Professional Documents

Culture Documents

ASTMC14M

ASTMC14M

Uploaded by

eng.usmanali2012Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ASTMC14M

ASTMC14M

Uploaded by

eng.usmanali2012Copyright:

Available Formats

Designation: C 14M – 04

METRIC

Standard Specification for

Concrete Sewer, Storm Drain, and Culvert Pipe [Metric]1

This standard is issued under the fixed designation C 14M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope C 822 Terminology Relating to Concrete Pipe and Related

1.1 This specification covers nonreinforced concrete pipe Products

intended to be used for the conveyance of sewage, industrial C 1116 Specification for Fiber-Reinforced Concrete and

--````,`-`-`,,`,,`,`,,`---

wastes, storm water, and for the construction of culverts. Shotcrete

1.2 This specification is the metric counterpart of Specifi- 3. Terminology

cation C 14.

3.1 Definitions of Terms Specific to This Standard—For

NOTE 1—This specification is a manufacturing and purchase specifica- definitions of terms relating to concrete pipe, see Terminology

tion only and does not include requirements for bedding, backfill, or the

C 822.

relationship between field load condition and the strength classification of

pipe. However, experience has shown that the successful performance of 4. Classification

this product depends upon the proper selection of the class of pipe, type

of bedding and backfill, and care that the installation conforms to the 4.1 Pipe manufactured according to this specification shall

construction specifications. The owner is cautioned that he must correlate be of three classes identified as “Class 1 Nonreinforced

the field requirements with the class of pipe specified and provide for or Concrete Pipe,” “Class 2 Nonreinforced Concrete Pipe,” and

require inspection at the construction site. “Class 3 Nonreinforced Concrete Pipe.” The corresponding

2. Referenced Documents 2 strength requirements are prescribed in Table 1.

2.1 ASTM Standards: 5. Basis of Acceptance

C 33 Specification for Concrete Aggregates 5.1 The acceptability of the pipe shall be determined by the

C 150 Specification for Portland Cement results of the test prescribed in this section, when required, and

C 309 Specification for Liquid Membrane-Forming Com- by inspection to determine whether the pipe conforms to this

pounds for Curing Concrete specification as to design and freedom from defects.

C 443M Specification for Joints for Circular Concrete 5.2 Acceptance as to Strength Properties—Pipe shall be

Sewer and Culvert Pipe, Using Rubber Gaskets [Metric] acceptable under the strength tests when they have met the

C 497M Test Methods for Concrete Pipe, Manhole Sec- requirements as prescribed in 10.3.

tions, or Tile [Metric] 5.3 Acceptance as to Absorption Properties—Pipe shall be

C 595 Specification for Blended Hydraulic Cements acceptable under the absorption test when they have met the

C 618 Specification for Coal Fly Ash and Raw or Calcined requirements as prescribed in 10.4.

Natural Pozzolan for Use as a Mineral Admixture in 5.4 Acceptance as to Permeability Properties—Pipe shall

Concrete be acceptable under the permeability test when they have met

the requirements as prescribed in 10.5.

1

This specification is under the jurisdiction of ASTM Committee C13 on NOTE 2—Prior to purchase, the owner has the option to specify the

Concrete Pipe and is the direct responsibility of Subcommittee C13.01 on hydrostatic test prescribed in 10.6 instead of the permeability test.

Reinforced Concrete Sewer, Drain, and Irrigation Pipe.

Current edition approved April 1, 2004. Published May 2004. Originally 5.5 Acceptance as to Hydrostatic Properties—Pipe shall be

approved in 1980. Last previous edition approved in 2003 as C 14M – 03. acceptable under the hydrostatic test when they have met the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or requirements as prescribed in 10.6.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Copyright ASTM International 1

Reproduced by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

C 14M – 04

TABLE 1 Physical and Dimensional Requirements for Nonreinforced Concrete PipeA

Class 1 Class 2 Class 3

Minimum Minimum Minimum

Internal Designated Minimum Strength, kN/ Minimum Strength, kN/ Minimum Strength, kN/

Diameter, mm Thickness of linear m, Thickness of linear m, Thickness of linear m,

