Professional Documents

Culture Documents

Aproval Material Spun Pile

Aproval Material Spun Pile

Uploaded by

Assiry JsnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aproval Material Spun Pile

Aproval Material Spun Pile

Uploaded by

Assiry JsnCopyright:

Available Formats

SURAT PERSETUJUAN BAHAN MATERIAL

PEKERJAAN PEMBANGUNAN DUST NET STOCKROOM PT.

GANDA ALAM MAKMUR

Nomor : 1/SPM/MLD-GAM/V/2024 Bidang Pekerjaan : Struktur / Arsitektur / Mekanikal / dan Elektrikal

Tanggal : 4-05-2024 Lampiran : Surat Penunjukan Contoh Material

1 Bahan / Material : Spun Pile Bahan Tersebut

[ ] Sesuai Gambar Pelaksanaan

2 Status Material : Produksi 14 hari [ ] Tidak Sesuai Gambar Pelaksanaan

[ ] Sesuai Shop Drawing

3 Type / Merk : Spun pile dia 500mm (8 meter) [ ] Tidak Sesuai Shop Drawing

Concrete strength : K-500 (500 kg/cm2) [ ] Sesuai RKS

Type of pile : Prestressed concrete [ ] Tidak Sesuai RKS

PO Strand : ASTM Grade 270 Uncoated [ ] Harus di Tes di Laboratorium

Maka Bahan Tersebut

4 Jumlah Pemakaian : 56 batang [ ] Di Terima

[ ] Di Tolak

[ ] Di Iijinkan Masuk Proyek

[ ] Di Larang Masuk Proyek

[ ] Brosur 1 Set Asli & 2 Set Copy

[ ] Contoh Bahan

[ ] Sertifikat

5 - Pabrik / Produk : PT. Balikpapan Ready Mix Pile

- Supplier :

- Sub Kontraktor :

6 Dipakai untuk Pekerjaan : Dust Net Stock Room JO

7 - Gambar Pelaksanaan No. :

- Shop Drawing :

- RKS :

8 Terlampir Tecnical Calculation

Status Material Paraf Owner Tanggal

[ ] Di Terima

[ ] Di Tolak

[ ] Di Terima Dengan Catatan

[ ] Di Kembalikan Untuk Dilengkapi

Evaluasi Persetujuan / Catatan :

Diajukan Oleh, Diperiksa Oleh, Disetui Oleh,

Kontraktor Pelaksana Owner Owner Owner

PT. Milda PT. Ganda Alam Makmur PT. Ganda Alam Makmur PT. Ganda Alam Makmur

Darwanto Gusti Nata K. Gunadi A Poltak Manik

Technical Calculation

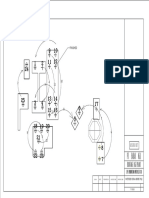

Interaction Diagram of PC Spunpile

Diameter 500 mm Type A (12 @ PC Bar 7.1 mm)

Pile Spesification

Concrete Compressive Strength fc' = 52 MPa

Effective Prestress fcp = 3.8 MPa

Cracking Moment M crack = 6.50 Ton.m 63.8 kN.m

Breaking Moment M break = 9.75 Ton.m 95.6 kN.m

Allowable Axial Load Pa = 189.94 Ton 1863.3 kN

Tension Load Lead to Decompression = 45.50 Ton 446.4 kN

Maximum Pile Length

Handling at Pile Marking = 28.00 m

Handling with "C Hook" at end Pile edge = 12.00 m

Erection with Sling at marking (1 point) = 12.00 m

Code Reference

Building Code Requirements for Structural Concrete (ACI 318-14)

PCI Design Handbook Manual

Dia 500 Type A - 12 - 7 mm OK PRECAST CONCRETE SOLUTION

Spunpile Spesification

I. Pile Dimension

Spunpile Diameter D= 500 mm

Wall thickness t= 90 mm

Concrete Cover Cc = 41.45 mm

Concrete Area Ac = 115,924.77 mm2

Bar No n= 12 pcs

Bar Diameter BD = 7.1 mm

12 @ PC Bar 7.1 mm

Strirrup Diameter SD = 4 mm

Stirrup Spacing s= 100 mm

Distance from center bar to end pile d=0.5*BD+SD+Cc 49 mm

II. Material Properties

a. Concrete Properties

weight of concrete gc = 24.52 kN/m3

Concrete strength at service fc' = 52 MPa

at initial = 8 hours after spining process (concrete strength minimum 50% fc')

Ref. ACI.318-14

Concrete strength at initial fc'i = 26 MPa Chapter 19 - Concrete Design Durability

Requirements

Modulus Elasticity of Concrete Eci = 4700fc'i = 23965.39171 MPa

at delivery = 14 days after production (concrete strength minimum 80% fc')

Ref. ACI.318-14

Concrete strength at initial fc'd = 41.6 MPa Chapter 19 - Concrete Design Durability

Requirements

Modulus Elasticity of Concrete Ecd = 4700fc'd = 30314.08913 MPa

at service = 28 days after production (concrete strength minimum 100% fc')

Ref. ACI.318-14

Concrete strength at initial fc' = 52 MPa Chapter 19 - Concrete Design Durability

Requirements

Modulus Elasticity of Concrete Ec = 4700fc'd = 33892.18199 MPa

Limit strain of concrete ecu = 0.003

Ratio of depth of rectangular compression block to depth of the neutral axis

For fc' <= 30 Mpa b1 = 0.85

For fc' > 30 Mpa b1 = 0.85-0.008(fc'-30)

b1 = 0.674

0.85

b. Prestress Rebar

Bar No n= 12 pcs

Bar Diameter BD = 7.1 mm

Angle betwen steel q= 360 / n 30 o

Cross Section Area Asb = 39.5919 mm2

Tensile Strength fpu = 1420 MPa

Modulus Elasticity Es = 190,000.00 MPa

Limit Strain epp 0.0075

c. Spiral Stirrup

Strirrup Diameter SD = 4 mm

Cross Section Area Ass= 12.56637061 mm2

Tensile Strength fps= 540 Mpa

Yield Strength fys= 440 MPa

III. Losses of Prestress Ref. PCI Design Handbook - Precast and Prestressed Concrete 3rd edition - Chapter 4.5 Loss of Prestress

Initial Prestress

Total Area of PC Bar Asg = n *Asb 475.10 mm2

Dia 500 Type A - 12 - 7 mm OK PRECAST CONCRETE SOLUTION

Jacking Force JF = 75%*fpu 1065 MPa

Concrete Area Ac = 115,924.77 mm2

Initial Prestress Pi = JF * Asg 505,984.76 N/mm2

Nett compres stress in conc at center of gravity of prestress.

force immediately after the prestress has been applied to conc

fcir fcir = Kcir(Pi/Ac+Pi.e2/Ig)-(Mg.e/Ig)

3.93 MPa

where : Kcir = 0.9

Concrete section inertia Ig = 2,553,243,035.41 mm4

Moment due to dead weight Mg = 0 Nm

eccentricity PC Bar to cgc e= 0 mm

Stress in conc at center of gravity of prestressing force immed. after the prestress has been applied to conc.

fcds fcds = Msd.e/Ig 0.00 MPa

Where moment superimpossed load Msd = 0 Nm

Estimating prestress loss

a. Elastic Shortening ES = Kes x Es x fcir / Eci

= 31.14 MPa

Where, Kes = 1

b. Creep CR = Kcr x Es / Ec x (fcir-fcds)

44.04

Where, Kcr = 2

c. Shringkage SH = 8.2E-6 x Kes x Es x (1-0.06V/S) x (100-RH)

