Professional Documents

Culture Documents

Poster Fyp

Poster Fyp

Uploaded by

U2003924 STUDENTCopyright:

Available Formats

You might also like

- Boundary Wall Design Staad File PDFDocument6 pagesBoundary Wall Design Staad File PDFParwan Exceltech0% (1)

- Bamboo Materials in Cement, Geopolymer and Reinforced Concrete AsDocument18 pagesBamboo Materials in Cement, Geopolymer and Reinforced Concrete AsabebechNo ratings yet

- Kermetico HVAF Protective Coatings For Internal Diameters of Pipe Lines, Vessels and Industrial EquipmentDocument9 pagesKermetico HVAF Protective Coatings For Internal Diameters of Pipe Lines, Vessels and Industrial EquipmentycwbycwbNo ratings yet

- AB0034 Alloy25Document12 pagesAB0034 Alloy25Scott LongmireNo ratings yet

- Pavement PerformanceDocument70 pagesPavement PerformanceAnonymous J9OnNRNo ratings yet

- Technical Data Sheet: ApplicationsDocument2 pagesTechnical Data Sheet: ApplicationsAndrei IvanovichNo ratings yet

- Mechanical and Tribological Properties of Ceramic Tiles: A ReappraisalDocument14 pagesMechanical and Tribological Properties of Ceramic Tiles: A ReappraisalSalih MohayaddinNo ratings yet

- Eural-6082-EN RohsDocument1 pageEural-6082-EN RohsRoger ColomaNo ratings yet

- Experimental Investigation On Waste Utilization Ofmarble Dust in Concrete With Partially Replacement of CementDocument7 pagesExperimental Investigation On Waste Utilization Ofmarble Dust in Concrete With Partially Replacement of CementIJRASETPublicationsNo ratings yet

- B1 Mix Design CVCDocument15 pagesB1 Mix Design CVCmazaqhoneyNo ratings yet

- Self-Compacting Concrete and Its Application in Hong KongDocument23 pagesSelf-Compacting Concrete and Its Application in Hong KongKris dNo ratings yet

- C-13-Test Methods-Composite Managers-2014Document44 pagesC-13-Test Methods-Composite Managers-2014robertopelusoNo ratings yet

- Poster Template - Capstone Project 2022-23 - UpdatedDocument1 pagePoster Template - Capstone Project 2022-23 - UpdatedEdwinNo ratings yet

- Krioni 2012Document3 pagesKrioni 2012MATTHEWS HENRIQUE COTA ARAUJONo ratings yet

- LGMMA Acrylic Coating Resin Brochure 2017 EDocument2 pagesLGMMA Acrylic Coating Resin Brochure 2017 EFausa Okta Ananta LaksaNo ratings yet

- Dafc Mars HabDocument45 pagesDafc Mars HabHungary UNHRC ShahNo ratings yet

- Base Isolator Untuk Rumah Tinggal Di Daerah Rawan GempaDocument26 pagesBase Isolator Untuk Rumah Tinggal Di Daerah Rawan Gempainsan fadilNo ratings yet

- Materials and Design: M.A.E.M. Ali, A.M. Soliman, M.L. NehdiDocument11 pagesMaterials and Design: M.A.E.M. Ali, A.M. Soliman, M.L. NehdidrpNo ratings yet

- Sonic Scanner, SPAN and NOVADocument2 pagesSonic Scanner, SPAN and NOVAleonardofr312No ratings yet

- Sonicscanner Spanrock Perforating Design ColombiaDocument2 pagesSonicscanner Spanrock Perforating Design ColombiaFaresdzbNo ratings yet

- A Throat Thickness Z Leg Length: DisadvantagesDocument5 pagesA Throat Thickness Z Leg Length: DisadvantagesSumit SharmaNo ratings yet

- Bituminous Soft Fibre BoardDocument1 pageBituminous Soft Fibre BoardTayyabah ZafarNo ratings yet

- Rock Reinforcement Modelling - Cable Bolts in PLAXIS 2DDocument12 pagesRock Reinforcement Modelling - Cable Bolts in PLAXIS 2Dchaymaa MRHARNo ratings yet