Wall, mm Three-Edge Wall, mm Three-Edge Wall, mm Three-Edge

Bearing Bearing Bearing

100 16 22.0 19 29.0 19 35.0

150 16 22.0 19 29.0 22 35.0

200 19 22.0 22 29.0 29 35.0

250 22 23.5 25 29.0 32 35.0

300 25 26.5 35 33.0 44 38.0

375 32 29.0 41 38.0 47 42.0

450 38 32.0 50 44.0 57 48.0

525 44 35.0 57 48.0 69 56.0

600 54 38.0 75 52.5 85 64.0

675 82 41.0 94 57.5 94 67.0

750 88 44.0 107 63.0 107 69.5

825 94 46.0 113 64.0 113 71.0

900 100 48.0 119 65.5 119 73.0

A

Subject to tolerance in Section 11.

6. Materials 8. Joints

6.1 Concrete—The concrete shall consist of cementitious 8.1 The joints shall be of such design and the ends of the

materials, mineral aggregates, and water. concrete pipe sections so formed, that the pipe can be laid

6.2 Cementitious Materials: together to make a continuous line of pipe compatible with the

6.2.1 Cement—Cement shall conform to the requirements permissible variations given in Section 11.

for portland cement of Specification C 150 or shall be portland

blast-furnace slag cement or portland-pozzolan cement con- 9. Manufacture

forming to the requirements of Specification C 595, except that

9.1 Mixture—The aggregates shall be sized, graded, propor-

the pozzolan constitutient in the Type IP portland-pozzolan

tioned, and mixed with such proportions of cementitious

cement shall be fly ash.

materials and water as will produce a homogeneous concrete

6.2.2 Fly Ash—Fly ash shall conform to the requirements of

mixture of such quality that the pipe will conform to the test

Specification C 618, Class F or Class C.

and design requirements of this specification. All concrete shall

6.2.3 Allowable Combinations of Cementitious Materials—

have a water-cementitious materials ratio not exceeding 0.53

The combination of cementitious materials used in the concrete

by weight. Cementitious materials shall be as specified in 6.2

shall be one of the following:

and shall be added to the mix in a proportion not less than 280

6.2.3.1 Portland cement only,

kg/m3 unless mix designs with a lower cementitious materials

6.2.3.2 Portland blast furnace slag cement only,

content demonstrate that the quality and performance of the

6.2.3.3 Portland pozzolan cement only, or

pipe meet the requirements of this specification.

6.2.3.4 A combination of portland cement and fly ash.

6.3 Aggregates—Aggregates shall conform to Specification 9.2 Curing—Pipe shall be subjected to any one of the

C 33, except that the requirement for gradation shall not apply. methods of curing described in 9.2.1 through 9.2.4 or to any

6.4 Admixtures and Blends—Admixtures and blends shall other method or combination of methods approved by the

only be used with the approval of the owner. owner that will give satisfactory results. The pipe shall be

6.5 Synthetic Fibers—Collated fibrillated virgin polypropy- adequately cured to obtain the strength properties as prescribed

lene fibers are permitted in concrete pipe as a nonstructural in 5.2.

manufacturing material. Only Type III synthetic fibers de- 9.2.1 Steam Curing—Pipe shall be placed in a curing

signed and manufactured specifically for use in concrete and chamber, free from outside drafts, and cured in a moist

conforming to the requirements of Specification C 1116 shall atmosphere maintained by the injection of steam for such time

be accepted. and such temperature as needed to enable the pipe to meet the

strength requirements. The curing chamber shall be so con-

7. Design structed as to allow full circulation of steam around the entire

7.1 Design Tables—Design requirements shall be in accor- pipe.

dance with Table 1. Wall thickness used shall be not less than 9.2.2 Water Curing—Concrete pipe shall be water-cured by

the value shown, except as affected by the tolerance herein covering with water-saturated material or by a system of

specified and by the provision for modified design. perforated pipes, mechanical sprinklers, porous hose, or by any

7.2 Modified or Special Design—Manufacturers shall sub- other approved method that will keep the pipe moist during the

mit to the owner for approval, prior to manufacture, wall specified curing period.

thicknesses other than those shown in Table 1. Such pipe shall 9.2.3 The manufacturer is not prohibited from combining

meet all of the physical requirements listed in Section 10 that the methods described in 9.2.1 and 9.2.2 provided the specified

are specified by the owner. strength is attained.

