymous AdofXEYAgENo ratings yet

- PAGE NO: 1 of 44 V-2153-004-154: SWGFD 23-002 A/B/C/D - Air Fin Cooler 11EPG18-1G05-CE-S-23 GC 001Document44 pagesPAGE NO: 1 of 44 V-2153-004-154: SWGFD 23-002 A/B/C/D - Air Fin Cooler 11EPG18-1G05-CE-S-23 GC 001karthickeyanclass4No ratings yet

- Process Calculation SWRO FROM MAHESHDocument40 pagesProcess Calculation SWRO FROM MAHESHgulfengsolutionsNo ratings yet

- Rail and Wheels: Guide ChannelDocument1 pageRail and Wheels: Guide ChannelnarumenonNo ratings yet

- Revision Index Description and / or Revised Sheets: Aker Kvaerner Process SystemsDocument2 pagesRevision Index Description and / or Revised Sheets: Aker Kvaerner Process SystemsAdilson MirandaNo ratings yet

- PPL NPL FOSL EGB PWIS INS DSH 008 - C01 - DatasheDocument3 pagesPPL NPL FOSL EGB PWIS INS DSH 008 - C01 - DatashesegunNo ratings yet

- Data Sheet Water Tank - STAMP AFCDocument6 pagesData Sheet Water Tank - STAMP AFCudantoNo ratings yet

- Piping and Instrumentation Diagram For HPU: Adcop - Abu Dhabi Crude Oil Pipeline Project Habshan - FujairahDocument4 pagesPiping and Instrumentation Diagram For HPU: Adcop - Abu Dhabi Crude Oil Pipeline Project Habshan - FujairahAdityaNo ratings yet

- QPE002342 - Technical BidDocument136 pagesQPE002342 - Technical BidMuhammed TamerNo ratings yet

- GD 2425 Ids 002Document1 pageGD 2425 Ids 002singhjyoti54.sjNo ratings yet

- 167.02.10 - EE-708 - Luminaires - Specification Sheet - Rev1Document6 pages167.02.10 - EE-708 - Luminaires - Specification Sheet - Rev1GHOST PAKNo ratings yet

- Dehumdifier 1Document46 pagesDehumdifier 1tssuwimal5973No ratings yet

- AIR CRASH INVESTIGATIONS - THE BOEING 737 MAX DISASTER PART 1 - The Crash of Lion Air Flight 610From EverandAIR CRASH INVESTIGATIONS - THE BOEING 737 MAX DISASTER PART 1 - The Crash of Lion Air Flight 610No ratings yet

- WiMedia UWB: Technology of Choice for Wireless USB and BluetoothFrom EverandWiMedia UWB: Technology of Choice for Wireless USB and BluetoothNo ratings yet

- Optimization and Business Improvement Studies in Upstream Oil and Gas IndustryFrom EverandOptimization and Business Improvement Studies in Upstream Oil and Gas IndustryNo ratings yet

- EPN-KSO-LBJ-TBBM-PIPE WORK PriceDocument4 pagesEPN-KSO-LBJ-TBBM-PIPE WORK PriceArif BinorikaNo ratings yet

- BQ Mi GacoanDocument9 pagesBQ Mi GacoanArif BinorikaNo ratings yet

- Tangga Rak GaramDocument1 pageTangga Rak GaramArif BinorikaNo ratings yet

- Estimasi Piping Accessories and Bulk Material For First Firing Unit #1Document4 pagesEstimasi Piping Accessories and Bulk Material For First Firing Unit #1Arif BinorikaNo ratings yet

- Lay Out Utility Pabrik WagirDocument1 pageLay Out Utility Pabrik WagirArif BinorikaNo ratings yet

- Lay Out Pembongkaran Line Utility Mini Primary GG GempolDocument1 pageLay Out Pembongkaran Line Utility Mini Primary GG GempolArif BinorikaNo ratings yet

- MEIA Bill of Quantity (BOQ) - For Review OnlyDocument532 pagesMEIA Bill of Quantity (BOQ) - For Review OnlyArif BinorikaNo ratings yet

- Uh CatalogDocument4 pagesUh CatalogArif BinorikaNo ratings yet

- Wagir Plant - MalangDocument13 pagesWagir Plant - MalangArif BinorikaNo ratings yet

- LAY OUT Hydrant. Alt.2Document1 pageLAY OUT Hydrant. Alt.2Arif BinorikaNo ratings yet

- Bill of Material Alt.2Document2 pagesBill of Material Alt.2Arif BinorikaNo ratings yet

- RAB MEIA MechanicalDocument362 pagesRAB MEIA MechanicalArif BinorikaNo ratings yet

- Meia Rab (14-3-2022)Document542 pagesMeia Rab (14-3-2022)Arif BinorikaNo ratings yet

- Data Material Isoplus Ex Project New SKM - Unit V Pt. Gudang Garam Tbk. - KediriDocument10 pagesData Material Isoplus Ex Project New SKM - Unit V Pt. Gudang Garam Tbk. - KediriArif BinorikaNo ratings yet

- Mapping Laydown MaspionDocument6 pagesMapping Laydown MaspionArif BinorikaNo ratings yet

- MAM 10th Shipment Packing List R1 - 20210314-Rev.1-BG-20210417-Rekap-BongkarDocument57 pagesMAM 10th Shipment Packing List R1 - 20210314-Rev.1-BG-20210417-Rekap-BongkarArif BinorikaNo ratings yet

- Canopy Parking at IF Area - R3 - ToVendorDocument8 pagesCanopy Parking at IF Area - R3 - ToVendorArif BinorikaNo ratings yet

- 1:100 0.00m Floor Layout: Cable SandwichDocument1 page1:100 0.00m Floor Layout: Cable SandwichArif BinorikaNo ratings yet