- Quasistatic Deformation and Failure Modes of Composite Square HoneycombsDocument27 pagesQuasistatic Deformation and Failure Modes of Composite Square HoneycombsfredNo ratings yet

- Foundation Plan 2Nd Floor Framing Plan: B C D A B C D ADocument1 pageFoundation Plan 2Nd Floor Framing Plan: B C D A B C D AMark Ruby OpawonNo ratings yet

- (MAKALE) A Review On Carbon-Based Self-Sensing Cementitious CompositesDocument14 pages(MAKALE) A Review On Carbon-Based Self-Sensing Cementitious CompositesİMİRZA OKAY ALTUNTAŞNo ratings yet

- Application of Metal Matrix Composite & Ceramic Matrix CompositeDocument5 pagesApplication of Metal Matrix Composite & Ceramic Matrix CompositeDzulkarnaen Mohd KamalNo ratings yet

- TALAT Lecture 5203: Anodizing of AluminiumDocument27 pagesTALAT Lecture 5203: Anodizing of AluminiumCORE Materials100% (2)

- 06 LANT DATASHEET SORIC XXF WebDocument1 page06 LANT DATASHEET SORIC XXF WebAlejandro AlbanesiNo ratings yet

- Paper Sanded Grout ThermalDocument4 pagesPaper Sanded Grout ThermalronaldoNo ratings yet

- Slide PresentationDocument17 pagesSlide PresentationCt Izzatul AisyahNo ratings yet

- Effects of Polymer Hardness On The Abrasive Wear Resistance of Thick Organic Offshore CoatingsDocument11 pagesEffects of Polymer Hardness On The Abrasive Wear Resistance of Thick Organic Offshore CoatingsJoao VitorNo ratings yet

- Drawing3 Layout1Document1 pageDrawing3 Layout1mohamedsshNo ratings yet

- Riyadh Work ShopDocument114 pagesRiyadh Work ShopMostafa AboaliNo ratings yet

- TCC15 Resistance of Retaining Members XLDocument8 pagesTCC15 Resistance of Retaining Members XLalexanderNo ratings yet

- Kuliah Ke 2 Dan 3 Polymer Nanocomposite KuliahDocument70 pagesKuliah Ke 2 Dan 3 Polymer Nanocomposite KuliahGilang KrisnawanNo ratings yet

- 1 s2.0 S187770581630563X MainDocument8 pages1 s2.0 S187770581630563X MainMarco FigueiredoNo ratings yet

- Sami PDFDocument15 pagesSami PDFGkou DojkuNo ratings yet

- A Comparison of Stress-Strain Behaviour of Conventional and High Strength ConcreteDocument4 pagesA Comparison of Stress-Strain Behaviour of Conventional and High Strength Concretemahesh1214No ratings yet

- FT 048 Ultramastic 850 HSHBDocument2 pagesFT 048 Ultramastic 850 HSHBdamibi16No ratings yet

- TemplateDocument17 pagesTemplatemamthaNo ratings yet

- Polipropilen Fibres 2Document11 pagesPolipropilen Fibres 2Ante KovacicNo ratings yet

- 1-s2.0-S0264127520301295-mainDocument7 pages1-s2.0-S0264127520301295-mainUttakantha DixitNo ratings yet

- Omega 900 InstructionsDocument27 pagesOmega 900 InstructionsRA Dental LaboratoryNo ratings yet

- Hfo Filter Skid: Civil WorksDocument2 pagesHfo Filter Skid: Civil Worksali mohammedNo ratings yet

- STR DWGDocument23 pagesSTR DWGsamerNo ratings yet

- Unit Price For Retrofitting WorksDocument2 pagesUnit Price For Retrofitting Workslaxmi29No ratings yet

- Integration Aspects For Damascene Copper Interconnect in Low K DielectricDocument3 pagesIntegration Aspects For Damascene Copper Interconnect in Low K DielectricKwanghoon Ken KimNo ratings yet