--````,`-`-`,,`,,`,`,,`---

Copyright ASTM International 2

Reproduced by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

C 14M – 04

9.2.4 Membrane Curing—A sealing membrane conforming The number of absorption test specimens shall be equal to the

to the requirements of Specification C 309 is not prohibited number of pipe provided for crushing strength testing. These

from being applied and left intact until the specified strength specimens shall be obtained from pipe that are acceptable as to

requirements are met. The concrete at the time of application strength, and shall be taken from pipe used in making the

shall be within 6°C of the atmospheric temperature. All strength test after the test is made. These specimens shall be

--````,`-`-`,,`,,`,`,,`---

surfaces shall be kept moist prior to the application of the marked with the number or identification mark of the pipe from

compounds and shall be damp when the compound is applied. which they were taken. Each Test Method A specimen shall

9.3 Specials: have an area of 77 to 129 cm2, as measured on one surface of

9.3.1 General Requirements—Special shapes or fittings the pipe, and a thickness equal to the pipe wall, and shall be

such as wyes, tees, bends, and adapters for use with concrete free of visible cracks. Pipe shall be acceptable when all test

pipe conforming to this specification shall conform to the pipe conform to the specified absorption requirements.

applicable requirements for concrete pipe of corresponding 10.5 Permeability Requirement—When subjected to the

class and internal diameter. Joints shall be compatible with permeability test, as specified in Test Methods C 497M, the

those used in adjoining concrete pipes. outer pipe surface of not less than 80 % of the pipe tested shall

9.3.2 Fabricated Branches—Fabricated branches for wyes show no moist or damp spots at the end of the test period due

and tees shall be securely attached to the wall of the pipe in to water passing through the walls of the pipe.

such a manner as not to restrict or otherwise interfere with the 10.6 Hydrostatic Requirement—When subjected to the hy-

flow characteristics of the pipe. drostatic test, as described in Test Methods C 497M, the pipe

shall show no leakage during 10 min at 70 kPa. Moisture

10. Physical Requirements appearing on the surface of the pipe in the form of patches or

10.1 Test Specimen—The specified number of pipe required beads adhering to the surface shall not be considered leakage.

for the tests shall be furnished by the manufacturer and shall be The test pipe shall be filled with water and held under 70 kPa

selected at random by the owner, and shall be pipe that would pressure for 24 h prior to the test, except that the manufacturer

not otherwise be rejected under this specification. The selection is not prohibited from reducing this presoak time or pressure,

shall be made at the point or points designated by the owner or both. The manufacturer is not prohibited from continuing

when placing the order. The test pipe shall first be freed from this test up to 24 h, and the pipe will be considered to have

all visible moisture. When dry, each pipe shall be measured and passed when, during any 10-min period, no leakage is ob-

inspected. The results of these observations shall be recorded. served. When the hydrostatic requirement is used for accep-

10.2 Number and Type of Test Specimens Required—The tance of the pipe joint as specified in Section 10 of Specifica-

manufacturer or seller shall furnish pipe for crushing and tion C 443M, it is not prohibited to use the same joint test runs

absorption tests, up to 0.5 % of the number of pipe of each size as the basis of acceptance for pipe hydrostatic requirements in

included in the order, except that in no case shall less than two accordance with 5.5 and 10.6 of this specification.

pipe be furnished. For the permeability test, 2 % of the number 10.7 Retest—Should more than 20 % of the samples fail to

of pipe of each size included in the order, but in no case less meet the specified requirements for the permeability or not

than two pipe shall be furnished. For the hydrostatic test, 0.5 % more than 20 % of the samples fail to meet the specified

of the number of pipe of each size included in the order, but in requirement for absorption or hydrostatic requirements of this

no case less than two pipe shall be furnished. section, it is not prohibited for the manufacturer to cull his

