Professional Documents

Culture Documents

Used Beverage Cans (UBC) : 1. Definition

Used Beverage Cans (UBC) : 1. Definition

Uploaded by

kali50673Copyright:

Available Formats

You might also like

- Instruction Manual On Corrugated BoxesDocument10 pagesInstruction Manual On Corrugated BoxesHussain100650% (4)

- 2-ASCE 7-16 (Minimum Design Load - American Sociaty of Civil Engineering)Document40 pages2-ASCE 7-16 (Minimum Design Load - American Sociaty of Civil Engineering)Ayham Aljawhary100% (2)

- The Effect of Cargo, Including Heavy Lift On Seaworthiness and Stability of ShipDocument57 pagesThe Effect of Cargo, Including Heavy Lift On Seaworthiness and Stability of ShipMJ Angeles100% (2)

- Earthwork and BlastingDocument15 pagesEarthwork and BlastingJoseph MagbanuaNo ratings yet

- B39-79 (2013) Standard Specification For NickelDocument3 pagesB39-79 (2013) Standard Specification For NickeldcardonasterNo ratings yet

- Seaworthy Packing ProcedureDocument10 pagesSeaworthy Packing ProcedureAnonymous gr5Pr9AVNo ratings yet

- Pressure VesselsDocument9 pagesPressure VesselsSajal KulshresthaNo ratings yet

- Astm D 6880-2005Document5 pagesAstm D 6880-2005Jarvis Wang0% (1)

- Class 1 Explosives: Class/ Divisions Description Label Examples DynamiteDocument6 pagesClass 1 Explosives: Class/ Divisions Description Label Examples DynamiteRhyze Leiane OrtizNo ratings yet

- Subcourse Edition FA 3117 B Us Army Field Artillery School Field Artillery Cannon AmmunitionDocument153 pagesSubcourse Edition FA 3117 B Us Army Field Artillery School Field Artillery Cannon AmmunitionVicente VelezNo ratings yet

- Ragnar's Homemade Detonators - H - Ragnar BensonDocument68 pagesRagnar's Homemade Detonators - H - Ragnar BensonFrederico WernerNo ratings yet

- Chemicals Handling: OGDCL Oil & Gas FieldDocument19 pagesChemicals Handling: OGDCL Oil & Gas FieldGHULAM MOHYUDDINNo ratings yet

- Alphabroder - Carton Specification-Version 7.0. 2019Document2 pagesAlphabroder - Carton Specification-Version 7.0. 2019DebashishDolonNo ratings yet

- Klipen Packing and Palletizing Standard 2022Document35 pagesKlipen Packing and Palletizing Standard 2022Roger Manrrique NinaNo ratings yet

- UBC Product Quality Specifications: Management Process/Procedures ManualDocument10 pagesUBC Product Quality Specifications: Management Process/Procedures ManualHafed AbdulhadiNo ratings yet

- MS 8314-05Document4 pagesMS 8314-05AkramNo ratings yet

- WFP 0000140775Document8 pagesWFP 0000140775teddynigusu5No ratings yet

- Floating Docks, Rafts and Boatwells: Plans For Build-It-YourselfDocument16 pagesFloating Docks, Rafts and Boatwells: Plans For Build-It-Yourselfjo_he_toNo ratings yet

- Issued By: Issue Date ReplacesDocument4 pagesIssued By: Issue Date ReplacesJAWAHAR TNo ratings yet

- 28 Inch Mattone Cupola - Oven - BrickWood OvensDocument19 pages28 Inch Mattone Cupola - Oven - BrickWood Ovensvidawo1012No ratings yet

- Testing of Corrugated BoxDocument5 pagesTesting of Corrugated BoxVinod NairNo ratings yet

- BP Strenght Vs CrushDocument3 pagesBP Strenght Vs CrushgetnaniNo ratings yet

- UN Dangerous Goods Brochure 2014Document17 pagesUN Dangerous Goods Brochure 2014Troy Theboy Mcnamara100% (3)

- Poly Drums: Protecting People, Property and The Planet. Since 1894Document16 pagesPoly Drums: Protecting People, Property and The Planet. Since 1894arachman297988No ratings yet

- 8314 08Document3 pages8314 08Pendurti SuryanarayanaNo ratings yet

- Acuflo Price List 2016Document35 pagesAcuflo Price List 2016anilrawat1987No ratings yet

- Carbon Black-Sampling Packaged Shipments: Standard Practice ForDocument3 pagesCarbon Black-Sampling Packaged Shipments: Standard Practice ForLemir LopezNo ratings yet

- Refuse Disposal FinalDocument46 pagesRefuse Disposal FinalAmirul Rasyid Shansul BahriNo ratings yet

- Barrier of Alu FoilDocument5 pagesBarrier of Alu FoilHOANGVUNL1988No ratings yet

- Efibca Q A Eng Final ADocument20 pagesEfibca Q A Eng Final ASunny GhadgeNo ratings yet

- Corrugated Fiberboard DesignDocument39 pagesCorrugated Fiberboard DesignsudarshanNo ratings yet

- Intalox PackingDocument16 pagesIntalox Packingmfaizal81No ratings yet

- FLS Packing ManualDocument50 pagesFLS Packing ManualDhaman A KokaNo ratings yet

- JBT8660-1997 - Hydropower Generating Units Packing, Transportation and Storage StandardDocument12 pagesJBT8660-1997 - Hydropower Generating Units Packing, Transportation and Storage StandarddadanjunkmailNo ratings yet

- B 900 - 99 - QjkwmaDocument12 pagesB 900 - 99 - QjkwmaLuis AndradeNo ratings yet

- Electrode ManualDocument18 pagesElectrode ManualAnonymous 4e7GNjzGWNo ratings yet

