Professional Documents

Culture Documents

OM Practice Problem Ans

OM Practice Problem Ans

Uploaded by

Bhaskar AnandCopyright:

Available Formats

You might also like

- Homework Assignment Module 2 - Process AnalysisDocument7 pagesHomework Assignment Module 2 - Process AnalysisRodrigo Isaac100% (3)

- Matching Supply With Demand Solutions To End of Chapter Problems 4Document6 pagesMatching Supply With Demand Solutions To End of Chapter Problems 4Omar Al-azzawi100% (1)

- ANIÑON - Problem Set #1 (2021)Document5 pagesANIÑON - Problem Set #1 (2021)Mia Kyla AninonNo ratings yet

- Guildelines For Developing Public Recreation Facility StandardsDocument99 pagesGuildelines For Developing Public Recreation Facility StandardsPogpog ReyesNo ratings yet

- OPIM101 - Spring 2009 - Exam 1 - SolutionsDocument12 pagesOPIM101 - Spring 2009 - Exam 1 - Solutionsjoe91bmwNo ratings yet

- InterViews. Learning The Craft of Qualitative Research Interviewing (1 Ed) - Kvale 1996 PDFDocument173 pagesInterViews. Learning The Craft of Qualitative Research Interviewing (1 Ed) - Kvale 1996 PDFquinojotaNo ratings yet

- PAN Grade 5Document28 pagesPAN Grade 5Maestro VarixNo ratings yet

- State of Maharashtra V. Praful B Desai (DR.), 2003 4 SCCDocument8 pagesState of Maharashtra V. Praful B Desai (DR.), 2003 4 SCCDrsika100% (1)

- Operation Management Case StudyDocument2 pagesOperation Management Case StudyPrabodh KuncheNo ratings yet

- 01 Session 01 Unit 2 Process AnalysisDocument22 pages01 Session 01 Unit 2 Process AnalysisAyesha RachhNo ratings yet

- Process & Capacity AnalysisDocument50 pagesProcess & Capacity AnalysisSri Krishna JayaramNo ratings yet

- Process Analysis Problems SolutionDocument2 pagesProcess Analysis Problems SolutionAnimikh PalitNo ratings yet

- Process Analysis ProblemsDocument1 pageProcess Analysis ProblemsAnimikh PalitNo ratings yet

- Problem Set #1 (Apr 2022)Document4 pagesProblem Set #1 (Apr 2022)Ralph EmmanuelNo ratings yet

- Activity 1 Speed, Distance, and TimeDocument2 pagesActivity 1 Speed, Distance, and TimePaulo AlegriaNo ratings yet

- Class V Unit 7Document6 pagesClass V Unit 7Subodh GurungNo ratings yet

- Course: MGT314 Section: 5 Group Number: 06Document5 pagesCourse: MGT314 Section: 5 Group Number: 06Sk. Shahriar RahmanNo ratings yet

- 03 Process AnalysisDocument30 pages03 Process Analysisbharat2580% (1)

- Early Grade Mathematics Assessment Grade 1 (Written Test)Document8 pagesEarly Grade Mathematics Assessment Grade 1 (Written Test)RACHEL ABENo ratings yet

- Jaylyn Allmon - Cookies Final ProjectDocument3 pagesJaylyn Allmon - Cookies Final Projectapi-640757865No ratings yet

- Module in Tstrat 4Document3 pagesModule in Tstrat 4Jera ObsinaNo ratings yet

- Solution CHP 7 EOQDocument6 pagesSolution CHP 7 EOQwasif ahmedNo ratings yet

- Early Grade Mathematics AssessmentDocument50 pagesEarly Grade Mathematics AssessmentJesie Bell Balaba BuroNo ratings yet

- How Many Possible Seating Arrangements Could Be Made If There Are 3 Chairs and Four Students?Document18 pagesHow Many Possible Seating Arrangements Could Be Made If There Are 3 Chairs and Four Students?xhingyeeNo ratings yet

