Professional Documents

Culture Documents

Inspection Instructions: Rigid Axles (With and Without Transmission)

Inspection Instructions: Rigid Axles (With and Without Transmission)

Uploaded by

Neal YangCopyright:

Available Formats

You might also like

- Flange Management Training Program 0Document31 pagesFlange Management Training Program 0Manohar Seetharam100% (4)

- SI1290F Crankcase Thru-Stud Locations, Repair of Oil LeakageDocument7 pagesSI1290F Crankcase Thru-Stud Locations, Repair of Oil Leakagedavid100% (1)

- VW Transporter T4 Workshop Manual Diesel 2000-2004From EverandVW Transporter T4 Workshop Manual Diesel 2000-2004Rating: 5 out of 5 stars5/5 (3)

- CF34 10EBSIJune09Document51 pagesCF34 10EBSIJune09ArturoACE75% (4)

- Holden VT 2000 Service TechlinesDocument177 pagesHolden VT 2000 Service Techlinescosky071% (7)

- 1 Site Layout Plan PDFDocument1 page1 Site Layout Plan PDFMuchena Stephen GiftNo ratings yet

- February 9, 2009 S-B-18.00/40a S-B-18.00/40 Dated October 28, 2008 18Document9 pagesFebruary 9, 2009 S-B-18.00/40a S-B-18.00/40 Dated October 28, 2008 18kevin gradinNo ratings yet

- TPI 2030685-5 - Oil Loss in Cylinder Head Areacylinder Head CoverDocument8 pagesTPI 2030685-5 - Oil Loss in Cylinder Head Areacylinder Head CoverDavianGiurcaNo ratings yet

- HH150 Smanual - MasterDocument43 pagesHH150 Smanual - Masterjacklyn ade putra80% (5)

- 1zua 5670-200 enDocument10 pages1zua 5670-200 enSURJIT SINGHNo ratings yet

- SEBF 8164 гизьзы 3500Document19 pagesSEBF 8164 гизьзы 3500Aminadav100% (1)

- Siddha Siddhanta Paddhati Natha YogisDocument35 pagesSiddha Siddhanta Paddhati Natha YogisNilkanth Yengde80% (10)

- Inspection Instructions: Steering AxlesDocument3 pagesInspection Instructions: Steering AxlesNeal YangNo ratings yet

- 0000bf-C-G0-G000-Pe-Pro-0001-B04 Flange Management Procedure - 12Document1 page0000bf-C-G0-G000-Pe-Pro-0001-B04 Flange Management Procedure - 12Eng.arifNo ratings yet

- Installation Instructions For PSI and Pikotek® Gaskets: Sleeves Through The Bolt HolesDocument4 pagesInstallation Instructions For PSI and Pikotek® Gaskets: Sleeves Through The Bolt Holesquiron2010No ratings yet

- On-Vehicle InspectionDocument5 pagesOn-Vehicle InspectionEdson CRNo ratings yet

- Piper SB 955 Engine Mount Nose Gear AttachmentDocument6 pagesPiper SB 955 Engine Mount Nose Gear AttachmentGeorgios AsimakopoulosNo ratings yet

- SL98-356 B&W Service LetterDocument14 pagesSL98-356 B&W Service LetterkamalNo ratings yet

- BOLTRIGHT Tightening Procedure 6 - 2500Document2 pagesBOLTRIGHT Tightening Procedure 6 - 2500Saad Abou-ZeidNo ratings yet

- Tpi 2026513 - 8 (02.07.2013)Document4 pagesTpi 2026513 - 8 (02.07.2013)mafejoNo ratings yet

- SB 1103BDocument5 pagesSB 1103BsandyNo ratings yet

- 1644 - 1 - sb-04-0314v2 - Db9 Sportspack Damper LeakDocument3 pages1644 - 1 - sb-04-0314v2 - Db9 Sportspack Damper Leakmink4uNo ratings yet

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 4Document24 pagesRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 4anony8103No ratings yet