- Document 5Document56 pagesDocument 5Ajin SNo ratings yet

- LBritton Static Hazards in FIBCDocument22 pagesLBritton Static Hazards in FIBCAnonymous 1XHScfCINo ratings yet

- AQIS Packing Declaration (01.AUG.09)Document1 pageAQIS Packing Declaration (01.AUG.09)Chze NienNo ratings yet

- Saw Storage HandlingDocument1 pageSaw Storage HandlingDave MulvihillNo ratings yet

- Shipping Platform Standards 2019 PDFDocument32 pagesShipping Platform Standards 2019 PDFPaula CordobaNo ratings yet

- Apparent and True Specific Gravity and Porosity of Lump CokeDocument3 pagesApparent and True Specific Gravity and Porosity of Lump CokeLuis Alberto Curtidor GuataquiNo ratings yet

- Corugated Boxes FinalDocument25 pagesCorugated Boxes FinalMoeez SaleemNo ratings yet

- Buried Pipe: A. Trench Design and Burial DepthsDocument6 pagesBuried Pipe: A. Trench Design and Burial DepthsjosethompsonNo ratings yet

- 31t-65-Exothermic Materials For Molded Exothermic SleevesDocument3 pages31t-65-Exothermic Materials For Molded Exothermic SleevesCharlie ChongNo ratings yet

- Ad 0670927Document27 pagesAd 0670927Evilneko1No ratings yet

- C 602 - 95a R01 QZYWMGDocument3 pagesC 602 - 95a R01 QZYWMGHumberto Gutierrez100% (1)

- 002AL Mineral Wool DatasheetDocument2 pages002AL Mineral Wool Datasheetgeorgekc77No ratings yet

- To Make A Spudgun: An Instructionally Informative Document by EnoctisDocument12 pagesTo Make A Spudgun: An Instructionally Informative Document by EnoctisSeanNo ratings yet

- Conditions For Acceptance of Waste in The Untertagedeponie HeilbronnDocument2 pagesConditions For Acceptance of Waste in The Untertagedeponie HeilbronnAmilton filhoNo ratings yet

- June 2005 Proper Packaging Required To Maintain TraceabilityDocument4 pagesJune 2005 Proper Packaging Required To Maintain TraceabilityJesika Andilia Setya WardaniNo ratings yet

- Basco IBC Catalog 2013Document16 pagesBasco IBC Catalog 2013Mario BarbarićNo ratings yet

- Waste-Containers BROCHURE FOR REFERENCEDocument2 pagesWaste-Containers BROCHURE FOR REFERENCEasnawisulong mohdNo ratings yet

- Sale Contract 1Document5 pagesSale Contract 1Nguyễn HuyềnNo ratings yet

- Nonperforated Hardwound Roll Towels: No. Feet/Roll Rolls/Case CaseDocument1 pageNonperforated Hardwound Roll Towels: No. Feet/Roll Rolls/Case Casenoelle90No ratings yet

- Secondary ContainmentDocument30 pagesSecondary ContainmentNghiem H. VUNo ratings yet

- TEC SPEC 40HC Oct17 - Rev2Document15 pagesTEC SPEC 40HC Oct17 - Rev2James DanielNo ratings yet

- D 5168 - 03 - RduxnjgDocument6 pagesD 5168 - 03 - Rduxnjgjamaljamal20No ratings yet

- Lab Glassware - Catalogue 2012 13 ScreenDocument100 pagesLab Glassware - Catalogue 2012 13 Screengameel alabsiNo ratings yet

- Tex 600JDocument44 pagesTex 600JLucio Rodriguez SifuentesNo ratings yet

- Corrugated BoardDocument5 pagesCorrugated Boardoanne_08No ratings yet

- 80080-GT-017-E - SIGNED - 2-Packing RequirementsDocument14 pages80080-GT-017-E - SIGNED - 2-Packing RequirementsPaul NieNo ratings yet

- Bill of Materials Template 18Document30 pagesBill of Materials Template 18Kerem İnanNo ratings yet

- Packaging Essential GlossaryDocument35 pagesPackaging Essential GlossarygisellaNo ratings yet

- Charge Block Demolition TNTDocument1 pageCharge Block Demolition TNTBlentica FlajicNo ratings yet

- Packaging Closures and Sealing SystemsFrom EverandPackaging Closures and Sealing SystemsNigel TheobaldNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Interzinc 52E Grey Part ADocument12 pagesInterzinc 52E Grey Part AkurniawanajisasonoNo ratings yet

- NHBC GasDocument132 pagesNHBC GasBart kaczynskiNo ratings yet

- Manual de Aspiradora WD1851Document40 pagesManual de Aspiradora WD1851Ale PalomoNo ratings yet

- ELVAX 3174 Ethylene Vinyl Acetate Copolymer-Hoja de Datos de Seguridad-EnDocument11 pagesELVAX 3174 Ethylene Vinyl Acetate Copolymer-Hoja de Datos de Seguridad-EnMauricio vascoNo ratings yet

- RIOSEIS GX-Plastic Shell - ENGDocument2 pagesRIOSEIS GX-Plastic Shell - ENGjesusjplNo ratings yet

- Safety Data Sheet Acetylene, Dissolved: SDS - MY - 000010021936Document8 pagesSafety Data Sheet Acetylene, Dissolved: SDS - MY - 000010021936abgemanNo ratings yet

- 1 Captain MsdsDocument5 pages1 Captain MsdsSaad IqbalNo ratings yet

- 4198 App BDocument10 pages4198 App BIvan BodnaryukNo ratings yet

- UN REPORT Rural Structures 5Document5 pagesUN REPORT Rural Structures 5Nicholas ThompsonNo ratings yet

