Professional Documents

Culture Documents

Evaluating The Performance of Vapor Compression Cycle by Adding Nanoparticle

Evaluating The Performance of Vapor Compression Cycle by Adding Nanoparticle

Copyright:

Available Formats

You might also like

- C1M5 Peer Reviewed OthersDocument27 pagesC1M5 Peer Reviewed OthersAshutosh KumarNo ratings yet

- Vapour Compression Refrigeration Systems Using Nano Materials Mixed With R718 in Secondary Circuit of Evaporator For Enhancing Thermodynamic PerformancesDocument12 pagesVapour Compression Refrigeration Systems Using Nano Materials Mixed With R718 in Secondary Circuit of Evaporator For Enhancing Thermodynamic PerformancesIjrei Journal100% (1)

- A Review On Use of Nano Refrigerants in Domestic Refrigeration System For Improvement in Coefficient of Performance and Energy Saving and Green EnvironmentDocument3 pagesA Review On Use of Nano Refrigerants in Domestic Refrigeration System For Improvement in Coefficient of Performance and Energy Saving and Green EnvironmentIJSTENo ratings yet

- The Theoretical Analysis of H O-Libr Absorption Refrigeration System Using Al O NanoparticlesDocument18 pagesThe Theoretical Analysis of H O-Libr Absorption Refrigeration System Using Al O NanoparticlesTJPRC PublicationsNo ratings yet

- Performance Study of A Domestic Refrigerator Using Cuo/Al O - R22 A Nano-Refrigerant As Working FluidDocument14 pagesPerformance Study of A Domestic Refrigerator Using Cuo/Al O - R22 A Nano-Refrigerant As Working FluidsunilbabaNo ratings yet

- Experimental Study On The Performance Analysis of A Domestic Refrigeration System With Nano Additives and Proven Alternative RefrigerantDocument9 pagesExperimental Study On The Performance Analysis of A Domestic Refrigeration System With Nano Additives and Proven Alternative RefrigerantIJRASETPublicationsNo ratings yet

- Graphene in R134aDocument7 pagesGraphene in R134achitta sandeep dattuNo ratings yet

- A Review On The Performance Analysis of VCR System Using NanorefrigerantsDocument8 pagesA Review On The Performance Analysis of VCR System Using NanorefrigerantsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Numerical Study On Application of CuO-Water NanoflDocument7 pagesNumerical Study On Application of CuO-Water NanoflvinodNo ratings yet

- Performance Analysis of Ice Plant Using Ecofriendly RefrigerantsDocument9 pagesPerformance Analysis of Ice Plant Using Ecofriendly RefrigerantsAungThawNyeinChanNo ratings yet

- Performance Analysis of Ice Plants PDFDocument9 pagesPerformance Analysis of Ice Plants PDFpallav gupta100% (1)

- FuzzyPIV-Optimization of Nanofluid-Engine CoolingDocument19 pagesFuzzyPIV-Optimization of Nanofluid-Engine CoolingMohammad SerajNo ratings yet

- MBM SAE PaperDocument11 pagesMBM SAE PaperRathod Manish100% (1)

- Methods For Improving Thermal Performances of Vapour Compression Refrigeration Systems Using Ecofriendly Refrigerant in The ExpanderDocument13 pagesMethods For Improving Thermal Performances of Vapour Compression Refrigeration Systems Using Ecofriendly Refrigerant in The ExpanderIjrei JournalNo ratings yet

- Peyghambarzadeh 2013Document9 pagesPeyghambarzadeh 2013aadarsh patilNo ratings yet

- BERK DAĞLARAŞTI Design of V-C Refrigeration Sys. For Ship Patent SearchingDocument5 pagesBERK DAĞLARAŞTI Design of V-C Refrigeration Sys. For Ship Patent Searchingberkdaglarasti009No ratings yet

- Articulo 1Document13 pagesArticulo 1Ariana NuñezNo ratings yet

- Thermodynamic Performance Analysis of Two Stage Vapour Compression Refrigeration Systems With Flash-Intercooler Using Eco-Friendly New RefrigerantsDocument6 pagesThermodynamic Performance Analysis of Two Stage Vapour Compression Refrigeration Systems With Flash-Intercooler Using Eco-Friendly New RefrigerantsIjrei JournalNo ratings yet

- Thermodynamic Analysis On VC Refrigeration CycleDocument50 pagesThermodynamic Analysis On VC Refrigeration Cyclemanshulakesh59No ratings yet

- DESIGN_AND_DEVELOPMENT_OF_ENCHANCEMENT_THERMAL_CONDUCTIVITY_COOLANTWITHINAUTOMOBILE_MA12013Document10 pagesDESIGN_AND_DEVELOPMENT_OF_ENCHANCEMENT_THERMAL_CONDUCTIVITY_COOLANTWITHINAUTOMOBILE_MA12013pkvssraoNo ratings yet

- Paper #3Document9 pagesPaper #3Banipal yaqobNo ratings yet

- Nano 3Document13 pagesNano 3Rehan RafiqNo ratings yet

- Electronics Cooling With NanofluidsDocument5 pagesElectronics Cooling With NanofluidsghulammNo ratings yet

- Thermal Performance Analysis of Al2O3R-134a Nanorefrigerant PDFDocument7 pagesThermal Performance Analysis of Al2O3R-134a Nanorefrigerant PDFr3155No ratings yet

- Experimental Performance Evaluation of Vapour Compression Refrigeration System Without Nano ParticlesDocument7 pagesExperimental Performance Evaluation of Vapour Compression Refrigeration System Without Nano ParticlesIjrei JournalNo ratings yet

- Project-II November, 2017: Chapter-2 Literature ReviewDocument5 pagesProject-II November, 2017: Chapter-2 Literature ReviewAkshat SharmaNo ratings yet

- A New Phase Change Material Based On Potassium Nitrate With Silica and Alumina Nanoparticles For Thermal Energy StorageDocument10 pagesA New Phase Change Material Based On Potassium Nitrate With Silica and Alumina Nanoparticles For Thermal Energy StorageJoe SarkcessNo ratings yet

- Performance Investigation of Refrigerants R290 and R134a As An Alternative To R22Document9 pagesPerformance Investigation of Refrigerants R290 and R134a As An Alternative To R22VikasNo ratings yet

- Energy Conversion and Management: Dehua Cai, Jingkai Jiang, Guogeng He, Keqiao Li, Lijuan Niu, Ruxi XiaoDocument12 pagesEnergy Conversion and Management: Dehua Cai, Jingkai Jiang, Guogeng He, Keqiao Li, Lijuan Niu, Ruxi XiaoKArenNo ratings yet

- Nanofluids As A Coolant in Automobile Radiator: A Review: Chandan KumarDocument6 pagesNanofluids As A Coolant in Automobile Radiator: A Review: Chandan KumarArun KumarNo ratings yet

- International Journal of Heat and Technology: Received: 10 October 2021 Accepted: 25 December 2021Document7 pagesInternational Journal of Heat and Technology: Received: 10 October 2021 Accepted: 25 December 2021Omar RAJADNo ratings yet

- Journal Pre-Proof: Theoretical and Applied Mechanics LettersDocument32 pagesJournal Pre-Proof: Theoretical and Applied Mechanics Letterscharles bonthaNo ratings yet

- 73 PDFDocument13 pages73 PDFshubhamarvikarNo ratings yet

- 1 s2.0 S2214157X18300704 MainDocument8 pages1 s2.0 S2214157X18300704 MainRendy SetiawanNo ratings yet

- Performance Enhancement of A Solar Powered Air Conditio - 2019 - Case Studies in PDFDocument8 pagesPerformance Enhancement of A Solar Powered Air Conditio - 2019 - Case Studies in PDFEr Chintan PatelNo ratings yet

- A Review On The Application of Nanofluids in Vehicle Engine Cooling SystemDocument6 pagesA Review On The Application of Nanofluids in Vehicle Engine Cooling SystemPetra Banda RamirezNo ratings yet

- Energy Efficiency in Building Using Co2 Heat Pump Water HeatingDocument7 pagesEnergy Efficiency in Building Using Co2 Heat Pump Water HeatingMarclauryn AdewaleNo ratings yet

- Materials Today: Proceedings: Uma Shankar Prasad, R.S. Mishra, R.K. DasDocument3 pagesMaterials Today: Proceedings: Uma Shankar Prasad, R.S. Mishra, R.K. DasYash SuryawanshiNo ratings yet

- Effect of Nanofluids On Heat Pipe Thermal Performance: A Review of The Recent LiteratureDocument5 pagesEffect of Nanofluids On Heat Pipe Thermal Performance: A Review of The Recent LiteratureerpublicationNo ratings yet

- Performance Improvement of Double-Tube Gas Cooler in Co Refrigeration System Using NanofluidsDocument10 pagesPerformance Improvement of Double-Tube Gas Cooler in Co Refrigeration System Using NanofluidsNikhilesh DNo ratings yet

- Chapter One 1.1 Background of StudyDocument6 pagesChapter One 1.1 Background of StudyifiokNo ratings yet

- Energy Reports: Faizan Ahmed, Waqar Ahmed KhanDocument9 pagesEnergy Reports: Faizan Ahmed, Waqar Ahmed KhanAli ZadehkafiNo ratings yet

- Comparison Study R744 R404A R290 Energy and Exergy AnalysisDocument8 pagesComparison Study R744 R404A R290 Energy and Exergy AnalysisMazen MendylNo ratings yet

- LNG Cold Utilization 2019Document6 pagesLNG Cold Utilization 2019fan faniNo ratings yet

