Professional Documents

Culture Documents

Aluminium Beams Technical Datasheets

Aluminium Beams Technical Datasheets

Uploaded by

Timothy SmithOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aluminium Beams Technical Datasheets

Aluminium Beams Technical Datasheets

Uploaded by

Timothy SmithCopyright:

Available Formats

ALUMINIUM BEAMS

LIGHTWEIGHT EXTRUDED SECTIONS

Technical

Data Sheets

Metric Specification

European Technical Office

Brickyard Road, Aldridge, Walsall WS9 8BW, UK.

Telephone: +44 1922 743743

Email: info@rmdkwikform.com

Website: www.rmdkwikform.com

European Data Date: 30/09/2021 Issue : AF01 Sheet 1

© The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

RMD Kwikform reserves the right to change any specification without giving prior notice.

ALUMINIUM BEAMS

LIGHTWEIGHT EXTRUDED SECTIONS

Contents

Ref Description Page

Contents

Contents 2-3

Introduction 4

1.0 Components

ABX11800 Albeam 1800mm

ABX12400 Albeam 2400mm 5

ABX12700 Albeam 2700mm 5

ABX13000 Albeam 3000mm 5

ABX13600 Albeam 3600mm 5

ABX14800 Albeam 4800mm 5

ABX15400 Albeam 5400mm 5

ABX16000 Albeam 6000mm 5

ABX17200 Albeam 7200mm 5

ABX18400 Albeam 8400mm 5

ABX19600 Albeam 9600mm 5

AFX11200 Alform Beam 1200mm 6

AFX11500 Alform Beam 1500mm 6

AFX11800 Alform Beam 1800mm 6

AFX12100 Alform Beam 2100mm 6

AFX12400 Alform Beam 2400mm 6

AFX12700 Alform Beam 2700mm 6

AFX13000 Alform Beam 3000mm 6

AFX13600 Alform Beam 3600mm 6

AFX14200 Alform Beam 4200mm 6

AFX14800 Alform Beam 4800mm 6

AFX15400 Alform Beam 5400mm 6

AFX16000 Alform Beam 6000mm 6

AFX16600 Alform Beam 6600mm 6

AFX17200 Alform Beam 7200mm 6

ALX11200 Alsec Beam 1200mm 7

ALX11500 Alsec Beam 1500mm 7

ALX11800 Alsec Beam 1800mm 7

ALX12100 Alsec Beam 2100mm 7

ALX12400 Alsec Beam 2400mm 7

ALX12700 Alsec Beam 2700mm 7

ALX13000 Alsec Beam 3000mm 7

ALX13600 Alsec Beam 3600mm 7

ALX14200 Alsec Beam 4200mm 7

ALX14800 Alsec Beam 4800mm 7

ALX15400 Alsec Beam 5400mm 7

ALX16000 Alsec Beam 6000mm 7

ALX17200 Alsec Beam 7200mm 7

PPU10004 Ply Sanded 2.44m - 1.22m - 18mm 8

PPU10001 Ply MDO 2.44m - 1.22m - 18mm 8

Note: Clicking the RMDK logo in the top right hand corner of any page will bring you back to this Contents page

European Data CONTENTS Date: 30/09/2021 Issue : AF01 Sheet 2

© The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

RMD Kwikform reserves the right to change any specification without giving prior notice.

ALUMINIUM BEAMS

LIGHTWEIGHT EXTRUDED SECTIONS

Contents

Ref Description Page

Components….continued

PPU10002 Ply Standard Film 2.44m - 1.22m - 18mm 8

PPU10003 Ply Premium Film 2.44m - 1.22m - 18mm 8

ALX10002 Flange to Flange Wedge Clamp 10

ALX10001 Universal Clamp 10

AFX20003 Alform Clamp Plate 11

AFX20022 M12 Unifix Bolt 11

BNU12001 M12 Hex Nut Plated 11

AFX20009 Alform Lok Clamp 12

AFX20007 Alform Internal Corner 13

AFX20002 Alform Alignment Angle 13

AFX20010 Outside Cornerstrap 14

AFX20009 Alform Lok Clamp 14

BNX16001 M16x75 Bolt gr8.8 BZP 14

BNU16001 M16 Hexagon Nut gr8 BZP 14

AFX20005 Alform External Corner Bracket 15

AFX20001 Alform Adjustable Internal Corner 16

AFX20003 Alform Tie Back Connector 17

AFA10050 Alform Lifting Bracket 17

AFA10015 Serrated Double Nut 18

AFA10020 Alform Prop Bracket 18

SSM23600 Superslim Stripping Corner Unit - 3600mm 19

SSM22700 Superslim Stripping Corner Unit - 2700mm 19

SSM21800 Superslim Stripping Corner Unit - 1800mm 19

SSM20900 Superslim Stripping Corner Unit - 900mm 19

AFA10040 Alform Vertical Walkway Handrail Post 20

AFX20025 Alform / GTX Concrete Pump Port 100mm 21-22

2.0 Contact Details

International Offices 23

European Data CONTENTS Date: 30/09/2021 Issue : AF01 Sheet 3

© The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

RMD Kwikform reserves the right to change any specification without giving prior notice.

ALUMINIUM BEAMS

LIGHTWEIGHT EXTRUDED SECTIONS

Introduction

Aluminium Beams combine the benefits of strength, lightness and the ease of handling with consistency, versatility and

exceptional durability. With an exceptional range of accessories, the beams form a complete system that can be used

in numerous configurations and applications. RMD Kwikform has a portfolio of three Aluminium Beams: Albeam, a

225mm deep heavy duty primary beam for slab support, with a very high bending and concentrated load capacity,

Alform, a 150mm deep beam designed for wall formwork and secondary bearer for soffit support applications and

Alsec, a more economical 150mm deep single web beam used for soffit support applications.

Health and Safety

Designers should make themselves familiar with the contents of Equipment Guidance Notes UIX10101 - Alform &

Superslim Wall Formwork and Application Risk Assessments UIX20100 - Formwork. These documents are available

to customers via hyperlinks embedded in PDF scheme drawings. Residual risks pertaining to design issues are

marked in this document with the symbol and, if relevant to the scheme being prepared, should be highlighted on

the RMDK scheme drawing.

Design to EN Standards

The majority of the Aluminium Beam components were designed before the conception of the EN design standards.

Extensive use was made of BS8118 backed up by load testing. Allowable working loads were established using a

lumped factor of safety of 1.7 on yield and 2 on failure, which is adequate to satisfy the requirements of EC9.

