Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

1 viewsBilco 1

Bilco 1

Uploaded by

bedoo54Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Claas Jaguar Error CodesDocument20 pagesClaas Jaguar Error Codesbedoo54100% (2)

- Cummins - QSB4.5 CM2350Document18 pagesCummins - QSB4.5 CM2350bedoo54100% (3)

- 5008S Fresenuis Service ManualDocument318 pages5008S Fresenuis Service ManualEslam Karam100% (10)

- EIL TenderDocument1,178 pagesEIL TenderSamrat Roy Chowdhury100% (10)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Nexus 4in 10k 2-Door WBA Stripper Manual - REV 13Document26 pagesNexus 4in 10k 2-Door WBA Stripper Manual - REV 13Pastor Velasquez100% (1)

- 07 StraddlesDocument12 pages07 StraddlesyariyantoNo ratings yet

- Comptia Security Sy0 601 Exam Objectives (2 0)Document24 pagesComptia Security Sy0 601 Exam Objectives (2 0)tha_flameNo ratings yet

- Audio Information and MediaDocument2 pagesAudio Information and Mediajosefalarka75% (4)

- BilcoDocument16 pagesBilcoruloNo ratings yet

- Grooved Piping System: Product DescriptionDocument4 pagesGrooved Piping System: Product DescriptionDGWNo ratings yet

- Banki Water Turbine Design and Construction ManualDocument65 pagesBanki Water Turbine Design and Construction ManualGreen Action Sustainable Technology Group100% (2)

- Bridge PlugsDocument9 pagesBridge Plugskaveh-bahiraeeNo ratings yet

- Catalogo Huck C50L PDFDocument8 pagesCatalogo Huck C50L PDFVladimir SepulvedaNo ratings yet

- Valve SelectDocument20 pagesValve SelectsajuhereNo ratings yet

- Ringlock SystemDocument8 pagesRinglock Systemdox4useNo ratings yet

- GCS0004Document21 pagesGCS0004RazkulNo ratings yet

- Brochure - VN - OL - Cracking Mill OLCC - SCREEN - NewDocument4 pagesBrochure - VN - OL - Cracking Mill OLCC - SCREEN - NewRodrigo Vieira FariaNo ratings yet

- Client:-Visa Power Limited: Released For ConstructionDocument36 pagesClient:-Visa Power Limited: Released For Constructionraj sekharNo ratings yet

- 2 Bridge PlugsDocument9 pages2 Bridge PlugsaaaNo ratings yet

- Review of Orifice Plate Steam Traps: ORNL/TM-2000/353/R1Document35 pagesReview of Orifice Plate Steam Traps: ORNL/TM-2000/353/R1Omar Ezzat100% (1)

- 400, 800, 2300, 2300D Series: Small, Two-Piece, Nonmetallic Raceway SystemsDocument8 pages400, 800, 2300, 2300D Series: Small, Two-Piece, Nonmetallic Raceway SystemsMohanathan VCNo ratings yet

- Bridge Plug-Cement RetainerDocument7 pagesBridge Plug-Cement RetainerhabibimarioNo ratings yet

- OhioBrass - 27-International Suspension InsulatorsDocument8 pagesOhioBrass - 27-International Suspension Insulatorslduong4No ratings yet

- Technical CharacteristicsDocument36 pagesTechnical Characteristics76027074No ratings yet

- Pedernales Electric Cooperative, Inc. Underground Installation SpecificationsDocument55 pagesPedernales Electric Cooperative, Inc. Underground Installation SpecificationsRemy JuniorNo ratings yet

- Tolomatic IMA 2011 CatalogDocument18 pagesTolomatic IMA 2011 CatalogElectromateNo ratings yet

- Butterfly Valves CatalogDocument48 pagesButterfly Valves CatalogHany Elsawy AbdelrahmanNo ratings yet

- Valve Selection & Specification Guide For Building Services: Ahead of The FlowDocument20 pagesValve Selection & Specification Guide For Building Services: Ahead of The FlowSimónSilvaRubio100% (1)

- WMTS 491 2016 Aluminium Alloy Piping System With Plastics Lining Lumbing Water Services ApplicationsDocument30 pagesWMTS 491 2016 Aluminium Alloy Piping System With Plastics Lining Lumbing Water Services ApplicationsAnonymous rLmr9GRM2No ratings yet

- Hdpe Pipe DesignDocument27 pagesHdpe Pipe Designblackk7100% (1)

- SNB Unit Main FeaturesDocument8 pagesSNB Unit Main FeaturesMas SusiloNo ratings yet

- Elpumps Catalog 2014 enDocument64 pagesElpumps Catalog 2014 enOnet DorelNo ratings yet

- DWC Pipe Cataloge (2) ImpDocument6 pagesDWC Pipe Cataloge (2) ImpJignasa ShahNo ratings yet

- 410 Fibre Optic Cable Blowing-In DevicesDocument17 pages410 Fibre Optic Cable Blowing-In DevicesKlanac BrčkoNo ratings yet

- Composite Floor System: Better BuildingDocument84 pagesComposite Floor System: Better BuildingDuc HoangNo ratings yet

- CSL1060Document6 pagesCSL1060Asep HidayatNo ratings yet

- Airport Underground Electrical Duct Banks and ConduitsDocument8 pagesAirport Underground Electrical Duct Banks and ConduitsDevrim Gürsel0% (1)

- Steam Orifice TrapsDocument31 pagesSteam Orifice TrapsPhanhai KakaNo ratings yet