- Comparative Energy and Exergy Analysis of R744, R404A and R290 Refrigeration CyclesDocument8 pagesComparative Energy and Exergy Analysis of R744, R404A and R290 Refrigeration CyclesBegjo Mesti BedjoNo ratings yet

- Design of Waste Heat Driven Vapour AdsorDocument5 pagesDesign of Waste Heat Driven Vapour AdsorsisayNo ratings yet

- Refrigerant Analysis: 1) Literature SurveyDocument3 pagesRefrigerant Analysis: 1) Literature SurveySham VarugheseNo ratings yet

- Memoi IJRR0030Document26 pagesMemoi IJRR0030Judicael GUEDENONNo ratings yet

- Energies - Enhanced Heat Transfer Using Oil-Based NanofluidDocument28 pagesEnergies - Enhanced Heat Transfer Using Oil-Based Nanofluidrshukla7075No ratings yet

- 09CTN10 2249Document10 pages09CTN10 2249IrIFM IUSTNo ratings yet

- Numerical Simulation of R1234ze Ejector-ExpansionDocument13 pagesNumerical Simulation of R1234ze Ejector-ExpansionrezarossNo ratings yet

- Study The Effect of Adding Heat Exchanger On The Refrigeration System PerformanceDocument15 pagesStudy The Effect of Adding Heat Exchanger On The Refrigeration System Performancemustafa11dahamNo ratings yet

- CFD Analysis of Enhancement of Heat Transfer of Automobile Radiator With Hybrid Nanofluid As A Coolant-IJRASETDocument12 pagesCFD Analysis of Enhancement of Heat Transfer of Automobile Radiator With Hybrid Nanofluid As A Coolant-IJRASETIJRASETPublications100% (1)

- Journal Paper 1Document9 pagesJournal Paper 1ER Mangal Singh LodhiNo ratings yet

- Feasibility Study For Recovering Waste Heat in TheDocument7 pagesFeasibility Study For Recovering Waste Heat in TheAlfonso BlancoNo ratings yet

- Thermal Performance of Three Stage Cascade Vapour Compression Refrigeration Systems Using New HFO in High and Intermediate Temperature Cycle and R32Document15 pagesThermal Performance of Three Stage Cascade Vapour Compression Refrigeration Systems Using New HFO in High and Intermediate Temperature Cycle and R32Ijrei JournalNo ratings yet

- Applied Thermal Engineering: Saad Ayub Jajja, Wajahat Ali, Ha Fiz Muhammad Ali, Aysha Maryam AliDocument7 pagesApplied Thermal Engineering: Saad Ayub Jajja, Wajahat Ali, Ha Fiz Muhammad Ali, Aysha Maryam AliSaad Ayub JajjaNo ratings yet

- Effect of Nanorefrigerant On Performance of VCR System A Review Ijariie7169Document5 pagesEffect of Nanorefrigerant On Performance of VCR System A Review Ijariie7169khaja ziauddinNo ratings yet

- J Matpr 2019 07 710Document6 pagesJ Matpr 2019 07 710sxasxasxNo ratings yet

- Sciencedirect: M.Z. Sharif, W.H. Azmi, A.A.M. Redhwan, R. MamatDocument10 pagesSciencedirect: M.Z. Sharif, W.H. Azmi, A.A.M. Redhwan, R. MamatMushini NagabhushanNo ratings yet

- Synthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsFrom EverandSynthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsTilman J. SchildhauerNo ratings yet

- MSMEs and Rural Prosperity: A Study of their Influence in Indonesian Agriculture and Rural EconomyDocument6 pagesMSMEs and Rural Prosperity: A Study of their Influence in Indonesian Agriculture and Rural EconomyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Prevalence of Microorganisms in UTI and Antibiotic Sensitivity Pattern among Gram Negative Isolates: A Cohort StudyDocument4 pagesPrevalence of Microorganisms in UTI and Antibiotic Sensitivity Pattern among Gram Negative Isolates: A Cohort StudyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Innovative Mathematical Insights through Artificial Intelligence (AI): Analysing Ramanujan Series and the Relationship between e and π\piDocument8 pagesInnovative Mathematical Insights through Artificial Intelligence (AI): Analysing Ramanujan Series and the Relationship between e and π\piInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Dynamic Analysis of High-Rise Buildings for Various Irregularities with and without Floating ColumnDocument3 pagesDynamic Analysis of High-Rise Buildings for Various Irregularities with and without Floating ColumnInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Nurturing Corporate Employee Emotional Wellbeing, Time Management and the Influence on FamilyDocument8 pagesNurturing Corporate Employee Emotional Wellbeing, Time Management and the Influence on FamilyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Geotechnical Assessment of Selected Lateritic Soils in Southwest Nigeria for Road Construction and Development of Artificial Neural Network Mathematical Based Model for Prediction of the California Bearing RatioDocument10 pagesGeotechnical Assessment of Selected Lateritic Soils in Southwest Nigeria for Road Construction and Development of Artificial Neural Network Mathematical Based Model for Prediction of the California Bearing RatioInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- An Explanatory Sequential Study of Public Elementary School Teachers on Deped Computerization Program (DCP)Document7 pagesAn Explanatory Sequential Study of Public Elementary School Teachers on Deped Computerization Program (DCP)International Journal of Innovative Science and Research TechnologyNo ratings yet

- Intrusion Detection and Prevention Systems for Ad-Hoc NetworksDocument8 pagesIntrusion Detection and Prevention Systems for Ad-Hoc NetworksInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- AI Robots in Various SectorDocument3 pagesAI Robots in Various SectorInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Fuzzy based Tie-Line and LFC of a Two-Area Interconnected SystemDocument6 pagesFuzzy based Tie-Line and LFC of a Two-Area Interconnected SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Integration of Information Communication Technology, Strategic Leadership and Academic Performance in Universities in North Kivu, Democratic Republic of CongoDocument7 pagesIntegration of Information Communication Technology, Strategic Leadership and Academic Performance in Universities in North Kivu, Democratic Republic of CongoInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Diode Laser Therapy for Drug Induced Gingival Enlaregement: A CaseReportDocument4 pagesDiode Laser Therapy for Drug Induced Gingival Enlaregement: A CaseReportInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Mediating Effect of Encouraging Attitude of School Principals On Personal Well-Being and Career Ethics of TeachersDocument10 pagesMediating Effect of Encouraging Attitude of School Principals On Personal Well-Being and Career Ethics of TeachersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Importance of Early Intervention of Traumatic Cataract in ChildrenDocument5 pagesImportance of Early Intervention of Traumatic Cataract in ChildrenInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- A Novel Approach to Template Filling with Automatic Speech Recognition for Healthcare ProfessionalsDocument6 pagesA Novel Approach to Template Filling with Automatic Speech Recognition for Healthcare ProfessionalsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Influence of Artificial Intelligence On Employment Trends in The United States (US)Document5 pagesThe Influence of Artificial Intelligence On Employment Trends in The United States (US)International Journal of Innovative Science and Research TechnologyNo ratings yet

- The Effects of Liquid Density and Impeller Size with Volute Clearance on the Performance of Radial Blade Centrifugal Pumps: An Experimental ApproachDocument16 pagesThe Effects of Liquid Density and Impeller Size with Volute Clearance on the Performance of Radial Blade Centrifugal Pumps: An Experimental ApproachInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Comparison of JavaScript Frontend Frameworks - Angular, React, and VueDocument8 pagesComparison of JavaScript Frontend Frameworks - Angular, React, and VueInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Breaking Down Barriers To Inclusion: Stories of Grade Four Teachers in Maintream ClassroomsDocument14 pagesBreaking Down Barriers To Inclusion: Stories of Grade Four Teachers in Maintream ClassroomsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Organizational Factors That Influence Information Security in Smes: A Case Study of Mogadishu, SomaliaDocument10 pagesOrganizational Factors That Influence Information Security in Smes: A Case Study of Mogadishu, SomaliaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Integrating Multimodal Deep Learning For Enhanced News Sentiment Analysis and Market Movement ForecastingDocument8 pagesIntegrating Multimodal Deep Learning For Enhanced News Sentiment Analysis and Market Movement ForecastingInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Analysis of Factors Obstacling Construction Work in The Tojo Una-Una Islands RegionDocument9 pagesAnalysis of Factors Obstacling Construction Work in The Tojo Una-Una Islands RegionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Occupational Safety: PPE Use and Hazard Experiences Among Welders in Valencia City, BukidnonDocument11 pagesOccupational Safety: PPE Use and Hazard Experiences Among Welders in Valencia City, BukidnonInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Classifying Crop Leaf Diseases Using Different Deep Learning Models With Transfer LearningDocument8 pagesClassifying Crop Leaf Diseases Using Different Deep Learning Models With Transfer LearningInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Disseminating The Real-World Importance of Conjunct Studies of Acculturation, Transculturation, and Deculturation Processes: Why This Can Be A Useful Technique To Analyze Real-World ObservationsDocument15 pagesDisseminating The Real-World Importance of Conjunct Studies of Acculturation, Transculturation, and Deculturation Processes: Why This Can Be A Useful Technique To Analyze Real-World ObservationsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Gender-Based Violence: Engaging Children in The SolutionDocument10 pagesGender-Based Violence: Engaging Children in The SolutionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Total Cost of Ownership of Electric Car and Internal Combustion Engine Car With Performance NormalizationDocument11 pagesTotal Cost of Ownership of Electric Car and Internal Combustion Engine Car With Performance NormalizationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Relationship of Total Quality Management Practices and Project Performance With Risk Management As Mediator: A Study of East Coast Rail Link Project in MalaysiaDocument19 pagesThe Relationship of Total Quality Management Practices and Project Performance With Risk Management As Mediator: A Study of East Coast Rail Link Project in MalaysiaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Pecha Kucha Presentation in The University English Classes: Advantages and DisadvantagesDocument4 pagesPecha Kucha Presentation in The University English Classes: Advantages and DisadvantagesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Development of Creative Thinking: Case Study of Basic Design StudioDocument9 pagesDevelopment of Creative Thinking: Case Study of Basic Design StudioInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Slip Joint ConnectionDocument17 pagesThe Slip Joint ConnectionTiago FerreiraNo ratings yet