- Plan For 2023Document7 pagesPlan For 2023doraemongee1No ratings yet

- MATERIALS NEEDED FOR FINALS 2nd SEM 2023 24Document4 pagesMATERIALS NEEDED FOR FINALS 2nd SEM 2023 24renalyntanaleon5No ratings yet

- Module 7-Measurement in Real LifeDocument24 pagesModule 7-Measurement in Real LifealfierapisuraNo ratings yet

- Sciencereport Final Pigatutra SuichiDocument5 pagesSciencereport Final Pigatutra Suichiapi-268742364No ratings yet

- Exercise1-Intro toManagementScienceDocument3 pagesExercise1-Intro toManagementScienceRealine BularioNo ratings yet

- Probability Lesson PlanDocument11 pagesProbability Lesson Planapi-94078224No ratings yet

- Grade 5 - Teacher's Guide - Lesson 1 - Tally MarksDocument6 pagesGrade 5 - Teacher's Guide - Lesson 1 - Tally MarksshipradangNo ratings yet

- Tiny Pixel Farm WalkthroughDocument4 pagesTiny Pixel Farm WalkthroughFakhrul RozanNo ratings yet

- Lesson Title:: Blended Learning Lesson PlanDocument7 pagesLesson Title:: Blended Learning Lesson Planapi-509820951No ratings yet

- PAN Grade 4Document24 pagesPAN Grade 4Maestro VarixNo ratings yet

- Solved Problems Practice Problems For OM New NewDocument37 pagesSolved Problems Practice Problems For OM New NewMukesh ParmarNo ratings yet

- OPIM101 - Spring 2013 - Assignment 2 - Solution B PDFDocument5 pagesOPIM101 - Spring 2013 - Assignment 2 - Solution B PDFjoe91bmwNo ratings yet

- Module 2 Lesson 2 - Working TogetherDocument12 pagesModule 2 Lesson 2 - Working Togetherapi-742584549No ratings yet

- Cookies Final Project Exemplar 1Document4 pagesCookies Final Project Exemplar 1api-242864146No ratings yet

- Problem Set 1Document16 pagesProblem Set 1Tutor ProNo ratings yet

- ResultDocument1 pageResultapi-350675057No ratings yet

- Solved - You Have Been Asked To Set Up An Assembly Line To Assemble A Computer Mouse. The Precedence..Document4 pagesSolved - You Have Been Asked To Set Up An Assembly Line To Assemble A Computer Mouse. The Precedence..Maritoni SulitNo ratings yet

- Module 2 - Capacity Planning Practice ProblemsDocument3 pagesModule 2 - Capacity Planning Practice ProblemsIsabel CalderonNo ratings yet

- Singapore Math Worksheets Grade 4 Whole NumbersDocument7 pagesSingapore Math Worksheets Grade 4 Whole NumbersKungfu Math100% (2)

- Basic Standar KerjaDocument30 pagesBasic Standar Kerjaadhirga_moesNo ratings yet

- General Mathematics: Quarter 1 - ModuleDocument15 pagesGeneral Mathematics: Quarter 1 - ModuleJinky Bon100% (1)

- BASIC MATHS-sem2 AnsDocument24 pagesBASIC MATHS-sem2 AnsSai TheebannNo ratings yet

- BE1401 Business Operations and Processes Answer Key For Exercises On Capacity AnalysisDocument4 pagesBE1401 Business Operations and Processes Answer Key For Exercises On Capacity Analysisgao linxinNo ratings yet

- Problem Solving StrategiesDocument12 pagesProblem Solving StrategiesANNA MARY GINTORONo ratings yet

- W - T NG H P IELTS Writing ProcessDocument55 pagesW - T NG H P IELTS Writing Processecovalley2023No ratings yet

- Assessment Lesson 2.2 AnswersDocument8 pagesAssessment Lesson 2.2 AnswersAnanel EpondulanNo ratings yet

- Simulation FinalllDocument73 pagesSimulation FinalllAlizeh FarooqNo ratings yet

- Grcelene Caba Laboratory ReportDocument8 pagesGrcelene Caba Laboratory ReportAgnes MontalboNo ratings yet