- Fiber Optic Piezometer MIB0056B RTSDocument1 pageFiber Optic Piezometer MIB0056B RTSLordbyron23No ratings yet

- Bending - Shear Interaction in Rbs Short Coupling Beams-LibreDocument10 pagesBending - Shear Interaction in Rbs Short Coupling Beams-LibreSakisNo ratings yet

- Polietileno 100% SolidoDocument4 pagesPolietileno 100% Solidohector stackNo ratings yet

- Anti-UV Waterborne Nanocomposite Coatings For Exterior WoodDocument21 pagesAnti-UV Waterborne Nanocomposite Coatings For Exterior WoodLong An ĐỗNo ratings yet

- General Construction Notes: Bureau of DesignDocument1 pageGeneral Construction Notes: Bureau of DesignGarry WaveNo ratings yet

- Meyco FIB 500 PDFDocument2 pagesMeyco FIB 500 PDFFrancois-No ratings yet

- WS I CalaanDocument13 pagesWS I CalaanI am CanapeeNo ratings yet

- Molins: Technical Data SheetDocument2 pagesMolins: Technical Data SheetsasidharkanthetiNo ratings yet

- 2005 Structural Architecture of Wide Span Enclosures Uncertainties in Reliability Assesment PDFDocument17 pages2005 Structural Architecture of Wide Span Enclosures Uncertainties in Reliability Assesment PDFdamandadinoNo ratings yet

- Experimental Pull-Out Tests and Design IndicationsDocument16 pagesExperimental Pull-Out Tests and Design Indicationsحسام رسميNo ratings yet

- BEHAVIOUR AND STRENGTH ASSESSMENT OF Masonry PrismsDocument42 pagesBEHAVIOUR AND STRENGTH ASSESSMENT OF Masonry Prismsmanish_shashikantNo ratings yet

- Experimental Study On Flexural Behaviour of RC Beams With Graphene Oxide and Bottom AshDocument35 pagesExperimental Study On Flexural Behaviour of RC Beams With Graphene Oxide and Bottom AshPraveen RajNo ratings yet

- Introduction To Acoustic Emission TestingDocument3 pagesIntroduction To Acoustic Emission TestingRaul Humberto Mora VillamizarNo ratings yet

- General Requirements For Alloy and Stainless Steel PipeDocument11 pagesGeneral Requirements For Alloy and Stainless Steel Pipergi178No ratings yet

- Lateral Earth PressureDocument2 pagesLateral Earth PressureLaura HernandezNo ratings yet

- HTTPDocument8 pagesHTTPColumb Virgiliu EmanoilNo ratings yet

- Lifting Lug Cal PDFDocument1 pageLifting Lug Cal PDFveeru2906No ratings yet

- Steel-Beam Design in Accordance To BS-5950: PreliminariesDocument16 pagesSteel-Beam Design in Accordance To BS-5950: PreliminariesRecardoNo ratings yet

- Low Voltage & Control Cables: Exploration & Production - OffshoreDocument2 pagesLow Voltage & Control Cables: Exploration & Production - OffshoreJorge Luis SuarezNo ratings yet

- Stair CaseDocument10 pagesStair CaseUmar AbidNo ratings yet

- RENR65060001 Hid 773Document21 pagesRENR65060001 Hid 773mauricio suarezNo ratings yet

- Strength Enhancement in Concrete Confined by Spirals: AbstractDocument6 pagesStrength Enhancement in Concrete Confined by Spirals: AbstracthemalcmistryNo ratings yet

- Dokumen - Tips - False Ceiling 6th Sem 59266234e630a PDFDocument17 pagesDokumen - Tips - False Ceiling 6th Sem 59266234e630a PDF1RW20AT019darshanNo ratings yet

- Fatigue Test: ObjectiveDocument4 pagesFatigue Test: Objectiveenzo1078No ratings yet

- Garuda Creek View BrochureDocument20 pagesGaruda Creek View Brochureroshniconcorde114No ratings yet

- KAT0130-0004-E Cables For Reeling SystemsDocument76 pagesKAT0130-0004-E Cables For Reeling Systemsfranklinr68No ratings yet