- Dror Paley - Principles of Deformity Correction (2002, Springer-Verlag Berlin Heidelberg) - 1-100Document100 pagesDror Paley - Principles of Deformity Correction (2002, Springer-Verlag Berlin Heidelberg) - 1-100Wilker AraújoNo ratings yet

- SpaceLogic Glass Touch Panels - LSSMTH07NSDocument2 pagesSpaceLogic Glass Touch Panels - LSSMTH07NSrohan modkeNo ratings yet

- Test Unit1Document4 pagesTest Unit1hoa truongNo ratings yet

- An Introduction To Regional Economics HooverDocument164 pagesAn Introduction To Regional Economics Hooversfdkhkfjsfnsk njfsnksfnNo ratings yet

- The Trend in Fish Species Diversity and Abundance at Asejire Reservoir South Western NigeriaDocument9 pagesThe Trend in Fish Species Diversity and Abundance at Asejire Reservoir South Western NigeriaHerald Scholarly Open AccessNo ratings yet

- My Little Island L3 U2 - WorkbookDocument16 pagesMy Little Island L3 U2 - WorkbookMaría Fernanda López AvilezNo ratings yet

- Conference Brochure GK UnivDocument11 pagesConference Brochure GK Univchakri pNo ratings yet

- Health 7 Module 10.1Document13 pagesHealth 7 Module 10.1Ryan BersaminNo ratings yet

- Shell Rimula R3 Turbo 15W-40Document2 pagesShell Rimula R3 Turbo 15W-40HUM CIREBON DFLTSNo ratings yet

- HDPE-100 Catalogue PDFDocument9 pagesHDPE-100 Catalogue PDFkumar sandeepNo ratings yet

- Sip Math DeptDocument4 pagesSip Math DeptJERRYCO GARCIANo ratings yet

- Journal Homepage: - : IntroductionDocument17 pagesJournal Homepage: - : IntroductionIJAR JOURNALNo ratings yet

- Homework-Assignment-3-Ceng2311 - Angle Measurements - Reduction & TraverseDocument4 pagesHomework-Assignment-3-Ceng2311 - Angle Measurements - Reduction & TraverseEhab2001No ratings yet

- Ant 101: Introduction To AnthropologyDocument20 pagesAnt 101: Introduction To AnthropologyAmina MatinNo ratings yet

- The Mechanics of Crushing Sugar Cane - Murry and HoltDocument77 pagesThe Mechanics of Crushing Sugar Cane - Murry and HoltRomina SalazarNo ratings yet

- En DVC 2018 35Document18 pagesEn DVC 2018 35Lina María CañónNo ratings yet

- Science 8 Q1 W3Document20 pagesScience 8 Q1 W3Renz LaraNo ratings yet

- Water Resources: Sources of Fresh WaterDocument13 pagesWater Resources: Sources of Fresh WaterdineshNo ratings yet

- E3sconf Riverflow2018 05032Document8 pagesE3sconf Riverflow2018 05032Lusia KrismiyatiNo ratings yet

- Asphalt MSDSDocument8 pagesAsphalt MSDSJunard M. Lu HapNo ratings yet

- 02 RAAD2019 HrickoDocument9 pages02 RAAD2019 HrickoHo Nhat LinhNo ratings yet

- Research Paper On IronDocument7 pagesResearch Paper On Ironafmctmvem100% (1)

- Nethravathi Y. MKTDocument11 pagesNethravathi Y. MKTREDDY TEJANo ratings yet

- GR 10 Maths P1 Nov 2023Document9 pagesGR 10 Maths P1 Nov 2023bontlemotlokoa476No ratings yet

- Dom Lab ManuelDocument56 pagesDom Lab ManuelMartin De Boras PragashNo ratings yet

- Lecture Notes - Sedimentation TankDocument45 pagesLecture Notes - Sedimentation TankJomer Levi PortuguezNo ratings yet

- H O Solutions: Hydroelectric Power Project: ObjectiveDocument2 pagesH O Solutions: Hydroelectric Power Project: ObjectiveImman Ray Loriezo AguilarNo ratings yet

- Structural Functionalism 2019-2020Document39 pagesStructural Functionalism 2019-2020Jesa Mae Vitales VergaraNo ratings yet

Evaluating The Performance of Vapor Compression Cycle by Adding Nanoparticle

Evaluating The Performance of Vapor Compression Cycle by Adding Nanoparticle

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Evaluating The Performance of Vapor Compression Cycle by Adding Nanoparticle

Evaluating The Performance of Vapor Compression Cycle by Adding Nanoparticle

Copyright:

Available Formats

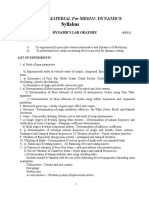

Volume 9, Issue 6, June – 2024 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165 https://doi.org/10.38124/ijisrt/IJISRT24JUN024

Evaluating the Performance of Vapor Compression

Cycle by Adding Nanoparticle

Utkarsh patil1∗; Rhutuja Tomake2; Shreeram Mali3; Karan Jankar4; Aniket Mengane5; Shubham Mirjkar6

Mechanical Engineering DY Patil Collage of Engineering and Technology Kasaba Bavda Kolhapur, Maharashtra, India

Abstract:- The discusses the improvements in refrigerant system, they were able to reduce energy

refrigeration systems using nano-refrigerants or consumption and increase C.O.P. by 2.4% and 4.4%,

nanofluids. It explores the compatibility, stability, and respectively. Soliman et al. [6] improved the efficiency of the

feasibility of using nanofluids in refrigeration systems, vapor compression cycle by combining R134a refrigerant

and how the performance of Al2O3 nanoparticle-based with an Al2O3-based POE nanofluid. Based on the findings

nanofluids can enhance the efficiency of vapor of the experiment, the heat transfer coefficient was increased

compression refrigeration systems. Additionally, it by 50%, cycle performance was improved by 10.5%, and

discusses a study on the impact of polyester oil-based energy consumption was decreased by 13.5%. R134a

multiwalled carbon nanotube nano lubricants on both the refrigerant is used to increase the concentration of Al2O3-

evaporator's heat dissipation and the compressor's power based POE nanofluid. Yusof et al. [7] found that the

consumption in a refrigerator. One ofthe potential heat refrigeration system's C.O.P. significantly improved and

transfer fluids in refrigeration systems is nano there was a 2.1% decrease in energy consumption.

refrigerant, which can significantly improve the

performance of vapor compression refrigerator systems. The technique of superheating and subcooling in

The study found that including nanoparticles in the conjunction with Al2O3 nanofluid has demonstrated superior

refrigerant increases viscosity, thermal conductivity, and performance for the refrigeration system to increase its

density, leading to enhanced heat transfer coefficients of efficiency. [8]. Significant heat transfer improvements were

performance and a reduction in power consumption. demonstrated in vapor compression refrigeration and an

absorption refrigeration system using water and an Al2O3

I. INTRODUCTION nanofluid based on ammonia. [9]. Other studies comparing

Al2O3-based nanofluid to other nanoparticles in the

For the past twenty years, introducing nanomaterials refrigeration system are available in the literature. [13–18]

into various base fluid types to boost heat transfer rate has where better nanoparticles have been used, like copper oxide,

greatly contributed to improving thermal system efficiency. In carbon nanotubes, and titanium dioxide. The researchers

1996–97, Choi S. found a way to improve the thermal found that the performance parameters of the refrigeration

conductivity of nanofluid using nanoparticles (Said et al., system were improved when utilizing these nanoparticles in

2023) They have shown how to use metal oxide nanoparticles comparison to Al2O3 nanoparticles. However, the

to measure the thermal conductivity of fluids. [2]. Since then, improvement was still greater when compared to the

a large body of research has backed the usage of nanoparticle- conventional refrigerant system that used Al2O3-based

based nanofluid to increase the thermal application's nanofluid. The current study examines the performance and

efficiency. Choi S.'s researchmade it possible to incorporate experimental aspects of the R134a and R600a-powered vapor

nanofluids in a variety of thermal applications. Additionally, compression refrigeration test rig. Due to the paucity of

the literature that is currently accessible for Al2O3-based information on Al2O3 experiments using R600a. [14]. The

nanofluid in refrigeration systems has been evaluated to current work compares an Al2O3-based nanofluid under

observe the performance parameters, primarily concentrating identical physical conditions to R134a and R600a. Choi

on power consumption and coefficient of performance created the first "Nanofluids," which are 100 nm

(C.O.P.). Biet al. [3] employed Al2O3 and TiO2 nanoparticles mixed with basic fluids including oil, ethylene

nanoparticles with HFC134a refrigerant in a home glycol, and water. Renewable energy is one of the fascinating

refrigerator and observed enhanced other performance applications of nanofluids. [11]. Renewable energy is one of

measures along with a 26.1% reduction in energy the fascinating applications of nanofluids. The remarkable

consumption. Jwo et al. [4] additionally mentioned that by qualities of nanofluids include their thermal characteristics,

utilizing Al2O3 – POE-based nano lubricant with R134a in steadiness, etc. Numerous studies have found that base fluids

therefrigerant system, there was a 2.4% decrease in energy are not as capableof convective heat transfer as nanofluids.

consumption and a 4.4% increase in C.O.P. Sendilet al. [5] [12] Appropriate heat management systems are crucial to the

carried out the experimental study with a nanofluid based on operation of car radiators. An image of nanofluids as a smart

Al2O3 and POE and varied R134a refrigerant charging. coolant for car radiators was created in a study by Choi [13].