10.3 External Load Crushing Requirement—The crushing stock and may eliminate whatever any of pipe and must so

strength of nonreinforced concrete pipe shall conform to the mark those pipe that will not be shipped. The required tests

requirements prescribed in Table 1. The individual results of shall be made on the balance of the order and they are

the various tests for each size of pipe and for each shipment acceptable if they conform to the specified requirements. If the

and plant shall be tabulated separately. The crushing strength second sample fails to meet the specified requirements, the

shall ordinarily be applied to not less than 75 % of the pipe whole lot is subject to rejection.

received for purpose of test. All tests shall be made in

accordance with Test Method C 497M. Pipe shall be acceptable 11. Dimensions and Permissible Variations

when all test pipe conform to the specified requirement. Should 11.1 Sizes and Dimensions—Pipe shall be furnished of the

any of the test pipe provided in 10.2 fail to meet the strength sizes, internal diameters, and dimensions prescribed in Table 1.

requirement, the manufacturer will be allowed to test two pipe 11.2 Permissible Variations in Dimensions—Permissible

for each pipe that failed, and the pipe shall be acceptable only variations in dimensions shall be limited to the following:

when all of these additional test pipe meet the strength 11.2.1 Internal Diameter—See Table 2. At the manufactur-

requirement. er’s option, the internal diameter shall be one of two alterna-

10.4 Absorption Requirement—When required by the tives, the Designated Diameter or the Converted English

owner, an absorption test shall be performed by either Test Diameter. Pipe sections that are intended to be jointed to each

Method A or Test Method B in accordance with Test Methods other shall be furnished with the same internal diameter

C 497M for the boiling absorption test. Absorption shall not alternative. The internal diameter of pipe manufactured to the

exceed 9 % for Test Method A or 8.5 % for Test Method B. The Designated Diameters shall vary from the Designated Diameter

individual results of the various tests for each size of pipe and not more than 65 mm for 300 mm pipe and smaller, 67 mm

for each shipment and plant shall be tabulated separately. All for 375 mm to 450 mm pipe, 68 mm for 525 mm pipe, and

tests shall be made in accordance with Test Methods C 497M. 610 mm for 600 mm pipe and larger. The internal diameter of

Copyright ASTM International 3

Reproduced by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

C 14M – 04

TABLE 2 Internal Diameters 13. Inspection

Designated Equivalent English Converted English 13.1 The quality of all materials and the finished pipe shall

Diameter, mm Diameter, in Diameter, mm

be subject to inspection and approval by the owner. Such

100 4 102

150 6 152

inspection shall be performed either at the point of manufacture

200 8 203 or delivery, or both. The method of marking as to acceptance or

250 10 254 rejection of pipe shall be agreed upon, prior to inspection,

300 12 305

375 15 381

between the owner and the manufacturer. Rejected pipe shall

450 18 457 be replaced by the manufacturer with pipe that meets the

525 21 533 requirements of this specification.

600 24 610

675 27 686 14. Rejection

750 30 762

825 33 838 14.1 Pipe shall be subject to rejection on account of failure

900 36 914

to conform to any of the specification requirements. This

specification is a manufacturing and purchase specification

only. Therefore, damage to pipe during installation or caused

pipe manufactured to the Converted English Diameters shall by field loading in the installed condition shall not be cause for

vary from the Converted English Diameter not more than 65 rejection on the basis of not meeting this specification. Indi-

mm for 305 mm pipe and smaller, 67 mm for 381 mm to 457 vidual sections of pipe are subject to rejection because of any

mm pipe, 68 mm for 533 mm pipe, and 610 mm for 610 mm of the following:

pipe and larger. For pipe manufactured to Converted English 14.1.1 Fractures or cracks passing through the wall or joints,

Diameters, the corresponding Designated Diameter shown in except that a single crack not exceeding 50 mm in length at

Table 2 shall apply for all other requirements of this specifi- either end of a pipe or a single fracture or spall in the joints not

cation. exceeding 75 mm around the circumference of the pipe nor 50

11.2.2 Thickness of Wall—The wall thickness shall be not mm in length into joint shall not be considered cause for

less than the values shown in Table 1 or the manufacturer’s rejection unless these defects exist in more than 5 % of the

designated thickness if greater than shown in Table 1 by more entire shipment or delivery.

than 2 mm for pipe 250 mm or less in diameter; by more than 14.1.2 The planes of the ends of the pipe are not perpen-

3 mm for pipe 300 to 600 mm in diameter; and by more than dicular to the longitudinal axis, subject to the limits of variation

5 mm for pipe more than 600 mm in diameter; or by more than as shown in 11.2.4.

