Professional Documents

Culture Documents

2024-05-30 Monoammonium Phosphate Process Line Costing Information

2024-05-30 Monoammonium Phosphate Process Line Costing Information

Uploaded by

Eng BassimCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2024-05-30 Monoammonium Phosphate Process Line Costing Information

2024-05-30 Monoammonium Phosphate Process Line Costing Information

Uploaded by

Eng BassimCopyright:

Available Formats

VANOO (SHANGHAI) CO.

,LTD

VANOO (SHANGHAI) Machinery Equipment CO.,LTD

Company name VANOO(SHANGHAI) CO.,LTD

VANOO(SHANGHAI) MACHINERY EQUIPMENT CO.,LTD

Email : antonia@vanoo.net

Address: NO. 585 , Jinbi Road , Jinhui Town , Fengxian district , Shanghai China

Tel : 86 -021-3178 1287

Fax: 86-021-5195 1564

Website : https://www.vanoo.net

https://www.vanoo.cc

Contact person : ( Miss ) Antonia

( 00 86 186 1650 4539)

Project proposal

Date : 2024-05-29

NO.VNOSLO -02-2000

Responsibility & Co-ordination

Website : https://www.vanoo.net email : antonia@vanoo.net

VANOO (SHANGHAI) CO.,LTD

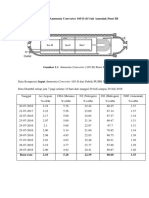

Production of Monoammonium phosphate

Process line

Ammonia neutralization method

1. Specification and dosage of chemical raw materials

1 The temperature of ammonia entering the neutralization reactor is 30 ℃, the

temperature of phosphoric acid is 60 ℃, and the temperature of the slurry is 82 ℃.

2 The fresh steam pressure is 0.30MPa (gauge pressure), and according to the steam

gauge, the saturated steam temperature is 143 ℃.

3 The vacuum degree of the second effect is -0.05MPa, and the pressure of the first

effect flash chamber is 0.05MPa (gauge pressure).

4 The water content of the second effect slurry is 43%, and the water content of the first

effect slurry is 25%.

5 The neutralization degree is 1.05.

6 The complete analysis of phosphoric acid is as follows:

P2O5-20%;MgO-1.65%;SO3-2.3%;Fe2O3-1.2%;Al2O3-0.8%;F-1.65%

2. Properties of ammonium phosphate system

2.1. Physical and chemical properties of solid ammonium phosphate

The main properties of ammonium phosphate orthophosphate are shown in Table 3-1

Table 3-1 Properties of ammonium phosphate salts

Responsibility & Co-ordination

Website : https://www.vanoo.net email : antonia@vanoo.net

VANOO (SHANGHAI) CO.,LTD

Project NH4H2PO4 (NH4)2HPO4 (NH4)3PO4

Crystalline morphology Orthorhombic Monoclinic crystal Orthorhombic

crystal system system

N% contains 12.2 21.2 28.6

P2O5% Contains 61.8 53.8 48.3

N:P2O5 1:5.1 1:2.5 1:1.7

Density (19℃),kg/m3 1803 1619 —

Heat capacity (25℃),kJ/mol·K 0.1424 0.1821 0.2301

Melting temperature ,℃ 190.5 decompose decompose

Heat of formation ,kJ/mol 1451 1574 1673

Heat of fusion,kJ/mol 35.6 — —

critical relative Humidity,%(30℃) 91.6 82.5 —

0.1mol/L Solution pH value 4.4 8.0 9.0

Monoammonium phosphate :

Ammonium phosphate has good thermal stability and is not easily hygroscopic. It has a

high solubility in water and is a fertilizer with excellent physical properties. Even if

monoammonium is heated to 100 ℃, it is difficult to detect the release of ammonia. It takes

about 200 ℃ for NH3 and H2O gases to be released:

The equilibrium pressure of ammonia and water vapor for solid ammonium phosphate is

shown in Table 3-2. From the data in the table, it can be seen that when drying ammonium

below 125 ℃, the ammonia loss is very small.