- Injector InstalacionDocument6 pagesInjector Instalacionjose luis herreraNo ratings yet

- Piston Height InspectDocument2 pagesPiston Height InspectbejoythomasNo ratings yet

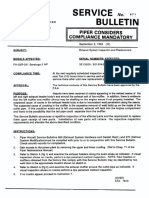

- Service Bulletin: Compliance MandatoryDocument8 pagesService Bulletin: Compliance MandatorySaharKhaneshiNo ratings yet

- B+V Manual - Hinge Casing Spider 200 SH TonsDocument7 pagesB+V Manual - Hinge Casing Spider 200 SH TonsCong BuiNo ratings yet

- VEH MB ML320 High Oil ConsumptionDocument3 pagesVEH MB ML320 High Oil Consumptiond9dNo ratings yet

- Brakes-Electronic Service Information System (ERWIN - ERWIN) PDFDocument6 pagesBrakes-Electronic Service Information System (ERWIN - ERWIN) PDFOleksiy OsiychukNo ratings yet

- ASB 412-09-137A Page 1 of 10 Approved For Public ReleaseDocument10 pagesASB 412-09-137A Page 1 of 10 Approved For Public Releasesebastian eduardoNo ratings yet

- Infinity Man Rider Airr Winch Model FA150KGiDocument16 pagesInfinity Man Rider Airr Winch Model FA150KGiVianey Zavala0% (1)

- 73 10 01 PDFDocument6 pages73 10 01 PDFAnonymous 298xlo3uUNo ratings yet

- Instruction and Operating Manual GHH Powerband Driven ENDocument15 pagesInstruction and Operating Manual GHH Powerband Driven ENPiw WatchareeNo ratings yet

- John Crane Inc.: 6400 West Oakton Street Morton Grove, IL 60053-0805Document9 pagesJohn Crane Inc.: 6400 West Oakton Street Morton Grove, IL 60053-0805Aan Sarkasi AmdNo ratings yet

- IMO WD H MaintenanceDocument19 pagesIMO WD H MaintenancetaytaytaytayNo ratings yet

- 505 As Bas B 5052335Document11 pages505 As Bas B 5052335Bruno Alonso PachecoNo ratings yet

- Brake Technicians Service Guide PDFDocument28 pagesBrake Technicians Service Guide PDFleonardo cardenasNo ratings yet

- BOLTRIGHT Tightening Procedure 3 2500Document2 pagesBOLTRIGHT Tightening Procedure 3 2500pedro ylarretaNo ratings yet

- Bearing InspectionDocument20 pagesBearing InspectionMoustapha SeyeNo ratings yet

- Class 10000 Fans Owner'S ManualDocument19 pagesClass 10000 Fans Owner'S ManualhaosfNo ratings yet

- CSB14 1Document12 pagesCSB14 1dzakubNo ratings yet

- Operator E-Jets News Rel 07Document12 pagesOperator E-Jets News Rel 07PDDELUCA100% (1)

- Pistons and Connecting Rods - Assemble: Shutdown SISDocument3 pagesPistons and Connecting Rods - Assemble: Shutdown SISВиталийNo ratings yet

- Vibration Damper - Check: Testing and AdjustingDocument2 pagesVibration Damper - Check: Testing and AdjustingbejoythomasNo ratings yet

- Installation Instructions: Dry Gas Dual Cartridge Canister Seal For Mixers and AgitatorsDocument8 pagesInstallation Instructions: Dry Gas Dual Cartridge Canister Seal For Mixers and AgitatorsDima ArfNo ratings yet

- Complete Expansion Joint Inspection ReportDocument3 pagesComplete Expansion Joint Inspection ReportsunnyartboyNo ratings yet

- SM95C AgDocument7 pagesSM95C AghernanNo ratings yet

- Piper SB 971 Exhaust System InspectionDocument5 pagesPiper SB 971 Exhaust System InspectionRichard FloydNo ratings yet

