Professional Documents

Culture Documents

Orifice Metering Design and Uncertainty Calculation

Orifice Metering Design and Uncertainty Calculation

Uploaded by

asesor.askaniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Orifice Metering Design and Uncertainty Calculation

Orifice Metering Design and Uncertainty Calculation

Uploaded by

asesor.askaniCopyright:

Available Formats

Knowledge Sharing

Custody transfer metering system :

Pengenalan Aspek Desain, Ketidakpastian

Pengukuran, Metrological Traceability dan

Implementasi di Lapangan

Yoyok Wiratmo

Metering Engineer

2 Desember 2023

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

1

Agenda Presentasi

1. Design Basis

2. Engineering document

3. Perhitungan Uncertainty

4. Optimasi Uncertainty

5. Perbandingan Uncertainty Design vs

Implementasi

6. Traceability

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

2

1. Design Basis

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

3

Design Basis (1)

◼ General

◆ Service : Natural Gas

◆ Type Flow Meter : Orifice meter

◆ Meter Run Size : 4” ANSI 300#

◆ Meter Configuration : 2 x 100% (1 standby stream)

◼ Flow Rate (Min/Nor/Max) : 0.6 / 5.3 / 8 MMSCFD

◼ Service Condition:

◆ Operating Press. (Min/Nor/Max) : 600/600/600 psig

◆ Operating Temp. (Min/Nor/Max) : 120/120/120 Deg F

◆ Design Press : 660 Psig

◆ Design Temp : 170 Deg F

◆ Base Press / Temp : 14.73 Psia / 60 Deg F

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

4

Design Basis (2)

◼ Gas Composition

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

5

Design Basis (3)

◼ Fluid Properties Result

Properties Value

Isentropic Exponent 1.3053971168078

Line Compressibility 0.935609096609986

Line Density at Normal Operating 1.9614374196 lb/ft3

Base Compressibility 0.997611368613929

Base Density 0.0491703248 lb/ft³

GHV 1018.56521467686 Btu/ft³

Viscosity 0.013 cP

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

6

Design Basis (4)

◼ Metering Standards

▪ Volumetric Flow : AGA 3

▪ GHV/Caloric Value : GPA 2172, 2009

▪ Gas Density & Compressibility : AGA 8, 1994

▪ Billing Unit : MMBTU

◼ Piping Code & Standards

▪ Design Piping Code : ASME B31.3

▪ Piping Material Specification : CS A106 GR.B (pipe) and

SS400 (structure)

▪ Piping Welding/NDT Code: Section IX of ASME/ ASME Sec V,

ASME B31.3

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

7

Design Basis (5)

◼ Safety & Protection

▪ Area Classification : Class 1 Zone 2 Group IIA, T3

▪ Certification Requirement:

ATEX approved or equivalent (FM, CSA, BASEEFA, IEC, DEKRA

or equivalent)

▪ Ingress Protection : IP-66

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

8

2. Engineering Document

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

9

P&ID Diagram

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

10

GA Drawing

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

11

System Arsitektur

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

12

3. Uncertainty Calculation

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

13

Gas Parameter

Sofware Tools: EMU-Orifice Fiscal Gas Metering Station, NFOGM

Technical reference:

• Handbook of Uncertainty Calculations Fiscal Orifice Gas and Turbine Oil Metering Stations.

Prepare for NFOGM, NPD & NIF, by Eivind Olav Dahl, Kjell-Eivind Froysa and Per Lunde (Christian

Michelsen Researcs AS)

• API MPMS 14.3.1

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

14

Pressure Measurement

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

15

Temperature Measurement

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

16

DP Measurement

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

17

Pipe Diameter

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

18

Orifice Plate

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

19

Beta

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

20

Expansibility

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

21

Discharge

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

22

Metering Station

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

23

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

24

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

25

4. Uncertainty Optimization

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

26

Uncertainty Optimation - Coefficient of discaharge

API MPMS 14.3.1:

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

27

Uncertainty Optimation - Beta Ratio

API MPMS 14.3.1:

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

28

USM Sizing Calculation

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

29

USM Sizing Calculation

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

30

5. Uncertainty Design vs Implementation

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

31

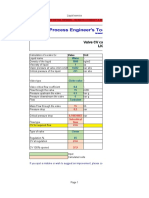

Uncertainty Design vs Implementation

Item Design Implementation

Equipment Accuracy Equipment Specs/ KHP/ Dimet Regulation

Manufacturer

calibration

Operating Condition As Per Design Basis Operational Data

Uncertainty 0.6306 0.6367

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

32

Uncertainty as per Implementation

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

33

Traceability

1. Calibrator

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

34

5. Traceability

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

35

Traceability

2. Transmitter Site Calibration

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

36

Traceability

3. Site Calibration Result

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

37

Traceability

3. Site Calibration Record

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

38

Terimakasih

| Document Number | March 23, 2016 |

© Yokogawa Electric Corporation

39

You might also like

- Equipment Calibration Record ChartDocument3 pagesEquipment Calibration Record ChartNatarajan MurugesanNo ratings yet

- Washout Valve and Air Valve SizingDocument3 pagesWashout Valve and Air Valve SizingA.ANo ratings yet

- Certificate of Compliance: Gasketed Pipe Fittings For Use With Aboveground Sprinkler SystemsDocument3 pagesCertificate of Compliance: Gasketed Pipe Fittings For Use With Aboveground Sprinkler SystemsJosé Luis ValderramaNo ratings yet

- SPC MSA GuidelinesDocument28 pagesSPC MSA Guidelinesbill100% (2)

- 0 2 Process Modeling-2Document31 pages0 2 Process Modeling-2deveshpratapchand.101421No ratings yet

- Fatigue Fortec FS32 Rolled thread BAS 2016Document4 pagesFatigue Fortec FS32 Rolled thread BAS 2016AKONo ratings yet

- Fatigue Fortec FS25 Rolled thread BAS 2016Document4 pagesFatigue Fortec FS25 Rolled thread BAS 2016AKONo ratings yet

- AZ-01 DPR Narhan Khas-RC HighDocument165 pagesAZ-01 DPR Narhan Khas-RC HighAzamgarh OfficeNo ratings yet

- 2SB1669 Datasheet, Equivalent, Cross Reference Search. Transistor CatalogDocument4 pages2SB1669 Datasheet, Equivalent, Cross Reference Search. Transistor CatalogDhany SiregarNo ratings yet

- Hook Excavator AnalysisDocument24 pagesHook Excavator Analysisdandy imam fauziNo ratings yet

- 23-2408679-PDA Full - 139954335Document7 pages23-2408679-PDA Full - 139954335gogoNo ratings yet

- Fatigue Fortec FS20 Rolled thread BAS 2016Document4 pagesFatigue Fortec FS20 Rolled thread BAS 2016AKONo ratings yet

- Aggregate 20mmDocument6 pagesAggregate 20mmTapan MohapatraNo ratings yet

- OEM Viscosity Compensated Flow Meter PDFDocument2 pagesOEM Viscosity Compensated Flow Meter PDF王敏No ratings yet

- Final Full ReportDocument54 pagesFinal Full ReportTNo ratings yet

- ASC Plant Management Data Sheet 4921240459 UK 2016.06.06Document19 pagesASC Plant Management Data Sheet 4921240459 UK 2016.06.06Daniel G. AmlakNo ratings yet

- BE-WI-248-01-F06 Datasheet Magnetic Flow MeterDocument3 pagesBE-WI-248-01-F06 Datasheet Magnetic Flow Metermika cabelloNo ratings yet

- 9500-WGEL-S003-ISGP-G00000-MP-4306-00017 - 01A - MTO PFF - by LayoutDocument7 pages9500-WGEL-S003-ISGP-G00000-MP-4306-00017 - 01A - MTO PFF - by Layoutsuresh100% (1)

- MEP20691 Presentation 20691 AU 202015 20ES10730-Effectively 20utilize 20REVIT 20for 20electrical 20design 20presentationDocument22 pagesMEP20691 Presentation 20691 AU 202015 20ES10730-Effectively 20utilize 20REVIT 20for 20electrical 20design 20presentationMuhammad NawazNo ratings yet

- LA LCM Report FarakkaDocument6 pagesLA LCM Report FarakkaSeam LukNo ratings yet