- Harga Jasa DuctingDocument1 pageHarga Jasa DuctingArif BinorikaNo ratings yet

- 2020-07-03 Indonesia MAM Starch and Sweetener Project DWG, DOC. Submission List EN RDocument4 pages2020-07-03 Indonesia MAM Starch and Sweetener Project DWG, DOC. Submission List EN RArif BinorikaNo ratings yet

- Den An Hormat, Bersama Ini Kami Menawarkan Harga Untuk Pembuatan Modif Kont, Dan Harga SBBDocument2 pagesDen An Hormat, Bersama Ini Kami Menawarkan Harga Untuk Pembuatan Modif Kont, Dan Harga SBBArif BinorikaNo ratings yet

- Galian PepiDocument2 pagesGalian PepiArif BinorikaNo ratings yet

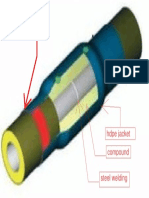

- Isoplus Joint PDFDocument1 pageIsoplus Joint PDFArif BinorikaNo ratings yet

- 1:100 7.00m Floor Layout: Laboratory Micro Culture Sterile RoomDocument1 page1:100 7.00m Floor Layout: Laboratory Micro Culture Sterile RoomArif BinorikaNo ratings yet

- Laporan Final Progress: NO. Deskripsi Q'Ty Unit KeteranganDocument3 pagesLaporan Final Progress: NO. Deskripsi Q'Ty Unit KeteranganArif BinorikaNo ratings yet

- GEA DryCoolers InstalationDocument28 pagesGEA DryCoolers InstalationArif BinorikaNo ratings yet

- Rubber Hose For Automotive Air and Vacuum Brake System: Standard Test Methods ForDocument5 pagesRubber Hose For Automotive Air and Vacuum Brake System: Standard Test Methods ForPyone Ei ZinNo ratings yet

- FEMA FilterManual 2011Document362 pagesFEMA FilterManual 2011ina_cri100% (1)

- Amendment 01 PHED BSR 2022 PDFDocument89 pagesAmendment 01 PHED BSR 2022 PDFRJ JangidNo ratings yet

- Brochure - GTT Pluto II Subsea Cryogenic PipelineDocument6 pagesBrochure - GTT Pluto II Subsea Cryogenic PipelinefralgiugiaNo ratings yet

- Cooling Tower NotesDocument12 pagesCooling Tower NotesHimTex GlobalNo ratings yet

- Staff Houses BOQDocument17 pagesStaff Houses BOQwellington chilufyaNo ratings yet

- Thick-Walled Cylinder and Compound Cylinder Theory October 2, 2008Document5 pagesThick-Walled Cylinder and Compound Cylinder Theory October 2, 2008Nyasha ChipokaNo ratings yet

- Sample of Form MDRDocument11 pagesSample of Form MDRYuwantoniAlNo ratings yet

- Foundations and Equipment PadsDocument32 pagesFoundations and Equipment Padsaksh007No ratings yet

- Manual Elevators Y, A, G, X, S Series BNC DC Lift SystemDocument20 pagesManual Elevators Y, A, G, X, S Series BNC DC Lift SystemFranklin Jose Almera AcostaNo ratings yet

- Instrument Valves - PGI-IV PDFDocument32 pagesInstrument Valves - PGI-IV PDFRahmat RiskiNo ratings yet

- Acoustic ResonanceDocument10 pagesAcoustic ResonancegauthamanNo ratings yet

- Ornl 2440Document325 pagesOrnl 2440jesusNo ratings yet

- Clamp CatalogueDocument33 pagesClamp CatalogueRaja Guru100% (2)

- GREE Hw18024pnadDocument24 pagesGREE Hw18024pnadEdward PeñaNo ratings yet

- Pipe Welding 6G SMAW CertificationDocument11 pagesPipe Welding 6G SMAW Certificationsijeshclt100% (1)

- Steady ConductionDocument4 pagesSteady ConductionSanith RenjalNo ratings yet

- Mid-Statyes - Carbon Steel Pipe Fitting - Straight TEEDocument2 pagesMid-Statyes - Carbon Steel Pipe Fitting - Straight TEETamer BannaNo ratings yet

- Line SizingDocument17 pagesLine SizingAllyssa Jane ErcillaNo ratings yet

- Purmo Technical Catalogue Trench Convectors AQUILO - 08 - 2015 - EN - PLDocument52 pagesPurmo Technical Catalogue Trench Convectors AQUILO - 08 - 2015 - EN - PLMetin TamNo ratings yet

- Table UCS-56-11 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 15EDocument5 pagesTable UCS-56-11 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 15EMechanicalNo ratings yet

- Lecture 4A - Understanding Sanitary Plumbing SystemDocument35 pagesLecture 4A - Understanding Sanitary Plumbing SystemWong Lipping100% (1)

- Packoff and Slim Hole Gas Lift MandrelsDocument3 pagesPackoff and Slim Hole Gas Lift MandrelsashwaniNo ratings yet

- Carpenter & Paterson Hardware Price Book CP-0213Document54 pagesCarpenter & Paterson Hardware Price Book CP-0213Sargunam SankaravadivelNo ratings yet

- Descon News Spring-Summer 2009Document36 pagesDescon News Spring-Summer 2009Hassan Safdar MalikNo ratings yet

- Electrode SelectionDocument85 pagesElectrode SelectionShaheen Andre Chikku100% (2)

- MDB Standard ListDocument8 pagesMDB Standard ListSAMARTHNo ratings yet

- Ahmsa Steel - EnglishDocument88 pagesAhmsa Steel - Englishmanipalaniusa100% (1)

- Phased Array UT Application For Boiler Tube Inspection in Manufacturing Anandamurugan S, Siva Sankar YDocument10 pagesPhased Array UT Application For Boiler Tube Inspection in Manufacturing Anandamurugan S, Siva Sankar YmuhdmsohNo ratings yet

