Professional Documents

Culture Documents

Braga 2004

Braga 2004

Uploaded by

Luis Felipe SchneiderCopyright:

Available Formats

You might also like

- Vertical Lift Hydraulic Gate DesignDocument40 pagesVertical Lift Hydraulic Gate Designmesam100% (3)

- Crossing Calculation API 1102 8inch Sch40 Api5lbrg 1.3depthDocument12 pagesCrossing Calculation API 1102 8inch Sch40 Api5lbrg 1.3depthJoe Kyla83% (6)

- NZS 3101-2006 Example 001Document8 pagesNZS 3101-2006 Example 001RMM100% (1)

- Steam Table Problems PDFDocument5 pagesSteam Table Problems PDFBenedick Jayson P. Marti100% (1)

- Adhesion in DentistryDocument184 pagesAdhesion in DentistryDevvrat Singh100% (4)

- Fea Assignment - IDocument13 pagesFea Assignment - Isakthivel balamuruganNo ratings yet

- Flowable CompositesDocument3 pagesFlowable Compositesrasagna reddyNo ratings yet

- Filler Dental ResinDocument10 pagesFiller Dental Resinmflorian69No ratings yet

- Evaluation of Bond Strength, Marginal Integrity, and Fracture Strength of Bulk-Vs Incrementally-Filled RestorationsDocument8 pagesEvaluation of Bond Strength, Marginal Integrity, and Fracture Strength of Bulk-Vs Incrementally-Filled RestorationsJzNo ratings yet

- Ari 15Document6 pagesAri 15mariaNo ratings yet

- J Esthet Restor Dent - 2022 - Falacho - Clinical in Situ Evaluation of The Effect of Rubber Dam Isolation On Bond StrengthDocument8 pagesJ Esthet Restor Dent - 2022 - Falacho - Clinical in Situ Evaluation of The Effect of Rubber Dam Isolation On Bond StrengthAmaranta AyalaNo ratings yet

- Usage of Fibre Reinforced Composite in Everyday Practice - A SurveyDocument10 pagesUsage of Fibre Reinforced Composite in Everyday Practice - A SurveyARAVINDAN GEETHA KRRISHNANNo ratings yet

- 1 s2.0 S1751616118300079 MainDocument8 pages1 s2.0 S1751616118300079 MainnolasNo ratings yet

- Análise Crítica Do Tratamento de Superfície de Pinos de Fibra: Uma RevisãoDocument11 pagesAnálise Crítica Do Tratamento de Superfície de Pinos de Fibra: Uma RevisãoKatherine Kelly Povis AresteguiNo ratings yet

- Denture Liners A Systematic Review Relative To AdhDocument12 pagesDenture Liners A Systematic Review Relative To AdhtovarichNo ratings yet

- Effectiveness of Indirect Composite Resin Silanization by Microtensile Bond Strength TestDocument7 pagesEffectiveness of Indirect Composite Resin Silanization by Microtensile Bond Strength TestpoojaNo ratings yet

- C FactorDocument7 pagesC FactorMuthia DewiNo ratings yet

- Effect of Denture Cleansers On Tensile Bond Strength of Soft Liners To Denture Base ResinDocument8 pagesEffect of Denture Cleansers On Tensile Bond Strength of Soft Liners To Denture Base ResinMUHAMMAD INDRANo ratings yet

- Tug As Translate Ne MenDocument7 pagesTug As Translate Ne MenFaris MahdaniNo ratings yet

- Artigo SolventesDocument7 pagesArtigo SolventesAlexis VázquezNo ratings yet

- Cement System and Surface Treatment Selection For Fiber Post LutingDocument8 pagesCement System and Surface Treatment Selection For Fiber Post LutingHitesh ChopraNo ratings yet

- Fibras Ribbond Disminuyen El GAP en El Piso de CavidadDocument8 pagesFibras Ribbond Disminuyen El GAP en El Piso de CavidadSuperOscar LazcanoNo ratings yet

- J Esthet Restor Dent - 2022 - Falacho - Clinical in Situ Evaluation of The Effect of Rubber Dam Isolation On Bond StrengthDocument8 pagesJ Esthet Restor Dent - 2022 - Falacho - Clinical in Situ Evaluation of The Effect of Rubber Dam Isolation On Bond StrengthEdson HoribeNo ratings yet

- 2020 Article 1037Document11 pages2020 Article 1037Hosam kamalNo ratings yet

- 1 s2.0 S0048969722061988 MainDocument10 pages1 s2.0 S0048969722061988 MaincutdianNo ratings yet

- Amalgam Vs CompositeDocument58 pagesAmalgam Vs Compositeanmol0% (1)

- 2018 Article 779Document9 pages2018 Article 779José AntonioNo ratings yet

- Clinical Study and Single-Bottle SystemsDocument7 pagesClinical Study and Single-Bottle SystemsSammer BurgosNo ratings yet

- Short Fiber-Reinforced Resin-Based Composites (SFRCS) Current Status andDocument8 pagesShort Fiber-Reinforced Resin-Based Composites (SFRCS) Current Status andPamela ENo ratings yet

- DirectCompositesversusIndirectCompositeInlays One YearResultsDocument11 pagesDirectCompositesversusIndirectCompositeInlays One YearResultsAya Ibrahim YassinNo ratings yet

- BisGMA TEGDMA Ratio and Filler Content Effects On Shrinkage Stress 2011 Dental MaterialsDocument7 pagesBisGMA TEGDMA Ratio and Filler Content Effects On Shrinkage Stress 2011 Dental MaterialsMarincean LauraNo ratings yet

- Surface Treatments For Improving Bond Strength To Prefabricated Fiber Posts: A Literature ReviewDocument10 pagesSurface Treatments For Improving Bond Strength To Prefabricated Fiber Posts: A Literature ReviewPascalis Adhi KurniawanNo ratings yet

- Factors Influencing Mechanical Properties of PolyuDocument12 pagesFactors Influencing Mechanical Properties of PolyukevinNo ratings yet

- Accepted Author VersionDocument65 pagesAccepted Author VersionLucianoNo ratings yet

- Materials Science and Engineering CDocument13 pagesMaterials Science and Engineering CAnonymous 5AmJ13mLkNo ratings yet

- Critical Reviews in Oral Biology & Medicine: Cementum and Periodontal Wound Healing and RegenerationDocument12 pagesCritical Reviews in Oral Biology & Medicine: Cementum and Periodontal Wound Healing and RegenerationsevattapillaiNo ratings yet

- Sadr 2020Document8 pagesSadr 2020Wendy SolaresNo ratings yet

- Analysis of Microleakage and Marginal Gap Presented by New Polymeric Systems in Class V Restorations: An in Vitro StudyDocument5 pagesAnalysis of Microleakage and Marginal Gap Presented by New Polymeric Systems in Class V Restorations: An in Vitro StudyAini AngelaNo ratings yet

- Journal of Dental Research: Impact of Curing Protocol On Conversion and Shrinkage StressDocument6 pagesJournal of Dental Research: Impact of Curing Protocol On Conversion and Shrinkage StressVikas DeepNo ratings yet

- EtchandrinseDocument6 pagesEtchandrinseLoraine RiveroNo ratings yet

- Factor C 2014Document8 pagesFactor C 2014lourdesmaritzatancararamosNo ratings yet

- Microleakage Resin Bis-Gma Dan Rmgic Fissure Sealant Pada: Perubahan Suhu Rongga MulutDocument8 pagesMicroleakage Resin Bis-Gma Dan Rmgic Fissure Sealant Pada: Perubahan Suhu Rongga MulutHigiene GigiNo ratings yet

- DirectResinCompositeRestorationsversusIndirectCompositeInlays One YearResultsDocument11 pagesDirectResinCompositeRestorationsversusIndirectCompositeInlays One YearResultsSweetz Viena ParamitaNo ratings yet

- 18-Year Survival of Posterior Composite Resin Restorations With and Without Glass Ionomer Cement As BaseDocument7 pages18-Year Survival of Posterior Composite Resin Restorations With and Without Glass Ionomer Cement As BaseHurianNo ratings yet

- Advances in Medical Adhesives Inspired by Aquatic Organisms ' AdhesionDocument9 pagesAdvances in Medical Adhesives Inspired by Aquatic Organisms ' Adhesionhbno91q2No ratings yet

- Burey Et Al-2017-Microscopy Research and TechniqueDocument10 pagesBurey Et Al-2017-Microscopy Research and Techniquelian liaanNo ratings yet

- New Resins For Dental Composites - PMCDocument13 pagesNew Resins For Dental Composites - PMCJefferson RegenteNo ratings yet

- JFB 13 00287Document20 pagesJFB 13 00287Paula Camila Bernal MartinezNo ratings yet

- The Effect of Amount Variation of Dental Polyethylene Fiber OnDocument7 pagesThe Effect of Amount Variation of Dental Polyethylene Fiber OnCristian PazNo ratings yet

- The Effect of Air Drying Time On Bonding (Self Etch)Document7 pagesThe Effect of Air Drying Time On Bonding (Self Etch)Salsabila Farah AzzahraNo ratings yet

- Recent Advances in Dental Implants: ReviewDocument10 pagesRecent Advances in Dental Implants: ReviewEndang Noor HidayatiNo ratings yet

- Composites Part BDocument23 pagesComposites Part BFoysal SirazeeNo ratings yet

- 10 3290@j Jad A42510Document9 pages10 3290@j Jad A42510Iván ForeroNo ratings yet