= 40.121616 MPa

Where, Kes = 1

V/S (mm) = 60

V/S (inch) = 2.36

R/H 70

Relative Humidity

d. Relaxation of Bar RE = (Kre- J (SH + CR + Es)) x C

= 31.30204303 MPa

Where Kre (Psi) 3800

Kre (Mpa) 26.2

J 0.04

C = 1 + 9 (JF - 0.7) 1.45

For JF betwen 70% to 75%

Total Losses TL = ES + CR + SH + RE 146.61 MPa

Loss by percentage = TL/JF 13.77%

Final Prestress Fpe = Pi - %TL x Pi 436,329.11 N

Prestress Losses (%) % TL 13.77%

Prestress Force fps = JF - %TL x JF 918.388354 MPa

e pe = fps / Es 0.004833623

Concrete Stress fcp = fps.Asg/(Ac-Asg) 3.779388284 MPa

e ce = fcp/Ec 0.000111512

Note : fps = stress in prestress steel after allowance for all prestress losses

e pe = strain in prestressing steel

fcp = compressive stress in concrete after allowance for all prestress losses

e ce = strain in concrete

Dia 500 Type A - 12 - 7 mm OK PRECAST CONCRETE SOLUTION

IV. Diagram Interaction Calculation - Basic Assumpsion similar to those made in regard to reinforced concrete column

1. Point of Pure compression

concrete strain steel strain

150

174.1

100 100.5

50 0.0

0 -100.5

-0.003 -0.002 -0.001 -174.1

-50 0

-201.0

-100

-150 0 0.0005 0.001 0.0015

assuming c = unlimited, failure occur when the strain reached e cu Nominal Resistance in pure compression

Dp e ps e ce - e cu = -0.002888488 Pn,o Cc - S Tp = 4,927.29 kN

e ps e pe + D e ps = 0.001945135 less than epp 0.0075

Since e ps less than limit strain, than: Design diagram in pure compression

e ps = 0.001945135 factored Pn.o f x Pn,o = 3,695.47 kN

Where f = 0.75

Steel stress fps = Es x e ps 369.5756524 MPa

Steel compression S Tp = fps x Asg 175,586.52 N Maximum acceptable cutoff compressive force

175.59 kN Pm l x f x Pn,o = 2,771.60 kN

Conc compression Cc = 0.85fc' (Ac - Asg) 5,102,875.23 N where, l = 0.75 for spiral tied

5,102.88 kN

Dia 500 Type A - 12 - 7 mm OK PRECAST CONCRETE SOLUTION

2. Point of Zero Tension in the concrete

concrete strain steel strain

400 0.00000 0.00100 0.00200 0.00300 0.00400 0.00500

200 201.0

174.1

0 100.5

-0.003 -0.002 -0.001 0 0.0

-200 -100.5

-174.1

-400

neutral axis c= 500 mm

depth of comp a = b1 x c 425 mm

Post No of PC Bar Area of PC Bar q d d' e cu x (d'-c)/c D e psi e psi fpsi Steel Force Steel Moment

(pcs) mm2 mm mm Mpa kN kN.m

1 1 40 0 201.0 49.00 -0.00271 -0.00259 0.00224 425.44 16.84 -3.39

2 2 79 30 174.1 75.93 -0.00254 -0.00243 0.00240 456.13 36.12 -6.29

3 2 79 60 100.5 149.50 -0.00210 -0.00199 0.00284 540.01 42.76 -4.30

4 2 79 90 0.0 250.00 -0.00150 -0.00139 0.00345 654.58 51.83 0.00

5 2 79 120 -100.5 350.50 -0.00090 -0.00079 0.00405 769.15 60.90 6.12

6 2 79 150 -174.1 424.07 -0.00046 -0.00034 0.00449 853.02 67.55 11.76

7 1 40 180 -201.0 451.00 -0.00029 -0.00018 0.00465 883.72 34.99 7.03

0 0 0 0 0.0 0.00 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0.00 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0.00 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0.00 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

Dia 500 Type A - 12 - 7 mm OK PRECAST CONCRETE SOLUTION

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

12 475 S 311 10.94

Sec Diameter Radius a y1 centroid Inertia Area Force Moment

mm mm mm mm mm mm4 mm2 kN kN.m

+ Ac 500 250 425 -175 21.3 2,281,441,233.99 177,880.86 7,862 168

- Ac 320 160 320 -160 0.0 514,718,540.36 -80,424.77 -3,555 0

Total 2,796,159,774.35 97,456.09 4,308 168

Steel Compression S Tp = S fps.Aps 311 kN Nominal Resistance in concrete zero tension condition

Pn,ot C - S Tp = 3,996.57 kN

Conc Compression C = 0.85 x fc' x Ag 4,307.56 kN Mn,ot Mn Conc + Mn Stell = 178.63 kN.m

corresp eccentricity Mn,ot / Pn,ot = 44.70 mm

design diagram in concrete zero tension condition

f= 0.75

f Pn,ot = 2,997.43 kN

f Mn,ot = 133.97 kNm

Dia 500 Type A - 12 - 7 mm OK PRECAST CONCRETE SOLUTION

3. Ballanced Point

concrete strain steel strain

400 0.00000 0.00200 0.00400 0.00600

200 201.0

174.1

0 100.5

-0.003 -0.002 -0.001 0 0.001 0.0

-200 -100.5

-174.1

-400

The strain of extrem tensile layer of steel is assumed equal to the yield to the yield strain e py 0.005

yield stress at e py = 0.005 fpy = 940.84 Mpa

e pp = 0.00495

neutral axis c= 450 mm

depth of comp a = b1 x c 382.5 mm

Post No of PC Bar Area of PC Bar q d d' e cu x (d'-c)/c D e psi e psi fpsi Steel Force Steel Moment

(pcs) mm2 mm mm Mpa kN kN.m

1 1 40 0 201.0 49.00 -0.00267 -0.00256 0.00227 431.64 17.09 -3.43

2 2 79 30 174.1 75.93 -0.00249 -0.00238 0.00245 465.75 36.88 -6.42

3 2 79 60 100.5 149.50 -0.00200 -0.00189 0.00294 558.94 44.26 -4.45

4 2 79 90 0.0 250.00 -0.00133 -0.00122 0.00361 686.24 54.34 0.00

5 2 79 120 -100.5 350.50 -0.00066 -0.00055 0.00428 813.54 64.42 6.47

6 2 79 150 -174.1 424.07 -0.00017 -0.00006 0.00477 906.73 71.80 12.50

7 1 40 180 -201.0 451.00 0.00001 0.00012 0.00495 940.84 37.25 7.49

0 0 0 0 0.0 0.00 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0.00 0.00000 0.00000 0.00000 0.00 0.00 0.00

Dia 500 Type A - 12 - 7 mm OK PRECAST CONCRETE SOLUTION

0 0 0 0 0.0 0.00 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0.00 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

12 475 S 326 12.16

Section Diameter Radius a y1 centroid Inertia Area Force Moment

mm mm mm mm mm mm4 mm2 kN kN.m

+ Ac 500 250 382.5 -132.5 39.4 1,887,160,968.64 161,177.23 7,124 281

- Ac 320 160 292.5 -132.5 6.2 -445,487,371.57 -77,075.22 -3,407 -21

Total 1,441,673,597.08 84,102.01 3,717 260

Steel Compression S Tp = S fps.Aps 326 kN Nominal Resistance in concrete ballance condition

Pnb C - S Tp = 3,391.27 kN

Conc Compression C = 0.85 x fc' x Ag 3,717.31 kN Mnb Mn Conc + Mn Stell = 271.66 kN.m

corresponding eccentricity Mnb / Pnb = 80.11 mm

design diagram in concrete ballance condition

f= 0.75

f Pnb = 2,543.45 kN

f Mnb = 203.74 kNm

Dia 500 Type A - 12 - 7 mm OK PRECAST CONCRETE SOLUTION

4. Point of Pure Bending

concrete strain steel strain

400 0.00000 0.00400 0.00800 0.01200 0.01600 0.02000 0.02400

200 201.0

174.1

0 100.5

-0.003 0.005 0.0

-200

-100.5

-174.1

-400

Pure bending occurs when the sum of force acting on the section (Pn) leads to = Pn = 0

neutral axis c= 63.01 mm

depth of comp a = b1 x c 53.5585 mm

Post No of PC Bar Area of PC Bar q d d' e cu x (d'-c)/c D e psi e psi fpsi Steel Force Steel Moment