- Con CastDocument5 pagesCon CastZubair AhmadNo ratings yet

- PX Pumps FolletoDocument4 pagesPX Pumps FolletoBenicio Joaquín Ferrero BrebesNo ratings yet

- Terminations Cold ContractileDocument2 pagesTerminations Cold ContractileAlberto UchihaNo ratings yet

- ACF86Document1 pageACF86gplese0No ratings yet

- ZKG 0605 005 - 9 ESPBypass - CMYKDocument4 pagesZKG 0605 005 - 9 ESPBypass - CMYKNazeeh Abdulrhman Albokary50% (2)

- Beany Block: Kerb Drainage at Its Most EfficientDocument2 pagesBeany Block: Kerb Drainage at Its Most EfficientMihaela TodiricaNo ratings yet

- Echnical Ulletin: Carbon Dioxide SystemsDocument4 pagesEchnical Ulletin: Carbon Dioxide SystemsLaura GalarzaNo ratings yet

- Nuhas BrochureDocument71 pagesNuhas BrochuremealysrNo ratings yet

- Cable Tray LadderDocument37 pagesCable Tray LadderrocketvtNo ratings yet

- Floating EquipmentDocument9 pagesFloating Equipmentkaveh-bahiraeeNo ratings yet

- Composite Bridge Plug: DescriptionDocument1 pageComposite Bridge Plug: Descriptionराजकुमार यादवNo ratings yet

- Technical Information ASSET DOC LOC 1543385Document21 pagesTechnical Information ASSET DOC LOC 1543385Alfonso ChNo ratings yet

- Pit Viper 235 Series: Atlas Copco Blasthole DrillsDocument4 pagesPit Viper 235 Series: Atlas Copco Blasthole DrillsJulio Acevedo MartinezNo ratings yet

- COA Standard Specifications For Public Works ConstructionDocument115 pagesCOA Standard Specifications For Public Works ConstructionQUEENIENo ratings yet

- 71 Busbar PowerDocument6 pages71 Busbar PowerMevlüt GünaydınNo ratings yet

- Gates MachineryDocument27 pagesGates MachineryAlex PeñaNo ratings yet

- Vortex TubesDocument10 pagesVortex TubeswatnaNo ratings yet

- 02-10 Scope ADocument6 pages02-10 Scope ASalman FaisalNo ratings yet

- On-Line Manual: Important InformationDocument66 pagesOn-Line Manual: Important InformationMilan GašićNo ratings yet

- Tube Fitting Installation SeminarDocument74 pagesTube Fitting Installation SeminarEscarabNo ratings yet

- Esfr Pend k17 DryDocument9 pagesEsfr Pend k17 DryitaloNo ratings yet

- E7207 0 05 11 - ECOmicron - 2 Fit - WWWDocument8 pagesE7207 0 05 11 - ECOmicron - 2 Fit - WWWHeller AriasNo ratings yet

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Practical, Made Easy Guide To Robotics & Automation [Revised Edition]From EverandPractical, Made Easy Guide To Robotics & Automation [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Tank VolumesDocument3 pagesTank Volumesbedoo54No ratings yet

- Eg 2 CalibDocument1 pageEg 2 Calibbedoo54No ratings yet

- Case Backhoe Loader - 580N (Tier 4)Document326 pagesCase Backhoe Loader - 580N (Tier 4)bedoo54100% (1)

- 7 CSG TallyDocument7 pages7 CSG Tallybedoo54No ratings yet

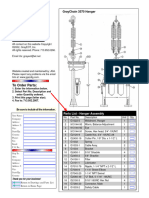

- HangerordfhDocument1 pageHangerordfhbedoo54No ratings yet

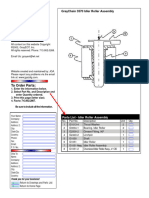

- IdrollerordfhDocument1 pageIdrollerordfhbedoo54No ratings yet

- Connector Mapping Guide: Efi P/N GND B+ IGN GND B+ Ign MilDocument1 pageConnector Mapping Guide: Efi P/N GND B+ IGN GND B+ Ign Milbedoo54No ratings yet

- CAT Engine - C4.4 (For CAT Machines UENR0647-06) .Prefix 444Document8 pagesCAT Engine - C4.4 (For CAT Machines UENR0647-06) .Prefix 444bedoo54No ratings yet

- Systems Operation 3406Document32 pagesSystems Operation 3406bedoo54No ratings yet

- Failure Code (DX16KA) Fan Pump EPC Sol. DiscDocument2 pagesFailure Code (DX16KA) Fan Pump EPC Sol. Discbedoo54100% (1)

- KOMATSU SAA4D95LE-7 SCR - DOC Emulator Plug and PlayDocument3 pagesKOMATSU SAA4D95LE-7 SCR - DOC Emulator Plug and Playbedoo54No ratings yet

- فلم يلا لقتنت فيك فلملا مسا رييغت نود تن ةحفص يلع ةحفصلا ظفح Mission statement ةحفصلا لفسا فلملا مسا يلع رسيلاا سوملا رزب طغضلا دعب كلذ نكميDocument30 pagesفلم يلا لقتنت فيك فلملا مسا رييغت نود تن ةحفص يلع ةحفصلا ظفح Mission statement ةحفصلا لفسا فلملا مسا يلع رسيلاا سوملا رزب طغضلا دعب كلذ نكميbedoo54No ratings yet

- Installation Instructions 31J K M N P Win7 H-2011-0216-HDocument11 pagesInstallation Instructions 31J K M N P Win7 H-2011-0216-Hbedoo54No ratings yet