- 1 SimulationsDocument42 pages1 Simulationsfrank obimoNo ratings yet

- AH X9 ActiveHome 2WeekFitnessJournalDocument13 pagesAH X9 ActiveHome 2WeekFitnessJournalPE ProjectNo ratings yet

- Converting Minutes Into Seconds Converting Hours Into MinutesDocument2 pagesConverting Minutes Into Seconds Converting Hours Into MinutesLubna ImranNo ratings yet

- Activity SheetDocument2 pagesActivity SheetLovejoy TiñaNo ratings yet

- Scratch Lessons Tutors ManualDocument22 pagesScratch Lessons Tutors ManualdipaliNo ratings yet

- Sols chp4Document6 pagesSols chp4Aryan SharmaNo ratings yet

- Presentation in Linear ProgrammingDocument34 pagesPresentation in Linear Programmingotok jacildoNo ratings yet

- Problem SolvingDocument46 pagesProblem SolvingMharlynne Nezlou L. PoliranNo ratings yet

- Quiz - WCMDocument1 pageQuiz - WCMROB101512No ratings yet

- At Secretariat Comment RequestDocument2 pagesAt Secretariat Comment RequestDocumentsZANo ratings yet

- Clarence-Smith, W. G., African and European Cocoa Producers On Fernando Poo, 1880s To 1910s', The Journal of African History, 35 (1994), 179-199Document22 pagesClarence-Smith, W. G., African and European Cocoa Producers On Fernando Poo, 1880s To 1910s', The Journal of African History, 35 (1994), 179-199OSGuineaNo ratings yet

- Passive VoiceDocument1 pagePassive VoiceElhassania ElmouatrachNo ratings yet

- Web Server Attacks and Mitigation Using SnortDocument14 pagesWeb Server Attacks and Mitigation Using SnortphilpqNo ratings yet

- Accomplishment Report BrigadaDocument2 pagesAccomplishment Report BrigadaVincent rexie AsuncionNo ratings yet

- Communityplan SV PDFDocument20 pagesCommunityplan SV PDFJeesson AlamarNo ratings yet

- Quizzz 2 102, Summer 20Document7 pagesQuizzz 2 102, Summer 20Samuel Muabia PlānetNo ratings yet

- Heart Songs - February 10 8 43 AmDocument2 pagesHeart Songs - February 10 8 43 Amapi-551678806No ratings yet

- IBIG 04 06 MA Deals Merger Models TranscriptDocument4 pagesIBIG 04 06 MA Deals Merger Models TranscriptіфвпаіNo ratings yet

- G10 Q4 Week2finalDocument10 pagesG10 Q4 Week2finalANALYN DEL CASTILLONo ratings yet

- Paul Bragg Healthy HeartDocument260 pagesPaul Bragg Healthy Heartdeborah81100% (9)

- O'connor Tweezer Dexterity TestDocument10 pagesO'connor Tweezer Dexterity TestEvelyn JiménezNo ratings yet

- The Art & Science of Coaching 2022Document23 pagesThe Art & Science of Coaching 2022ak cfNo ratings yet

- Bhupal Case Study PDFDocument4 pagesBhupal Case Study PDFSuman ChaudharyNo ratings yet

- Stargate tv6Document4 pagesStargate tv6Paul SavvyNo ratings yet

- Thesis Statement For ApushDocument4 pagesThesis Statement For ApushCustomPaperWritingUK100% (2)

- Home Brew Mart Homework SeriesDocument6 pagesHome Brew Mart Homework Seriesh48j8gwb100% (1)

- WHAP AP Review Session 6 - 1900-PresentDocument46 pagesWHAP AP Review Session 6 - 1900-PresentNajlae HommanNo ratings yet

- Environmental Term Paper TopicsDocument8 pagesEnvironmental Term Paper Topicsea6p1e99100% (1)

- Reaction Paper On PK (Film)Document2 pagesReaction Paper On PK (Film)Justine Mae dela CruzNo ratings yet

- Lesson 5: Targeting Job Search: Mobilize Your NetworkDocument20 pagesLesson 5: Targeting Job Search: Mobilize Your NetworkJohn Raven Monte100% (1)