(pcs) mm2 mm mm Mpa kN kN.m

1 1 40 0 201.0 49.00 -0.00067 -0.00056 0.00428 812.84 32.18 -6.47

2 2 79 30 174.1 75.93 0.00062 0.00073 0.00556 1056.44 83.65 -14.56

3 2 79 60 100.5 149.50 0.00412 0.00423 0.00906 1058.09 83.78 -8.42

4 2 79 90 0.0 250.00 0.00890 0.00901 0.01385 1064.81 84.32 0.00

5 2 79 120 -100.5 350.50 0.01369 0.01380 0.01863 1076.66 85.25 8.57

6 2 79 150 -174.1 424.07 0.01719 0.01730 0.02214 1092.42 86.50 15.06

7 1 40 180 -201.0 451.00 0.01847 0.01858 0.02342 1109.81 43.94 8.83

0 0 0 0 0.0 0.00 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0.00 0.00000 0.00000 0.00000 0.00 0.00 0.00

Dia 500 Type A - 12 - 7 mm OK PRECAST CONCRETE SOLUTION

0 0 0 0 0.0 0.00 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0.00 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

0 0 0 0 0.0 0 0.00000 0.00000 0.00000 0.00 0.00 0.00

12 475 S 500 3.01

Section Diameter Radius a y1 centroid Inertia Area Force Moment

mm mm mm mm mm mm4 mm2 kN kN.m

+ Ac 500 250 53.5585 196.4415 218.1 539,764,639.87 11,302.98 500 109

- Ac 0 0 0 0 0.0 0.00 0.00 0 0

Total 539,764,639.87 11,302.98 500 109

Steel Compression S Tp = S fps.Aps 499.6 kN Nominal Resistance in pure bending condition

Pn,ot C - S Tp = 0.0 kN

Conc Compression C = 0.85 x fc' x Ag 499.6 kN Mn,ot Mn Conc + Mn Stell = 111.955 kN.m

11.41 T.m

design diagram in pure bending condition

f= 0.75

f Pn,ot = 0.0 kN

f Mn,ot = 83.97 kNm

8.56 T.m

Dia 500 Type A - 12 - 7 mm OK PRECAST CONCRETE SOLUTION

5. Service Diagram

To determine points on interaction curve, select axial load to calculate service moment load capacity

equate the extreme fibre stresses to the allowable values an solve for the smaller values of M:

Position No of PC Bar Area of PC Bar q d Transformed Steel In Transformed properties :

(pcs) mm2 mm mm4 Ic = Concrete inertia

Ic = p (D -d ) / 64

4 4

1 1 40 0 201.0 7,406,508.94

2 2 79 30 174.1 11,109,474.64 Ic = 2,553,243,035.41 mm4

3 2 79 60 100.5 3,703,543.24

4 2 79 90 0.0 577.54 Str = Transformed Section Modulus

5 2 79 120 -100.5 3,703,543.24 Str = (Conc. Inertia + Steel Inertia) / 1/2 H

6 2 79 150 -174.1 11,109,474.64 Str = 10,390,730.67 mm4

7 1 40 180 -201.0 7,406,508.94

0 0 0 0 0.0 0.00 Atr = Transformed Steel

0 0 0 0 0.0 0.00 Atr = Ac + ((Es/Ec)-1) x Aps

0 0 0 0 0.0 0.00 Atr = 118,113.10 mm2

0 0 0 0 0.0 0.00

0 0 0 0 0.0 0.00 SERVICE DIAGRAM CALC (example)

0 0 0 0 0.0 0.00 Fpe = Prestress force at zero concrete strain

0 0 0 0 0.0 0.00 e pe x Es x Aps

0 0 0 0 0.0 0.00 436329.1145 N

0 0 0 0 0.0 0.00 436.33 kN

0 0 0 0 0.0 0.00

0 0 0 0 0.0 0.00 P = Service axial load

0 0 0 0 0.0 0.00 0.00 kN

0 0 0 0 0.0 0.00

12 475 44,439,631.17

a. PERMANENT CONDITION b. TEMPORARY CONDITION

Allowable concrete compression = 0.45*fc' Ref. ACI Allowable concrete compression = 0.6*fc' Ref. ACI

534R-12

23.40 Mpa 534R-12 31.20 Mpa Chapter 4

Chapter 4 Structural

P/Atr + Fpe/Atr + M/Str = 23.40 Mpa Structural P/Atr + Fpe/Atr + M/Str = 31.20 Mpa

strength design

0 + 3.7 + M/10390730.67 = 23.40 Mpa strength design 0 + 3.7 + M/10390730.67 = 31.20 Mpa and allowable

and allowable service capacity

Service Moment = 204,758,038.47 N.mm service capacity Service Moment = 285,805,737.67 N.mm - table 4.3.2.8

Service Moment = 204.76 kN.m - table 4.3.2.8 Service Moment = 285.81 kN.m

Dia 500 Type A - 12 - 7 mm OK PRECAST CONCRETE SOLUTION

Allowable concrete tension = no tension Allow. conc. tension (Marine Work) = -0.25 sqrt (fc')

P/Atr + Fpe/Atr - M/Str = 0.00 Mpa P/Atr + Fpe/Atr - M/Str = -1.80 Mpa

0 + 3.7 - M/10390730.67 = 0.00 Mpa 0 + 3.7 - M/10390730.67 = -1.80 Mpa

Service Moment = 38,385,059.12 N.mm Service Moment = 57,117,215.22 N.mm

Service Moment = 38.39 kN.m Service Moment = 57.12 kN.m

Dia 500 Type A - 12 - 7 mm OK PRECAST CONCRETE SOLUTION

c. PILE ALLOWABLE COMPRESSION AND TENSION

Ref. ACI 534R-12 Chapter 4 Structural strength design and allowable service capacity - table 4.3.3 Where

1. Pile Allow Axial Comp. Pa = (0.33fc' - 0.27 fce) x (Ac - Aps) Transformed Area (Atr) = 118,113.10 mm2

1863.3074 kN Eff Prestress (fpe = 436.33 kN

Ma = 0 kNm Conc. Area (Ac) = 115,924.77 mm2

2. Tension load lead to decomp. = -Atr x fps / An Steel Area (Aps) = 475.10 mm2

-446.3953 kN Conc. Nett Area (An) = 115,449.67 mm2

3. Nominal Resist of member Nn = Aps x fpu

674.65 kN

5. Cracking Condition

Pure Bending Pure tension

at service - 28 days after production (concrete strength min 100% fc') fcr = Tensile stress on ground concrete area

Fpe = 436.33 kN -0.33x sqrt (fc')

Ref. ACI 318-14 - chapter 24. Ref. ACI 318-14 - chapter 24.

fc' = 52 Mpa Serviceability requirement

-2.380 Mpa Serviceability requirement

fr = 1.0 sqrt (fc') Ncrack = Atr x (fcr - Fpe/Ac)

7.211 Mpa -725.635 kN

Mcrack = (Fpe/Ac + fr) x Str Stress of prestressing steel just before first cracking

Mcrack = 114.04 kN.m fps cr* = fpe + [(Es/Ec) x Ncrack / Atr)] 401.89 Mpa

Mcrack = 11.62 Ton.m < fpu 1,420.00 MPa

Stress of prestressing steel after first cracking

fps cr = Ncrack / Aps 1,527.32 MPa

RESUME OF POINT IN DIAGRAM INTERACTION

Point of: Pn Mn f f Pn f Mn

Pure Compression 4927 0 0.75 3695 0

Zero Tension 3997 179 0.75 2997 134

Ballance Condition 3391 272 0.75 2543 204

Pure Bending 0 112 0.75 0 84

cut off comp 2771.599899

Limit diagram 602.8087984

The lower limit of diagram is extended by transition segment from point where compressive force is equal 0.1 fc' Ag