- Shortfiber Reinforcedresin BasedcompositescurrentstatusandfutureperspectivesDocument9 pagesShortfiber Reinforcedresin BasedcompositescurrentstatusandfutureperspectivesmasoudNo ratings yet

- The Development of Filler Morphology in Dental Resin Composites: A ReviewDocument21 pagesThe Development of Filler Morphology in Dental Resin Composites: A ReviewRanulfo Castillo PeñaNo ratings yet

- Carrilho 2007Document6 pagesCarrilho 2007Ali Al-QaysiNo ratings yet

- Clinical Performance of Bulk-Fill and Conventional Resin Composite Restorations in Posterior Teeth: A Systematic Review and Meta-AnalysisDocument13 pagesClinical Performance of Bulk-Fill and Conventional Resin Composite Restorations in Posterior Teeth: A Systematic Review and Meta-AnalysisNicolás SotoNo ratings yet

- Residual Decontamination Chemical Agents Negatively Affect Adhesion and Proliferation of Osteoblast-Like Cells On Implant SurfaceDocument9 pagesResidual Decontamination Chemical Agents Negatively Affect Adhesion and Proliferation of Osteoblast-Like Cells On Implant Surfacebr grNo ratings yet

- 28 6ee 3Document8 pages28 6ee 3Ramy AmirNo ratings yet

- 2023 Article 3217Document20 pages2023 Article 3217LeandroMartinsNo ratings yet

- VallittuPKetal DentmaterDocument4 pagesVallittuPKetal DentmaterPaulette Sarmiento RosalesNo ratings yet

- 1991 15038 2 PBDocument12 pages1991 15038 2 PBEduardo FernandezNo ratings yet

- Properties of Composite Materials Used For Bracket BondingDocument5 pagesProperties of Composite Materials Used For Bracket BondingFabian BarretoNo ratings yet

- Effect of Double Layer Application On Bond Quality of AdhesiveDocument9 pagesEffect of Double Layer Application On Bond Quality of AdhesiveErika NuñezNo ratings yet

- Patel 2018Document10 pagesPatel 2018Luis Felipe SchneiderNo ratings yet

- Condon 2000Document7 pagesCondon 2000Luis Felipe SchneiderNo ratings yet

- Chisini 2Document11 pagesChisini 2Luis Felipe SchneiderNo ratings yet

- To What Extent Do Patients' Racial Characteristics Affect Our Clinical Decisions?Document2 pagesTo What Extent Do Patients' Racial Characteristics Affect Our Clinical Decisions?Luis Felipe SchneiderNo ratings yet

- Dema 2016 - Ferracane - MeaningfulDocument10 pagesDema 2016 - Ferracane - MeaningfulLuis Felipe SchneiderNo ratings yet

- 2020 JPDDocument5 pages2020 JPDLuis Felipe SchneiderNo ratings yet

- Bicalho 2016Document10 pagesBicalho 2016Luis Felipe SchneiderNo ratings yet

- 2005 - Revista FopDocument4 pages2005 - Revista FopLuis Felipe SchneiderNo ratings yet

- J Esthet Restor Dent - 2023 - Magne - Shrinkage Induced Cuspal Deformation and Strength of Three Different ShortDocument8 pagesJ Esthet Restor Dent - 2023 - Magne - Shrinkage Induced Cuspal Deformation and Strength of Three Different ShortLuis Felipe SchneiderNo ratings yet

- 3D - 2024 - Sprintray CrownDocument15 pages3D - 2024 - Sprintray CrownLuis Felipe SchneiderNo ratings yet

- 3D - 2024 - Detax FreeprintDocument11 pages3D - 2024 - Detax FreeprintLuis Felipe SchneiderNo ratings yet

- 3D - Printed Crowns - Cost EffectiveDocument4 pages3D - Printed Crowns - Cost EffectiveLuis Felipe SchneiderNo ratings yet

- 2022 BDS ClareamentoDocument10 pages2022 BDS ClareamentoLuis Felipe SchneiderNo ratings yet

- 3D 2023 DEMA AirborneDocument11 pages3D 2023 DEMA AirborneLuis Felipe SchneiderNo ratings yet

- 2024 Bor Qas OrtoDocument10 pages2024 Bor Qas OrtoLuis Felipe SchneiderNo ratings yet

- What Is Needed in Transformer Models?Document12 pagesWhat Is Needed in Transformer Models?brunoscarpaNo ratings yet

- Assignment 1Document28 pagesAssignment 1Atul KumarNo ratings yet

- Attached PubblicazioniDocument9 pagesAttached PubblicazioniAnonymous 0mXnmNRNo ratings yet

- Safety PlugDocument5 pagesSafety PlugJairo RiveraNo ratings yet

- PP For CH 30Document40 pagesPP For CH 30allah rakha swabiNo ratings yet

- Differential Equation For The Rate of Capillary Action of Water On A Single Brand Tissue PaperDocument8 pagesDifferential Equation For The Rate of Capillary Action of Water On A Single Brand Tissue Paperjohn_42494No ratings yet

- Steel SlagDocument13 pagesSteel SlagHemanth Peddavenkatappa GariNo ratings yet

- PDF 4 1 PDFDocument139 pagesPDF 4 1 PDFMohammed Mohsen Tadulan Tawfiq100% (1)

- Raex 500Document4 pagesRaex 500Daniel MauricioNo ratings yet

- Stephane - Mespoulet 1998 PHD Thesis PDFDocument246 pagesStephane - Mespoulet 1998 PHD Thesis PDFJavicontryNo ratings yet

- SEM IntroDocument5 pagesSEM IntroSayan KarNo ratings yet

- Applications of Conductive Polymers As SensitizersDocument7 pagesApplications of Conductive Polymers As SensitizersCentral Asian StudiesNo ratings yet

- Ebook - Light Matter InteractionDocument433 pagesEbook - Light Matter InteractionHp InfinixNo ratings yet

- Jihai Cheng, Weitao Bao, Dechun Zhu, Changan Tian, Qiyi Yin, Ming DingDocument3 pagesJihai Cheng, Weitao Bao, Dechun Zhu, Changan Tian, Qiyi Yin, Ming DingkinecamposNo ratings yet

- 6-79-0016 Rev 1Document11 pages6-79-0016 Rev 1abhishek100% (1)

- Formulation Development & Characterization of Nanoparticles With Some Antidiabetic DrugsDocument12 pagesFormulation Development & Characterization of Nanoparticles With Some Antidiabetic DrugsPradeep NimaseNo ratings yet

- Contribution To The Modelling of Chocolate Tempering ProcessDocument18 pagesContribution To The Modelling of Chocolate Tempering ProcessSantosh RajuNo ratings yet

- Repair and MaintenanceDocument4 pagesRepair and MaintenanceElMacheteDelHuesoNo ratings yet

- Strength of Material Exp 4 Rockwell Hardness TestDocument11 pagesStrength of Material Exp 4 Rockwell Hardness Testhayder alaliNo ratings yet

- Transmission Electron Microscopy and Its ApplicationsDocument12 pagesTransmission Electron Microscopy and Its ApplicationsMoayad TeimatNo ratings yet

- Application Field of Slipper Rings and FLUOR S TapesDocument2 pagesApplication Field of Slipper Rings and FLUOR S TapesAnurag JainNo ratings yet

- Creep PDFDocument236 pagesCreep PDFoshadhivNo ratings yet

- Bathnagar Et Al 2016Document13 pagesBathnagar Et Al 2016Marcelo CifuentesNo ratings yet

- PD3A Component DesignDocument38 pagesPD3A Component DesignShashank SundiNo ratings yet

- Development and Ballistic Testing of A Functionally Gradient Ceramic Metal AppliqueDocument12 pagesDevelopment and Ballistic Testing of A Functionally Gradient Ceramic Metal Appliquegrindormh53No ratings yet

Braga 2004

Braga 2004

Uploaded by

Luis Felipe SchneiderOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Braga 2004

Braga 2004

Uploaded by

Luis Felipe SchneiderCopyright:

Available Formats

Critical Reviews http://cro.sagepub.

com/

in Oral Biology & Medicine

Alternatives in Polymerization Contraction Stress Management

R.R. Braga and J.L. Ferracane

CROBM 2004 15: 176

DOI: 10.1177/154411130401500306

The online version of this article can be found at:

http://cro.sagepub.com/content/15/3/176

Published by:

http://www.sagepublications.com

On behalf of:

International and American Associations for Dental Research

Additional services and information for Critical Reviews in Oral Biology & Medicine can be found at:

Email Alerts: http://cro.sagepub.com/cgi/alerts

Subscriptions: http://cro.sagepub.com/subscriptions

Reprints: http://www.sagepub.com/journalsReprints.nav

Permissions: http://www.sagepub.com/journalsPermissions.nav

>> Version of Record - May 1, 2004

What is This?

Downloaded from cro.sagepub.com at BOSTON UNIV on September 27, 2014 For personal use only. No other uses without permission.

International and American Associations for Dental Research

ALTERNATIVES IN POLYMERIZATION CONTRACTION

STRESS MANAGEMENT

R.R. Braga*

University of São Paulo, School of Dentistry, Department of Dental Materials, Av. Prof. Lineu Prestes, 2227, São Paulo-SP 05508-900, Brazil; *corresponding author, rrbraga@usp.br

J.L. Ferracane

Oregon Health & Science University, School of Dentistry, Division of Biomaterials and Biomechanics, Department of Restorative Dentistry, Portland, OR, USA

ABSTRACT: Polymerization contraction stress of dental composites is often associated with marginal and interfacial fail-

ures of bonded restorations. The magnitude of stress depends on composite composition (filler content and matrix com-

position) and its ability to flow before gelation, which is related to the cavity configuration and curing characteristics of

the composite. This article reviews variations among studies regarding contraction-stress-testing methods and contraction

stress values of current composites, and discusses the validity of contraction stress studies in relation to results from

microleakage tests. The effects of lower curing rates and alternative curing routines on contraction stress values are also

discussed, as well as the use of low-elastic-modulus liners. Moreover, studies with experimental dimethacrylate-based

composites and recent developments in low-shrinkage monomers are described.

