Professional Documents

Culture Documents

Auto Watch 446

Auto Watch 446

Uploaded by

MshiboniumOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Auto Watch 446

Auto Watch 446

Uploaded by

MshiboniumCopyright:

Available Formats

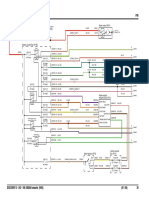

REAR VIEW OF UNIT ANTENNA

MANDATORY WIRING

CAN programming connection. Do not sleeve or tape

Refer to programming antenna with other wires.

instructions. Run antenna separately

and try to position CAN HIGH

away from metallic

objects

CAN LOW

GROUND

CHASSIS

PIN 2 CHASSIS

+ 12 VOLTS

LED PIN 3

+ 12 VOLTS

CAN STATUS

PIN 10 GROMMET

PIN 11

WIRE HARNESS INTO THE VEHICLE PRIOR

TO PLUGGING CONTROL MODULE IN

BATTERY BACK UP SIREN

REFER TO “VEHICLE SPECIFIC INFORMATION” FOR REQUIRED WIRING

PIN 7 NEG BONNET

INTERNAL RELAY CONFIGURATION SIREN

SLEEVED

SPEAKER RED + 12 V

PIN 12 OUTPUT

+12V

UNLOCK RELAY BLACK

N.O. - GREY PIN 14 See Note

9.0

PIN 15 FUSE +12V

N.C. - YELLOW

COMMON - BLUE PIN 13 BLACK

PIN 19 INDICATOR

LOCK RELAY PIN 23 + 12 VOLTS BONNET

N.O. - BROWN

PIN 24 +12V

N.C. - VIOLET

COMMON - GREEN

PIN 22 IGNITION (FUSED)

+12V WHEN THE IGNITION IS

IN THE ON AND CRANK POSITION. Ignition

NOTE : FUSES ARE switch

BLACK/GREY SERVICE PIN 9 NOT SUPPLIED

IGNITION

PIN 17

BLACK

(UNDER CARPET SWITCH) USED FOR VALET MODE

AND ADDITIONAL FEATURES (SEE 4.0, 13.0 & 14.0) DOORS

INDICATORS BOOT

PIN 18

JOIN TO THE INDICATORS PIN 20 BOOT

PIN 21

POSITIVE WIRE

+ OF INDICATOR + + 12 V

LIGHTS Hazard Pulse INTERIOR LIGHT

See Note 11.0 See Note 10.0

& Table 1 (8,9) Connect to and Table1 (8.3)

LEFT RIGHT

“BLUE" Door wire

THE OUTPUT BELOW IS NEGATIVE

SWITCHING (MAXIMUM CURRENT 300mA)

WHITE/ DOORS

BLACK PIN 1 RELAY REQUIRED FOR POSITIVE

WINDOWS INTERIOR LIGHT.

Drives interior light WITH POSITIVE DOOR SWITCHING

Requires additional Window Closer Module See Note 10.0 & Table1 (8.3) DRIVER'S

INTERIOR LIGHT WILL NOT FADE

(PFK Part No. 210-000) DOOR

SWITCH ON AND OFF

To select this function see 4.0

& Table 1. (5.1, 5.2, 5.3 & 5.4)

Wiring information will be supplied with the Module

OR } PIN 4

G.P. RELAY Part No. 436-900

(NOT SUPPLIED)

OR +12V Common

30 85 86

PAGER/TRACKING +12V

Coil

RELAY

WHITE/ Coil

Can be connected to Pager Module/Tracking System. BLACK + 12 V

To select this function see note 4.0 & Table 1 (5.1) INTERIOR Not N.Closed

87a 87

LIGHT connected N.Open

POS DOORS See Note 10.0

THESE OUTPUTS BELOW ARE NEGATIVE SWITCHING (MAXIMUM CURRENT 300mA) PIN 8 } OR

SELECTIVE UNLOCKING TRUNK RELEASE

Refer to To select & adjust this Function See Note 7.0 POSITIVE PULSE

Selective Unlocking see Note 4.0 & Table 1 PIN & Table 1 (7.4)

Options on Pg4 16

& See note 1.5 (4.1, 4.2, 4.3 & 4.4)".

OR

NEG

NEG OUT WHEN ARMED

To select this function

OR } OUT

TRUNK RELEASE

To ground or +12V Common

30 85 86

as required

see Note 4.0 & Table 1 (4,4) Coil

+12V

RELAY

PIN 5 BLACK/YELLOW WIRE Coil

GP RELAY TRUNK RELEASE

PFK PART NO.436 900 N.Closed

Not connected

87a 87

30 N.Open

To other side TO TRUNK RELEASE SOLENOID

of circuit to be (PFK SOLENOID PART NO. 088-510)

immobilised NOT SUPPLIED - G.P. RELAY

87 Part No. 436-900

Not Connected 85

To ignition

To one side of circuit 87a 86 Connect to neg out

to be immobilised when armed.

REAR VIEW OF

1.

2.

3.

4.

Negative Doors + Dome Light driving

Can High

Can Low

Aux 2 (Windows/Pager) (White/Black wire)

13.

14.

15.

16.

Unlock - Common (Blue wire) SLEEVED WITH

Unlock - N/O (Grey wire)

Unlock - N/C (Yellow wire)

WIRES FROM

}

PIN 22, 23 & 24

Aux 1 (Selective Unlock / Neg. Out when armed)

24-WAY HARNESS

5. Aux 3 (Trunk release) (Black/Yellow wire) 17. Ignition

6. Not Used 18. Indicators

7. Neg. Bonnet 19. Indicator +12V

8. Positive Doors 20. Indicators

9. Service 21. Negative Boot

}

10. Ground 22. Lock - Common (Green wire) SLEEVED WITH

11. + 12V 23. Lock - N/O (Brown wire) WIRES FROM

12. Speaker / Siren / Horn 24. Lock - N/C (Violet wire) PIN 13, 14 & 15

REV. 2 PAGE

AUTOWATCH 446 RLC ALARM WIRING DIAGRAM 01/04/09

DPFK 695/522 1 OF 5

Downloaded from www.Manualslib.com manuals search engine

Split-eye Ultrasonic Sensor Microwave Sensor

SENSORS Part No. 362-000 (Digital Part No. 567-000

See Note : 2.0 with Automatic Gain Control

4

ie. no adjustment)

SO E

B IC

A EY

N

K

R IT-

L

LT L

U SP

ED

R

BLACK

RED

WIRE HARNESS OR

INTO THE VEHICLE ALARM STATUS LED

PRIOR TO PLUGGING Part No. 198-954

CONTROL MODULE IN MOUNT FOR MAXIMUM VISIBILITY.