- Dua-e-Nudba Translated by Naba Cultural OrganizationDocument31 pagesDua-e-Nudba Translated by Naba Cultural OrganizationWhizbeeNo ratings yet

- Chapter 3 OntologyDocument15 pagesChapter 3 OntologyabrehamNo ratings yet

- DC Motor Control Using CDocument6 pagesDC Motor Control Using Cankitguptaims100% (2)

- RBI - Report On Current and Finance 2005-06Document364 pagesRBI - Report On Current and Finance 2005-06_lucky_No ratings yet

- Adulterants Used in Carbohydrates CognosyDocument8 pagesAdulterants Used in Carbohydrates CognosyTanmay WalunjNo ratings yet

OM Practice Problem Ans

OM Practice Problem Ans

Uploaded by

Bhaskar AnandOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OM Practice Problem Ans

OM Practice Problem Ans

Uploaded by

Bhaskar AnandCopyright:

Available Formats

A toy manufacturer receives crafted toys from local carpenters and performs the final operations before

stocking them for sale. The process consists of five steps. The first step is cleaning and placing a toy in

a tray. After this, the tray moves to the next station, where the toys are pre-treated. This is to increase

the toys’ life, prevent them from pest attacks in the future, and also to improve the effectiveness of the

painting operation. The next step is to send it to the spray-painting chamber, where it is painted as per

the specifications and it is dried. At present, there is one spray-painting machine. After painting, some

of the toys are sent for inspection. Finally, all the toys are packed. The steps in the process, along with

the relevant details, are as follows:

Step 1 Prepare

Step 2 Pre-treatment

Step 3 Painting

Step 4 Inspection

Step 5 Packaging

Step 1 has 1 resource.

Step 2 has 3 resources parallelly. A toy needs to visit only one of the resources.

Step 3 has 1 resource.

Step 4 has 1 resource. Only 20% of the toys go through Step 4.

Step 5 has 2 resources. All the toys go through Step 5. 20% of the toys that go through Step 4 will be

packed by Resource 1. 80% of the toys that don’t go through Step 4 will be packed by Resource 2.

Answer the following questions:

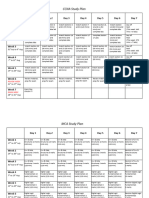

a. Fill the blank spaces in the given diagram (Time or Capacity).

b. Compute the capacity of total resources at all the steps (Imagine you have a pattern where

there's one toy that needs step 4 and then the next four toys that don't need step 4. This sequence

keeps repeating.)

c. Identify the bottleneck for this process.

d. What is the cycle time for this process?

e. What is the production rate?

Answer:

a.

b.

Step Calculation Capacity

Step 1 12 toys/hr

Step 2 6 + 4 + 5 = 15 toys/hr 15 toys/hr

Step 3 16 toys/hr

Step 4 20%(30 min) + 80%(0 min) = 6 min 10 toys/hr

Capacity = 60/6 = 10/hr

(or)

The first toy is inspected. It will take 30 mins to inspect it. The next

four toys are not inspected. So, at the end of 30 mins, you’ll have 5

toys ready for step 5. After the next 30 mins, you’ll have another 5

toys ready for step 5. So, the capacity is 10 toys/hr.

Step 5 20%(10 min) + 80%(4 min) = 5.2 min 11.54 toys/hr

Capacity = 60/5.2 = 11.54 toys/hr

c. Step 4 (Inspecting)

d. 6 min

Bottleneck step’s processing time

e. 10 toys/hr

You might also like

- Homework Assignment Module 2 - Process AnalysisDocument7 pagesHomework Assignment Module 2 - Process AnalysisRodrigo Isaac100% (3)

- Matching Supply With Demand Solutions To End of Chapter Problems 4Document6 pagesMatching Supply With Demand Solutions To End of Chapter Problems 4Omar Al-azzawi100% (1)

- ANIÑON - Problem Set #1 (2021)Document5 pagesANIÑON - Problem Set #1 (2021)Mia Kyla AninonNo ratings yet