- Latitude-E6420-Xfr - Service Manual - En-UsDocument81 pagesLatitude-E6420-Xfr - Service Manual - En-Usbedoo54No ratings yet

- Axis PM User ManualDocument81 pagesAxis PM User Manualbedoo54No ratings yet

- To NitrogenDocument54 pagesTo Nitrogenbedoo54No ratings yet

- Dell Latitude E6420 XFR: Real-World RuggedDocument2 pagesDell Latitude E6420 XFR: Real-World Ruggedbedoo54No ratings yet

- Setting The Pace: Hydraulic Crawler DrillsDocument8 pagesSetting The Pace: Hydraulic Crawler Drillsbedoo54100% (1)

- Special Instruction: Procedure For Installing Migration Kits On Certain C9.3-C15 ACERT Tier 4 Interim ProductsDocument1 pageSpecial Instruction: Procedure For Installing Migration Kits On Certain C9.3-C15 ACERT Tier 4 Interim Productsbedoo54No ratings yet

- Worksheet Research-Title FINALDocument3 pagesWorksheet Research-Title FINALJierroe EvangelistaNo ratings yet

- 1951 1obli ChronicleDocument18 pages1951 1obli Chronicleapi-198872914No ratings yet

- Whittaker Dynamics 17Document442 pagesWhittaker Dynamics 17Mahmoud Ahmed 202201238No ratings yet

- Piping Stress AnalysisDocument10 pagesPiping Stress AnalysisM Alim Ur Rahman100% (1)

- DX-790-960-65-16.5i-M Model: A79451600v02: Antenna SpecificationsDocument2 pagesDX-790-960-65-16.5i-M Model: A79451600v02: Antenna SpecificationsakiselNo ratings yet

- Reducing Major Defects in Radiators Manufacturing: Kumar P., Sonawane B.S., Sontakke R.R., Surves.B., Wasnik A.RDocument5 pagesReducing Major Defects in Radiators Manufacturing: Kumar P., Sonawane B.S., Sontakke R.R., Surves.B., Wasnik A.RKrushnaNo ratings yet

- Biomedx Workshop AgendaDocument6 pagesBiomedx Workshop AgendabiomedxNo ratings yet

- Soc TB 25 May 2017Document37 pagesSoc TB 25 May 2017Ipie BsaNo ratings yet

- MT2OL-Ia6 2 1Document136 pagesMT2OL-Ia6 2 1QUILIOPE, JUSTINE JAY S.No ratings yet

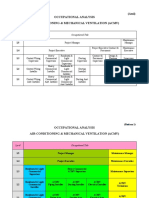

- Occupational StructureDocument3 pagesOccupational StructureEmirul FairuzNo ratings yet

- Nemo Complete Documentation 2017Document65 pagesNemo Complete Documentation 2017Fredy A. CastañedaNo ratings yet

- 9A03501 Thermal Engineering IIDocument4 pages9A03501 Thermal Engineering IIsivabharathamurthyNo ratings yet

- LC1D32M7: Product Data SheetDocument7 pagesLC1D32M7: Product Data SheetCHAHRHLHOHSNo ratings yet

- Lienard EquationDocument9 pagesLienard EquationmenguemengueNo ratings yet

- Maximo Training Material Day 2Document41 pagesMaximo Training Material Day 2ckombo9912100% (2)

- Tranzen1A Income TaxDocument46 pagesTranzen1A Income TaxMonica SorianoNo ratings yet

- DLL Mother TongueDocument41 pagesDLL Mother TongueMarxPascualBlancoNo ratings yet

- Kisi-Kisi BHS Inggris-Soal Pas Kelas 8 K13Document6 pagesKisi-Kisi BHS Inggris-Soal Pas Kelas 8 K13Joko PrayitnoNo ratings yet

- Murphy'S Laws: Anything That Can Go Wrong Will Go WrongDocument2 pagesMurphy'S Laws: Anything That Can Go Wrong Will Go WrongAshwin ReddyNo ratings yet

- Kingsmill Materia MedicaDocument32 pagesKingsmill Materia Medicamax quayleNo ratings yet

- SPECALOG Hitachi Ex2600-6Document7 pagesSPECALOG Hitachi Ex2600-6andrefilthNo ratings yet

- Commerce EMDocument344 pagesCommerce EMSTAR E WORLDNo ratings yet

- Suntrust VeronaDocument12 pagesSuntrust Veronalyanca majanNo ratings yet

- Mic 2 Mkii Installation Instructions and Reference Handbook 4189320057 UkDocument70 pagesMic 2 Mkii Installation Instructions and Reference Handbook 4189320057 Ukkamel kamelNo ratings yet

- Ai PresentationDocument13 pagesAi Presentationapi-534191655No ratings yet

- Anesthetic Consideration in Thyroid SurgeryDocument36 pagesAnesthetic Consideration in Thyroid Surgerymaulina13No ratings yet

- (Human Behavior and Environment 8) Carol M. Werner, Irwin Altman, Diana Oxley (Auth.), Irwin Altman, Carol M. Werner (Eds.) - Home Environments-Springer US (1985)Document355 pages(Human Behavior and Environment 8) Carol M. Werner, Irwin Altman, Diana Oxley (Auth.), Irwin Altman, Carol M. Werner (Eds.) - Home Environments-Springer US (1985)Carlos Roberto JúniorNo ratings yet

Bilco 1

Bilco 1

Uploaded by

bedoo540 ratings0% found this document useful (0 votes)