- Explosion Proof CCTVDocument4 pagesExplosion Proof CCTVAhmad AjiNo ratings yet

- Explosive Forming or HERFDocument6 pagesExplosive Forming or HERFharicoolestNo ratings yet

- 110105207n - TartrazineDocument12 pages110105207n - Tartrazinetalita.solerNo ratings yet

- P.O.M ProjectDocument18 pagesP.O.M Projectazeem bhatti0% (1)

- Analysis of Explosives and Explosive Residues. Part 1" Chemical TestsDocument8 pagesAnalysis of Explosives and Explosive Residues. Part 1" Chemical TestsNelson GomesNo ratings yet

- Ebook Process Safety Calculations PDF Full Chapter PDFDocument67 pagesEbook Process Safety Calculations PDF Full Chapter PDFdawn.stpierre822100% (36)

- T Ovex Section: Personal Protective EquipmentsDocument8 pagesT Ovex Section: Personal Protective EquipmentsShahab Ud DinNo ratings yet

- 5912 KX 99 - (Usa)Document7 pages5912 KX 99 - (Usa)keltorNo ratings yet

- Is 12681 1989Document15 pagesIs 12681 1989dipen royNo ratings yet

- Jet-A1 MSDS Gulf Aviation 2014Document13 pagesJet-A1 MSDS Gulf Aviation 2014Son NguyenNo ratings yet

- Cdi 6 Fire Tech2Document102 pagesCdi 6 Fire Tech2Clark James Dacillo RodaNo ratings yet

- 100-028-544 - ALLIANT SPORT PISTOL POWDER, 1LB - 69B - DefaultDocument13 pages100-028-544 - ALLIANT SPORT PISTOL POWDER, 1LB - 69B - DefaultDavid WilliamsNo ratings yet

- Icheme Symposium Series No. 124Document16 pagesIcheme Symposium Series No. 124rusli bahtiarNo ratings yet

- Blasting ConceptsDocument80 pagesBlasting ConceptsAnil Kumar garadaNo ratings yet

Used Beverage Cans (UBC) : 1. Definition

Used Beverage Cans (UBC) : 1. Definition

Uploaded by

kali50673Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Used Beverage Cans (UBC) : 1. Definition

Used Beverage Cans (UBC) : 1. Definition

Uploaded by

kali50673Copyright:

Available Formats

Used Beverage Cans (UBC)

This is the Tri-Arrows / Logan Aluminum specification for Used Beverage Cans (UBC) in Bales

and Biscuit Forms.

1. Definition

Used Beverage Cans (UBC) – Used aluminum cans (post-consumer) free of other scrap metals,

foil, tin cans, food cans, steel cans, plastic bottles, paper, glass and other non-metallic items. All

UBC scrap must be magnetically separated prior to baling regardless of Processing Origin and

free of steel, lead, bottle caps, plastic cans and other plastic, glass, wood, dirt, grease, trash and

other foreign substances. Aluminum items other than UBC are unacceptable and are grounds for

rejection. Variations to this specification should be agreed between TAA and the seller prior to

shipment and documented in the Purchase Order. Material thickness for UBC of all current types

is <0.0200” max.

2. Purchase Order Contingency

Each purchase order or contract is contingent upon the supplier’s acceptance of these terms.

Supplier acknowledges that delivery of any material to TAA / Logan shall be deemed acceptance

of these terms, and agrees that any terms and conditions contained in a proposal, quotation,

acknowledgement, acceptance, invoice, or other document of supplier which are different from or

in addition to these terms and conditions shall not constitute a part of the purchase order and are

hereby expressly rejected, and that no employee of TAA nor Logan is authorized to or may, waive

nor modify these rights.

3. Supporting Documentation

Shipping documentation must accompany each load. The documentation must be either provided

by the driver or affixed to the shipping container. The documentation must be accurate and clearly

state the following:

• Purchase order number

• Appointment Number

• Bill of Lading number

• Material Classification

• Material Source (yard/origin)

• Items Shipped

• Piece Count of each material type

• Gross, tare weights of each material type

Incorrect/missing information on the shipment documentation may result in either a delay in

unloading or in a rejection of the receipt of the material.

3.1 Split Loads

Documentation must support the material on the truck. The recommendation for loading split

loads is to load the material type with the greatest quantity first. Then load the material type with

the second greatest quantity next. Then the remainder of the material can be loaded. No more

than 3 material types per load without prior approval.

UBC Specification page 1 of 11

Used Beverage Cans (UBC)

4. Insurance

Each vendor selling scrap or metal to TAA / Logan shall have and maintain adequate minimum

insurance coverage including but not limited to, general and product liability insurance coverage,

protective of both TAA / Logan and supplier from any and all claims and liabilities for property

damage, personal injury, death, and economic damage, that arise from the material and

associated activities, hereunder, endorsed as required, at all times while conducting business

with TAA / Logan.

5. Material Safety Data Sheet

Per the requirements of 29 CFR 1910.1200, the supplier, vendor, or importer must provide a

Material Safety Data Sheet (MSDS) for the metal or scrap sold to TAA.

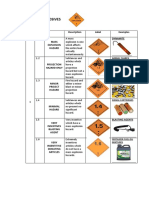

6. Types by Processing Origin

All UBC scrap must be designated by its Processing Origin. Failure to properly designate UBC

Processing Origin is grounds for rejection. The hierarchy for “processing origin” is as follows, in

order from 6.1 to 6.5.

6.1 UBC-MRF: UBC Originated from Municipal Recycle Facilities (any location)

6.2 UBC-Deposit: UBC originating from deposit collection programs in USA/CAN

6.3 UBC-D: All Other Domestic UBC originating inside USA or CANADA

6.4 UBC-M: Imported UBC originating from Mexico

6.5 UBC-I: Imported UBC originating from countries other than Mexico

*All Inbound scrap deliveries MUST include the origin location on the BOL provided*

7. UBC Bale Types

UBC is acceptable in Bale, HD Bale, and Biscuit form for all bulk density less than 55 lb/cubic ft.