- Guildelines For Developing Public Recreation Facility StandardsDocument99 pagesGuildelines For Developing Public Recreation Facility StandardsPogpog ReyesNo ratings yet

- OPIM101 - Spring 2009 - Exam 1 - SolutionsDocument12 pagesOPIM101 - Spring 2009 - Exam 1 - Solutionsjoe91bmwNo ratings yet

- InterViews. Learning The Craft of Qualitative Research Interviewing (1 Ed) - Kvale 1996 PDFDocument173 pagesInterViews. Learning The Craft of Qualitative Research Interviewing (1 Ed) - Kvale 1996 PDFquinojotaNo ratings yet

- PAN Grade 5Document28 pagesPAN Grade 5Maestro VarixNo ratings yet

- State of Maharashtra V. Praful B Desai (DR.), 2003 4 SCCDocument8 pagesState of Maharashtra V. Praful B Desai (DR.), 2003 4 SCCDrsika100% (1)

- Operation Management Case StudyDocument2 pagesOperation Management Case StudyPrabodh KuncheNo ratings yet

- 01 Session 01 Unit 2 Process AnalysisDocument22 pages01 Session 01 Unit 2 Process AnalysisAyesha RachhNo ratings yet

- Process & Capacity AnalysisDocument50 pagesProcess & Capacity AnalysisSri Krishna JayaramNo ratings yet

- Process Analysis Problems SolutionDocument2 pagesProcess Analysis Problems SolutionAnimikh PalitNo ratings yet

- Process Analysis ProblemsDocument1 pageProcess Analysis ProblemsAnimikh PalitNo ratings yet

- Problem Set #1 (Apr 2022)Document4 pagesProblem Set #1 (Apr 2022)Ralph EmmanuelNo ratings yet

- Activity 1 Speed, Distance, and TimeDocument2 pagesActivity 1 Speed, Distance, and TimePaulo AlegriaNo ratings yet

- Class V Unit 7Document6 pagesClass V Unit 7Subodh GurungNo ratings yet

- Course: MGT314 Section: 5 Group Number: 06Document5 pagesCourse: MGT314 Section: 5 Group Number: 06Sk. Shahriar RahmanNo ratings yet

- 03 Process AnalysisDocument30 pages03 Process Analysisbharat2580% (1)

- Early Grade Mathematics Assessment Grade 1 (Written Test)Document8 pagesEarly Grade Mathematics Assessment Grade 1 (Written Test)RACHEL ABENo ratings yet

- Jaylyn Allmon - Cookies Final ProjectDocument3 pagesJaylyn Allmon - Cookies Final Projectapi-640757865No ratings yet

- Module in Tstrat 4Document3 pagesModule in Tstrat 4Jera ObsinaNo ratings yet

- Solution CHP 7 EOQDocument6 pagesSolution CHP 7 EOQwasif ahmedNo ratings yet

- Early Grade Mathematics AssessmentDocument50 pagesEarly Grade Mathematics AssessmentJesie Bell Balaba BuroNo ratings yet

- How Many Possible Seating Arrangements Could Be Made If There Are 3 Chairs and Four Students?Document18 pagesHow Many Possible Seating Arrangements Could Be Made If There Are 3 Chairs and Four Students?xhingyeeNo ratings yet

- Plan For 2023Document7 pagesPlan For 2023doraemongee1No ratings yet

- MATERIALS NEEDED FOR FINALS 2nd SEM 2023 24Document4 pagesMATERIALS NEEDED FOR FINALS 2nd SEM 2023 24renalyntanaleon5No ratings yet

- Module 7-Measurement in Real LifeDocument24 pagesModule 7-Measurement in Real LifealfierapisuraNo ratings yet

- Sciencereport Final Pigatutra SuichiDocument5 pagesSciencereport Final Pigatutra Suichiapi-268742364No ratings yet

- Exercise1-Intro toManagementScienceDocument3 pagesExercise1-Intro toManagementScienceRealine BularioNo ratings yet

- Probability Lesson PlanDocument11 pagesProbability Lesson Planapi-94078224No ratings yet