- Facility Safety & Security ChecklistDocument2 pagesFacility Safety & Security Checklistilrf100% (1)

- Muncie CS12 PTO Part ListDocument2 pagesMuncie CS12 PTO Part ListfugegaNo ratings yet

- Contract ReportDocument412 pagesContract ReportMcDonald WesleyNo ratings yet

- Revised Plumbing Code of The Philippines - Part1Document2 pagesRevised Plumbing Code of The Philippines - Part1MBA103003No ratings yet

- Legend:: Makati Development CorporationDocument1 pageLegend:: Makati Development CorporationCharles NunezNo ratings yet

- Lindner KatalogDocument64 pagesLindner KatalogAnonymous hISvHbfiB1No ratings yet

- Bearing QuestionsDocument6 pagesBearing QuestionsSatyajit PandaNo ratings yet

- 11 Green Building Materials That Are Way Better Than Concrete - Inhabitat - Green Design, Innovation, Architecture, Green BuildingDocument19 pages11 Green Building Materials That Are Way Better Than Concrete - Inhabitat - Green Design, Innovation, Architecture, Green BuildingCarlo IbuyanNo ratings yet

- Silt Content TestDocument3 pagesSilt Content Testdreamboy87100% (2)

- Install Manual RFHM Eng 0904Document9 pagesInstall Manual RFHM Eng 0904Ernesto MarceloNo ratings yet

- DWG-04.11-ME-011 Pri - Sludge - Pump - Station 3 - 5 (r.6) PDFDocument5 pagesDWG-04.11-ME-011 Pri - Sludge - Pump - Station 3 - 5 (r.6) PDFAhmed HussienNo ratings yet

- PriceList Royu Wires Devices JAN 2018 Issue V1Document6 pagesPriceList Royu Wires Devices JAN 2018 Issue V1Rafael VillafloresNo ratings yet

- Mechanical Services HVAC Design MES v2017.05Document14 pagesMechanical Services HVAC Design MES v2017.05Elie BaradhyNo ratings yet

- Course IntroDocument6 pagesCourse IntrosuirezNo ratings yet

Poster Fyp

Poster Fyp

Uploaded by

U2003924 STUDENTOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Poster Fyp

Poster Fyp

Uploaded by

U2003924 STUDENTCopyright:

Available Formats

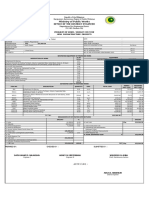

Study on Thermal Properties of Spent Mushroom Substrate

Final Year Project Incorporated Concrete Brick

Poster Presentation

2023 / 2024

NURUL ATHIRA BINTI NOORULLA (U2003924/1)

Department of Civil Engineering, Faculty of Engineering, Universiti Malaya, Kuala Lumpur

FYP30

INTRODUCTION RESULTS

1. Compressive strength

BRICKS :

80.0

❖ High demand in the construction industry due to: 70.0

Compressive strength (Mpa)

-Durability 60.0

-Thermal mass

50.0

-Aesthetic appeal

40.0

30.0

SPENT MUSHROOM SUBSTRATE (SMS) : 20.0

10.0

❖ Agricultural waste product from mushroom

0.0

cultivation.

SMS-0 SMS-5 SMS-10 SMS-15 SMS-20 SMS-25

❖ Improve the mechanical properties, durability, and -10.0

SMS replacement (%)

thermal insulation of bricks.

❖ Low-cost materials. 3rd day Strength (MPa) 7th day Strength (MPa) 28th day Strength (MPa)

Problem statement : 2. Modulus of rupture (Flexural strength)

❖ SMS is frequently discarded as garbage which is environmental challenge such as ground AVE. MODULUS OF RUPTURE (MPA)

water contamination and unpleasant odour due to open dumping. 6

5

RESEARCH OBJECTIVES 4

3

To optimise mix proportions for SMS to achieve the desired qualities by analyse the

1 relationship between percentage of SMS and performance of concrete bricks. 2

1

To investigate the way the presence of SMS influences the durability and

2 compressive strength of bricks to meet industry standards.