1 views2 pagesOriginal Title

Bilco1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

1 views2 pagesBilco 1

Bilco 1

Uploaded by

bedoo54Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 2

MAIN OFFICE: (985) 851-2240

P.O. BOX 9064 Fax: (985) 872-6970

Houma, LA 70361 Watts: 1-800-222-1873

107 CLENDENNING RD. www.bilcotools.com

TUBULAR HANDLING TOOLS

DUAL AUTOMATIC SPIDER-ELEVATOR*

BILCO’s Dual Tools were designed for use with cementing or production equipment and were engineered to safely pull or run two strings of tubing or casing

simultaneously. SAVES VALUABLE RIG TIME. A total of three to four hours of rig up & rig down time may be saved , per job, through the use of BILCO’S DUAL

AUTOMATIC SPIDER-ELEVATOR*. The IN-LINE ELEVATOR* patented design carries the load directly in-line under the bail; enabling one joint of tubing to be

pulled or run without fear of bending the pipe from too heavy of a load positioned on one side. The SPLIT-BOWL SPIDER* is the only Spider known that has

been used in snubbing units while running or pulling dual strings. This is accomplished by installing a Spider, in lieu of an Elevator, on top of the jack or lift. A

complete open hole can be obtained in less than two minutes with the easy removal of one bolt, holding the spider together. Equipment of up to six inches in

diameter may be run through the Spider without necessitating its removal. For applications where deep-water or larger O.D. tubulars are needed, BILCO’s NEW

Dual Sliding Tools can run up to 5 1/2” X 5 1/2” strings.

TRIPLE TOOLS*

TRIPLE HANDLING TOOLS* system is capable of handling two strings up to 2 7/8” diameter pipe and another string of up to 2 3/8 ” diameter, on 6.5” centers.

Special features of this system is the 5 seconds to hydraulically retract the slip bowls, in open position will allow for tool diameters of up to 8.5” to rapidly pass

through the spider. Both systems (spider & elevator) are air operated from an operator’s console.

PRECISION SLIPS & ELEVATORS* DESIGNED FOR DEEP-WATER

PRECISION SLIPS & ELEVATORS* are one of BILCO’s newest technological advances for Deep-water applications utilizing a SLIDING SPIDER* that gives you

a 21” open hole for running control and umbilical lines, along with the PRECISION SLIPS & ELEVATOR’S* used in preventing tubular damage from die marks

unlike conventional slips and elevators. Each slip body is free to articulate independently of the other slip bodies, when a gripping force is applied to each slip,

the die teeth adjust to contact the pipe with a uniform force, thus distributing the pipe load equally, leaving virtually no die tooth surface penetration (typically

less than 0.003 inches) and equally important, is that this slip design allows for the running of up to 20” diameter tools without disassembly of the slips. All

of BILCO’S TOOL handling systems are designed for deep-water demands of running unencumbered umbilical and control lines, along with pulling or running

multiple production strings. The early innovation of the PRECISION SLIPS & ELEVATORS* earned BILCO a finalist OTC Best Mechanical Engineering Award in

1994. With BILCO’s continuous improvements incorporated over the years, as operator’s demands on deep-water, multi-string completions and the assurance

of the safe running of control & umbilical lines provided by these systems.

NEUTRALLY BALANCED TONG*

Traditional power tong systems create misalignment during connection make-up & break-out, producing a condition referred to as “Side Loading” which leads

to thread galling and false under-torque readings at time of make-up, factors that increase and promote “Connection Failure”. The often termed NBT* is a

truly mechanically correct tong; the tong floats and is designed to relieve the stress factor of side-loading, these tongs provide more accurate torque readings,

computerized make-up graphs, and basically eliminates the “thread galling” or misalignment of the threads during make-up and provide better metal to metal

seals on connections.

SOFT-TOUCH* & HYDRUALIC FRICTION GRIP TONG*

BILCO was the first company to prove the theory of use of special tong dies to eliminate the die “teeth marks” left on chrome alloy, externally coated, stainless

steel, or other expensive special alloy tubulars. By using smooth dies in the tong and the use of a special metal, the typical “teeth marks” that lead to premature

corrosive effects on the tubulars is virtually eliminated. BILCO’s SOFT-TOUCH* TONG provides maximum control through a 3-speed design feature with an

adjustable range from 1/4 to 20 RPM’s to ensure maximum make-up speed, while reducing over-torque due to operator error and provides a “fail-safe” torque

limit device which automatically stops the tong rotation at the pre-set make-up torque. The HYDRAULIC FRICTION GRIP* TONG was developed in conjunction

with the SOFT-TOUCH* system to reduce die mark damage by the use of smooth metal dies that allows for higher torque, while preventing damage to the

tubulars. These innovations earned BILCO a Finalist Award at the 1986 OTC for Best Mechanical Engineering Achievement, a Special Meritorious Award for

Engineering Innovation from SPE’s Petroleum International in 1987, and a FIRST PLACE AWARD FOR BEST MECHANICAL ENGINEERING ACHIEVEMENT at OTC

in 1990.

FIBER GRIP* TONG

BILCO’s FIBER GRIP* TONG was developed to handle the running of fiber-glass tubing. These tongs utilize a belt gripping system over an area of 95% of the

tube body; self-aligning floating heads on the tong and back-up tong; cover tubing and casing sizes from 2 3/8” to 14” respectively; no metal touches the pipe

and may also be used with specially treated and/or coated steel tubulars (i.e. FRP or FRP API steel coated tubulars), if required. FIBER GRIP* is an excellent

choice for running expandable casing.