- Grade 5 - Teacher's Guide - Lesson 1 - Tally MarksDocument6 pagesGrade 5 - Teacher's Guide - Lesson 1 - Tally MarksshipradangNo ratings yet

- Tiny Pixel Farm WalkthroughDocument4 pagesTiny Pixel Farm WalkthroughFakhrul RozanNo ratings yet

- Lesson Title:: Blended Learning Lesson PlanDocument7 pagesLesson Title:: Blended Learning Lesson Planapi-509820951No ratings yet

- PAN Grade 4Document24 pagesPAN Grade 4Maestro VarixNo ratings yet

- Solved Problems Practice Problems For OM New NewDocument37 pagesSolved Problems Practice Problems For OM New NewMukesh ParmarNo ratings yet

- OPIM101 - Spring 2013 - Assignment 2 - Solution B PDFDocument5 pagesOPIM101 - Spring 2013 - Assignment 2 - Solution B PDFjoe91bmwNo ratings yet

- Module 2 Lesson 2 - Working TogetherDocument12 pagesModule 2 Lesson 2 - Working Togetherapi-742584549No ratings yet

- Cookies Final Project Exemplar 1Document4 pagesCookies Final Project Exemplar 1api-242864146No ratings yet

- Problem Set 1Document16 pagesProblem Set 1Tutor ProNo ratings yet

- ResultDocument1 pageResultapi-350675057No ratings yet

- Solved - You Have Been Asked To Set Up An Assembly Line To Assemble A Computer Mouse. The Precedence..Document4 pagesSolved - You Have Been Asked To Set Up An Assembly Line To Assemble A Computer Mouse. The Precedence..Maritoni SulitNo ratings yet

- Module 2 - Capacity Planning Practice ProblemsDocument3 pagesModule 2 - Capacity Planning Practice ProblemsIsabel CalderonNo ratings yet

- Singapore Math Worksheets Grade 4 Whole NumbersDocument7 pagesSingapore Math Worksheets Grade 4 Whole NumbersKungfu Math100% (2)

- Basic Standar KerjaDocument30 pagesBasic Standar Kerjaadhirga_moesNo ratings yet

- General Mathematics: Quarter 1 - ModuleDocument15 pagesGeneral Mathematics: Quarter 1 - ModuleJinky Bon100% (1)

- BASIC MATHS-sem2 AnsDocument24 pagesBASIC MATHS-sem2 AnsSai TheebannNo ratings yet

- BE1401 Business Operations and Processes Answer Key For Exercises On Capacity AnalysisDocument4 pagesBE1401 Business Operations and Processes Answer Key For Exercises On Capacity Analysisgao linxinNo ratings yet

- Problem Solving StrategiesDocument12 pagesProblem Solving StrategiesANNA MARY GINTORONo ratings yet

- W - T NG H P IELTS Writing ProcessDocument55 pagesW - T NG H P IELTS Writing Processecovalley2023No ratings yet

- Assessment Lesson 2.2 AnswersDocument8 pagesAssessment Lesson 2.2 AnswersAnanel EpondulanNo ratings yet

- Simulation FinalllDocument73 pagesSimulation FinalllAlizeh FarooqNo ratings yet

- Grcelene Caba Laboratory ReportDocument8 pagesGrcelene Caba Laboratory ReportAgnes MontalboNo ratings yet

- 1 SimulationsDocument42 pages1 Simulationsfrank obimoNo ratings yet

- AH X9 ActiveHome 2WeekFitnessJournalDocument13 pagesAH X9 ActiveHome 2WeekFitnessJournalPE ProjectNo ratings yet

- Converting Minutes Into Seconds Converting Hours Into MinutesDocument2 pagesConverting Minutes Into Seconds Converting Hours Into MinutesLubna ImranNo ratings yet

- Activity SheetDocument2 pagesActivity SheetLovejoy TiñaNo ratings yet

- Scratch Lessons Tutors ManualDocument22 pagesScratch Lessons Tutors ManualdipaliNo ratings yet

- Sols chp4Document6 pagesSols chp4Aryan SharmaNo ratings yet

- Presentation in Linear ProgrammingDocument34 pagesPresentation in Linear Programmingotok jacildoNo ratings yet

