Professional Documents

Culture Documents

CTC CW Maxigard High-Range-R203

CTC CW Maxigard High-Range-R203

Uploaded by

John97112Copyright:

Available Formats

You might also like

- Renr1368 05 01 All PDFDocument2 pagesRenr1368 05 01 All PDFJonathan Luiz Poleza50% (2)

- Haffir Dam Guide LineDocument41 pagesHaffir Dam Guide Linesubxaanalah100% (6)

- Manual Sediment Transport Measurements in Rivers Estuaries and Coastal SeasDocument352 pagesManual Sediment Transport Measurements in Rivers Estuaries and Coastal SeasNorito KozakiNo ratings yet

- CTC CW Liquidewt-R210Document2 pagesCTC CW Liquidewt-R210John97112No ratings yet

- Comptector & Chiller (Cdu) Controller (Fx32C Series) : Precaution For UseDocument5 pagesComptector & Chiller (Cdu) Controller (Fx32C Series) : Precaution For UseFcma0903100% (1)

- Asco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm)Document2 pagesAsco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm)Khyle Laurenz DuroNo ratings yet

- Asco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm) PDFDocument2 pagesAsco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm) PDFKhyle Laurenz DuroNo ratings yet

- European Catalog Solenoid Valves 2 2 Pilot Operated Built in Pilot Floating Diaphragm Series 238 Asco en 5080052Document2 pagesEuropean Catalog Solenoid Valves 2 2 Pilot Operated Built in Pilot Floating Diaphragm Series 238 Asco en 5080052Farhan HirsanNo ratings yet

- Cooling Water Treatment Control and Dosage Chart - MAN Diesel SE Medium-Speed 4-Stroke EnginesDocument2 pagesCooling Water Treatment Control and Dosage Chart - MAN Diesel SE Medium-Speed 4-Stroke EnginesvipmamaNo ratings yet

- B 81417 EfaDocument2 pagesB 81417 EfaIshak EnginerNo ratings yet

- Manual For SP1 7890-0552 PDFDocument30 pagesManual For SP1 7890-0552 PDFvzimak2355No ratings yet

- Manual Stop - PetzlDocument21 pagesManual Stop - PetzlAlan AraujoNo ratings yet

- Technical Notice STOP 1Document21 pagesTechnical Notice STOP 1Rodrigo GlückNo ratings yet

- Package Contents: Detector Unit: ȸDocument2 pagesPackage Contents: Detector Unit: ȸTEUKUNo ratings yet

- General Notes: S Piping and Instrument Diagram - Gen1 - System 0000Document1 pageGeneral Notes: S Piping and Instrument Diagram - Gen1 - System 0000sanjay masoodNo ratings yet

- 719pro Qreng0000Document2 pages719pro Qreng0000Jomally Parada AgredaNo ratings yet

- Fire Pump RoomDocument1 pageFire Pump Roomhelohop514No ratings yet

- Arbonia Column RadiatorsDocument100 pagesArbonia Column RadiatorsMikhailNo ratings yet

- Sfal Ab9Document1 pageSfal Ab9adrianbstrd02No ratings yet

- Fluid Codes Limits Process Flow Connections Valve Symbology: IG N E DDocument1 pageFluid Codes Limits Process Flow Connections Valve Symbology: IG N E DSebastian RamirezNo ratings yet

- Se090100 027 01-DcoDocument1 pageSe090100 027 01-DcoNobletruthslover NtlNo ratings yet

- Solenoid Valve 3V Series Air Valve 3A Series: Pneumatic PneumaticDocument8 pagesSolenoid Valve 3V Series Air Valve 3A Series: Pneumatic PneumaticVivin Welroy RodriguesNo ratings yet

- 2 ME FD 31825.idw - SignedDocument1 page2 ME FD 31825.idw - SignedMilovan BalevicNo ratings yet

- FORD 4R44E, 4R55E, 5R44E, 5R55E Zip Kit: Installation DiagramDocument10 pagesFORD 4R44E, 4R55E, 5R44E, 5R55E Zip Kit: Installation DiagramMatias Ignacio ZavalaNo ratings yet

- 81731E CRTi 8.63 2piecDocument1 page81731E CRTi 8.63 2piecUmar IkramNo ratings yet

- MSB 9000 Om 2018Document21 pagesMSB 9000 Om 2018Camila RochaNo ratings yet

- Deluge ValveDocument1 pageDeluge ValveJosé Daniel ArenasNo ratings yet

- Sharp Runtka611wjqz psd-0698 Psu SCHDocument2 pagesSharp Runtka611wjqz psd-0698 Psu SCHMarko VujinovićNo ratings yet

- TM Daikin 50Hz SingaporeDocument86 pagesTM Daikin 50Hz SingaporeericyuenNo ratings yet

- Prancha 01 - InstalaçõesDocument1 pagePrancha 01 - InstalaçõesGeraldo FilhoNo ratings yet