5 % of the tabulated or designated wall thickness, whichever is 14.1.3 Defects that indicate mixing and molding not in

greater. Localized variations in wall thickness exceeding those accordance with 9.1.

specified above shall be accepted if the physical test require- 14.1.4 Cracks sufficient to impair the strength, durability, or

ments specified herein are met. serviceability of the pipe.

11.2.3 Length—The length of any section of pipe shall vary

not more than − 13 mm from a specified or designated design 15. Product Marking

length. 15.1 The following information shall be legibly marked on

11.2.4 Length of Two Opposite Sides—The length of two each pipe:

opposite sides of any section of pipe shall vary not more than 15.1.1 The pipe class and specification designation,

6 mm or 2 % of the designated diameter, whichever is larger. 15.1.2 The date of manufacture.

11.2.5 Straightness—Pipe intended to be straight shall not 15.1.3 The name or trademark of the manufacturer, and

vary in alignment more than 10 mm/m of length. 15.1.4 Identification of the plant.

15.2 Marking shall be indented on the pipe section or

12. Repairs painted thereon with waterproof paint.

--````,`-`-`,,`,,`,`,,`---

12.1 Pipe repaired because of imperfections in manufacture

or damage during handling are acceptable if, in the opinion of 16. Keywords

the owner, the repaired pipe conforms to the requirements of 16.1 concrete sewer; culvert; nonreinforced; pipe; storm

this specification. drain

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

Copyright ASTM International 4

Reproduced by IHS under license with ASTM

No reproduction or networking permitted without license from IHS Not for Resale

You might also like

- Astm C825Document3 pagesAstm C825ivan_cm17100% (3)

- Astm C 76-00 PDFDocument11 pagesAstm C 76-00 PDFbladiNo ratings yet

- C 76M - 15 PDFDocument11 pagesC 76M - 15 PDFIan TumulakNo ratings yet

- Astm C14Document4 pagesAstm C14Julio Demer100% (1)

- Concrete Construction Article PDF - Using The New ACI 301Document3 pagesConcrete Construction Article PDF - Using The New ACI 301NoNa Mohammed0% (1)

- Mathcad - 21-Design of StairDocument3 pagesMathcad - 21-Design of StairMrAlittle FingerNo ratings yet

- Types of Portland CementDocument5 pagesTypes of Portland CementBrian Kaile Garma100% (1)

- Flat Slab Design ExampleDocument5 pagesFlat Slab Design ExampleKong SooYit58% (12)

- Nonreinforced Concrete Sewer, Storm Drain, and Culvert Pipe: Standard Specification ForDocument4 pagesNonreinforced Concrete Sewer, Storm Drain, and Culvert Pipe: Standard Specification Forsharon blushteinNo ratings yet

- E-Cld-3002 - Astm C-14Document5 pagesE-Cld-3002 - Astm C-14Andre FarfanNo ratings yet

- C14MDocument5 pagesC14Msharon blushteinNo ratings yet

- C 14M - 03 - Qze0tqDocument4 pagesC 14M - 03 - Qze0tqEmre DalgicNo ratings yet

- C014M PDFDocument4 pagesC014M PDFleo_pio_ochoaNo ratings yet

- Nonreinforced Concrete Sewer, Storm Drain, and Culvert Pipe (Metric)Document5 pagesNonreinforced Concrete Sewer, Storm Drain, and Culvert Pipe (Metric)VictorAndresMillaSalazarNo ratings yet

- Nonreinforced Concrete Sewer, Storm Drain, and Culvert Pipe (Metric)Document5 pagesNonreinforced Concrete Sewer, Storm Drain, and Culvert Pipe (Metric)Ahmad Zubair RasulyNo ratings yet

- Astm C14 PDFDocument4 pagesAstm C14 PDFBrahim Rabaj0% (1)

- Reinforced Concrete D-Load Culvert, Storm Drain, and Sewer PipeDocument6 pagesReinforced Concrete D-Load Culvert, Storm Drain, and Sewer Pipekevin.platinium23No ratings yet