According to the trial results, the C.O.P. significantly In applications related to the renewable energy sector, these

improved and energy consumption was reduced by 10.32%. nanofluids have shown promising results, such as

additionally mentioned that by utilizing Al2O3—a POE- improvements in convective heat transfer characteristics and

based nano lubricant—in conjunction with R134a in the effective thermal conductivity. Therefore, the remarkable

IJISRT24JUN024 www.ijisrt.com 539

Volume 9, Issue 6, June – 2024 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165 https://doi.org/10.38124/ijisrt/IJISRT24JUN024

qualities of nanofluid as presented allow researchers to compares the vapor compression cycle 1-2-3-4 to the

explore the innovative idea of nano- refrigerants. Coolants reversed Carnot cycle 1-2-3-4 or 1-2- 3-4, both operating

and lubricants are the two primary areas of applications for between the identical temperature limitations of Tk and To.

nanofluids. While nanoparticles in refrigerant-based systems During the vapor compression cycle.

are added directly to the refrigerant, in lubricant-based

systems, the nanoparticles are mixed with the lubricant before refrigeration effect qₒ = aera 1-4-d-eHeat rejected qₖ =area 2-

being added to the refrigerant. [14]. While lubricants like 2՛-3-c-e

polyol ester oil (POE) are lubricants, nano refrigerants are Word done w = qₖ -qₒ = area 1-2-2՛-3-c-d-4-1

refrigerants that contain well-dispersed nanoparticles. tiny

particles. Even though nano lubricants and nano refrigerants

are not the same thing, researchers have extensively studied

the thermal properties of refrigeration systems employing

nanofluids without making this distinction. As a result, the

impact of nanoparticles on refrigeration system performance

has not been thoroughly assessed. However, after reviewing

the literature, we discovered four noteworthy findings from

earlier research. [15–26]

As a result, numerous researchers have looked into

refrigeration systems that can lower GWPand ODP, mostly

by employing two strategies. The initial strategy entails

swapping out low-GWP refrigerants combined with

conventional refrigerants [27–30] Based on the concept of

nanofluids [43–45]. Nanorefrigerants are refrigerants that Fig 1: Vapour Comperssion Cycle on T-s Diagram

contain evenly distributed nanoparticles, whereas

nanolubricants are lubricants that incorporate nanoparticles, It may be seen that the vapour compression cycle

such as polyester oil (POE). Although nanorefrigerants are

presents three deviation from the reversedCarnot cycle

distinct from nanolubricants, researchers have extensively

studied the thermal properties of refrigeration systems ,as indicated below

utilizing nanofluids without categorizing them as

nanorefrigerants or nanolubricants. As a result, they have not

conducted a comprehensive evaluation of nanoparticles'

effects on refrigeration system performance. However, based

on a literature assessment, we discovered four notable

findings from earlier investigations [31–42]. An R113-based

carbon nanotube (CNT) nanofluid was shown to have

improved thermal conductivity in an experimental study.

Mahbubul, et al. [32]

Solubility studies with R134a and a POE lubricant

containing scattered TiO2 nanoparticles revealed that the

nanoparticles had no effect on solubility. Furthermore,

Cremaschi et al. [42] discovered that Al2O3 nanoparticles

suspended in R22 can enhance the boiling heat transfer

coefficient. Park and Jung [34] shown experimentally that a

nano lubricant can boost the pool boiling heat transfer Fig 2: Vapour Compersion Cycle on p-v Diagram

coefficient of the refrigerant. Furthermore, using

experimental data, they developed a model that can estimate (i) Area 4-4'-c-d represents the loss of refrigerating effect due

the boiling heat transfer coefficient in an evaporator to throttling. (ii) Area 4-4^-c-d represents a loss of

containing the nano lubricant. The third reported by earlier positive work, Aw, caused by the failure to recoup

researches [38, 39, 41]2. expansion work. It canbe seen that regions 4-4'-c-d and 3-

f-4 are identical. (iii) Dry compression causes an increase

II. VAPOR COMPRESSION SYSTEM in negative work (Awk) in the superheat horn area (2-2^-

2^). As a result, the theoretical COP of the vapor

compression cycle is lower than that of the reverse Carnot

The cycle with the two modifications described above is cycle. Nonetheless, it is closer to the Carnot cycle than

known as the vapor compression cycle, and it is the most other cycles, and its COP approaches the Carnot value.

commonly utilized in commercial refrigeration systems due [46]

to its high performance or efficiency index. Figures 3.4 and

3.5 illustrate a complete vapor compression cycle on the T-S

diagram and the p-v diagram, respectively. Figure 3.4 also

IJISRT24JUN024 www.ijisrt.com 540

Volume 9, Issue 6, June – 2024 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165 https://doi.org/10.38124/ijisrt/IJISRT24JUN024

Fig 3: Vapor Compression System

III. NANOFLUID illustrated in Fig. 2. Nanoparticles include metals such as

copper, nickel, and aluminum, as well as oxides such as

A. Synthesis of Nano-Refrigerants Al2O3, TiO2, CuO, and SiO2. Variations in kind,

The synthesis of nano-refrigerants, as well as the concentration, size, form, and preparation process must be

preparation of well-dispersed nanofluids and nano- evaluated. for refrigeration system efficiency. Section 6

refrigerants, has long been a major problem for researchers. describes the behavior of migration and aggregation later on.

In the one-step procedure, nanoparticles are first generated Peng and associates. [46] An orbital incubator shaker can be

and then distributed in the base fluid using any conceivable used to spread nanoparticles intothe refrigerant and prevent

approach. This approach demonstrates how rapidly them from evaporating. CuO-R113-based nano-refrigerant

nanoparticles settle in the base fluid; it is critical to ensure was ultrasonically combined with TiO2 nanoparticles for 6

that nanoparticles do not cluster together before dispersing in hours to avoid sedimentation. The suspension remained

the base fluid. The two-step strategy is recommended in this stable for up to 12 hours after preparation.

case because it is simpler and more cost-effective, as

Fig 4: A Two-Step Liquid-State Nano-Refrigerant Preparation Method

B. Development of Nano-Refrigerants and Nano-Lubricants compressor can consume as much as half of the lubricant in

While nanoparticles are combined with oil in nano- the system,the evaporator and dryer can use as much as 20%

lubricant to reduce compressor power, they are equally of it each, and the condenser and hoses can use as much as

dispersed throughout base refrigerant in nano-refrigerant, a 10% of it. [35] Nano refrigerants improve the VCR system's

subtype of refrigerant. Because of their improved ability to absorb heat or cold, while nano lubricants increase

thermophysical and tribological qualities, respectively, nano- compressor efficiency. [36,37] Two main researchapproaches

refrigerants and nano-lubricants have demonstrated can be distinguished in nano-refrigerant research. While one

remarkable thermodynamic efficiency and mechanical group of researchers looks into the direct incorporation of

performance in vapor compression refrigeration systems. The nanoparticles into the base refrigerant, another group

compressor contains most of the lubricant in a vapor evaluates the efficacy of suspending nanoparticles in

compression refrigeration (VCR) system, with the remaining lubricant. When particles are distributed throughout the

part mixed in a predetermined ratio with the refrigerant. refrigerant-lubricant blend, nano-refrigerants and nano-

According to the manufacturer of HVAC equipment, the lubricants are produced.For instance, when nanoparticles and

IJISRT24JUN024 www.ijisrt.com 541

Volume 9, Issue 6, June – 2024 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165 https://doi.org/10.38124/ijisrt/IJISRT24JUN024

refrigerants combine, nano-refrigerants show better heat in the experiment. As the basis fluid for the manufacture of

transmission qualities than tribological traits. However, the nanofluid, compressor lubrication oil is utilized tocreate

because the nanoparticles in the compressor lubricant are the right mixture. In this experiment, R134a and R600a are

more concentrated than in the refrigerant, nano-lubricants the refrigerants used. The lubrication oil used in the R600a is

exhibit better tribological performance. The system's flow, mineral oil (MO), whereas the R134a uses polyester oil

pool boiling heat transfer properties, and pool flowing (POE). An average particle size of 35 nm was used in the

condensation heat transfer are all improved by the experiment with Al2O3 nanoparticles.The 99% pure Al2O3

refrigerant's improved thermalcharacteristics. Because nano- nanoparticles from Platonic Nanotech Private Ltd. were

refrigerants have exceptional heat conductivity, It is possible classified as having the following thermophysical

to attain heat transfer coefficients with substantially lower characteristics in Table 1. The stability combination and

pumping power. [38] The enhanced tribology characteristics synthesis technique of oil and nanoparticles in the

of nano lubricant extend the life of mechanical components refrigeration system are crucial since there shouldn't be any

while simultaneously raising the wear rate and coefficient of nanoparticles settling there. By using the synthesis approach

friction of the compressor. The greater viscosity caused by the 99% purity and thermophysical characteristics of the

the higher concentration of nanoparticles, however, is the Al2O3 nanoparticles supplied by Platonic Nanotech Private

primary obstacle to the performance. Therefore, the Ltd. Since there shouldn't be any nanoparticles settling within

performance of a refrigeration system depends on the the refrigeration system,the synthesis process and the stable

appropriate concentration of nanoparticles. The following mixing of oil and nanoparticles in the system are crucial. By

features of adding nanoparticles to refrigerant are present [27] using the synthesis approach [48], To achieve the appropriate