0

0% 5% 10% 15% 20% 25% 30%

To evaluate impact of SMS on thermal performance and insulation characteristics of

3 Ave. Modulus of rupture (MPa)

bricks to gain better understanding of their thermal behaviour.

3. Water absorption

30.0 10.0

METHODOLOGY water absorption at 5 hours (%)

Initial Rate of Absorbtion (kg/m²/min)

water absorption at 24 hours (%)

25.0 5.0

1. Material properties

Water Absorption (%)

Sand SMS

20.0 0.0

Specific gravity 2.66 1.00

Finesse modulus 2.56 2.29 15.0 -5.0

Water absorption (%) 0.4 21.8

10.0 -10.0

2. Mix design

5.0 -15.0

SMS Cement Sand (kg/m3) SMS (kg/m3) Water (kg/m3) Density

REPLACEMENT (kg/m3) (kg/m3)

0.0 -20.0

0 5 10 15 20 25

0% 556.7 1670.1 0.0 180.9 2226.7 SMS Replacement (%)

5% 556.7 1586.6 32.3 180.9 2143.3 4. Thermal acoustic

10% 556.7 1503.1 64.6 180.9 2059.8 160.0

15% 556.7 1419.6 96.9 180.9 1976.3

140.0

20% 556.7 1336.1 129.2 180.9 1892.8

25% 556.7 1252.6 161.5 180.9 1809.3 120.0

Temperature (˚C)

3. Testing 100.0

80.0

60.0

40.0

20.0

0.0

0 2000 4000 6000 8000 10000 12000

Time (s)

0% SMS 5% SMS

10% SMS 15% SMS

20% SMS 25% SMS

Compressive strength test Flexural strength test

CONCLUSION

• Optimum mix design : cement to sand ratio is 1:3 and water to cement ratio is 0.325 .

• SMS reduce the overall strength of brick, requiring mix design adjustment for structural

integrity .

• SMS can enhance thermal properties of cement bricks.

• SMS incorporating bricks can be cost-effective due to waste utilization and material saving.

• Supports the development of sustainable and promotes the recycling of agricultural waste.

Water absorption test Thermal conductivity test

You might also like

- Boundary Wall Design Staad File PDFDocument6 pagesBoundary Wall Design Staad File PDFParwan Exceltech0% (1)

- Bamboo Materials in Cement, Geopolymer and Reinforced Concrete AsDocument18 pagesBamboo Materials in Cement, Geopolymer and Reinforced Concrete AsabebechNo ratings yet

- Kermetico HVAF Protective Coatings For Internal Diameters of Pipe Lines, Vessels and Industrial EquipmentDocument9 pagesKermetico HVAF Protective Coatings For Internal Diameters of Pipe Lines, Vessels and Industrial EquipmentycwbycwbNo ratings yet

- AB0034 Alloy25Document12 pagesAB0034 Alloy25Scott LongmireNo ratings yet

- Pavement PerformanceDocument70 pagesPavement PerformanceAnonymous J9OnNRNo ratings yet

- Technical Data Sheet: ApplicationsDocument2 pagesTechnical Data Sheet: ApplicationsAndrei IvanovichNo ratings yet

- Mechanical and Tribological Properties of Ceramic Tiles: A ReappraisalDocument14 pagesMechanical and Tribological Properties of Ceramic Tiles: A ReappraisalSalih MohayaddinNo ratings yet

- Eural-6082-EN RohsDocument1 pageEural-6082-EN RohsRoger ColomaNo ratings yet

- Experimental Investigation On Waste Utilization Ofmarble Dust in Concrete With Partially Replacement of CementDocument7 pagesExperimental Investigation On Waste Utilization Ofmarble Dust in Concrete With Partially Replacement of CementIJRASETPublicationsNo ratings yet

- B1 Mix Design CVCDocument15 pagesB1 Mix Design CVCmazaqhoneyNo ratings yet

- Self-Compacting Concrete and Its Application in Hong KongDocument23 pagesSelf-Compacting Concrete and Its Application in Hong KongKris dNo ratings yet