0.1 fc' Ac = 602808.7984 N

602.8087984 kN

Dia 500 Type A - 12 - 7 mm OK PRECAST CONCRETE SOLUTION

V. Shear Capacity

Shear capacity at initial - 8 hours after process (concrete strength min 50% fc')

Shear strength of concrete Shear strenght of Reinforcement Shear Strength

fc' = 26 Mpa Stirrup Dia DS = 4 mm Shear Capacity (f Vn) = f Vc + f Vs

bw = 180 mm Stirrup spacing s= 100 mm Shear Capacity (f Vn) = 68.79 kN

d= 348 mm Avs = 25.13274123 mm2 Shear Capacity (f Vn) = 6.88 Ton

f= 0.75 fys = 440 Mpa

Vc = (1/6) sqrt (fc') bw d Vs = min (Avs.fys.d/s ; (2/3) sqrt (fc') bw d) Ref. ACI 318-14 - chapter 22

53,233.76 N 38.48 kN Sectional Strength

f Vc = 39.93 kN f Vs = 28.86 kN

Shear capacity at delivery - 14 days after production (concrete strength min 80% fc')

Shear strength of concrete Shear strenght of Reinforcement Shear Strength

fc' = 41.6 Mpa Stirrup Dia DS = 4 mm Shear Capacity (f Vn) = f Vc + f Vs

bw = 180 mm Stirrup spacing s= 100 mm Shear Capacity (f Vn) = 79.36 kN

d= 348 mm Avs = 25.13274123 mm2 Shear Capacity (f Vn) = 7.94 Ton

f= 0.75 fys = 440 Mpa

Vc = (1/6) sqrt (fc') bw d Vs = min (Avs.fys.d/s ; (2/3) sqrt (fc') bw d) Ref. ACI 318-14 - chapter 22

67,335.98 N 38.48 kN Sectional Strength

f Vc = 50.50 kN f Vs = 28.86 kN

Shear capacity at service - 28 days after production (concrete strength min 100% fc')

Shear strength of concrete Shear strenght of Reinforcement Shear Strength

fc' = 52 Mpa Stirrup Dia DS = 4 mm Shear Capacity (f Vn) = f Vc + f Vs

bw = 180 mm Stirrup spacing s= 100 mm Shear Capacity (f Vn) = 85.33 kN

d= 348 mm Avs = 25.13274123 mm2 Shear Capacity (f Vn) = 8.53 Ton

f= 0.75 fys = 440 Mpa

Vc = (1/6) sqrt (fc') bw d Vs = min (Avs.fys.d/s ; (2/3) sqrt (fc') bw d) Ref. ACI 318-14 - chapter 22

75,283.91 N 38.48 kN Sectional Strength

f Vc = 56.46 kN f Vs = 28.86 kN

Shear Capacity at service : Based on Standard formula

2

Qcr = t x l / Str x sqrt((sg + 2f st) - sg )

2

291,060.80 N

29.11 Ton

Where :

fc' = 52 MPa Conc comp strength cylinder N = 2,137,501.92 N

fcu = 62.7 MPa conc comp strength cube st = 3.61 MPa

t= 90 mm thickness of pile se = 3.78 MPa

Ae = 115,924.77 mm2 Area of pile f= 0.5

I = 2,553,243,035.41 mm4 sg = 22.22

Dia 500 Type A - 12 - 7 mm OK PRECAST CONCRETE SOLUTION

V. Handling Control

At initial - 8 hours after process (concrete strength min 50% fc')

Initial losses = SH + ES Losses

Initial losses = 71.27 Mpa Loss by perventage 6.69%

Prestress force FPe (8 hr) = 472,126.30 kN

fci' = 26 Mpa (Concrete strength min 50% fc')

fr = 0.415 sqrt (fc') 2.116093 Mpa

M allow (8 hr) = (Fpe/Ac + fr) Str

64,306,036.74 N.mm

64.31 kN.m when axial = 0

6.6 ton.m

at delivery - 14 days after production (concrete strength min 80% fc')

Initial losses = SH + ES + RE Losses

Initial losses = 102.57 Mpa Loss by perventage 9.63%

Prestress force FPe (14 day) = 457,254.60 kN

fci' = 41.6 Mpa (Concrete strength min 80% fc')

fr = 0.415 sqrt (fc') 2.67667 Mpa

M allow (8 hr) = (Fpe/Ac + fr) Str

68,797,835.26 N.mm

68.80 kN.m when axial = 0

7.0 ton.m

at service - 28 days after production (concrete strength min 100% fc')

Initial losses = SH + ES + RE + CR Losses

Initial losses = 146.61 Mpa Loss by perventage 13.77%

Prestress force FPe (14 day) = 436,329.11 kN

fci' = 52 Mpa (Concrete strength min 100% fc')

fr = 0.415 sqrt (fc') 2.992608 Mpa

M allow (8 hr) = (Fpe/Ac + fr) Str

70,205,039.24 N.mm

70.21 kN.m when axial = 0

7.2 ton.m

Dia 500 Type A - 12 - 7 mm OK PRECAST CONCRETE SOLUTION

1. Handling with spreader beam

At initial - 8 hours after process (concrete strength min 50% fc')

Concrete weight = 2.84 kN/m

Impact load = 60% for stripping

Section Inertia = 2,553,243,035.41 mm4

Modulus of Elasticity = 23,965.39 MPa

Allow. moment and axial force

:

M allow = 64.31 kNm

Axial Allow = 68.79 kN

Load factor DL = 1

handling at production control

Pile Length Flexural Moment (DL + I) Vu max Deflection Mallow/ (MDL + L) Check f Vn / Vu Shear Cap Resume Resume

at : a at : b

6 -3.27 4.09 8.19 0.008 15.71 under M allow 8.40 Sufficient shear cap Comply Spec

7 -4.46 5.57 9.55 0.015 11.54 under M allow 7.20 Sufficient shear cap Comply Spec

8 -5.82 7.28 10.92 0.025 8.84 under M allow 6.30 Sufficient shear cap Comply Spec

9 -7.37 9.21 12.28 0.040 6.98 under M allow 5.60 Sufficient shear cap Comply Spec

10 -9.10 11.37 13.64 0.060 5.66 under M allow 5.04 Sufficient shear cap Comply Spec

11 -11.01 13.76 15.01 0.089 4.67 under M allow 4.58 Sufficient shear cap Comply Spec

12 -13.10 16.37 16.37 0.125 3.93 under M allow 4.20 Sufficient shear cap Comply Spec

Dia 500 Type A - 12 - 7 mm OK PRECAST CONCRETE SOLUTION

13 -15.37 19.22 17.74 0.173 3.35 under M allow 3.88 Sufficient shear cap Comply Spec

14 -17.83 22.29 19.10 0.232 2.89 under M allow 3.60 Sufficient shear cap Comply Spec

15 -20.47 25.58 20.47 0.306 2.51 under M allow 3.36 Sufficient shear cap Comply Spec

16 -23.29 29.11 21.83 0.396 2.21 under M allow 3.15 Sufficient shear cap Comply Spec

17 -26.29 32.86 23.19 0.505 1.96 under M allow 2.97 Sufficient shear cap Comply Spec

18 -29.47 36.84 24.56 0.635 1.75 under M allow 2.80 Sufficient shear cap Comply Spec

19 -32.84 41.05 25.92 0.788 1.57 under M allow 2.65 Sufficient shear cap Comply Spec

20 -36.38 45.48 27.29 0.968 1.41 under M allow 2.52 Sufficient shear cap Comply Spec

21 -40.11 50.14 28.65 1.176 1.28 under M allow 2.40 Sufficient shear cap Comply Spec

22 -44.02 55.03 30.02 1.417 1.17 under M allow 2.29 Sufficient shear cap Comply Spec