To facilitate a simplified scheme design using established permissible load methods, load performance data in this

document is displayed as an ‘Allowable Working Load’. Should Limit State Design be required, the Design Resistance

may be obtained by multiplying the Allowable Working Load values by 1.5.

European Data INTRODUCTION Date: 30/09/2021 Issue : AF01 Sheet 4

© The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

RMD Kwikform reserves the right to change any specification without giving prior notice.

ALUMINIUM BEAMS

LIGHTWEIGHT EXTRUDED SECTIONS

Albeam

A 225mm deep x 100mm wide aluminium extrusion used as a primary beam in falsework applications.

Albeam Properties 70

Gross Area 33.06cm2

Second Moment of area I xx 2131cm4

Flexural Rigidity EI 1468kNm2

Shear Rigidity GA xx 35110kN

Maximum Bending Moment xx 25kNm

Self Weight 8.4kg/m

225

220mm - Intermediate Bearing 120kN

200mm - Intermediate Bearing 115kN

170mm - Intermediate Bearing 100kN

110mm - End Bearing 38.5kN

100

Section

Code Description Weight

ABX11800 Albeam 1800mm 15.1 kg

ABX12400 Albeam 2400mm 20.1 kg

ABX12700 Albeam 2700mm 22.7 kg

ABX13000 Albeam 3000mm 25.2 kg

ABX13600 Albeam 3600mm 30.2 kg

ABX14800 Albeam 4800mm 40.3 kg

ABX15400 Albeam 5400mm 45.3 kg

ABX16000 Albeam 6000mm 50.3 kg

ABX17200 Albeam 7200mm 60.4 kg

ABX18400 Albeam 8400mm 70.5 kg

ABX19600 Albeam 9600mm 80.5 kg

Note: Non standard lengths are available on a sale

only basis.

European Data COMPONENTS Date: 30/09/2021 Issue : AF01 Sheet 5

© The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

RMD Kwikform reserves the right to change any specification without giving prior notice.

ALUMINIUM BEAMS

LIGHTWEIGHT EXTRUDED SECTIONS

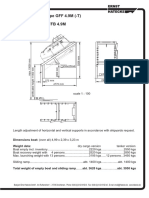

Alform Beams

An aluminium beam with recycled plastic insert used as a primary and / or secondary beams in falsework applications.

Unique inclined twin webs, together with edge stiffening lips provide great lateral stability and robustness in use.

Plywood formwork is simply attached by nail connection to the insert provided in the upper flange, and the bevelled

edge to the top flange allows for easy removal of the formwork on completion of use.

40

Alform Beam Properties

Gross Area 17.6cm2

Modulus of Elasticity E 6890kN/cm²

40

Second Moment of area I xx 558cm4

Flexural Rigidity EI 385kNm2

Shear Rigidity GA xx 18489kN

150

Position of Neutral Axis above base 74.6mm

Section Modulus xx 74.1cm3

Maximum Bending Moment xx 10kNm

Max Reaction (Intermediate) 75mm bearing 55kN

Max Reaction (End) 44mm bearing 40kN

Self Weight (with recycled plastic insert) 5.66kg/m 90

Section

Code Description Weight

AFX11200 Alform Beam 1200mm 6.80 kg

AFX11500 Alform Beam 1500mm 8.50 kg

AFX11800 Alform Beam 1800mm 10.1 kg

AFX12100 Alform Beam 2100mm 11.3 kg

AFX12400 Alform Beam 2400mm 13.5 kg

AFX12700 Alform Beam 2700mm 15.2 kg

AFX13000 Alform Beam 3000mm 16.9 kg

AFX13600 Alform Beam 3600mm 20.3 kg

AFX14200 Alform Beam 4200mm 23.7 kg

AFX14800 Alform Beam 4800mm 27.1 kg

AFX15400 Alform Beam 5400mm 30.5 kg

AFX16000 Alform Beam 6000mm 33.9 kg

AFX16600 Alform Beam 6600mm 37.3 kg

AFX17200 Alform Beam 7200mm 40.7 kg

European Data COMPONENTS Date: 30/09/2021 Issue : AF01 Sheet 6

© The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

RMD Kwikform reserves the right to change any specification without giving prior notice.

ALUMINIUM BEAMS

LIGHTWEIGHT EXTRUDED SECTIONS

Alsec Beams

A lightweight and more economical aluminium beam with recycled plastic insert used as a secondary beam in

falsework applications. Plywood formwork is simply attached by nail connection to the insert provided in the upper

flange, and the bevelled edge to the top flange allows for easy removal of the formwork on completion of use.

40

Alsec Beam Properties

Gross Area 12.47cm2

Second Moment of area I xx 389cm4

40

Flexural Rigidity EI 268kNm2

Shear Rigidity GA xx 12000kN

Maximum Bending Moment xx 7kNm

150

Max Reaction (Intermediate) 75mm bearing 33kN

Max Reaction (End) 44mm bearing 15kN

Self Weight (with recycled plastic insert) 4.65kg/m

75

Section

Code Description Weight

ALX11200 Alsec Beam 1200mm 5.57 kg

ALX11500 Alsec Beam 1500mm 6.97 kg

ALX11800 Alsec Beam 1800mm 8.36 kg

ALX12100 Alsec Beam 2100mm 9.76 kg

ALX12400 Alsec Beam 2400mm 11.2 kg

ALX12700 Alsec Beam 2700mm 12.6 kg

ALX13000 Alsec Beam 3000mm 14.0 kg

ALX13600 Alsec Beam 3600mm 16.8 kg

ALX14200 Alsec Beam 4200mm 19.5 kg

ALX14800 Alsec Beam 4800mm 22.3 kg

ALX15400 Alsec Beam 5400mm 25.1 kg

ALX16000 Alsec Beam 6000mm 27.9 kg

ALX17200 Alsec Beam 7200mm 33.5 kg

European Data COMPONENTS Date: 30/09/2021 Issue : AF01 Sheet 7

© The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

RMD Kwikform reserves the right to change any specification without giving prior notice.

ALUMINIUM BEAMS

LIGHTWEIGHT EXTRUDED SECTIONS

Plywood

RMD Kwikform Plywood is manufactured from high quality pine veneers

bonded together with a cross banded construction with phenolic resin.

Sheets are supplied with the face grain parallel to the long edge of the board.

Ply is manufactured from sustainable renewable sources and is certified by

both the PEFC and FSC chain of custody schemes. It is certified by TECO

to comply with the American standard PS 1-07 for Exterior bond and panel

grade 1. RMD Kwikform Ltd is at present in the process of obtaining PEFC

and FSC accreditation.

