Professional Documents

Culture Documents

FlowMeter Datasheet XpiroFlow

FlowMeter Datasheet XpiroFlow

Uploaded by

Renan ValenteCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FlowMeter Datasheet XpiroFlow

FlowMeter Datasheet XpiroFlow

Uploaded by

Renan ValenteCopyright:

Available Formats

Turbine Flow Meter

Model 1200

DESCRIPTION

The Blancett Model 1200 in-line turbine flow meter was engineered

for applications in highly corrosive environments. Developed for use

in petrochemical and other process industries with liquid chemical

flows, the Model 1200 turbine meter provides accuracy and

durability in aggressive industrial environments. The meter features

a 303 stainless steel body and internal wetted parts, with two

type-440 stainless steel ball bearings.

The Model 1200 maintains measurement accuracy and mechanical

integrity in the corrosive and abrasive fluids commonly found in oil

field water flood projects and many industrial applications.

When paired with a Blancett flow monitor, the Model 1200 turbine

meter meets a wide range of measurement requirements. This

makes it ideal for applications such as pipelines, production/

injection fields, mining operations, offshore facilities, and other

industrial applications. For a full list of Blancett flow monitors, see INSTALLATION

www.badgermeter.com.

The Model 1200 turbine meter is simple to install and service. It

FEATURES operates in a horizontal orientation with the flow direction arrow

aligned in the same direction as the actual line flow. For optimum

• Offers accurate and repeatable flow measurement in ranges performance, install the flow meter with a minimum of 10 diameters

from 0.25…25 gpm (0.57…94.64 lpm) upstream straight pipe length and 5 diameters downstream straight

• Cost-effective solution for turbine flow meter applications pipe length.

• 303 stainless steel construction offers long service life in severe

operating environments

• Available in NPT end connections

• NIST traceable calibration

• Installation in pipe sizes 1/4…3/4 inch (6.35…19 mm), with or

without a bypass line

• Integrates electronically with a Blancett B2900 flow monitor

• K-factor Scaler, or the F to I/F to V Intelligent Converter Field

replaceable repair kits allow for turbine replacement without

loss of accuracy

TRB-DS-02785-EN-06 (June 2022) Product Data Sheet

Turbine Flow Meter, Model 1200

OPERATING PRINCIPLE

Fluid entering the meter passes through the inlet flow conditioner, which reduces its turbulent flow pattern and improves the fluid’s

velocity profile. The fluid then passes through the turbine, causing the turbine to rotate at a speed proportional to the fluid velocity. As each

turbine blade passes through the magnetic field, the blade generates an AC voltage pulse in the pickup coil at the base of the magnetic

pickup (see Figure 1). These pulses produce an output frequency proportional to the volumetric flow through the meter. The output

frequency represents flow rate and/or totalization of fluid passing through the turbine flow meter.

Magnetic Pickup

or

Other Frequency

Output Device

Output

Turbine Rotor Signal

Figure 1: Schematic illustration of electric signal generated by rotor movement

K-Factor

The K-factor represents the number of output pulses transmitted per gallon of fluid passing through the turbine meter. Each turbine has a

unique K-factor. However, turbine meters are not functionally consistent throughout the full flow range of the meter.

There are several forms of friction inherent in the turbine meters that retard the rotational movement of the turbine rotor. These frictional

forces include: magnetic drag, created by electromagnetic forces of pickup transducers; mechanical drag, due to bearing friction; and

viscous drag, produced by flowing fluid.

As flow increases, the frictional forces are minimized and the free-wheeling motion of the turbine rotor becomes more linear (proportional

to flow). The K-factor becomes relatively constant and the linear throughout the balance of the linear flow range. This is approximately a

10:1 turndown ratio from the maximum flow rate down to the minimum flow rate.