- MC 10192120 9999Document4 pagesMC 10192120 9999Sam LorcaNo ratings yet

- Api Plan 11Document6 pagesApi Plan 11johnsaballaNo ratings yet

- Handling and Service Instructions For High Pressure Flexible HosesDocument20 pagesHandling and Service Instructions For High Pressure Flexible HosesRhdh kldmkNo ratings yet

- Cleveland Brake Technicians Service GuideDocument24 pagesCleveland Brake Technicians Service GuidesparkyoshidaNo ratings yet

- ENP-652 Cylinder Boss Wear and RepairDocument7 pagesENP-652 Cylinder Boss Wear and RepaireparodiesNo ratings yet

- Cleveland Wheel & Brakes Technician Service Guide AWBTSG0001Document28 pagesCleveland Wheel & Brakes Technician Service Guide AWBTSG0001Richard MayNo ratings yet

- Installation Instructions: Durametallic ML-200 SeriesDocument8 pagesInstallation Instructions: Durametallic ML-200 SerieslubangjarumNo ratings yet

- Owner GuideDocument741 pagesOwner Guidealfatih1407497100% (1)

- Torque Value PDFDocument8 pagesTorque Value PDF7761430No ratings yet

- Oil Filter Installation & ServiceDocument16 pagesOil Filter Installation & ServicemdhelicoptersNo ratings yet

- SUBJECT: Protection No.4 of Injection Pipe Crack From Vibration Models: Musso & Korando ConditionDocument4 pagesSUBJECT: Protection No.4 of Injection Pipe Crack From Vibration Models: Musso & Korando Conditionfrancisca19No ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Squirrels of Indian SubcontinentDocument14 pagesSquirrels of Indian SubcontinentAkshay MotiNo ratings yet

- Antena Parabolica HP4 71W P3A A RPE Andrew 12Document7 pagesAntena Parabolica HP4 71W P3A A RPE Andrew 12eduardo-mwNo ratings yet

- CWall Ex1Document5 pagesCWall Ex1Virginia gabyella saraunNo ratings yet

- Lê Thị Thu Thuỷ - Luận vănDocument97 pagesLê Thị Thu Thuỷ - Luận vănĐào Nguyễn Duy TùngNo ratings yet

- Masonic SymbolismDocument19 pagesMasonic SymbolismOscar Cortez100% (7)

- Physiology of LactationDocument29 pagesPhysiology of Lactationcorzpun16867879% (14)

- People vs. Asjali DigestDocument3 pagesPeople vs. Asjali DigestEmir Mendoza100% (1)

- School of Mount St. Mary, Inc.: Learning Module in Arts 10Document20 pagesSchool of Mount St. Mary, Inc.: Learning Module in Arts 10C'toik Y DweyNo ratings yet

- Narasimha Kavacham by Bhakta Prahlada - Bengali - PDF - File5475Document11 pagesNarasimha Kavacham by Bhakta Prahlada - Bengali - PDF - File5475Raghavendra RaghavendraNo ratings yet

- Workshop Manual: Engine Series 3 - 4 LDDocument48 pagesWorkshop Manual: Engine Series 3 - 4 LDNenadStojicNo ratings yet

- Detention Pond Design Excel PDFDocument31 pagesDetention Pond Design Excel PDFRenukadevi Rpt100% (1)

- Arts 7 - Q3 - Mod3 - TheLandofPromiseArtsofMindanao - V1Document28 pagesArts 7 - Q3 - Mod3 - TheLandofPromiseArtsofMindanao - V1DIANE BORROMEO,No ratings yet

- Notice 1658958950Document64 pagesNotice 1658958950Subrat NaikNo ratings yet

- English Test - Imterchange 1 - Unit 1-8Document5 pagesEnglish Test - Imterchange 1 - Unit 1-8GabrielaNo ratings yet