Key words. Composites, polymerization stress, elastic modulus, shrinkage.

Introduction version, referred to as the 'gel point', at which an insoluble net-

work is formed within the resin phase. At this point, the elastic

D imethacrylate-based composites have been used in den-

tistry for over 30 years. Developments in filler technology

and initiation systems have considerably improved composite

modulus of the composite has increased substantially, and the

composite's elastic limit has reached a level that does not allow

physical properties and expanded their clinical applications. enough plastic deformation (or flow) to compensate for the

Notwithstanding, since early composites, the volumetric reduction in volume. Beyond this stage, additional contraction

shrinkage resulting from conversion of dimethacrylate may generate significant stress within the composite. If com-

monomers into long, cross-linked polymeric chains has been posite is bonded to cavity walls, shrinkage forces will develop,

identified as a critical limitation that needed to be addressed resulting in stresses on the bond between composite and tooth

(Bowen, 1963). Bonding of composite to cavity walls seemed to structure. These forces are not uniformly distributed along the

be a reasonable solution for the problem. This quest prompted cavity walls (Kinomoto and Torii, 1998). The bond strength

prolific research activity on the subject of dental adhesives and between tooth and composite also varies along the bonded sur-

dentin permeability, that brought remarkable advances such face (Shono et al., 1999). Therefore, in areas where the shrinkage

as wet bonding and self-etching primers. Unfortunately, in forces are higher than the composite-to-dental-substrate bond,

spite of the significant increase in bond strength values report- a gap will develop, increasing the chance for post-operative

ed over the years, the occurrence of microleakage and gap for- sensitivity and recurrent caries (Brännström, 1984; Eick and

mation, mostly at the dentin/composite interface, did not Welch, 1986). A recent study demonstrated that the percentage

seem to decrease at a similar rate (Hilton, 2002; Irie et al., 2002). of dentinal gaps in a composite restoration placed in vivo may

Concurrently, research on polymerization kinetics and poly- vary between 14% and 54% of the total interface, depending on

merization contraction stress began to intensify, producing the materials and techniques used (Hannig and Friedrichs,

enhanced knowledge of factors influencing the magnitude of 2000). Other consequences of contraction stress are the devel-

forces developed at bonded interfaces. opment of enamel cracks (Jorgensen et al., 1975; Kanca and Suh,

Dental composite polymerization shrinkage ranges 1999) and cuspal movement (Sheth et al., 1988; Sulliman et al.,

between 2 and 6% by volume (Labella et al., 1999). Besides vol- 1993; Alomari et al., 2001).

ume reduction, chain growth and cross-linking also result in The phenomenon of force development in contracting

increased elastic modulus (Braem et al., 1987; Dauvillier et al., materials was first described in the dental literature by Bowen

2000). During polymerization, there is a stage in monomer con- (1967). In that study, the author discussed the influence of set-

176 Crit Rev Oral Biol Med

Downloaded from cro.sagepub.com at BOSTON UNIV on September 27, 2014 For personal use only. No other uses without permission.

15(3):176-184 (2004)

International and American Associations for Dental Research

ting material confinement as the main factor associated with

contraction stress. But it was not until studies by Davidson and

de Gee (1984) and Feilzer et al. (1987) that the subject of poly-

merization contraction stress began to be studied in depth. It is

well-established that the magnitude of contraction stress devel-

opment depends on factors related to the geometry of the cav-

ity preparation (or the testing specimen), as well as on the com-

positional and curing characteristics of the composite.

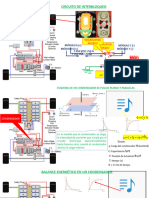

The most frequent method of measuring contraction stress

is the tensilometer (Bowen, 1967). In this test, contraction stress

values vary according to the ratio of the bonded to the free sur-

face area of the composite. This ratio has been called the con-

figuration factor, or C-factor (Feilzer et al., 1987). It has been

hypothesized that a large unbonded area would facilitate com-

posite plastic deformation during polymerization before the

gel point is reached, thus reducing the final stress values

(Feilzer et al., 1990). This concept of the effect of configuration

factor on contraction stress has been validated, to a certain

extent, by microtensile bond strength studies reporting that Figure 1. Diagram of the contraction stress test set-up.

values to deep dentin were lower when specimens were

obtained from restored cavities, compared with specimens

obtained from flat dental substrates (Yoshikawa et al., 1999;

Nikaido et al., 2002). It was hypothesized that lower bond

strengths were caused by a higher incidence of gaps at the entific evidence, the variety of available alternatives to reduce

dentin-resin interface due to higher contraction stresses polymerization contraction stress and improve interfacial

(Yoshikawa et al., 1999). The volume of shrinking composite integrity of direct and indirect bonded restorations.

also influences stress values (Miguel and de la Macorra, 2001).

This finding supports those of a previous study that showed Contraction Stress Measurements

that the incidence of marginal gaps in composite restorations Polymerization contraction stress has been evaluated by many

was related to the volume of composite and to the bonded cav- different methods. Stress distribution in simulated cavities has

ity wall area (Hansen and Asmussen, 1985). been estimated by finite element analysis (Versluis and

Contraction stress is also determined by characteristics of Tantbirojn, 1999; Ausiello et al., 2002) and photoelastic analysis

the composite. Filler content and resin matrix composition dic- (Kinomoto and Torii, 1998; Kinomoto et al., 1999). Direct mea-

tate the amount of volumetric shrinkage and elastic modulus surements of stress (or strain) are usually accomplished with

values of the material (Labella et al., 1999). Polymerization acti- the use of strain gauges (Sakaguchi and Ferracane, 1998) or a

vation mode and types and concentrations of initiators regulate tensilometer (Bowen, 1967; Feilzer et al., 1987; Condon and

degree of conversion and reaction kinetics (Venhoven et al., Ferracane, 1998). In the typical test set-up with a tensilometer

1996). The higher the degree of conversion, the higher the final (Fig. 1), the composite is placed between two opposing mount-

shrinkage and elastic modulus of the composite, both of which ing rods (made of metal or glass), one of which is attached to a

contribute to producing higher stresses (Braga and Ferracane, load cell and the other to a movable cross-head on the testing

2002). Similarly, faster polymerization rates imply that the machine. A feedback system, composed of an extensometer

polymerizing matrix moves more quickly through the critical attached to the rods, is used to maintain a constant distance

conversion for gelation, rapidly producing stiffness in the com- between the rods and to simulate a situation of confinement for

posite and simultaneously reducing its flow capacity (Feilzer et the shrinking composite. In this set-up, the value recorded rep-

al., 1993). Since the gel point refers to a particular degree of con- resents the force necessary to counteract axial composite

version, it itself should not be affected by alterations in reaction shrinkage and maintain rod distance at its initial value. One

kinetics. However, a faster reaction rate would be associated calculates the nominal stress by dividing the measured force by

with a more rapid growth of modulus both before and after the the cross-sectional area of the mounting rod.

gel point, and this necessarily will result in more rapid devel- As in any mechanical test, there is some controversy about

opment of stress compared with a slower curing scheme. a few aspects of the tensilometer method. The main point of

Based on the knowledge accumulated over the years, dif- dispute seems to be the compliance of the testing system.

ferent approaches have been proposed to reduce the magni- During the test, some of the contraction force is dissipated

tude and the effects of contraction stress in dental composites. through deformation of the components of the testing system

These methods include incremental placement technique (Lutz (e.g., load cell, mounting rods, adhesive layer). However, when

et al., 1986), development of light units with gradually increas- a feedback system is used, compliance is reduced to a near-zero

ing irradiance or pulsed emission (Kanca and Suh, 1999), and condition, since virtually all deformation occurring outside of

the use of low-modulus intermediate layers (Unterbrink and the extensometer limits is not taken into account. Some authors

Liebenberg, 1999). Also, modifications of the current Bis-GMA believe that this rigid situation overestimates stress values,

resin-based composites have been proposed as a means to since tooth compliance would prevent development of such

reduce stress without compromising composite mechanical high stresses (Miguel and de la Macorra, 2001; Watts et al.,

properties (Condon and Ferracane, 1998, 2002). 2003). When a feedback system is not included in the testing

The purpose of this article is to discuss, based on the sci- apparatus, shrinking composite is free to pull the rods togeth-

15(3):176-184 (2004) Crit Rev Oral Biol Med

Downloaded from cro.sagepub.com at BOSTON UNIV on September 27, 2014 For personal use only. No other uses without permission.

