Professional Documents

Culture Documents

145 Air Pipe Sizing

145 Air Pipe Sizing

Uploaded by

Nelson EnviromatchOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

145 Air Pipe Sizing

145 Air Pipe Sizing

Uploaded by

Nelson EnviromatchCopyright:

Available Formats

Technical Bulletin 145

Aeration Pipe Sizes

by:

Environmental Dynamics International

Published: 12/2011

DISCLAIMER

Technical Bulletins are presented as a service by Environmental Dynamics International

headquartered in Columbia, Missouri USA. For additional more information regarding this

particular bulletin or your specific aeration application contact Environmental Dynamics

D

International by calling +1.573.474.9456, toll free at +1.877.EDI.AIR8 (877.334-2478),

(877.334 or

via email at techbulletins@wastewater.com

techbulletins@wastewater.com.

Technical Bulletin 145 – Aeration Pipe Sizing

1

Copyright © Environmental Dynamics International 2012 – All Rights Reserved

TECHNICAL BULLETIN 145 – AERATION PIPE SIZING

For sizing of aeration piping system and the piping system between blowers to the aeration tank it

is important to have rational design criteria to allow economical pipe sizing and efficient pipe sizing.

EDI has established a rational design metho

method d for sizing piping for any type of pipe or any aeration

application to deliver economical operating conditions. The most common criteria to size aeration

piping in the industry is to use one of two methods:

A. Limit the amount of pressure drop per unit of pipe length, i.e. inches of water column or

kPa per 100 feet (30.5m) as an example.

B. Set a maximum air velocity in the piping system, i.e. ft/sec or m/sec.

EDI has reviewed these two design methods and have found the criteria for pressure loss per unit u

of pipe length is the consistent method that can be applied rationally and economically for any pipe

size and any type pipe.. EDI designs are all based on limiting a maximum pressure loss per unit of

piping length for optimum performance.

When designers

ners use air velocities for sizing pipe, the tendency is to specify a maximum allowable

air velocity and apply it in a broad range of pipe diameters. This is not logical and results in

significant and excessive pressure losses in small diameter pipe while offering insignificant or very

minor losses with oversizing in larger diameter pipe, i.e. excessive pipe cost.

The use of air velocity in the design of piping systems is convertible to the pressure loss per unit of

length of piping; however, the air vel

velocity should not remain constant for all diameters of pipe.

pipe If the

air velocity criteria is employed it will demonstrate the pressure loss in small diameter pipe with a

typical engineering velocity specification of 12 meters per second will be as much as three times

the pressure loss per unit of length vs a system that has large diameter pipe with the same velocity

limit of 12 meter per second. An example of this would be appropriate:

Technical Bulletin 145 – Aeration Pipe Sizing

2

Copyright © Environmental Dynamics International 2012 – All Rights Reserved

Example: With a limiting velocity of 12 meters per second, a pipe that is 4 inches in diameter or

approximately 100 mm in diameter in PVC would have a pressure loss of approximately 2.7 inches

of water column per 100 feet (0.67 kPa per 30.5 meters). This is a reasonable pressure loss and is

quite acceptable and typical design criteria for 100 mm diameter pipe.

Now let’s compare this 12 meters per second limitation in a PVC pipe that is 12 inches diameter

(300 mm diameter). Pressure loss in this case is only 0.7 inches per 100 feet (0.17 kPa per 30.5

meters). Larger diameter pipes make velocity losses less significant at the same velocity. For even

larger piping used in air headers the 12 m per sec can be extremely costly.

This demonstrates that using an air velocity that is a constant value does not recognize the

cumulative effects of pressure. Allowing the pressure loss per unit of pipe length to be variable is

costing significant extra capital cost for large piping systems or creating excess pressure loss on

small piping systems. A rational pipe sizing method will recognize pressure losses at any portion of

the system have equal and accumulative impact on blower pressure and energy consumption.

It should also be noted that the use of a single constant design air velocity does not take into

account the material of construction of the piping, i.e. stainless steel versus cast iron pipe, etc. It is

clear that piping systems that use plastic piping or smooth stainless steel have much lower

pressure losses per unit of length than systems that might use cast iron or ductile iron piping. Air

velocity also ignores age or condition of the pipe. Again, the fixed velocity limitation does not

provide for a rational evaluation of all systems.

EDI’s design criteria using pressure limitations

EDI proposes the optimum or economical design of aeration piping and aeration systems will

incorporate a pressure criteria per unit length of air piping. This takes full account of the effect of

diameter on pressure loss, plus it can take into account any roughness, coefficient, or pipe

characteristics that are involved on any project. This is a universal and rational design procedure

and has used successfully by EDI for over 20 years. EDI generally employs criteria limiting

pressure loss in the piping to approximately 3 inches water column per 100 feet (0.75 kPa per 30.5

meters)! This criteria can be applied to any type pipe, any size pipe, and give a economical capital

cost and a low operating cost system. This criteria is consistently applied to assign equal weight to

all pressure losses in the aeration system piping.