- Digital Image Processing - S. Jayaraman, S. Esakkirajan and T. VeerakumarDocument4 pagesDigital Image Processing - S. Jayaraman, S. Esakkirajan and T. VeerakumarBenedict IsaacNo ratings yet

- NARA T733 R4 Guide 60 PDFDocument140 pagesNARA T733 R4 Guide 60 PDFKurt MeyerNo ratings yet

- Gayatri MantraDocument2 pagesGayatri MantraAnandh ShankarNo ratings yet

- Written Report: Lydia Hall: Care, Cure, Core Nursing TheoryDocument12 pagesWritten Report: Lydia Hall: Care, Cure, Core Nursing TheoryAldrin Limcuando100% (1)

- Sales Budget in Millions $Document13 pagesSales Budget in Millions $IkramNo ratings yet

- Assignment2 1Document16 pagesAssignment2 1api-335877104No ratings yet

- ACP194Document32 pagesACP194Samar SamerNo ratings yet

- MATH CHALLENGE GRADE 2 - Google FormsDocument5 pagesMATH CHALLENGE GRADE 2 - Google FormsAivy YlananNo ratings yet

- WikiHow Is An Online WikiDocument4 pagesWikiHow Is An Online Wikiksdnfi ouvynNo ratings yet

- Explore (As) : Types of Commission and InterestsDocument4 pagesExplore (As) : Types of Commission and InterestsTiffany Joy Lencioco GambalanNo ratings yet

- Curriculum OF Environmental Science BS/MS: (Revised 2013)Document120 pagesCurriculum OF Environmental Science BS/MS: (Revised 2013)Jamal Ud Din QureshiNo ratings yet

- Vikram-Betal Case StudyDocument5 pagesVikram-Betal Case StudyRavi SawantNo ratings yet

- Neuromusic IIIDocument3 pagesNeuromusic IIIJudit VallejoNo ratings yet

- Renesas Application Note AN1340Document6 pagesRenesas Application Note AN1340Rip_BarNo ratings yet

Inspection Instructions: Rigid Axles (With and Without Transmission)

Inspection Instructions: Rigid Axles (With and Without Transmission)

Uploaded by

Neal YangOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection Instructions: Rigid Axles (With and Without Transmission)

Inspection Instructions: Rigid Axles (With and Without Transmission)

Uploaded by

Neal YangCopyright:

Available Formats

F Passau GmbH

Doc.no.:19075003

INSPECTION INSTRUCTIONS

Revision: -- Rigid axles

(with and without transmission)

1. Description

1.1 Assembly instructions

Apply oil SAE - 90 LS (API - class 5GL) to moving parts like bearings, gears as well as to brake

disks and disks of limited slip differential according to specification MIL - L - 2105 D.

To be done during assembly!

Spray approx. 1 lLt of the specified oil into the interior of hubs/outputs and axle housing with axle

insert (to prevent corrosion!)

1.2. Brake test:

1.2.1 Multi-disc brake

Breathe brake! Actuate brake approx. 10 times and then carry out the following pressure test.

a) Low-pressure test:

Generate an excess pressure of 5 bar (by means of a hydraulic press), the generated excess pressure

must not drop within a test duration of approx. 5 minutes.

TEST MEDIA: MOTOR OILS SAE 10 W MIL - L 2104 C

MIL - L 46152

API-CC;CD;SC;SD;SE

ATF - OILS TYPE A SUFFIC A

DEXRON OF II D

Datei: 19075003_-- Formblatt: 05069003 A6 Seite 1 von 4

F Passau GmbH

Doc.no.:19075003

INSPECTION INSTRUCTIONS

Revision: -- Rigid axles

(with and without transmission)

b) High pressure test:

Apply a high pressure of 150 bar, wait approx. 1 min.; the new default value (∼ 145 bar)

must not drop by more than 3% within 5 minutes.

1.3 Drum brake:

Make basic setting, i.e. loosen fixing screw of brake adjustment, fully spread adjusting device -

centering) refasten screws tightly. Clear brake shoes by backing-off adjusting nut by 3-5 notches.