Board Finishes

Sheets are supplied in four finishes: Sanded, MDO, Standard Film and Premium Film.

Sanded Finish

An economical sheet with one side only having a smooth face without open defects. An ideal plywood where very

few re-uses are required or the quality of the finish to the cast concrete is unimportant.

MDO Grade

The front face of the sheet is overlaid with a phenolic resin impregnated paper weighing 370g/m2. which covers the

natural face grain and gives a matt finish to the struck concrete. With careful site treatment MDO can be used for up

to 20 fair faced uses. The rear of the sheet is overlaid with a 75-120g/m2 brown film with a phenolic resin content of

35% and provides a moisture barrier.

Standard Film Grade

Both front and rear faces of the sheet are overlaid with a 120g/m2 brown film with a phenolic resin content of 35%.

The film covers most of the natural face grain and gives a gloss finish to the struck concrete and produces good

results for up to 20 pours.

Premium Film Grade

Both front and rear faces of the sheet are overlaid with a phenolic resin impregnated paper weighing 205g/m2 and a

robust 130g/m2 black phenolic resin film overlay. The overlays cover all the natural face grain and give a gloss finish

to the struck concrete for 30 pours or more.

Notes on Use

• Sheet edges are sealed during manufacture to prevent moisture penetration. Seal all cut edges to prevent

moisture penetration which may otherwise cause degradation.

• We recommend the use of a release agent that has been formulated specifically for use with MDO grade

boarding. Apply two coats of release agent to MDO Grade prior to first use.

• We recommend use of non-metallic tools to clean the forms to help prevent damage to the face.

• Although sheets are resistant to abrasion and impact, take care during cleaning and use to prevent surface

damage. Select appropriate vibrators and techniques to protect the ply surface through all stages of use.

• Stated numbers of re-uses are for guidance purposes only and can not be guaranteed.

• Dispose of used plywood in accordance with applicable waste handling regulations.

Code Description Weight

PPU10004 Ply Sanded 2.44m - 1.22m - 18mm 26.0 kg

PPU10001 Ply MDO 2.44m - 1.22m - 18mm 30.9 kg

PPU10002 Ply Standard Film 2.44m - 1.22m - 18mm 30.9 kg

PPU10003 Ply Premium Film 2.44m - 1.22m - 18mm 30.9 kg

European Data COMPONENTS Date: 30/09/2021 Issue : AF01 Sheet 8

© The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

RMD Kwikform reserves the right to change any specification without giving prior notice.

ALUMINIUM BEAMS

LIGHTWEIGHT EXTRUDED SECTIONS

Geometry and Packaging

Panel thickness and construction 18mm +/- 0.4mm - 7 Ply

Sheet size and tolerance 1220x2440mm +0/ -1.6mm

Supplied in packs of 50 sheets weighing approximately 1550kg

Structural Properties

Direction

of face

PERMISSIBLE STRESSES

grain relative

to span General and Soffits Wall Formwork

Bending Stiffness Parallel 3.44 3.97

EI (kNm2/m) Perpendicular 1.97 2.27

Moment of Resistance Parallel 0.472 0.493

fZ (kNm/m) Perpendicular 0.294 0.307

Shear Load Parallel 7.94 8.29

qA (kN/m) Perpendicular 4.26 4.45

Allowable Spans

Maximum Alform and Alsec beam centres are shown below. Please note that data is valid for applications with the face

grain perpendicular to the support beams for 3 or more spans and with deflection limited to span/270. Live load is not

considered when checking deflection in slab applications. For soffit applications a concrete density of 24.5kN/m3 has

been allowed plus a live load in accordance with BS5975 (2008).

Soffit Formwork Applications Wall Formwork Applications

GTX Beam Maximum Slab GTX Beam Maximum Concrete

Centres / mm Thickness / mm Centres / mm Pressure kN/m2

610 490 407 41

488 940 349 59

407 1490 305 73

349 2200 271 85

305 2740 244 99

271 3250 222 115

244 3780 203 132

European Data COMPONENTS Date: 30/09/2021 Issue : AF01 Sheet 9

© The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

RMD Kwikform reserves the right to change any specification without giving prior notice.

ALUMINIUM BEAMS

LIGHTWEIGHT EXTRUDED SECTIONS

Secondary to Primary Beam Connections

Flange to Flange Wedge Clamp (ALX10002) weight 0.75kg

A fast lightweight and secure clamp used for connection of backing members to

primary beams in strip and erect applications for all falsework systems. Connects

Albeam, Alform, Alsec and Superslim in any combination.

AWL Tension = 1.6kN

AWL Slip = 0.25kN Secondary to Primary Connection

Strip & Erect Applications

Flange to Flange

Wedge Clamp

(ALX10002).

Stagger alternate

clamps

Universal Clamp (ALX10001) weight 0.75kg

A secure serrated clamp used with all falsework systems in heavier crane handled

applications. Connects Albeam, Alform, Alsec, Superslim Soldiers, GTX150 and T200

composite timber beams in any combination. Tighten the unit by tapping the wings of

the nut with a hammer.

AWL Tension = 2.5kN

AWL Slip = 0.35kN Secondary to Primary Connection

Crane Handled Applications

Universal Clamp

(ALX10001).

Stagger alternate

clamps

European Data COMPONENTS Date: 30/09/2021 Issue : AF01 Sheet 10

© The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

RMD Kwikform reserves the right to change any specification without giving prior notice.

ALUMINIUM BEAMS

LIGHTWEIGHT EXTRUDED SECTIONS

Underslung Clamp

A secure clamp supplied in three parts used to connect underslung aluminium beams where a

known load capacity for the connection is required. Note that one of the connected beams

must be either an Alform or an Albeam. When four clamps are used both beams must be an

Alform or an Albeam. AWL with 2 clamps = 5kN, AWL with 4 clamps = 10kN

Code Description Weight

AFX20003 Alform Clamp Plate 0.01 kg

AFX20022 M12 Unifix Bolt 0.01 kg

BNU12001 M12 Hex Nut Plated 0.01 kg

Underslung Beam Connection Underslung Beam Connection

using 2 No. Clamps using 4 No. Clamps

Alform Beam Clamp Alform Beam Clamp

Plate, M12 Unifix Plate, M12 Unifix

Bolt & M12 Hexgon Bolt & M12 Hexgon

Nut (AFX20003 + Nut (AFX20003 +

AFX20002 + AFX20002 +

5kN BNU12001) 10kN BNU12001)

Max Max

European Data COMPONENTS Date: 30/09/2021 Issue : AF01 Sheet 11

© The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

RMD Kwikform reserves the right to change any specification without giving prior notice.