• Adding nanoparticles as additives can improve the thermal dispersion, the Al2O3 nanoparticles were vibrated using a

and thermophysical characteristics of refrigerants; dispersing probe ultra sonicator. Although it increases the stability ofthe

nanoparticles into the lubricant can lower the wear rate and nanofluid, the surfactant was not utilized in this experiment.

friction coefficient; and enhancing the compatibility between The mass fractions of the nanofluid produced with POE and

refrigerants and lubricants. Wang et al. [39] MO separately were 0.02 wt%, 0.04 wt%, 0.07 wt%, and 0.1

wt%. With R134a and R600a, two different compressors

Carried out the first experiment utilizing nano- were utilized in conjunction with the POE and MO-based

refrigerants with lubricant, and it showed that the nanofluids. The characteristics of the MO and POE are

refrigeration system's COP performance was improved. presented in Tables 2 and 3. Because of their superior quality,

utilizing the nano refrigerant TiO2-R134a-MO. Godrej Pvt Ltd. POE oil and mineral oil werechosen for the

Consequently, Jiang et al. anticipated an improved theory of nanofluid production. The sonication process was carried out

nano- refrigerant thermal conductivity. [40] founded on the using Epishear's probe ultrasonicator, and KEPRO's

notion of particle aggregation. Many studies have been weighing equipment was utilized to determine the amount of

conducted by researchers to enhance lubrication, decrease nanoparticles needed for each mass fraction of nanofluid. The

friction, and lessen wear on mechanical components. By the graphic that depicts the morphology and particle size of

20th century, research on nano lubricants had been done for Al2O3 nanoparticles is based on a SEM image provided by

many different purposes. The first experimental research on Platonic Nanotech Pvt. Ltd. (Fig. 1,2). The produced Al2O3-

nano-lubricants for cooling systems was carried out in 2007. based nanofluid with varying massfractions, POE, and MO

Kedzierski and Gong evaluated the efficiency of CuOPOE- are displayed in Figs. 3 and 4. After being tested for

R134a nano-lubricant-refrigerant in heat transfer during pool sedimentation for 48 hours, the produced nanofluid

boiling [41] and observed gains of as much as 275%. They demonstrated good stability. To achieve the appropriate

also found that even a little increase in thermal conductivity dispersion, the Al2O3 nanoparticles were vibrated using a

resulted in a noticeable improvement in heat transfer. Bartelt probe ultrasonicator. Although it increases the stability of the

et al. [42] then looked at the same kind of nano-lubricants, nanofluid, the surfactant was not utilized in this experiment.

concentrating on the R134a-POE mixture's flow boiling in a The mass fractions of the nanofluid produced with POE and

horizontal tube. MO separately were 0.02 wt%, 0.04 wt%, 0.07 wt%, and 0.1

wt%. R134a was utilized with both the POE- and MO-based

C. Synthesis and Stability of Nanofluid nanofluids.

Before adding the nanoparticles to the refrigeration

system, they must be used as nanofluid. Two types of

refrigerants must be encountered by the necessary nanofluid

Table 1: Thermophysical Property of Al2O3 Nanoparticle

Sr. No. Specification Value

1 Molecular weight 101.96 gm/mol

2 Molecular Formula Al2O3

3 Purity 99.9%

4 Average Particle size 30–50 nm

5 Sp. Surface area 120–140 m2/g

6 Melting Point 2055 0C

7 Bulk Density 0.2–0.4 gm/cm3

IJISRT24JUN024 www.ijisrt.com 542

Volume 9, Issue 6, June – 2024 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165 https://doi.org/10.38124/ijisrt/IJISRT24JUN024

Table 2: Property of Polyester Oil

5 Acid value 0.12 mg KOH/gm

6 Density 0.98 gm/ml

7 Colour 260

5 Acid value 0.12 mg KOH/gm

6 Density 0.98 gm/ml

Table 3: Property of Mineral Oil

Sr. No. Poe Oil Characteristic Unit

1 oil type 160PZ

2 Viscosity at 40 °c 32.5 cSt

3 Pour point -45 °c (max)

4 Flash point 178°c

5 Acid value 0.07 mg KOH/gm

6 Density 0.9 gm/ml

7 Colour None

Fig 7: Different Concentration of AL2O3 Nanofluid with

POE Oil

Fig 5: SEM Image for AL203 Nanoparticle Particle Size

IV. PERFORMANCE ENHANCEMENT OF

NANOFLUID

A. Nano-Refrigerants and Their Impacts

Researchers employ nanotechnology as one strategy to

improve system performance. The benefits of incorporating

nanoparticles into the working fluid for enhancement are the

researchers' main area of interest. Nano-refrigerants are fluids

that contain a combination of refrigerant and nanoparticles.

Because of its higher thermal conductivity, it could improve

theperformance of refrigeration and air conditioning systems.

[49] According to recent research on nano-refrigerants,

adding nanomaterial to convectional refrigerant enhances the

system's overall performance, thermophysical characteristics,

and heat transfer efficiency. Mahbubul and associates [50]

According to recent research on nano-refrigerants, adding

nanomaterial to convectional refrigerant enhances the

system's overall performance, thermophysical characteristics,

and heat transfer efficiency. Mahbubul and associates [52].

Rahman et al. [53] found that at 305K, there was a 15.6%

Fig 6: SEM Image for AL2O3 Nanoparticle Uniformity

increase in thermal conductivity and a 4.93% decline inthe

specific heat of SWCNT/R407c. On the other hand, the

IJISRT24JUN024 www.ijisrt.com 543

Volume 9, Issue 6, June – 2024 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165 https://doi.org/10.38124/ijisrt/IJISRT24JUN024

viscosity of the refrigerant boostedby nanoparticles increased refrigerants. The performance of R1234yf nano-enhanced

with the addiction to nanoparticles and decreased with the refrigerants in terms of heat transfer and pressure drop

operatingtemperature. [54–57]. Chauhan et al. determined the characteristics require more investigation. Using simulation

viscosities of TiO2/R134a on the suction and discharge techniques and mathematical models, this study examines the

side.[58] and they discovered that at 0.3% volume CuO/R1234yf refrigerant's heat transfer properties and

concentration, the maximumviscosity value was 0.38 mPas pressure drop. The numerical findings of the simulation

and 0.2 mPas. Additionally, the findings showed that adding method are compared with the mathematical models, which

nanoparticles to the refrigerant increases its specific heat have been validated by previous types of publications. In this

capacity and latent heat with temperature, which enhances its analysis, the temperature ranges from 0 ◦C to 65 ◦C, and the

potential for heat transfer. [51,59]. Alawi et al. [51] showed concentration of nanoparticles in the puree refrigerant varies

that the specific heat decreased with volume concentration from 0.2% to 1%.

when nanoparticles were added to the refrigerant. The "Cp"

value of Al2O3/R141b was discovered to be 2.6% lower than B. Co-efficient of performance

that ofthe R141b refrigerant. Additionally, they concluded The refrigeration system's coefficient of performance

that the volume percentage of nanoparticles increased and the was greatly raised with the use of nanofluid. A pure

temperature lowered the novel refrigerant's density. refrigerant, R600a, was found to perform significantly better

Mahbubul and associates. [50] found that there is an 11% than the refrigerant R134a. As the mass fraction of Al2O3

increase in the density of Al2O3/R134a refrigerant. Parkash nanoparticles increased, the C.O.P. of the R134a-POE-based

et al.'s research [60] demonstrates how temperature and nanofluid improved. With 0.02 weight percent of Al2O3,

volume fraction affect ZnO/R134a's density. Studies on nano- 19.38% with 0.04weight percent of Al2O3, 22.44% with 0.07

refrigerants have demonstrated superior refrigeration system weight percent of Al2O3, and 29.5% with 0.1 weight percent

performance compared to traditional refrigerants. By mixing of Al2O3 utilizing R134a-POE nanofluid, the refrigeration

R140a refrigerant with Al2O3 nanoparticles, the system's system's C.O.P. improved. Performance was better in the

efficiency increased by 40% [61]. C.O.P. observation using R600a-MO than it was withR134a-

POE. When compared to pure R134a refrigerant, the C.O.P.

The Ambhore et al. studies [55] obtained the COP of the was improved only by the pure R600a refrigerant. Using

system with Al2O3/R134a as 2.03. Similarly, Subhedar et al. R600a-MO, the C.O.P. increased by 3% with 0.02 weight

[56] found approximately 85% of enhancement in the COP percent. of Al2O3, 0.04 weight percent of Al2O3, 0.07

with the Al2O3/R134a refrigerant. Payyala et al. [62] weight percent of Al2O3, 10.25% of Al2O3, and 14.95% of

indicated that adding Al2O3 to R140a increased the pressure Al2O3. The maximum C.O.P. of 2.69 was attained using

ratio, COP, and energy efficiency ratio. When the CuO R600a-MO- based nanofluid, even though the pace at which

nanomaterial was mixed with R134a, the friction coefficient R134a-POE-based nanofluid enhanced the C.O.P. differed

decreased by 9.9% and the COP increased by 14.55%. [63]. significantly from that of R600a-MO. [70].