177

International and American Associations for Dental Research

class V cavities restored in one single incre-

TABLE ment (Choi et al., 2000a). Comparison between

Contraction Stress of Current Composites results of contraction stress tests and

microleakage in class I porcelain inlays having

Study Configuration Feedback Type of Maximum Stress all enamel margins showed that resin cements

Factor* System** Composite (MPa) present higher contraction stress values and

higher microleakage scores when tested in

Bouschlicher et al. Hybrid 4.6

C=3 no dual-cure mode compared with self-cure

(1997) Microfill 3.4

mode (Braga et al., 2002a). However, in the

same study, scanning electronic microscopy

Condon and Ferracane Hybrid 5.5-7.0

C=1 yes analysis was unable to detect differences in

(2000) Microfill 4.0-4.5

terms of percentage of interfacial gaps. A

Chen et al. Hybrid 2.5 direct relationship was also verified between

C = 0.33 no contraction stress and microleakage in class V

(2001) Packable 3.3-4.6

cavities for three commercial restorative com-

Lim et al. Hybrid 8.8-12.5 posites (Ferracane and Mitchem, 2003). It

C=3 yes should be kept in mind that the values

(2002) Microfill 7.7

obtained from contraction stress tests repre-

Watts et al. C = 4.16 Hybrid 5.4-7.8 sent the average of a heterogeneous stress dis-

no

(2003) C = 6.25 4.9-7.0 tribution, while marginal gap formation is the

result of a localized bond failure. Moreover,

Braga et al. Hybrid 7.4-9.0 the analysis of sectioned specimens is very

C=3 yes

(2003) Microfill 6.1 limiting, and may not be representative of the

Flowable 6.0-9.1 whole specimen. Therefore, the fact that some

* Ratio of bonded to unbonded surfaces of the composite. correlation between contraction stress and

** Indicates the use of a near-zero compliance set-up. microleakage could be observed is a very pos-

itive indicator of the validity of the stress test

method.

er, and the value registered is the result of the contraction force

exerted by the material. In this case, the values registered are Polymerization Contraction Stress

usually lower than those found when a feedback system is of Current Composites

used (Hegdahl and Gjerdet, 1977; Bouschlicher et al., 1997; Studies evaluating the contraction stress of current commercial

Chen et al., 2001; Miguel and de la Macorra, 2001). Depending composites are summarized in the Table. Similar to other

on the rigidity of the test set-up, the relationship between stress mechanical tests, the absolute values of the results from differ-

and the ratio of bonded-to-unbonded surfaces of the composite ent contraction stress studies are hardly comparable. Testing

specimen (C-factor) varies. In near-zero compliance set-ups, system compliance, composite sample dimensions, force mon-

this relationship is direct (Feilzer et al., 1987; Choi et al., 2000a). itoring period, and direction of photo-activation may all vary.

An inverse relationship has been observed when non-rigid set- Nevertheless, with respect to the compositional character-

ups were used (Bouschlicher et al., 1997; Watts et al., 2003). istics of composites, it has been observed that microfill com-

Another important aspect of contraction stress tests is that posites tend to develop lower contraction stress than hybrids

only the forces developing uniaxially are registered. Due to (Bouschlicher et al., 1997; Condon and Ferracane, 2000; Lim et

specimen geometry and boundary restraints, the distribution al., 2002; Braga et al., 2003). Microfilled composites present

of forces in the specimen is rather complex. A finite element lower elastic modulus than, but volumetric shrinkage similar

study (Laughlin et al., 2002) verified that forces developed dur- to, that of hybrids, despite the lower filler content of the former

ing composite contraction generate a triaxial stress state, due to (Labella et al., 1999). This apparent contradiction is explained

the high aspect ratio of specimen diameter to height. Therefore, by the presence of pre-polymerized filler particles in most of

contraction values registered by means of the tensilometer rep- the microfilled composites, which serves to reduce the amount

resent only a fraction of the forces exerted on the system by the of resin matrix available to shrink. As a result, the contraction

shrinking material. The composite sample thickness also affects stress for microfills is generally smaller than that of more

stress distribution. Some investigators (Feilzer et al., 1989) have densely filled composites.

suggested that, in thin composite films, the contraction vector The contraction stress of packable composites has been

is strongly influenced by the boundary restraints. In fact, the evaluated (Chen et al., 2001). All five packable materials tested

above-mentioned study (Laughlin et al., 2002) verified that the presented significantly higher stresses than the non-packable

end restraints affect the entire volume of the shrinking com- control. Since the control material had a filler level similar to

posite. Apparently, this effect is accentuated in thin layers, con- that of the packable composites tested, the authors suggested

tributing to an inverse relationship between film thickness and that, rather than being correlated to the overall filler content,

contraction stress (Alster et al., 1997a,b). stress was related to the presence of large filler particles in the

A few studies have tried to correlate the results from con- packable composites. It was supposed that these large fillers

traction stress tests with those from microleakage tests. The contributed to an increase in elastic modulus compared with

thickness of unfilled resin used to bond composite to glass in that of the control, resulting in higher contraction stress. It

the tensilometer was shown to be inversely related to the con- should be noted, however, that other studies have shown sim-

traction stress, and also caused a reduction in microleakage of ilar elastic modulus and volumetric shrinkage for packable and

178 Crit Rev Oral Biol Med

Downloaded from cro.sagepub.com at BOSTON UNIV on September 27, 2014 For personal use only. No other uses without permission.

15(3):176-184 (2004)

International and American Associations for Dental Research

non-packable composites (Choi et al., 2000b), which empha- forces (approximately 33%), lower curing rate (approximately

sizes the importance of control choice in such comparative 20%), and similar degree of conversion compared with contin-

studies. uous-light activation (Bouschlicher and Rueggeberg, 2000). In

Flowable composites present stress values similar to those the same study, use of a stepped curing mode (Highlight, 3M

of more densely filled materials (Braga et al., 2003). Their low ESPE) did not significantly reduce contraction force. A two-step

filler content causes them to develop high volumetric shrink- curing technique allowed for stress reduction between 19% and

age, approaching 6% in some products (Bayne et al., 1998; 30% for three different composites when compared with a con-

Labella et al., 1999). This finding, in spite of the low elastic mod- tinuous-light exposure using equivalent energy density, with-

ulus, seems to be the main cause for their high contraction out compromising the degree of conversion (Lim et al., 2002).

stresses. Clinically, this result means that the risks of interfacial According to the authors, when a two-step curing routine is

debonding for flowable and non-flowable composites due to adopted, three aspects should be observed: the initial light

shrinkage stress are similar. Nevertheless, the low elastic mod- intensity, the exposure duration of the initial low-intensity irra-

ulus of flowable composites may be advantageous for main- diation, and the time interval between the two irradiations.

taining the interfacial integrity of the restoration in the face of Marginal integrity studies with 'soft start' polymerization

different sources of stress (Kemp-Scholte and Davidson, show contradictory results. While some studies showed

1990b). improved marginal integrity with non-continuous curing

The contraction stresses of three dual-cure resin cements methods (Mehl et al., 1997; Luo et al., 2002), others did not find

were evaluated in both dual-cure and self-cure modes (Braga et significant differences between those and conventional (contin-

al., 2002a). For all cements, the contraction stress in dual-cure uous) curing (Friedl et al., 2000; Sahafi et al., 2001). One aspect

mode (4.5-6.4 MPa) was higher than that in self-cure mode (3.4- that remains unclear is the effect of non-continuous irradiation

4.0 MPa). The reduced stress in self-cure mode may have been on polymer structure. It has been hypothesized that low curing

the result of two concurrent factors. First, it is likely that there rates may result in longer polymeric chains and less cross-link-

was a delay in stress build-up within the cements in self-cure ing, thereby affecting the mechanical properties of the polymer

mode due to a slower setting rate and a resultant extended flow (Asmussen and Peutzfeldt, 2001). However, others have char-

and pre-gel shrinkage stage. Second, a lower degree of conver- acterized the structure and properties of cross-linked

sion of the cements in the absence of photo-activation (Braga et dimethacrylate polymers cured at low and high conversion

al., 2002b) should result in a reduction in both the volumetric rates, and found no significant difference in properties or over-

shrinkage and the elastic modulus of the material. all conversion rates (Lovell et al., 2001).

Besides the curing rate, another aspect related to photo-

Influence of Photo-activation Methods activation that affects contraction stress is the total energy

on Contraction Stress delivered to the composite (ED = PD x time = mW x s/cm2 =

As mentioned previously, contraction stress magnitude is high- mJ/cm2). Use of high energy density to cure composite has

ly dependent on the composite's viscous component. Stress been associated with superior mechanical properties and

reduction by viscous flow may occur in two ways. First, the degree of conversion (Rueggeberg et al., 1994). The relationship

unbonded composite allows the material to deform when between energy density and degree of conversion, however, is

shrinking (external flow). Second, the longer it takes for the not linear (Sakaguchi and Berge, 1998). In other words, there is

composite to develop a high elastic modulus, the more time is a limit where higher energy levels do not correspond to signif-

available for polymeric chains to deform and slip into new icant increases in degree of conversion or mechanical proper-

positions to adjust to the shrinkage (internal flow), reducing or ties (Suh, 1999). Unfortunately, the relationship between ener-

delaying contraction stress build-up. In other words, if a high- gy density and post-gel shrinkage strain was found to be linear

er proportion of the total volumetric contraction takes place (Sakaguchi and Berge, 1998; Silikas et al., 2000). Therefore, high

while the composite remains in a non-rigid state, a smaller frac- energy densities translate into higher stress levels, but do not

tion of the shrinkage will effectively be responsible for stress necessarily result in high degrees of conversion or superior

development (Watts and Al Hindi, 1999). mechanical properties.