Brake drum must be clear.

Same as 1.2.1 a + b but TEST MEDIA: see parts list!

1.4 Disk brake:

Same as 1.2.1 a + b but TEST MEDIA: see parts list!

1.5 Slotted nuts in the outputs:

To ensure a correct process of the safety related components urgently observe the following:

a) The tightening torques of the nut on hub carriers are recorded by a documenting screwdriver and

are then documented.

b) Should this thool (documenting screwdriver) not be available e.g. in service organizations or in

field assembly, so the operator, together with a second person, must monitor the tightening process

and confirm its correctness by signing the assembly order.

Then mark nut and counter piece with a securing agent (on the effected procedure).

Datei: 19075003_-- Formblatt: 05069003 A6 Seite 2 von 4

F Passau GmbH

Doc.no.:19075003

INSPECTION INSTRUCTIONS

Revision: -- Rigid axles

(with and without transmission)

1.6 Contact pattern check of bevel gear set

1.7 Check leakage of shaft seal:

In case of a separate oil circuit, turn in test connections into oil drain holes of axle housing and of

both outputs, and build up a pressure of 0.3 bar – consecutively axle housing /outputs.

In case of a common oil system, connect just 1x on the axle housing and build up pressure.

No pressure drop must be visible within 3 min.

During pressure test rotate input flange with fixing bracket, ensure that both outputs are evenly

rotating in the correct sense of rotation.

1.8 Others:

Check axle according to installation drawing

(Random sampling inspection during assembly):

• Hole pattern of spring pad

• Flange position

• Sense of rotation

• Input flange

• Wheel bolts

Datei: 19075003_-- Formblatt: 05069003 A6 Seite 3 von 4

F Passau GmbH

Doc.no.:19075003

INSPECTION INSTRUCTIONS

Revision: -- Rigid axles

(with and without transmission)

1.9 Check of identification plate

1.10 Check of general condition

2. Application/purpose

These instructions shall be applicable in the Service department for axle types AP, MT, MTC.

FOR INTERNAL USE ONLY

Erstellt Geprüft Freigabe

Bereich Bereich Bereich

Datum Datum Datum Dokument-Nr.

Name Name Name 19075003

Datei: 19075003_-- Formblatt: 05069003 A6 Seite 4 von 4

You might also like

- Flange Management Training Program 0Document31 pagesFlange Management Training Program 0Manohar Seetharam100% (4)

- SI1290F Crankcase Thru-Stud Locations, Repair of Oil LeakageDocument7 pagesSI1290F Crankcase Thru-Stud Locations, Repair of Oil Leakagedavid100% (1)

- VW Transporter T4 Workshop Manual Diesel 2000-2004From EverandVW Transporter T4 Workshop Manual Diesel 2000-2004Rating: 5 out of 5 stars5/5 (3)

- CF34 10EBSIJune09Document51 pagesCF34 10EBSIJune09ArturoACE75% (4)

- Holden VT 2000 Service TechlinesDocument177 pagesHolden VT 2000 Service Techlinescosky071% (7)

- 1 Site Layout Plan PDFDocument1 page1 Site Layout Plan PDFMuchena Stephen GiftNo ratings yet

- February 9, 2009 S-B-18.00/40a S-B-18.00/40 Dated October 28, 2008 18Document9 pagesFebruary 9, 2009 S-B-18.00/40a S-B-18.00/40 Dated October 28, 2008 18kevin gradinNo ratings yet

- TPI 2030685-5 - Oil Loss in Cylinder Head Areacylinder Head CoverDocument8 pagesTPI 2030685-5 - Oil Loss in Cylinder Head Areacylinder Head CoverDavianGiurcaNo ratings yet

- HH150 Smanual - MasterDocument43 pagesHH150 Smanual - Masterjacklyn ade putra80% (5)