Briquettes/Bricks (ISRI designation TALDORK “Briquetted Aluminum UBC scrap”) with high bulk

density >55 lb/cubic ft are NOT acceptable.

Table 7.1 Acceptable and Unacceptable UBC Bale Types and Bulk Density Values

Logan

Package Industry BULK Acceptable /

Code Name ISRI Name DENSITY Logan Bale/Bundle Size Not Accepted

Bale Standard “TALDON” 14-25 lb/ft3 Volume >30 cubic ft each Acceptable

Bale Bale 24-40” x 30-52” x 40-72”

HD Bale Hi Density n/a 25-30 lb/ft3 Volume >40 cubic ft each Acceptable

Bale Bale 24-40” x 30-52” x 40-72”

Biscuit Biscuit- “TALDACK” 35-55 lb/ft3 Weight <50 lb per biscuit Acceptable

Densified Bale 41-44” x 51-54” x 54-65”

Biscuit 10-13”x10¼-20”x 6¼-9”

HD Bricks, “TALDORK” >55 lb/ft3 Weight < 4,000 lb per Bale NOT ACCEPTED

Briquette Briquettes Bale 24-40” x 30-52” x 40-72”

Brick A12-24” x B12-24” x 8-48”

where A=B

UBC Specification page 2 of 11

Used Beverage Cans (UBC)

8. Moisture Deduction:

UBC should be dry; therefore, it is suggested that material not be stored or processed outside.

A random sample will be pulled from each load to calculate a moisture percentage. Shipments

with moisture in excess of 4% will be subject to a weight deduction or rejection. The deduction

will equal the tested moisture percent minus 2%. See example below.

Table 8.1 Example of Moisture Deduction Calculation

9. Contamination

The presence of the following items in a load of UBC material may be deemed reason for

DOWNGRADE or REJECTION. See Section 11. Items include, but are not limited to:

a) Paper

b) Iron & Steel, brass, bronze and other nonferrous metals

c) Batteries

d) Rocks, dirt, sand and glass

e) Rubber, foil, pie pans, and wood

f) Insulated beverage containers

g) Excessive Moisture – Please note that loads with a moisture level greater than 4% of

the load weight will be subject to a weight deduction (financial penalty) or rejection.

h) Plastic – This includes both free plastic and/or plastic added to UBC during the

manufacturing process such as plastic label sleeves, plastic in bottle caps, plastic screw

tops, nitrous widget balls, plastic nitrous tops, etc.

i) Food cans, steel cans, other non- beverage cans.

j) Oxidation.

10. Material Packaging Specifications

Improper packaging is grounds for rejection. TAA / Logan accepts Bales, high density Bales,

and Biscuit forms of UBC in appropriate packaging as listed below. Failure to follow these

packaging specifications is cause for downgrade or rejection.

10.1 Bales (TALDON)

See Table 7.1 for dimensions and bulk density.

Proper Banding:

Wire Ties – minimum 4, maximum 10

o Wire 10-gauge aluminum or

o Wire 13-gauge steel

Banding – minimum 4, maximum 6

o Bands 5/8” x 0.020” steel or

o Bands 5/8” x 0.036” plastic

Bales should separate into sections when banding/wire is cut

UBC Specification page 3 of 11

Used Beverage Cans (UBC)

Bales of uniform size are preferred.

Use of support sheets (cardboard, plastic, etc) is not acceptabl

10.2 HD Bales (no ISRI name)

See Table 7.1 for dimensions and bulk density.

Proper Banding:

Wire Ties – minimum 4, maximum 10

o Wire 10-gauge aluminum or

o Wire 13-gauge steel

Banding – minimum 4, maximum 6

o Bands 5/8” x 0.020” steel or

o Bands 5/8” x 0.036” plastic

Bales should separate into sections when banding/wire is cut

Bales of uniform size are preferred.

Use of support sheets (cardboard, plastic, etc) is not acceptable.

10.3 Biscuits (TALDACK)

See Table 7.1 for dimensions and bulk density.

Proper Banding:

Banding – banding slots in both directions (2 vertical, minimum 4 horizontal)

o 5/8” x 0.020” steel or

o 5/8” x 0.036” plastic

Bales should separate into sections when banding/wire is cut

Bales of uniform size are preferred.

Use of support sheets (cardboard, plastic, etc) is not acceptable.

Per Table 7.1, bales of High Density Briquettes / Bricks >55 lb/ft3 (ISRI “Taldork”) are NOT accepted by

TAA/Logan.

Examples of Proper Packaging

UBC Std Bale – at least 4 wires UBC Biscuit w/ Steel Bands UBC Biscuit w/ Steel Bands

UBC Specification page 4 of 11

Used Beverage Cans (UBC)

Examples of Improper Packaging

UBC Specification page 5 of 11

Used Beverage Cans (UBC)

11. Material Downgrade/Rejection

Material that does not meet the requirements of this specification *OR* additional appropriate

requirements set forth in the purchase order may be subject to Downgrade or Rejection.

11.1 Downgrades

If the material is deemed acceptable by an assignable downgrade of the material, the vendor has

two options:

Option 1 - The vendor can accept a downgrade of the material accompanied by an

adjustment to the terms of the purchase of the material.

Option 2 - Vendor can arrange to have the material picked up and removed from Logan

property

Vendor has 48 hours after receipt to dispute a downgrade, after which, the load will be

automatically accepted with the associated downgrade.