(* Denotes both U.S. and International Patents where applicable)

BILCO TOOLS CAN BE MODIFIED OR CUSTOMIZED TO

SATISFY CUSTOMER’S NEEDS, UPON REQUEST

BILCO.indd 1 8/23/04 11:25:31 AM

MAIN OFFICE: (985) 851-2240

P.O. BOX 9064 Fax: (985) 872-6970

Houma, LA 70361 Watts: 1-800-222-1873

107 CLENDENNING RD. www.bilcotools.com

BILCO ANALYSIS MAKEUP SYSTEM (BAM)

BILCO has conventional torque turn and has developed an analytical system which goes beyond the parameters of the current “torque time” and torque turn

systems and uses exclusive, innovative technology to supply accurate information and control.

CONNECTION SIGNATURE TRACER (CST)*

The BILCO CST* provides monitoring of rotational rates and/or connection torque, followed by monitoring of axial strain, torsional strain, and hoop strain

as monitored by a specially designed clamping device attached to the connection. CST* is a special feature of BAM* and provides the industry with a new

dimension in torque, turns (revolutions), and time plotting. The use of this special testing device will result in fewer connection failures. (CST)* was the FIRST

PLACE WINNER AT THE 1991 OTC FOR THE BEST MECHANICAL ENGINEERING AWARD.

CONNNECTION INTEGRITY ASSURANCE (CIA) – PRESSURE SIGNATURE TRACER (PST)*

BILCO’s PST* offers a method of detecting a leak in a connection, even when pipe dope has sealed it off temporarily. Pipe dope has been found to “hide”, in

many cases the passage of water and gas for periods exceeding 20 minutes. These long hold times make typical hydrostatic or “sniffer” testing uneconomical

due to excessive rig time. With the development of the PRESSURE SIGNATURE TRACER (PST)* operators now have an option to the costly solution of premature

failures that go undetected, or even untested, due to failures in conventional testing methods. A detection fixture is quickly applied to the connection and

monitors the displacement of the connection material when pressure is applied. BILCO’S BAM computer displays these signatures along with the pressure

curve as graphic trends or “signatures”. Connections with leaking primary seals displace the connection material uniquely, and therefore do not show the

characteristic signature of a good connection. This testing method can be used on tubing and casing, couple or integral connections. Leaks can be detected at

less pressure than traditional test methods. PRESSURE SIGNATURE TRACER (PST)* is the only method for absolute confirmation of a leak-safe connection.

BILCO’s WELL-BORE CLEANOUT TOOLS

RISER JET TOOL & WELLHEAD JET TOOL

BILCO’s RISER JET Tool efficiently removes attached solids by directing jet forces to BOP and riser wall. Jetting Tool has options of jetting upward, outward,

downward, or any combination there of according to customer’s needs. The tool has three fluid flow positions: 1) The first position directs fluid to string end. 2)

The second position directs flow to riser cleaning jets. 3) The third position redirects flow to string end. All flow positions can easily handle flow rates of 20 or

more barrels per minute. Flow direction is changed by the use of darts which can be easily removed if a wire line operation is necessary.

BILCO “TOUGH BOY”™ RISER BRUSH TOOL

The RISER BRUSH TOOL used to remove caked material attached to the inside of casing and risers. These tools can be both rotated and/or reciprocated.

Brushes are protected by a stabilizer element which insures uniform brush contact with 360° casing.

RISER WASTE RETRIEVER TOOL (patent pending)

A very special type of “Riser Junk Basket” used to capture heavy solids removed from the well-bore. The riser basket has a 14-gallon capacity. The Tool has a

series of Venturi Jets which manipulate fluid flow to assist solids capture & has automatic drains for fluid removal.

MULTI-USE WASTE RETRIEVER TOOL

Special type of basket allows fluid to easily flow through the basket while trapping solids. A Labyrinth Seal prevents fluid flow around basket or can also

be run without. Outer sleeve protects the inner screen & has a solid core from which the sleeve and screen are easily disassembled. The basket has a

5-gallon capacity.

CIRCULATING LINER TOP & SWIVEL TOOL

CIRCULATING Tool (patent pending) is a special tool with fluid ports which open and close upon contact with liner top. Fluid flow can be optionally directed to

string end or through ports above liner. Tool ports can be repeatedly opened and closed for optimal fluid path when washing debris from casing. SWIVEL Tool

allows the string above to rotate, preventing the small, light string below (inside liner) from rotating & possibly twisting off.

BILCO “TOUGH BOY”™ CASING SCRAPER & BRUSH TOOLS

Is designed to provide 100% scraping coverage when cleaning the inner walls of well casings and liners. Can remove film, cement cakes, mud cakes, shot

burrs, or any type of scaly material & has been in service since 1981. Our customers continue to be impressed by the “Tough Boy’s” reliability, versatility,

minimum upkeep, and the excellent results provides the industry with a NEW concept of wall cleaning. Features heavy-duty construction and easy on-site

assembly and maintenance. The new 45-degree blade angle provides 100% scraping coverage and excellent results when run behind a bit or mill & comes in

sizes 2 3/8” up to 20” for special applications. Scraper can be fitted with brushes to complete the cleaning process.

BILCO “TOUGH BOY”™ MAGNET TOOL (patent pending)

This new tool is built BILCO tough just like the scrapers that have been in use around the globe since 1982. This magnet is recommended for most milling,

fishing and complex wellbore cleanup applications. The large carrying capacity and strong magnetic field make this tool ideal for side track well completions

or operations were ferrous metal debris is a concern.