Table 3-2 Ammonia and Water Vapor Equilibrium Pressure of Solid Monoammonium

Phosphate

Responsibility & Co-ordination

Website : https://www.vanoo.net email : antonia@vanoo.net

VANOO (SHANGHAI) CO.,LTD

Temp./℃ NH3/Pa H2O/Pa Temp./℃ NH3/Pa H2O/Pa

125.1 9.5 60.0 179.1 1823 9093

4

135.0 15.7 537 199.0 5517 2.05×10

4

144.9 40.2 617 219.5 6803 1.93×10

4 4

150.9 99.3 1000 199.5 1.82×10 1.79×10

4 4

160.7 164 1023 349.4 2.09×10 2.37×10

170.0 1350 5138

3. Calculation of the amount of producing one ton of

monoammonium phosphate

2NH3 P2O5 3H2O 2NH4H2PO4

2×17 142 2×115

x7 141.47 y7

Ammonia consumption in the production of monoammonium phosphate:

Ammonia consumption including ammonium sulfate and other ammonium salts:

14.70+37.44=52.14kg NH3

It is known that 1% ammonia is lost during the neutralization and concentration process,

but the actual total amount of ammonia required is 52.14/99%=52.67kg NH3

Among them, NH3 loss during neutralization process is 0.7%: 52.67 × 0.7%=0.3687 kg

NH3 loss during concentration process: 0.3%: 52.67 × 0.3%=0.1580 kg

Total feeding amount: 1000+52.67=1052.67 kg

Table 3-7 Quantity and composition of ammonium phosphate products

produced per ton of wet process phosphoric acid (dry basis)

Responsibility & Co-ordination

Website : https://www.vanoo.net email : antonia@vanoo.net

VANOO (SHANGHAI) CO.,LTD

Component NH4H2PO4 (NH4)2HPO4 MgHPO 4 ·3H 2 O FePO 4 ·2H 2 O

Quality/kg 229.14 13.85 71.78 28.05

% 53.13 3.21 16.64 6.50

Component AlPO 4 ·2H 2 O (NH4)2SO4 (NH4)2SiF6 Totally

Quality/kg 24.78 37.95 25.76 431.31

% 5.75 8.80 5.97 100

4. Calculation of water content in ammonia slurry (before

vaporization and dehydration)

Total P2O5 content percentage of ammonium phosphate (dry basis):

The percentage of water-soluble P2O5 content in ammonium phosphate

Nitrogen content percentage of ammonium phosphate

5. Heat balance calculation of wet process phosphoric acid

Responsibility & Co-ordination

Website : https://www.vanoo.net email : antonia@vanoo.net

VANOO (SHANGHAI) CO.,LTD

ammonification process

Table 3-8 Relationship between specific heat capacity and water content of

ammonium phosphate

Water content in slurry % 20 25 30 40 50 60

Specific heat capacity

1.841 1.987 2.134 2.427 2.720 3.192

KJ/ Kg·K

According to the interpolation method, when the water content of the slurry is 59.0%, its

specific heat capacity is 3.150 KJ/Kg · K

Phosphoric acid begins to boil and vaporize from 60 ℃ to 108 ℃

By looking up the table and using interpolation method, the evaporation heat of water in

the slurry at 108 ℃ is 2237.7 KJ/Kg

Table 5-1 Standard generation heat

H3PO4 NH3 H2SO4 NH4H2PO4

Substance

(Liquid) (sir) (liquid) (solid)

¢

△H ,KJ/mol -1279 -46.1 -811 -1451

f

(NH4)2HPO4 (NH4)2SO4 H2SiF6 (NH4)2SiF6

Substance

(Solid) (Solid) (water liquid) (water liquid)

¢

△H ,KJ/mol

f -1574 -1181 -2331 -2602

6. Dry Material Balance Sheet

Feeding Discharge

NO.