Typical K-factor Curve (Pulse per US Gallon)

+1%

OUTPUT FREQUENCY (CYCLES/SEC)

LINEARITY (DESIGN DEVIATION)

K-FACTOR (PULSES/GALLON)

K-FACTOR (CYCLES/GALLON)

+%

% OF VALUE AT FLOW RATE

100%

K-FA N)

AVG. K-FACTOR (K) CTO LO

50% R ( P U L S E/GAL

-%

0% 10% 50% 100% -1%

FULL FLOW RANGE

LINEAR FLOW RANGE STANDARD TURNDOWN APPROX. 10:1

-1%

Figure 2: Typical K-factor

Page 2 TRB-DS-02785-EN-06 June 2022

Specifications

SPECIFICATIONS

Body 303 stainless steel

Rotor CD4MCU stainless steel

Materials of Bearings Two (2) type-440 stainless steel ball bearings

Construction Rotor Shaft 303 stainless steel

Rotor Support 303 stainless steel

Housing Epoxy encapsulated module

Meter –60…350° F (–51…1777° C)

Operating Temperature Module –20…160° F (–7…71° C)

Pickup –150…325° F (–101…162° C)

Pressure Rating 4000 psi (276 bar) maximum

End Connection NPT male

Turndown Ratio —

Accuracy ±1.0% of reading

Repeatability ±0.1%

Calibration MIL-PRF-7024E, Type II (NIST traceable calibration)

Pickup —

Certification —

Input Signal 1 millihenry carrier pickup

RF Preamplifier

Output Signal 10V peak to peak square wave

Power 7…30V DC

50 ft maximum between pickup and RF preamplifier

Distance Specification

1000 ft maximum between preamplifier and receiving unit

Electrical Connection Terminal strip

CONDUIT THREAD

1" NPT MAGNETIC

PICK-UP

1" NPT FLOW DIRECTION RETAINING RING RETAINING RING

ARROW GROOVE GROOVE

(BOTH ENDS)

UPSTREAM DOWNSTREAM

2.31 ROTOR SUPPORT

ROTOR SUPPORT

2.96

FLOW

FLOW DIRECTION FLOW DIRECTION

ARROW ARROW

RETAINING ROTOR FLOW METER FLOW DIRECTION RETAINING

RING ASSEMBLY BODY ARROW RING

1.85

1.31 3.69

DIA.

Figure 3: Dimensions Figure 4: Exploded View

June 2022 TRB-DS-02785-EN-06 Page 3

Turbine Flow Meter, Model 1200

PART NUMBER INFORMATION

Meter with pickups

Flow Ranges Strainer Approx. K-factor End to End

Part Number Bore Size End Connections Max PSI Weight

gpm (lpm) Mesh Pulses/Gal Length

B121-225 1/4 in. 1/2 in. Male NPT 4000 0.25…2.5 (0.95…9.46) 60 29,000…33,000 — —

B121-275 3/4 in. 1 in. Male NPT 4000 2.5…25 (9.46…94.64) 60 2800…3000 — —

Meter only (no pickups)

Flow Ranges Strainer Approx. K-factor End to End

Part Number Bore Size End Connections Max PSI Weight

gpm (lpm) Mesh Pulses/Gal Length

B121227 1/4 in. 1/2 in. Male NPT 4000 0.25…2.5 (0.95…9.46) 60 29,000…33,000 — —

B121276 3/4 in. 1 in. Male NPT 4000 2.5…25 (9.46…94.64) 60 2800…3000 — —

Control. Manage. Optimize.

Blancett is a registered trademark of Badger Meter, Inc. Other trademarks appearing in this document are the property of their respective entities. Due to continuous research,

product improvements and enhancements, Badger Meter reserves the right to change product or system specifications without notice, except to the extent an outstanding

contractual obligation exists. © 2022 Badger Meter, Inc. All rights reserved.

www.badgermeter.com

You might also like

- Rectifier Inverter DC Link 1 3 5 2 6 4Document58 pagesRectifier Inverter DC Link 1 3 5 2 6 4akm-ntpc100% (4)

- Prathama Solarconnect Energy Private Limited: Short Circuit Study ReportDocument18 pagesPrathama Solarconnect Energy Private Limited: Short Circuit Study Reportramesh cuppuNo ratings yet

- Tundish Cover Ladle NodularizingDocument2 pagesTundish Cover Ladle Nodularizingarnaldorcr8646No ratings yet

- Titanium Cladded Sheet Welding ProcedureDocument4 pagesTitanium Cladded Sheet Welding ProcedureNaveenNo ratings yet

- TRB-DS-01217-EN Blancett 1100 Turbine Flow Meter Product Data SheetDocument4 pagesTRB-DS-01217-EN Blancett 1100 Turbine Flow Meter Product Data SheetFershaalNo ratings yet