ALUMINIUM BEAMS

LIGHTWEIGHT EXTRUDED SECTIONS

Alform Lok Clamp (AFX20009) weight 1.17kg

A cast unit that facilitates secure connection of a stop end tie, Light Duty Corner Strap or

Heavy Duty Corner Shoe.

Prior to loading the Alform Lok Clamp, its integral bolts shall be torqued to 45Nm.

AWL = 20kN (single clamp), 30kN (twin adjacent clamps in contact)

136

Ø20 hole 91 30

15 18 32

85

Integral

M12x40 Bolts 48.5

Side Elevation

63

Front Elevation

15mm Rapid

Knock On Wing Bar Tie x Knock On Wing

Nut (BTX10001) 0.5m long Nut (BTX10001)

Rapid Tie

Hexagon Nut

50mm

Standard Waler (BTX10017)

Plate (BTX10021) Lok Clamp

Single Lok

Clamp

(AWL=20kN)

Twin Lok

15mm Rapid Clamps

Bar Tie (AWL=30kN)

Typical Panel Joint Detail

Fit Lok Clamp panel joint connection on

bottom three Alform Beams and then at

Typical Stop-End Detail nominally 1.0m vertical centres

European Data COMPONENTS Date: 30/09/2021 Issue : AF01 Sheet 12

© The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

RMD Kwikform reserves the right to change any specification without giving prior notice.

ALUMINIUM BEAMS

LIGHTWEIGHT EXTRUDED SECTIONS

Alform Internal Corner (AFX20007) weight 1.07kg

Use with a 75x75mm vertical timber to support the plywood for 90 degree internal

corners in formwork applications.

225

150

225

150

Plan

90

Side Elevation

Alform Alignment Angle (AFX20002) weight 2.01kg

Use to support the Alform Internal Corner (AFX20007) or two Alform beams set at 90

degrees to one another in formwork applications - fixed with 4 No. M12 Unifix Bolts

and 4 No. M12 Hexagon Nuts gr8 BZP (AFX20002 + BNU12001).

200

50

55

200

95

Plan

50

50 95 55

2 No. Ø14x40mm slots

per face

75

Side Elevation

European Data COMPONENTS Date: 30/09/2021 Issue : AF01 Sheet 13

© The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

RMD Kwikform reserves the right to change any specification without giving prior notice.

ALUMINIUM BEAMS

LIGHTWEIGHT EXTRUDED SECTIONS

Alform Outside Corner Strap

Used in conjunction with 2 No. Alform Lok Clamps to connect Alform Beams together at

external corners in formwork applications.

Qty Code Description Weight

1 AFX20010 Outside Cornerstrap 6.18 kg

2 AFX20009 Alform Lok Clamp 1.17 kg

2 BNX16001 M16x75 Bolt gr8.8 BZP 0.15 kg

2 BNU16001 M16 Hexagon Nut gr8 BZP 0.03 kg

Prior to loading the Alform Lok Clamp, its integral bolts shall be torqued to 45Nm.

AWL = 28.3kN tension for 90° corners

Note: Where external corners are not rectangular, the maximum load on the Outside

Corner Strap is dependent upon the maximum allowable Lok Clamp load of 20kN.

514

164

104

Elevation

60

124

Plan

The table below shows the number of Alform waling spacings between Outside Corner Strap positions. Please note it

is recommended that straps shall always be fitted to the bottom three walings.

Concrete Pressure / Wall Thickness (mm)

Alform centres / mm

kN/m² 100 150 200 250 300 350 400 450 500

348 40 4 4 4 3 3 3 3 3 2

348 50 4 4 4 3 3 3 3 2 2

305 60 4 4 3 3 3 3 2 2 2

305 65 4 4 3 3 2 2 2 2 2

Example: Where the number 4 is indicated in the table, the 1st, 2nd, 3rd, 7th and 11th walings have Outside Corner

Strap connections. (Spacings may be increased as concrete pressure reduces towards the top of the shutter).

Fix dummy soldiers local to the corner to transmit forces from intermediate walings where Corner Straps are not fitted.

(Dummy soldiers can be omitted if Outside Corner Straps are used at every Alform waling position).

European Data COMPONENTS Date: 30/09/2021 Issue : AF01 Sheet 14

© The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

RMD Kwikform reserves the right to change any specification without giving prior notice.

ALUMINIUM BEAMS

LIGHTWEIGHT EXTRUDED SECTIONS

Alform External Corner Bracket (AFX20005) weight 3.79kg

Fix to horizontal Alform walings to provide support to vertical Superslim Soldiers set at 45

degrees for heavier duty external corner connections. Connect to Alform Beam using 2 No.

M12 Unifix Bolts and M12 Hexagon Nuts gr8 BZP (AFX20022 + BNU12001) and to the

Superslim Soldier using a M12x260 Bolt gr8.8 BZP and 150x150x6x14mm Plate Washer

(BNX12008 + BNX20009).

Maximum allowable working load in corner tie rod = 80kN (between adjacent External

Corner Brackets)

90 Ø42x30mm spigot 12 240 Ø14 holes

Captive

M12 Nut

146

90

205

End View Side Elevation Plan

External Corner

Brackets fixed to every

Alform Beam waling

using 2 No. M12 Unifix

Bolts & M12 Hexagon

Nuts

Alform Lok Clamps at

External Corner

Bracket positions

either side of Rapid 150x150x6x14mm Plate

Tie Bar Washer & M12x260 Bolt

at nominally 1.0m ctrs

on vertical soldier

Prior to loading the Alform Lok Clamp, its integral bolts shall be torqued to 45Nm.

Note: It is recommended that External Corner Brackets are always fitted to the bottom two Alform walings and a tie rod

located between them.

European Data COMPONENTS Date: 30/09/2021 Issue : AF01 Sheet 15

© The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

RMD Kwikform reserves the right to change any specification without giving prior notice.

ALUMINIUM BEAMS

LIGHTWEIGHT EXTRUDED SECTIONS

Alform Adjustable Internal Corner (AFX20001) weight 3.81kg

Used to connect Alform Beams together at angles between 45° and 200° - fixed to

beams with 4 No. Splice Clamp Blocks and 4 No. M12 Hexagon Nuts gr8 BZP

(AFX20013 + BNU12001). See below right for AWL’s

Note: Where additional AWL is required fit Lok Clamps with M16x75 Bolts gr8.8

BZP & M16 Hexagon Nuts gr8 BZP (BNX16001 + BNU16001).