- Solenoid Valves 2/2 210: Pilot Operated FL Oating Diaphragm 3/8 To 2Document4 pagesSolenoid Valves 2/2 210: Pilot Operated FL Oating Diaphragm 3/8 To 2AlexanderNo ratings yet

- 2100.016 SHORTSTOP 3-WAY 300D Full Encirclement Tee W Guide BarsDocument4 pages2100.016 SHORTSTOP 3-WAY 300D Full Encirclement Tee W Guide BarsMORELLI silvioNo ratings yet

- Airend Engine AsslyDocument2 pagesAirend Engine AsslyabhijitNo ratings yet

- Electircal SLDDocument25 pagesElectircal SLDEzhu MalaiNo ratings yet

- S001Document1 pageS001Yong Hui OngNo ratings yet

- SCG238 Series PDFDocument2 pagesSCG238 Series PDFrika monikaNo ratings yet

- Engine JETTA 2012Document7 pagesEngine JETTA 2012Rogelio ArenasNo ratings yet

- Serial CabinDocument1 pageSerial CabinFidan LatifiNo ratings yet

- Acs 6t UsermanualDocument4 pagesAcs 6t UsermanualMuhammad rizkiNo ratings yet

- HOP SummaryDocument3 pagesHOP SummaryKeetah100% (2)

- Gas Compression (PFD)Document1 pageGas Compression (PFD)Rubens SerpaNo ratings yet

- FORD 4R44E, 4R55E, 5R44E, 5R55E Zip Kit: Installation Diagram Installation DiagramDocument10 pagesFORD 4R44E, 4R55E, 5R44E, 5R55E Zip Kit: Installation Diagram Installation DiagramAlejandro LopezNo ratings yet

- 2016 H 100 D 2.5 Tci-A2-DiagramDocument1 page2016 H 100 D 2.5 Tci-A2-DiagramMAXIMILIANO CASTILLO ANTONIONo ratings yet

- Features: NC FunctionDocument4 pagesFeatures: NC FunctionSachin MoreNo ratings yet

- Ach-Car ConnectionsDocument1 pageAch-Car ConnectionsFidan LatifiNo ratings yet

- STEIGER 350, 400, 450, 500, 550, and 600 Tractor Series QUADTRAC 450, 500, 550 and 600 Tractor Series Hydraulic Schematic RAC 84416539Document1 pageSTEIGER 350, 400, 450, 500, 550, and 600 Tractor Series QUADTRAC 450, 500, 550 and 600 Tractor Series Hydraulic Schematic RAC 84416539matt porchNo ratings yet

- SAT PIW PE SD Taman Salmon SG BulojDocument13 pagesSAT PIW PE SD Taman Salmon SG BulojJohan RamliNo ratings yet

- 966H 972H Hydraulic Schematic RENR8828Document2 pages966H 972H Hydraulic Schematic RENR8828Freddy Quispe100% (1)

- 83 Plano Elec PDFDocument6 pages83 Plano Elec PDFManuel CanazaNo ratings yet

- .Trashed-1721226984-Engine Controls (Powertrain Management) - ALLDATA RepairDocument5 pages.Trashed-1721226984-Engine Controls (Powertrain Management) - ALLDATA RepaircarlosNo ratings yet

- P-51D Mustang: Safety PrecautionsDocument10 pagesP-51D Mustang: Safety PrecautionsWujek BellNo ratings yet

- F1 2023 Silverstone MapDocument1 pageF1 2023 Silverstone MapultrabaileyNo ratings yet

- QA-QC Checklist - Fire ExtinguisherDocument1 pageQA-QC Checklist - Fire Extinguisherabdullah albahraniNo ratings yet

- Axact 9 and 11 ManualDocument4 pagesAxact 9 and 11 ManualAnand sNo ratings yet

- SBBR - Kogli 1b - Ukena 2a Rwy 29r - Sid - 20210812Document1 pageSBBR - Kogli 1b - Ukena 2a Rwy 29r - Sid - 20210812Calebe TavaresNo ratings yet

- DVS 2203-2Document3 pagesDVS 2203-2Miteshshinde17No ratings yet

- 20 Bahia - Cumberland 2013Document1 page20 Bahia - Cumberland 2013miguel fuentesNo ratings yet

- Eaton Bussman RTMR DrawingsDocument4 pagesEaton Bussman RTMR DrawingsdeNsNo ratings yet

- GA Molino de Bolas 26x40.5 - PolymetDocument1 pageGA Molino de Bolas 26x40.5 - PolymetElias PaxiNo ratings yet

- Dongshin Hydraulics Co., LTD.: Head OfficeDocument24 pagesDongshin Hydraulics Co., LTD.: Head OfficePabloCesarParraSalazarNo ratings yet

- Flowmeter With ReedswitchDocument1 pageFlowmeter With ReedswitchKaye TrishaNo ratings yet