NOTE : THE STATUS LED MUST BE CONNECTED WITH THE SENSOR SHOWN.

NOTE : TO FULLY UNDERSTAND THE OPERATION OFTHE 446 RLC, YOU MUST 3.0 FIRST TIME INSTALL

GO THROUGH THIS DOCUMENT IN CONJUNCTION WITH THE OWNERS – ENSURING YOUR CAN VEHICLE IS LEARNT IN

MANUAL SUPPLIED WITH THE PRODUCT. The 446 is supplied with the latest set of supported vehicles pre-installed.

MECHANICAL INSTALLATION (Consult your distributer or Autowatch Portal for details). The learn process

MOUNTING is simple. Plug in the alarm and turn ON the ignition key. In normal

The control module must be installed in a concealed location inside the vehicle. Do not operation the CAN LED on the back of the unit provides details as to the

plug in the control module until the wiring is complete. All wire joints must be soldered current state of your unit.

and well insulated. Mount the control module vertically with the wires exiting from the

bottom to prevent damage resulting from water leaking into the vehicle and into the unit. STATE: CAN LED:

Awaiting CAN activity Single Flash

0.0 OVERVIEW [200ms ON ; 200ms OFF] every 800ms

The 446 has been designed to read and write to the vehicle’s CANBus,

allowing some, if not all wiring besides CANH, CANL, +12V and GND to be Vehicle BAUD rate detected Double Flash

left unwired. This is dependent on your vehicle and its specific CANBus Searching for Vehicle 2x [200ms ON 200ms OFF] every

functionality. Kindly consult the “Vehicle Specific Information” to determine 800ms

what additional wiring is required for your installation. Vehicle Detection Disabled 2x [200m/600ms* ON 200ms OFF]

every 800ms

The following functionality is available on the 446 RLC:

Alarm Ready Four flashes

INPUTS OUTPUTS Vehicle Self-Identified 4x[200ms ON 200ms OFF] every

Ignition Lock 800ms

Doors Unlock Vehicle Forced Married 4x[200ms/600ms* ON 200ms OFF]

Boot Selective Unlock every 800ms

Bonnet Trunk Release

ARM from OE Remote Window Closure Serial Flash Empty Five flashes

DISARM from OE Remote Horn 5x [200ms ON ; 200ms OFF] every

TRUNK RELEASE alarm isolation from OE Remote Hazards 800ms

*Functions which are not CAN enabled on your vehicle are required to *The CAN LED alternates between 200ms and 600ms for ON cycles. *

be hardwired. Vehicle Detection is disabled immediately after a Forced Unmarry (See

1.0 WIRING Note 3.1) and will remain disabled until the power is removed and re-

NOTE : DO NOT REMOVE WIRE LABELS UNTIL THE INSTALLATION IS applied.

TESTED AND WORKING. The alarm has been successfully configured when 4 flashes are observed.

1.1 MANDATORY WIRING: When the alarm in learnt into a new vehicle for the first time, the vehicle that

CANH / CANL was detected is displayed on the CAN STATUS LED in the manner

Connect the wire marled “CANH” to the CANH of your vehicle and the wire described in 3.12.

marked “CANL” to the CANL or alternately to the GROUND of your vehicle in If the 446 is married to a particular vehicle, after a timed period of no CAN

1-wire CAN vehicles. Be sure to limit the length of each wire to < 30cm. activity, the unit will enter a low current sleep mode. In this mode, the CAN

STATUS LED remains permanently OFF. Any CAN or alarm activity will

1.2 +12V wake up the unit and prompt the currently married vehicle to be displayed

Connect the wire marked “+12V” supply line to a fused +12V. on the CAN STATUS LED (as per 3.12). Following this, the 446 will then

begin to flashing 4 times, indicating the alarm's learnt and ready state.

1.3 GROUND/CHASSIS

Connect the wires marked "Ground" to two independent earth points. The latest update of supported vehicles may be uploaded into your 446

using the CANBus programming cable (Part Number 691-000) and

VEHICLE SPECIFIC WIRING software GUI. All software, software guides and vehicle updates are

1.4 CENTRAL LOCKING available on the Autowatch Portal.

The 446 has two relays for full central locking (see page 3) and low current 3.1 CANBus SPECIFIC FUNCTIONALITY (See 4.0 and Table 1)

negative central locking on the brown and white wires (see page 1). The time There may be cases where the unit is incorrectly identified or not identified

can be extended from 0.3 seconds to 3.0 seconds if required. See table 1. If at all using the Automatic Vehicle Detection. In this case you may have little

your vehicle supports locking on CANBus, either setting may be selected. or incomplete CAN functionality for your vehicle. In these cases the

1.5 SELECTIVE UNLOCKING SEE 4.0 & TABLE 1 additional abilities are provided: Refer to 4.0 on how to enter the

Two methods of selective unlocking are available. Program option 123 41. programmable features.