NO. Name Quantity(kg) % Name Qua。

(kg) %

1 Concentrated 575.08 100 1 Water 135.06 23.49

Solution evaporation

2 NH3 LOSS 4.313 0.75

2

3 Ammonium 435.71 75.77

phosphate

products

Totally 575.08 100 Totally 575.08 100

Theoretical calculation of consumption quota and product specifications:

Responsibility & Co-ordination

Website : https://www.vanoo.net email : antonia@vanoo.net

VANOO (SHANGHAI) CO.,LTD

Mainly raw material consumption quota (per ton of ammonium phosphate

product):

wet-process phosphoric acid : ( 20% P2O5 ) 1000/435.71=2.295t H3PO4/t Product gas

ammonia

(100%NH3) 52.67×2.295/1000=0.121t NH3/t Product

Theoretical composition of the product

NO. Name Mass of substances % N(kg) P2O5(kg)

(kg) Contains Contains

1 NH4H2PO4 229.14 52.59 27.90 141.47

2 (NH4)2HPO4 13.85 3.18 2.94 7.45

3 (NH4)2SO4 37.95 8.71 8.05 —

4 (NH4)2SiF6 25.76 5.91 4.05 —

5 FePO 4 ·2H 2 O 28.05 6.44 — 10.65

6 AlPO 4 ·2H 2 O 24.78 5.69 — 11.14

7 MgHPO 4 ·3H 2 O 71.78 16.47 — 29.29

8 Loss -4.313 0.99 — —

9 H2O 8.71 2.00 — —

Totally 435.71 100 42.94 200

Product contains nitrogen:42.94×14/17=35.36kg

The percentage of nitrogen in the product is:42.94/435.71×100%=9.86%

The total amount of P2O5 in the product:200 kg

The percentage of P2O5 in the product is:200/435.71×100%=45.9%

The product specifications are represented as:10—46—0

7. Cost Calculations

The cost required to produce one ton of monoammonium phosphate

1 Phosphoric acid (20%P2O5 at leaste ) :2.259 tons

2 Gas ammonia: 0.121 ton

3 Steam Consumption :1 ton Steam /Now we design the evaporation crystallizer with MVR type and

multi-effect for client choice .

4 Power consumption :150 150 kWh electricity Depends on client use MVR type or Mulit -effect type

5 Cooling water consuption :Depends ( circulation use )

6 Labor, safety, environmental protection, sales costs, and factory construction costs

Responsibility & Co-ordination

Website : https://www.vanoo.net email : antonia@vanoo.net

You might also like

- Acetone Production Process From Iso-propyl-Alcohol (IPA)Document36 pagesAcetone Production Process From Iso-propyl-Alcohol (IPA)Serkan91% (44)

- Preboard Final November 2021Document15 pagesPreboard Final November 2021Francis Verbo100% (3)

- Che 455 Fall 2012 Major 1 Cumene Production Background: H C H C H CDocument38 pagesChe 455 Fall 2012 Major 1 Cumene Production Background: H C H C H CmoheedNo ratings yet

- Production of Acetic Acid by Methanol CarbonylationDocument68 pagesProduction of Acetic Acid by Methanol CarbonylationNoman Aslam100% (5)

- Australian Standard: Concrete Structures For Retaining Liquids-Commentary (Supplement To AS 3735-2001)Document66 pagesAustralian Standard: Concrete Structures For Retaining Liquids-Commentary (Supplement To AS 3735-2001)Andy100% (3)

- Umm Lulu - UMMLULU201810Document6 pagesUmm Lulu - UMMLULU201810asad raza100% (2)

- Bonny LightDocument1 pageBonny LightIsabelNo ratings yet

- Lab Manual 3.1 - LEVEL 1 - Determination of Head Loss in Pipes Due To Friction, Fittings, Sudden Expansion and Contraction.Document4 pagesLab Manual 3.1 - LEVEL 1 - Determination of Head Loss in Pipes Due To Friction, Fittings, Sudden Expansion and Contraction.Coi50% (2)

- SCM As Copper TailingDocument27 pagesSCM As Copper TailingSangamesh KarbariNo ratings yet

- Production of Cumene From Benzene and Propylene: C H + C H C HDocument2 pagesProduction of Cumene From Benzene and Propylene: C H + C H C HDarnell HendersonNo ratings yet

- Crude Summary Report: Crude: OSEBERG 2016 04 Reference: OSEBERG201604Document3 pagesCrude Summary Report: Crude: OSEBERG 2016 04 Reference: OSEBERG201604Jorge Rodriguez HerreraNo ratings yet