23 -48.12 60.15 31.38 1.693 1.07 under M allow 2.19 Sufficient shear cap Comply Spec

24 -52.39 65.49 32.75 2.007 0.98 Over M Allow 2.10 Sufficient shear cap Not Comply Spec

25 -56.85 71.06 34.11 2.363 0.90 Over M Allow 2.02 Sufficient shear cap Not Comply Spec

26 -61.49 76.86 35.47 2.764 0.84 Over M Allow 1.94 Sufficient shear cap Not Comply Spec

27 -66.31 82.89 36.84 3.215 0.78 Over M Allow 1.87 Sufficient shear cap Not Comply Spec

28 -71.31 89.14 38.20 3.718 0.72 Over M Allow 1.80 Sufficient shear cap Not Comply Spec

29 -76.50 95.62 39.57 4.278 0.67 Over M Allow 1.74 Sufficient shear cap Not Comply Spec

30 -81.86 102.33 40.93 4.899 0.63 Over M Allow 1.68 Sufficient shear cap Not Comply Spec

Note : Max Pile Length 23.00 meter

Dia 500 Type A - 12 - 7 mm OK PRECAST CONCRETE SOLUTION

2. Handling at pile marking

At delivery - 14 days after production (concrete strength min 80% fc')

Concrete weight = 2.84 kN/m

Impact load = 20% for stripping

Section Inertia = 2,553,243,035.41 mm4

Modulus of Elasticity = 30,314.09 MPa

Allow. moment and axial force

:

M allow = 68.80 kNm

Axial Allow = 79.36 kN

Load factor DL = 1

handling at production control

Pile Length Flexural Moment (DL + I) Vu max Deflection Mallow/ (MDL + L) Check fVn / Vu Shear Cap Resume Resume

at : a at : b

6 -2.46 3.07 6.14 0.006 22.41 under M allow 12.93 Sufficient shear cap Comply Spec

7 -3.34 4.18 7.16 0.011 16.46 under M allow 11.08 Sufficient shear cap Comply Spec

8 -4.37 5.46 8.19 0.020 12.61 under M allow 9.69 Sufficient shear cap Comply Spec

9 -5.53 6.91 9.21 0.031 9.96 under M allow 8.62 Sufficient shear cap Comply Spec

10 -6.82 8.53 10.23 0.048 8.07 under M allow 7.76 Sufficient shear cap Comply Spec

11 -8.25 10.32 11.26 0.070 6.67 under M allow 7.05 Sufficient shear cap Comply Spec

Dia 500 Type A - 12 - 7 mm OK PRECAST CONCRETE SOLUTION

12 -9.82 12.28 12.28 0.099 5.60 under M allow 6.46 Sufficient shear cap Comply Spec

13 -11.53 14.41 13.30 0.137 4.77 under M allow 5.97 Sufficient shear cap Comply Spec

14 -13.37 16.71 14.33 0.184 4.12 under M allow 5.54 Sufficient shear cap Comply Spec

15 -15.35 19.19 15.35 0.242 3.59 under M allow 5.17 Sufficient shear cap Comply Spec

16 -17.46 21.83 16.37 0.313 3.15 under M allow 4.85 Sufficient shear cap Comply Spec

17 -19.72 24.64 17.40 0.399 2.79 under M allow 4.56 Sufficient shear cap Comply Spec

18 -22.10 27.63 18.42 0.502 2.49 under M allow 4.31 Sufficient shear cap Comply Spec

19 -24.63 30.78 19.44 0.623 2.23 under M allow 4.08 Sufficient shear cap Comply Spec

20 -27.29 34.11 20.47 0.765 2.02 under M allow 3.88 Sufficient shear cap Comply Spec

21 -30.08 37.61 21.49 0.930 1.83 under M allow 3.69 Sufficient shear cap Comply Spec

22 -33.02 41.27 22.51 1.120 1.67 under M allow 3.53 Sufficient shear cap Comply Spec

23 -36.09 45.11 23.54 1.338 1.53 under M allow 3.37 Sufficient shear cap Comply Spec

24 -39.29 49.12 24.56 1.587 1.40 under M allow 3.23 Sufficient shear cap Comply Spec

25 -42.64 53.30 25.58 1.868 1.29 under M allow 3.10 Sufficient shear cap Comply Spec

26 -46.12 57.65 26.61 2.185 1.19 under M allow 2.98 Sufficient shear cap Comply Spec

27 -49.73 62.16 27.63 2.541 1.11 under M allow 2.87 Sufficient shear cap Comply Spec

28 -53.48 66.86 28.65 2.939 1.03 under M allow 2.77 Sufficient shear cap Comply Spec

29 -57.37 71.72 29.68 3.382 0.96 Over M Allow 2.67 Sufficient shear cap Not Comply Spec

30 -61.40 76.75 30.70 3.873 0.90 Over M Allow 2.59 Sufficient shear cap Not Comply Spec

Note : Max Pile Length 28.00 meter

Dia 500 Type A - 12 - 7 mm OK PRECAST CONCRETE SOLUTION

3. Handling with C Hook at Pile end

At delivery - 14 days after production (concrete strength min 80% fc')

Concrete weight = 2.84 kN/m

Impact load = 20% for stripping

Section Inertia = 2,553,243,035.41 mm4

Modulus of Elasticity = 30,314.09 MPa

Allow. moment and axial force :

M allow = 68.80 kNm

Axial Allow = 79.36 kN

Load factor DL = 1

handling at production control

Pile Length Flexural Moment (DL +Vu

I) max Deflection Mallow/ (MDL + L) Check fVn / Vu Shear Cap Resume Resume

at : b

6 15.35 10.23 0.620 4.48 under M allow 7.76 Sufficient shear cap Comply Spec

7 20.89 11.94 1.148 3.29 under M allow 6.65 Sufficient shear cap Comply Spec

8 27.29 13.64 1.959 2.52 under M allow 5.82 Sufficient shear cap Comply Spec

9 34.54 15.35 3.137 1.99 under M allow 5.17 Sufficient shear cap Comply Spec

10 42.64 17.05 4.782 1.61 under M allow 4.65 Sufficient shear cap Comply Spec

11 51.59 18.76 7.001 1.33 under M allow 4.23 Sufficient shear cap Comply Spec

Dia 500 Type A - 12 - 7 mm OK PRECAST CONCRETE SOLUTION

12 61.40 20.47 9.916 1.12 under M allow 3.88 Sufficient shear cap Comply Spec

13 72.06 22.17 13.658 0.95 Over M Allow 3.58 Sufficient shear cap Not Comply Spec

14 83.57 23.88 18.370 0.82 Over M Allow 3.32 Sufficient shear cap Not Comply Spec

15 95.93 25.58 24.208 0.72 Over M Allow 3.10 Sufficient shear cap Not Comply Spec

16 109.15 27.29 31.339 0.63 Over M Allow 2.91 Sufficient shear cap Not Comply Spec

17 123.22 28.99 39.939 0.56 Over M Allow 2.74 Sufficient shear cap Not Comply Spec

18 138.14 30.70 50.198 0.50 Over M Allow 2.59 Sufficient shear cap Not Comply Spec

19 153.92 32.40 62.318 0.45 Over M Allow 2.45 Sufficient shear cap Not Comply Spec

20 170.55 34.11 76.510 0.40 Over M Allow 2.33 Sufficient shear cap Not Comply Spec

21 188.03 35.82 92.999 0.37 Over M Allow 2.22 Sufficient shear cap Not Comply Spec

22 206.36 37.52 112.018 0.33 Over M Allow 2.12 Sufficient shear cap Not Comply Spec

23 225.55 39.23 133.817 0.31 Over M Allow 2.02 Sufficient shear cap Not Comply Spec

24 245.59 40.93 158.651 0.28 Over M Allow 1.94 Sufficient shear cap Not Comply Spec

25 266.48 42.64 186.792 0.26 Over M Allow 1.86 Sufficient shear cap Not Comply Spec