Type 1 is suited to aftermarket installations where central locking motors

are retrofitted to the vehicle. This option isolates the passenger motors by 3.1.1 FORCED MARRY (See 4.0 and Table 1 note 9,3)

interrupting the high current wire to the motor while the drivers door unlocks. Post selecting this feature, the user to required to input 4 additional digits

If your vehicle supports selective unlocking on CANBus, Selective [a,b,c,d] to represent the vehicle in the same manner as the feature

Unlocking, Type 1 MUST be selected. Program option 123 42. Type 2 is selection was entered.

suited to OEM central locking configurations. With this system the unlock

pulse unlocks the drivers door only, and the selective unlock pulse unlocks These digits represent:

the other doors. a: Manufacturer ID (Tens)

2.0 MOVEMENT SENSOR (Split-Eye Sensor Part Number 362 000) b: Manufacturer (Units)

The ultrasonic can be mounted on opposite sides of the vehicle. The c: Model ID (Tens)

sensors must face into the vehicle and be firmly mounted in place with no d: Model ID (Units)

obstructions immediately in front of them. Note that the two ultrasonic

transducers are not the same. When plugging the sensors into the split-eye Eg. The Mercedes Vito VSI shows this car to have a Vehicle ID Reference

interface unit ensure that the red sleeved sensor is plugged into the two way of 21-06. In this case a=2,b=1,c=0 and d=6. Note that a 0 is represented by

connector which is marked “RED” on the housing and the black sleeved 10 flashes.

sensor into the connector which is marked “BLACK” on the housing.

The list of Manufacturer and Model ID’s can be found on the Autowatch

Mount the ultrasonic control module and secure the separate sensor cables Portal and are additionally stated on each Vehicle Specific Information

to the main loom to prevent accidental unplugging of the sensors. sheet (VSI). This feature can be selected while the unit is in any state (ie if

Note : The split-eye ultrasonic sensor may be optionally replaced by a the BAUD has not been detected, or if the unit has already been learnt into

microwave sensor (Part No. 267-000) for vehicles with soft tops. another vehicle).

2.1 EARLY WARNING (SEE 4.0 & TABLE 1) If the vehicle is “found”, the vehicle selected will be displayed on the CAN

To select early warning refer to the programming procedure and enter the Status LED in the menu described in 3.12. If the vehicle is not found, the

code 123 77. See 4.0 & Table 1 CAN Status LED flash rate will remain unchanged.

Note: To include an early warning sensor you will require the 2 to 1

special adapter harness (PFK Part No 446-450).

REV. 2 PAGE

AUTOWATCH 446 RLC ALARM WIRING DIAGRAM 01/04/09 DPFK 695/522 2 OF 5

Downloaded from www.Manualslib.com manuals search engine

3.1.2 DISPLAY CURRENTLY MARRIED VEHICLE (See 4.0 & Table 1 446 RLC FEATURE SELECTION TABLE

note 9.4)

OPTION

Enter the program code 1,2,3 followed by the Feature Selection Code

Post selecting this feature the CAN STATUS LED will become FEATURE INDICATION

FEATURE SELECTION

illuminated for 3 seconds, followed by a flashing sequence that CODE ONE BEEP TWO BEEPS

involves 4 sets of counts. 1,1 Trigger Report back (See 5.0) 1,1 LED FLASHES SWITCH IGNITION

RAPIDLY - 2 SECS OFF TO CLEAR

3,3 Unlock with Ignition 3,3 ON OFF *

These sets of counts are displayed in the following order:

3,4 Lock with Ignition 3,4 ON OFF *

Manufacturer (Tens) 3,6 Double Unlock Pulse (See 1.5) 3,6 ON OFF *

Manufacturer (Units) 3,7 Double Lock Pulse (See 1.5) 3,7 ON OFF *

Model (Tens) A. If Neg. Out when Armed is not used: (See wiring diagram for explanation)

Model (Units) 4,1 Selective Unlock - Type 1 (See 1.5) 4,1 ON OFF *

The sequence is terminated by a final 3 second pulse. 4,2 Selective Unlock - Type 2 (See 1.5) 4,2 ON OFF *

4,3 Selective Unlock Inhibit (See 1.5) 4,3 ON OFF *

Eg If the 4 sets of counts return 3 flashes à 2 flashes à 10 flashes 4,4 Selective Unlock / Neg. Out when armed 4,4 Neg. Out * Selective

à 1 flash the 446 is learnt into ManufacturerID 32 & ModelID 01. 5,1 Window / Pager (See 6.0) 5,1 PAGER WINDOW *

B. If Pager is not used, the following window options may be selected:

The relationship between Manufacturer & Model ID’s and the 5,2 Window 10 second wind time 5,2 ON * OFF

vehicles they represent can be found on the Autowatch Portal. This 5,3 Window 45 second wind time 5,3 ON OFF *

relationship is additionally stated on each Vehicle Specific 5,4 Window 120 second wind time 5,4 ON OFF *

Information sheet (VSI) and each ManufacturerID / ModelID 6,1 Arm/disarm tones on/off 6,1 ON * OFF

combination describes a unique vehicle. 7,4 Pos Doors/Trunk Isolation Input (See 7.0) 7,4 Trunk Isolation Input Positive Doors*

7,7 Early Warning (See 2.1) 7,7 ON OFF *

Arm/disarm Hazard Confirmation

If the unit has not been married to a vehicle, there are just two 3 7,8 with OE Remote 7,8 ON OFF *

second pulses in succession. Note again that a 0 is represented by Arm/disarm Hazard Confirmation

10 flashes. 8,1 with Autowatch Remote 8,1 OFF * ON

8,2 “Stop Sounding” with Arm Button 8,2 OFF ON *

This flashing sequence additionally occurs each time the 446 8,3 Interior / Dome Light 8,3 OFF ON *

awakes from its low current sleep mode. 8,4 Auto rearm time 8,4 30 seconds 120 seconds*

8,5 Auto Arming alarm (See 8.0) 8,5 ON OFF *

8,6 Auto Rearming alarm (See 8.0) 8,6 ON * OFF

3.1.3 UNMARRY & DISABLE VEHICLE DETECTION (See 4.0 & Table 1 8,7 Lock when Auto Arming or Auto Rearming 8,7 ON OFF *

note 9.5) 8,8 Door open audible warning 8,8 ON * OFF

If a vehicle has been married incorrectly this feature will allow the 8,9 Hazard Pulse 8,9 ON OFF *

user to unmarry it and force the 446 to disable AutoDetection. Whilst C. CANBus Specific functionality #

the unmarrying does occur automatically when forcing a new 9,3 Vehicle Forced Marriage 9,3,a,b,c,d N/A N/A

marriage (See 3.1.1) this feature is still provided in case of any 9,4 Display Current Vehicle 9,4 N/A N/A

difficulties with a busy CANBus or other unknown irregularities. 9,5 Unmarry & Disable Vehicle Detection 9,5 N/A N/A