DHO-DS-200-1320-001 Mechanical Datasheet Jet A1 Fuel Storage Tank

DHO-DS-200-1320-001 Mechanical Datasheet Jet A1 Fuel Storage Tank

Uploaded by

Arif Binorika0 ratings0% found this document useful (0 votes)

2 views5 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

2 views5 pagesDHO-DS-200-1320-001 Mechanical Datasheet Jet A1 Fuel Storage Tank

DHO-DS-200-1320-001 Mechanical Datasheet Jet A1 Fuel Storage Tank

Uploaded by

Arif BinorikaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 5

MECHANICAL DATASHEET

PT. JAGAT TRIBUANA SAKTI

JET A-1 STORAGE TANK

WIKA - ALUPHI KSO

DOCUMENT NO. REV : 2A

AVIATION FUEL DEPOT PROJECT

PAGES :

DHO-DS-200-1320-001 DHOHO INTERNATIONAL AIRPORT

1 OF 5

CLIENT : PT. SURYA DHOHO INVESTAMA

PMCM : PT. JAGAT TRIBUANA SAKTI

CONTRACTOR : PT. WIJAYA KARYA (PERSERO) Tbk – PT ALUPHI KSO

PROJECT TITLE : AVIATION FUEL DEPOT PROJECT

DHOHO INTERNATIONAL AIRPORT

LOCATION : KEDIRI, EAST JAVA, INDONESIA

NO. PROJECT : TBA

2A 06/09/23 ISSUED FOR CONSTRUCTION MILADO BAGUS P.T. VISIE F.V.

1A 24/08/23 ISSUED FOR APPROVAL MILADO BAGUS P.T. VISIE F.V.

PREPARED CHECKED APPROVED CHECKED APPROVED

REV. DATE DESCRIPTION

WIKA - ALUPHI KSO PT. JAGAT

MECHANICAL DATASHEET

JET A-1 STORAGE TANK

PT. JAGAT TRIBUANA SAKTI KSO WIKA - ALUPHI

DOCUMENT NO. REV : 2A

AVIATION FUEL DEPOT PROJECT

PAGES :

DHO-DS-200-1320-001 DHOHO INTERNATIONAL AIRPORT

2 OF 5

REVISION SHEET

NO Rev. Client Comment Contractor Respond Page

1 2A - Design has been revised as Process calculation

update

MECHANICAL DATASHEET

PT. JAGAT TRIBUANA SAKTI

JET A-1 STORAGE TANK

KSO WIKA - ALUPHI

DOCUMENT NO. REV : 2A

AVIATION FUEL DEPOT PROJECT

PAGES :

DHO-DS-200-1320-001 DHOHO INTERNATIONAL AIRPORT 3 of 5

1 PLANT : DHOHO INTERNATIONAL AIRPORT LOCATION : KEDIRI, EAST JAVA, INDONESIA

2 TANK NO : 200-TK-3-01/02/03 NO. REQUIRED : 3

3 PRODUCT : AVTUR / JET A-1 CLASS : -

4 DESIGN CONDITION

5 MAXIMUM CAPACITY 1085 kL NORMAL CAPACITY 1000 M3

6 CRITICAL HIGH LEVEL 9596 (note 1) mm MIN LOW LEVEL 445 (note 1) mm

7 DESIGN PUMPING RATES IN 210 KL/Hr OUT 210 KL/Hr

8 VAPOR PRESSURE 0.01 barG

9 INTERNAL DIAMETER 12000 mm HEIGHT 10400 mm

10 DESIGN/ACTUAL SPECIFIC GRAVITY 1/0.83

0

11 DESIGN/OPERATING PRESSURE FULL OF WATER/ATM DESIGN/MIN METAL TEMP 60/-20 C

12 ROOF 1 mm ROOF STRUCTURE 2 mm SHELL 2 mm

CORROSION ALLOWANCE

13 BOTTOM 2 mm ANNULAR 2 mm

14 SHELL DESIGN BASIC STANDARD API 650 APPENDIX A APPENDIX E

15 BASIC STANDARD API 650 APPENDIX C

ROOF DESIGN

16 APPENDIX G APPENDIX H

17 FRANGIBLE ROOF JOINT YES NO

18 LIVE 0.01 kg/cm2 (A) INSULATION ROOF/SHELL 0 /0 mm

19 ROOF DESIGN LOAD SNOW N.A kg/cm2 (A) SPECIAL LOADS (PROVIDE SKETCH) N.A kg/cm2 (A)

20 RAINFALL mm/h GASES IN THE VAPOR SPACE NITROGEN

21 ROOF TIE RODS YES NO

22 SEISMIC USE GROUP (E.3.1) SUG III SITE CLASS (E.4.4) D

23 VERTICAL SEISMIC DESIGN (E.6.1.3) YES NO

24 EARTHQUAKE DESIGN BASIS OF LATERAL ACCELERATION (SELECT ONE)

25 (PPENDIX E) MAPPED SEISMIC PARAMETERS (E.4.1) Ss = 0.8294 (g) ; S1 = 0.3924 (g) ;