- MD-512-0G00-CN-PI-CAL-KB64-0003 - C01 Pipe Stress Analysis ST The End of LineDocument1,111 pagesMD-512-0G00-CN-PI-CAL-KB64-0003 - C01 Pipe Stress Analysis ST The End of LinerajeevfaNo ratings yet

- Bendaway Plus: Rubber-Cal, IncDocument2 pagesBendaway Plus: Rubber-Cal, IncninatenaNo ratings yet

- EH Coriolis & Ultrasonic DSDocument5 pagesEH Coriolis & Ultrasonic DSsendutdutNo ratings yet

- 9839-MUTU-ZIRA-00-STA-DST-0003 - Rev.A MDS Fire Water TankDocument3 pages9839-MUTU-ZIRA-00-STA-DST-0003 - Rev.A MDS Fire Water TankFikri MakhlufNo ratings yet

- LTJ-PGAS-GTLT-EN-DS-014 Vaporizer Data SheetDocument15 pagesLTJ-PGAS-GTLT-EN-DS-014 Vaporizer Data SheetsswahyudiNo ratings yet

- ROX000405521AB - Process Data Sheet MPFMDocument17 pagesROX000405521AB - Process Data Sheet MPFMKAABECHE SlimaneNo ratings yet

- Calibration Status of InstrumentsDocument1 pageCalibration Status of InstrumentsKumara SubramanianNo ratings yet

- Za 6Document21 pagesZa 6Yashvant NayarNo ratings yet

- Friction & Wear Monitoring of Sintered Spherical Iron Bush of Radiator FanDocument8 pagesFriction & Wear Monitoring of Sintered Spherical Iron Bush of Radiator FanIJIERT-International Journal of Innovations in Engineering Research and TechnologyNo ratings yet

- 0 4 Controller Building & OperationDocument59 pages0 4 Controller Building & OperationDevesh Pratap ChandNo ratings yet

- Instrument: Muara Karang Peaker Gas Meter Project Specification For CCTVDocument17 pagesInstrument: Muara Karang Peaker Gas Meter Project Specification For CCTVsugeng wahyudiNo ratings yet

- MSR206 Programmer's ManualDocument28 pagesMSR206 Programmer's ManualEnzo NovelloNo ratings yet

- Paramagnetic Oxygen Analyzer PDFDocument5 pagesParamagnetic Oxygen Analyzer PDFAnand PatelNo ratings yet

- 5 Ton Electrical DrawingDocument29 pages5 Ton Electrical DrawingMohammadNo ratings yet

- 6163 6M PPP0006 Mech StopDocument4 pages6163 6M PPP0006 Mech StopEdward MenaNo ratings yet

- Change Request Estimation AgreementDocument3 pagesChange Request Estimation AgreementRafayNo ratings yet

- HKKJR LJDKJ D'F"K, Oka Fdlku Dy K.K Ea Ky D'F"K) LGDKFJRK, Oa Fdlku Dy K.K Fohkkx) E'Khuhdj.K, Oa Izks - KSFXDH IzhkkxDocument31 pagesHKKJR LJDKJ D'F"K, Oka Fdlku Dy K.K Ea Ky D'F"K) LGDKFJRK, Oa Fdlku Dy K.K Fohkkx) E'Khuhdj.K, Oa Izks - KSFXDH IzhkkxFred WilfNo ratings yet

- Technical Drawings and Lists: Mazidaği Fertilizer Complex Project Doc - No: ETBMFCP-CTS-PI-ITP-0001 Rev.A Sheet 1 / 3Document3 pagesTechnical Drawings and Lists: Mazidaği Fertilizer Complex Project Doc - No: ETBMFCP-CTS-PI-ITP-0001 Rev.A Sheet 1 / 3HAKANNo ratings yet

- Material Test ReportDocument3 pagesMaterial Test ReportJuan Carlos Sua SuaNo ratings yet

- EFirePump Tornatech Jockey Pump JP3 Controller SubmittalDocument9 pagesEFirePump Tornatech Jockey Pump JP3 Controller SubmittalDaRio VasquezNo ratings yet

