Professional Documents

Culture Documents

Downdraft Plasma Cutting Table

Downdraft Plasma Cutting Table

Uploaded by

Br LaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Downdraft Plasma Cutting Table

Downdraft Plasma Cutting Table

Uploaded by

Br LaCopyright:

Available Formats

instructables

Downdraft Plasma Cutting Table

by geotek

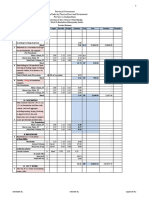

This table starts out as the Cutting Table Kit from clean.

You-weld-it.com. The kit cost $225 which very

reasonable for a kit of this quality. Plasma cutting You will need a supply of sheet metal, a length of 6"

generates a very fine brown dust which gets into galvanized duct and cap, some piano hinge, and an

everything. It can also generate fumes which are not exhaust blower.

good. Converting the table to a downdraft table does

a lot to remove the dust and fumes and keep the shop

Step 1: Build the Kit As Instructed With One Exception

There are several You-tube videos that show how to build the kit. so I won't bother with that here. I used a small 70

Amp MIG welder, and it did just fine. The main difference is the location of the bottom tray. I placed it down about

18 inches below the table top to make room for the exhaust duct. I wanted the duct far enough away from the top

so there would be no danger of it getting cut.

Downdraft Plasma Cutting Table: Page 1

Step 2: Paint the Frame and Cut the Slats

Since I planned to use galvanized sheet metal, I primed and painted the table after the weld-up. The table does not

come with slats, since shipping costs for the slat would cost more than the material. Buy some 1-1/2" x 1/4" hot-

rolled strap from your local metal supplier and cut it to fit your table. Slat length varies a bit from table to table

depending how you did your weld joints. Do not paint the slats.

Downdraft Plasma Cutting Table: Page 2

Step 3: The Exhaust Duct

The purpose of the exhaust duct is to make sure air is sure to only put holes in the part of the duct that will

exhausted evenly across the entire top of the table. be inside the cabinet.

The exhaust duct is a length of normal HVAC

galvanized ducting. When you buy it, the seam will be After the duct was finished I placed a partial roll of

open, this is a good thing. Using a hand punch to aluminum widow screen inside the duct and let it

punch a series of 1/2" holes on both sides of the unroll to fill the duct. This will help prevent sparks and

seam. If you don't have a large hand punch, a step small debris from getting into the duct.

drill works very well with thin sheet metal. It would be

a good idea to wear gloves during this process. Be

Step 4: Cut the Back and Sides, Then Install the Duct

Cut a piece of sheet metal for the back. Secure it to inches above the bottom of the cabinet. I first made

the frame with self drilling screws. Both sides are my exhaust with the open end on the left, but

symmetrical so they can be cut to the same size. Cut changed my mind a swapped it to exhaust to the

a 6" hole for the duct in one end piece. Then mount a right. Self drilling screws work well for securing the

6" duct cap to the inside of the other end to hold the sheet metal together.

end of the duct. Make sure the duct is located a few

Downdraft Plasma Cutting Table: Page 3

Step 5: Make the Front Panel and Mount the Exhaust Blower

You can make a solid front panel, but to clean the cabinet you would have to remove the slats. I decided to cut

doors in the front panel to make clean-out easier. The doors are simple, held with piano hinges and sliding bolt

latches.

The blower was left over from a Chinese laser cutter. It worked well for this purpose. Blowers like this can be found

on eBay for very reasonable prices.

Downdraft Plasma Cutting Table: Page 4

Step 6: Install the Table and Build an Optional Top Skirt

The table should exhaust to the outside through metal of sheet metal with piano hinges at the corners. It sits

ducting. Make the run as short as possible. Make in z-brackets screwed to the sides of the top. The

sure the duct exhausts towards non-flammable skirt can be easily removed and set aside if you have

material (like concrete). It is possible a spark could to cut large pieces of stock.

make it through the blower and go outside. Putting

the exhaust near grass or other flammable material The last photo is our welding lab at The MakerBarn.

would be a bad idea. Covering the walls with galvalume "R" panels makes

to lab safer and cleaner.