Likewise, Bartelt et al. [64]at 1% volume concentration, the

heat transfer coefficient of CuO/R134a was shown to have C. Power Consumption

enhanced by 42–82%. Katoch and associates.[65] analyzed The use of pure R600a refrigerant resulted in much

theCuO/R113a nano-refrigerant in the refrigeration system lower power consumption. Watts per 24 hours were

and discovered that the energy consumption decreased by employed in the experiment to assess power consumption,

19.82% at 0.5% of the nanoparticle addition. CuO/LPG- similar to C.O.P. Incorporating further.The addition of

based systems see increases in heat transfer rate and nanofluid greatly reduced the amount of electricity used by

efficiency of 36% and 46%, respectively. [66]. Adelekan et the refrigeration system. When 0.02 wt%, 0.04 wt%, 0.07

al. [67] looked into how a nano-refrigerant based on wt%, and 0.1 wt% Al2O3-R134a-POE based nanofluid was

TiO2/LPG affected a home refrigerator. They found that used, power consumptions were reduced by 6.7%, 13.51%,

using 50g of LPG with 0.2 g/lit nano-lubricant produced the 15.63%, and 25.16%, respectively. using mass fractions of

lowest power consumption index (44W), whereas 40g of LPG 0.02 wt%, 0.04 wt%, 0.07 wt%, and 0.1 wt%, power

with 0.4 g/lit produced the highest COP of 2.8. Dhamneya consumption reductions using Al2O3-R600a-MO were

and associates [68] showed that the TiO2/R134a 8.76%, 10.04%, 11.21%, and 21.4%. Al2O3-R600a-MO

evaporatively cooled condenser's performance was much nanofluid with a 0.1 weight percent mass fraction was

enhanced, with a 51% increase in COP. Rahman and determined tohave the largest power consumption reduction

associates. [53] discovered that there was a 4.59% increase in of any refrigerant (28.7%).

the COP anda 34% decrease in compressor power. According

to the assessments, the system's overall performance and heat V. FUTURE SCOPE

transfer efficiency are enhanced by the nano-refrigerants, and

the COP rises with increasing nanoparticle concentration. This work makes use of both numerical and

[69]. R1234yf's primary drawback is that it performs less well simulation methodologies. The identification of nano

than R134a. Therefore, the main topic of this study is the refrigerant performance and energy efficiency in

employment of nanoparticles to increase the efficiency of practical cooling systems requires experimental

the R1234yf system. Few research has been doneon the

verification, which is outside the scope of this research.

pressure drop, heat transfer capacity, and thermo-transport

characteristics of R1234yf- based nano-enhanced

IJISRT24JUN024 www.ijisrt.com 544

Volume 9, Issue 6, June – 2024 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165 https://doi.org/10.38124/ijisrt/IJISRT24JUN024

Fig 8: Comparison of numerical and simulation results for 0.2% CuO/R1234yf.

Fig 9: Comparison of Numerical and Simulation Results for 0.2% CuO/R1234yf.

The current research investigation focuses on future research, it could be expanded to higher concentrations,

nanoparticles with lower concentrations and smaller sizes. In varied forms,and sizes of nanoparticles in the refrigerant.

IJISRT24JUN024 www.ijisrt.com 545

Volume 9, Issue 6, June – 2024 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165 https://doi.org/10.38124/ijisrt/IJISRT24JUN024

VI. CONCLUSION the efficiency,performance, and sustainability of refrigeration

systems. With ongoing advancements and concerted efforts

In conclusion, the integration of nano-refrigerants or towards technological innovation, these novel fluids are

nanofluids represents a groundbreaking advancement in the poised to redefinethe landscape of refrigeration, ushering in a

field of refrigeration systems, offering substantial new era of energy-efficient and environmentally conscious

improvements in efficiency, performance, and sustainability. cooling solutions.

The extensive research conducted on these innovative fluids,

particularly focusing on Al2O3 nanoparticle-based REFERENCES

nanofluids, highlights their immense potential to

revolutionize traditional vapor compression refrigeration [1]. S.U.S. Choi, J.A. Eastman, Enhancing thermal

systems the fundamental aspects driving the adoption of conductivity of fluids with nanoparticles, in

nanofluids in refrigeration are their compatibility and International Mechanical Engineering Congress &

stability within the system. Studies have consistently Exposition, ASME, San Fransisco, 1995.

demonstrated that nanofluids exhibit favourable https://www.osti.gov/biblio/196525-

compatibility with system materials and maintain stability enhancingthermal- conductivity-fluids-

underdiverse operational conditions. This ensures seamless nanoparticles

integration into existing refrigeration infrastructures without [2]. S. Lee, -S. Choi, S. Li, J.A. Eastman, Measuring

compromising system integrity or longevity. The thermal conductivity of fluids containing oxide

incorporation of nanoparticles into refrigerants imparts nanoparticles, Trans. ASME. 121 (1999) 280–289.

remarkable enhancements in fluid properties, notably [3]. S. Shan Bi, L. Shi, L. li Zhang, Application of

viscosity, thermal conductivity, and density. These nanoparticles in domestic refrigerators Applied

improvements result in significantly enhanced heat transfer Thermal Engineering. 28 2008 1834 1843 10.1016/j.

characteristics, leading to higher coefficients of performance applthermaleng.2007.11.018.

(COP) and reduced power consumption in refrigeration System, Procedia Manufacturing. Elsevier B.V.

systems. By facilitating more efficient heat transfer (2019) 112–117, https://doi.org/

processes, nano-refrigerants contribute to substantial energy 10.1016/j.promfg.2019.05.012.

savings and environmental benefits, aligning with global [4]. V. Nair, A.D. Parekh, P.R. Tailor, Experimental

efforts to mitigate climate change and reduce greenhouse gas investigation of a vapour compression refrigeration

emissions. Furthermore, research efforts have delved into the system using R134a/Nano-oil mixture, Int. J. Refrig.

multifaceted impacts of nanofluids on various components of 112 (2020) 21–36,

refrigeration systems. Studies examining the effects of nano https://doi.org/10.1016/j.ijrefrig.2019.12.009.

lubricants, such as multiwalled carbon nanotube-based [5]. J.K. Lee, J. Koo, H. Hong, Y.T. Kang, The effects of

lubricants, on evaporator heat dissipation and compressor nanoparticles on absorption heat and mass transfer

power consumption have unveiled promising outcomes. performance in NH3/H2O binary nanofluids, Int. J.

These nano-enhanced lubricants exhibit the potential to Refrig. 33 (2010) 269– 275,

optimize system efficiency and minimize energy https://doi.org/10.1016/j.ijrefrig.2009.10.004.

consumption, further underscoring the transformative [6]. V.M. v. Padmanabhan, S. Palanisamy, The use of

potential of nanotechnology in refrigeration. The implications TiO 2 nanoparticles to reduce refrigerator ir-

of these advancements extend beyond mere efficiency gains, reversibility Energy Conversion and Management.

encompassing broader economic and environmental 59 2012 122 132 10.1016/j.enconman.2012.03.002.

ramifications. Enhanced energy efficiency translates into [7]. D. Elcock, Potential impacts of nanotechnology on

reduced operational costs for refrigeration systems, offering energy transmission applications andneeds, Argonne

significant long- term savings for industries and consumers National Lab.(ANL), Argonne, IL (United States),

alike. Moreover, by reducing energy consumption and 2007.

reliance on conventional refrigerants with high global [8]. C. Choi, H.S. Yoo, J.M. Oh, Preparation and heat

warming potential, nanofluids contribute to mitigating transfer properties of nanoparticle-in-transformer oil

environmental impact and fostering sustainable practices dispersions as advanced energy-efficient coolants,

within the refrigeration sector. Looking ahead, continued Curr. Appl. Phys. 8 (6) (2008) 710–712.

research and development efforts are paramountto unlock the [9]. V. Nair, P.R. Tailor, A.D. Parekh, Nanorefrigerants:

full potential of nano-refrigerants and nanofluids. Addressing A comprehensive review on its past, present and

challenges such as cost-effectiveness, scalability, and future, Int. J. Refrig. 67 (2016) 290–307.

optimization of nanoparticle dispersion will be crucial in [10]. W. Azmi, et al., Potential of nanorefrigerant and

accelerating their widespread adoption in commercial nanolubricant on energy saving in refrigeration

refrigeration applications. system–A review, Renew. Sustain. Energy Rev. 69

(2017) 415–428.

Additionally, interdisciplinary collaboration between [11]. M.Z. Sharif, et al., Mechanism for improvement in

researchers, engineers, and industry stakeholders will be refrigeration system performance by using

essential to drive innovation and ensure the seamless nanorefrigerants and nanolubricants – A review, Int.

integration of nanotechnology into future refrigeration Commun. Heat Mass Transfer 92 (2018) 56–63.

systems. In summary, nano-refrigerants and nanofluids hold

immense promise as game-changing solutions for enhancing

IJISRT24JUN024 www.ijisrt.com 546

Volume 9, Issue 6, June – 2024 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165 https://doi.org/10.38124/ijisrt/IJISRT24JUN024

[12]. O.A. Alawi, N.A.C. Sidik, M.h. Beriache, [24]. W. Jiang, G. Ding, K. Wang, Calculation of the

Applications of nanorefrigerant and nanolubricants conductivity of nanorefrigerant based on particles

in refrigeration, air-conditioning and heat pump aggregation theory, J.-Shanghai Jiaotong

systems: A review, Int. Commun. Heat Mass University-Chinese Edition 40 (8) (2006) 1272.

Transfer 68 (2015) 91-97. [25]. M.A. Kedzierski, M. Gong, Effect of CuO

[13]. C.-S. Jwo, L.-Y. Jeng, T.-P. Teng, H. Chang, Effects nanolubricant on R134a pool boiling heat transfer,

of nanolubricant on the performance of hydrocarbon Int. J. Refrig. 32 (5) (2009) 791–799

refrigerant system, J. Vacuum Sci. Technol. B: [26]. K. Bartelt, et al., Flow-boiling of R-134a/POE/CuO

Microelectron. Nanometer Struct. 27 (2009) 1473, nanofluids in a horizontal tube, 2008

https://doi.org/10.1116/1.3089373. [27]. R. Downing, History of the organic fluorine

[14]. S. Kumar, R. Elansezhian, Experimental Study on industry, Kirk-Othmer Encycl. Chem. Technol. 9

Al2O3-R134a Nano Refrigerant in Refrigeration (1966) 704–707.