- Physicochemical Analysis of Water From Various Sources and Their Comparative StudiesDocument5 pagesPhysicochemical Analysis of Water From Various Sources and Their Comparative Studieskirito kirigayaNo ratings yet

- Iot-Based Monitoring of Aquaculture SystemDocument25 pagesIot-Based Monitoring of Aquaculture SystemGlobal Research and Development ServicesNo ratings yet

- 10016-COM-020 Rev0 Procedure For Commissioning of MBF UnitDocument15 pages10016-COM-020 Rev0 Procedure For Commissioning of MBF UnitsithulibraNo ratings yet

- Emulsion Stability Determination From TurbidityDocument4 pagesEmulsion Stability Determination From TurbidityalinerhcNo ratings yet

- Zeosorb Brochure PDFDocument4 pagesZeosorb Brochure PDFcfaguaNo ratings yet

- Chitin and Chitosan As Natural Flocculants For Beer ClarificationDocument6 pagesChitin and Chitosan As Natural Flocculants For Beer ClarificationWILLIAM EDUARDO GOMEZ HERNANDEZNo ratings yet

- NTU in Brine DisplacementDocument17 pagesNTU in Brine DisplacementMAHAN4231No ratings yet

- SCADA PresentationDocument6 pagesSCADA PresentationGigih PramonoNo ratings yet

- Convert I DoDocument43 pagesConvert I Do71403971No ratings yet

- Polyacrylamide PomeDocument10 pagesPolyacrylamide PomeumegeeNo ratings yet

- Presentation On Effluent Treatment PlantDocument17 pagesPresentation On Effluent Treatment Plantarun dubeyNo ratings yet

- Perhitungan PBPAMDocument1,174 pagesPerhitungan PBPAMArif GemardiNo ratings yet

- SQ Prove 300 - Analytical Procedures and Appendices 2017-07Document264 pagesSQ Prove 300 - Analytical Procedures and Appendices 2017-07Rizali MaulanaNo ratings yet

- S7ia 1Document5 pagesS7ia 1به شدار ازاد عبدالرحمن عليNo ratings yet

- Determination of Water TurbidityDocument3 pagesDetermination of Water TurbidityawaaanNo ratings yet

- Env Lab ReportDocument7 pagesEnv Lab ReportsajedulNo ratings yet

- Physicochemical and Microbiological Analysis of Drinking Water in Al Kamleen City, Gezira StateDocument3 pagesPhysicochemical and Microbiological Analysis of Drinking Water in Al Kamleen City, Gezira StateInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- SUEZ CT Proposal For SojitzDocument25 pagesSUEZ CT Proposal For SojitzShami MudunkotuwaNo ratings yet

- WTW TurbidityDocument6 pagesWTW TurbidityIndra AditamaNo ratings yet

- Turbidity AWWA Standard Methods 22Document4 pagesTurbidity AWWA Standard Methods 22Marco AzambujaNo ratings yet

- Wastewater Treatment Using Bio CoagulantDocument5 pagesWastewater Treatment Using Bio CoagulantFAHAD KHURRAMNo ratings yet

- Turbidity Meter AL250T-IR: With Infra-Red Light SourceDocument1 pageTurbidity Meter AL250T-IR: With Infra-Red Light SourcemegacobNo ratings yet

- Final Report Civil Engg. GitamDocument37 pagesFinal Report Civil Engg. Gitampruthvish kanumuryNo ratings yet

- TOPIC 4 Water Characteristics and Drinking Water QualityDocument17 pagesTOPIC 4 Water Characteristics and Drinking Water QualityJayson Paul BulosanNo ratings yet

- Satwater Communicator Installation ReportDocument4 pagesSatwater Communicator Installation ReportShahzadNo ratings yet

- Silt Density Index (SDI) of Water: Standard Test Method ForDocument3 pagesSilt Density Index (SDI) of Water: Standard Test Method Fordecio ventura rodrigues miraNo ratings yet

- Rainwater HarvestingDocument55 pagesRainwater Harvestingnur67% (3)

- Flocculation: Prepared By: Esteban, Alyssa Rose C Class #13Document15 pagesFlocculation: Prepared By: Esteban, Alyssa Rose C Class #13Dan Philip RamiloNo ratings yet

CTC CW Maxigard High-Range-R203

CTC CW Maxigard High-Range-R203

Uploaded by

John97112Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CTC CW Maxigard High-Range-R203

CTC CW Maxigard High-Range-R203

Uploaded by

John97112Copyright:

Available Formats

CONTROL TEST CARD

Use in conjunction with:

DOSAGE REQUIREMENTS PAGE

ONBOARD LOG

COOLING WATER TREATMENT – MAXIGARD® HIGH-RANGE

Read SDSs before running these tests. Before testing, samples should be cooled to 25°C (77°F).

CWT TITRETS PROCEDURE WEEKLY TEST – SYSTEM WATER

Note: If the sample is colored or turbid, filter before running the test. If the sample remains cloudy after the first filtering, the sample should again be filtered through the same paper since the filter becomes more retentive on the second filtration.