# Note that whilst the ALARM STATUS LED is used to select the digits for feature selections 9,3 ; 9,4 ;

3.1.4 PROGRAMMABLE FEATURES. 9,5, it is the CAN STATUS LED which returns the Flashing Sequence to identify the vehicle.

Programming the selectable features is as easy as 1,2,3! The #Note too that depending on your vehicle, Feature Selections 9,3 ; 9,4 ; 9,5 may not be reliable using the

number 1,2,3, is entered using the flashing LED and either the ignition switch and it is thus strongly suggested to use the grey wired valet mode button as the input

method for these selections.

ignition switch or the valet mode button. By entering the additional

two digits the features as described in the Table 1. can be selected or 9,9 Central locking time 0.3/3.0 sec 9,9 0.3 sec * 3.0 sec

de-selected. NOTE THAT A ZERO IS REPRESENTED BY 10 LED FLASHES

*

FLASHES. 0,4 Reset (Revert to Factory Setting) 0,4 RAPIDLY FOR

2 SECONDS TABLE 1

If you are at any stage confused by the number of flashes, wait for 10

flashes then simply start from the beginning again. NOTE : A ZERO IS REPRESENTED BY TEN FLASHES

4.0 ENTERING FEATURE SELECTIONS

FACTORY SETTINGS HIGHLIGHTED WITH A IN THE TABLE ABOVE. *

Once the installation is complete, do a functional test to ensure that

the installation is working. Once you are satisfied that the basic 5.0 TRIGGER REPORT BACK (SEE 4.0 & TABLE 1 note 1.1)

features are working: In the event of a false alarm complaint from a customer, the cause can be

accessed using the Trigger Report Back feature. To access this information,

a. Enter Program Mode. This can be done in one of two ways.

i. Switch the ignition on/off 5 times in 10 seconds enter the program code, 1,2,3, followed by the code 1,1. The Alarm Status

ii. Press and hold the Valet Mode button for 5seconds or more. LED begins to flash a number of times to indicate the cause of the alarm.

These flashes are as follows:

Program Mode will be confirmed by the LED remaining steady ON. 1 Flash : Movement Sensor (Ultrasonic)

The following example will continue using the Ignition switch to 2 Flashes : Wireless Sensor Zone

select digits. The following are however identical in functionality:

(When allocated to its own zone)

Turning ON and keeping the <Or> Pressing and holding the 3 Flashes : Panic

Ignition ON Valet Mode Button 4 Flashes : Ignition

Turning OFF and keeping the <Or> Releasing

Button.

the Valet Mode 5 Flashes : Negative Door

Ignition OFF 6 Flashes : Positive Door

b. Switch the ignition OFF, the LED will start to flash. After 1 flash, 7 Flashes : Boot

Turn the ignition ON. The LED will be steady ON. This is the first 8 Flashes : Bonnet

digit - “1” entered.

The trigger information is cleared once the alarm has been turned on and off

.

c.Switch the ignition OFF, the LED will start to flash. After 2 flashes, 10 times without triggering.

turn the ignition ON. The LED will be steady ON. This is the

second digit “2” entered. 6.0 WINDOW PAGER & TRACKING OUTPUT. (SEE 4.0 & TABLE 1 note 5.1)

.

d.Switch the ignition OFF, the LED will start to flash. After 3 Pager & Tracking output : The output is a low current output that can be

flashes, turn the ignition ON. The LED will flash rapidly to connected to a pager or a tracking unit. It will switch to ground five seconds

indicate that you have entered the third digit "3" correctly and that

you are in program mode. Wait until the LED is steady on again. after the alarm is triggered.

Window Output : The line is pulled low for the duration specified in by 5,2 – 5,3

e. Enter the first 2 digits of the feature you require. As an example,

to select Early Warning, the digits 7,7 would need to be entered. or 5,4. Note: the Window Winding time is irrelevant for CANBus enabled

vehicles and the feature need only be selected

Proceed as follows:-

i. Switch the ignition OFF, the LED will start to flash. After 7 7.0 POS DOORS / TRUNK RELEASE INPUT (SEE 4.0 & TABLE 1 note 7,4)

flashes, turn the ignition ON. The LED will be steady ON. This The Pos Doors input may alternately be enabled as a Trunk Isolation input.

is the first function digit - "7" entered. When enabled, a positive pulse on this wire will temporarily isolate the alarm

ii. Switch the ignition OFF, the LED will start to flash. After 7 for 20 seconds. If the trunk is seen open during this 20 second period, the door

flashes, turn the ignition ON. The LED will flash rapidly to and movement sensor inputs will remain isolated until the trunk closes again.

indicate that you have entered the second digit "7" correctly

and the siren will sound once. The early warning feature is 8.0 AUTO ARMING/AUTO REARMING (SEE 3.0 & TABLE 1 note 8.5, 8.6 & 8.7)

selected.

You may select and deselect additional features by simply The factory default is to auto rearm but auto arming can be selected. The

entering its two digit selection code - it is not necessary to re- doors can be programmed to lock when auto arming or auto rearming. Consult

enter 1,2,3 again. with the owner before selecting this option as it can result in the keys being

locked in the vehicle! Auto rearming may be deselected.

REV. 2 PAGE

AUTOWATCH 446 RLC ALARM WIRING DIAGRAM 01/04/09 DPFK 695/522 3 OF 5

Downloaded from www.Manualslib.com manuals search engine

9.0 SIREN Turning ON and keeping the Ignition <Or> Pressing and holding the Valet

ON Mode Button

Connect the bonnet switch to the single black wire coming out of the

siren. Feed the thick black multicore wire through a grommet into the Turning OFF and keeping the Releasing the Valet Mode Button.

Ignition OFF <Or>

vehicle interior and connect up as shown on page 1.

10 INTERIOR LIGHT (SELECTABLE) (SEE 4.0 & TABLE 1 note 8.3) b. Enter each digit of the code using the flashing LED and ignition switch.