(* Denotes both U.S. and International Patents where applicable)

BILCO.indd 2 8/23/04 11:25:33 AM

You might also like

- Claas Jaguar Error CodesDocument20 pagesClaas Jaguar Error Codesbedoo54100% (2)

- Cummins - QSB4.5 CM2350Document18 pagesCummins - QSB4.5 CM2350bedoo54100% (3)

- 5008S Fresenuis Service ManualDocument318 pages5008S Fresenuis Service ManualEslam Karam100% (10)

- EIL TenderDocument1,178 pagesEIL TenderSamrat Roy Chowdhury100% (10)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Nexus 4in 10k 2-Door WBA Stripper Manual - REV 13Document26 pagesNexus 4in 10k 2-Door WBA Stripper Manual - REV 13Pastor Velasquez100% (1)

- 07 StraddlesDocument12 pages07 StraddlesyariyantoNo ratings yet

- Comptia Security Sy0 601 Exam Objectives (2 0)Document24 pagesComptia Security Sy0 601 Exam Objectives (2 0)tha_flameNo ratings yet

- Audio Information and MediaDocument2 pagesAudio Information and Mediajosefalarka75% (4)

- BilcoDocument16 pagesBilcoruloNo ratings yet

- Grooved Piping System: Product DescriptionDocument4 pagesGrooved Piping System: Product DescriptionDGWNo ratings yet

- Banki Water Turbine Design and Construction ManualDocument65 pagesBanki Water Turbine Design and Construction ManualGreen Action Sustainable Technology Group100% (2)

- Bridge PlugsDocument9 pagesBridge Plugskaveh-bahiraeeNo ratings yet

- Catalogo Huck C50L PDFDocument8 pagesCatalogo Huck C50L PDFVladimir SepulvedaNo ratings yet

- Valve SelectDocument20 pagesValve SelectsajuhereNo ratings yet

- Ringlock SystemDocument8 pagesRinglock Systemdox4useNo ratings yet

- GCS0004Document21 pagesGCS0004RazkulNo ratings yet

- Brochure - VN - OL - Cracking Mill OLCC - SCREEN - NewDocument4 pagesBrochure - VN - OL - Cracking Mill OLCC - SCREEN - NewRodrigo Vieira FariaNo ratings yet

- Client:-Visa Power Limited: Released For ConstructionDocument36 pagesClient:-Visa Power Limited: Released For Constructionraj sekharNo ratings yet

- 2 Bridge PlugsDocument9 pages2 Bridge PlugsaaaNo ratings yet

- Review of Orifice Plate Steam Traps: ORNL/TM-2000/353/R1Document35 pagesReview of Orifice Plate Steam Traps: ORNL/TM-2000/353/R1Omar Ezzat100% (1)

- 400, 800, 2300, 2300D Series: Small, Two-Piece, Nonmetallic Raceway SystemsDocument8 pages400, 800, 2300, 2300D Series: Small, Two-Piece, Nonmetallic Raceway SystemsMohanathan VCNo ratings yet

- Bridge Plug-Cement RetainerDocument7 pagesBridge Plug-Cement RetainerhabibimarioNo ratings yet

- OhioBrass - 27-International Suspension InsulatorsDocument8 pagesOhioBrass - 27-International Suspension Insulatorslduong4No ratings yet

- Technical CharacteristicsDocument36 pagesTechnical Characteristics76027074No ratings yet

- Pedernales Electric Cooperative, Inc. Underground Installation SpecificationsDocument55 pagesPedernales Electric Cooperative, Inc. Underground Installation SpecificationsRemy JuniorNo ratings yet

- Tolomatic IMA 2011 CatalogDocument18 pagesTolomatic IMA 2011 CatalogElectromateNo ratings yet

- Butterfly Valves CatalogDocument48 pagesButterfly Valves CatalogHany Elsawy AbdelrahmanNo ratings yet

- Valve Selection & Specification Guide For Building Services: Ahead of The FlowDocument20 pagesValve Selection & Specification Guide For Building Services: Ahead of The FlowSimónSilvaRubio100% (1)

- WMTS 491 2016 Aluminium Alloy Piping System With Plastics Lining Lumbing Water Services ApplicationsDocument30 pagesWMTS 491 2016 Aluminium Alloy Piping System With Plastics Lining Lumbing Water Services ApplicationsAnonymous rLmr9GRM2No ratings yet

- Hdpe Pipe DesignDocument27 pagesHdpe Pipe Designblackk7100% (1)

- SNB Unit Main FeaturesDocument8 pagesSNB Unit Main FeaturesMas SusiloNo ratings yet

- Elpumps Catalog 2014 enDocument64 pagesElpumps Catalog 2014 enOnet DorelNo ratings yet

- DWC Pipe Cataloge (2) ImpDocument6 pagesDWC Pipe Cataloge (2) ImpJignasa ShahNo ratings yet

- 410 Fibre Optic Cable Blowing-In DevicesDocument17 pages410 Fibre Optic Cable Blowing-In DevicesKlanac BrčkoNo ratings yet

- Composite Floor System: Better BuildingDocument84 pagesComposite Floor System: Better BuildingDuc HoangNo ratings yet

- CSL1060Document6 pagesCSL1060Asep HidayatNo ratings yet

- Airport Underground Electrical Duct Banks and ConduitsDocument8 pagesAirport Underground Electrical Duct Banks and ConduitsDevrim Gürsel0% (1)