- Problem SolvingDocument46 pagesProblem SolvingMharlynne Nezlou L. PoliranNo ratings yet

- Quiz - WCMDocument1 pageQuiz - WCMROB101512No ratings yet

- At Secretariat Comment RequestDocument2 pagesAt Secretariat Comment RequestDocumentsZANo ratings yet

- Clarence-Smith, W. G., African and European Cocoa Producers On Fernando Poo, 1880s To 1910s', The Journal of African History, 35 (1994), 179-199Document22 pagesClarence-Smith, W. G., African and European Cocoa Producers On Fernando Poo, 1880s To 1910s', The Journal of African History, 35 (1994), 179-199OSGuineaNo ratings yet

- Passive VoiceDocument1 pagePassive VoiceElhassania ElmouatrachNo ratings yet

- Web Server Attacks and Mitigation Using SnortDocument14 pagesWeb Server Attacks and Mitigation Using SnortphilpqNo ratings yet

- Accomplishment Report BrigadaDocument2 pagesAccomplishment Report BrigadaVincent rexie AsuncionNo ratings yet

- Communityplan SV PDFDocument20 pagesCommunityplan SV PDFJeesson AlamarNo ratings yet

- Quizzz 2 102, Summer 20Document7 pagesQuizzz 2 102, Summer 20Samuel Muabia PlānetNo ratings yet

- Heart Songs - February 10 8 43 AmDocument2 pagesHeart Songs - February 10 8 43 Amapi-551678806No ratings yet

- IBIG 04 06 MA Deals Merger Models TranscriptDocument4 pagesIBIG 04 06 MA Deals Merger Models TranscriptіфвпаіNo ratings yet

- G10 Q4 Week2finalDocument10 pagesG10 Q4 Week2finalANALYN DEL CASTILLONo ratings yet

- Paul Bragg Healthy HeartDocument260 pagesPaul Bragg Healthy Heartdeborah81100% (9)

- O'connor Tweezer Dexterity TestDocument10 pagesO'connor Tweezer Dexterity TestEvelyn JiménezNo ratings yet

- The Art & Science of Coaching 2022Document23 pagesThe Art & Science of Coaching 2022ak cfNo ratings yet

- Bhupal Case Study PDFDocument4 pagesBhupal Case Study PDFSuman ChaudharyNo ratings yet

- Stargate tv6Document4 pagesStargate tv6Paul SavvyNo ratings yet

- Thesis Statement For ApushDocument4 pagesThesis Statement For ApushCustomPaperWritingUK100% (2)

- Home Brew Mart Homework SeriesDocument6 pagesHome Brew Mart Homework Seriesh48j8gwb100% (1)

- WHAP AP Review Session 6 - 1900-PresentDocument46 pagesWHAP AP Review Session 6 - 1900-PresentNajlae HommanNo ratings yet

- Environmental Term Paper TopicsDocument8 pagesEnvironmental Term Paper Topicsea6p1e99100% (1)

- Reaction Paper On PK (Film)Document2 pagesReaction Paper On PK (Film)Justine Mae dela CruzNo ratings yet

- Lesson 5: Targeting Job Search: Mobilize Your NetworkDocument20 pagesLesson 5: Targeting Job Search: Mobilize Your NetworkJohn Raven Monte100% (1)

- Dua-e-Nudba Translated by Naba Cultural OrganizationDocument31 pagesDua-e-Nudba Translated by Naba Cultural OrganizationWhizbeeNo ratings yet

- Chapter 3 OntologyDocument15 pagesChapter 3 OntologyabrehamNo ratings yet

- DC Motor Control Using CDocument6 pagesDC Motor Control Using Cankitguptaims100% (2)

- RBI - Report On Current and Finance 2005-06Document364 pagesRBI - Report On Current and Finance 2005-06_lucky_No ratings yet

- Adulterants Used in Carbohydrates CognosyDocument8 pagesAdulterants Used in Carbohydrates CognosyTanmay WalunjNo ratings yet