For product dimensions

refer to Alform Tie Back

Connector (AFX20023)

Straight Joints

Slip load along beam without

Lok Clamp = ±6kN

Plan

Slip load along beam with

Lok Clamp = ±23.3kN

45° min to With angle at 45°

200° max slip load along

Side Elevation

beam without Lok

Clamp = ±13.5kN

Acute & Obtuse Corners

Slip load along beam without

Lok Clamp = ±6kN

Slip load along beam with

Lok Clamp = ±13.5kN

90 Degree Corners

European Data COMPONENTS Date: 30/09/2021 Issue : AF01 Sheet 16

© The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

RMD Kwikform reserves the right to change any specification without giving prior notice.

ALUMINIUM BEAMS

LIGHTWEIGHT EXTRUDED SECTIONS

Alform Tie Back Connector (AFX20023) weight 2.04kg

(previously part of AFX20001)

Used to connect inclined ratchet lashings to an Alform Beam or Albeam at the edge

of a pour to prevent overturning and / or provide lateral restraint - fixed to beam with

2 No. Splice Clamp Blocks and 2 No. M12 Hexagon Nuts gr8 BZP (AFX20013 +

BNU12001).

66 200 2 No. Ø13x40mm slots

Ø16mm pin

=

66

77

18

153

=

18 Ø17x40mm slot R-Clip

50 75 Plan

Front Elevation Side Elevation

Alform Lifting Bracket (AFA10050) weight 3.27kg

A bracket that enables Alform & Superslim shutters to be lifted when the Alform

beams are orientated vertically. To be used in conjunction with 2 No. Serrated

Double Nuts & 4 No. M12x25 Set Pins gr8.8 BZP (AFA10015 + BNX12009).

AWL = 10kN Tension (perpendicular to Alform Beam)

20kN Shear (parallel to Alform Beam)

Ø23.5 hole for 2 No, Serrated Double

shackle Nuts (AFA10015)

Alform Lifting AWL 10kN Serrated face

Bracket

(AFA10050)

4 No. M12x25 Set

Pins gr8.8 BZP

AWL 20kN

(BNX12009)

Alform Beam or

Albeam

Serrated Double Nuts MUST be placed with the serrated side towards the Lifting Bracket as shown on detail

(above right) and M12 Set Pins shall be torqued to 45Nm.

European Data COMPONENTS Date: 30/09/2021 Issue : AF01 Sheet 17

© The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

RMD Kwikform reserves the right to change any specification without giving prior notice.

ALUMINIUM BEAMS

LIGHTWEIGHT EXTRUDED SECTIONS

Serrated Double Nut (AFA10015) weight 0.1kg

Used to provide a secure connection between a vertical Alform beam or Albeam

and an Alform Lifting Bracket or an Alform Prop Bracket.

To be used in conjunction with 2 no. M12x25 Gr8.8 Set Pins (BNX12009).

AWL = 10kN Shear (in the slot of the Alform Beam or Albeam)

Alform Prop Bracket (AFA10020) weight 3.45kg

A bracket that enables connection of a push pull prop to a vertical Alform or Albeam.

(To be used in conjunction with a Serrated Double Nut & 2 No M12x25 Gr.8.8 Set

Pins (AFA10015 & BNX12009).

AWL = 10kN Shear (in the slot of the Alform Beam or Albeam)

Serrated Double Nut MUST be placed with the serrated side towards the

Alform Prop Bracket as shown on detail (below right) and M12 Set Pins

shall be torqued to 45Nm.

Serrated Double Nut Serrated face

Alform Prop Bracket (AFA10015)

(AFA10020)

2 No. M12x25 Set

Pins gr8.8 BZP

(BNX12009)

AWL 10kN

Alform Beam or

Albeam

Turnbuckle or Push Pull Prop

connected with Superslim

19mm pin & R-Clip

(SSX10046)

European Data COMPONENTS Date: 30/09/2021 Issue : AF01 Sheet 18

© The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

RMD Kwikform reserves the right to change any specification without giving prior notice.

ALUMINIUM BEAMS

LIGHTWEIGHT EXTRUDED SECTIONS

Superslim Stripping Corners

Available in four different heights, Superslim Stripping Corners are used to facilitate

easy striking of shutters at internal corner positions in core formwork applications.

Code Description Weight

SSM23600 Superslim Stripping Corner Unit - 3600mm 78.2 kg

SSM22700 Superslim Stripping Corner Unit - 2700mm 58.9 kg

SSM21800 Superslim Stripping Corner Unit - 1800mm 41.6 kg

SSM20900 Superslim Stripping Corner Unit - 900mm 22.0 kg

155

250

Tighten wing nut to

clamp corner to

plywood

155

150

1050

max

Enlarged Plan

250

max

150

Plywood

1100

1000

200

Alform Beam

Part Plan on Inner Corner

700

1100

200

1050

700

500

250

250

200

200

3600mm 2700mm 1800mm 900mm

European Data COMPONENTS Date: 30/09/2021 Issue : AF01 Sheet 19

© The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

RMD Kwikform reserves the right to change any specification without giving prior notice.

ALUMINIUM BEAMS

LIGHTWEIGHT EXTRUDED SECTIONS

Alform Vertical Walkway Handrail Post (AFA10040) weight 13.4kg

Used to provide access for placing concrete, fixing ties etc. Connected to the

vertical Alform Beam with a Serrated Double Nut & 2 No. M12x25 Gr.8.8 Set Pins

(AFA10015 & BNX12009).

AWL = 10kN slip on Alform

Serrated Double Nut MUST be placed with the serrated side towards the

Alform Vertical Walkway Handrail Post as shown on detail (below right)

and M12 Set Pins shall be torqued to 45Nm.

Ø48.3mm CHS

Scaffold tube handrail

connected using 2”x2”

90 degree couplers

(SFX10002)

1500

Plywood & timbers

NOT scaffold boards

2 No. Ø14 holes

75x50mm SHS

160

40

90 855 Vertical Alform

Rear Elevation Side Elevation Typical Application

113 330 325 87

Plan

European Data COMPONENTS Date: 30/09/2021 Issue : AF01 Sheet 20

© The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

RMD Kwikform reserves the right to change any specification without giving prior notice.