- Steam Orifice TrapsDocument31 pagesSteam Orifice TrapsPhanhai KakaNo ratings yet

- Con CastDocument5 pagesCon CastZubair AhmadNo ratings yet

- PX Pumps FolletoDocument4 pagesPX Pumps FolletoBenicio Joaquín Ferrero BrebesNo ratings yet

- Terminations Cold ContractileDocument2 pagesTerminations Cold ContractileAlberto UchihaNo ratings yet

- ACF86Document1 pageACF86gplese0No ratings yet

- ZKG 0605 005 - 9 ESPBypass - CMYKDocument4 pagesZKG 0605 005 - 9 ESPBypass - CMYKNazeeh Abdulrhman Albokary50% (2)

- Beany Block: Kerb Drainage at Its Most EfficientDocument2 pagesBeany Block: Kerb Drainage at Its Most EfficientMihaela TodiricaNo ratings yet

- Echnical Ulletin: Carbon Dioxide SystemsDocument4 pagesEchnical Ulletin: Carbon Dioxide SystemsLaura GalarzaNo ratings yet

- Nuhas BrochureDocument71 pagesNuhas BrochuremealysrNo ratings yet

- Cable Tray LadderDocument37 pagesCable Tray LadderrocketvtNo ratings yet

- Floating EquipmentDocument9 pagesFloating Equipmentkaveh-bahiraeeNo ratings yet

- Composite Bridge Plug: DescriptionDocument1 pageComposite Bridge Plug: Descriptionराजकुमार यादवNo ratings yet

- Technical Information ASSET DOC LOC 1543385Document21 pagesTechnical Information ASSET DOC LOC 1543385Alfonso ChNo ratings yet

- Pit Viper 235 Series: Atlas Copco Blasthole DrillsDocument4 pagesPit Viper 235 Series: Atlas Copco Blasthole DrillsJulio Acevedo MartinezNo ratings yet

- COA Standard Specifications For Public Works ConstructionDocument115 pagesCOA Standard Specifications For Public Works ConstructionQUEENIENo ratings yet

- 71 Busbar PowerDocument6 pages71 Busbar PowerMevlüt GünaydınNo ratings yet

- Gates MachineryDocument27 pagesGates MachineryAlex PeñaNo ratings yet

- Vortex TubesDocument10 pagesVortex TubeswatnaNo ratings yet

- 02-10 Scope ADocument6 pages02-10 Scope ASalman FaisalNo ratings yet

- On-Line Manual: Important InformationDocument66 pagesOn-Line Manual: Important InformationMilan GašićNo ratings yet

- Tube Fitting Installation SeminarDocument74 pagesTube Fitting Installation SeminarEscarabNo ratings yet

- Esfr Pend k17 DryDocument9 pagesEsfr Pend k17 DryitaloNo ratings yet

- E7207 0 05 11 - ECOmicron - 2 Fit - WWWDocument8 pagesE7207 0 05 11 - ECOmicron - 2 Fit - WWWHeller AriasNo ratings yet

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Practical, Made Easy Guide To Robotics & Automation [Revised Edition]From EverandPractical, Made Easy Guide To Robotics & Automation [Revised Edition]Rating: 1 out of 5 stars1/5 (1)

- Tank VolumesDocument3 pagesTank Volumesbedoo54No ratings yet

- Eg 2 CalibDocument1 pageEg 2 Calibbedoo54No ratings yet

- Case Backhoe Loader - 580N (Tier 4)Document326 pagesCase Backhoe Loader - 580N (Tier 4)bedoo54100% (1)

- 7 CSG TallyDocument7 pages7 CSG Tallybedoo54No ratings yet

- HangerordfhDocument1 pageHangerordfhbedoo54No ratings yet

- IdrollerordfhDocument1 pageIdrollerordfhbedoo54No ratings yet

- Connector Mapping Guide: Efi P/N GND B+ IGN GND B+ Ign MilDocument1 pageConnector Mapping Guide: Efi P/N GND B+ IGN GND B+ Ign Milbedoo54No ratings yet

- CAT Engine - C4.4 (For CAT Machines UENR0647-06) .Prefix 444Document8 pagesCAT Engine - C4.4 (For CAT Machines UENR0647-06) .Prefix 444bedoo54No ratings yet

- Systems Operation 3406Document32 pagesSystems Operation 3406bedoo54No ratings yet

- Failure Code (DX16KA) Fan Pump EPC Sol. DiscDocument2 pagesFailure Code (DX16KA) Fan Pump EPC Sol. Discbedoo54100% (1)

- KOMATSU SAA4D95LE-7 SCR - DOC Emulator Plug and PlayDocument3 pagesKOMATSU SAA4D95LE-7 SCR - DOC Emulator Plug and Playbedoo54No ratings yet

- فلم يلا لقتنت فيك فلملا مسا رييغت نود تن ةحفص يلع ةحفصلا ظفح Mission statement ةحفصلا لفسا فلملا مسا يلع رسيلاا سوملا رزب طغضلا دعب كلذ نكميDocument30 pagesفلم يلا لقتنت فيك فلملا مسا رييغت نود تن ةحفص يلع ةحفصلا ظفح Mission statement ةحفصلا لفسا فلملا مسا يلع رسيلاا سوملا رزب طغضلا دعب كلذ نكميbedoo54No ratings yet

- Installation Instructions 31J K M N P Win7 H-2011-0216-HDocument11 pagesInstallation Instructions 31J K M N P Win7 H-2011-0216-Hbedoo54No ratings yet