The interior light illumination is connected to the negative door wire (Blue After entering the last digit, the LED will flash rapidly for 2 seconds.

wire). The light will fade on and off. See table 1 (8.3) Pg 2 for feature

selection. c. Enter the two digit code 3, 3. The LED will flash rapidly for two seconds.

NOTE : If the vehicle has positive door switching this feature can still be

wired using an additional relay but without the fade facility. (SEE WIRING d. Within 8 seconds activate the wireless sensor. The LED will turn on, and

DIAGRAM PAGE 1) a barp will be heard indicating that the sensor has been detected. Within

5 seconds, the sensor needs to be added into a zone. To add it into the

11 HAZARD PULSE same zone as the hardwired movement sensors press the “Arm/Lock”

To check that the ‘Hazard Pulse’ mode is suitable for a particular car, on the alarm transmitter. To add it to an independant wireless sensor

access the back of the vehicle’s hazard light switch and momentarily zone press the Off/Unlock button and a barp will be heard to confirm

connect a ground (via a 5Amp fuse) to the switched side. The hazard successful programming.

lights should start flashing and will continue to flash until the ground wire

is connected again to the same point on the switch. If the test is e. Note if neither the On or Off button is pressed within 5 seconds of

satisfactory, enable ‘hazard’ while programming (Table 1 option 8.9) and ....receiving a wireless sensor signal the sensor will not be added to

connect the yellow wire from the alarm to the switched side of the hazard ....memory. You can still activate an alternate sensor for an additional 5

light switch. Note that if Hazard functionality is available on CANBus, this ....seconds and then program it into the required zone.

feature may still need to set up depending on your vehicle (Consult the

specific vehicle information). f. To exit program mode, wait for 10 seconds or switch the ignition off.

12 QUICK TEST

To enter quick test, enter the Program Code, 1,2,3. The arming time and

the siren time are shortened to facilitate quick and easy testing. To exit

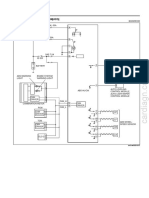

CENTRAL LOCKING CONFIGURATIONS

quick test, do not trigger the alarm for a period of two minutes and the unit NOTE : The 446 RLC has full central locking capability on board.

will exit automatically. Alternatively, select any programmable feature. Connector outputs - as per diagram.

13 PROGRAMMING NEW REMOTE CONTROLS POSITIVE TO LOCK AND POSITIVE TO UNLOCK

Whilst the alarm is not supplied with any remotes, the unit has the ability ALTERNATE POSITIVE

to learn up to 6 remotes.

GREEN - LOCK JOIN TO VEHICLE’S

To program, refer to the 5 digit user code supplied with the unit or the CENTRAL LOCKING

BLUE - UNLOCK CONTROL WIRES

code attached to the control module and proceed as follows.

SL GREY

EE

a) The process is started in one of two ways. VE

D

CONNECT BOTH WIRES TO

i) Switch the ignition on/off 5 times in 10 seconds A +12V FUSED LINE (20 AMP)

ii) Press and hold the Valet Mode button for 5 seconds or more. BROWN

YELLOW NOT CONNECTED. INSULATE WELL

VIOLET NOT CONNECTED. INSULATE WELL

The example will continue using the Ignition switch to select digits.

The following are however identical in functionality: NEGATIVE TO LOCK AND NEGATIVE TO UNLOCK

HIGH CURRENT - ALTERNATE NEGATIVE

Turning ON and keeping the <Or> Pressing and holding the Valet GREEN - LOCK JOIN TO VEHICLE’S

Ignition ON Mode Button CENTRAL LOCKING

BLUE - UNLOCK CONTROL WIRES

Turning OFF and keeping the <Or> Releasing the Valet Mode

Ignition OFF Button.

GREY

SL CONNECT BOTH WIRES

EE

VE TO A RELIABLE BATTERY

b. Enter each digit of the code using the flashing LED and ignition D NEGATIVE/EARTH POINT

.....switch. After entering the last digit, the LED will flash rapidly for 2 ON THE VEHICLE

.....seconds. BROWN

YELLOW NOT CONNECTED. INSULATE WELL

VIOLET NOT CONNECTED. INSULATE WELL

c. Enter the two digit code 1, 1 leaving the ignition ON after the final digit.

....The LED will flash rapidly for two seconds.

ALTERNATING POLARITY - TO DRIVE 4 SLAVE MOTORS

d. Transmit with the new remote for approximately half a second, BLUE COMMON UNLOCK

.....pausing for half a second between each transmission, until the LED GREEN COMMON LOCK

.....flashes rapidly indicating that the remote is now programmed. Further

.....remotes may now also be programmed.

SL

EE

VE

e. Note that if a seventh transmitter is programmed into the alarm D

VIOLET N/C LOCK

.....system it will override the first code learnt. To remove all transmitters,

.....fill the 6 memory spaces with 6 new transmitters, or a single YELLOW N/C UNLOCK

.....transmitter 6 times.

GREY N/O UNLOCK

f. To exit program mode, either wait for 10 seconds without transmitting + 12 V

BROWN N/O LOCK

.....or switch the ignition off. (FUSED 20A)

14 PROGRAMMING NEW WIRELESS SENSORS (Optional Sensors) PNEUMATIC PUMP CONTROL (MERCEDES BENZ)

The unit has the ability to learn up to 6 wireless sensors. BLUE - TO PUMP MOTOR CUT CONTROL

To program, refer to the 5 digit user code supplied with the unit or the WIRE AND JOIN

VIOLET - TO DOOR AS SHOWN

code attached to the control module and proceed as follows:

CONNECT TO A +12V

GREY FUSED LINE (20 AMP)

a) The process is started in one of two ways.

SL

i) Switch the ignition on/off 5 times in 10 seconds EE

VE

D

ii) Press and hold the Valet Mode button for 5 seconds or more. BROWN

CONNECT TO A RELIABLE

EARTH POINT

GREEN JOIN TOGETHER AND

The example will continue using the Ignition switch to select digits.

YELLOW INSULATE WELL WITH TAPE

The following are however identical in functionality: NOTE :

A longer pulse duration is required for the pumps to operate efficiently.