ALUMINIUM BEAMS

LIGHTWEIGHT EXTRUDED SECTIONS

Alform / GTX Concrete Pump Port 100mm (AFX20025) weight 19.8kg

Use in conjunction with the Alform / GTX Pump Port Plunger (AFX20026) to allow

concrete to be pumped in through the face of the shutter. Bolt to Alform Beams using

M12 Unifix Bolts and M12 Nyloc Nuts gr8.8 (AFX20022 + BNA11202) or screw to

GTX Beams using M8x50mm Turbo Coach Screws (BNX00008).

It is the Customer's responsibility to control the pumping regime on site to

ensure that the design concrete pressure of the formwork is not exceeded

240 Ø14x40 slots Captive R-Clip

80 80 385 238

Sliding closure

plate

305*

375

135

Ø101 internal

Ø9 holes

Rear Elevation Front Elevation Side Elevation

* A few early versions exist with this dimension as 325mm.

35

25

Alform Beam Connection

6 No. M12 Unifix Bolts and

M12 Nyloc Nuts gr8.8

160

(AFX20022 + BNA11202)

305*

Sliding closure Ø108

18

plate

Ø110 hole required in form face

Plan GTX Beam Connection

8 No. M8x50 Turbo Coach

Screws (BNX00008)

305*

Couple Ø100 concrete pump

line here

European Data COMPONENTS Date: 30/09/2021 Issue : AF01 Sheet 21

© The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

RMD Kwikform reserves the right to change any specification without giving prior notice.

ALUMINIUM BEAMS

LIGHTWEIGHT EXTRUDED SECTIONS

Alform / GTX Pump Port Plunger (AFX20026) weight 3.79kg

Use in conjunction with the Alform / GTX Concrete Pump Port (AFX20025) to push

out wet concrete from behind the Pump Port sliding closure plate, so as to provide a

flush finish to the hardened concrete face.

368

232 14 Ø127 Ø127

Ø98

Ø98

48

Side Elevation

Front Elevation Rear Elevation

Connect with 100mm

concrete pump line coupler

(not supplied)

Instructions for Use

1. Once the pour has reached the desired fill level, shut off the concrete pump, remove the R-Clip from the Pump

Port and close off the Pump Port by striking the sliding closure plate until it is fully closed. Replace the R-Clip in

the other side of this plate to secure it in position.

2. Disconnect the concrete pump coupler and release the pump from the Pump Port.

3. Wash out the wet concrete from the inside of the Pump Port.

4. Insert the Pump Port Plunger into the Pump Port and secure in place using the Concrete Pump Coupler.

advance the plunger until it contacts the slider plate and back off 1/4 turn.

5. Remove the R-Clip from the sliding closure plate & strike the plate until it is fully open once again. Replace the

R-Clip to secure this plate in the open position.

6. Advance the Pump Port Plunger until the captive washer hits the captive nut. The face of the plunger will now

be fully engaged & flush with the plywood face. Wash any concrete or grout off the outside of the unit.

7. At the earliest possible time after concrete has taken a first set, undo the pump coupler and pull out the plunger.

Clean all components thoroughly taking care to remove all grout from the inside of the bore. Oil the bore to

protect against corrosion.

European Data COMPONENTS Date: 30/09/2021 Issue : AF01 Sheet 22

© The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

RMD Kwikform reserves the right to change any specification without giving prior notice.

ALUMINIUM BEAMS

LIGHTWEIGHT EXTRUDED SECTIONS

Contact Details: International Offices

Europe Middle East Asia Pacific

Head Office – United Kingdom UAE Australia

RMD Kwikform, Brickyard Road, RMD Kwikform, RMD (Australia) Pty. Ltd.

Aldridge, Walsall WS9 8BW, UK. PO Box 5801, Sharjah, PO Box 169, Melrose Park,

Tel: +44 1922 743743 United Arab Emirates. South Australia, 5039.

Email: info@rmdkwikform.com Tel: +971 6502 5888 Tel: +61 8 8179 8200

Email: rmd.uae@rmdkwikform.com Email: rmd.australia@rmdformwork.com

Ireland

RMD Kwikform, Qatar Hong Kong

Ballyboggan Road, RMD Kwikform, RMD Kwikform,

Finglas, Dublin 11, Ireland. PO Box 405, Doha, Qatar. 22/F Excel Center,

Tel: +353 1 830 2500 Tel: +974 4465 3034 483A Castle Peak Road,

Email: rmd.dublin@rmdkwikform.com Email: rmd.qatar@rmdkwikform.com Cheung Sha Wan, Kowloon, Hong Kong.

Tel: +852 2415 4882

Bahrain Email: rmd.hongkong@rmdkwikform.com

South America RMD Kwikform,

C/O CGH , New Zealand

Chile

Building 829, Flat 11, RMD (New Zealand) Ltd.

RMD Kwikform,

Block 408, Sanabis, PO Box 22-316, 101-105 Station Road,

La Estera 811,

Kingdom of Bahrain. Otahuhu, Auckland 6, New Zealand.

Parque Industrial Ville Grande,

Tel: +973 1738 2724 Tel: +64 9 276 5955

Lampa, Santiago, Chile.

Email: rmd.bahrain@rmdkwikform.com Email: rmd.auckland@rmdformwork.com

Tel: +56 2 747 1414

Email: rmd.chile@rmdkwikform.com

Oman Philippines

RMD Kwikform Oman LLC RMD Kwikform,

America PO Box 889 Units 2406-2409,

USA Post Code 115 Raffles Corporate Center,

9351 Grant Street, Muscat F. Ortigas Jr. Road,

Suite 200, Sultanate of Oman Ortigas Center,

Thornton, Colorado, 80229 Tel: +968 2413 6448 Pasig City,

Tel: +1 303 252 7000 Email: rmd.oman@rmdkwikform.com Philippines.

Email: usa@rmdkwikform.com Tel: +632 696 7635

Email: rmd.manila@rmdkwikform.com

India

RMD Kwikform,

No.28/2, 1st Floor, AMG Towers,

Lawyer Jagannathan Street, G.S.T. Road,

Alandhur, Chennai—60016, Tamil Nadu, India Guam

Tel: +91 44 6693 3300 RMD Kwikform.

Email: rmd.india@rmdkwikform.com 321 East Harmon Industrial Park Road,

Unit F, Tamuning, Guam.