26 SITE-SPECIFIC PROCEDURES (E.4.2) MCE DESIGN REQUIRED YES

27 OTHER (NON-ASCE7)METHODS (E.4.3)

28 SLOSHING WAVE FREEBOARD FOR SUG I (E.7.2) YES NO

29 FOR NON-U.S. SITES 50 YEARS WIND SPEED (3-SECOND GUST) 120 km/h

30 WIND LOAD PROVIDE INTERMEDIATE WIND GIRDER YES NO

31 TOP WIND GIRDER FOR USE AS WALKWAY YES NO

32 FOUNDATION TYPE EARTH CONCRETE SLAB OTHERS

33 CONSTRUCTION FEATURES

34 ROOF A283-C STUCTURE A-36 BOTTOM A283-C

MATERIAL SPECIFICATIONS

35 SHELL A283-C ANNULAR A283-C

36 COURSE WIDTH (mm) LENGTH (mm) THICKNESS MATERIAL

37 1 1800 6000 10 A283-C

38 2 1800 6000 8 A283-C

39 3 1800 6000 6 A283-C

40 4 1800 6000 6 A283-C

41 5 1800 6000 6 A283-C

42 6 1800 6000 6 A283-C

43 TANK SHELL

44

45

46

47

48

49

50

51 ANNULAR 8 mm

52 BOTTOM 8 mm

TANK BOTTOM

53 JOINT TYPE LAP JOINT BUTT JOINT

54 SLOPE 1/30 TO CENTER FROM CENTER

55 CONE SLOPE N/A DOME RADIUS 9600 (*) mm

56 TANK ROOF SUPPORTED SELF-SUPPORTED INTERNAL FLOATING EXTERNAL FLOATING

57 THICKNESS 6 mm LAP JOINT BUTT JOINT

58 Note :

59

60

61

62

MECHANICAL DATASHEET

JET A-1 STORAGE TANK

PT. JAGAT TRIBUANA SAKTI

KSO WIKA - ALUPHI

DOCUMENT NO. REV : 2A

AVIATION FUEL DEPOT PROJECT

PAGES :

DHO-DS-200-1320-001 DHOHO INTERNATIONAL AIRPORT 4 of 5

1 PAINTING REQUIRMENT (note 26)

2 SURFACE PREPARATION

SHELL

3 EXTERIOR YES NO INTERIOR YES NO

4 SURFACE PREPARATION

BOTTOM

5 UNDERSIDE YES NO INTERIOR YES NO

6 SURFACE PREPARATION

ROOF

7 EXTERIOR YES NO INTERIOR YES NO

8 SURFACE PREPARATION

STRUCTURE

9 EXTERIOR YES NO INTERIOR YES NO

10 INSPECTION AND TESTING

11 INSPECTION BY SHOP FIELD

12 WELD EXAM RADIOGRAPH FILMS

13 SUPPL EXAM LIQUID PENETRANT ULTRASONIC

14 LEAK TEST ROOF SHELL BOTTOM

15 MILL TEST YES NO PLATES YES NO

16 APPURTUNANCES

17 STAIRWAY SPIRAL STRAIGHT ANGLE TO HORIZONTAL 45 deg LADDER

18 WALKWAY ROOF PERIPHERY SHELL TOP TO TANK CENTER WIDTH 800 mm

19 DRAW OF SUMP STANDARD SPECIAL DIAMETER 1220 mm (*) DEPTH 600 mm

20 BOLTED SHEET DOOR YES NO (APP. A TANK ONLY) RAISE FLUSH

21 SWING LINE SUCTION LINE DRAWOFF LINE FLOATING SUCTION

INTERNAL PIPING

22 HEATING COIL SURFACE AREA 0 m2

23 ROOF DRAIN HOSE SWIVEL SIPHON

24 ANCHOR YES NO SIZE M36 QUANTITY 16

25 PLATFORM ROOF PLATFORM FIRE SPRAY ROOF & SHELL RING

26 SHELL NOZZLE

27 SIZE FLANGED PROJ ELEV.

MARK Qty ORIENTATION N=0 SERVICE

28 (INCH) SCH DBL RE PAD (mm) (mm) 2A

29 N1 8 40 150# WN RF 6 mm 1 200 (note 15) 240 Fluid Inlet w/ Inlet Diffuser

30 N2 4 40 150# WN RF 6 mm 1 250 (note 15) 531 Fluid Inlet from Shifting Pump

31 N3 A 6 40 150# WN RF 6 mm 1 200 (note 15) 350 Product Drain

32 N3 B 2 80 150# WN RF 0 1 150 (note 15) 350 Water Drawoff

33 N4 A 2 80 150# WN RF 0 1 150 (note 15) 445 Sampling Connection

34 N4 B 2 80 150# WN RF 0 1 150 (note 15) 599 Sampling Connection

35 N5 A 2 80 150# WN RF 0 1 150 (note 15) 9441 Level Switch

36 N5 B 2 80 150# WN RF 0 1 150 (note 15) 9596 Level Switch

37 N6 A 2 40 150# WN RF 6 mm 1 200 (note 15) 9900 Level Transmitter

38 N6 B 2 80 150# WN RF 0 1 150 (note 15) 200 Level Transmitter

39 N7 16 40 150# WN RF 6 mm 1 175 (note 15) 425 Fluid Outlet

40 N8 4 40 150# WN RF 6 mm 1 200 (note 15) 600 Foam Connection

N13 6 40 150# WN RF 6 mm 1 200 (note 15) 600 Outlet to Shifting Pump

N16 4 40 150# WN RF 6 mm 1 200 (note 15) 600 Fluid Inlet from Drain Pump

41 M2 A 42 API 650 API 650 6 mm 1 275 (note 15) 1050 Shell Manway w/ Cover, Bolts & Nuts, Davit

42 M2 B 24 API 650 API 650 6 mm 1 269 (note 15) 750 Shell Manway w/ Cover, Bolts & Nuts, Davit

43 LUG A/B 2

44

45

46 ROOF NOZZLE, INCLUDING VENTING CONNECTION

47 SIZE DISTANCE FROM

MARK SCH FLANGED RE PAD Qty ORIENTATION N=0 SERVICE

48 (INCH) CENTER (mm)

49 N9 6 40 150# WN RF 6 mm 1 (note 15) 5000 ATG

50 N10 2 80 150# WN RF 6 mm 1 (note 15) 5000 Free Vent w/ Flame Arrester and Bug Screen

51 N11 12 40 150# WN RF 6 mm 1 (note 15) 400 Gauge Hatch w/ Emergency Vent

52 N12 4 40 150# WN RF 6 mm 1 (note 15) 5000 Level Switch (HH)

53 N14 2 80 150# WN RF 6 mm 1 (note 15) 5000 Pressure Transmitter

54 N15 2 80 150# WN RF 6 mm 1 (note 15) 3210 Temperature Transmitter

M1A 6 mm 1 (note 15) Roof Opening (Rectangular 1200 x 900 mm)