- 1zua 5670-200 enDocument10 pages1zua 5670-200 enSURJIT SINGHNo ratings yet

- SEBF 8164 гизьзы 3500Document19 pagesSEBF 8164 гизьзы 3500Aminadav100% (1)

- Siddha Siddhanta Paddhati Natha YogisDocument35 pagesSiddha Siddhanta Paddhati Natha YogisNilkanth Yengde80% (10)

- Inspection Instructions: Steering AxlesDocument3 pagesInspection Instructions: Steering AxlesNeal YangNo ratings yet

- 0000bf-C-G0-G000-Pe-Pro-0001-B04 Flange Management Procedure - 12Document1 page0000bf-C-G0-G000-Pe-Pro-0001-B04 Flange Management Procedure - 12Eng.arifNo ratings yet

- Installation Instructions For PSI and Pikotek® Gaskets: Sleeves Through The Bolt HolesDocument4 pagesInstallation Instructions For PSI and Pikotek® Gaskets: Sleeves Through The Bolt Holesquiron2010No ratings yet

- On-Vehicle InspectionDocument5 pagesOn-Vehicle InspectionEdson CRNo ratings yet

- Piper SB 955 Engine Mount Nose Gear AttachmentDocument6 pagesPiper SB 955 Engine Mount Nose Gear AttachmentGeorgios AsimakopoulosNo ratings yet

- SL98-356 B&W Service LetterDocument14 pagesSL98-356 B&W Service LetterkamalNo ratings yet

- BOLTRIGHT Tightening Procedure 6 - 2500Document2 pagesBOLTRIGHT Tightening Procedure 6 - 2500Saad Abou-ZeidNo ratings yet

- Tpi 2026513 - 8 (02.07.2013)Document4 pagesTpi 2026513 - 8 (02.07.2013)mafejoNo ratings yet

- SB 1103BDocument5 pagesSB 1103BsandyNo ratings yet

- 1644 - 1 - sb-04-0314v2 - Db9 Sportspack Damper LeakDocument3 pages1644 - 1 - sb-04-0314v2 - Db9 Sportspack Damper Leakmink4uNo ratings yet

- Rolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 4Document24 pagesRolls-Royce M250-C20R SERIES OPERATION AND MAINTENANCE 720000 - 4anony8103No ratings yet

- Injector InstalacionDocument6 pagesInjector Instalacionjose luis herreraNo ratings yet

- Piston Height InspectDocument2 pagesPiston Height InspectbejoythomasNo ratings yet

- Service Bulletin: Compliance MandatoryDocument8 pagesService Bulletin: Compliance MandatorySaharKhaneshiNo ratings yet

- B+V Manual - Hinge Casing Spider 200 SH TonsDocument7 pagesB+V Manual - Hinge Casing Spider 200 SH TonsCong BuiNo ratings yet

- VEH MB ML320 High Oil ConsumptionDocument3 pagesVEH MB ML320 High Oil Consumptiond9dNo ratings yet

- Brakes-Electronic Service Information System (ERWIN - ERWIN) PDFDocument6 pagesBrakes-Electronic Service Information System (ERWIN - ERWIN) PDFOleksiy OsiychukNo ratings yet

- ASB 412-09-137A Page 1 of 10 Approved For Public ReleaseDocument10 pagesASB 412-09-137A Page 1 of 10 Approved For Public Releasesebastian eduardoNo ratings yet

- Infinity Man Rider Airr Winch Model FA150KGiDocument16 pagesInfinity Man Rider Airr Winch Model FA150KGiVianey Zavala0% (1)

- 73 10 01 PDFDocument6 pages73 10 01 PDFAnonymous 298xlo3uUNo ratings yet

- Instruction and Operating Manual GHH Powerband Driven ENDocument15 pagesInstruction and Operating Manual GHH Powerband Driven ENPiw WatchareeNo ratings yet

- John Crane Inc.: 6400 West Oakton Street Morton Grove, IL 60053-0805Document9 pagesJohn Crane Inc.: 6400 West Oakton Street Morton Grove, IL 60053-0805Aan Sarkasi AmdNo ratings yet