The longer pulse duration is selectable. See note 1.4 & Table 1 (9,9)

REV. 2 PAGE

AUTOWATCH 446 RLC ALARM WIRING DIAGRAM 01/04/09 DPFK 695/522 4 OF 5

Downloaded from www.Manualslib.com manuals search engine

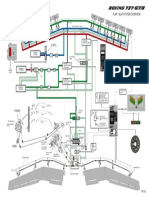

SELECTIVE UNLOCKING WIRING OPTIONS

OPTION 1A THIS CONFIGURATION IS IDEAL WHEN USING SLAVE DOOR MOTORS

GREY

+ 12 VOLTS

BROWN (FUSED 20A) PASSENGER

AND REAR

VIOLET DOOR

SL

EE YELLOW DRIVERS MOTORS

VE

D

DOOR

MOTOR

GP RELAY

PFK PART

NO.436 900 GREEN LOCK LOCK

ALTERNATING

30 POLARITY

BLUE UNLOCK UNLOCK

87

NORMALLY 85

OPEN: +12V

DO NOT 87a 86

CONNECT CONNECT TO SELECTIVE UNLOCK FROM ALARM

OPTION 1 (B) THIS CONFIGURATION IS IDEAL WHEN INSTALLING A 4-DOOR CENTRAL LOCKING KIT

AL

DRIVERS FRONT REAR

AR

PASSENGER

M

DOOR PASSENGER

UN

MOTOR DOOR DOOR

TI

MOTOR MOTORS

LOCK

CENTRAL UNLOCK

COMMON

GP RELAY

PFK PART

LOCK

NO.436 900 BROWN MODULE LOCK GREEN LOCK

BROWN/WHITE UNLOCK BLUE

30 UNLOCK

BLUE

NORMALLY 87

OPEN: 85

DO NOT +12V

CONNECT 87a 86 CONNECT TO SELECTIVE UNLOCK FROM ALARM

OPTION 2 THIS CONFIGURATION IS IDEAL FOR MODIFYING NOTE :

FACTORY FITTED CENTRAL LOCKING MOTORS Following this modification, the passenger

doors will no longer unlock when the driver's

door is unlocked manually.

AL

AR

M

UN

FITTING THE SECURITY HOUSING

IT

FRONT REAR Once the installation is complete and fully

DRIVERS PASSENGER PASSENGER tested the security cover can be fitted.

DOOR DOOR DOOR

MOTOR MOTOR MOTORS

Ensure that the slide in the security

housing is not fitted and route all the wires,

with the exception off the LED and

MOVEMENT SENSOR wires, through the

BROWN/WHITE

slot and fit the slide.

BROWN

Attach the security housing to the main

casing using the screws provided and

LOCK

insert the anti-tamper Screw caps.

UNLOCK

CENTRAL COMMON

LOCK

LOCK LOCK

MODULE UNLOCK

UNLOCK

CUT AND INSULATE

GP RELAY

PFK PART # The 'active' polarity is the opposite

NO.436 900 polarity of the motors at rest.

NORMALLY OPEN:CONNECT TO 87 30

GROUND OR +12V AS REQUIRED 85

TO DRIVE MOTORS # +12V

CONNECT TO 'REST STATE' OF MOTOR WIRES 87a 86

(determined by the polarity of the motors at rest) CONNECT TO SELECTIVE UNLOCK FROM ALARM

REV. 2 PAGE

AUTOWATCH 446 RLC ALARM WIRING DIAGRAM 01/04/09 DPFK 695/522 5 OF 5

Downloaded from www.Manualslib.com manuals search engine

You might also like

- 2002 ICON International Wiring DiagramDocument1 page2002 ICON International Wiring DiagramRaul E. SoliNo ratings yet

- Volvo BL60B (Sistemas Elétricos)Document228 pagesVolvo BL60B (Sistemas Elétricos)Willian HenriqueNo ratings yet

- Clifford Arrow 3 WiringDocument2 pagesClifford Arrow 3 WiringBill Stevens100% (1)

- Manual Chevy Spark 2012Document1 pageManual Chevy Spark 2012Mario Ruiz del SolNo ratings yet

- Manual de Partes Crown We - WS2300Document240 pagesManual de Partes Crown We - WS2300Andrey Fernando Luque Segura100% (1)

- I30 Electric Scheme PDF FreeDocument207 pagesI30 Electric Scheme PDF Freepedrodany9098No ratings yet

- 14 Sequoia (Cont. Next Page) : Electronic Modulated Air SuspensionDocument3 pages14 Sequoia (Cont. Next Page) : Electronic Modulated Air SuspensionWaleed AlshgaaaNo ratings yet

- Autowatch 457rli-PfkdocumentationDocument4 pagesAutowatch 457rli-Pfkdocumentation6Pacman100% (1)

- Generic With Curtis 1268 5411 ControlDocument6 pagesGeneric With Curtis 1268 5411 Controlpavli999No ratings yet

- Model W210 Electric Seat AdjustmentDocument29 pagesModel W210 Electric Seat AdjustmentNacho100% (2)

- C2 G 20 Max 3080000 Btu Output 10 To 1 TurndownDocument8 pagesC2 G 20 Max 3080000 Btu Output 10 To 1 TurndownBülent KabadayiNo ratings yet

- Hydraulic Analogy of Supersonic Flow - Lab Notes: EUROAVIA SymposiumDocument9 pagesHydraulic Analogy of Supersonic Flow - Lab Notes: EUROAVIA SymposiumaminvelayatNo ratings yet

- Em12r1u PDFDocument482 pagesEm12r1u PDFAnwar ZaibNo ratings yet

- Wabco E Basic ECU PDFDocument1 pageWabco E Basic ECU PDFاحمد ابو عبداللهNo ratings yet

- Ecu (Engine Control Unit - DSL) : 5-8 Electrical Wiring DiagramsDocument8 pagesEcu (Engine Control Unit - DSL) : 5-8 Electrical Wiring DiagramsJuan Sebastian Hernandez SolanoNo ratings yet

- Et4wiringdiagramcompressed 10120Document1 pageEt4wiringdiagramcompressed 10120Jack YauNo ratings yet