- Astm C 76 - 99Document11 pagesAstm C 76 - 99LNo ratings yet

- Reinforced Concrete Culvert, Storm Drain, and Sewer Pipe: Standard Specification ForDocument11 pagesReinforced Concrete Culvert, Storm Drain, and Sewer Pipe: Standard Specification ForDalberto RamirezNo ratings yet

- C14.1265935-1-Nonreinforce Concrete Sewer, CulvertDocument4 pagesC14.1265935-1-Nonreinforce Concrete Sewer, Culvertphett sopanhchaknaNo ratings yet

- Reinforced Concrete Culvert, Storm Drain, and Sewer Pipe (Metric)Document11 pagesReinforced Concrete Culvert, Storm Drain, and Sewer Pipe (Metric)Cris BandaNo ratings yet

- Nonreinforced Concrete Sewer, Storm Drain, and Culvert Pipe: Standard Specification ForDocument5 pagesNonreinforced Concrete Sewer, Storm Drain, and Culvert Pipe: Standard Specification ForAdeel FaisalNo ratings yet

- Reinforced Concrete Culvert, Storm Drain, and Sewer Pipe (Metric)Document11 pagesReinforced Concrete Culvert, Storm Drain, and Sewer Pipe (Metric)Việt VũNo ratings yet

- Astm C76MDocument11 pagesAstm C76MPedro Henrry Marza ColqueNo ratings yet

- ASTM C506-08a Reinforced Concrete Arch Culvert, Storm Drain, and Sewer PipeDocument7 pagesASTM C506-08a Reinforced Concrete Arch Culvert, Storm Drain, and Sewer PipeLiu ZhenguoNo ratings yet

- Precast Reinforced Concrete Monolithic Box Sections For Culverts, Storm Drains, and SewersDocument25 pagesPrecast Reinforced Concrete Monolithic Box Sections For Culverts, Storm Drains, and SewersSadique K Muhammed100% (1)

- ASTMC76MDocument11 pagesASTMC76Meng.usmanali2012No ratings yet

- C76M 14Document11 pagesC76M 14diego rodriguezNo ratings yet

- C14M.1265935-1-Nonreinforce Concrete Storm Drain PDFDocument5 pagesC14M.1265935-1-Nonreinforce Concrete Storm Drain PDFphett sopanhchaknaNo ratings yet

- ASTM C1433M 07aDocument10 pagesASTM C1433M 07aEyas hamadNo ratings yet

- Nonreinforced Concrete Sewer, Storm Drain, and Culvert Pipe: Standard Specification ForDocument5 pagesNonreinforced Concrete Sewer, Storm Drain, and Culvert Pipe: Standard Specification ForRobbi Shobri RakhmanNo ratings yet

- C507Document9 pagesC507sameh emaryNo ratings yet

- ASTM C 14M - 15aDocument5 pagesASTM C 14M - 15aBambang Kardito100% (1)

- Reinforced Concrete Elliptical Culvert, Storm Drain, and Sewer Pipe (Metric)Document10 pagesReinforced Concrete Elliptical Culvert, Storm Drain, and Sewer Pipe (Metric)Materiales FicNo ratings yet

- Reinforced Concrete Culvert, Storm Drain, and Sewer Pipe: Standard Specification ForDocument11 pagesReinforced Concrete Culvert, Storm Drain, and Sewer Pipe: Standard Specification Forkevin.platinium23No ratings yet

- Reinforced Concrete Culvert, Storm Drain, and Sewer Pipe (Metric)Document11 pagesReinforced Concrete Culvert, Storm Drain, and Sewer Pipe (Metric)irfanquadriNo ratings yet

- Steel Fiber Reinforced Concrete Culvert, Storm Drain, and Sewer PipeDocument6 pagesSteel Fiber Reinforced Concrete Culvert, Storm Drain, and Sewer PipeEligio Antonio CerdaNo ratings yet

- Astm C 76-19Document12 pagesAstm C 76-19Carlos Manuel Ampié BerriosNo ratings yet