After installing the unit, I decided to make a

removable skirt for the top. It consists of three pieces

Downdraft Plasma Cutting Table: Page 5

You might also like

- 100 Detailed Things To Find in A DungeonDocument9 pages100 Detailed Things To Find in A Dungeonhamerp hamerp100% (1)

- Build A Simple Solar Water HeaterDocument36 pagesBuild A Simple Solar Water HeaterAdithya Adiga100% (1)

- The Handyman's Guide To Homebrew Construction Practices From Copper To ManhattanDocument11 pagesThe Handyman's Guide To Homebrew Construction Practices From Copper To ManhattanJanIgnatius100% (4)

- 1911 Frame TutorialDocument22 pages1911 Frame Tutorialblackta6100% (7)

- AVX Pier ExtensionDocument4 pagesAVX Pier ExtensionDaniel Ernesto EspitiaNo ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1From EverandPlastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1Rating: 5 out of 5 stars5/5 (2)

- Stainless Steel Flat Products For Building - The Grades in EN 10088-4 ExplainedDocument28 pagesStainless Steel Flat Products For Building - The Grades in EN 10088-4 ExplainedLeo TuckerNo ratings yet

- Barrel IncineratorDocument29 pagesBarrel IncineratorEmijo.ANo ratings yet

- V4 Pannier Attachment System Posted To V-Strom Forum NewDocument42 pagesV4 Pannier Attachment System Posted To V-Strom Forum NewAshan SanNo ratings yet

- Easy To Build Stirling Engine FanDocument14 pagesEasy To Build Stirling Engine Fanpatel_kalpesh1241100% (1)

- Build ADIYLaminatorDocument22 pagesBuild ADIYLaminatoredwin delgado riosNo ratings yet

- Electronic Drum PadDocument44 pagesElectronic Drum PadMarinko TikvickiNo ratings yet

- Full Download Book Nursing Delegation and Management of Patient Care PDFDocument22 pagesFull Download Book Nursing Delegation and Management of Patient Care PDFblanca.flanagan396100% (23)

- Router Cabinet Down DraughtDocument7 pagesRouter Cabinet Down DraughtwoodsdgNo ratings yet

- DIY Fume ExtractorDocument10 pagesDIY Fume ExtractoryemNo ratings yet

- Building Vacuum FormingDocument13 pagesBuilding Vacuum FormingAndrew Tan100% (2)

- Ebook PDF of Matemática 8º Ano Projeto Telaris Luiz Roberto Dante Full ChapterDocument53 pagesEbook PDF of Matemática 8º Ano Projeto Telaris Luiz Roberto Dante Full Chaptertiabouelvin100% (9)

- Paintcan Gasifier StoveDocument9 pagesPaintcan Gasifier StoveecosarahNo ratings yet

- How To Build A Tesla CoilDocument33 pagesHow To Build A Tesla Coil盾謙100% (1)

- How To Build A Kerosene Fired Egg IncubatorDocument12 pagesHow To Build A Kerosene Fired Egg IncubatorSchool Vegetable Gardening100% (1)

- Forge Build PDFDocument7 pagesForge Build PDFEdson GordianoNo ratings yet

- BHManual Fuselage46 79rev1Document34 pagesBHManual Fuselage46 79rev1viorelu99No ratings yet

- Dơnload Digital Design and Computer Architecture RISC V Edition Sarah Harris Full ChapterDocument24 pagesDơnload Digital Design and Computer Architecture RISC V Edition Sarah Harris Full Chaptermallmaamod9100% (5)

- Building Yagi AntennasDocument3 pagesBuilding Yagi Antennasmopolavi2No ratings yet

- Half Pipe PlansDocument13 pagesHalf Pipe PlansRiverNo ratings yet

- Another Drum SanderDocument13 pagesAnother Drum SanderAdam Hemsley100% (1)

- Awesome Trailer Mounted SmokerDocument19 pagesAwesome Trailer Mounted SmokerAnonymous e2GKJupNo ratings yet

- SEAL Wolf Pursuit Terry Spear Full Chapter PDFDocument24 pagesSEAL Wolf Pursuit Terry Spear Full Chapter PDFtugbognauto0100% (11)

- Diy Pellet BurnerDocument17 pagesDiy Pellet BurnerAlbu Ionut Daniel100% (1)

- Van de Graaf Generator PlansDocument13 pagesVan de Graaf Generator PlansgocipedamaNo ratings yet

- Build A 15,000 RPM Tesla Turbine Using Hard Drive Platters: 9 Steps (With Pictures)Document12 pagesBuild A 15,000 RPM Tesla Turbine Using Hard Drive Platters: 9 Steps (With Pictures)Dragan PiticNo ratings yet

- Build Filament ExtruderDocument46 pagesBuild Filament Extruderxxenys2127No ratings yet