- F Electrical Wiring Diagram (System Circuits) : LAND CRUISER Station Wagon (EWD342F) LAND CRUISER Station Wagon (EWD342F)Document1 pageF Electrical Wiring Diagram (System Circuits) : LAND CRUISER Station Wagon (EWD342F) LAND CRUISER Station Wagon (EWD342F)وليدمطهر الشجاعNo ratings yet

- Schematic DiagramDocument13 pagesSchematic DiagramSas WajiNo ratings yet

- Accord 2000 (Ecm)Document3 pagesAccord 2000 (Ecm)jamespituco3No ratings yet

- Saab V4 Wiring DiagramDocument1 pageSaab V4 Wiring DiagramHenrique Correia100% (1)

- Uni-Swc 3Document48 pagesUni-Swc 3AbrahamAcostaGonzalez50% (2)

- DPX-MP3110 DPX-MP3110S DPX-MP5110U DPX-MP5110US Service ManualDocument56 pagesDPX-MP3110 DPX-MP3110S DPX-MP5110U DPX-MP5110US Service ManualLIKINNo ratings yet

- ESP (ETS) Module Pin-Out 2Document2 pagesESP (ETS) Module Pin-Out 2Ridwan RafiifNo ratings yet

- 2003 Ranger 2.3 at WiringDocument3 pages2003 Ranger 2.3 at WiringReese BlalockNo ratings yet

- Computer Control SystemDocument67 pagesComputer Control SystemToua YajNo ratings yet

- Fgtech Tested EcuDocument9 pagesFgtech Tested EcuHarris RaoNo ratings yet

- Grote Catalog 2016 Flashers and Turn Signal SwitchesDocument10 pagesGrote Catalog 2016 Flashers and Turn Signal SwitchesmiguelcastilloNo ratings yet

- Vdo Ecu PinDocument3 pagesVdo Ecu PinjjoehairyNo ratings yet

- 321 Aim Pectel T6 100 EngDocument5 pages321 Aim Pectel T6 100 EngmisdeismoNo ratings yet

- Fusilera Peugeot 308 Mk2 2013-15Document3 pagesFusilera Peugeot 308 Mk2 2013-15skpppNo ratings yet

- DTC Chart Power TrainDocument156 pagesDTC Chart Power TrainHuguito DiazNo ratings yet

- ECU Pin-Out 90-93 MTDocument1 pageECU Pin-Out 90-93 MTAkis AlmasidisNo ratings yet

- Wiring DigramDocument8 pagesWiring Digramazeemm1No ratings yet

- Denso 112500-1xxx DSM HinoDocument3 pagesDenso 112500-1xxx DSM HinoSlamat AgungNo ratings yet

- Mmcflash Vehicle ReprogrammingDocument11 pagesMmcflash Vehicle ReprogrammingMetro WirandaNo ratings yet

- 2015 Mercedes-Benz S550 4matic 4.6LDocument174 pages2015 Mercedes-Benz S550 4matic 4.6LData TécnicaNo ratings yet

- Electronic Engine ControlsDocument6 pagesElectronic Engine ControlstuningNo ratings yet

- Bosch Edc17cp15 Xrom Tc1796 Mitsubishi 1033Document3 pagesBosch Edc17cp15 Xrom Tc1796 Mitsubishi 1033ddf_dedoNo ratings yet

- Deep Sea Electronics: Model 5220 Installation and Configuration InstructionsDocument2 pagesDeep Sea Electronics: Model 5220 Installation and Configuration InstructionsNaing Min HtunNo ratings yet

- Power Source: 78 HIACE (EWD622E)Document4 pagesPower Source: 78 HIACE (EWD622E)Egoro KapitoNo ratings yet

- CGC Vehicles: Date: 12 Apr 24 S.No Asset ID Description Model Year Make Current K.M Fuel Consumption (Gal/km) ProjectDocument3 pagesCGC Vehicles: Date: 12 Apr 24 S.No Asset ID Description Model Year Make Current K.M Fuel Consumption (Gal/km) Projectanwar.alhaririNo ratings yet

- Murr Elektronik Catalog PDFDocument32 pagesMurr Elektronik Catalog PDFSosialNo ratings yet

- Obd 2 CodesDocument29 pagesObd 2 CodescalvinyewNo ratings yet

- 5 - 12 Section 5 - Diagnosis J-1 ECM Connector Identification (1 of 2 J-1)Document8 pages5 - 12 Section 5 - Diagnosis J-1 ECM Connector Identification (1 of 2 J-1)MyBriggsNo ratings yet

- 3412C Emcp Ii Electrical System + For PEEC Engines: Ptl1-Up 9EP1-UP Bcw1-Up 4BZ1-UPDocument4 pages3412C Emcp Ii Electrical System + For PEEC Engines: Ptl1-Up 9EP1-UP Bcw1-Up 4BZ1-UPCH MUBASHER MAQSOOD ALAMNo ratings yet

- DTC P055B-P055D: Applies ToDocument5 pagesDTC P055B-P055D: Applies ToWillie AustineNo ratings yet

- HTG GCU GS7d36sg Installation v12Document9 pagesHTG GCU GS7d36sg Installation v12Ioan Alexandru DragomirNo ratings yet

- Cat Electronic Technician 2015A v1.0 Product Status ReportDocument7 pagesCat Electronic Technician 2015A v1.0 Product Status ReportAnonymous YFDU14WP0UNo ratings yet

- 99 Impreza Wiring Diagram PDFDocument55 pages99 Impreza Wiring Diagram PDFwilderNo ratings yet

- 3zr ToyotaDocument9 pages3zr ToyotaDavid ParariNo ratings yet

- 320C Excavator Electrical System: Electrical Schematic Symbols and DefinitionsDocument2 pages320C Excavator Electrical System: Electrical Schematic Symbols and DefinitionsDiego Orlando Santos BuitragoNo ratings yet

- Headless Connection: AE 7206 System Wiring DiagramDocument1 pageHeadless Connection: AE 7206 System Wiring Diagramalan rangelNo ratings yet