- M242MDocument5 pagesM242MFRANZ RICHARD SARDINAS MALLCONo ratings yet

- Reinforced Concrete Arch Culvert, Storm Drain, and Sewer PipeDocument7 pagesReinforced Concrete Arch Culvert, Storm Drain, and Sewer PipeEligio Antonio CerdaNo ratings yet

- ASTM C1417M Standard Specification For Manufacture of Reinforced Concrete Sewer, Storm Drain, and Culvert Pipe For Direct DesignDocument8 pagesASTM C1417M Standard Specification For Manufacture of Reinforced Concrete Sewer, Storm Drain, and Culvert Pipe For Direct DesignLiu ZhenguoNo ratings yet

- Reinforced Concrete D-Load Culvert, Storm Drain, and Sewer PipeDocument4 pagesReinforced Concrete D-Load Culvert, Storm Drain, and Sewer PipeFRANZ RICHARD SARDINAS MALLCONo ratings yet

- Precast Reinforced Concrete Manhole Sections: Standard Specification ForDocument9 pagesPrecast Reinforced Concrete Manhole Sections: Standard Specification ForEligio Antonio CerdaNo ratings yet

- c-443Document4 pagesc-443carlosNo ratings yet

- Astm C 1227 - (Med To Heavy Traffic)Document5 pagesAstm C 1227 - (Med To Heavy Traffic)HaniAminNo ratings yet

- Reinforced Concrete Arch Culvert Storm Drain, and Sewer Pipe (Metric)Document7 pagesReinforced Concrete Arch Culvert Storm Drain, and Sewer Pipe (Metric)Katerin HernandezNo ratings yet

- Concrete Masonry Units For Construction of Catch Basins and ManholesDocument2 pagesConcrete Masonry Units For Construction of Catch Basins and ManholesNada Khlif100% (1)

- Reinforced Concrete Culvert, Storm Drain, and Sewer Pipe: Standard Specification ForDocument11 pagesReinforced Concrete Culvert, Storm Drain, and Sewer Pipe: Standard Specification ForMahmoud HakimNo ratings yet

- C507M 15Document10 pagesC507M 15Liu ZhenguoNo ratings yet

- Astm C1433M 01Document6 pagesAstm C1433M 01Eyas hamadNo ratings yet

- Astm 443-98Document4 pagesAstm 443-98Bugoy VouyNo ratings yet

- C 507-MDocument9 pagesC 507-Msameh emaryNo ratings yet

- Synthetic Fiber Reinforced Concrete Culvert, Storm Drain, and Sewer PipeDocument8 pagesSynthetic Fiber Reinforced Concrete Culvert, Storm Drain, and Sewer PipeConnieNo ratings yet

- Astm C76M-16Document12 pagesAstm C76M-16bestoon RamadhanNo ratings yet

- ASTMC12Document7 pagesASTMC12eng.usmanali2012No ratings yet

- C 14 PDFDocument4 pagesC 14 PDFAnwar MohiuddinNo ratings yet

- C12 - Installing Vitrified Clay Pipe LinesDocument7 pagesC12 - Installing Vitrified Clay Pipe LinesKingNo ratings yet

- Concrete Pipe For Irrigation or Drainage (Metric)Document4 pagesConcrete Pipe For Irrigation or Drainage (Metric)ABINASH BEHERANo ratings yet

- ASTM C990-01a Specification For Joints For Concrete Pipe, Manholes, and Precast Box Sections Using Preformed Flexible Joint Sealants.Document4 pagesASTM C990-01a Specification For Joints For Concrete Pipe, Manholes, and Precast Box Sections Using Preformed Flexible Joint Sealants.Liu ZhenguoNo ratings yet

- Mortar For Unit MasonryDocument13 pagesMortar For Unit MasonryCarlos Raul Caballero LeonNo ratings yet

- 03 Organisation Du GarageDocument12 pages03 Organisation Du GarageNgoambe Patrick VivianNo ratings yet

- C270Document13 pagesC270Heriberto Yau BNo ratings yet

- Astm C1319Document2 pagesAstm C1319Alex SalgadoNo ratings yet

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeFrom EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNo ratings yet

- Liftformslabconstruction 160907075019 PDFDocument12 pagesLiftformslabconstruction 160907075019 PDFishikaNo ratings yet