26 288.23 44.34 218.521 0.24 Over M Allow 1.79 Sufficient shear cap Not Comply Spec

27 310.82 46.05 254.129 0.22 Over M Allow 1.72 Sufficient shear cap Not Comply Spec

28 334.28 47.75 293.921 0.21 Over M Allow 1.66 Sufficient shear cap Not Comply Spec

29 358.58 49.46 338.213 0.19 Over M Allow 1.60 Sufficient shear cap Not Comply Spec

30 383.73 51.16 387.332 0.18 Over M Allow 1.55 Sufficient shear cap Not Comply Spec

Note : Max Pile Length 12.00 meter

Dia 500 Type A - 12 - 7 mm OK PRECAST CONCRETE SOLUTION

4. Pile errection at pile marking

at service - 28 days after production (concrete strength min 100% fc')

Concrete weight = 2.84 kN/m

Impact load = 20% for stripping

Section Inertia = 2,553,243,035.41 mm4

Modulus of Elasticity = 33,892.18 MPa

Allow. moment and axial force :

M allow = 70.21 kNm

Axial Allow = 85.33 kN

Load factor DL = 1

handling at production control

Pile Length Flexural Moment (DL + I) Vu max Deflection Mallow/ (MDL + L) Check fVn / Vu Shear Cap Resume Resume

at : a at : b

6 -1.71 14.92 10.23 0.27 4.70 under M allow 8.34 Sufficient shear cap Comply Spec

7 -1.71 20.47 11.94 0.55 3.43 under M allow 7.15 Sufficient shear cap Comply Spec

8 -1.71 26.86 13.64 1.03 2.61 under M allow 6.25 Sufficient shear cap Comply Spec

9 -1.71 34.11 15.35 1.75 2.06 under M allow 5.56 Sufficient shear cap Comply Spec

10 -1.71 42.21 17.05 2.81 1.66 under M allow 5.00 Sufficient shear cap Comply Spec

11 -1.71 51.16 18.76 4.28 1.37 under M allow 4.55 Sufficient shear cap Comply Spec

12 -1.71 60.97 20.47 6.26 1.15 under M allow 4.17 Sufficient shear cap Comply Spec

Dia 500 Type A - 12 - 7 mm OK PRECAST CONCRETE SOLUTION

13 -1.71 71.63 22.17 8.87 0.98 Over M Allow 3.85 Sufficient shear cap Not Comply Spec

14 -1.71 83.14 23.88 12.22 0.84 Over M Allow 3.57 Sufficient shear cap Not Comply Spec

15 -1.71 95.51 25.58 16.43 0.74 Over M Allow 3.34 Sufficient shear cap Not Comply Spec

16 -1.71 108.72 27.29 21.65 0.65 Over M Allow 3.13 Sufficient shear cap Not Comply Spec

17 -1.71 122.79 28.99 28.03 0.57 Over M Allow 2.94 Sufficient shear cap Not Comply Spec

18 -1.71 137.72 30.70 35.72 0.51 Over M Allow 2.78 Sufficient shear cap Not Comply Spec

19 -1.71 153.49 32.40 44.90 0.46 Over M Allow 2.63 Sufficient shear cap Not Comply Spec

20 -1.71 170.12 34.11 55.74 0.41 Over M Allow 2.50 Sufficient shear cap Not Comply Spec

21 -1.71 187.60 35.82 68.43 0.37 Over M Allow 2.38 Sufficient shear cap Not Comply Spec

22 -1.71 205.94 37.52 83.18 0.34 Over M Allow 2.27 Sufficient shear cap Not Comply Spec

23 -1.71 225.12 39.23 100.19 0.31 Over M Allow 2.18 Sufficient shear cap Not Comply Spec

24 -1.71 245.16 40.93 119.69 0.29 Over M Allow 2.08 Sufficient shear cap Not Comply Spec

25 -1.71 266.06 42.64 141.90 0.26 Over M Allow 2.00 Sufficient shear cap Not Comply Spec

26 -1.71 287.80 44.34 167.07 0.24 Over M Allow 1.92 Sufficient shear cap Not Comply Spec

27 -1.71 310.40 46.05 195.45 0.23 Over M Allow 1.85 Sufficient shear cap Not Comply Spec

28 -1.71 333.85 47.75 227.30 0.21 Over M Allow 1.79 Sufficient shear cap Not Comply Spec

29 -1.71 358.15 49.46 262.89 0.20 Over M Allow 1.73 Sufficient shear cap Not Comply Spec

30 -1.71 383.31 51.16 302.51 0.18 Over M Allow 1.67 Sufficient shear cap Not Comply Spec

Note : Max Pile Length 12.00 meter

Dia 500 Type A - 12 - 7 mm OK PRECAST CONCRETE SOLUTION

VI. Joint of Pile

Joint Plate Joint Plate Dimension for PC Pile 500 mm

Material = JIS 3101 SS400 or A26 a= 6 mm

Tensile strength = 400 Mpa b= 15 mm

yield stress fy = 245 MPa Outer Dia = 798 mm

Inner Dia = 768 mm

Welding ya = yb 399 mm

Material = AWS A5.1 E6013 Welding section properties

Tensile strength = 60 Ksi Area = 36,898.01 mm2

Tensile strength = 413.4 Mpa Inertia = 2,828,757,934.74 mm4

Section Inertia = 7,089,618.88 mm3

Check welding strength

a. Due to cracking moment

Mjoint = s allow x section inertia

(2/3) x fy joint plate x section inertia

1,157.97 kN.m

118.04 Ton.m > 11.62 Ton.m Pile cracking moment

b. Due to breaking moment

Mjoint = s allow x section inertia

fy joint plate x section inertia

1,736.96 kN.m

177.06 Ton.m > 11.41 Ton.m Pile breaking moment

c. Due to tension to decompression force

Pjoint = s t x section area

Pjoint = 0.7 x 2/3 x fy joint plate x section area

Pjoint = 4,218.67 kN

Pjoint = 430.04 Ton > 45.50 Ton Tension to decompression

d. Due to tension to ultimit

Pjoint = s t x section area

Pjoint = fy joint plate x section area

Pjoint = 9,040,011.40 kN

Pjoint = 921,509.83 Ton > 68.77 Ton Tension to decompression

e. Due to tension to ultimit

Pjoint = s h x section area

Pjoint = 0.6 x fy joint plate x section area

Pjoint = 5,424,006.84 kN

Pjoint = 552,905.90 Ton > 8.53 Ton based on ACI formula

29.11 Ton based on Standard Formula

Dia 500 Type A - 12 - 7 mm OK PRECAST CONCRETE SOLUTION

Interaction Diagram Moment - Axial Load

Diameter 500 mm Type A (12 @ PC Bar 7.1 mm) M crack 6.5 Tm , fc' 52 Mpa , eff Pts 3.8 Mpa

Interaction Diagram of PC Spun Pile

6000

5000 4927

4000 Nominal

3,695

fMn0t, fPn0t

3000 Cut Off FactoredfMn , fPn

134, 2,997

2771.599899 b b

Axial (kN)

204, 2,543

et=0 eb

2000 1863.307405

1000

602.81 Crack, 64 602.81

0 84 112

0 50 100 150 200 250 300

-1000

-2000 Moment (kN.m)

Dia 500 Type A - 12 - 7 mm OK PRECAST CONCRETE SOLUTION

NOTE :

1 Cube compressive strength at 28 days

is 600 kg/cm2

2 Pile generally comply to JIS A.5335-1985

3 The calculation of nominal bending moment is

based on formula taken from PCI Design

handbook, 4th edition.