- 19 (1985) 219-223 Elsevier Science Publishers V., Amsterdam - Printed in The Netherlands 219Document5 pages19 (1985) 219-223 Elsevier Science Publishers V., Amsterdam - Printed in The Netherlands 219Syukri ZainuddinNo ratings yet

- Zentiva DataDocument19 pagesZentiva DataJay Sheth9No ratings yet

- Gas ChromatographyDocument19 pagesGas ChromatographyNauman Mithani100% (2)

- High Temperature Millisecond Pyrolysis of Residue, Yuanjun Che, Yuanyu Tian, Yingyun QiaoDocument4 pagesHigh Temperature Millisecond Pyrolysis of Residue, Yuanjun Che, Yuanyu Tian, Yingyun QiaoLOLA PATRICIA MORALES DE LA CUBANo ratings yet

- Alvheim Blend 2013 09Document5 pagesAlvheim Blend 2013 09Tree SilviaNo ratings yet

- Final Report Integration CPE614Document25 pagesFinal Report Integration CPE614Amni Saufian100% (1)

- Government College of TechnologyDocument44 pagesGovernment College of TechnologyHemathi KarthiNo ratings yet

- 15-12-2009 Blr#1effDocument5 pages15-12-2009 Blr#1effpulakjaiswal85No ratings yet

- 10.1515 - Epoly 2013 0126Document8 pages10.1515 - Epoly 2013 0126poonam4927No ratings yet

- Agbami 2012 03Document5 pagesAgbami 2012 03eke23100% (1)

- Hydrome ProjectDocument10 pagesHydrome Projectapi-598052719No ratings yet

- Torre 103Document6 pagesTorre 103Camila Florencia ScarlatoNo ratings yet

- Efeitos Do Acido Cloridrico em Argamassas de CimentoDocument12 pagesEfeitos Do Acido Cloridrico em Argamassas de Cimentorogerio rosaNo ratings yet

- Daftar Pustaka Dan Lampiran Skripsi Nurita-SukmaDocument12 pagesDaftar Pustaka Dan Lampiran Skripsi Nurita-SukmaJamalusNo ratings yet

- Prevod PinosavaDocument7 pagesPrevod PinosavaDajana LjujićNo ratings yet

- Quad Tube Furnace: Table 1: Crucible Blank Level ComparisonDocument2 pagesQuad Tube Furnace: Table 1: Crucible Blank Level Comparison张群利No ratings yet

- Assignment-4 Umar IqbalDocument12 pagesAssignment-4 Umar IqbalAyush DubeyNo ratings yet

- Messrs. Petrobras Global Trading B.V / Eni Trading & Shipping S.P.A Certificate of Quality JOB MA 007/16Document1 pageMessrs. Petrobras Global Trading B.V / Eni Trading & Shipping S.P.A Certificate of Quality JOB MA 007/16Marcones SáNo ratings yet

- CO2 Capture ReportDocument15 pagesCO2 Capture ReportMuchammad AdriyanNo ratings yet

- Choice of Coal Vs Design Asb13 - 1-4Document51 pagesChoice of Coal Vs Design Asb13 - 1-4Jerry MateoNo ratings yet

- Absorption: Procédés de Séparation de L'industrie Pétrochimique. CGP241Document11 pagesAbsorption: Procédés de Séparation de L'industrie Pétrochimique. CGP241Hiba GhandourNo ratings yet

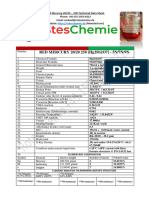

- Red Mercury 2020 Technical Data SheetDocument2 pagesRed Mercury 2020 Technical Data SheetThe UniversNo ratings yet

- Parameter SheetDocument1 pageParameter SheetKhôi NguyễnNo ratings yet

- EXCEL TPP (DipulihkanOtomatis)Document107 pagesEXCEL TPP (DipulihkanOtomatis)Adam MufarijNo ratings yet

- DP2023 - Project Brief - Version 2.1Document10 pagesDP2023 - Project Brief - Version 2.1spamNo ratings yet

- Calculation PurposeDocument31 pagesCalculation Purposenps1966No ratings yet

- Hydration of Propylene Via Sulfation HydrationDocument4 pagesHydration of Propylene Via Sulfation HydrationDineshNo ratings yet