To some extent, it is clinically possible to reduce composite The relationship between degree of conversion (DC) and

curing rate by lowering the light intensity used for photo-acti- contraction stress seems to be more complex. Apparently, there

vation. Conversion rate is proportional to the square root of the is a threshold in the DC above which non-significant increases

power density (PD = mW/cm2) (Bouschlicher and Rueggeberg, correspond to significantly higher stress levels (Braga and

2000). Alternative curing routines using stepped, pulsed, or Ferracane, 2002). Clinically, it is almost impossible to determine

ramped energy delivery have been developed with the intent which energy level would provide the best relationship among

of improving restoration interfacial integrity by reducing com- degree of conversion, mechanical properties, and contraction

posite curing rate, therefore increasing its flow capacity (Uno stress. Still, it is important to keep in mind that over-exposing

and Asmussen, 1991; Christensen et al., 1999; Kanca and Suh, the composite to photo-activation might increase the risk of

1999; Hofmann et al., 2002). However, to be effective, these new marginal and interfacial debonding, as well as a heat build-up

'soft start' curing methods should be able to reduce contraction within the tooth.

stress and improve marginal integrity significantly, without

compromising the degree of conversion or composite mechan- The Use of Low-elastic-modulus Liners

ical properties. as Stress-absorbing Layers

Studies evaluating alternative curing routines with respect The magnitude of stress developed at the restoration interface

to contraction stress development are few. One light unit that is related to the compliance of the surrounding structures. If the

provided a logarithmic energy increase (Trilight, 3M ESPE, St. substrate to which the shrinking composite is bonded can yield

Paul, MN, USA) was found to originate lower contraction to contraction forces, the developed stress is lower (Alster et al.,

15(3):176-184 (2004) Crit Rev Oral Biol Med

Downloaded from cro.sagepub.com at BOSTON UNIV on September 27, 2014 For personal use only. No other uses without permission.

179

International and American Associations for Dental Research

(Behle, 1997; Unterbrink and Liebenberg, 1999; Jackson

and Morgan, 2000). In general, flowable composites have

lower elastic moduli than more densely filled materials

(Labella et al., 1999; Price et al., 2000; Sabbagh et al., 2002).

However, the results of microleakage studies conducted in

vitro are contradictory. While some authors reported lower

microleakage with the use of a pre-polymerized layer of

flowable composite (Jain and Belcher, 2000; Peutzfeldt and

Asmussen, 2002; Yazici et al., 2003), others were unable to

detect any improvement in marginal integrity (Leevailoj et

al., 2001; Wibowo and Stockton, 2001). Besides differences

in layer thickness among studies, a possible explanation

for this inconsistency is the broad range of elastic moduli

of flowable composites. One study (Labella et al., 1999)

reported values between 6.5 and 12.5 GPa for 12 different

flowable composites. For comparison purposes, in the

same study, the elastic modulus of an unfilled Bis-GMA

resin was 4.6 GPa. Another study (Sabbagh et al., 2002)

reported values ranging between 1.4 and 4.4 GPa for five

low-viscosity materials.

A previous study (Braga et al., 2003) verified the influ-

ence of the elastic modulus of a pre-cured composite layer

on the contraction stress developed by a subsequent layer

of densely filled composite. Four flowable composites

were evaluated, with elastic moduli ranging between 4.1

and 8.2 GPa. An unfilled resin (elastic modulus: 2.1 GPa)

was also included in the study. In spite of the high thick-

ness of the pre-cured layer used in the study (1.4 mm), a

large and significant stress relief (approximately 41%) was

observed only with the unfilled resin as the pre-cured

material when compared with the value obtained with a

pre-cured layer built with a densely filled composite (elas-

tic modulus: 12.3 GPa). Only one of the flowable compos-

Figure 2. Volumetric shrinkage (top) and contraction stress (bottom)

of an oxirane- and a silorane-based composite compared with two ites allowed for a potentially significant stress relief (approxi-

commercial composites. mately 19%).

Strategies for Stress Reduction in Experimental

Bis-GMA-based Composites

Modifications of composite composition have been proposed

1997b). The application of a low-elastic-modulus material to for the reduction of contraction stress development. The gener-

the cavity walls represents a way to increase the compliance of al idea is to increase the opportunity for stress relief by flow,

the prepared cavity artificially. Besides the elastic modulus of since the monomers present are the same found in the current-

the liner, the thickness of the applied layer may also influence ly commercial composites and, therefore, the same levels of

stress relief. The thicker the layer, the better are the chances of volumetric shrinkage are expected.

significant stress relief (Unterbrink and Liebenberg, 1999). The use of non-bonded nanofillers (40-nm colloidal silica)

Finite element analysis studies support this idea (Rees et al., was tested as an alternative to provide internal sites for stress

1999; Ausiello et al., 2002). relief without compromising composite mechanical properties

Use of a 150-µm layer of unfilled resin under a bulk-cured (Condon and Ferracane, 1998). In the experimental nanofilled

layer of a high-modulus composite was shown to improve composite, close to 50% reduction in stress was observed when

marginal sealing of class V restorations significantly and non-functional silane-treated particles were added, compared

reduce stress values significantly (Kemp-Scholte and with the control material that contained particles with a func-

Davidson, 1990a). More recently, it was verified that applica- tional (methacrylate) silane. The experimental hybrid compos-

tion of unfilled resin layers, in the range of 100 to 200 µm, ite produced 31% less stress when non-silanated nanofill parti-

reduced contraction stress between 13 and 24%, and signifi- cles were added. Though it was not directly observed, the pro-

cantly reduced microleakage in class V cavities (Choi et al., posed mechanism of stress relief was that non-bonded

2000a). However, as noted by the authors, the clinical use of nanofillers allowed the resin matrix to flow around them and

unfilled resin in thick layers is problematic. First, the material react without constraint, similar to the mechanism proposed

is radiolucent, interfering in radiographic diagnosis, and, sec- for the stress reduction in unfilled resins with admixed porosi-

ond, the material's fluidity would make application somewhat ty (Alster et al., 1992). No reductions in flexural modulus,

difficult in some areas of the cavity. degree of conversion, or fracture toughness were observed in

Use of low-viscosity ('flowable') composites as stress- these experimental materials (Hilton et al., 1997). A recent study

absorbing-layer materials has been advocated by many authors (Condon and Ferracane, 2002) further investigated the effect of

180 Crit Rev Oral Biol Med

Downloaded from cro.sagepub.com at BOSTON UNIV on September 27, 2014 For personal use only. No other uses without permission.

15(3):176-184 (2004)

International and American Associations for Dental Research

non-bonded nanofiller and verified that the optimal non-bond- Similar alternatives to dimethacrylates for dental composite

ed nanofiller content was independent of the presence of filler matrices were recently discussed by Guggenberger and

particles of different sizes. Weinmann (2000), who described a family of molecules called

The effect of increased inhibitor concentrations (BHT, buty- siloranes, the name being derived from the combination of

lated hydroxytoluene) on contraction stress, degree of conver- siloxanes and oxiranes (epoxies). These molecules polymerize

sion, and volumetric shrinkage has also been evaluated (Braga by cationic photoinitiation and produce dental composites

and Ferracane, 2002). A significant stress reduction (approxi- with comparable properties and slightly reduced shrinkage

mately 39%) was observed when BHT concentration was compared with Bis-GMA-based materials. We have evaluated

increased from 0.05% (by weight) to 1.0%. The inhibitor mole- some of the properties of silorane- and oxirane-based compos-

cules react with the free radicals generated by photo-activation, ites and have verified that they do, in fact, have lower volu-

and polymerization proceeds at a reduced rate until inhibitor is metric shrinkage and lower contraction stress than commercial

completely consumed. This reduction effectively extends the Bis-GMA-based composites when tested after 60 minutes and

pre-gel phase. Intermediate inhibitor concentrations caused 10 minutes, respectively (Fig. 2). Since cationic polymerizations

significant reductions in curing rate, but not in contraction typically continue for extended periods of time, there is a pos-

stress, suggesting that the reaction speed must be reduced sibility that ultimate stress levels may be higher than those

below a certain threshold if contraction stress is to be signifi- shown here. It should also be noted that the extent of the reac-

cantly reduced. Degree of conversion and volumetric shrink- tion was not measured for the composites shown in the Fig.,

age were not significantly affected. However, further studies and this would obviously affect the final stress values as well.

are necessary to verify whether composites with high inhibitor An esterified multi-methacrylate oligomer of poly(iso-

concentrations have adequate mechanical properties. propylidenediphenol) (BPA) mixed with TEGDMA produced

The addition of high-density polyethylene spheres (HDPE) resins with a 10-15% reduction in polymerization shrinkage

to hybrid and nanofilled experimental composites has also compared with Bis-GMA-based resins (Culbertson et al.,

been shown as a stress relief mechanism (Ferracane et al., 2003). 1997b,c). However, these new resins did not cure as well as the

In both cases, the addition of 20 wt% of HDPE spheres led to Bis-GMA-based materials, and again, this factor is the likely

significant stress reduction compared with the respective con- reason for their lower contraction. The contraction stress of

trol groups (between 26% and 29%). In the hybrid composite, these materials has not been tested, but due to their greater

polyethylene spheres replaced filler, and stress reduction rigidity than Bis-GMA, it is doubtful that they would have

seemed to be related to a reduction in elastic modulus. In the lower shrinkage stress.

nanofilled composite, spheres were added to the control mate- Interesting bismethacrylates with lower shrinkage than

rial without altering the resin-to-filler ratio. In that case, stress Bis-GMA have been produced by reacting various branching

reduction was associated with a reduction in volumetric molecules at the hydroxy groups of the Bis-GMA (Holter et al.,

shrinkage. However, a general trend for lower mechanical 1997). However, initial results suggest that these polymers have

properties with increased HDPE levels was observed, most a low elastic modulus. While this low modulus and lower

noticeably with the hybrid materials. shrinkage would likely result in lower contraction stress than

in Bis-GMA-based polymers, the low modulus (50% of Bis-

Recent Developments in Low-shrinkage GMA-based resins) may limit their usefulness as dental