4 PC Bar is Sumitwist of PC Grooved Wire

( JIS 3109 Class D 1275/1420 )

50X20 = 1000 (L1) A L2 50X20 = 1000 (L1)

500

L

MIDDLE PILE

Scale : Nts

50X20 = 1000 (L1) 50X20 = 1000 (L1) 20 480

L2

500

100

L

BOTTOM PILE

Scale : Nts ENGINEERING :

PT. BRM PILE HEAD OFFICE :

JL Hasanudin RT 007

Kariangau Balikpapan

Kalimantan Timur Indonesia

Telp.(0542) 7588287,7588278

Fax. (0542) 7588279

STANDAR DRAWING

500 TYPE A

PC SPUN PILE SPECIFICATION MIDDLE AND BOTTOM PILE

500 500 PC BAR 12 7.1 mm

90 320 90 90 320 90 Diameter Prestressing Steel Length

(mm) f'c / K PC Bar (M)

500 f'c. 52 6-9 DRAWN BY : SUKAMDANI

K-600

SCALE NTS DATE 01-Juni-13

ENGINEER

PC SPUN PILE CAPACITY SUKAMDANI

Diameter Bending Moment (Ton.m) Compression (Ton) DESIGN CHECKER

(mm) Crack Breaking Allowable

500 500

LANGGENG BIHARJO

500 6.50 9.75 189.94

TOP/JOIN PLATE SECTION A APPROVE

Scale : Nts Scale : Nts

GLENN NIRWAN

COMPANY PROJECT NUMBER REV

BRMP GB/BRMP/ENG/31 R1

You might also like

- Villa - Interior B.O.Q. (Egypt)Document30 pagesVilla - Interior B.O.Q. (Egypt)Moustapha AlgoharyNo ratings yet

- SMM (Standard Method of Meacurement of Building Works)Document72 pagesSMM (Standard Method of Meacurement of Building Works)Edwar RinaldiNo ratings yet

- Brick Dimension TablesDocument5 pagesBrick Dimension TablesdavidongpongNo ratings yet

- Datasheet For Drum Scrubber of Line B & CDocument4 pagesDatasheet For Drum Scrubber of Line B & Clarbiaboumadi363No ratings yet

- Hex BoltDocument1 pageHex Boltchris dianNo ratings yet

- Request For Quotation - PR300008068 - Coupling ShaftDocument2 pagesRequest For Quotation - PR300008068 - Coupling ShaftDodi SuhendraNo ratings yet

- Dike Wall and Slab Design Calculation - RevisedDocument84 pagesDike Wall and Slab Design Calculation - RevisedRichard ChavezNo ratings yet

- Form RFIDocument5 pagesForm RFIMuhammad FajarNo ratings yet

- Bayu Pinasthika (1200960234) Friska Oktaviana (1200986681)Document36 pagesBayu Pinasthika (1200960234) Friska Oktaviana (1200986681)fikriaulia13No ratings yet

- MAS Cable TrayDocument5 pagesMAS Cable TrayJofey SimonNo ratings yet

- 2.form Inspeksi Bore PileDocument1 page2.form Inspeksi Bore Pilerian1099No ratings yet

- Results of Compressive Strength of Concrete / Grout CubesDocument1 pageResults of Compressive Strength of Concrete / Grout CubesSABEASNNo ratings yet

- Armay Golf Club Job No 603Document2 pagesArmay Golf Club Job No 603Azmotulla RionNo ratings yet

- Inspaction and Test Plan Edit ExcelDocument100 pagesInspaction and Test Plan Edit ExcelDenny .PNo ratings yet

- Approval Command Center Perekat Bata RinganDocument7 pagesApproval Command Center Perekat Bata Ringangame elswordNo ratings yet

- BTB P22 - Warehouse 03.07.2021Document4 pagesBTB P22 - Warehouse 03.07.2021Kevin JuwonoNo ratings yet

- Summary Materials: Project Time of Issue Nien Made Project Factory 3-6Document11 pagesSummary Materials: Project Time of Issue Nien Made Project Factory 3-6thang TranNo ratings yet

- AF Scafolding For Support Electrikal Team TA (H)Document10 pagesAF Scafolding For Support Electrikal Team TA (H)Antoni GultomNo ratings yet

- PM Panelmotor Exaust Frame Blower A 88TK-2 GT#1 PM021L1Document1 pagePM Panelmotor Exaust Frame Blower A 88TK-2 GT#1 PM021L1Mudafar MumenNo ratings yet

- ATECH-KLJ-Anchor ReportDocument6 pagesATECH-KLJ-Anchor ReportRanjit S KashyapNo ratings yet

- Tuban Extension Trestle and Jetty Submitted To MWT Oct 18 2021Document212 pagesTuban Extension Trestle and Jetty Submitted To MWT Oct 18 2021sigit herlambangNo ratings yet

- MA Painting SBGDocument1 pageMA Painting SBGAlif riskiNo ratings yet

- Metode Pelaksanaan Stressing PCI GirderDocument14 pagesMetode Pelaksanaan Stressing PCI GirderYudi Bahrain100% (1)

- Geotekindo - Option 2 - Commercial Proposal of DSM Works at KEK Sei Mangke Project R00Document4 pagesGeotekindo - Option 2 - Commercial Proposal of DSM Works at KEK Sei Mangke Project R00Âlberd Mâriø TâmbunanNo ratings yet

- List Material OH ME Unit 1Document14 pagesList Material OH ME Unit 1Dangol100% (1)

- Total Cost For Steel Super StructureDocument1 pageTotal Cost For Steel Super Structurezakaria200811060No ratings yet

- Quotation For TP-ALP-21-213 SURGE VESSEL 1m3Document2 pagesQuotation For TP-ALP-21-213 SURGE VESSEL 1m3Port VideoNo ratings yet

- 4. Material Approval ProcedureDocument9 pages4. Material Approval ProcedureMuhamad FatchanudinNo ratings yet

- Rekind QC Check Sheet: STG BuildingDocument3 pagesRekind QC Check Sheet: STG BuildingBayu RahmanNo ratings yet

- Test Report: Compressive Strength of Paver BlockDocument1 pageTest Report: Compressive Strength of Paver BlockCiviltech LabNo ratings yet

- Hilti Design CalculationDocument4 pagesHilti Design CalculationJohn Vincent MusngiNo ratings yet

- RC-2 Blank FormatDocument5 pagesRC-2 Blank Formatratoooooja24No ratings yet

- RFA BetonDocument1 pageRFA BetonParid SuwantoNo ratings yet

- Inquiry For Power and Control Cable Rev.0Document81 pagesInquiry For Power and Control Cable Rev.0Dang ThiNo ratings yet

- Shop Fabrication ProcedureDocument6 pagesShop Fabrication ProcedureAdrian IrawanNo ratings yet

- RFA & RFI For 400KV Gantry Verticality CheckingDocument3 pagesRFA & RFI For 400KV Gantry Verticality Checkingsathya2040No ratings yet

- 002 - Himshree Work Order For Silt Flushing PipesDocument3 pages002 - Himshree Work Order For Silt Flushing Pipesbishnu sahNo ratings yet

- Pqf-File 11-09-2022Document20 pagesPqf-File 11-09-2022Raphael Nico CastañedaNo ratings yet

- Sil Aaipl RC PT 458 (4) 1924 R2Document3 pagesSil Aaipl RC PT 458 (4) 1924 R2amit_saxena_10No ratings yet

- AozayDocument11 pagesAozayheryfiononanapierrette01No ratings yet

- Summary Myanmar Materials: Project Time of Issue Nien Made Project Factory 3-6Document9 pagesSummary Myanmar Materials: Project Time of Issue Nien Made Project Factory 3-6thang TranNo ratings yet

- TBE For Crude Oil Tank - PlateDocument1 pageTBE For Crude Oil Tank - PlateprtamaekaputraNo ratings yet

- Roundness Check Record of 1St Shell CourseDocument1 pageRoundness Check Record of 1St Shell CourseRhannie GarciaNo ratings yet

- TEC-033000 - MET-DoR-PIV-P635 (CMethod Statement For General RCC Work.)Document8 pagesTEC-033000 - MET-DoR-PIV-P635 (CMethod Statement For General RCC Work.)Haymanot BaynesagnNo ratings yet