- Kucica Za PticeDocument9 pagesKucica Za PticeNikola0302No ratings yet

- BHManual Wing1 28rev0Document28 pagesBHManual Wing1 28rev0viorelu99100% (1)

- Reprap OrgDocument19 pagesReprap Orgvijjy471No ratings yet

- Saw Dust Burning Space Heater StoveDocument10 pagesSaw Dust Burning Space Heater StovepitufitoNo ratings yet

- SLA 3d PrinterDocument80 pagesSLA 3d Printerbitu&piutaNo ratings yet

- Southern GP35 Bob HarpeDocument94 pagesSouthern GP35 Bob Harpepwmvsi100% (2)

- Stompbox WorkshopDocument18 pagesStompbox Workshopchris_holden249580% (10)

- Brewery Construction GuideDocument23 pagesBrewery Construction GuideCesar Diaz100% (6)

- T-Nuts in FoamDocument6 pagesT-Nuts in Foamscribd4uall100% (1)

- 2 - How To Make A SilencerDocument5 pages2 - How To Make A SilencerFlavio Marçal100% (3)

- Assingment 1 Welding TechnologyDocument14 pagesAssingment 1 Welding TechnologyMuhammad Sufi MustafaNo ratings yet

- Lab11 WPDocument18 pagesLab11 WPironman9879357No ratings yet

- My Hovercraft Build DiaryDocument74 pagesMy Hovercraft Build DiaryLeonel Rodriguez100% (2)

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3From EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3No ratings yet

- Make A Ribbon ControllerDocument16 pagesMake A Ribbon ControllerVaclav MullerNo ratings yet

- 2 Meter VerticalDocument16 pages2 Meter VerticalEndarika Yulianto Eka100% (1)

- Brewery Construction GuideDocument23 pagesBrewery Construction GuideodairnettoNo ratings yet

- AT-420 Assembly GuideDocument10 pagesAT-420 Assembly GuidegdudgshsNo ratings yet

- A Home-Grown FoundryDocument12 pagesA Home-Grown Foundryjraju1974100% (4)

- My Roof Repair - Facebook3LINKS IPDocument10 pagesMy Roof Repair - Facebook3LINKS IPJames EastNo ratings yet

- How to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityFrom EverandHow to Make Electrical Machines: Containing Full Directions for Making Electrical Machines, Induction Coils, Dynamos, and Many Novel Toys to Be Worked by ElectricityNo ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2From EverandPlastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2No ratings yet

- Family Handyman Ultimate 1 Day ProjectsFrom EverandFamily Handyman Ultimate 1 Day ProjectsRating: 5 out of 5 stars5/5 (1)

- Fix it Yourself - Home Repairs Made Easy - A Completely Indexed Manual for Home Owners and Handy Men on Woodworking, Painting, Plumbing, Electrical Appliances, Concrete, and Metal WorkFrom EverandFix it Yourself - Home Repairs Made Easy - A Completely Indexed Manual for Home Owners and Handy Men on Woodworking, Painting, Plumbing, Electrical Appliances, Concrete, and Metal WorkRating: 5 out of 5 stars5/5 (1)

- 06-10-10 Fast Screwing Technology TCFDocument8 pages06-10-10 Fast Screwing Technology TCFBr LaNo ratings yet

- MCC10005 8932 HVAC Pocket Guide English r9 WEBDocument63 pagesMCC10005 8932 HVAC Pocket Guide English r9 WEBBr LaNo ratings yet

- 06-03-20 FDS-Aplication Overview Audi BIWDocument9 pages06-03-20 FDS-Aplication Overview Audi BIWBr LaNo ratings yet

- NIKON Labophot-2Document32 pagesNIKON Labophot-2Br LaNo ratings yet

- Caramel Slice-Candy Bar CookiesDocument1 pageCaramel Slice-Candy Bar CookiesBr LaNo ratings yet

- Smi 162Document6 pagesSmi 162Br LaNo ratings yet

- 2007 PM49 CaliberDocument361 pages2007 PM49 CaliberBr LaNo ratings yet

- Install Rear Brake Caliper and Disk To Hub - SRT-4Document3 pagesInstall Rear Brake Caliper and Disk To Hub - SRT-4Br LaNo ratings yet

- ETI102Document16 pagesETI102Br LaNo ratings yet

- Pantry Make OverDocument2 pagesPantry Make OverBr LaNo ratings yet

- Sine Plate - Locking StrapDocument1 pageSine Plate - Locking StrapBr LaNo ratings yet