55 M1B 24 API 650 API 650 6 mm 1 (note 15) Roof Manway

56

57 Note :

58

59

60

61

62

63

MECHANICAL DATASHEET

PT. JAGAT TRIBUANA SAKTI

JET A-1 STORAGE TANK

KSO WIKA - ALUPHI

DOCUMENT NO. REV : 2A

AVIATION FUEL DEPOT PROJECT

PAGES :

DHO-DS-200-1320-001 DHOHO INTERNATIONAL AIRPORT 5 of 5

1 PLANT : DHOHO INTERNATIONAL AIRPORT LOCATION : KEDIRI, EAST JAVA, INDONESIA

2 TANK NO : 200-TK-3-01/02/03 NO. REQ'D : 3

3 PRODUCT : AVTUR / JET A-1 CLASS : -

4

5 SKETCH

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33 2A

34

35 LEVEL DIAGRAM

36

37

38 HHLL = 9781 mm

39 HLL = 9626 mm

40 LLL = 784 mm

41 LLLL = 630 mm

42

43 Datum = 50 mm

44

45

46

47 NOTES

48 1. Datum plate 50 mm

49 2. Nozzle allowable stress refers to API 650 Annex P

50 3. Nozzle N3B shall be provided with internal pipe (until draw off sump)

51 4. 16" Floating Suction

52 5. * = Vendor to Advice and Confirm

53 6. Gauge Hatch to be installed 1 m from ATG

54 7. Vendor shall provide shop drawing before fabrication.

55 8. Vendor to determine the thickness and guarantee them on strength.

56 9. Vendor to provide all required data for MIGAS Certification.

57 10. Design of internal will be specified by Vendor during detail engineering stage.

58 11. Detail of internal shall be include in Vendor scope.

59 12. Detail drawing will be specified in the shop drawing

60 13. All nozzle flanges shall be as per ASME B 16.5,

61 14. Vendor to calculate overall weight of the tank with all of tank internals.

62 15. Due to differentiation of each tank position related to the pipe system, nozzle orientation to be detailed on the General Assembly Drawing

63 16. All gauge glass level controls, alarms, etc having two connections are to be set with jig.

64 17. Vendor to consider nozzle load at detail engineering stage.

65 18. Free vent shall be included. Vendor to provide piping & flanges, bolts & nuts, gasket and installation of flame arester (if any)

66 19. All accessories will be provied by vendor

67 20. All this data shall to be confirmed and / or defined by the manufacturer, they are given for information as they are common rules.

68 21. Vendor shall provide material certificate 3.1 for pressure part and 2.2 for non pressure part

69 22. Riser for fire water include vendor scope and will be specified by vendor in the shop drawing

70 23. Vendor provide from riser pipe, pipe around the tank, until nuts for nozzle.

71 24. Nozzle for fire water supplied by wika.

72 25. Design lifetime for 20 years

73 26. Tank painting procedures shall refer to Painting Specification DHO-200-SP-1320-004

74

75

76

77

78

79

80

You might also like

- Thrust Boring Method StatementDocument8 pagesThrust Boring Method StatementVIGNESH100% (3)

- Vv216a-109-A-808 - 07 - 0001 - Bolt Tightening ProcedureDocument17 pagesVv216a-109-A-808 - 07 - 0001 - Bolt Tightening Proceduretonful143No ratings yet

- DHO-DS-200-1320-003 Mechanical Datasheet Fire Water TankDocument5 pagesDHO-DS-200-1320-003 Mechanical Datasheet Fire Water TankArif BinorikaNo ratings yet

- Chiyoda Malaysia Sdn. BHDDocument2 pagesChiyoda Malaysia Sdn. BHDmeeNo ratings yet

- Submersible PumpDocument105 pagesSubmersible PumpRamKS80100% (1)

- Dwg./Doc. Approval: Wha Water Co., LTDDocument47 pagesDwg./Doc. Approval: Wha Water Co., LTDธนาชัย เต็งจิรธนาภาNo ratings yet

- 1100-ME-DST-001 - Rev.1A - Data Sheet Hari Pig Launcher (1194-V-101)Document6 pages1100-ME-DST-001 - Rev.1A - Data Sheet Hari Pig Launcher (1194-V-101)Didi Hadi RiantoNo ratings yet

- YKL-APC - SDO.PKS-MII-001 - Mechanical Item Installation R1Document12 pagesYKL-APC - SDO.PKS-MII-001 - Mechanical Item Installation R1PencarianbakatNo ratings yet

- Tendernotice - 1 - 2020-09-27T221316.129 PDFDocument426 pagesTendernotice - 1 - 2020-09-27T221316.129 PDFPratik GuptaNo ratings yet

- Oxy DP Das 101 - ADocument6 pagesOxy DP Das 101 - AImthiyas MohamedNo ratings yet

- CI-G08-DP-0304 Rev 00Document23 pagesCI-G08-DP-0304 Rev 00Bashir AlamNo ratings yet

- Mucog 1910502 Mec DS 055Document12 pagesMucog 1910502 Mec DS 055vinodNo ratings yet

- Desalter DrumDocument4 pagesDesalter DrumHsein WangNo ratings yet

- TP-WMS-05969-DAS-A4-D1-K - Demulsifier DatasheetDocument9 pagesTP-WMS-05969-DAS-A4-D1-K - Demulsifier Datasheetbmanojkumar16No ratings yet

- 05020-250-090-MDS-116-01-01 Rev.2 (090TK-001,002) DCU FEED TANKSDocument5 pages05020-250-090-MDS-116-01-01 Rev.2 (090TK-001,002) DCU FEED TANKSSelim SelimNo ratings yet