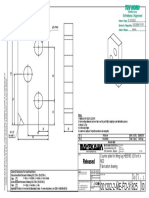

1. Fill the Sample Cup (included) to the 25 ml mark with treated cooling water sample (Fig. 1).

2. Slide the flexible rubber end of the Valve Assembly over the tapered tip of the Titret to the white Reference Line for a snug fit (Fig. 2). 1 2 Slide Over 3 Snap

Valve

Valve

3. Snap the tip of the Titret (ampoule) at the Score Mark (Fig. 3). ml

25 Score Assembly Score Assembly

4. Lift the control bar and insert the Titret assembly into the body of the Titrettor (Fig. 4). 20 Mark Mark

5. With the tip of the Valve Assembly immersed in the sample, press the control bar firmly, but briefly, to pull in a small amount of 15 3

10 Reference

sample (Fig. 5). The contents will turn a GREEN color. CAUTION: Do not press the control bar unless the tip of the Valve Assembly is 5 Line

Titret Titret

immersed below the surface of the liquid.

6. Press the control bar again briefly to allow another small amount of sample to be drawn into the Titret (Fig. 5).

7. After each addition, rock the entire assembly to mix the contents of the Titret. Watch for color to change from GREEN to BRIGHT 4 Titrettor 5 6

Watch for

ORANGE. NOTE: Immediately before the contents turn BRIGHT ORANGE, they will briefly turn BLUE. Make further additions with care. Lift

Color Change 1.4

Insert Here Value

8. Repeat steps 5 through 7 until a permanent color change occurs. Control

Here Read

1.5

= 1.5

Bar 1.6

9. When the color of the liquid in the Titret remains BRIGHT ORANGE, remove the Titret from the Titrettor. Hold in a vertical position and Press

Control Bar

Here

carefully read the depth scale on the Titret that corresponds to the liquid level at the bottom of the concave meniscus (Fig. 6). Refer to Sample

the chart below for dosage adjustments.

6

TEST RESULTS AND CONTROL DOSAGE REQUIREMENTS CONVERSION CHART

DEPTH SCALE UNITS 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.8 2.0 2.5 3.0 3.5 4.0 5.0 7.0 10.0

MAXIGARD (PCN 0034405)

as ppm product

12,000* 13,000 14,000 16,000 17,000 18,000 19,000 22,000 24,000 30,000 36,000 **42,000 48,000 60,000 84,000 120,000

DOSAGE in liters/ton OK OK HIGH HIGH

23 23 22 22 22 22 19 16 13 8 3 HIGH

Initial = 33.0 liters/ton No Dosing No Dosing HIGH HIGH

*If readings are below 12,000 (scale unit 1.0), add 25.0 ltr/ton and retest. If system has been partially drained and refilled, use initial dosage. As long as the system is not foaming and is at or under

* * Minimum requirements for High-Range Engine Program. There is no need to go significantly above these requirements.

Within Control Range a product ppm of 84,000, the high levels can be

reduced by the normal makeup process if that will

occur within a month, otherwise, partially drain and

freshen the system.

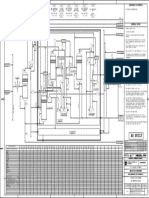

COOLING WATER CHLORIDE TEST PROCEDURE WEEKLY TEST – SYSTEM WATER

Note: If the sample is colored or turbid, filter before running the test. If the sample remains cloudy after the first filtering, the sample should again be filtered through the same paper since the filter becomes more retentive on the second filtration.

1. Add one scoop (0.5 g) of Sample Pretreatment (available individually, not part of Chloride LMP Test Kit) to approximately 70 ml of

cooling water, collected in Beaker 100 ml - Clear Plastic, and stir until granules dissolve into solution (Fig. 1). 1 2 3

2

2. WAIT 2 MINUTES to allow precipitates to settle .

3. Filter the sample by folding Filter Paper in quarters and overlapping three sections to form a funnel. Pour water through the Filter

OR

Paper and Funnel - Plastic (Fig. 2). Proceed with the chloride determination using the Chloride LMP Test Kit. Sample

~70 ml WAIT 2 MINUTES 10 ml

4. For samples < 100 ppm chlorides: Rinse the Plastic Vial and fill to the mark (10 ml) with the sample to be tested (Fig. 3). Pretreatment

then

2

ml

For samples > 100 ppm chloride: Rinse the tall Glass Vial (test tube) and fill to the mark (2 ml) with the sample to be tested (Fig. 3). Filter Sample

5. Neutralize the sample by adding 3 drops of Phenolphthalein Indicator to the sample. Swirl to mix. If the sample turns PINK add

Sulfuric Acid N/10 drop by drop while swirling until the sample turns CLEAR. Afterwards, add one more drop (Fig. 4).