Examples of Downgrades

UBC Specification page 6 of 11

Used Beverage Cans (UBC)

11.2 Rejections

If the material in a load is inspected and REJECTED based on the specification, purchase order, or other

reasonable means then the Vendor will take the load back per the Commercial Agreement or Purchase

Order with TAA. Due to space limitations, all rejected material must be removed as soon as possible.

Material rejected at the time of delivery will automatically be reloaded on the truck it was delivered on.

Material rejected and off-loaded will have two working days to be removed from Logan Aluminum. If the

rejected material has not been removed in the allotted time, a truck will be scheduled for pickup and the

material sent collect to the vender or location of the vendor’s choice. The vendor is responsible for costs of

shipping and return for rejected materials.

11.3 Other Safety Items Deemed Reasons for Rejection

The presence of any amount of the following items in a load of UBC are hazardous to the customers and

employees of Logan Aluminum and their Associates and as such are cause for immediate rejection and

potential disqualification due to the threat they pose. Items include, but are not limited to:

a) Butane lighters - Butane lighters can have the strength of three sticks of dynamite when

submerged into molten metal. More commonly found in UBC loads, and sometimes seen on the

floor of the truck when unloading

b) Medical waste/hypodermic needles - Needles, surgical gloves, medical waste, etc. will not

be accepted. Logan Aluminum is not set up to process/deal with this type of material

c) Ordinance, ammunition, or explosive subassemblies, live rounds, or scrap of any kind -

Explosion potential for both shredding and melting operations. The assumption is, if there is one

in the load there may be additional ones that are not visible and there is no guarantee that there

are no live rounds.

d) Liquid storage and transfer vessels that can contain residual liquids (fuel/oil/antifreeze)

– These tanks have both a potential closed container risk as well as the risk associated with

flammable liquid/fumes. Material should be shredded and allow to be dried or verified that no fuel

is present prior to melting or rejected.

e) Fertilizers/oxidizers - Fertilizer is an oxidizer. When an oxidizer (Nitrates/Sulfates etc.) are

mixed with molten metal a violent reaction will occur. It takes very little material to create an

explosion

f) Closed Containers – Closed containers can include but are not limited to oxygen tanks, fire

extinguishers, crimped closed tubing, Freon tanks, aerosol cans, beer kegs, and baseball bats.

Closed containers can develop extreme pressure when submerged in molten metal. Once the

pressure reaches the burst limit of the vessel it can spray molten metal or present additional

explosion potentials

g) Hazardous Chemicals – Hazardous chemicals such as PCB’s, pesticides, asbestos, etc. or

loads that are labeled to include these materials will not be accepted

h) Free lead

i) Radioactive sources or Materials displaying Radioactive Warning Labels - Materials that

fail to pass the gate radiation detector inspection process and any materials with a radioactive

warning label will be rejected and returned following regulatory guidelines

j) Unidentifiable materials/substance

k) Infestation of the UBC by insects, rodents, etc.

l) Batteries (lead cell)

m) Excessive hydrocarbons

UBC Specification page 7 of 11

Used Beverage Cans (UBC)

Examples of Rejections

UBC Specification page 8 of 11

Used Beverage Cans (UBC)

12. General Inspection

12.1 Inspection Report Documentation

Documentation of the inspection reports will be supplied in order to expedite settlement of

issues such as weight discrepancies, downgrades and rejected loads.

12.2 Quality Verification

Each load will be inspected upon delivery. The material will be verified that it meets the criteria

established within the purchase specification agreement. The material will be inspected for

items such as excessive moisture, oil, dirt, garbage, plastic, glass, non-aluminum contaminants,

aluminum fines, nitrates, sulfates, safety hazards, packaging issues, contamination of any kind.

The results of the material inspection may be subject to a load rejection or if agreed upon, the

material may be downgraded. Issues noted during inspection will be photographed and

documented to the shipper.

During inspection, a determination will be made as to whether the material meets the purchase

specification. If the load is determined to meet expectations, no deduction will be made

regarding contamination.

Items that will be subject to immediate rejection of the entire load if found during the inspection

include, but are not limited to: butane lighters, aerosol cans, hypodermic needles, live

ammunition, explosives, gasoline, propane bottles or other gas cylinders or bottles, medical

waste / infectious materials, radioactive material, PCB’s, mercury, asbestos, Freon, poisons,

acids, fertilizer, rodents, excessive corrosion, oxidizers, flammable liquids, closed containers,

crimped tubing, lead paint and other questionable items. The presence of these items poses a

safety hazard to personnel and is not debatable.

12.3 Moisture Sampling Procedure

Sampling will be performed on all UBCs according to Logan Aluminum’s standard operating

procedure 5.01.001.006. A SINGLE TEST will be performed upon delivery for determining

moisture content. Material will be sampled under cover out of the elements. Loads with moisture

levels exceeding an agreed upon threshold will automatically be put on hold. A load will be held

for two working days for notification to the supplier. If in the allotted time a decision to accept or

reject the test results has not been relayed to Logan Aluminum. The test results will be

accepted, and the load will be identified in inventory as ready for production. Downgrades will

be handled in accordance with Table 8.1 Example of Moisture Deduction Calculation.

12.4 Radioactive or Hazardous Material Detection

Material delivered to Logan Aluminum and found to be contaminated by radiation will be

handled according to Logan policy. Any material triggering either of the two Logan radiation

detectors will be rejected. Scrap, raw materials or packaging must not contain or be

contaminated with hazardous material. TAA/Logan will have the right to revoke the acceptance

of the material at any time. All costs and liability associated with radioactive material will be the

responsibility of the supplier.

UBC Specification page 9 of 11

Used Beverage Cans (UBC)

If radiation is present, the truck must remain on site while a US DOT SP-10656 form is

completed by a Logan Aluminum ESS Representative. Upon completion, the form will be

submitted to the necessary members of the US DOT.