System, International Journal of Modern [28]. P. Brohan, et al., Uncertainty estimates in regional

Engineering Research (IJMER), Vol.2, Issue. 5, pp- and global observed temperature changes: A new

3927-3929. data set from 1850, J. Geophys. Res. Atmos. 111

[15]. A.M.A. Soliman, S.H. Taher, A.K. Abdel-Rahman, (D12) (2006).

S. Ookawara, Performance Enhancement of Vapor [29]. E. Gao, et al., A review of application status and

Compression Cycle Using Nano Materials, replacement progress of refrigerants in the Chinese

International Conference on Renewable Energy cold chain industry, Int. J. Refrig. 128 (2021) 104–

Research and Applications Proceedings. 117.

[16]. T.M. Yusof, A.M. Arshad, M.D. Suziyana, L.G. [30]. V. Nair, HFO refrigerants: A review of present status

Chui, M.F. Basrawi, Experimental study of a and future prospects, Int. J. Refrig.122 (2021) 156–

domestic refrigerator with POE-Al2O3 170.

nanolubricant, Int. J. Automot. Mech. Eng. 11 [31]. H. Peng, et al., Heat transfer characteristics of

(2015) 2243–2252. refrigerant-based nanofluid flow boiling inside a

[17]. M. Aktas, A.S. Dalkilic, A. Celen, A. Cebi, O. horizontal smooth tube, Int. J. Refrig. 32 (6) (2009)

Mahian, S. Wongwises, A Theoretical Comparative 1259–1270.

Study on Nanorefrigerant Performance in a Single- [32]. V. Trisaksri, S. Wongwises, Nucleate pool boiling

Stage Vapor- Compression Refrigeration Cycle, heat transfer of TiO2–R141b nanofluids, Int. J. Heat

Hindawi publishing corporation, Article ID 138725. Mass Transf. 52 (5) (2009) 1582–1588.

[18]. Sözen, E. Özbas_, T. Menlik, M.T. Çakir, M. Gürü, [33]. N. Sezer, M.A. Atieh, M. Koç, A comprehensive

K. Boran, Improving the thermal performance of review on synthesis, stability, thermophysical

diffusion absorption refrigeration system with properties, and characterization of nanofluids,

alumina nanofluids: An experimental study, Int. J. Powder Technol. 344 (2019) 404–431.

Refrig 44 (2014) 73–80, [34]. D. Elcock, Potential impacts of nanotechnology on

https://doi.org/10.1016/j.ijrefrig.2014.04.018. energy transmission applications and needs,

[19]. F. Jiang, J. Zhu, G. Xin, Experimental investigation Argonne National Lab.(ANL), Argonne, IL (United

on Al2O3-R123 nanorefrigerant heat transfer States), 2007.

performances in evaporator based on organic [35]. C. Choi, H.S. Yoo, J.M. Oh, Preparation and heat

Rankine cycle, Int. J. Heat MassTransf. 127 (2018) transfer properties of nanoparticle-in- transformer

145–153, oil dispersions as advanced energy-efficient

https://doi.org/10.1016/j.ijheatmasstransfer.2018.07 coolants, Curr. Appl. Phys. 8 (6) (2008) 710–712.

.061. [36]. V. Nair, P.R. Tailor, A.D. Parekh, Nanorefrigerants:

[20]. O.O. Ajayi, D.E. Ukasoanya, M. Ogbonnaya, E.Y. A comprehensive review on its past, present and

Salawu, I.P. Okokpujie, S.A. Akinlabi, E.T. future, Int. J. Refrig. 67 (2016) 290–307.

Akinlabi, F.T. Owoeye, Investigation of the effect of [37]. W. Azmi, et al., Potential of nanorefrigerant and

R134a/Al2O3 -nanofluid on the performance of a nanolubricant on energy saving in refrigeration

domestic vapour compression refrigeration system–A review, Renew. Sustain. Energy Rev. 69

[21]. W.H. Azmi, et al., Potential of nanorefrigerant and (2017) 415–428.

nanolubricant on energy saving in refrigeration [38]. M.Z. Sharif, et al., Mechanism for improvement in

system – A review, Renew. Sustain. Energy Rev. 69 refrigeration system performance by using

(2017) 415–428. nanorefrigerants and nanolubricants – A review, Int.

[22]. W.H. Azmi, et al., Heat transfer and friction factor Commun. Heat Mass Transfer 92 (2018) 56–63.

of water based TiO2 and SiO2 nanofluids under [39]. O.A. Alawi, N.A.C. Sidik, M.h. Beriache,

turbulent flow in a tube, Int. Commun. Heat Mass Applications of nanorefrigerant and nanolubricants

Transfer 59 (2014) 30–38. in refrigeration, air-conditioning and heat pump

[23]. R. Wang, et al., A refrigerating system using systems: A review, Int. Commun. Heat Mass

HFC134a and mineral lubricant appended with n- Transfer 68 (2015) 91-97.

TiO2 (R) as working fluids, Tsinghua University

Press, Beijing, China, 2003.

IJISRT24JUN024 www.ijisrt.com 547

Volume 9, Issue 6, June – 2024 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165 https://doi.org/10.38124/ijisrt/IJISRT24JUN024

[40]. W.H. Azmi, et al., Potential of nanorefrigerant and [54]. D. Ambhore, A. Tiwari, U. Patel, J. Patil, M.

nanolubricant on energy saving in refrigeration Ramachandran, Effect of aluminum oxide nano filler

system – A review, Renew. Sustain. Energy Rev. 69 in tetrafluoroethane (R-134a) refrigerant, IOP Conf.

(2017) 415–428. Ser. Mater. Sci. Eng. 810 (1) (2020), 012018,

[41]. W.H. Azmi, et al., Heat transfer and friction factor https://doi.org/10.1088/1757-899x/810/1/012018.

of water based TiO2 and SiO2 nanofluids under [55]. D.G. Subhedar, J.Z. Patel, B.M. Ramani,

turbulent flow in a tube, Int. Commun. Heat Mass Experimental studies on vapour compression

Transfer 59 (2014) 30–38. refrigeration system using Al2O3/mineral oil nano-

[42]. R. Wang, et al., A refrigerating system using lubricant, Aust. J. Mech. Eng. 20 (4) (2020) 1136–

HFC134a and mineral lubricant appended with n- 1141,

TiO2 (R) as working fluids, Tsinghua University https://doi.org/10.1080/14484846.2020.1784558.

Press, Beijing, China, 2003. [56]. Mahbubul, S. Fadhilah, R. Saidur, K. Leong, M.

[43]. W. Jiang, G. Ding, K. Wang, Calculation of the Amalina, Thermophysical properties and heat

conductivity of nanorefrigerant based on particles transfer performance of Al2O3/R-134a

aggregation theory, J.-Shanghai Jiaotong nanorefrigerants, Int. J. Heat Mass Tran. 57 (1)

University-Chinese Edition 40 (8) (2006) 1272. (2013) 100–108,

[44]. M.A. Kedzierski, M. Gong, Effect of CuO https://doi.org/10.1016/j.ijheatmasstransfer.2012.10

nanolubricant on R134a pool boiling heat transfer, .007.

Int. J. Refrig. 32 (5) (2009) 791–799. [57]. S.S. Chauhan, R. Kumar, S.P.S. Rajput,

[45]. K. Bartelt, et al., Flow-boiling of R-134a/POE/CuO Performance investigation of ice plant working with

nanofluids in a horizontal tube, 2008 CP AROARA R134a and different concentrations of POE/TiO2

by Refrigeration and air conditioning nano lubricant using experimental method, J. Braz.

[46]. V. Trisaksri, S. Wongwises, Nucleate pool boiling Soc. Mech. Sci. Eng. 41 (4) (2019),

heat transfer of TiO2–R141bnanofluids, Int. J. Heat https://doi.org/10.1007/s40430-019-1657-3.

Mass Transf. 52 (5) (2009) 1582–1588 [58]. S. Bi, K. Guo, Z. Liu, J. Wu, Performance of a

[47]. Y. Xuan, W. Roetzel, Conceptions for heat transfer domestic refrigerator using TiO2-R600a nano-

correlation of nanofluids, International Journal of refrigerant as working fluid, Energy Convers.

Heat and Mass Transfer, Volume 43 Issue 19, Pages Manag. 52 (1) (2011) 733–737,

3701-3707 https://doi.org/10.1016/S0017- https://doi.org/10.1016/j.enconman.2010.07.052.

9310(99)00369-5. [59]. J. Parkash, S. Saini, A. Kohli, B. Singh,

[48]. L. Cremaschi, A.A.M. Bigi, T. Wong, P. Deokar, Comparative analysis of thermohydraulic properties

Thermodynamic properties of Al2O3 of nano-refrigerants, Int. J. Eng. Adv. Technol. 7 (4)

nanolubricatns: Part 1- Effects on the two-phase (2018) 34,

pressure drop, Sci. Technol. Built Environ. 21(2015) https://doi.org/10.14419/ijet.v7i4.12.20988, m.

607–620. Anushanagaswapnasri, n.V.V. S. Sudheer, k.C.H.

[49]. V. Bianco, O. Manca, S. Nardini, Performance Kishorkumar, Experimental investigation on effect

analysis of turbulent convection heat transfer of of nano lubrication in a VCR system using R410a

Al2O3 water-nanofluid in circular tubes at constant refrigerant with Al2O3 nanoparticles, Int. J. Mech.

wall temperature, Energy 77 (2014) 403–413. Prod. Eng. Res. Dev. 10 (3) (2020) 1761–1768.