Tel: +671 647 7635

Saudi Arabia

Email: rmd.guam@rmdkwikform.com

PO Box 921, Entrance 1, North 2nd Floor, Room 4A

Gulf Star Building, Prince Turki Abdulaziz Street,

Comiche, Al Khobar 31952, Kingdom of Saudi Arabia

Tel: +966 13 896 8665

Email: rmd.ksa@rmdkwikform.com

European Data Date: 30/09/2021 Issue : AF01 Sheet 23

© The information contained within these data sheets remain the property of RMD Kwikform and is not to be altered or reproduced without permission.

RMD Kwikform reserves the right to change any specification without giving prior notice.

You might also like

- Bystronic Xact Smart - Datasheet - Eng - OriginalDocument2 pagesBystronic Xact Smart - Datasheet - Eng - OriginalIlian Avramov100% (1)

- IBT Sample Questions: ScienceDocument2 pagesIBT Sample Questions: Scienceshrutiverma_1100% (1)

- Forklift Extensions Lifting365Document1 pageForklift Extensions Lifting365Patrick MurphyNo ratings yet

- Superslim Technical Datasheets 1Document117 pagesSuperslim Technical Datasheets 1Fei Fan ChanNo ratings yet

- Superslim-Technical-Datasheets 17 MARCH 2020Document117 pagesSuperslim-Technical-Datasheets 17 MARCH 2020Miguel PAvonNo ratings yet

- Strip Footing: Pu 1060 KN Pu 1060 KNDocument1 pageStrip Footing: Pu 1060 KN Pu 1060 KNEderango JackNo ratings yet

- Renee Alpha ONE - Dimensions With MakeOver Unit - 210623Document3 pagesRenee Alpha ONE - Dimensions With MakeOver Unit - 210623ganeshsingh25819No ratings yet

- Segment Model Name Size (Sweep) MRP: Polycab India LimitedDocument3 pagesSegment Model Name Size (Sweep) MRP: Polycab India LimitedSanket PhatangareNo ratings yet

- S-1.1 Proposed Filling Station (Caltex Station) : Typical Column-Footing (C1-F1) DetailDocument1 pageS-1.1 Proposed Filling Station (Caltex Station) : Typical Column-Footing (C1-F1) DetailCarmela Andrea BuenafeNo ratings yet

- CV 24 PDFDocument1 pageCV 24 PDFJorge Farias S.No ratings yet

- ETP Filter Media Setup-ModelDocument1 pageETP Filter Media Setup-ModelMd SuruzzamanNo ratings yet

- 1840P Cebu I.T Park Bpo 5 (Additional Acp Cladding)Document4 pages1840P Cebu I.T Park Bpo 5 (Additional Acp Cladding)Vin Yaoshua de CastroNo ratings yet

- Denah AokiDocument5 pagesDenah AokiAndika PangestuNo ratings yet

- P3 Price List Structural PDFDocument11 pagesP3 Price List Structural PDFLorena NovaNo ratings yet

- Company Price ListDocument1 pageCompany Price ListUsman UmarNo ratings yet

- TWE-690 Floor PlanDocument1 pageTWE-690 Floor PlanstuartNo ratings yet

- Structure Drawing 2x9 3x4Document4 pagesStructure Drawing 2x9 3x4gerac87730No ratings yet

- SMS Projector CL H Secret-Produktblad-EnGDocument2 pagesSMS Projector CL H Secret-Produktblad-EnGjpa77No ratings yet

- Total Kebutuhan KabelDocument8 pagesTotal Kebutuhan KabelTaufiq HidayatNo ratings yet

- File 5Document1 pageFile 5Anandan HrNo ratings yet

- Pelan PTFJSBDocument1 pagePelan PTFJSBPusatTuisyen FaizaJaya Sg BesiNo ratings yet

- Arc AtcDocument2 pagesArc AtcsomuNo ratings yet

- Multi Form ScaffoldingDocument40 pagesMulti Form ScaffoldingSuresh RamNo ratings yet

- Detail Window and Dome PDFDocument1 pageDetail Window and Dome PDFJoane ColipanoNo ratings yet

- Public StopperDocument1 pagePublic StopperTech MongerNo ratings yet

- Capacitacion Sistemas MDU by DirectTV PDFDocument31 pagesCapacitacion Sistemas MDU by DirectTV PDFRocío100% (1)

- KRS 2Document1 pageKRS 2tejasaiNo ratings yet

- Zico ZM - SeriesDocument4 pagesZico ZM - Seriesnikunjsingh04No ratings yet

- SKETCH - Bull Nose For HOLCIM IndonesiaDocument1 pageSKETCH - Bull Nose For HOLCIM IndonesiaSafrin SangiaNo ratings yet

- CertikinDocument9 pagesCertikinAshok BhandaryNo ratings yet

- Airodek Technical DatasheetsDocument81 pagesAirodek Technical DatasheetsTimothy SmithNo ratings yet

- Lavaal CatalogDocument18 pagesLavaal CatalogAbhishek VyasNo ratings yet

- Location: Production Area 1Document1 pageLocation: Production Area 1kitnaNo ratings yet

- Proposal For Church of Sts Peter - PaulDocument17 pagesProposal For Church of Sts Peter - Paulданияр баяновNo ratings yet

- TATU Access Design LayoutDocument2 pagesTATU Access Design LayoutNana Kwame Osei AsareNo ratings yet

- Typical Lift-1 Section at A-A: Scale 1: 20Document1 pageTypical Lift-1 Section at A-A: Scale 1: 20moin uddinNo ratings yet

- 16 02Document206 pages16 02debiachyatiNo ratings yet

- Pipe Conveyor SpecificationsDocument3 pagesPipe Conveyor SpecificationsSuresh VedalaNo ratings yet

- Lattice TowerDocument1 pageLattice Towerisan.structural TjsvgalavanNo ratings yet

- Optibelt OMEGA FAN POWER Product ReferenceDocument2 pagesOptibelt OMEGA FAN POWER Product Referencecherou.abdelkarimNo ratings yet

- Prma049m PDFDocument1 pagePrma049m PDFsaptianNo ratings yet

- Prma 049 MDocument1 pagePrma 049 Mmuhammad rizkiNo ratings yet

- Prma 049 MDocument1 pagePrma 049 MLilik KhoiriyahNo ratings yet

- Freefall-Lifeboat, Type GFF 4.9M (-T) With Sliding Ramp, Type FFB 4.9MDocument1 pageFreefall-Lifeboat, Type GFF 4.9M (-T) With Sliding Ramp, Type FFB 4.9MsaptianNo ratings yet