- 10624-Master Index For Pipe SupportsDocument36 pages10624-Master Index For Pipe SupportsSARFRASNo ratings yet

- PPL NPL FOSL EGB PWIS INS DSH 006 - C02 - DatasheDocument7 pagesPPL NPL FOSL EGB PWIS INS DSH 006 - C02 - DatashesegunNo ratings yet

- Instrument Pressure Piping Hook-Up (N-Htr/Plant Area) : Contractor Doc. #Document82 pagesInstrument Pressure Piping Hook-Up (N-Htr/Plant Area) : Contractor Doc. #Tahir100% (1)

- Pile Foundation Design V 82510 - R1Document39 pagesPile Foundation Design V 82510 - R1Tarique MosharrufNo ratings yet

- Painampuram, Muthukurmandal, S.P.S.R. Nellore District, A.PDocument53 pagesPainampuram, Muthukurmandal, S.P.S.R. Nellore District, A.Pkkumar_717405No ratings yet

- F-94 D 25-2020 Counterforces For Anchor Chain Cable (Repeated) 18.05.2020Document1 pageF-94 D 25-2020 Counterforces For Anchor Chain Cable (Repeated) 18.05.2020Gaurav MaithilNo ratings yet

- NPT10111-PE-V-DS-621101-030 - Instrument Datasheet - Level Gauge F & B Rev-00Document6 pagesNPT10111-PE-V-DS-621101-030 - Instrument Datasheet - Level Gauge F & B Rev-00kkumar_717405No ratings yet

- 11 86 Me DTS 00008Document3 pages11 86 Me DTS 00008Erdal CanNo ratings yet

- Itp Piping Rev 0Document2 pagesItp Piping Rev 0Angel Rebollo100% (1)

- LPP-30-W4-DS-202-R Rev.4 Instrument Air Dryer Package Unit Data SheetDocument4 pagesLPP-30-W4-DS-202-R Rev.4 Instrument Air Dryer Package Unit Data SheetNyssaMaurillaNo ratings yet

- Alarm Trip SettingsDocument6 pagesAlarm Trip Settingsavenir334No ratings yet

- J-DMS: Issued For InformationDocument2 pagesJ-DMS: Issued For InformationNerubian AssasinNo ratings yet

- Civil Ga of Cct r0-Model-model 240115 132341Document1 pageCivil Ga of Cct r0-Model-model 240115 132341Shimendi GebreslassieNo ratings yet

- Civil Ga of Cct r0-Model-modelDocument1 pageCivil Ga of Cct r0-Model-modelShimendi GebreslassieNo ratings yet

- V-3111-002-A-712 - 2 Method Statement For Shallow Drilling WorkDocument5 pagesV-3111-002-A-712 - 2 Method Statement For Shallow Drilling WorkWidya PrasetyaNo ratings yet

- E1881-DS-2210-M-0001-RA1Document11 pagesE1881-DS-2210-M-0001-RA1Anonymous bySKOTNo ratings yet

- Saka Indonesia Pangkah Limited Contract No. 4600012838: Piping Test Package W3-0103-01 Production HeaderDocument19 pagesSaka Indonesia Pangkah Limited Contract No. 4600012838: Piping Test Package W3-0103-01 Production HeaderriandiNo ratings yet

- Q3710 U Int Ge DSH 6111 2116Document2 pagesQ3710 U Int Ge DSH 6111 2116Rachid El KinanyNo ratings yet

- V-3111-002-A-713 - 2 Method Statement For Lifting PlanDocument135 pagesV-3111-002-A-713 - 2 Method Statement For Lifting PlanWidya PrasetyaNo ratings yet

- RT Request: Hail Surface Facilities Eps ProjectDocument4 pagesRT Request: Hail Surface Facilities Eps ProjectAnonymous AdofXEYAgENo ratings yet

- Subsea Basis of DesignDocument29 pagesSubsea Basis of DesignShah Alam100% (1)

- KG98 2 ONT OMF in 7861 DS 152 R4 Differential Pressure Transmitter Datasheet (Code 1)Document7 pagesKG98 2 ONT OMF in 7861 DS 152 R4 Differential Pressure Transmitter Datasheet (Code 1)Madheswaran DharmapuriNo ratings yet

- KG982-ONT-PR-OGT-DS-00001 - Process Datasheet For Gas Separators - Rev.ADocument5 pagesKG982-ONT-PR-OGT-DS-00001 - Process Datasheet For Gas Separators - Rev.Asumit kumarNo ratings yet

- Indra: KSB Pumps LimitedDocument2 pagesIndra: KSB Pumps Limitedvsv mnaNo ratings yet

- Oxy DP Das 001 - ADocument6 pagesOxy DP Das 001 - AImthiyas MohamedNo ratings yet

- 2.3.1 PSV DatasheetDocument3 pages2.3.1 PSV Datasheetph0inixNo ratings yet

- SA - L LYX - RIS - GA#3 - Shining Mark - 051022Document1 pageSA - L LYX - RIS - GA#3 - Shining Mark - 051022Hafizuddin SuhaimanNo ratings yet

- Guara B.V.: Seawater Electrolyzer Data Sheet - E-UE-5121502Document2 pagesGuara B.V.: Seawater Electrolyzer Data Sheet - E-UE-5121502Adalton BritoNo ratings yet

- 501abcde 016Document30 pages501abcde 016husen123 alhusadaNo ratings yet

- Zi Gam02 U4839 Dts en 001 WiproDocument4 pagesZi Gam02 U4839 Dts en 001 Wiprosantoshkumarnavik264No ratings yet

- Centrifugal Pump Data Sheet: Doc. No.Document6 pagesCentrifugal Pump Data Sheet: Doc. No.Mahdi KazemiNo ratings yet