Monomers restorative resins. New trimethacrylate monomers (1,1,1-Tris[4-

Several approaches have been pursued in the past to reduce (2'-hydroxy-3'-methacryloxyloxypropoxy)phenyl]ethane and 1,1,1-

polymerization shrinkage in dental resins. Expanding Tris[4-(2'-hydroxy-3'-methacryloxyloxypropoxy)phenyl]methane)

monomers based on spiroorthocarbonates (SOC) were first were developed, producing composites with slightly reduced

attempted for dental composites, but the materials were not polymerization shrinkage and lower water sorption than Bis-

successfully commercialized (Thompson et al., 1979). The addi- GMA-based composites, but with similar conversion and flex-

tion of SOCs to dimethacrylate resins cured by free radical ural strength (Chung et al., 2002a,b).

polymerization (Stansbury, 1992) and to epoxy resins cured by Other approaches proposed for reducing polymerization

cationic polymerization (Byerley et al., 1992; Eick et al., 1993) contraction in dental composites include the development of

has been attempted within the past 10 years. Though studies liquid crystal monomers (Rawls et al., 1997) and cyclopolymer-

showed lower shrinkage and subsequently lower shrinkage izable di- and multi-functional acrylate resins (Stansbury et al.,

stress with the epoxy-based systems, it is likely that the reduc- 1995). A methacrylated derivative of styrene-allyl alcohol,

tions are related to lower overall monomer conversion in these MSAA, to be used as a comonomer for dental composites, was

systems (Chappelow et al., 1997). The 'radical ring opening' synthesized to improve strength and conversion (Culbertson et

approach, using unsaturated spiroorthocarbonates or vinylcy- al., 1997a). In one study, MSAA was used to replace 20% of Bis-

clopropanes (VCP), has also been pursued to reduce composite GMA in a highly filled Bis-GMA/TEGDMA composite and

shrinkage (Miyazaki et al., 1997; Moszner et al., 1997). Though showed a 20% reduction in polymerization contraction stress

no commercial product has been realized from these approach- (Condon and Ferracane, 2000). The addition of large amounts

es to date, work is continuing. of MSAA has a significant negative effect on mechanical prop-

Cycloaliphatic epoxy resins (also called oxiranes), formu- erties, however.

lated with polyols, such as polytetrahydrofuran, have been

investigated and proposed as photocurable, cationic polymer- Conclusion

ized resins for dental composites with nearly one-half of the Polymerization contraction stress has been the subject of

polymerization shrinkage of Bis-GMA-based resins (Tilbrook, intense research activity over the last few years. Though most

2000). These resins also have the advantage of no air-inhibited of the factors involved in stress development have been identi-

layer and high strength, but relatively high water sorption. fied, further studies are necessary to access the individual con-

15(3):176-184 (2004) Crit Rev Oral Biol Med

Downloaded from cro.sagepub.com at BOSTON UNIV on September 27, 2014 For personal use only. No other uses without permission.

181

International and American Associations for Dental Research

tributions of the composite's physical properties (namely, volu- of conversion and reaction kinetics. J Dent Res 81:114-118.

metric shrinkage and elastic modulus) and curing kinetics (as a Braga RR, Ferracane JL, Condon JR (2002a). Polymerization con-

factor determining stress relief by viscous flow), and the poten- traction stress in dual-cure cements and its effect on interfacial

tial interactions between them. Some of the proposed non-con- integrity of bonded inlays. J Dent 30:333-340.

tinuous curing routines have been shown to reduce contraction Braga RR, Condon JR, Ferracane JL (2002b). In vitro wear simula-

stress significantly. However, results of interfacial integrity tion measurements of composite versus resin-modified glass

studies are inconsistent, and, in some cases, stress reduction ionomer luting cements for all-ceramic restorations. J Rest

might be caused by a lower degree of conversion. Stress reduc- Esthet Dent 14:368-376.

tion with the use of low-elastic-modulus liners seems to require Braga RR, Ferracane JL, Hilton TJ (2003). Contraction stress of flow-

able composites and their efficacy as stress-relieving layers. J

materials with stiffness close to that of unfilled resins.

Am Dent Assoc 134:721-728.

Apparently, many of the flowable composites currently avail-

Brännström M (1984). Communication between the oral cavity and

able are too rigid to be used for this purpose. Developing low- the dental pulp associated with restorative treatment. Oper Dent

shrinkage monomers that could match other clinically impor- 9:57-68.

tant properties found in Bis-GMA-based composites is a chal- Byerley TJ, Eick JD, Chen GP, Chappelow CC, Millich F (1992).

lenging task. Nevertheless, some studies have shown promis- Synthesis and polymerization of new expanding dental

ing results regarding contraction stress reduction. monomers. Dent Mater 8:345-350.

Chappelow CC, Pinzino CS, Power MD, Eick JD (1997).

Acknowledgment Photocured epoxy/SOC matrix resin systems for dental com-

posites. Polymer Preprints 38:90-91.

This paper is based on a presentation at the 39th Meeting of the Brazilian Chen HY, Manhart J, Hickel R, Kunzelmann K-H (2001).

Academy of Dental Materials (July, 2003). Portions were printed as pro- Polymerization contraction stress in light-cured packable com-

ceedings in, and are reprinted here with permission of, the Journal of Applied posite resins. Dent Mater 17:253-259.

Oral Science. Choi KK, Condon JR, Ferracane JL (2000a). The effects of adhesive

thickness on polymerization contraction stress of composite. J

Dent Res 79:812-817.

REFERENCES Choi KK, Ferracane JL, Hilton TJ, Charlton DJ (2000b). Properties of

Alomari QD, Reinhardt JW, Boyer DB (2001). Effect of liners on packable dental composites. J Esthet Dent 12:216-226.

cusp deflection and gap formation in composite restorations. Christensen RP, Palmer TM, Ploeger BJ, Yost MP (1999). Resin poly-

Oper Dent 26:406-411. merization problems—are they caused by resin curing lights,

Alster D, Feilzer AJ, de Gee AJ, Mol A, Davidson CL (1992). The resin formulations, or both? Compend Contin Educ Dent Suppl

dependence of shrinkage stress reduction on porosity concen- 25:S42-54.

tration in thin resin layers. J Dent Res 71:1619-1622. Chung C-M, Kim M-S, Kim J-G, Jang D-O (2002a). Synthesis and

Alster D, Feilzer AJ, de Gee AJ, Davidson CL (1997a). photopolymerization of trifunctional methacrylates and their

Polymerization contraction stress in thin resin layers as a func- application as dental monomers. J Biomed Mater Res 62:622-627.

tion of layer thickness. Dent Mater 13:146-150. Chung C-M, Kim J-G, Kim M-S, Kim K-M, Kim K-N (2002b).

Alster D, Venhoven BAM, Feilzer AJ, Davidson CL (1997b). Development of a new photocurable composite resin with

Influence of compliance of the substrate materials on polymer- reduced curing shrinkage. Dent Mater 18:174-178.

ization contraction stress in thin resin layers. Biomaterials Condon JR, Ferracane JL (1998). Reduction of composite contrac-

18:337-341. tion stress through non-bonded microfiller particles. Dent Mater

Asmussen E, Peutzfeldt A (2001). Influence of pulse-delay curing 14:256-260.

on softening of polymer structures. J Dent Res 80:1570-1573. Condon JR, Ferracane JL (2000). Assessing the effect of composite

Ausiello P, Apicella A, Davidson CL (2002). Effect of adhesive layer formulation on polymerization stress. J Am Dent Assoc 131:497-

properties on stress distribution in composite restorations—a 503.

3D finite element analysis. Dent Mater 18:295-303. Condon JR, Ferracane JL (2002). Reduced polymerization stress

Bayne SC, Thompson JY, Swift EJ Jr, Stamatiades P, Wilkerson M through non-bonded nanofiller particles. Biomaterials 23:3807-

(1998). A characterization of first-generation flowable compos- 3815.

ites. J Am Dent Assoc 129:567-577. Culbertson BM, Tong Y, Wan Q (1997a). Copolymerization of multi-

Behle C (1997). Flowable composites: properties and applications. methacrylate derivatives of styrene-allyl alcohol copolymer

Pract Periodont Aesthet Dent 10:347-351. with styrene and methyl methacrylate monomers. J Macromolec

Bouschlicher MR, Rueggeberg FA (2000). Effect of ramped light Sci-Pure Appl Chem 34(A):1249-1260.

intensity on polymerization force and conversion in a photoac- Culbertson BM, Wan Q, Tong Y (1997b). Preparation and evalua-

tivated composite. J Esthet Dent 12:328-339. tion of visible light-cured multi-methacrylates for dental com-

Bouschlicher MR, Vargas MA, Boyer DB (1997). Effect of composite posites. J Macromolec Sci-Pure Appl Chem 34(A):2405-2421.

type, light intensity, configuration factor and laser polymeriza- Culbertson BM, Wan Q, Tong Y (1997c). Synthesis, characterization

tion on polymerization contraction forces. Am J Dent 10:88-96. and evaluation of new BPA based multi-methacrylates for den-

Bowen RL (1963). Properties of a silica-reinforced polymer for den- tal composites. Polymer Preprints 38:100-102.

tal restorations. J Am Dent Assoc 66:57-64. Dauvillier BS, Feilzer AJ, de Gee AJ, Davidson CL (2000). Visco-

Bowen RL (1967). Adhesive bonding of various materials to hard elastic parameters of dental restorative materials during set-

tissues. VI. Forces developing in direct-filling materials during ting. J Dent Res 79:818-823.

hardening. J Am Dent Assoc 74:439-445. Davidson CL, de Gee AJ (1984). Relaxation of polymerization con-

Braem M, Lambrechts P, Vanherle G, Davidson CL (1987). Stiffness traction stresses by flow in dental composites. J Dent Res 63:146-

increase during the setting of dental composite resins. J Dent 148.