[50]. O.A. Alawi, J.M. Salih, A. Mallah, Thermo-physical [60]. Peyyala, M.N.S. Sri, N. Sudheer, K.C.K. Kumar,

properties effectiveness on the coefficient of Experimental investigation on effect of Nano

performance of Al2O3/R141b nano-refrigerant, Int. lubrication in a VCR system using R410A

Commun. Heat Mass Tran. 103 (2019) 54–61, Refrigerant with Al2O3 nanoparticles, International

https://doi.org/10.1016/j.icheatmasstransfer.2019.0 Journal of Mechanical and Production Engineering

2.011. Research and Development (IJMPERD) ISSN (P):

[51]. L. Yang, Y. Hu, Toward TiO2 nanofluids—Part 2: 2249–6890; ISSN (E): 2249–8001 10 (Issue 3)

applications and challenges,Nanoscale Res. Lett. 12 (2020) 1761–1768.

(1) (2017), https://doi.org/10.1186/s11671-017- [61]. A.C. Yilmaz, Performance evaluation of a

2185-7. refrigeration system using nanolubricant, Appl.

[52]. S. Rahman, S. Issa, Z. Said, M. El Haj Assad, R. Nanosci. 10 (5) (2020) 1667–1678,

Zadeh, Y. Barani, Performance enhancement of a https://doi.org/10.1007/s13204- 020-01258-5.

solar powered air conditioning system using passive [62]. K. Bartelt, Flow-Boiling of R-134a/POE/CuO

techniques and SWCNT/R-407c nano refrigerant, Nanofluids in a Horizontal Tube, Purdue e- Pubs,

Case Stud. Therm. Eng. 16 (2019), 100565, 2008. https://docs.lib.purdue.edu/iracc/928/.

https://doi.org/10.1016/j.csite.2019.100565. [63]. A. Katoch, F.A. Razak, A. Suresh, B. BS, E.

[53]. M.A.M. Soheel S.M.H., Energy Observation Gundabattini, Performance analysis of nano-

Technique for Vapour Absorption Using NanoFluid refrigerants used in the vapor compression

Refrigeration | International Journal of Advanced refrigeration system using MATLAB-Simulink,

Science and Technology, 2020, May Proc. IME C J. Mech. Eng.

http://sersc.org/journals/index.php/IJAST/article/vi Sci. 236 (12) (2022) 6948–6966,

ew/22608. https://doi.org/10.1177/09544062211069886

IJISRT24JUN024 www.ijisrt.com 548

Volume 9, Issue 6, June – 2024 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165 https://doi.org/10.38124/ijisrt/IJISRT24JUN024

[64]. S. Kumar, B. Kanimozhi, M. Sunil Kumar,

Performance evaluation of refrigerationsystem using

nano-fluid, Mater. Today: Proc. 44 (2021) 3838–

3845, https:// doi.org/10.1016/j.matpr.2020.12.339.

[65]. D.S. Adelekan, O.S. Ohunakin, T.O. Babarinde,

M.K. Odunfa, R.O. Leramo, S.O. Oyedepo, D.C.

Badejo, Experimental performance of LPG

refrigerant charges with varied concentration of TiO

2 nano-lubricants in a domestic refrigerator, Case

Stud. Therm. Eng. 9 (2017) 55–61,

https://doi.org/10.1016/j. csite.2016.12.002.

[66]. A.K. Dhamneya, S. Rajput, A. Singh, Comparative

performance analysis of ice plant testrig with TiO 2 -

R-134a nano refrigerant and evaporative cooled

condenser, Case Stud. Therm.Eng. 11 (2018) 55–61,

https://doi.org/10.1016/j.csite.2017.12.004.

[67]. Katoch, F. Abdul Razak, A. Suresh, B.S. Bibin, E.

Gunda bating, M.Z. Yusoff, Performance of

nanoparticles in refrigeration systems: a review,

Journal of Nanofluids 11 (4) (2022) 469–486,

https://doi.org/10.1166/jon.2022.1809.

[68]. Yogesh Joshi Performance investigation of vapor

compression refrigeration system using R134a and

R600a refrigerants and Al2O3 nanoparticle-based

suspensionhttps://doi.org/10.1016/j.matpr.2020.11.7

32

[69]. Zafar Said , Shek M.A. Rahman , Maham A. Sohail

,Ammar M. Bahman , Mohammad Alim , Saboor

Shaik , Ali M. Radwan ,Ibrahim I. El-Sharkawy

Nano-refrigerants and nano- lubricants in

refrigeration: Synthesis, mechanisms, applications,

and challenges

https://doi.org/10.1016/j.applthermaleng.2023.1212

11

[70]. Bibin B.S, Edison Gundabattini,Investigation on

transport properties, heat transfercharacteristics and

pressure drop of CuO enhanced R1234yf based

refrigerant

https://doi.org/10.1016/j.csite.2023.103229

IJISRT24JUN024 www.ijisrt.com 549

Volume 9, Issue 6, June – 2024 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165 https://doi.org/10.38124/ijisrt/IJISRT24JUN024

Mr. Utkarsh Narayan Patil is working as Assistant Professor Mechanical Engineering

Department at D Y Patil College of Engineering and Technology Kolhapur. He has done

ME in heat power Engineering.

(unpdypmech21@gmail.com)

Rhutuja Ramesh Tomake is Currently Studying in Final year of B.Tech in Mechanical

Engineering from D Y Patil Collage of Engineering and Technology kolhapur India. She is

area of Interest in include Advance Manufacturing Technology, Advance Thermodynamics

and Combustion, Design of Air Conditioning Systems

( pratikvadgavkar45@gmail.com )

Shreeram Dattatray Mali is Currently Studying in Final year B.Tech in Mechanical

Engineering from D Y Patil College of Engineering and Technology Kolhapur India. His area

of Interest in include Machine Design, 3D - CAD, I. C. Engine, Automobile Engineering,

Robotics, Heat Transfer, Refrigeration and Air Conditioning.

( shreerammali.432@gmail.com )

Aniket Nitin Mengane is Currently Studying in Final year B.Tech in Mechanical Engineering

from D Y Patil Collage of Engineering and Technology kolhapur India. His area of Interest in

include Advance Manufacturing Technology , I.C Engine & Quality control systems.

(aniketmengane10@gmail.com)

Shubham Nitin Mirajkar is Currently Studying in Final year B.Tech in Mechanical

Engineering from D Y Patil Collage of Engineering and Technology kolhapur India. His area of

Interest in include Advance Manufacturing Technology , I.C Engine & Quality control systems.

(shubhammirajkar2002@gmail.com)

Karan Rajesh Jankar is Currently Studying in Final year B.Tech in Mechanical Engineering

from D Y Patil College of Engineering and Technology kolhapur India. His area of Interest in

include Advance Manufacturing Technology , & Quality control systems.

(karanjankar2002@gmail.com@gmail.com)

IJISRT24JUN024 www.ijisrt.com 550

You might also like

- C1M5 Peer Reviewed OthersDocument27 pagesC1M5 Peer Reviewed OthersAshutosh KumarNo ratings yet

- Vapour Compression Refrigeration Systems Using Nano Materials Mixed With R718 in Secondary Circuit of Evaporator For Enhancing Thermodynamic PerformancesDocument12 pagesVapour Compression Refrigeration Systems Using Nano Materials Mixed With R718 in Secondary Circuit of Evaporator For Enhancing Thermodynamic PerformancesIjrei Journal100% (1)

- A Review On Use of Nano Refrigerants in Domestic Refrigeration System For Improvement in Coefficient of Performance and Energy Saving and Green EnvironmentDocument3 pagesA Review On Use of Nano Refrigerants in Domestic Refrigeration System For Improvement in Coefficient of Performance and Energy Saving and Green EnvironmentIJSTENo ratings yet

- The Theoretical Analysis of H O-Libr Absorption Refrigeration System Using Al O NanoparticlesDocument18 pagesThe Theoretical Analysis of H O-Libr Absorption Refrigeration System Using Al O NanoparticlesTJPRC PublicationsNo ratings yet

- Performance Study of A Domestic Refrigerator Using Cuo/Al O - R22 A Nano-Refrigerant As Working FluidDocument14 pagesPerformance Study of A Domestic Refrigerator Using Cuo/Al O - R22 A Nano-Refrigerant As Working FluidsunilbabaNo ratings yet

- Experimental Study On The Performance Analysis of A Domestic Refrigeration System With Nano Additives and Proven Alternative RefrigerantDocument9 pagesExperimental Study On The Performance Analysis of A Domestic Refrigeration System With Nano Additives and Proven Alternative RefrigerantIJRASETPublicationsNo ratings yet

- Graphene in R134aDocument7 pagesGraphene in R134achitta sandeep dattuNo ratings yet

- A Review On The Performance Analysis of VCR System Using NanorefrigerantsDocument8 pagesA Review On The Performance Analysis of VCR System Using NanorefrigerantsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Numerical Study On Application of CuO-Water NanoflDocument7 pagesNumerical Study On Application of CuO-Water NanoflvinodNo ratings yet

- Performance Analysis of Ice Plant Using Ecofriendly RefrigerantsDocument9 pagesPerformance Analysis of Ice Plant Using Ecofriendly RefrigerantsAungThawNyeinChanNo ratings yet

- Performance Analysis of Ice Plants PDFDocument9 pagesPerformance Analysis of Ice Plants PDFpallav gupta100% (1)

- FuzzyPIV-Optimization of Nanofluid-Engine CoolingDocument19 pagesFuzzyPIV-Optimization of Nanofluid-Engine CoolingMohammad SerajNo ratings yet

- MBM SAE PaperDocument11 pagesMBM SAE PaperRathod Manish100% (1)