6. Adjust the color of the sample by adding 6 drops of Potassium Chromate. The sample will be YELLOW (Fig. 5). 4 5 6

4

7. Counting the drops, add Silver Nitrate N/10 drop by drop. Swirl between drops until the sample turns ORANGE (Fig. 6). OR &

8. Calculate the chloride concentration:

If plastic vial (< 100 ppm) was used in Step 4: - Number of drops of Silver Nitrate N/10 * 10 = ppm chloride

# #

If glass test tube (> 100 ppm) was used in Step 4: - Number of drops of Silver Nitrate N/10 * 50 = ppm chloride 10 ml 10 ml 10 ml 10 ml 10 ml

TEST RESULTS

Chloride 50 ppm (See Note 1) Maximum Limit

Note 1: If manufacturer’s recommendations are more stringent, take those limits into account.

CW_MAXIGARD HIGH-RANGE-CONTROL TEST CARD_R203

MAKEUP WATER CONTAMINANTS WEEKLY TEST –MAKEUP WATER CONTAMINANTS

NOTE: The use of high quality, distilled makeup water is recommended as the best means to control scale. Makeup tanks

should be tested every week or more often if there is a change in the source or mixture of the water or any upset is suspected. PARAMETER MAXIMUM LIMIT

If at all possible, do not introduce makeup water with Chlorides above 50 ppm or Hardness over 170 ppm, especially if system Chloride 50 ppm Maximum Limit

water is not sufficiently below these limits to dilute the intended makeup water. Hardness 170 ppm Maximum Limit

MAKEUP WATER CHLORIDE TEST PROCEDURE WEEKLY TEST – MAKEUP WATER CHLORIDE

Note: If the sample is colored or turbid, filter before running the test. If the sample remains cloudy after the first filtering, the sample should again be filtered through the same paper since the filter becomes more retentive on the second filtration.

1a. For samples < 100 ppm chlorides: Rinse the Plastic Vial and fill to the mark (10 ml) with the sample to be tested (Fig. 1).

1b. For samples > 100 ppm chloride: Rinse the tall Glass Vial (test tube) and fill to the mark (2 ml) with the sample to be tested (Fig. 1). 1 2

2. Neutralize the sample by adding 3 drops of Phenolphthalein Indicator to the sample. Swirl to mix. If the sample turns PINK add

Sulfuric Acid N/10 drop by drop while swirling until the sample turns CLEAR. Afterwards, add one more drop (Fig. 2). OR

OR &

3. Adjust the color of the sample by adding 6 drops of Potassium Chromate. The sample will be YELLOW (Fig. 3).

10 ml

4. Counting the drops, add Silver Nitrate N/10 drop by drop. Swirl between drops until the sample turns ORANGE (Fig. 4). 2

ml

10 #

10 ml 10 ml 10 ml

5. Calculate the chloride concentration:

If plastic vial (< 100 ppm) was used in Step 4: - Number of drops of Silver Nitrate N/10 * 10 = ppm chloride

If glass test tube (> 100 ppm) was used in Step 4: - Number of drops of Silver Nitrate N/10 * 50 = ppm chloride 3 4

TEST RESULTS

#

Chloride 50 ppm (See Note 1) Maximum Limit 10 ml 10 ml

Note 1: If manufacturer’s recommendations are more stringent, take those limits into account.

MAKEUP WATER HARDNESS TEST PROCEDURE WEEKLY TEST – MAKEUP WATER CHLORIDE

Note: If the sample is colored or turbid, filter before running the test. If the sample remains cloudy after the first filtering, the sample should again be filtered through the same paper since the filter becomes more retentive on the second filtration.

1. Rinse and fill the Sample Cup to the 25 ml mark with makeup water sample (Fig. 1).

2. Slide the flexible rubber end of the Valve Assembly over the tapered tip of the Titret to the white Reference Line for a snug fit (Fig. 2). 1 2 Slide Over 3 Snap

Valve

3. Snap the tip of the Titret (ampoule) at the Score Mark (Fig. 3). ml

Score

Valve

Assembly Score Assembly

25

4. With the tip of the valve assembly immersed in the sample, squeeze the bead valve briefly to add a small amount of sample to the 20 Mark Mark

15

Titret (Fig. 4). The red indicator in the Valve Assembly will also be added to the Titret. 10 Reference

NOTE: Do not squeeze the bead value unless the tip of the Valve Assembly is immersed below the surface of the liquid. 5 Line

Titret Titret

5. Rock the Titret to mix the contents. The contents of the Titret will turn a BLUE color.

6. Continue to add small amounts of sample until the liquid in the Titret turns from BLUE to PINK. Be sure to rock the Titret to mix the

contents after each addition of sample. When the color of the liquid in the Titret changes to PINK, the end point has been reached. 4 55

Stop the test, hold the Titret in a vertical position and carefully read the depth scale on the Titret that corresponds to the liquid level at Squeeze 26

Value

the bottom of the concave meniscus (Fig. 5). Results are in ppm total hardness as calcium carbonate CaCO3. Bead