- FINAL-ITP For Concreting Work Rev.2 25-Oct-2014Document12 pagesFINAL-ITP For Concreting Work Rev.2 25-Oct-2014Mohammed MujahidNo ratings yet

- Dual Fuel Engine Project ReportDocument23 pagesDual Fuel Engine Project ReportPushkar KhobareNo ratings yet

- Mughal ArchitectureDocument20 pagesMughal ArchitectureDiplina SahariaNo ratings yet

- SG-02 Safety Guideline For Working at HeightDocument48 pagesSG-02 Safety Guideline For Working at Heighttariq1987No ratings yet

- ATFA Timber Floors Magazine Issue 02Document24 pagesATFA Timber Floors Magazine Issue 02RainNo ratings yet

- H.G. Silos, INC.: Bill of MaterialsDocument42 pagesH.G. Silos, INC.: Bill of MaterialsJustine YapNo ratings yet

- Panelling ModelDocument1 pagePanelling ModelcharuNo ratings yet

- Cma 414 - Muhammad Shaffiq (Individual Assignment)Document5 pagesCma 414 - Muhammad Shaffiq (Individual Assignment)Shaffiq SharuddinNo ratings yet

- Efaz Et Al 2022 Combined Load Test and Nde Novel Method To Diagnose and Load Rate Prestressed Concrete Girder BridgesDocument16 pagesEfaz Et Al 2022 Combined Load Test and Nde Novel Method To Diagnose and Load Rate Prestressed Concrete Girder BridgesTONY VILCHEZ YARIHUAMANNo ratings yet

- Short Panel Concrete Pavement and White ToppingDocument41 pagesShort Panel Concrete Pavement and White ToppingsombansNo ratings yet

- Eng0303 1 RevA 31.08.22Document19 pagesEng0303 1 RevA 31.08.22srimalbandara333No ratings yet

- Bibaha Mandap 1Document3 pagesBibaha Mandap 1Anu PathakNo ratings yet

- UPVC CHECKLIST As ASTM 1748/BS 7413/ EN 12608: General NotesDocument2 pagesUPVC CHECKLIST As ASTM 1748/BS 7413/ EN 12608: General NotesAhmed DawodNo ratings yet

- Final Deviation (MCH Bhadrak)Document85 pagesFinal Deviation (MCH Bhadrak)Tapan JenaNo ratings yet

- Industrial Training Report FinalDocument29 pagesIndustrial Training Report FinalMattam AbhishekNo ratings yet

- Quiz 3 NotesDocument18 pagesQuiz 3 NotesKyleNo ratings yet

- Art Education and AppreciationDocument122 pagesArt Education and AppreciationKarlyn RamosNo ratings yet

- Abel Earthquake Engineering Assignment 2Document5 pagesAbel Earthquake Engineering Assignment 2therese abelNo ratings yet

- Raft Slab Bottom Short Bars DetailsDocument1 pageRaft Slab Bottom Short Bars DetailsDINESH M.NNo ratings yet

- Aluminium Framing Members in Facades: Key Engineering Materials September 2016Document7 pagesAluminium Framing Members in Facades: Key Engineering Materials September 2016layaljamal2No ratings yet

- General ITP For MEP Work at Electrical RoomDocument3 pagesGeneral ITP For MEP Work at Electrical RoomWaqar KhanNo ratings yet

- Kami Export - Ahlani Myers - Globe Theater Scavenger Hunt PDFDocument2 pagesKami Export - Ahlani Myers - Globe Theater Scavenger Hunt PDFAhlani MyersNo ratings yet

- 1.introduction To Building Construction MaterialsDocument18 pages1.introduction To Building Construction Materialsabc enterpriseNo ratings yet

- Combined Bulletin 9 and 10 - StructuralDocument50 pagesCombined Bulletin 9 and 10 - StructuralDimitrios VoulgarisNo ratings yet

- Chapter 4 - LumberDocument36 pagesChapter 4 - LumberTechMusic GuyNo ratings yet

- Coil Protect 040 W - 272606Document1 pageCoil Protect 040 W - 272606SüleymanŞentürkNo ratings yet

- SECTION 07 60 00 Flashing and Sheet MetalDocument31 pagesSECTION 07 60 00 Flashing and Sheet MetalJuanPaoloYbañezNo ratings yet

- Karpinski Ghost Tube InstructionsDocument1 pageKarpinski Ghost Tube InstructionsEvan Buso-JarnisNo ratings yet