- Product Data Sheet: Turbine Flow MeterDocument4 pagesProduct Data Sheet: Turbine Flow MeterJavier EncaladaNo ratings yet

- Ingedrive Mv500 EngDocument2 pagesIngedrive Mv500 EnginakigarateNo ratings yet

- Turbine Meter Tech GuideDocument22 pagesTurbine Meter Tech GuideOscar MarinNo ratings yet

- FT 1000 - FP 1000 - TG L111eDocument12 pagesFT 1000 - FP 1000 - TG L111eoni tofanNo ratings yet

- FT 1000 - FP 1000 - TG L111eDocument12 pagesFT 1000 - FP 1000 - TG L111eaditya pamungkasNo ratings yet

- Turbine Meter Tech GuideDocument24 pagesTurbine Meter Tech GuideDenilson Souto Dos Santos100% (1)

- Manual Inter-M Potencias ServiceDocument20 pagesManual Inter-M Potencias ServiceTati RossiNo ratings yet

- Dual Laterolog ToolDocument44 pagesDual Laterolog ToolTo Pham Ha TrieuNo ratings yet

- Catalogue of Flow MeterDocument24 pagesCatalogue of Flow Metermahmoudebrahim96745No ratings yet

- Ad9901 PDFDocument8 pagesAd9901 PDFDeep SahaniNo ratings yet

- Turn Ratio TestDocument8 pagesTurn Ratio TestImran Nawaz MehthalNo ratings yet

- 24.3 Cách Đo Ripple & Transient - Analog DeviceDocument8 pages24.3 Cách Đo Ripple & Transient - Analog Devicetai08cdt2No ratings yet

- Turbine FL Ow Meter SCFT AnalogueDocument5 pagesTurbine FL Ow Meter SCFT AnalogueCésar PérezNo ratings yet

- X ErCharProtDocument10 pagesX ErCharProtNavaneethakrishnan MurugesanNo ratings yet

- Esign IPS: Reducing Switching Losses in Portable DC/DC ConvertersDocument2 pagesEsign IPS: Reducing Switching Losses in Portable DC/DC ConvertersAbhishek SinghNo ratings yet

- Deadbeat Flux Level Control of Direct Field-Oriented High Horse Power Induction Servo Motor Using Adaptive Rotor Flux ObserverDocument9 pagesDeadbeat Flux Level Control of Direct Field-Oriented High Horse Power Induction Servo Motor Using Adaptive Rotor Flux Observerapi-3826450No ratings yet

- A800sales GuidebookDocument64 pagesA800sales GuidebookTarek KhafagaNo ratings yet

- 3 A40Z090100i en Regulation InterfaceDocument3 pages3 A40Z090100i en Regulation InterfacepdealersNo ratings yet

- Turbine Meters Design & ApplicationDocument33 pagesTurbine Meters Design & ApplicationAnnisa RahmadayantiNo ratings yet

- SCFT Measurement Turbine: Device FeaturesDocument4 pagesSCFT Measurement Turbine: Device FeaturesBHAART PANCHALNo ratings yet

- CRI Openwell PumpsDocument24 pagesCRI Openwell PumpskanaliNo ratings yet

- Red Lion MP Sensor Product Manual PDFDocument2 pagesRed Lion MP Sensor Product Manual PDFJigneshNo ratings yet

- F 4600 Inline Ultrasonic Flow Meter Catalog Sheet Doc 0003429Document4 pagesF 4600 Inline Ultrasonic Flow Meter Catalog Sheet Doc 0003429henryNo ratings yet

- Service Manual: AmplifierDocument20 pagesService Manual: AmplifierHakan Atak100% (1)

- Ip300 3100Document8 pagesIp300 3100sugianto barusNo ratings yet

- High Performance Turbine Meter: A Product Sheet of Neptune Technology GroupDocument4 pagesHigh Performance Turbine Meter: A Product Sheet of Neptune Technology GroupRajibNo ratings yet

- Catologe BHS LBSDocument16 pagesCatologe BHS LBSKien Tran TrungNo ratings yet

- Energy Efficiecy in Electrical SystemDocument34 pagesEnergy Efficiecy in Electrical Systemindra lukmanNo ratings yet