- IMO WD H MaintenanceDocument19 pagesIMO WD H MaintenancetaytaytaytayNo ratings yet

- 505 As Bas B 5052335Document11 pages505 As Bas B 5052335Bruno Alonso PachecoNo ratings yet

- Brake Technicians Service Guide PDFDocument28 pagesBrake Technicians Service Guide PDFleonardo cardenasNo ratings yet

- BOLTRIGHT Tightening Procedure 3 2500Document2 pagesBOLTRIGHT Tightening Procedure 3 2500pedro ylarretaNo ratings yet

- Bearing InspectionDocument20 pagesBearing InspectionMoustapha SeyeNo ratings yet

- Class 10000 Fans Owner'S ManualDocument19 pagesClass 10000 Fans Owner'S ManualhaosfNo ratings yet

- CSB14 1Document12 pagesCSB14 1dzakubNo ratings yet

- Operator E-Jets News Rel 07Document12 pagesOperator E-Jets News Rel 07PDDELUCA100% (1)

- Pistons and Connecting Rods - Assemble: Shutdown SISDocument3 pagesPistons and Connecting Rods - Assemble: Shutdown SISВиталийNo ratings yet

- Vibration Damper - Check: Testing and AdjustingDocument2 pagesVibration Damper - Check: Testing and AdjustingbejoythomasNo ratings yet

- Installation Instructions: Dry Gas Dual Cartridge Canister Seal For Mixers and AgitatorsDocument8 pagesInstallation Instructions: Dry Gas Dual Cartridge Canister Seal For Mixers and AgitatorsDima ArfNo ratings yet

- Complete Expansion Joint Inspection ReportDocument3 pagesComplete Expansion Joint Inspection ReportsunnyartboyNo ratings yet

- SM95C AgDocument7 pagesSM95C AghernanNo ratings yet

- Piper SB 971 Exhaust System InspectionDocument5 pagesPiper SB 971 Exhaust System InspectionRichard FloydNo ratings yet

- MC 10192120 9999Document4 pagesMC 10192120 9999Sam LorcaNo ratings yet

- Api Plan 11Document6 pagesApi Plan 11johnsaballaNo ratings yet

- Handling and Service Instructions For High Pressure Flexible HosesDocument20 pagesHandling and Service Instructions For High Pressure Flexible HosesRhdh kldmkNo ratings yet

- Cleveland Brake Technicians Service GuideDocument24 pagesCleveland Brake Technicians Service GuidesparkyoshidaNo ratings yet

- ENP-652 Cylinder Boss Wear and RepairDocument7 pagesENP-652 Cylinder Boss Wear and RepaireparodiesNo ratings yet

- Cleveland Wheel & Brakes Technician Service Guide AWBTSG0001Document28 pagesCleveland Wheel & Brakes Technician Service Guide AWBTSG0001Richard MayNo ratings yet

- Installation Instructions: Durametallic ML-200 SeriesDocument8 pagesInstallation Instructions: Durametallic ML-200 SerieslubangjarumNo ratings yet

- Owner GuideDocument741 pagesOwner Guidealfatih1407497100% (1)

- Torque Value PDFDocument8 pagesTorque Value PDF7761430No ratings yet

- Oil Filter Installation & ServiceDocument16 pagesOil Filter Installation & ServicemdhelicoptersNo ratings yet

- SUBJECT: Protection No.4 of Injection Pipe Crack From Vibration Models: Musso & Korando ConditionDocument4 pagesSUBJECT: Protection No.4 of Injection Pipe Crack From Vibration Models: Musso & Korando Conditionfrancisca19No ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Squirrels of Indian SubcontinentDocument14 pagesSquirrels of Indian SubcontinentAkshay MotiNo ratings yet

- Antena Parabolica HP4 71W P3A A RPE Andrew 12Document7 pagesAntena Parabolica HP4 71W P3A A RPE Andrew 12eduardo-mwNo ratings yet