- Anchorage Systems For Reinforced Concrete Structures Strengthened With Fiber-Reinforced Polymer Composites: State-Of-The-Art ReviewDocument18 pagesAnchorage Systems For Reinforced Concrete Structures Strengthened With Fiber-Reinforced Polymer Composites: State-Of-The-Art ReviewoussNo ratings yet

- Concrete Mix ProportionDocument29 pagesConcrete Mix ProportionVi'ren BoharaNo ratings yet

- The Ingalls BuildingDocument4 pagesThe Ingalls Buildingthekrauser96No ratings yet

- Homework No. 1: PASTRANA, Lead Alyssa R. Engr. Bernard Villaverde CE152P/B1 May 5, 2014Document4 pagesHomework No. 1: PASTRANA, Lead Alyssa R. Engr. Bernard Villaverde CE152P/B1 May 5, 2014Marvin OlaNo ratings yet

- Bs 5911-4Document18 pagesBs 5911-4Sammy KongNo ratings yet

- CM - Question Bank - Unit I IIDocument2 pagesCM - Question Bank - Unit I IIpatlninadNo ratings yet

- Precast Case StudyDocument5 pagesPrecast Case StudyTauwab DanishNo ratings yet

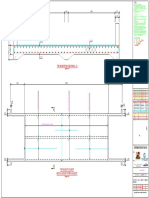

- Top Slab Details Section A - A) : Scale 1: 30Document1 pageTop Slab Details Section A - A) : Scale 1: 30Oseni MomoduNo ratings yet

- Introduction To Concrete PetrographyDocument26 pagesIntroduction To Concrete Petrographyamerie joy onateNo ratings yet

- Grade Slab Design For Heavy LoadsDocument2 pagesGrade Slab Design For Heavy LoadsIrshad Farrukh100% (1)

- Construction OF Hotel With BasementDocument26 pagesConstruction OF Hotel With BasementDuniya da RajaNo ratings yet

- Noah NcubeDocument18 pagesNoah Ncubedave tafadzwa kuyeriNo ratings yet

- Chapter 07 - MPWRD PDFDocument7 pagesChapter 07 - MPWRD PDFVarshil ParikhNo ratings yet

- Lime - Cement - Aggregates - MortarDocument57 pagesLime - Cement - Aggregates - MortarMr. R. Ramesh Asst Prof CIVILNo ratings yet

- Analisa Perbandingan Dua Merek Semen Dengan Kebersihan Material Terhadap Kuat Tekan Beton K-250Document12 pagesAnalisa Perbandingan Dua Merek Semen Dengan Kebersihan Material Terhadap Kuat Tekan Beton K-250Filter INDNo ratings yet

- 19pedro NDocument62 pages19pedro NmayasNo ratings yet

- General Purpose and Blended Cements: Australian StandardDocument7 pagesGeneral Purpose and Blended Cements: Australian StandardKrist Jan Jimenez SeparaNo ratings yet

- Performance of Geopolymer Concrete Reinforced With FRP Rebars - A ReviewDocument7 pagesPerformance of Geopolymer Concrete Reinforced With FRP Rebars - A ReviewSushil Singh BAGHELNo ratings yet

- Half Elevation of P.S.C Girder: Construction DrawingsDocument1 pageHalf Elevation of P.S.C Girder: Construction DrawingsAqib JavidNo ratings yet

- Day 2 S2 BNBC 2020Document38 pagesDay 2 S2 BNBC 2020November RainNo ratings yet

- Concrete Construction PDFDocument40 pagesConcrete Construction PDFTejay TolibasNo ratings yet

- Assessment of Behaviour of High Performance Concrete On Incorporation of Waste MaterialsDocument6 pagesAssessment of Behaviour of High Performance Concrete On Incorporation of Waste MaterialsIJRASETPublicationsNo ratings yet

- Chrysoplast ME210 PDFDocument2 pagesChrysoplast ME210 PDFmanil_5No ratings yet

- Slump TestDocument6 pagesSlump TestYing Huey100% (1)

- Concrete HistoryDocument49 pagesConcrete HistoryBAbitaNo ratings yet