- Relay Test Set: MOT - RTS: FeaturesDocument2 pagesRelay Test Set: MOT - RTS: Featuresamiya_driemsNo ratings yet

- XCT Analisys PDFDocument2 pagesXCT Analisys PDFNewton BELINONo ratings yet

- TTRM 301 TTRM 302: ScopeDocument6 pagesTTRM 301 TTRM 302: ScopeMarco CornelioNo ratings yet

- CT Turns Ratio ModificationDocument5 pagesCT Turns Ratio ModificationeramidopulNo ratings yet

- Reactive Power and Harmonic Filter - ABBDocument49 pagesReactive Power and Harmonic Filter - ABBpongpumNo ratings yet

- Protection Coordination Report: Camerich Paper Private LTDDocument42 pagesProtection Coordination Report: Camerich Paper Private LTDramesh cuppuNo ratings yet

- Relay Coordination Preliminary Report Draft-BDocument4 pagesRelay Coordination Preliminary Report Draft-Bramesh1950No ratings yet

- Features Description: SBVS017A - AUGUST 2001Document12 pagesFeatures Description: SBVS017A - AUGUST 2001Stefano Romeu ZeplinNo ratings yet

- Transformer SizingDocument15 pagesTransformer SizingRaj100% (1)

- 048 Venkatesh AUPEC01paperDocument5 pages048 Venkatesh AUPEC01paperDante FilhoNo ratings yet

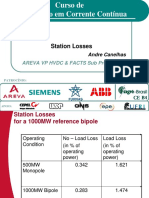

- Curso de Transmissão em Corrente Contínua: Station LossesDocument10 pagesCurso de Transmissão em Corrente Contínua: Station LossesCarlos FigueiredoNo ratings yet

- CIGRE Curso HVDC - Perdas - Canelhas PDFDocument10 pagesCIGRE Curso HVDC - Perdas - Canelhas PDFcarlosrenatorcNo ratings yet

- Elektronika Daya KuliahDocument50 pagesElektronika Daya KuliahAndiHilmySyahirNo ratings yet

- Euramet M T-S1Document20 pagesEuramet M T-S1Juan AriasNo ratings yet

- AMD 4 S-4135E Sep8.2016 PDFDocument4 pagesAMD 4 S-4135E Sep8.2016 PDFEsmaelyNo ratings yet

- ON Icon: Inline Ultrasonic Flow MeterDocument4 pagesON Icon: Inline Ultrasonic Flow MeterJayaminNo ratings yet

- LMCB24-SR (-T) : Proportional Control, Non-Spring Return, Direct Coupled, 24V, For 2 To 10 VDC and 4 To 20 MaDocument5 pagesLMCB24-SR (-T) : Proportional Control, Non-Spring Return, Direct Coupled, 24V, For 2 To 10 VDC and 4 To 20 MaHector Hugo GutierrezNo ratings yet

- Fluid Couplings PDFDocument32 pagesFluid Couplings PDFIvano VerbiNo ratings yet

- Chap 10Document32 pagesChap 10zwolfNo ratings yet

- Tateetal2009 InstrumentedJunction AirQualityConference2009 Id171Document4 pagesTateetal2009 InstrumentedJunction AirQualityConference2009 Id171sahrNo ratings yet

- DynaregDocument6 pagesDynaregchakipuuNo ratings yet

- F001 AtosDocument2 pagesF001 Atoschandushar1604No ratings yet

- Tek 575 1960Document124 pagesTek 575 1960bobvillaisthemanNo ratings yet

- WEST COAST MAGNETICS - Application Notes: Alnt 1440, Revision 1 Flyback Converter DesignDocument6 pagesWEST COAST MAGNETICS - Application Notes: Alnt 1440, Revision 1 Flyback Converter DesignkhsniperNo ratings yet

- LLC ModelingDocument25 pagesLLC ModelingbiswajitntpcNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Analysis and Design of Multicell DC/DC Converters Using Vectorized ModelsFrom EverandAnalysis and Design of Multicell DC/DC Converters Using Vectorized ModelsNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reer Mosaic Safety PLCDocument44 pagesReer Mosaic Safety PLCRenan ValenteNo ratings yet

- NUM CNC User Guide 750tDocument117 pagesNUM CNC User Guide 750tRenan ValenteNo ratings yet