Res 66:1713-1716. Eick JD, Welch FH (1986). Polymerization shrinkage of posterior

Braga RR, Ferracane JL (2002). Contraction stress related to degree composite resins and its possible influence on postoperative

182 Crit Rev Oral Biol Med

Downloaded from cro.sagepub.com at BOSTON UNIV on September 27, 2014 For personal use only. No other uses without permission.

15(3):176-184 (2004)

International and American Associations for Dental Research

sensitivity. Quintessence Int 17:103-111. restorative systems. J Prosthet Dent 64:658-664.

Eick JD, Byerley TJ, Chappell RP, Chen GP, Bowles CQ, Chappelow Kinomoto Y, Torii M (1998). Photoelastic analysis of polymerization

CC (1993). Properties of expanding SOC/epoxy copolymers for contraction stresses in resin composite restorations. J Dent

dental use in dental composites. Dent Mater 9:123-127. 26:165-171.

Feilzer AJ, de Gee AJ, Davidson CL (1987). Setting stress in com- Kinomoto Y, Torii M, Takeshige F, Ebisu S (1999). Comparison of

posite resin in relation to configuration of the restoration. J Dent polymerization contraction stresses between self-and light-cur-

Res 66:1636-1639. ing composites. J Dent 27:383-389.

Feilzer AJ, de Gee AJ, Davidson CL (1989). Increased wall-to-wall Labella R, Lambrechts P, Van Meerbeek B, Vanherle G (1999).

curing contraction in thin bonded resin layers. J Dent Res 68:48- Polymerization shrinkage and elasticity of flowable composites

50. and filled adhesives. Dent Mater 15:128-137.

Feilzer AJ, de Gee AJ, Davidson CL(1990). Quantitative determina- Laughlin GA, Williams JL, Eick D (2002). The influence of system

tion of stress reduction by flow in composite restorations. Dent compliance and sample geometry on composite polymeriza-

Mater 6:167-171. tion shrinkage stress. J Biomed Mater Res (Appl Biomater) 63:671-

Feilzer AJ, de Gee AJ, Davidson CL (1993). Setting stresses in com- 678.

posites for two different curing modes. Dent Mater 9:2-5. Leevailoj C, Cochran MA, Matis BA, Moore BK, Platt JA (2001).

Ferracane JL, Mitchem JC (2003). Relationship between composite Microleakage of posterior packable resin composites with and

contraction stress and leakage in class V cavities. Am J Dent without flowable liners. Oper Dent 26:302-307.

16:239-243. Lim B-S, Ferracane JL, Sakaguchi RL, Condon JR (2002). Reduction

Ferracane JL, Ferracane LL, Braga RR (2003). Effect of admixed of polymerization contraction stress for dental composites by

high-density polyethylene (HDPE) spheres on contraction two-step light-activation. Dent Mater 18:436-444.

stress and properties of experimental composites. J Biomed Lovell LG, Lu H, Elliott JE, Stansbury JW, Bowman CN (2001). The

Mater Res Part B: Appl Biomat 66(B):318-323. effect of cure rate on the mechanical properties of dental resins.

Friedl KH, Schmalz G, Hiller KA, Markl A (2000). Marginal adap- Dent Mater 17:504-511.

tation of class V restorations with and without 'softstart-poly- Luo Y, Lo ECM, Wei SHY, Tay FR (2002). Comparison of pulse acti-

merization'. Oper Dent 25:26-32. vation vs conventional light-curing on marginal adaptation of a

Guggenberger R, Weinmann W (2000). Exploring beyond compomer conditioned using a total-etch or a self-etch tech-

methacrylates. Am J Dent 13:82D-84D. nique. Dent Mater 18:36-48.

Hannig M, Friedrichs C (2001). Comparative in vivo and in vitro Lutz F, Krejci I, Oldenburg TR (1986). Elimination of polymeriza-

investigation of interfacial bond variability. Oper Dent 26:3-11. tion stresses at the margins of posterior composite resin restora-

Hansen EK, Asmussen E (1985). Cavity preparation for restorative tions: a new restorative technique. Quintessence Int 17:777-784.

resins used with dentin adhesives. Scand J Dent Res 93:474-479. Mehl A, Hickel R, Kunzelmann KH (1997). Physical properties and

Hegdahl T, Gjerdet NR (1977). Contraction stresses of composite gap formation of light-cured composite with and without 'soft-

resin filling materials. Acta Odontol Scand 35:191-195. start-polymerization'. J Dent 25:321-330.

Hilton TJ (2002). Can modern restorative procedures and materials Miguel A, de la Macorra JC (2001). A predictive formula of the con-

reliably seal cavities? In vitro investigations. Part 1. Am J Dent traction stress in restorative and luting materials attending to

15:198-210. free and adhered surfaces, volume and deformation. Dent

Hilton TJ, Ferracane JL, Lamerand S (1997). The effect of colloidal Mater 17:241-246.

silica surface treatment on composite properties. J Dent Res Miyazaki K, Endo T, Sanda F, Moriya O, Fukushima T, Antonucci

76:28-30. JM (1997). Synthesis and polymerization of acrylic monomers

Hofmann N, Hugo B, Klaiber B (2002). Effect of irradiation type with pendant spiro ortho ester and cyclic carbonate groups.

(LED or QTH) on photo-activated composite shrinkage strain Polymer Preprints 38:165-166.

kinetics, temperature rise, and hardness. Eur J Oral Sci 110:471- Moszner N, Volkel T, Zeuner F, Rheinberger V (1997). Radical ring-

479. opening monomers for dental composites. Polymer Preprints

Holter D, Frey H, Mulhaupt R (1997). Branched bismethacrylates 38:86-87.

based on Bis-GMA—a systematic route to low shrinkage com- Nikaido T, Kunzelmann K-H, Chen H, Ogata M, Harada N,

posites. Polymer Preprints 38:84-85. Yamaguchi S, et al. (2002). Evaluation of thermal cycling and

Irie M, Suzuki K, Watts DC (2002). Marginal gap formation of light- mechanical loading on bond strength of a self-etching primer

activated restorative materials: effects of immediate setting system to dentin. Dent Mater 18:269-275.

shrinkage and bond strength. Dent Mater 18:203-210. Peutzfeldt A, Asmussen E (2002). Composite restorations: influence

Jackson RD, Morgan M (2000). The new posterior resins and a sim- of flowable and self-curing resin composite linings on

plified placement technique. J Am Dent Assoc 131:375-383. microleakage in vitro. Oper Dent 27: 569-575.

Jain P, Belcher M (2000). Microleakage of class II resin-based com- Price RB, Rizkalla AS, Hall GC (2000). Effect of stepped light expo-

posite restorations with flowable composite in the proximal sure on the volumetric polymerization shrinkage and bulk

box. Am J Dent 13:235-238. modulus of dental composites and an unfilled resin. Am J Dent

Jorgensen KD, Asmussen E, Shimokobe H (1975). Enamel damage 13:176-180.

caused by contracting restorative resins. Scand J Dent Res Rawls HR, Wellinghoff VT, Norling BK, Leamon SH, Swynnerton

83:120-122. NF, Wellinghoff ST (1997). Low shrinkage resins from liquid

Kanca J III, Suh BI (1999). Pulse activation: reducing resin-based crystal diacrylate monomers, Polymer Preprints 38:167-168.

composite contraction stresses at the enamel cavosurface mar- Rees JS, O'Dougherty D, Pullin R (1999). The stress reducing capac-

gins. Am J Dent 12:107-112. ity of unfilled resin in class V cavity. J Oral Rehabil 26:422-427.

Kemp-Scholte CM, Davidson CL (1990a). Complete marginal seal Rueggeberg FA, Caughman WF, Curtis JW Jr (1994). Effect of light

of class V resin composite restorations effected by increased intensity and exposure duration on cure of resin composite.

flexibility. J Dent Res 69:1240-1243. Oper Dent 19:26-32.

Kemp-Scholte CM, Davidson CL (1990b). Marginal integrity relat- Sabbagh J, Vreven J, Leloup G (2002). Dynamic and static moduli of

ed to bond strength and strain capacity of composite resin elasticity of resin-based materials. Dent Mater 18:64-71.

15(3):176-184 (2004) Crit Rev Oral Biol Med

Downloaded from cro.sagepub.com at BOSTON UNIV on September 27, 2014 For personal use only. No other uses without permission.

183

International and American Associations for Dental Research

Sahafi A, Peutzfeldt A, Asmussen E (2001). Soft-start polymeriza- Thompson VP, Williams EF, Bailey WJ (1979). Dental resins with

tion and marginal gap formation in vitro. Am J Dent 14:145-147. reduced shrinkage during hardening. J Dent Res 58:1522-1532.