Technical Bulletin 145 – Aeration Pipe Sizing

3

Copyright © Environmental Dynamics International 2012 – All Rights Reserved

With the EDI rational design method, consistent or rational design velocities for aeration piping

range from 8 m/sec for 2 inch (DN 50) pipe to over 27m/sec for 12 inch diameter (DN300) pipe

when limiting loss to 3 inch wc/100 ft (0.75kPa/3.05m).

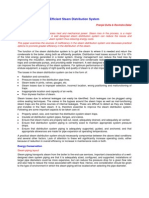

EDI uses a computer analysis to calculate pressure losses and pipe sizes accurately; however it is

possible to create a guideline chart for selection of pipe diameters. The attached chart provides an

EDI guideline of the maximum m design air handling capacity for satisfactory plastic or stainless steel

pipe systems in any aeration application. As a companion, the chart also includes the approximate

velocity allowed in feet per second and meters per second for this 3 inch wc/100 fftt economical and

consistent pressure loss design basis.

IPS Pipe Metric Pipe

Typical

Recommended Typical Airflow Headloss Velocity* Recommended Airflow Headloss Velocity*

Pipe Size (in) Limit (scfm) (in W.C./100 ft) (ft/sec) Pipe Size (mm) Limit (Sm3/h) (kPa/30.5 m) (m/sec)

2 40 3.0 26.3 50 mm 68 0.75 8.0

3 120 3.0 34.5 90 mm 204 0.75 10.5

4 250 3.0 42.1 110 mm 425 0.75 12.8

6 750 3.0 56.7 150 mm 1274 0.75 17.3

8 1550 3.0 68.3 200 mm 2633 0.75 20.8

10 2850 3.0 80.2 250 mm 4842 0.75 24.4

12 4500 3.0 89.6 300 mm 7646 0.75 27.3

* Based on Sch10 SS piping.

For other material - wall thickness and roughness coefficient variables must be considered.

Technical Bulletin 145 – Aeration Pipe Sizing

4

Copyright © Environmental Dynamics International 2012 – All Rights Reserved

You might also like

- Compressed Air Distribution SystemsDocument5 pagesCompressed Air Distribution SystemsVarrit VejpongsaNo ratings yet

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Transformation Leadership in A Digital Era: EY StrategyDocument24 pagesTransformation Leadership in A Digital Era: EY StrategyakashNo ratings yet

- Piping System DesignDocument66 pagesPiping System DesignChinmoy12533995100% (2)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Arc Flash Protection Goggle W/ Nose Shield. ATPV 12 Calories. Product DetailsDocument1 pageArc Flash Protection Goggle W/ Nose Shield. ATPV 12 Calories. Product DetailsFabiánArcos100% (1)

- Normal DistributionDocument43 pagesNormal Distributionkrystel basaNo ratings yet

- AL Problem Solving Process Manual - Updated 10 - May 2016Document74 pagesAL Problem Solving Process Manual - Updated 10 - May 2016Akshi Karthikeyan100% (1)

- Design of Duct For A Two Storey Retail Shop 30-1-2017Document5 pagesDesign of Duct For A Two Storey Retail Shop 30-1-2017Mir Aqueel AliNo ratings yet

- Chapter 3 - PlumbingDocument8 pagesChapter 3 - PlumbingPrabhakaran DakshinNo ratings yet

- IEICOS Wind Tunnel Catalog 2012Document8 pagesIEICOS Wind Tunnel Catalog 2012cparamesNo ratings yet

- Apie Plastikini Vamzdyna CPDModuleOct07entireDocument3 pagesApie Plastikini Vamzdyna CPDModuleOct07entirestarykltNo ratings yet

- Ubbink Air Excellent BrochureDocument24 pagesUbbink Air Excellent BrochureRazvan AlexandrescuNo ratings yet

- Efficient Pneumatic ConveyingDocument14 pagesEfficient Pneumatic Conveying설동하100% (2)

- Pipeline Hydraulic Design Lec5Document25 pagesPipeline Hydraulic Design Lec5Kokab AzazNo ratings yet

- Pipeline DesignDocument60 pagesPipeline DesignEduardo Paulini Villanueva0% (1)

- Reasonable VelocityDocument4 pagesReasonable VelocityRaithab IlsurNo ratings yet

- Pipeline Design and Selection. Optimum Pipeline DiameterDocument23 pagesPipeline Design and Selection. Optimum Pipeline DiameterProcessing Maintenance 1No ratings yet

- Force Main SewersDocument8 pagesForce Main SewersljupkaNo ratings yet

- Modeling and Simulation of Duct Routing System Using Equal Friction MethodDocument38 pagesModeling and Simulation of Duct Routing System Using Equal Friction MethodSai Ram PrabhakarNo ratings yet