An individual from the US DOT will then issue the permit US DOT SP-10656 for the carrier to

return the load to the point of origin. The permit must be placed on the outside of the trailer. A

copy of the US DOT SP-10656 permit will also be given to the driver in case of any damage

caused to the original during transit.

Logan personnel will obtain the necessary permit for the shipment to leave plant-site, ensuring

that regulatory requirements for the state of Kentucky have been met.

Once the shipment has left the plant, Logan/TAA is no longer liable, and it is the full

responsibility of the carrier/supplier to meet any other regulatory requirements imposed

by other states.

13. Trucks – Expectations and Procedures

13.1 Prep

Drivers must exit the cab, give their keys to Logan personnel, and chock the wheels of their

trailer.

13.2 Driver Safety

Driver must (a) stay in an area designated by Logan personnel and (b) wear “approved PPE” at

all times.

Approved PPE: Safety Glasses, Hard Hat, Long Pants, Long Sleeve Shirt, Closed Toed Shoes,

and High Visibility Clothing. If any of this is not worn when arriving at any dock, it will result in

automatic rejection of the LOAD.

UBC Specification page 10 of 11

Used Beverage Cans (UBC)

13.3 Process for Truck Delivery

Drivers must check in at Truck Processing with correct unload number and paperwork upon

arrival.

Drivers for all Inbound Deliveries to Logan Aluminum will leave their Driver’s License at the

Gatehouse upon check in. The Driver’s License will be returned once the trucks have been

correctly out-processed.

Truck drivers will be instructed by Truck Processing Attendants of plant rules and required PPE.

After being checked-in drivers will be sent to the truck staging area to wait for unloading.

Truck drivers will wait at staging area with load secured. Operators will direct drivers to the

designated area for unloading.

Drivers are required to wear proper PPE when out of truck unstrapping load.

If driver must get on trailer to unstrap load, safety rails must be attached to trailer. Safety rails are

located at Metal Control, Hotmill unloading area, and Tarping areas.

All drivers must chock the wheels of their trailer, before the unloading operator will start

unloading/loading process.

All drivers must give ignition key(s) to the unloading operator who will maintain possession of the

key(s) until the unloading/loading process has been completed.

Forklift operator will not start unloading trailer until all straps and/or chains are rolled up and/or

put away.

All drivers and passengers must remain OUT OF THEIR TRUCK and stay in the designated

waiting areas provided by Logan Aluminum until the unloading/loading process has been

completed.

Absolutely NO cans, bottles, or butane lighters allowed onsite.

All drivers are responsible for cleaning/sweeping out their own trailers into designated area

provided by Logan Aluminum.

No one other than Logan Aluminum personnel allowed on the dock areas at any time.

When unloading is complete driver will be instructed how to exit to the outbound scales.

ANY INDIVIDUALS THAT DO NOT FOLLOW LOGAN ALUMINUM SAFETY REQUIREMENTS

WILL BE REQUESTED TO LEAVE THE PROPERTY IMMEDIATELY.

13.4 Van Trailer - Expectations for Vans During Delivery

1. The minimum height requirement is 105 inches.

2. All vans must have floors in good condition. Any vans found to have unsafe floor conditions will

not be unloaded.

3. Material must be braced or loaded in a manner to prevent material shifting. If the material has

shifted it will not be unloaded if determined to be unsafe to the operator or damage to the trailer

may occur.

4. Sufficient spacing must be maintained between the material and the roof/sides of the trailer.

Material packed or wedged into the trailer will not be unloaded unless the trucking company or

driver signs a waiver releasing Logan and Logan personnel of all liability.

5. Trucks must remain in line near the truck scale until called for unloading. Trucks must not

proceed to the unloading area without permission of the Logan unloading personnel.

6. Drivers must follow all safety rules communicated to them when at the gatehouse. Drivers must

stay with their truck. Drivers may enter the Recycle Receiving office but must not enter any

production areas.

7. Dunnage must not be left at Logan and must leave with the truck.

8. Logan personnel will not be responsible for sweeping out trailers.

UBC Specification page 11 of 11

You might also like

- Instruction Manual On Corrugated BoxesDocument10 pagesInstruction Manual On Corrugated BoxesHussain100650% (4)

- 2-ASCE 7-16 (Minimum Design Load - American Sociaty of Civil Engineering)Document40 pages2-ASCE 7-16 (Minimum Design Load - American Sociaty of Civil Engineering)Ayham Aljawhary100% (2)

- The Effect of Cargo, Including Heavy Lift On Seaworthiness and Stability of ShipDocument57 pagesThe Effect of Cargo, Including Heavy Lift On Seaworthiness and Stability of ShipMJ Angeles100% (2)

- Earthwork and BlastingDocument15 pagesEarthwork and BlastingJoseph MagbanuaNo ratings yet

- B39-79 (2013) Standard Specification For NickelDocument3 pagesB39-79 (2013) Standard Specification For NickeldcardonasterNo ratings yet

- Seaworthy Packing ProcedureDocument10 pagesSeaworthy Packing ProcedureAnonymous gr5Pr9AVNo ratings yet

- Pressure VesselsDocument9 pagesPressure VesselsSajal KulshresthaNo ratings yet

- Astm D 6880-2005Document5 pagesAstm D 6880-2005Jarvis Wang0% (1)

- Class 1 Explosives: Class/ Divisions Description Label Examples DynamiteDocument6 pagesClass 1 Explosives: Class/ Divisions Description Label Examples DynamiteRhyze Leiane OrtizNo ratings yet

- Subcourse Edition FA 3117 B Us Army Field Artillery School Field Artillery Cannon AmmunitionDocument153 pagesSubcourse Edition FA 3117 B Us Army Field Artillery School Field Artillery Cannon AmmunitionVicente VelezNo ratings yet