Sakaguchi RL, Berge HX (1998). Reduced light energy density Tilbrook DA (2000). Photocurable epoxy-polyol matrices for use in

decreases post-gel contraction while maintaining degree of con- dental composites I. Biomaterials 21:1743-1753.

version in composites. J Dent 26:695-700. Uno S, Asmussen E (1991). Marginal adaptation of a restorative

Sakaguchi RL, Ferracane JL (1998). Stress transfer from polymer- resin polymerized at reduced rate. Scand J Dent Res 99:440-444.

ization shrinkage of a chemical-cured composite bonded to a Unterbrink GL, Liebenberg WH (1999). Flowable resin composites

pre-cast composite substrate. Dent Mater 14:106-111. as 'filled adhesives': literature review and clinical recommenda-

Sheth JJ, Fuller JL, Jensen ME (1988). Cuspal deformation and frac- tions. Quintessence Int 30:249-257.

ture resistance of teeth with dentin adhesives and composites. J Venhoven BAM, de Gee AJ, Davidson CL (1996). Light initiation of

Prosthet Dent 60:560-569. dental resins: dynamics of the polymerization. Biomaterials

Shono Y, Ogawa T, Terashita M, Carvalho RM, Pashley EL, Pashley 17:2313-2318.

DH (1999). Regional measurement of resin-dentin bonding as Versluis A, Tantbirojn D (1999). Theoretical considerations of con-

an array. J Dent Res 78:699-705. traction stress. Compend Cont Educ 25:24-32.

Silikas N, Eliades G, Watts DC (2000). Light intensity effects on Watts DC, Al Hindi A (1999). Intrinsic 'soft-start' polymerization

resin-composite degree of conversion and shrinkage strain. shrinkage-kinetics in an acrylate-based resin-composite. Dent

Dent Mater 16:292-296. Mater 15:39-45.

Stansbury JW (1992). Synthesis and evaluation of new oxaspiro Watts DC, Marouf AS, Al-Hindi AM (2003). Photo-polymerization

monomers for double-ring opening polymerization. J Dent Res shrinkage-stress kinetics in resin-composites: methods devel-

71:1408-1412. opment. Dent Mater 19:1-11.

Stansbury JW, Dickens B, Liu D-W (1995). Preparation and charac- Wibowo G, Stockton L (2001). Microleakage of class II composite

terization of cyclopolymerizable resin formulations. J Dent Res restorations. Am J Dent 14:177-185.

74:1110-1115. Yazici AR, Baseren M, Dayangac B (2003). The effect of flowable

Suh BI (1999). Controlling and understanding the polymerization resin composite on microleakage in class V cavities. Oper Dent

shrinkage induced stresses in light-cured composites. Compend 28:42-46.

Cont Educ 20(Suppl 25):S34-S41. Yoshikawa T, Sano H, Burrow MF, Tagami J, Pashley DH (1999).

Suliman AA, Boyer DB, Lakes RS (1993). Cusp movement in pre- Effects of dentin depth and cavity configuration on bond

molars resulting from composite polymerization shrinkage. strength. J Dent Res 78:898-905.

Dent Mater 9:6-10.

184 Crit Rev Oral Biol Med

Downloaded from cro.sagepub.com at BOSTON UNIV on September 27, 2014 For personal use only. No other uses without permission.

15(3):176-184 (2004)

International and American Associations for Dental Research

You might also like

- Vertical Lift Hydraulic Gate DesignDocument40 pagesVertical Lift Hydraulic Gate Designmesam100% (3)

- Crossing Calculation API 1102 8inch Sch40 Api5lbrg 1.3depthDocument12 pagesCrossing Calculation API 1102 8inch Sch40 Api5lbrg 1.3depthJoe Kyla83% (6)

- NZS 3101-2006 Example 001Document8 pagesNZS 3101-2006 Example 001RMM100% (1)

- Steam Table Problems PDFDocument5 pagesSteam Table Problems PDFBenedick Jayson P. Marti100% (1)

- Adhesion in DentistryDocument184 pagesAdhesion in DentistryDevvrat Singh100% (4)

- Fea Assignment - IDocument13 pagesFea Assignment - Isakthivel balamuruganNo ratings yet

- Flowable CompositesDocument3 pagesFlowable Compositesrasagna reddyNo ratings yet

- Filler Dental ResinDocument10 pagesFiller Dental Resinmflorian69No ratings yet

- Evaluation of Bond Strength, Marginal Integrity, and Fracture Strength of Bulk-Vs Incrementally-Filled RestorationsDocument8 pagesEvaluation of Bond Strength, Marginal Integrity, and Fracture Strength of Bulk-Vs Incrementally-Filled RestorationsJzNo ratings yet

- Ari 15Document6 pagesAri 15mariaNo ratings yet

- J Esthet Restor Dent - 2022 - Falacho - Clinical in Situ Evaluation of The Effect of Rubber Dam Isolation On Bond StrengthDocument8 pagesJ Esthet Restor Dent - 2022 - Falacho - Clinical in Situ Evaluation of The Effect of Rubber Dam Isolation On Bond StrengthAmaranta AyalaNo ratings yet

- Usage of Fibre Reinforced Composite in Everyday Practice - A SurveyDocument10 pagesUsage of Fibre Reinforced Composite in Everyday Practice - A SurveyARAVINDAN GEETHA KRRISHNANNo ratings yet

- 1 s2.0 S1751616118300079 MainDocument8 pages1 s2.0 S1751616118300079 MainnolasNo ratings yet

- Análise Crítica Do Tratamento de Superfície de Pinos de Fibra: Uma RevisãoDocument11 pagesAnálise Crítica Do Tratamento de Superfície de Pinos de Fibra: Uma RevisãoKatherine Kelly Povis AresteguiNo ratings yet

- Denture Liners A Systematic Review Relative To AdhDocument12 pagesDenture Liners A Systematic Review Relative To AdhtovarichNo ratings yet

- Effectiveness of Indirect Composite Resin Silanization by Microtensile Bond Strength TestDocument7 pagesEffectiveness of Indirect Composite Resin Silanization by Microtensile Bond Strength TestpoojaNo ratings yet

- C FactorDocument7 pagesC FactorMuthia DewiNo ratings yet

- Effect of Denture Cleansers On Tensile Bond Strength of Soft Liners To Denture Base ResinDocument8 pagesEffect of Denture Cleansers On Tensile Bond Strength of Soft Liners To Denture Base ResinMUHAMMAD INDRANo ratings yet

- Tug As Translate Ne MenDocument7 pagesTug As Translate Ne MenFaris MahdaniNo ratings yet

- Artigo SolventesDocument7 pagesArtigo SolventesAlexis VázquezNo ratings yet

- Cement System and Surface Treatment Selection For Fiber Post LutingDocument8 pagesCement System and Surface Treatment Selection For Fiber Post LutingHitesh ChopraNo ratings yet

- Fibras Ribbond Disminuyen El GAP en El Piso de CavidadDocument8 pagesFibras Ribbond Disminuyen El GAP en El Piso de CavidadSuperOscar LazcanoNo ratings yet

- J Esthet Restor Dent - 2022 - Falacho - Clinical in Situ Evaluation of The Effect of Rubber Dam Isolation On Bond StrengthDocument8 pagesJ Esthet Restor Dent - 2022 - Falacho - Clinical in Situ Evaluation of The Effect of Rubber Dam Isolation On Bond StrengthEdson HoribeNo ratings yet

- 2020 Article 1037Document11 pages2020 Article 1037Hosam kamalNo ratings yet

- 1 s2.0 S0048969722061988 MainDocument10 pages1 s2.0 S0048969722061988 MaincutdianNo ratings yet

- Amalgam Vs CompositeDocument58 pagesAmalgam Vs Compositeanmol0% (1)

- 2018 Article 779Document9 pages2018 Article 779José AntonioNo ratings yet

- Clinical Study and Single-Bottle SystemsDocument7 pagesClinical Study and Single-Bottle SystemsSammer BurgosNo ratings yet

- Short Fiber-Reinforced Resin-Based Composites (SFRCS) Current Status andDocument8 pagesShort Fiber-Reinforced Resin-Based Composites (SFRCS) Current Status andPamela ENo ratings yet

- DirectCompositesversusIndirectCompositeInlays One YearResultsDocument11 pagesDirectCompositesversusIndirectCompositeInlays One YearResultsAya Ibrahim YassinNo ratings yet

- BisGMA TEGDMA Ratio and Filler Content Effects On Shrinkage Stress 2011 Dental MaterialsDocument7 pagesBisGMA TEGDMA Ratio and Filler Content Effects On Shrinkage Stress 2011 Dental MaterialsMarincean LauraNo ratings yet

- Surface Treatments For Improving Bond Strength To Prefabricated Fiber Posts: A Literature ReviewDocument10 pagesSurface Treatments For Improving Bond Strength To Prefabricated Fiber Posts: A Literature ReviewPascalis Adhi KurniawanNo ratings yet

- Factors Influencing Mechanical Properties of PolyuDocument12 pagesFactors Influencing Mechanical Properties of PolyukevinNo ratings yet

- Accepted Author VersionDocument65 pagesAccepted Author VersionLucianoNo ratings yet

- Materials Science and Engineering CDocument13 pagesMaterials Science and Engineering CAnonymous 5AmJ13mLkNo ratings yet

- Critical Reviews in Oral Biology & Medicine: Cementum and Periodontal Wound Healing and RegenerationDocument12 pagesCritical Reviews in Oral Biology & Medicine: Cementum and Periodontal Wound Healing and RegenerationsevattapillaiNo ratings yet