- Metro ViewerDocument5 pagesMetro ViewerSteve WanNo ratings yet

- Analysis of Residual Solvents in Packaging and Container MaterialsDocument2 pagesAnalysis of Residual Solvents in Packaging and Container MaterialsknbiolabsNo ratings yet

- DEIPA - Liebert Et Al 1983 - Final Report On The Safety Assessment of Triethanolamine, Diethanolamine, and MonoethanolamineDocument53 pagesDEIPA - Liebert Et Al 1983 - Final Report On The Safety Assessment of Triethanolamine, Diethanolamine, and MonoethanolamineListya Eka AnggrainiNo ratings yet

- Torre 102Document6 pagesTorre 102Camila Florencia ScarlatoNo ratings yet

- Flowsheet 2Document2 pagesFlowsheet 2Mohammed GhanemNo ratings yet

- Natural Gas SeparationDocument2 pagesNatural Gas SeparationAndrésFelipeQuirogaMirandaNo ratings yet

- OM-0001 ESP & EFF Manual PDFDocument45 pagesOM-0001 ESP & EFF Manual PDFKaushal KishoreNo ratings yet

- RDF CompositionDocument2 pagesRDF Compositionmaz zlsNo ratings yet

- Production of Ammonia Through Haber S Process.: Department of Chemical EngineeringDocument2 pagesProduction of Ammonia Through Haber S Process.: Department of Chemical EngineeringRushikesh uNo ratings yet

- Neraca Massa TK OMAR-FAUZANDocument4 pagesNeraca Massa TK OMAR-FAUZANwahyudi s gultomNo ratings yet

- Cumene212 PDFDocument10 pagesCumene212 PDFtiaradyepiNo ratings yet

- Wireless Remote Control Smoove Origin IoDocument3 pagesWireless Remote Control Smoove Origin IoasanjurjogNo ratings yet

- CPP Assignment 3 and 4 ComplexDocument3 pagesCPP Assignment 3 and 4 ComplexHamza RahimNo ratings yet

- GasificaciónDocument27 pagesGasificaciónStiven SofanNo ratings yet

- Separation of Alcohols: Type Your Name Here 5/12/2016Document8 pagesSeparation of Alcohols: Type Your Name Here 5/12/2016Naeem AkramNo ratings yet

- Material Balance: Engineering Services by KBR Technical Services, IncDocument3 pagesMaterial Balance: Engineering Services by KBR Technical Services, IncSanju ChauhanNo ratings yet

- Drilling Fluid Drilling Fluid Drilling Fluid Drilling Fluid Contaminants ContaminantsDocument51 pagesDrilling Fluid Drilling Fluid Drilling Fluid Drilling Fluid Contaminants ContaminantsAmine BiroukNo ratings yet

- Behaviour of A Sustainable Concrete in Acidic Environment: SustainabilityDocument13 pagesBehaviour of A Sustainable Concrete in Acidic Environment: Sustainabilitym_shahbaghiNo ratings yet

- Residual Fuel OilsDocument1 pageResidual Fuel OilsVilius BukysNo ratings yet

- Urals Crude AssayDocument1 pageUrals Crude AssayAsif IqbalNo ratings yet

- Application of IC-MS and IC-ICP-MS in Environmental ResearchFrom EverandApplication of IC-MS and IC-ICP-MS in Environmental ResearchRajmund MichalskiNo ratings yet

- Synthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsFrom EverandSynthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsTilman J. SchildhauerNo ratings yet

- Product CatalogueDocument6 pagesProduct CatalogueEng BassimNo ratings yet

- 03 - Cpe 2019 3Document11 pages03 - Cpe 2019 3Eng BassimNo ratings yet

- Numerical Investigation of Effect of Aeration Rate On Ethanol Production Numerical Investigation of Effect of Aeration Rate On Ethanol ProductionDocument9 pagesNumerical Investigation of Effect of Aeration Rate On Ethanol Production Numerical Investigation of Effect of Aeration Rate On Ethanol ProductionEng BassimNo ratings yet