- Ragnar's Homemade Detonators - H - Ragnar BensonDocument68 pagesRagnar's Homemade Detonators - H - Ragnar BensonFrederico WernerNo ratings yet

- Chemicals Handling: OGDCL Oil & Gas FieldDocument19 pagesChemicals Handling: OGDCL Oil & Gas FieldGHULAM MOHYUDDINNo ratings yet

- Alphabroder - Carton Specification-Version 7.0. 2019Document2 pagesAlphabroder - Carton Specification-Version 7.0. 2019DebashishDolonNo ratings yet

- Klipen Packing and Palletizing Standard 2022Document35 pagesKlipen Packing and Palletizing Standard 2022Roger Manrrique NinaNo ratings yet

- UBC Product Quality Specifications: Management Process/Procedures ManualDocument10 pagesUBC Product Quality Specifications: Management Process/Procedures ManualHafed AbdulhadiNo ratings yet

- MS 8314-05Document4 pagesMS 8314-05AkramNo ratings yet

- WFP 0000140775Document8 pagesWFP 0000140775teddynigusu5No ratings yet

- Floating Docks, Rafts and Boatwells: Plans For Build-It-YourselfDocument16 pagesFloating Docks, Rafts and Boatwells: Plans For Build-It-Yourselfjo_he_toNo ratings yet

- Issued By: Issue Date ReplacesDocument4 pagesIssued By: Issue Date ReplacesJAWAHAR TNo ratings yet

- 28 Inch Mattone Cupola - Oven - BrickWood OvensDocument19 pages28 Inch Mattone Cupola - Oven - BrickWood Ovensvidawo1012No ratings yet

- Testing of Corrugated BoxDocument5 pagesTesting of Corrugated BoxVinod NairNo ratings yet

- BP Strenght Vs CrushDocument3 pagesBP Strenght Vs CrushgetnaniNo ratings yet

- UN Dangerous Goods Brochure 2014Document17 pagesUN Dangerous Goods Brochure 2014Troy Theboy Mcnamara100% (3)

- Poly Drums: Protecting People, Property and The Planet. Since 1894Document16 pagesPoly Drums: Protecting People, Property and The Planet. Since 1894arachman297988No ratings yet

- 8314 08Document3 pages8314 08Pendurti SuryanarayanaNo ratings yet

- Acuflo Price List 2016Document35 pagesAcuflo Price List 2016anilrawat1987No ratings yet

- Carbon Black-Sampling Packaged Shipments: Standard Practice ForDocument3 pagesCarbon Black-Sampling Packaged Shipments: Standard Practice ForLemir LopezNo ratings yet

- Refuse Disposal FinalDocument46 pagesRefuse Disposal FinalAmirul Rasyid Shansul BahriNo ratings yet

- Barrier of Alu FoilDocument5 pagesBarrier of Alu FoilHOANGVUNL1988No ratings yet

- Efibca Q A Eng Final ADocument20 pagesEfibca Q A Eng Final ASunny GhadgeNo ratings yet

- Corrugated Fiberboard DesignDocument39 pagesCorrugated Fiberboard DesignsudarshanNo ratings yet

- Intalox PackingDocument16 pagesIntalox Packingmfaizal81No ratings yet

- FLS Packing ManualDocument50 pagesFLS Packing ManualDhaman A KokaNo ratings yet

- JBT8660-1997 - Hydropower Generating Units Packing, Transportation and Storage StandardDocument12 pagesJBT8660-1997 - Hydropower Generating Units Packing, Transportation and Storage StandarddadanjunkmailNo ratings yet

- B 900 - 99 - QjkwmaDocument12 pagesB 900 - 99 - QjkwmaLuis AndradeNo ratings yet

- Electrode ManualDocument18 pagesElectrode ManualAnonymous 4e7GNjzGWNo ratings yet

- Document 5Document56 pagesDocument 5Ajin SNo ratings yet

- LBritton Static Hazards in FIBCDocument22 pagesLBritton Static Hazards in FIBCAnonymous 1XHScfCINo ratings yet

- AQIS Packing Declaration (01.AUG.09)Document1 pageAQIS Packing Declaration (01.AUG.09)Chze NienNo ratings yet

- Saw Storage HandlingDocument1 pageSaw Storage HandlingDave MulvihillNo ratings yet

- Shipping Platform Standards 2019 PDFDocument32 pagesShipping Platform Standards 2019 PDFPaula CordobaNo ratings yet

- Apparent and True Specific Gravity and Porosity of Lump CokeDocument3 pagesApparent and True Specific Gravity and Porosity of Lump CokeLuis Alberto Curtidor GuataquiNo ratings yet

- Corugated Boxes FinalDocument25 pagesCorugated Boxes FinalMoeez SaleemNo ratings yet

- Buried Pipe: A. Trench Design and Burial DepthsDocument6 pagesBuried Pipe: A. Trench Design and Burial DepthsjosethompsonNo ratings yet

- 31t-65-Exothermic Materials For Molded Exothermic SleevesDocument3 pages31t-65-Exothermic Materials For Molded Exothermic SleevesCharlie ChongNo ratings yet

- Ad 0670927Document27 pagesAd 0670927Evilneko1No ratings yet

- C 602 - 95a R01 QZYWMGDocument3 pagesC 602 - 95a R01 QZYWMGHumberto Gutierrez100% (1)

- 002AL Mineral Wool DatasheetDocument2 pages002AL Mineral Wool Datasheetgeorgekc77No ratings yet

- To Make A Spudgun: An Instructionally Informative Document by EnoctisDocument12 pagesTo Make A Spudgun: An Instructionally Informative Document by EnoctisSeanNo ratings yet