- C-13-Test Methods-Composite Managers-2014Document44 pagesC-13-Test Methods-Composite Managers-2014robertopelusoNo ratings yet

- Poster Template - Capstone Project 2022-23 - UpdatedDocument1 pagePoster Template - Capstone Project 2022-23 - UpdatedEdwinNo ratings yet

- Krioni 2012Document3 pagesKrioni 2012MATTHEWS HENRIQUE COTA ARAUJONo ratings yet

- LGMMA Acrylic Coating Resin Brochure 2017 EDocument2 pagesLGMMA Acrylic Coating Resin Brochure 2017 EFausa Okta Ananta LaksaNo ratings yet

- Dafc Mars HabDocument45 pagesDafc Mars HabHungary UNHRC ShahNo ratings yet

- Base Isolator Untuk Rumah Tinggal Di Daerah Rawan GempaDocument26 pagesBase Isolator Untuk Rumah Tinggal Di Daerah Rawan Gempainsan fadilNo ratings yet

- Materials and Design: M.A.E.M. Ali, A.M. Soliman, M.L. NehdiDocument11 pagesMaterials and Design: M.A.E.M. Ali, A.M. Soliman, M.L. NehdidrpNo ratings yet

- Sonic Scanner, SPAN and NOVADocument2 pagesSonic Scanner, SPAN and NOVAleonardofr312No ratings yet

- Sonicscanner Spanrock Perforating Design ColombiaDocument2 pagesSonicscanner Spanrock Perforating Design ColombiaFaresdzbNo ratings yet

- A Throat Thickness Z Leg Length: DisadvantagesDocument5 pagesA Throat Thickness Z Leg Length: DisadvantagesSumit SharmaNo ratings yet

- Bituminous Soft Fibre BoardDocument1 pageBituminous Soft Fibre BoardTayyabah ZafarNo ratings yet

- Rock Reinforcement Modelling - Cable Bolts in PLAXIS 2DDocument12 pagesRock Reinforcement Modelling - Cable Bolts in PLAXIS 2Dchaymaa MRHARNo ratings yet

- Quasistatic Deformation and Failure Modes of Composite Square HoneycombsDocument27 pagesQuasistatic Deformation and Failure Modes of Composite Square HoneycombsfredNo ratings yet

- Foundation Plan 2Nd Floor Framing Plan: B C D A B C D ADocument1 pageFoundation Plan 2Nd Floor Framing Plan: B C D A B C D AMark Ruby OpawonNo ratings yet

- (MAKALE) A Review On Carbon-Based Self-Sensing Cementitious CompositesDocument14 pages(MAKALE) A Review On Carbon-Based Self-Sensing Cementitious CompositesİMİRZA OKAY ALTUNTAŞNo ratings yet

- Application of Metal Matrix Composite & Ceramic Matrix CompositeDocument5 pagesApplication of Metal Matrix Composite & Ceramic Matrix CompositeDzulkarnaen Mohd KamalNo ratings yet

- TALAT Lecture 5203: Anodizing of AluminiumDocument27 pagesTALAT Lecture 5203: Anodizing of AluminiumCORE Materials100% (2)

- 06 LANT DATASHEET SORIC XXF WebDocument1 page06 LANT DATASHEET SORIC XXF WebAlejandro AlbanesiNo ratings yet

- Paper Sanded Grout ThermalDocument4 pagesPaper Sanded Grout ThermalronaldoNo ratings yet

- Slide PresentationDocument17 pagesSlide PresentationCt Izzatul AisyahNo ratings yet

- Effects of Polymer Hardness On The Abrasive Wear Resistance of Thick Organic Offshore CoatingsDocument11 pagesEffects of Polymer Hardness On The Abrasive Wear Resistance of Thick Organic Offshore CoatingsJoao VitorNo ratings yet

- Drawing3 Layout1Document1 pageDrawing3 Layout1mohamedsshNo ratings yet

- Riyadh Work ShopDocument114 pagesRiyadh Work ShopMostafa AboaliNo ratings yet

- TCC15 Resistance of Retaining Members XLDocument8 pagesTCC15 Resistance of Retaining Members XLalexanderNo ratings yet