- Ventilation of Long TunnelsDocument13 pagesVentilation of Long TunnelsClifford Allen CooperNo ratings yet

- A1200 Red Thread II PipingDocument0 pagesA1200 Red Thread II PipingjimmycabreraNo ratings yet

- DuctworkDocument12 pagesDuctworkNiong David100% (1)

- Compressed Air Systems PipingDocument5 pagesCompressed Air Systems PipingAnonymous DJrec250% (2)

- AC Duct Design PDFDocument6 pagesAC Duct Design PDFkumar123rajuNo ratings yet

- Efficient Steam Distribution SystemDocument8 pagesEfficient Steam Distribution Systempavan_chinta_2No ratings yet

- Pipes and Pipe SizingDocument22 pagesPipes and Pipe SizingAhmed Abo RashedNo ratings yet

- Compressed Piping Related Docs - 1Document5 pagesCompressed Piping Related Docs - 1Ashik HasanNo ratings yet

- Pipeline Hydroulic Design Lec 1Document32 pagesPipeline Hydroulic Design Lec 1Kokab AzazNo ratings yet

- AED Design Requirements - Water Tanks and System Distribution - Sep09 PDFDocument23 pagesAED Design Requirements - Water Tanks and System Distribution - Sep09 PDFAvonodOiratulcNo ratings yet

- Sanitaire Difussers AerationDocument16 pagesSanitaire Difussers Aerationxbelda5041No ratings yet

- Pipe Flow Measurement - Orifice Plates - IsO 5167-3, BS 1042-1-1.2 and ASME MFC-3MDocument7 pagesPipe Flow Measurement - Orifice Plates - IsO 5167-3, BS 1042-1-1.2 and ASME MFC-3Msowman tungNo ratings yet

- Paxtonengineeringbulletin PipingDocument4 pagesPaxtonengineeringbulletin PipingMuhammadObaidullahNo ratings yet

- Assignment Fluid Mechanics LastDocument15 pagesAssignment Fluid Mechanics Lastizzatamirul1010No ratings yet

- Sizing DuctsDocument41 pagesSizing DuctsSergio Semm100% (1)

- Design of Duct For A Three Storey Retail ShopDocument4 pagesDesign of Duct For A Three Storey Retail ShopAnonymous CUPykm6DZNo ratings yet

- PIM300 Piping System Design PDFDocument66 pagesPIM300 Piping System Design PDFmika cabelloNo ratings yet

- Determination of Maximum Span Between Pipe SupportsDocument3 pagesDetermination of Maximum Span Between Pipe SupportsrockieballNo ratings yet

- Piping Design - Unit 3 & 4Document125 pagesPiping Design - Unit 3 & 4Abhay RajputNo ratings yet

- Steam Pipe CalculationDocument22 pagesSteam Pipe CalculationNallathambiNo ratings yet

- Compressed Air Pipe SystemDocument9 pagesCompressed Air Pipe Systemkeanncruz100% (1)

- ABTG Aeration EngineeringDocument2 pagesABTG Aeration EngineeringChris ClayburnNo ratings yet

- Duct & Vent EngineeringDocument70 pagesDuct & Vent Engineeringtop20202080% (5)

- Spraying Solutions: Evaporative Cooling: Two Options Atomising Nozzles Over High Pressure Hydraulic Nozzles?Document4 pagesSpraying Solutions: Evaporative Cooling: Two Options Atomising Nozzles Over High Pressure Hydraulic Nozzles?Francois HamiauxNo ratings yet

- Piping, Fittings, and ValvesDocument9 pagesPiping, Fittings, and Valvesaasatti100% (1)

- DIPRA Hydraulic Analysis of DI PipeDocument8 pagesDIPRA Hydraulic Analysis of DI Pipehussien_azahariNo ratings yet

- Metering and Regulating StationsDocument9 pagesMetering and Regulating StationsBeatriz Adams Garcia100% (2)

- Mechatronic Design of Digital Hydraulic Micro Valve Package: SciencedirectDocument11 pagesMechatronic Design of Digital Hydraulic Micro Valve Package: SciencedirectbrgrNo ratings yet

- 2nd Lab FLUIDSDocument6 pages2nd Lab FLUIDSMuhammadZAmjadNo ratings yet

- Pipeline Sizing: Learning ObjectivesDocument7 pagesPipeline Sizing: Learning Objectivesbikas_sahaNo ratings yet

- AD01166M NUFLO Liquid Turbine Flow Meters Data SheetDocument8 pagesAD01166M NUFLO Liquid Turbine Flow Meters Data SheetsarkaftNo ratings yet

- Flowtite Product Guide 2010Document28 pagesFlowtite Product Guide 2010Anonymous 87xpkIJ6CFNo ratings yet