- Conditions For Acceptance of Waste in The Untertagedeponie HeilbronnDocument2 pagesConditions For Acceptance of Waste in The Untertagedeponie HeilbronnAmilton filhoNo ratings yet

- June 2005 Proper Packaging Required To Maintain TraceabilityDocument4 pagesJune 2005 Proper Packaging Required To Maintain TraceabilityJesika Andilia Setya WardaniNo ratings yet

- Basco IBC Catalog 2013Document16 pagesBasco IBC Catalog 2013Mario BarbarićNo ratings yet

- Waste-Containers BROCHURE FOR REFERENCEDocument2 pagesWaste-Containers BROCHURE FOR REFERENCEasnawisulong mohdNo ratings yet

- Sale Contract 1Document5 pagesSale Contract 1Nguyễn HuyềnNo ratings yet

- Nonperforated Hardwound Roll Towels: No. Feet/Roll Rolls/Case CaseDocument1 pageNonperforated Hardwound Roll Towels: No. Feet/Roll Rolls/Case Casenoelle90No ratings yet

- Secondary ContainmentDocument30 pagesSecondary ContainmentNghiem H. VUNo ratings yet

- TEC SPEC 40HC Oct17 - Rev2Document15 pagesTEC SPEC 40HC Oct17 - Rev2James DanielNo ratings yet

- D 5168 - 03 - RduxnjgDocument6 pagesD 5168 - 03 - Rduxnjgjamaljamal20No ratings yet

- Lab Glassware - Catalogue 2012 13 ScreenDocument100 pagesLab Glassware - Catalogue 2012 13 Screengameel alabsiNo ratings yet

- Tex 600JDocument44 pagesTex 600JLucio Rodriguez SifuentesNo ratings yet

- Corrugated BoardDocument5 pagesCorrugated Boardoanne_08No ratings yet

- 80080-GT-017-E - SIGNED - 2-Packing RequirementsDocument14 pages80080-GT-017-E - SIGNED - 2-Packing RequirementsPaul NieNo ratings yet

- Bill of Materials Template 18Document30 pagesBill of Materials Template 18Kerem İnanNo ratings yet

- Packaging Essential GlossaryDocument35 pagesPackaging Essential GlossarygisellaNo ratings yet

- Charge Block Demolition TNTDocument1 pageCharge Block Demolition TNTBlentica FlajicNo ratings yet

- Packaging Closures and Sealing SystemsFrom EverandPackaging Closures and Sealing SystemsNigel TheobaldNo ratings yet

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- Interzinc 52E Grey Part ADocument12 pagesInterzinc 52E Grey Part AkurniawanajisasonoNo ratings yet

- NHBC GasDocument132 pagesNHBC GasBart kaczynskiNo ratings yet

- Manual de Aspiradora WD1851Document40 pagesManual de Aspiradora WD1851Ale PalomoNo ratings yet

- ELVAX 3174 Ethylene Vinyl Acetate Copolymer-Hoja de Datos de Seguridad-EnDocument11 pagesELVAX 3174 Ethylene Vinyl Acetate Copolymer-Hoja de Datos de Seguridad-EnMauricio vascoNo ratings yet

- RIOSEIS GX-Plastic Shell - ENGDocument2 pagesRIOSEIS GX-Plastic Shell - ENGjesusjplNo ratings yet

- Safety Data Sheet Acetylene, Dissolved: SDS - MY - 000010021936Document8 pagesSafety Data Sheet Acetylene, Dissolved: SDS - MY - 000010021936abgemanNo ratings yet

- 1 Captain MsdsDocument5 pages1 Captain MsdsSaad IqbalNo ratings yet

- 4198 App BDocument10 pages4198 App BIvan BodnaryukNo ratings yet

- UN REPORT Rural Structures 5Document5 pagesUN REPORT Rural Structures 5Nicholas ThompsonNo ratings yet

- Explosion Proof CCTVDocument4 pagesExplosion Proof CCTVAhmad AjiNo ratings yet

- Explosive Forming or HERFDocument6 pagesExplosive Forming or HERFharicoolestNo ratings yet

- 110105207n - TartrazineDocument12 pages110105207n - Tartrazinetalita.solerNo ratings yet

- P.O.M ProjectDocument18 pagesP.O.M Projectazeem bhatti0% (1)

- Analysis of Explosives and Explosive Residues. Part 1" Chemical TestsDocument8 pagesAnalysis of Explosives and Explosive Residues. Part 1" Chemical TestsNelson GomesNo ratings yet

- Ebook Process Safety Calculations PDF Full Chapter PDFDocument67 pagesEbook Process Safety Calculations PDF Full Chapter PDFdawn.stpierre822100% (36)

- T Ovex Section: Personal Protective EquipmentsDocument8 pagesT Ovex Section: Personal Protective EquipmentsShahab Ud DinNo ratings yet

- 5912 KX 99 - (Usa)Document7 pages5912 KX 99 - (Usa)keltorNo ratings yet

- Is 12681 1989Document15 pagesIs 12681 1989dipen royNo ratings yet

- Jet-A1 MSDS Gulf Aviation 2014Document13 pagesJet-A1 MSDS Gulf Aviation 2014Son NguyenNo ratings yet

- Cdi 6 Fire Tech2Document102 pagesCdi 6 Fire Tech2Clark James Dacillo RodaNo ratings yet

- 100-028-544 - ALLIANT SPORT PISTOL POWDER, 1LB - 69B - DefaultDocument13 pages100-028-544 - ALLIANT SPORT PISTOL POWDER, 1LB - 69B - DefaultDavid WilliamsNo ratings yet

- Icheme Symposium Series No. 124Document16 pagesIcheme Symposium Series No. 124rusli bahtiarNo ratings yet

- Blasting ConceptsDocument80 pagesBlasting ConceptsAnil Kumar garadaNo ratings yet