- CWall Ex1Document5 pagesCWall Ex1Virginia gabyella saraunNo ratings yet

- Lê Thị Thu Thuỷ - Luận vănDocument97 pagesLê Thị Thu Thuỷ - Luận vănĐào Nguyễn Duy TùngNo ratings yet

- Masonic SymbolismDocument19 pagesMasonic SymbolismOscar Cortez100% (7)

- Physiology of LactationDocument29 pagesPhysiology of Lactationcorzpun16867879% (14)

- People vs. Asjali DigestDocument3 pagesPeople vs. Asjali DigestEmir Mendoza100% (1)

- School of Mount St. Mary, Inc.: Learning Module in Arts 10Document20 pagesSchool of Mount St. Mary, Inc.: Learning Module in Arts 10C'toik Y DweyNo ratings yet

- Narasimha Kavacham by Bhakta Prahlada - Bengali - PDF - File5475Document11 pagesNarasimha Kavacham by Bhakta Prahlada - Bengali - PDF - File5475Raghavendra RaghavendraNo ratings yet

- Workshop Manual: Engine Series 3 - 4 LDDocument48 pagesWorkshop Manual: Engine Series 3 - 4 LDNenadStojicNo ratings yet

- Detention Pond Design Excel PDFDocument31 pagesDetention Pond Design Excel PDFRenukadevi Rpt100% (1)

- Arts 7 - Q3 - Mod3 - TheLandofPromiseArtsofMindanao - V1Document28 pagesArts 7 - Q3 - Mod3 - TheLandofPromiseArtsofMindanao - V1DIANE BORROMEO,No ratings yet

- Notice 1658958950Document64 pagesNotice 1658958950Subrat NaikNo ratings yet

- English Test - Imterchange 1 - Unit 1-8Document5 pagesEnglish Test - Imterchange 1 - Unit 1-8GabrielaNo ratings yet

- Digital Image Processing - S. Jayaraman, S. Esakkirajan and T. VeerakumarDocument4 pagesDigital Image Processing - S. Jayaraman, S. Esakkirajan and T. VeerakumarBenedict IsaacNo ratings yet

- NARA T733 R4 Guide 60 PDFDocument140 pagesNARA T733 R4 Guide 60 PDFKurt MeyerNo ratings yet

- Gayatri MantraDocument2 pagesGayatri MantraAnandh ShankarNo ratings yet

- Written Report: Lydia Hall: Care, Cure, Core Nursing TheoryDocument12 pagesWritten Report: Lydia Hall: Care, Cure, Core Nursing TheoryAldrin Limcuando100% (1)

- Sales Budget in Millions $Document13 pagesSales Budget in Millions $IkramNo ratings yet

- Assignment2 1Document16 pagesAssignment2 1api-335877104No ratings yet

- ACP194Document32 pagesACP194Samar SamerNo ratings yet

- MATH CHALLENGE GRADE 2 - Google FormsDocument5 pagesMATH CHALLENGE GRADE 2 - Google FormsAivy YlananNo ratings yet

- WikiHow Is An Online WikiDocument4 pagesWikiHow Is An Online Wikiksdnfi ouvynNo ratings yet

- Explore (As) : Types of Commission and InterestsDocument4 pagesExplore (As) : Types of Commission and InterestsTiffany Joy Lencioco GambalanNo ratings yet

- Curriculum OF Environmental Science BS/MS: (Revised 2013)Document120 pagesCurriculum OF Environmental Science BS/MS: (Revised 2013)Jamal Ud Din QureshiNo ratings yet

- Vikram-Betal Case StudyDocument5 pagesVikram-Betal Case StudyRavi SawantNo ratings yet

- Neuromusic IIIDocument3 pagesNeuromusic IIIJudit VallejoNo ratings yet

- Renesas Application Note AN1340Document6 pagesRenesas Application Note AN1340Rip_BarNo ratings yet