- Material / Product Approval Request: Upgrading Pot Technology For 1 Potline at Inalum Reduction Plant ProjectDocument1 pageMaterial / Product Approval Request: Upgrading Pot Technology For 1 Potline at Inalum Reduction Plant ProjectSiti Iyaroh dearni SaragihNo ratings yet

- 7 Days Cube TestDocument6 pages7 Days Cube TestSurajit SahaNo ratings yet

- Hvac BoqDocument5 pagesHvac Boqmuhammad herdiansyahNo ratings yet

- MOF-Proposal-Container RoofDocument7 pagesMOF-Proposal-Container RoofRaka S PurwotoNo ratings yet

- BTB P22 - Warehouse 24.06.2021Document4 pagesBTB P22 - Warehouse 24.06.2021Kevin JuwonoNo ratings yet

- BGF F ProdDocument13 pagesBGF F Proddidi sudiNo ratings yet

- CompressiveStrength (ASTM-C39) Test ReportDocument21 pagesCompressiveStrength (ASTM-C39) Test ReportNadira PervinNo ratings yet

- Company ProfileDocument10 pagesCompany ProfileDeny AristyaNo ratings yet

- QF-CM-006 Rev.00 - Material ApprovalDocument7 pagesQF-CM-006 Rev.00 - Material Approvalrahmat hidayatNo ratings yet

- Mir Anchor BoltDocument1 pageMir Anchor BoltBagas Lesta CoratiesNo ratings yet

- F08643S-1501-08-CALCULATION OF CP FOR CONDENSER-DR-FA-R1-A4-ModelDocument6 pagesF08643S-1501-08-CALCULATION OF CP FOR CONDENSER-DR-FA-R1-A4-ModelSalmanEjazNo ratings yet

- Sample Submission Form: Verified by Contractor ( or N/A) Specification According To Contract N/A N/ADocument2 pagesSample Submission Form: Verified by Contractor ( or N/A) Specification According To Contract N/A N/AcRi SocietyNo ratings yet

- Den So 080922 Revise-1 Sub Panel For Injection 11Document16 pagesDen So 080922 Revise-1 Sub Panel For Injection 11eirNo ratings yet

- Blue Ladder Epc Solutions Pvt. LTD.: Job No. Project ClientDocument10 pagesBlue Ladder Epc Solutions Pvt. LTD.: Job No. Project ClientJitendra PNo ratings yet

- SLG DBK ProjectDocument19 pagesSLG DBK Projectalukard2012No ratings yet

- Technical Specification of DG-1Document33 pagesTechnical Specification of DG-1Shariq AkhtarNo ratings yet

- Ashish Sogani: O P T (D & E)Document3 pagesAshish Sogani: O P T (D & E)rohanbagadiyaNo ratings yet

- Nota Kabel TryDocument2 pagesNota Kabel TryAssiry JsnNo ratings yet

- Bore Pile Rev1-Model 2Document1 pageBore Pile Rev1-Model 2Assiry JsnNo ratings yet

- Bore Pile Rev1-ModelDocument1 pageBore Pile Rev1-ModelAssiry JsnNo ratings yet

- Catalog SylvaniaDocument8 pagesCatalog SylvaniaAssiry JsnNo ratings yet

- Kebutuhan Material TowerlampDocument1 pageKebutuhan Material TowerlampAssiry JsnNo ratings yet

- Material KM 33Document7 pagesMaterial KM 33Assiry JsnNo ratings yet

- Cover LaporanDocument1 pageCover LaporanAssiry JsnNo ratings yet

- Kebutuhan Material Tanggal 25-5-23Document2 pagesKebutuhan Material Tanggal 25-5-23Assiry JsnNo ratings yet

- Surat Persetujuan Material Cable Connector (Milda)Document2 pagesSurat Persetujuan Material Cable Connector (Milda)Assiry JsnNo ratings yet

- Beam, Slab, Column, Footing Steel CriteriaDocument19 pagesBeam, Slab, Column, Footing Steel CriteriaNikhilNo ratings yet

- Testsdumps: Latest Test Dumps For It Exam CertificationDocument7 pagesTestsdumps: Latest Test Dumps For It Exam CertificationSekharNo ratings yet

- Design of Two Way Slab: Ly/LxDocument3 pagesDesign of Two Way Slab: Ly/LxSandy KavitakeNo ratings yet

- BlockworkDocument5 pagesBlockworkVikram DhabaleNo ratings yet

- Trenches Shop DrawingDocument1 pageTrenches Shop DrawingMEAGAN CHNGNo ratings yet

- Pani Community Center Case StudyDocument42 pagesPani Community Center Case Studyarkosakib45No ratings yet

- 02-02 - SUB-ABUTMENT See Pile PDFDocument14 pages02-02 - SUB-ABUTMENT See Pile PDFجميل عبد الله الحماطيNo ratings yet

- Sample Name: Cement Type Concrete Grade - G 40 Time Min Slump MM Material Target 200 +/-25 Per m3 Trial 02 - Wet Mix Ppc/Insee RF + Target S. MMDocument1 pageSample Name: Cement Type Concrete Grade - G 40 Time Min Slump MM Material Target 200 +/-25 Per m3 Trial 02 - Wet Mix Ppc/Insee RF + Target S. MMYasndra AbeygunewardhaneNo ratings yet

- Modern Formwork Casestudies FinalDocument33 pagesModern Formwork Casestudies FinalVikas PatelNo ratings yet

- Structural ReportDocument85 pagesStructural ReportSravani PrabhalaNo ratings yet

- Construction Requirements For Chemical TankersDocument35 pagesConstruction Requirements For Chemical TankersRitesh100% (1)

- Square FootingDocument9 pagesSquare FootingFrancis Ko Badongen-Cawi Tabaniag Jr.No ratings yet

- Sliding Window SectionsDocument52 pagesSliding Window SectionsVSMS8678No ratings yet

- Coopers - Concertina Smoke CurtainDocument1 pageCoopers - Concertina Smoke CurtainGeorge CamarisoNo ratings yet

- Session Plan Carpentry Nc2 PDFDocument16 pagesSession Plan Carpentry Nc2 PDFmark abayon100% (1)

- Mapeh 9arts - Q1 - Summative TestDocument2 pagesMapeh 9arts - Q1 - Summative TestJunard CenizaNo ratings yet

- Ari 430-99Document18 pagesAri 430-99DanZel DanNo ratings yet

- ProjectDocument46 pagesProjectniyaskottapparaNo ratings yet

- The Use of Iron & SteelDocument7 pagesThe Use of Iron & SteelMaureen AlboresNo ratings yet

- Ambrose Kirk The Marvellous and The Monstrous in The Sculpture of Twelfth-Century EuropeDocument204 pagesAmbrose Kirk The Marvellous and The Monstrous in The Sculpture of Twelfth-Century Europedina100% (1)

- History of Architecture Board Exam Reviewer PDFDocument139 pagesHistory of Architecture Board Exam Reviewer PDFalain lana100% (3)

- Sample Architectural Plan 3Document1 pageSample Architectural Plan 3Al DrinNo ratings yet

- Dakshinachitra, Chennai: Case StudyDocument20 pagesDakshinachitra, Chennai: Case StudyDiv A 08 Shweta BelapurkarNo ratings yet

- Barry Farm Powerpoint SlidesDocument33 pagesBarry Farm Powerpoint SlidessarahNo ratings yet

- Geometric Design of A Masonry Lattice Space Dome Titled KARBANDI in Persian ArchitectureDocument19 pagesGeometric Design of A Masonry Lattice Space Dome Titled KARBANDI in Persian ArchitectureMaher hawariNo ratings yet

- Aws Solution ArchitectDocument1 pageAws Solution ArchitectJaswant Singh0% (2)

- Imagicle On Cisco CCWDocument7 pagesImagicle On Cisco CCWchindi.comNo ratings yet