- RT Request: Hail Surface Facilities Eps ProjectDocument4 pagesRT Request: Hail Surface Facilities Eps ProjectAnonymous AdofXEYAgENo ratings yet

- PAGE NO: 1 of 44 V-2153-004-154: SWGFD 23-002 A/B/C/D - Air Fin Cooler 11EPG18-1G05-CE-S-23 GC 001Document44 pagesPAGE NO: 1 of 44 V-2153-004-154: SWGFD 23-002 A/B/C/D - Air Fin Cooler 11EPG18-1G05-CE-S-23 GC 001karthickeyanclass4No ratings yet

- Process Calculation SWRO FROM MAHESHDocument40 pagesProcess Calculation SWRO FROM MAHESHgulfengsolutionsNo ratings yet

- Rail and Wheels: Guide ChannelDocument1 pageRail and Wheels: Guide ChannelnarumenonNo ratings yet

- Revision Index Description and / or Revised Sheets: Aker Kvaerner Process SystemsDocument2 pagesRevision Index Description and / or Revised Sheets: Aker Kvaerner Process SystemsAdilson MirandaNo ratings yet

- PPL NPL FOSL EGB PWIS INS DSH 008 - C01 - DatasheDocument3 pagesPPL NPL FOSL EGB PWIS INS DSH 008 - C01 - DatashesegunNo ratings yet

- Data Sheet Water Tank - STAMP AFCDocument6 pagesData Sheet Water Tank - STAMP AFCudantoNo ratings yet

- Piping and Instrumentation Diagram For HPU: Adcop - Abu Dhabi Crude Oil Pipeline Project Habshan - FujairahDocument4 pagesPiping and Instrumentation Diagram For HPU: Adcop - Abu Dhabi Crude Oil Pipeline Project Habshan - FujairahAdityaNo ratings yet

- QPE002342 - Technical BidDocument136 pagesQPE002342 - Technical BidMuhammed TamerNo ratings yet

- GD 2425 Ids 002Document1 pageGD 2425 Ids 002singhjyoti54.sjNo ratings yet

- 167.02.10 - EE-708 - Luminaires - Specification Sheet - Rev1Document6 pages167.02.10 - EE-708 - Luminaires - Specification Sheet - Rev1GHOST PAKNo ratings yet

- Dehumdifier 1Document46 pagesDehumdifier 1tssuwimal5973No ratings yet

- AIR CRASH INVESTIGATIONS - THE BOEING 737 MAX DISASTER PART 1 - The Crash of Lion Air Flight 610From EverandAIR CRASH INVESTIGATIONS - THE BOEING 737 MAX DISASTER PART 1 - The Crash of Lion Air Flight 610No ratings yet

- WiMedia UWB: Technology of Choice for Wireless USB and BluetoothFrom EverandWiMedia UWB: Technology of Choice for Wireless USB and BluetoothNo ratings yet

- Optimization and Business Improvement Studies in Upstream Oil and Gas IndustryFrom EverandOptimization and Business Improvement Studies in Upstream Oil and Gas IndustryNo ratings yet

- EPN-KSO-LBJ-TBBM-PIPE WORK PriceDocument4 pagesEPN-KSO-LBJ-TBBM-PIPE WORK PriceArif BinorikaNo ratings yet

- BQ Mi GacoanDocument9 pagesBQ Mi GacoanArif BinorikaNo ratings yet

- Tangga Rak GaramDocument1 pageTangga Rak GaramArif BinorikaNo ratings yet

- Estimasi Piping Accessories and Bulk Material For First Firing Unit #1Document4 pagesEstimasi Piping Accessories and Bulk Material For First Firing Unit #1Arif BinorikaNo ratings yet

- Lay Out Utility Pabrik WagirDocument1 pageLay Out Utility Pabrik WagirArif BinorikaNo ratings yet

- Lay Out Pembongkaran Line Utility Mini Primary GG GempolDocument1 pageLay Out Pembongkaran Line Utility Mini Primary GG GempolArif BinorikaNo ratings yet

- MEIA Bill of Quantity (BOQ) - For Review OnlyDocument532 pagesMEIA Bill of Quantity (BOQ) - For Review OnlyArif BinorikaNo ratings yet

- Uh CatalogDocument4 pagesUh CatalogArif BinorikaNo ratings yet

- Wagir Plant - MalangDocument13 pagesWagir Plant - MalangArif BinorikaNo ratings yet

- LAY OUT Hydrant. Alt.2Document1 pageLAY OUT Hydrant. Alt.2Arif BinorikaNo ratings yet

- Bill of Material Alt.2Document2 pagesBill of Material Alt.2Arif BinorikaNo ratings yet

- RAB MEIA MechanicalDocument362 pagesRAB MEIA MechanicalArif BinorikaNo ratings yet

- Meia Rab (14-3-2022)Document542 pagesMeia Rab (14-3-2022)Arif BinorikaNo ratings yet

- Data Material Isoplus Ex Project New SKM - Unit V Pt. Gudang Garam Tbk. - KediriDocument10 pagesData Material Isoplus Ex Project New SKM - Unit V Pt. Gudang Garam Tbk. - KediriArif BinorikaNo ratings yet

- Mapping Laydown MaspionDocument6 pagesMapping Laydown MaspionArif BinorikaNo ratings yet

- MAM 10th Shipment Packing List R1 - 20210314-Rev.1-BG-20210417-Rekap-BongkarDocument57 pagesMAM 10th Shipment Packing List R1 - 20210314-Rev.1-BG-20210417-Rekap-BongkarArif BinorikaNo ratings yet

- Canopy Parking at IF Area - R3 - ToVendorDocument8 pagesCanopy Parking at IF Area - R3 - ToVendorArif BinorikaNo ratings yet

- 1:100 0.00m Floor Layout: Cable SandwichDocument1 page1:100 0.00m Floor Layout: Cable SandwichArif BinorikaNo ratings yet