- Kuliah Ke 2 Dan 3 Polymer Nanocomposite KuliahDocument70 pagesKuliah Ke 2 Dan 3 Polymer Nanocomposite KuliahGilang KrisnawanNo ratings yet

- 1 s2.0 S187770581630563X MainDocument8 pages1 s2.0 S187770581630563X MainMarco FigueiredoNo ratings yet

- Sami PDFDocument15 pagesSami PDFGkou DojkuNo ratings yet

- A Comparison of Stress-Strain Behaviour of Conventional and High Strength ConcreteDocument4 pagesA Comparison of Stress-Strain Behaviour of Conventional and High Strength Concretemahesh1214No ratings yet

- FT 048 Ultramastic 850 HSHBDocument2 pagesFT 048 Ultramastic 850 HSHBdamibi16No ratings yet

- TemplateDocument17 pagesTemplatemamthaNo ratings yet

- Polipropilen Fibres 2Document11 pagesPolipropilen Fibres 2Ante KovacicNo ratings yet

- 1-s2.0-S0264127520301295-mainDocument7 pages1-s2.0-S0264127520301295-mainUttakantha DixitNo ratings yet

- Omega 900 InstructionsDocument27 pagesOmega 900 InstructionsRA Dental LaboratoryNo ratings yet

- Hfo Filter Skid: Civil WorksDocument2 pagesHfo Filter Skid: Civil Worksali mohammedNo ratings yet

- STR DWGDocument23 pagesSTR DWGsamerNo ratings yet

- Unit Price For Retrofitting WorksDocument2 pagesUnit Price For Retrofitting Workslaxmi29No ratings yet

- Integration Aspects For Damascene Copper Interconnect in Low K DielectricDocument3 pagesIntegration Aspects For Damascene Copper Interconnect in Low K DielectricKwanghoon Ken KimNo ratings yet

- Fiber Optic Piezometer MIB0056B RTSDocument1 pageFiber Optic Piezometer MIB0056B RTSLordbyron23No ratings yet

- Bending - Shear Interaction in Rbs Short Coupling Beams-LibreDocument10 pagesBending - Shear Interaction in Rbs Short Coupling Beams-LibreSakisNo ratings yet

- Polietileno 100% SolidoDocument4 pagesPolietileno 100% Solidohector stackNo ratings yet

- Anti-UV Waterborne Nanocomposite Coatings For Exterior WoodDocument21 pagesAnti-UV Waterborne Nanocomposite Coatings For Exterior WoodLong An ĐỗNo ratings yet

- General Construction Notes: Bureau of DesignDocument1 pageGeneral Construction Notes: Bureau of DesignGarry WaveNo ratings yet

- Meyco FIB 500 PDFDocument2 pagesMeyco FIB 500 PDFFrancois-No ratings yet

- WS I CalaanDocument13 pagesWS I CalaanI am CanapeeNo ratings yet

- Molins: Technical Data SheetDocument2 pagesMolins: Technical Data SheetsasidharkanthetiNo ratings yet

- 2005 Structural Architecture of Wide Span Enclosures Uncertainties in Reliability Assesment PDFDocument17 pages2005 Structural Architecture of Wide Span Enclosures Uncertainties in Reliability Assesment PDFdamandadinoNo ratings yet

- Experimental Pull-Out Tests and Design IndicationsDocument16 pagesExperimental Pull-Out Tests and Design Indicationsحسام رسميNo ratings yet

- BEHAVIOUR AND STRENGTH ASSESSMENT OF Masonry PrismsDocument42 pagesBEHAVIOUR AND STRENGTH ASSESSMENT OF Masonry Prismsmanish_shashikantNo ratings yet

- Experimental Study On Flexural Behaviour of RC Beams With Graphene Oxide and Bottom AshDocument35 pagesExperimental Study On Flexural Behaviour of RC Beams With Graphene Oxide and Bottom AshPraveen RajNo ratings yet

- Introduction To Acoustic Emission TestingDocument3 pagesIntroduction To Acoustic Emission TestingRaul Humberto Mora VillamizarNo ratings yet