Valve Read

28

= 28

Here 30

TEST RESULTS

Hardness 170 ppm Maximum Limit

APPARATUS AND REAGENTS

CWT Titrets: CWT Titrets (PCN 0367012) Beaker 100 ml Plastic: Beaker 100 ml - Clear Plastic (PCN 0247016)

Chlorides: Chloride LMP Test Kit (PCN 0373019) Filter Paper: Filter Paper - 100/BX (PCN 0225012)

Pretreatment: Sample Pretreatment (PCN 0374025) (for SYSTEM Water Chloride Test) Funnel: Funnel - Plastic (PCN 0221010)

Hardness: Total Hardness Titrets (PCN 0378019) Stirring Rod: Stirring Rod - 150 mm Plastic (PCN 0417015)

CW_MAXIGARD HIGH-RANGE-CONTROL TEST CARD_R203

You might also like

- Renr1368 05 01 All PDFDocument2 pagesRenr1368 05 01 All PDFJonathan Luiz Poleza50% (2)

- Haffir Dam Guide LineDocument41 pagesHaffir Dam Guide Linesubxaanalah100% (6)

- Manual Sediment Transport Measurements in Rivers Estuaries and Coastal SeasDocument352 pagesManual Sediment Transport Measurements in Rivers Estuaries and Coastal SeasNorito KozakiNo ratings yet

- CTC CW Liquidewt-R210Document2 pagesCTC CW Liquidewt-R210John97112No ratings yet

- Comptector & Chiller (Cdu) Controller (Fx32C Series) : Precaution For UseDocument5 pagesComptector & Chiller (Cdu) Controller (Fx32C Series) : Precaution For UseFcma0903100% (1)

- Asco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm)Document2 pagesAsco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm)Khyle Laurenz DuroNo ratings yet

- Asco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm) PDFDocument2 pagesAsco Series 238 ASCO Pilot Operated Solenoid Valves (Floating Diaphragm) PDFKhyle Laurenz DuroNo ratings yet

- European Catalog Solenoid Valves 2 2 Pilot Operated Built in Pilot Floating Diaphragm Series 238 Asco en 5080052Document2 pagesEuropean Catalog Solenoid Valves 2 2 Pilot Operated Built in Pilot Floating Diaphragm Series 238 Asco en 5080052Farhan HirsanNo ratings yet

- Cooling Water Treatment Control and Dosage Chart - MAN Diesel SE Medium-Speed 4-Stroke EnginesDocument2 pagesCooling Water Treatment Control and Dosage Chart - MAN Diesel SE Medium-Speed 4-Stroke EnginesvipmamaNo ratings yet

- B 81417 EfaDocument2 pagesB 81417 EfaIshak EnginerNo ratings yet

- Manual For SP1 7890-0552 PDFDocument30 pagesManual For SP1 7890-0552 PDFvzimak2355No ratings yet

- Manual Stop - PetzlDocument21 pagesManual Stop - PetzlAlan AraujoNo ratings yet

- Technical Notice STOP 1Document21 pagesTechnical Notice STOP 1Rodrigo GlückNo ratings yet

- Package Contents: Detector Unit: ȸDocument2 pagesPackage Contents: Detector Unit: ȸTEUKUNo ratings yet

- General Notes: S Piping and Instrument Diagram - Gen1 - System 0000Document1 pageGeneral Notes: S Piping and Instrument Diagram - Gen1 - System 0000sanjay masoodNo ratings yet

- 719pro Qreng0000Document2 pages719pro Qreng0000Jomally Parada AgredaNo ratings yet

- Fire Pump RoomDocument1 pageFire Pump Roomhelohop514No ratings yet

- Arbonia Column RadiatorsDocument100 pagesArbonia Column RadiatorsMikhailNo ratings yet

- Sfal Ab9Document1 pageSfal Ab9adrianbstrd02No ratings yet

- Fluid Codes Limits Process Flow Connections Valve Symbology: IG N E DDocument1 pageFluid Codes Limits Process Flow Connections Valve Symbology: IG N E DSebastian RamirezNo ratings yet

- Se090100 027 01-DcoDocument1 pageSe090100 027 01-DcoNobletruthslover NtlNo ratings yet

- Solenoid Valve 3V Series Air Valve 3A Series: Pneumatic PneumaticDocument8 pagesSolenoid Valve 3V Series Air Valve 3A Series: Pneumatic PneumaticVivin Welroy RodriguesNo ratings yet

- 2 ME FD 31825.idw - SignedDocument1 page2 ME FD 31825.idw - SignedMilovan BalevicNo ratings yet

- FORD 4R44E, 4R55E, 5R44E, 5R55E Zip Kit: Installation DiagramDocument10 pagesFORD 4R44E, 4R55E, 5R44E, 5R55E Zip Kit: Installation DiagramMatias Ignacio ZavalaNo ratings yet