- Latitude-E6420-Xfr - Service Manual - En-UsDocument81 pagesLatitude-E6420-Xfr - Service Manual - En-Usbedoo54No ratings yet

- Axis PM User ManualDocument81 pagesAxis PM User Manualbedoo54No ratings yet

- To NitrogenDocument54 pagesTo Nitrogenbedoo54No ratings yet

- Dell Latitude E6420 XFR: Real-World RuggedDocument2 pagesDell Latitude E6420 XFR: Real-World Ruggedbedoo54No ratings yet

- Setting The Pace: Hydraulic Crawler DrillsDocument8 pagesSetting The Pace: Hydraulic Crawler Drillsbedoo54100% (1)

- Special Instruction: Procedure For Installing Migration Kits On Certain C9.3-C15 ACERT Tier 4 Interim ProductsDocument1 pageSpecial Instruction: Procedure For Installing Migration Kits On Certain C9.3-C15 ACERT Tier 4 Interim Productsbedoo54No ratings yet

- Worksheet Research-Title FINALDocument3 pagesWorksheet Research-Title FINALJierroe EvangelistaNo ratings yet

- 1951 1obli ChronicleDocument18 pages1951 1obli Chronicleapi-198872914No ratings yet

- Whittaker Dynamics 17Document442 pagesWhittaker Dynamics 17Mahmoud Ahmed 202201238No ratings yet

- Piping Stress AnalysisDocument10 pagesPiping Stress AnalysisM Alim Ur Rahman100% (1)

- DX-790-960-65-16.5i-M Model: A79451600v02: Antenna SpecificationsDocument2 pagesDX-790-960-65-16.5i-M Model: A79451600v02: Antenna SpecificationsakiselNo ratings yet

- Reducing Major Defects in Radiators Manufacturing: Kumar P., Sonawane B.S., Sontakke R.R., Surves.B., Wasnik A.RDocument5 pagesReducing Major Defects in Radiators Manufacturing: Kumar P., Sonawane B.S., Sontakke R.R., Surves.B., Wasnik A.RKrushnaNo ratings yet

- Biomedx Workshop AgendaDocument6 pagesBiomedx Workshop AgendabiomedxNo ratings yet

- Soc TB 25 May 2017Document37 pagesSoc TB 25 May 2017Ipie BsaNo ratings yet

- MT2OL-Ia6 2 1Document136 pagesMT2OL-Ia6 2 1QUILIOPE, JUSTINE JAY S.No ratings yet

- Occupational StructureDocument3 pagesOccupational StructureEmirul FairuzNo ratings yet

- Nemo Complete Documentation 2017Document65 pagesNemo Complete Documentation 2017Fredy A. CastañedaNo ratings yet

- 9A03501 Thermal Engineering IIDocument4 pages9A03501 Thermal Engineering IIsivabharathamurthyNo ratings yet

- LC1D32M7: Product Data SheetDocument7 pagesLC1D32M7: Product Data SheetCHAHRHLHOHSNo ratings yet

- Lienard EquationDocument9 pagesLienard EquationmenguemengueNo ratings yet

- Maximo Training Material Day 2Document41 pagesMaximo Training Material Day 2ckombo9912100% (2)

- Tranzen1A Income TaxDocument46 pagesTranzen1A Income TaxMonica SorianoNo ratings yet

- DLL Mother TongueDocument41 pagesDLL Mother TongueMarxPascualBlancoNo ratings yet

- Kisi-Kisi BHS Inggris-Soal Pas Kelas 8 K13Document6 pagesKisi-Kisi BHS Inggris-Soal Pas Kelas 8 K13Joko PrayitnoNo ratings yet

- Murphy'S Laws: Anything That Can Go Wrong Will Go WrongDocument2 pagesMurphy'S Laws: Anything That Can Go Wrong Will Go WrongAshwin ReddyNo ratings yet

- Kingsmill Materia MedicaDocument32 pagesKingsmill Materia Medicamax quayleNo ratings yet

- SPECALOG Hitachi Ex2600-6Document7 pagesSPECALOG Hitachi Ex2600-6andrefilthNo ratings yet

- Commerce EMDocument344 pagesCommerce EMSTAR E WORLDNo ratings yet

- Suntrust VeronaDocument12 pagesSuntrust Veronalyanca majanNo ratings yet

- Mic 2 Mkii Installation Instructions and Reference Handbook 4189320057 UkDocument70 pagesMic 2 Mkii Installation Instructions and Reference Handbook 4189320057 Ukkamel kamelNo ratings yet

- Ai PresentationDocument13 pagesAi Presentationapi-534191655No ratings yet

- Anesthetic Consideration in Thyroid SurgeryDocument36 pagesAnesthetic Consideration in Thyroid Surgerymaulina13No ratings yet

- (Human Behavior and Environment 8) Carol M. Werner, Irwin Altman, Diana Oxley (Auth.), Irwin Altman, Carol M. Werner (Eds.) - Home Environments-Springer US (1985)Document355 pages(Human Behavior and Environment 8) Carol M. Werner, Irwin Altman, Diana Oxley (Auth.), Irwin Altman, Carol M. Werner (Eds.) - Home Environments-Springer US (1985)Carlos Roberto JúniorNo ratings yet

![Practical, Made Easy Guide To Robotics & Automation [Revised Edition]](https://imgv2-1-f.scribdassets.com/img/word_document/253466853/149x198/4281882d40/1709916831?v=1)