- Harga Jasa DuctingDocument1 pageHarga Jasa DuctingArif BinorikaNo ratings yet

- 2020-07-03 Indonesia MAM Starch and Sweetener Project DWG, DOC. Submission List EN RDocument4 pages2020-07-03 Indonesia MAM Starch and Sweetener Project DWG, DOC. Submission List EN RArif BinorikaNo ratings yet

- Den An Hormat, Bersama Ini Kami Menawarkan Harga Untuk Pembuatan Modif Kont, Dan Harga SBBDocument2 pagesDen An Hormat, Bersama Ini Kami Menawarkan Harga Untuk Pembuatan Modif Kont, Dan Harga SBBArif BinorikaNo ratings yet

- Galian PepiDocument2 pagesGalian PepiArif BinorikaNo ratings yet

- Isoplus Joint PDFDocument1 pageIsoplus Joint PDFArif BinorikaNo ratings yet

- 1:100 7.00m Floor Layout: Laboratory Micro Culture Sterile RoomDocument1 page1:100 7.00m Floor Layout: Laboratory Micro Culture Sterile RoomArif BinorikaNo ratings yet

- Laporan Final Progress: NO. Deskripsi Q'Ty Unit KeteranganDocument3 pagesLaporan Final Progress: NO. Deskripsi Q'Ty Unit KeteranganArif BinorikaNo ratings yet

- GEA DryCoolers InstalationDocument28 pagesGEA DryCoolers InstalationArif BinorikaNo ratings yet

- Rubber Hose For Automotive Air and Vacuum Brake System: Standard Test Methods ForDocument5 pagesRubber Hose For Automotive Air and Vacuum Brake System: Standard Test Methods ForPyone Ei ZinNo ratings yet

- FEMA FilterManual 2011Document362 pagesFEMA FilterManual 2011ina_cri100% (1)

- Amendment 01 PHED BSR 2022 PDFDocument89 pagesAmendment 01 PHED BSR 2022 PDFRJ JangidNo ratings yet

- Brochure - GTT Pluto II Subsea Cryogenic PipelineDocument6 pagesBrochure - GTT Pluto II Subsea Cryogenic PipelinefralgiugiaNo ratings yet

- Cooling Tower NotesDocument12 pagesCooling Tower NotesHimTex GlobalNo ratings yet

- Staff Houses BOQDocument17 pagesStaff Houses BOQwellington chilufyaNo ratings yet

- Thick-Walled Cylinder and Compound Cylinder Theory October 2, 2008Document5 pagesThick-Walled Cylinder and Compound Cylinder Theory October 2, 2008Nyasha ChipokaNo ratings yet

- Sample of Form MDRDocument11 pagesSample of Form MDRYuwantoniAlNo ratings yet

- Foundations and Equipment PadsDocument32 pagesFoundations and Equipment Padsaksh007No ratings yet

- Manual Elevators Y, A, G, X, S Series BNC DC Lift SystemDocument20 pagesManual Elevators Y, A, G, X, S Series BNC DC Lift SystemFranklin Jose Almera AcostaNo ratings yet

- Instrument Valves - PGI-IV PDFDocument32 pagesInstrument Valves - PGI-IV PDFRahmat RiskiNo ratings yet

- Acoustic ResonanceDocument10 pagesAcoustic ResonancegauthamanNo ratings yet

- Ornl 2440Document325 pagesOrnl 2440jesusNo ratings yet

- Clamp CatalogueDocument33 pagesClamp CatalogueRaja Guru100% (2)

- GREE Hw18024pnadDocument24 pagesGREE Hw18024pnadEdward PeñaNo ratings yet

- Pipe Welding 6G SMAW CertificationDocument11 pagesPipe Welding 6G SMAW Certificationsijeshclt100% (1)

- Steady ConductionDocument4 pagesSteady ConductionSanith RenjalNo ratings yet

- Mid-Statyes - Carbon Steel Pipe Fitting - Straight TEEDocument2 pagesMid-Statyes - Carbon Steel Pipe Fitting - Straight TEETamer BannaNo ratings yet

- Line SizingDocument17 pagesLine SizingAllyssa Jane ErcillaNo ratings yet

- Purmo Technical Catalogue Trench Convectors AQUILO - 08 - 2015 - EN - PLDocument52 pagesPurmo Technical Catalogue Trench Convectors AQUILO - 08 - 2015 - EN - PLMetin TamNo ratings yet

- Table UCS-56-11 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 15EDocument5 pagesTable UCS-56-11 Postweld Heat Treatment Requirements For Carbon and Low Alloy Steels - P-No. 15EMechanicalNo ratings yet

- Lecture 4A - Understanding Sanitary Plumbing SystemDocument35 pagesLecture 4A - Understanding Sanitary Plumbing SystemWong Lipping100% (1)

- Packoff and Slim Hole Gas Lift MandrelsDocument3 pagesPackoff and Slim Hole Gas Lift MandrelsashwaniNo ratings yet

- Carpenter & Paterson Hardware Price Book CP-0213Document54 pagesCarpenter & Paterson Hardware Price Book CP-0213Sargunam SankaravadivelNo ratings yet

- Descon News Spring-Summer 2009Document36 pagesDescon News Spring-Summer 2009Hassan Safdar MalikNo ratings yet

- Electrode SelectionDocument85 pagesElectrode SelectionShaheen Andre Chikku100% (2)

- MDB Standard ListDocument8 pagesMDB Standard ListSAMARTHNo ratings yet

- Ahmsa Steel - EnglishDocument88 pagesAhmsa Steel - Englishmanipalaniusa100% (1)

- Phased Array UT Application For Boiler Tube Inspection in Manufacturing Anandamurugan S, Siva Sankar YDocument10 pagesPhased Array UT Application For Boiler Tube Inspection in Manufacturing Anandamurugan S, Siva Sankar YmuhdmsohNo ratings yet