- 81731E CRTi 8.63 2piecDocument1 page81731E CRTi 8.63 2piecUmar IkramNo ratings yet

- MSB 9000 Om 2018Document21 pagesMSB 9000 Om 2018Camila RochaNo ratings yet

- Deluge ValveDocument1 pageDeluge ValveJosé Daniel ArenasNo ratings yet

- Sharp Runtka611wjqz psd-0698 Psu SCHDocument2 pagesSharp Runtka611wjqz psd-0698 Psu SCHMarko VujinovićNo ratings yet

- TM Daikin 50Hz SingaporeDocument86 pagesTM Daikin 50Hz SingaporeericyuenNo ratings yet

- Prancha 01 - InstalaçõesDocument1 pagePrancha 01 - InstalaçõesGeraldo FilhoNo ratings yet

- Solenoid Valves 2/2 210: Pilot Operated FL Oating Diaphragm 3/8 To 2Document4 pagesSolenoid Valves 2/2 210: Pilot Operated FL Oating Diaphragm 3/8 To 2AlexanderNo ratings yet

- 2100.016 SHORTSTOP 3-WAY 300D Full Encirclement Tee W Guide BarsDocument4 pages2100.016 SHORTSTOP 3-WAY 300D Full Encirclement Tee W Guide BarsMORELLI silvioNo ratings yet

- Airend Engine AsslyDocument2 pagesAirend Engine AsslyabhijitNo ratings yet

- Electircal SLDDocument25 pagesElectircal SLDEzhu MalaiNo ratings yet

- S001Document1 pageS001Yong Hui OngNo ratings yet

- SCG238 Series PDFDocument2 pagesSCG238 Series PDFrika monikaNo ratings yet

- Engine JETTA 2012Document7 pagesEngine JETTA 2012Rogelio ArenasNo ratings yet

- Serial CabinDocument1 pageSerial CabinFidan LatifiNo ratings yet

- Acs 6t UsermanualDocument4 pagesAcs 6t UsermanualMuhammad rizkiNo ratings yet

- HOP SummaryDocument3 pagesHOP SummaryKeetah100% (2)

- Gas Compression (PFD)Document1 pageGas Compression (PFD)Rubens SerpaNo ratings yet

- FORD 4R44E, 4R55E, 5R44E, 5R55E Zip Kit: Installation Diagram Installation DiagramDocument10 pagesFORD 4R44E, 4R55E, 5R44E, 5R55E Zip Kit: Installation Diagram Installation DiagramAlejandro LopezNo ratings yet

- 2016 H 100 D 2.5 Tci-A2-DiagramDocument1 page2016 H 100 D 2.5 Tci-A2-DiagramMAXIMILIANO CASTILLO ANTONIONo ratings yet

- Features: NC FunctionDocument4 pagesFeatures: NC FunctionSachin MoreNo ratings yet

- Ach-Car ConnectionsDocument1 pageAch-Car ConnectionsFidan LatifiNo ratings yet

- STEIGER 350, 400, 450, 500, 550, and 600 Tractor Series QUADTRAC 450, 500, 550 and 600 Tractor Series Hydraulic Schematic RAC 84416539Document1 pageSTEIGER 350, 400, 450, 500, 550, and 600 Tractor Series QUADTRAC 450, 500, 550 and 600 Tractor Series Hydraulic Schematic RAC 84416539matt porchNo ratings yet

- SAT PIW PE SD Taman Salmon SG BulojDocument13 pagesSAT PIW PE SD Taman Salmon SG BulojJohan RamliNo ratings yet

- 966H 972H Hydraulic Schematic RENR8828Document2 pages966H 972H Hydraulic Schematic RENR8828Freddy Quispe100% (1)

- 83 Plano Elec PDFDocument6 pages83 Plano Elec PDFManuel CanazaNo ratings yet

- .Trashed-1721226984-Engine Controls (Powertrain Management) - ALLDATA RepairDocument5 pages.Trashed-1721226984-Engine Controls (Powertrain Management) - ALLDATA RepaircarlosNo ratings yet

- P-51D Mustang: Safety PrecautionsDocument10 pagesP-51D Mustang: Safety PrecautionsWujek BellNo ratings yet

- F1 2023 Silverstone MapDocument1 pageF1 2023 Silverstone MapultrabaileyNo ratings yet

- QA-QC Checklist - Fire ExtinguisherDocument1 pageQA-QC Checklist - Fire Extinguisherabdullah albahraniNo ratings yet

- Axact 9 and 11 ManualDocument4 pagesAxact 9 and 11 ManualAnand sNo ratings yet

- SBBR - Kogli 1b - Ukena 2a Rwy 29r - Sid - 20210812Document1 pageSBBR - Kogli 1b - Ukena 2a Rwy 29r - Sid - 20210812Calebe TavaresNo ratings yet

- DVS 2203-2Document3 pagesDVS 2203-2Miteshshinde17No ratings yet

- 20 Bahia - Cumberland 2013Document1 page20 Bahia - Cumberland 2013miguel fuentesNo ratings yet