- JP3-Jockey-ControllerDocument9 pagesJP3-Jockey-Controller2331031115No ratings yet

- Waqas Ahmsd (2019-Msee-203)Document25 pagesWaqas Ahmsd (2019-Msee-203)muneebsaifNo ratings yet

- PDD CDM Talara-2022Document49 pagesPDD CDM Talara-2022Pawfuls mainNo ratings yet

- O&M Conf 2017 Paper - Mouda Learing by PUBDocument23 pagesO&M Conf 2017 Paper - Mouda Learing by PUBPrag SoodNo ratings yet

- MKP 05 en IC LST 001 Instrument IndexDocument5 pagesMKP 05 en IC LST 001 Instrument Indexsugeng wahyudiNo ratings yet

- 01) CP Training-STARDOM-NPAS POUDocument17 pages01) CP Training-STARDOM-NPAS POUSaad BroNo ratings yet

- Pre-Fat b90 Busbar Diff Test ReportDocument18 pagesPre-Fat b90 Busbar Diff Test ReportNgigiDanielNo ratings yet

- YKEPL MPI Procedure For A668 RMDocument4 pagesYKEPL MPI Procedure For A668 RMDeepak HoleNo ratings yet

- 23a02.nd30-08 Pompa Cip Uf SwroDocument7 pages23a02.nd30-08 Pompa Cip Uf SwroArsa WijayaNo ratings yet

- Tubeandpipejournal20200405-Dl Using Welding Code For WPSDocument52 pagesTubeandpipejournal20200405-Dl Using Welding Code For WPSjiao longNo ratings yet

- 20.00mm 16.00mm 12.50mm 10.00mm 4.75mm: Test ResultDocument2 pages20.00mm 16.00mm 12.50mm 10.00mm 4.75mm: Test ResultSainath AmudaNo ratings yet

- Control Circuit Protection: 5SJ4 Branch Circuit Protectors 5SY4 Supplementary Protectors 5SY6 Supplementary ProtectorsDocument30 pagesControl Circuit Protection: 5SJ4 Branch Circuit Protectors 5SY4 Supplementary Protectors 5SY6 Supplementary ProtectorsOscar Arnulfo Ardila LeonNo ratings yet

- Calibration Plan FROM 1 / 1 / 2016 TO 31/ 12 /2016Document4 pagesCalibration Plan FROM 1 / 1 / 2016 TO 31/ 12 /2016mohamed hamedNo ratings yet

- BE-WI-248-01-F07 Datasheet Turbine FlowmeterDocument3 pagesBE-WI-248-01-F07 Datasheet Turbine Flowmetermika cabelloNo ratings yet

- Full Thesis On GasDocument48 pagesFull Thesis On GasMd. Mominul IslamNo ratings yet

- Transco Abu DhabiDocument88 pagesTransco Abu DhabiShubham Prakhar100% (1)

- DS Flow IndicatorDocument4 pagesDS Flow IndicatornathaNo ratings yet

- (Sample) 6143-MAR-CU-0048 - R0 - Material Approval Request - Sikadur®-31 CF SlowDocument77 pages(Sample) 6143-MAR-CU-0048 - R0 - Material Approval Request - Sikadur®-31 CF SlowMuhammad AfrasiyabNo ratings yet

- Catalogo Actualizado ChintDocument39 pagesCatalogo Actualizado Chint12dante1767% (3)

- High Voltage Measurement Techniques: Fundamentals, Measuring Instruments, and Measuring MethodsFrom EverandHigh Voltage Measurement Techniques: Fundamentals, Measuring Instruments, and Measuring MethodsNo ratings yet

- Proceedings of the 6th International Workshop on Hydro Scheduling in Competitive Electricity MarketsFrom EverandProceedings of the 6th International Workshop on Hydro Scheduling in Competitive Electricity MarketsArild HelsethNo ratings yet

- Summary Review on the Application of Computational Fluid Dynamics in Nuclear Power Plant DesignFrom EverandSummary Review on the Application of Computational Fluid Dynamics in Nuclear Power Plant DesignNo ratings yet

- ISO - 4126-3 2006 (E) AngDocument18 pagesISO - 4126-3 2006 (E) AngDH BNo ratings yet