- B20S / B25S / B30S / B32S - 5 BC20S / BC25S / BC30S - 5: B20S-5 STD, FFL B20S-5 FFT B25S-5 STD, FFLDocument6 pagesB20S / B25S / B30S / B32S - 5 BC20S / BC25S / BC30S - 5: B20S-5 STD, FFL B20S-5 FFT B25S-5 STD, FFLEASY TECHNo ratings yet

- SMS Projector CL H Secret-RitningDocument1 pageSMS Projector CL H Secret-Ritningjpa77No ratings yet

- Aventos HK HK-S HK-XS (Retail)Document8 pagesAventos HK HK-S HK-XS (Retail)ALvin SaLvaNo ratings yet

- Pickhammers: IR2 - IR12Document4 pagesPickhammers: IR2 - IR12Jamal HabbasNo ratings yet

- Typical Cross Section: Existing Parallel Bridge Width (Verify)Document1 pageTypical Cross Section: Existing Parallel Bridge Width (Verify)Erika Faye GutierrezNo ratings yet

- Condensor Line 1Document3 pagesCondensor Line 1MaxNo ratings yet

- Tuesday, October 17, 2017: Dutco Balfour Beatty L.L.C. Scaffolding & Formwork DivisionDocument1 pageTuesday, October 17, 2017: Dutco Balfour Beatty L.L.C. Scaffolding & Formwork DivisionxyzhynNo ratings yet

- Column Detailing ModelDocument1 pageColumn Detailing Modelpratik ranaNo ratings yet

- Formwork For Colum-ModelDocument1 pageFormwork For Colum-ModelJun Rey MoralesNo ratings yet

- Formwork For Colum-Model'Document1 pageFormwork For Colum-Model'Jun Rey MoralesNo ratings yet

- TH12803 SK1 A Class SectionsDocument1 pageTH12803 SK1 A Class SectionsGhassan Abood HabeebNo ratings yet

- Cable and Materials DetailsDocument12 pagesCable and Materials DetailsSubhadipSamanta OfficialNo ratings yet

- s4 PongDocument1 pages4 PongJeffNo ratings yet

- Front Elevation of Building: SCALE 1: 100Document1 pageFront Elevation of Building: SCALE 1: 100Anandan HrNo ratings yet

- Maruyasu Utility SizeDocument8 pagesMaruyasu Utility SizetribhuNo ratings yet

- Member Stability Bracing: Appendix 6Document8 pagesMember Stability Bracing: Appendix 6mabuhamdNo ratings yet

- 4 Cooling Load CalculationDocument11 pages4 Cooling Load Calculationjethro ganeloNo ratings yet

- Basic Civil and Mechanical Engineering Jan 2023Document2 pagesBasic Civil and Mechanical Engineering Jan 2023ssmbsuperstar022No ratings yet

- TDS Dekguard E2000 India3Document4 pagesTDS Dekguard E2000 India3Er Krishan YadavNo ratings yet

- Tube SupportsDocument8 pagesTube SupportsSyahirul AlimNo ratings yet

- Angle of Repose - Unit WtsDocument2 pagesAngle of Repose - Unit Wtsmahen2010No ratings yet

- Pressure Rating ClassesDocument2 pagesPressure Rating ClassesDonPulubi Prokopyo100% (1)

- Project Report On CPVC and SWR Pipes and FittingsDocument7 pagesProject Report On CPVC and SWR Pipes and FittingsEIRI Board of Consultants and Publishers0% (1)

- Casestudy Uttarayan Art Village JhaspurDocument5 pagesCasestudy Uttarayan Art Village JhaspurAnonymous BqLSSexONo ratings yet

- Evaluation of Steam Jet EjectorsDocument11 pagesEvaluation of Steam Jet EjectorsRajeh Somrani100% (3)

- Specific Heat Capacity GLY11Document1 pageSpecific Heat Capacity GLY11Alyssa ColeNo ratings yet

- HVAC InstallDocument18 pagesHVAC Installwolf1254No ratings yet

- En18379 2 02 18 - HFS2100 - OelDocument4 pagesEn18379 2 02 18 - HFS2100 - Oelhangmann169No ratings yet

- The Structural Design of Light Gauge Silo Hoppers 2Document27 pagesThe Structural Design of Light Gauge Silo Hoppers 2userhieNo ratings yet

- 19xl 3pd PDFDocument38 pages19xl 3pd PDFDione SilvaNo ratings yet

- Valtek ValdiskDocument8 pagesValtek ValdiskGustavo Garcia100% (1)

- Damage Evolution LawDocument15 pagesDamage Evolution LawRafael ZanettiNo ratings yet

- Belimo 2013 PGPLDocument419 pagesBelimo 2013 PGPLJorge Gustavo GoyecheaNo ratings yet

- Piping and Valve Material Specification: in Salah Gas Project Engineering Procurement & Construction PhaseDocument18 pagesPiping and Valve Material Specification: in Salah Gas Project Engineering Procurement & Construction PhasetariqNo ratings yet

- (Environmental Science and Engineering) Jaime Klapp, Leonardo Di G. Sigalotti, Abraham Medina, Abel López, Gerardo Ruiz-Chavarría (Eds.)-Recent Advances in Fluid Dynamics With Environmental ApplicatioDocument509 pages(Environmental Science and Engineering) Jaime Klapp, Leonardo Di G. Sigalotti, Abraham Medina, Abel López, Gerardo Ruiz-Chavarría (Eds.)-Recent Advances in Fluid Dynamics With Environmental ApplicatioKyler GreenwayNo ratings yet

- DI-9103E - Addressable ROR & FIX Heat DetectorDocument2 pagesDI-9103E - Addressable ROR & FIX Heat Detectortaqwa.saberindoNo ratings yet

- Bulletin673 Cavity BattensDocument8 pagesBulletin673 Cavity BattensStephen MaartenszNo ratings yet

- Metal Weather Proof SocketDocument5 pagesMetal Weather Proof SocketIbrahim SNo ratings yet

- 7 Pyrotek CrossfeederDocument27 pages7 Pyrotek CrossfeederMuhamad Hafidz RyansyahNo ratings yet

- To 1-1a-9Document288 pagesTo 1-1a-9CarlozNo ratings yet

- Building Design ReportDocument6 pagesBuilding Design ReportJohn Rhey Almojallas BenedictoNo ratings yet

- Refrig Lec6Document14 pagesRefrig Lec6samadonyNo ratings yet

- EC2 Continuous Beam DesignDocument14 pagesEC2 Continuous Beam Designikanyu79No ratings yet

- Intro Bridge ProjectDocument30 pagesIntro Bridge ProjectKaushik RejaNo ratings yet