- Spe 120632 MS PDocument0 pagesSpe 120632 MS PMagaña AuryNo ratings yet

- Air Distribution Systems GuideDocument3 pagesAir Distribution Systems GuidejchuatsonNo ratings yet

- Flow Assurance Nov6Document5 pagesFlow Assurance Nov6Vinh PhamthanhNo ratings yet

- BE ProdBulletin AD1250AirMeasDocument6 pagesBE ProdBulletin AD1250AirMeasMaria Gabriela BusteloNo ratings yet

- PPR-C Pipe SpecificationDocument25 pagesPPR-C Pipe SpecificationAlex Dulay85% (13)

- Qualification of FlexibleDocument10 pagesQualification of FlexibleAFZAL M BAKSHINo ratings yet

- Piping DesignDocument9 pagesPiping Designjmclaug502No ratings yet

- Process Equipment Design (Pinoy Edition)Document40 pagesProcess Equipment Design (Pinoy Edition)Rachel HechanovaNo ratings yet

- The Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationFrom EverandThe Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationRating: 1 out of 5 stars1/5 (1)

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- SECOND Semester, AY 2022-2023: Mission VisionDocument34 pagesSECOND Semester, AY 2022-2023: Mission Visionjeyyy BonesssNo ratings yet

- Hydrology2B (HYOCIB2) Department: Civil Engineering Technology Programme: Bachelor of Engineering Technology (BET) : CivilDocument14 pagesHydrology2B (HYOCIB2) Department: Civil Engineering Technology Programme: Bachelor of Engineering Technology (BET) : CivilnickyNo ratings yet

- Laudon Traver Ec16 PPT Ch09 Accessible 26022023 080617pmDocument49 pagesLaudon Traver Ec16 PPT Ch09 Accessible 26022023 080617pmGreson JamesNo ratings yet

- Contemporary Issues On Cash Waqf: A Review of The LiteratureDocument26 pagesContemporary Issues On Cash Waqf: A Review of The LiteratureSharifah NurulhudaNo ratings yet

- Ge MMWDocument7 pagesGe MMWJunjie Dela RamosNo ratings yet

- PCUPDocument6 pagesPCUPBonn PustaNo ratings yet

- Solutions To Homework 7oDocument5 pagesSolutions To Homework 7ojcvoscribNo ratings yet

- 02 Security Market Indices and Market Efficiency PDFDocument27 pages02 Security Market Indices and Market Efficiency PDFNgân Hà NguyễnNo ratings yet

- MKT 460.6 Final AssignmentDocument93 pagesMKT 460.6 Final AssignmentSirajis SalekinNo ratings yet

- TDS EN PluxbentonN PDFDocument1 pageTDS EN PluxbentonN PDFusr1suNo ratings yet

- IOT Notes AllUnits PDFDocument50 pagesIOT Notes AllUnits PDFSuganthi Ravindren100% (1)

- KBT65DP15 15RT0Document1 pageKBT65DP15 15RT0Andre LanaNo ratings yet

- Applications of SolaviteDocument2 pagesApplications of SolaviteWorkshopNo ratings yet

- Me Market-StructureDocument3 pagesMe Market-Structurebenedick marcialNo ratings yet

- Rights in Land and Pattadar Pass Books Rules 1989Document42 pagesRights in Land and Pattadar Pass Books Rules 1989raju634No ratings yet

- Explained - Hydrophobic and HydrophilicDocument2 pagesExplained - Hydrophobic and HydrophilicSiddhartha Narasimha Reddy MNo ratings yet

- Legal Brief - MetahumansDocument3 pagesLegal Brief - MetahumansEver Alcazar50% (2)

- 096 Floor Statement On Presidents Decision To Increase Troops in Iraq Obama SpeechDocument3 pages096 Floor Statement On Presidents Decision To Increase Troops in Iraq Obama SpeechDivya Deepika MaddireddyNo ratings yet

- 000000000001001849Document544 pages000000000001001849Dante Filho100% (1)

- Sap 1Document51 pagesSap 1muneebNo ratings yet

- Case Digest in Tax Review-Income TaxDocument7 pagesCase Digest in Tax Review-Income TaxMaria Salee MoraNo ratings yet

- Bolivia - Bilateral Relations: GeneralDocument11 pagesBolivia - Bilateral Relations: Generalbansalanuj24No ratings yet

- Safari BagDocument1 pageSafari BagZikoNo ratings yet

- Final Project MrunalDocument53 pagesFinal Project MrunalPravin RamtekeNo ratings yet

- Define National Income Eco415Document3 pagesDefine National Income Eco415aishahNo ratings yet

- Duolingo 50 Words Essay Questions and AnswerDocument7 pagesDuolingo 50 Words Essay Questions and AnswerMaria AgnesNo ratings yet