- Sciencedirect Sciencedirect SciencedirectDocument6 pagesSciencedirect Sciencedirect SciencedirectEng BassimNo ratings yet

- Vogel - Qualitative Inorganic Analysis, 5 EdDocument617 pagesVogel - Qualitative Inorganic Analysis, 5 EdThuane SalesNo ratings yet

- Gas Power Cycles Study Guide in Powerpoint: To AccompanyDocument68 pagesGas Power Cycles Study Guide in Powerpoint: To AccompanyexceptionalhighdeeNo ratings yet

- Tropical ClimateDocument4 pagesTropical Climatealiyah khalidNo ratings yet

- Floating FilmDocument13 pagesFloating Filmchittam suvarnaNo ratings yet

- 5questions Cell Membrane and Transport Learn How Transporters Keep Cells HealthyDocument2 pages5questions Cell Membrane and Transport Learn How Transporters Keep Cells HealthyLeanne DerigeNo ratings yet

- Practical Heat Stress Assessment Methods For Use in The UKDocument7 pagesPractical Heat Stress Assessment Methods For Use in The UKmuhammadsuhaibNo ratings yet

- Book Chapter - Measuring Surface Tension and Free Surfce EnergyDocument13 pagesBook Chapter - Measuring Surface Tension and Free Surfce EnergyIhlas AhamedNo ratings yet

- Example 7: Reduced Diesel Fuel and Quake Variation: GRLWEAP Standard ExamplesDocument2 pagesExample 7: Reduced Diesel Fuel and Quake Variation: GRLWEAP Standard ExamplesbozarromegustaNo ratings yet

- LSI Park Avenue Series Brochure 1994Document8 pagesLSI Park Avenue Series Brochure 1994Alan MastersNo ratings yet

- Limate: Download All Ncert Books Pdfs From WWW - Ncert.OnlineDocument16 pagesLimate: Download All Ncert Books Pdfs From WWW - Ncert.OnlineHavyash SharmaNo ratings yet

- Msa20111000007 87029177Document5 pagesMsa20111000007 87029177Mario Misael Machado LòpezNo ratings yet

- Zebra Extend PrintHead LifeDocument3 pagesZebra Extend PrintHead LifeZoltán AntalNo ratings yet

- Lab Heat EnergyDocument8 pagesLab Heat EnergyFaruk IbrahimovicNo ratings yet

- Classical - Electromagnetic.theory Jack VanderlindeDocument7 pagesClassical - Electromagnetic.theory Jack Vanderlindeekosatria0040% (1)

- Bernoulli Equation11 PDFDocument10 pagesBernoulli Equation11 PDFbassam lateefNo ratings yet

- Agarwal-Int J Heat Mass Transfer-2021Document11 pagesAgarwal-Int J Heat Mass Transfer-2021TOufiqueNo ratings yet

- Steel FachaDocument59 pagesSteel FachaviyfNo ratings yet

- HW #6Document2 pagesHW #6c_sierra340% (1)

- Kinetics of Clay DehydrationDocument10 pagesKinetics of Clay DehydrationAnnastacia PrissyliaNo ratings yet

- Current ElectricityDocument70 pagesCurrent ElectricitycodeNo ratings yet

- Dust and Opacity Monitoring Background, Legislation and ComplianceDocument39 pagesDust and Opacity Monitoring Background, Legislation and ComplianceChristianChalcoGonzalesNo ratings yet

- Atmospheric ChemistryDocument44 pagesAtmospheric ChemistryTayyab AkhlassNo ratings yet

- GTS Academy Free Demo Test PDFDocument10 pagesGTS Academy Free Demo Test PDFHallo KhanNo ratings yet

- VSP White Tiger UCP@A - Report - Aug22Document32 pagesVSP White Tiger UCP@A - Report - Aug22Khoa Nguyen MinhNo ratings yet

- Cooling TowersDocument37 pagesCooling TowerssvvsnrajuNo ratings yet

- Recovery of Zinc From DrossDocument3 pagesRecovery of Zinc From DrossBivek SapkotaNo ratings yet

- Mounting LEBW4974-03 PDFDocument52 pagesMounting LEBW4974-03 PDFrilemasfakNo ratings yet