- Pressure Reducing ValveDocument15 pagesPressure Reducing ValveGabrielGrecoNo ratings yet

- HT Cengel - Chapter 7 - Mazlan 2016Document15 pagesHT Cengel - Chapter 7 - Mazlan 2016Afwan IrfanNo ratings yet

- Valve CV Calculation Tool Liquid: Value UnitDocument11 pagesValve CV Calculation Tool Liquid: Value UnitNoureddine MerahNo ratings yet

- Equipment Descriptions, Operating Characteristics, and Requirements PDFDocument50 pagesEquipment Descriptions, Operating Characteristics, and Requirements PDFHKHKBOOKSNo ratings yet

- Pulsatile Flow of Non-Newtonian Fluids Through Arterial StenosesDocument10 pagesPulsatile Flow of Non-Newtonian Fluids Through Arterial StenosesinsanNo ratings yet

- Mesh ShipDocument7 pagesMesh ShipPranshu MalikNo ratings yet

- Pme 111 - L3-5 - DmimDocument22 pagesPme 111 - L3-5 - DmimAbu SayeedNo ratings yet

- Hyd System - Part 1 Single Lift Pump (25,1.0,35,1.6, RR) (02.0-14.0-001)Document6 pagesHyd System - Part 1 Single Lift Pump (25,1.0,35,1.6, RR) (02.0-14.0-001)rorroscNo ratings yet

- Fluid Mechanics Professor: Salvador Vargas Díaz Final Theoretical Quiz Student NameDocument6 pagesFluid Mechanics Professor: Salvador Vargas Díaz Final Theoretical Quiz Student NameSALVADOR VARGAS DIAZNo ratings yet

- Design and Modeling of Fluid Power Systems: ME 597/ABE 591 - Lecture 6Document30 pagesDesign and Modeling of Fluid Power Systems: ME 597/ABE 591 - Lecture 6Elias80No ratings yet

- Paper 3Document10 pagesPaper 3saebimojtaba604No ratings yet

- Lec 7.Document57 pagesLec 7.Jejemon AntenorNo ratings yet

- FM PPT 4Document22 pagesFM PPT 4sagar mittalNo ratings yet

- MTD-99 100Document33 pagesMTD-99 100quoctrangbk02No ratings yet

- 4 HydraulicsDocument89 pages4 HydraulicsIvan Andres Seguel BristiloNo ratings yet

- FM Lab VivaDocument20 pagesFM Lab VivaXanely D'souza50% (2)

- Hydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)Document24 pagesHydrodynamic Calculation Butterfly Valve For Pump Operation (Lattice Disc)met-calcNo ratings yet

- Comparison Horizontal Vs Vertical SeparatorDocument54 pagesComparison Horizontal Vs Vertical SeparatorEng Kim Wei100% (6)

- FM Chapter2Document3 pagesFM Chapter2Drkumar SwamyNo ratings yet

- AE1110x 3c TranscriptDocument2 pagesAE1110x 3c TranscriptfffNo ratings yet

- Theoretical Calculations of The Distribution of Aerodynamic Loading On A Delta WingDocument35 pagesTheoretical Calculations of The Distribution of Aerodynamic Loading On A Delta WingHarsha HarNo ratings yet

- 2.2 CLSS PumpsDocument47 pages2.2 CLSS PumpsKevine Khaled100% (3)

- Resume 26jul2016without AnnexuresDocument15 pagesResume 26jul2016without AnnexuresDeekshith YennamNo ratings yet

- Listado de Partes Bomba FLOMAX 30 Mesas de CargaDocument1 pageListado de Partes Bomba FLOMAX 30 Mesas de CargaLibardo GonzalezNo ratings yet

- Seamless Butt Welding Fittings - ASTM A403M & ASME B16.9Document1 pageSeamless Butt Welding Fittings - ASTM A403M & ASME B16.9RICHARDNo ratings yet

- Piping & Instrumentation DiagramDocument1 pagePiping & Instrumentation DiagramSearch45No ratings yet

- Wca-01 Rolls Royce - Bulk Handling System BHS 608 PDFDocument146 pagesWca-01 Rolls Royce - Bulk Handling System BHS 608 PDFANo ratings yet