- 2008 Mazda MPV - Brake - Symptom Troubleshooting (ABS)Document15 pages2008 Mazda MPV - Brake - Symptom Troubleshooting (ABS)lo mio es mioNo ratings yet

- PDFDocument5 pagesPDFJohn Mark CorralesNo ratings yet

- Schematic DrawingDocument10 pagesSchematic DrawingponpisutNo ratings yet

- 207 - USER ManualDocument28 pages207 - USER ManualQsanac KumbaraNo ratings yet

- Subaru Immobilizer (Diagnostics)Document24 pagesSubaru Immobilizer (Diagnostics)Amon KiayNo ratings yet

- Focus C307 All SchematicsDocument113 pagesFocus C307 All SchematicsTadeusz KlimaszewskiNo ratings yet

- 2.0L FS & 1.6L ZM EngineDocument707 pages2.0L FS & 1.6L ZM EngineKamil Charmik Luža100% (1)

- Wiring Diagram Leyland Diesel 154 - With Supplimentary Alternator DiagramDocument3 pagesWiring Diagram Leyland Diesel 154 - With Supplimentary Alternator DiagramJeremy Jones0% (1)

- Bmw/Mini All Cas1/Cas2/Cas3/Cas3+ Remote/Proximity : Brand Area Model Key Type Year Show Key CountDocument3 pagesBmw/Mini All Cas1/Cas2/Cas3/Cas3+ Remote/Proximity : Brand Area Model Key Type Year Show Key CountOscar GonzalezNo ratings yet

- Steel Strong-Wall Single Wall Portal 1 5 Multi-Ply HeadersDocument1 pageSteel Strong-Wall Single Wall Portal 1 5 Multi-Ply HeaderskrlosNo ratings yet

- Engineering Standards: Typical 2 Lane Urban Road SectionDocument1 pageEngineering Standards: Typical 2 Lane Urban Road SectionFitri ArianggiNo ratings yet

- Panoramic Power Wireless Sensors Bridge DatasheetDocument1 pagePanoramic Power Wireless Sensors Bridge DatasheettiagoorgadoNo ratings yet

- OSP-P300/P300A: Relocation Detection UnitDocument12 pagesOSP-P300/P300A: Relocation Detection UnitMINH DAONo ratings yet

- Home Security SystemDocument8 pagesHome Security SystemBiplav ChoudhuryNo ratings yet

- Quinsyn Compressor FluidsDocument6 pagesQuinsyn Compressor FluidsRoberto AlfaroNo ratings yet

- Flow Properties and Design Procedures For Coal Storage Bins PDFDocument401 pagesFlow Properties and Design Procedures For Coal Storage Bins PDFEmaVanni100% (2)

- What Is Cloud ComputingDocument21 pagesWhat Is Cloud ComputinganilkarriiNo ratings yet

- B737NG - 27 50 A3 01 PDFDocument1 pageB737NG - 27 50 A3 01 PDFMuhammed MudassirNo ratings yet

- The Sproutling Baby Monitor Keep Tabs On Your Newborn With This Smart Ankle BraceletDocument2 pagesThe Sproutling Baby Monitor Keep Tabs On Your Newborn With This Smart Ankle BraceletAllanStevenNo ratings yet

- At9000 GTX60GDocument9 pagesAt9000 GTX60Gjuan valderramaNo ratings yet

- Ancon EdjPro EPHIMini Edge Lifting SystemDocument2 pagesAncon EdjPro EPHIMini Edge Lifting SystemsashilaNo ratings yet

- The Integration of Core and BHI and Resulting Depo Model - Moreni Field Central Romania, EAGE, 2012Document4 pagesThe Integration of Core and BHI and Resulting Depo Model - Moreni Field Central Romania, EAGE, 2012Paul V GrechNo ratings yet

- Arson Invest 2Document100 pagesArson Invest 2Harrison sajorNo ratings yet

- Ship Power PlantDocument141 pagesShip Power Plantnguyentrunghieu51dltt100% (2)

- Sonic Logging: M. P. Tixier R. P. AlgerDocument9 pagesSonic Logging: M. P. Tixier R. P. Algersaeed65No ratings yet

- Introducing The Qest Broker: Scaling The Iot by Bridging MQTT and RestDocument6 pagesIntroducing The Qest Broker: Scaling The Iot by Bridging MQTT and RestM. A. BNo ratings yet

- Crouzet Switch CatalogDocument51 pagesCrouzet Switch Cataloghammondelec100% (2)

- Diagram SankeyDocument5 pagesDiagram SankeyNur WidyaNo ratings yet

- Explicit Frequency Equation and Mode Shapes of A Cantilever Beam Coupled in Bending and Torsion PDFDocument15 pagesExplicit Frequency Equation and Mode Shapes of A Cantilever Beam Coupled in Bending and Torsion PDFHossam T BadranNo ratings yet

- 8 Sem Report 190060106004 Mehul Chauhan Final Report Last SemDocument53 pages8 Sem Report 190060106004 Mehul Chauhan Final Report Last SemLalji AhirNo ratings yet

- PM EquipmentDocument16 pagesPM Equipmentsiva prasadNo ratings yet

- Ti CQDocument4 pagesTi CQPradeepNo ratings yet

- Eis-Cms-Pk - 023-Replacement of Girth Gear Assembly For 03-Vr-2701abDocument5 pagesEis-Cms-Pk - 023-Replacement of Girth Gear Assembly For 03-Vr-2701abhastmishNo ratings yet

- Sting-S4 Poh UlDocument63 pagesSting-S4 Poh UlJorge E. Arias VargasNo ratings yet

- Copyright ProtectionDocument6 pagesCopyright ProtectionKamalbir KaurNo ratings yet

- LB 47Document2 pagesLB 47roozbehxoxNo ratings yet

- INNOVA 2.0E/2.0G (Auto) (Minor Change) : Model Code: TGN40Document4 pagesINNOVA 2.0E/2.0G (Auto) (Minor Change) : Model Code: TGN40Ismail IbrahimNo ratings yet

- Graduate Program CoursesDocument11 pagesGraduate Program CoursesAhmed Adel IbrahimNo ratings yet