- Eaton Bussman RTMR DrawingsDocument4 pagesEaton Bussman RTMR DrawingsdeNsNo ratings yet

- GA Molino de Bolas 26x40.5 - PolymetDocument1 pageGA Molino de Bolas 26x40.5 - PolymetElias PaxiNo ratings yet

- Dongshin Hydraulics Co., LTD.: Head OfficeDocument24 pagesDongshin Hydraulics Co., LTD.: Head OfficePabloCesarParraSalazarNo ratings yet

- Flowmeter With ReedswitchDocument1 pageFlowmeter With ReedswitchKaye TrishaNo ratings yet

- Physicochemical Analysis of Water From Various Sources and Their Comparative StudiesDocument5 pagesPhysicochemical Analysis of Water From Various Sources and Their Comparative Studieskirito kirigayaNo ratings yet

- Iot-Based Monitoring of Aquaculture SystemDocument25 pagesIot-Based Monitoring of Aquaculture SystemGlobal Research and Development ServicesNo ratings yet

- 10016-COM-020 Rev0 Procedure For Commissioning of MBF UnitDocument15 pages10016-COM-020 Rev0 Procedure For Commissioning of MBF UnitsithulibraNo ratings yet

- Emulsion Stability Determination From TurbidityDocument4 pagesEmulsion Stability Determination From TurbidityalinerhcNo ratings yet

- Zeosorb Brochure PDFDocument4 pagesZeosorb Brochure PDFcfaguaNo ratings yet

- Chitin and Chitosan As Natural Flocculants For Beer ClarificationDocument6 pagesChitin and Chitosan As Natural Flocculants For Beer ClarificationWILLIAM EDUARDO GOMEZ HERNANDEZNo ratings yet

- NTU in Brine DisplacementDocument17 pagesNTU in Brine DisplacementMAHAN4231No ratings yet

- SCADA PresentationDocument6 pagesSCADA PresentationGigih PramonoNo ratings yet

- Convert I DoDocument43 pagesConvert I Do71403971No ratings yet

- Polyacrylamide PomeDocument10 pagesPolyacrylamide PomeumegeeNo ratings yet

- Presentation On Effluent Treatment PlantDocument17 pagesPresentation On Effluent Treatment Plantarun dubeyNo ratings yet

- Perhitungan PBPAMDocument1,174 pagesPerhitungan PBPAMArif GemardiNo ratings yet

- SQ Prove 300 - Analytical Procedures and Appendices 2017-07Document264 pagesSQ Prove 300 - Analytical Procedures and Appendices 2017-07Rizali MaulanaNo ratings yet

- S7ia 1Document5 pagesS7ia 1به شدار ازاد عبدالرحمن عليNo ratings yet

- Determination of Water TurbidityDocument3 pagesDetermination of Water TurbidityawaaanNo ratings yet

- Env Lab ReportDocument7 pagesEnv Lab ReportsajedulNo ratings yet

- Physicochemical and Microbiological Analysis of Drinking Water in Al Kamleen City, Gezira StateDocument3 pagesPhysicochemical and Microbiological Analysis of Drinking Water in Al Kamleen City, Gezira StateInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- SUEZ CT Proposal For SojitzDocument25 pagesSUEZ CT Proposal For SojitzShami MudunkotuwaNo ratings yet

- WTW TurbidityDocument6 pagesWTW TurbidityIndra AditamaNo ratings yet

- Turbidity AWWA Standard Methods 22Document4 pagesTurbidity AWWA Standard Methods 22Marco AzambujaNo ratings yet

- Wastewater Treatment Using Bio CoagulantDocument5 pagesWastewater Treatment Using Bio CoagulantFAHAD KHURRAMNo ratings yet

- Turbidity Meter AL250T-IR: With Infra-Red Light SourceDocument1 pageTurbidity Meter AL250T-IR: With Infra-Red Light SourcemegacobNo ratings yet

- Final Report Civil Engg. GitamDocument37 pagesFinal Report Civil Engg. Gitampruthvish kanumuryNo ratings yet

- TOPIC 4 Water Characteristics and Drinking Water QualityDocument17 pagesTOPIC 4 Water Characteristics and Drinking Water QualityJayson Paul BulosanNo ratings yet

- Satwater Communicator Installation ReportDocument4 pagesSatwater Communicator Installation ReportShahzadNo ratings yet

- Silt Density Index (SDI) of Water: Standard Test Method ForDocument3 pagesSilt Density Index (SDI) of Water: Standard Test Method Fordecio ventura rodrigues miraNo ratings yet

- Rainwater HarvestingDocument55 pagesRainwater Harvestingnur67% (3)

- Flocculation: Prepared By: Esteban, Alyssa Rose C Class #13Document15 pagesFlocculation: Prepared By: Esteban, Alyssa Rose C Class #13Dan Philip RamiloNo ratings yet