- X9241A Digital PotentiometerDocument18 pagesX9241A Digital PotentiometerRenan ValenteNo ratings yet

- Pressure Reducing Valve Bosch RexrothDocument12 pagesPressure Reducing Valve Bosch RexrothRenan ValenteNo ratings yet

- Beginnings of A Game: Lab Exercise FourDocument2 pagesBeginnings of A Game: Lab Exercise FourAnonymous 20wFhEPNo ratings yet

- MilRoyal D Type Specification Data SheetDocument4 pagesMilRoyal D Type Specification Data SheetYurizki LhzNo ratings yet

- ResultsDocument30 pagesResultssunilkumar_863570770No ratings yet

- Differential Pressure Hazards in DivingDocument4 pagesDifferential Pressure Hazards in DivingmrudhulrajNo ratings yet

- 7RW80 Manual A4 V040300 UsDocument264 pages7RW80 Manual A4 V040300 UsvinodmpvNo ratings yet

- All India Cfo Cio Ceo Data SampleDocument5 pagesAll India Cfo Cio Ceo Data SampleMuralidhara PrasadNo ratings yet

- Rfa Monitoring - PGHDocument76 pagesRfa Monitoring - PGHRigelle DionisioNo ratings yet

- Mec042 - Theory of Machines and MechanismsDocument10 pagesMec042 - Theory of Machines and MechanismsAmanpreet SinghNo ratings yet

- Hemanth GATE ResumeDocument3 pagesHemanth GATE ResumeHemanth JNo ratings yet

- L4 - Steel Structures PDFDocument53 pagesL4 - Steel Structures PDFalexrodriguezabcNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 16504-1 Home Automation SystemDocument23 pagesITCC in Riyadh Residential Complex J10-13300 16504-1 Home Automation SystemuddinnadeemNo ratings yet

- Krasnov Aerodynamics PDFDocument513 pagesKrasnov Aerodynamics PDFmisterno94No ratings yet

- LIST of EN81 RequirementDocument3 pagesLIST of EN81 RequirementAshraf MuhtarNo ratings yet

- Systems Engineering Manager in Chicago IL Resume Daniel O'MalleyDocument2 pagesSystems Engineering Manager in Chicago IL Resume Daniel O'MalleyDanielOMalleyNo ratings yet

- Amst Brochure NV PDFDocument8 pagesAmst Brochure NV PDFpritam099No ratings yet

- B. Inggris Report TextDocument1 pageB. Inggris Report TextPetra CoolNo ratings yet

- Viar Vor Rwy 16Document1 pageViar Vor Rwy 16Amitoj SinghNo ratings yet

- Family Member's Docs.Document2 pagesFamily Member's Docs.hishamNo ratings yet

- Fieldwork Exercise No. 5 Differential Leveling: STA BA HI FS Elevation RemarksDocument3 pagesFieldwork Exercise No. 5 Differential Leveling: STA BA HI FS Elevation RemarksBeaumont Serene Del ReigoNo ratings yet

- Vaisala PTB330 Datasheet B210708EN EDocument2 pagesVaisala PTB330 Datasheet B210708EN Ezivko13No ratings yet

- 1234yf MSDSDocument12 pages1234yf MSDSrajamanickam_csNo ratings yet

- Oriana Phase 3 CFC: Project ContractorDocument1 pageOriana Phase 3 CFC: Project ContractorCivil SanamNo ratings yet

- Rec PrechargeDocument3 pagesRec PrechargePrabha Karan.nNo ratings yet

- Subengineermarks MechDocument306 pagesSubengineermarks MechsivakrprasadNo ratings yet

- Labsheet Translation Mechanical SystemDocument33 pagesLabsheet Translation Mechanical SystemMuhammad Ehsan Abdul Halim0% (1)

- The Petroleum RulesDocument89 pagesThe Petroleum Rulesgpskumar22No ratings yet

- Answer Sheet Q1 Week 1Document25 pagesAnswer Sheet Q1 Week 1kristel guanzonNo ratings yet

- Wall Colmonoy Properties of Selected Ni and Fe Based Brazing Filler MetalsDocument10 pagesWall Colmonoy Properties of Selected Ni and Fe Based Brazing Filler MetalsrezaNo ratings yet