- General Requirements For Alloy and Stainless Steel PipeDocument11 pagesGeneral Requirements For Alloy and Stainless Steel Pipergi178No ratings yet

- Lateral Earth PressureDocument2 pagesLateral Earth PressureLaura HernandezNo ratings yet

- HTTPDocument8 pagesHTTPColumb Virgiliu EmanoilNo ratings yet

- Lifting Lug Cal PDFDocument1 pageLifting Lug Cal PDFveeru2906No ratings yet

- Steel-Beam Design in Accordance To BS-5950: PreliminariesDocument16 pagesSteel-Beam Design in Accordance To BS-5950: PreliminariesRecardoNo ratings yet

- Low Voltage & Control Cables: Exploration & Production - OffshoreDocument2 pagesLow Voltage & Control Cables: Exploration & Production - OffshoreJorge Luis SuarezNo ratings yet

- Stair CaseDocument10 pagesStair CaseUmar AbidNo ratings yet

- RENR65060001 Hid 773Document21 pagesRENR65060001 Hid 773mauricio suarezNo ratings yet

- Strength Enhancement in Concrete Confined by Spirals: AbstractDocument6 pagesStrength Enhancement in Concrete Confined by Spirals: AbstracthemalcmistryNo ratings yet

- Dokumen - Tips - False Ceiling 6th Sem 59266234e630a PDFDocument17 pagesDokumen - Tips - False Ceiling 6th Sem 59266234e630a PDF1RW20AT019darshanNo ratings yet

- Fatigue Test: ObjectiveDocument4 pagesFatigue Test: Objectiveenzo1078No ratings yet

- Garuda Creek View BrochureDocument20 pagesGaruda Creek View Brochureroshniconcorde114No ratings yet

- KAT0130-0004-E Cables For Reeling SystemsDocument76 pagesKAT0130-0004-E Cables For Reeling Systemsfranklinr68No ratings yet

- Facility Safety & Security ChecklistDocument2 pagesFacility Safety & Security Checklistilrf100% (1)

- Muncie CS12 PTO Part ListDocument2 pagesMuncie CS12 PTO Part ListfugegaNo ratings yet

- Contract ReportDocument412 pagesContract ReportMcDonald WesleyNo ratings yet

- Revised Plumbing Code of The Philippines - Part1Document2 pagesRevised Plumbing Code of The Philippines - Part1MBA103003No ratings yet

- Legend:: Makati Development CorporationDocument1 pageLegend:: Makati Development CorporationCharles NunezNo ratings yet

- Lindner KatalogDocument64 pagesLindner KatalogAnonymous hISvHbfiB1No ratings yet

- Bearing QuestionsDocument6 pagesBearing QuestionsSatyajit PandaNo ratings yet

- 11 Green Building Materials That Are Way Better Than Concrete - Inhabitat - Green Design, Innovation, Architecture, Green BuildingDocument19 pages11 Green Building Materials That Are Way Better Than Concrete - Inhabitat - Green Design, Innovation, Architecture, Green BuildingCarlo IbuyanNo ratings yet

- Silt Content TestDocument3 pagesSilt Content Testdreamboy87100% (2)

- Install Manual RFHM Eng 0904Document9 pagesInstall Manual RFHM Eng 0904Ernesto MarceloNo ratings yet

- DWG-04.11-ME-011 Pri - Sludge - Pump - Station 3 - 5 (r.6) PDFDocument5 pagesDWG-04.11-ME-011 Pri - Sludge - Pump - Station 3 - 5 (r.6) PDFAhmed HussienNo ratings yet

- PriceList Royu Wires Devices JAN 2018 Issue V1Document6 pagesPriceList Royu Wires Devices JAN 2018 Issue V1Rafael VillafloresNo ratings yet

- Mechanical Services HVAC Design MES v2017.05Document14 pagesMechanical Services HVAC Design MES v2017.05Elie BaradhyNo ratings yet

- Course IntroDocument6 pagesCourse IntrosuirezNo ratings yet