Professional Documents

Culture Documents

MOT Unit 2 6 Mei 2021

MOT Unit 2 6 Mei 2021

Uploaded by

ali habibiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MOT Unit 2 6 Mei 2021

MOT Unit 2 6 Mei 2021

Uploaded by

ali habibiCopyright:

Available Formats

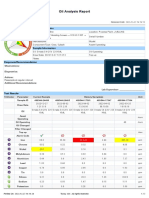

PLTU Banjarsari

Location: Unit 2

Unit ID: Turbin-->Turbin

Model:

Component Type: Turbine, Steam

Observations :

Large Fe, ppm is severely high; V40, cSt is abnormally low

Diagnostics :

• Suspect Fe source to be wear of shaft, reduction gear, bearings, piping, or

structural components.

• Viscosity change may be due to contamination, severly degraded oil, or wrong fluid

added.

Recommended Actions :

• Feed and bleed reservoir with correct lubricant.

• Investigate equipment urgently.

Additional Recommendations :

06 May 2021

Oil Shell Turbo Oil T32 Sample ID 15640-15 15640-11 15640-4 15640-2

Draw Date 06 May 2021 09 Apr 2021 22 Mar 2021 19 Mar 2021

Notes:

Released Date 06 May 2021 09 Apr 2021 22 Mar 2021 19 Mar 2021

Asset Operating (hours)

Oil Operating (hours)

Top up (l)

Iron ppm 0.1 0.0 0.19 0.0

Chrome ppm 0.0 0.0 0.0 0.0

Nickel ppm 0.0 0.0 0.0 0.0

Aluminium ppm 0.0 0.11 0.09 0.2

Lead ppm 0.0 0.0 0.0 0.0

Copper ppm 0.01 0.0 0.0 0.0

Tin ppm 0.34 0.94 0.56 0.73

Titanium ppm 0.0 0.0 0.0 0.0

Wear Silver ppm 0.0 0.0 0.0 0.0

Antimony ppm 0.12 0.0 0.0 0.87

Cadmium ppm 0.0 0.0 0.0 0.03

Manganese ppm 0.0 0.0 0.0 0.0

Fatigue >20u part./ml 11.01 8.0 6.01 6.01

Non-Metallic >20u part./ml 38.04 9.0 35.05 4.01

Large Fe ppm ppm 0.22 0.11 0.0 0.02

Fe Wear Severity Index 0.05 0.01 0.0 0.0

Total Fe < 100u ppm 0.22 0.11 0.0 0.02

Boron ppm 0.0 0.0 0.0 0.0

Silicon ppm 0.59 0.45 0.64 0.17

Sodium ppm 0.0 0.0 0.0 0.0

Vanadium ppm 0.06 0.0 0.0 0.0

Potassium ppm 0.0 0.0 0.06 0.0

Lithium ppm 0.0 0.0 0.0 0.0

ISO 4406 Code (>4µm) 18.0 20.0 19.0 20.0

ISO 4406 Code (>6µm) 16.0 18.0 17.0 17.0

ISO 4406 Code (>14µm) 14.0 13.0 13.0 12.0

Contamination

Cnts >4 part./ml 1537.4 5942.3 4257.1 5587.0

Cnts >6 part./ml 579.3 1430.6 696.1 922.3

Cnts >14 part./ml 100.1 44.0 66.1 22.0

Cutting >20u part./ml 4.0 3.0 3.0 0.0

Sliding >20u part./ml 6.01 15.0 4.01 5.01

Free Water abs/0.1mm abs/0.1mm 0.0 0.0 0.0 0.0

Bubbles 1.32 1.31 1.31 1.3

Water ppm 48.0 52.0 39.0 36.0

Large Fe % 100.0 100.0 0.0 100.0

TruVu 360 Software

--

Printed on: May 6, 2021 All right reserved 1

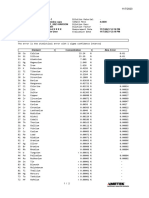

Oil Shell Turbo Oil T32 Sample ID 15640-15 15640-11 15640-4 15640-2

Draw Date 06 May 2021 09 Apr 2021 22 Mar 2021 19 Mar 2021

Notes:

Released Date 06 May 2021 09 Apr 2021 22 Mar 2021 19 Mar 2021

Asset Operating (hours)

Oil Operating (hours)

Top up (l)

Molybdenum ppm 0.0 0.0 0.0 0.03

Calcium ppm 0.0 0.0 0.0 0.0

Magnesium ppm 0.0 0.1 0.0 0.0

Phosphorus ppm 0.0 0.0 0.0 1.46

Zinc ppm 4.75 5.23 5.87 6.96

Chemistry Barium ppm 0.0 0.0 0.0 0.0

TAN mg KOH/g 0.17 0.14 0.18 0.21

Oxidation abs/0.1mm 1.87 1.88 1.83 1.81

Visc 40 cSt 28.6 29.5 29.7 28.3

Visc 100 cSt 5.2 5.2 5.2 5.1

Fluid Integrity 97.6 98.0 96.9 96.3

Date 06 May 2021 Lab Supervisor ________________________________

TruVu 360 Software

--

Printed on: May 6, 2021 All right reserved 2

Analysis Trend Charts

PLTU Banjarsari Location:

Unit 2

TruVu 360 Software

--

Printed on: May 6, 2021 All right reserved 3

Analysis Trend Charts

PLTU Banjarsari Location:

Unit 2

TruVu 360 Software

--

Printed on: May 6, 2021 All right reserved 4

Analysis Trend Charts

PLTU Banjarsari Location:

Unit 2

TruVu 360 Software

--

Printed on: May 6, 2021 All right reserved 5

Analysis Trend Charts

PLTU Banjarsari Location:

Unit 2

TruVu 360 Software

--

Printed on: May 6, 2021 All right reserved 6

Analysis Trend Charts

PLTU Banjarsari Location:

Unit 2

TruVu 360 Software

--

Printed on: May 6, 2021 All right reserved 7

Analysis Trend Charts

PLTU Banjarsari Location:

Unit 2

TruVu 360 Software

--

Printed on: May 6, 2021 All right reserved 8

Analysis Trend Charts

PLTU Banjarsari Location:

Unit 2

TruVu 360 Software

--

Printed on: May 6, 2021 All right reserved 9

Analysis Trend Charts

PLTU Banjarsari Location:

Unit 2

TruVu 360 Software

--

Printed on: May 6, 2021 All right reserved 10

PLTU Banjarsari Sample ID 15640-15

Draw Date 06 May 2021

Unit ID: Turbin-->Turbin Released Date 06 May 2021

Model:

Component Type: Turbine, Steam

Particle analysis and shape classification with LaserNet Fines-C

Method: ML. Analysis refers to particles >= 20 µm

Cutting >20u 4 part./ml

Scale 63:1

(1 cm equals to 158 µm)

Sliding >20u 6 part./ml

Scale 63:1

(1 cm equals to 158 µm)

Fatigue >20u 11 part./ml

Scale 63:1

(1 cm equals to 158 µm)

TruVu 360 Software

--

Printed on: May 6, 2021 All right reserved 11

Non-Metallic >20u 38 part./ml

Scale 63:1

(1 cm equals to 158 µm)

TruVu 360 Software

--

Printed on: May 6, 2021 All right reserved 12

You might also like

- Astm A449Document1 pageAstm A449Vitor Rigueira de GodoyNo ratings yet

- (Alexei Lapkin, David Constable) Green Chemistry Me (B-Ok - CC) PDFDocument337 pages(Alexei Lapkin, David Constable) Green Chemistry Me (B-Ok - CC) PDFAlex Sustaita100% (1)

- Rima Water CompositionsDocument4 pagesRima Water Compositionssarah96.alshawamikhNo ratings yet

- Measurement Details: Property Alarm Sample Date: Sample ID: Fluid: AlarmDocument1 pageMeasurement Details: Property Alarm Sample Date: Sample ID: Fluid: AlarmOkky HeljaNo ratings yet

- Normal-Davit Lifeboat PS-1295701-Hydraulic System-30-06-2020Document2 pagesNormal-Davit Lifeboat PS-1295701-Hydraulic System-30-06-2020Douglas David SilvaNo ratings yet

- Oil Analysis. TOTAL Office Air Comp BDocument4 pagesOil Analysis. TOTAL Office Air Comp Bserge.borrellNo ratings yet

- CIPW Norm HollacherDocument1 pageCIPW Norm HollacherBrandon Nils Calderón PomaNo ratings yet

- CIPW NormDocument1 pageCIPW NormGARY ERLAND QUIROZ FLORESNo ratings yet

- CIPW Norm Hollacher Norm4Document2 pagesCIPW Norm Hollacher Norm4Lucas CabelierNo ratings yet

- Attention Sample Data: Lube Oil Analysis ReportDocument1 pageAttention Sample Data: Lube Oil Analysis ReportnurdinzaiNo ratings yet

- Attention Sample Data: Lube Oil Analysis ReportDocument1 pageAttention Sample Data: Lube Oil Analysis ReportnurdinzaiNo ratings yet

- Simulacion Antiincrustante AWC A 102Document6 pagesSimulacion Antiincrustante AWC A 102Richard Franklin Pacheco QuiscaNo ratings yet

- Reverse Osmosis System Analysis For Filmtec™ Membranes Rosa 9.1 Configdb U399339 - 282 Project: Swro 38000 Tds Case: 1 Deisy, 12/15/2016Document3 pagesReverse Osmosis System Analysis For Filmtec™ Membranes Rosa 9.1 Configdb U399339 - 282 Project: Swro 38000 Tds Case: 1 Deisy, 12/15/2016MoulyaniNo ratings yet

- Copie de CIPW Norm HollacherDocument1 pageCopie de CIPW Norm HollacherLouis NahimanaNo ratings yet

- Outlet WaterDocument2 pagesOutlet WaterMohammed GhanemNo ratings yet

- Work - October 30 (Chemistry Assignment)Document3 pagesWork - October 30 (Chemistry Assignment)taco bNo ratings yet

- MTO For Repair of Cooler - IdenmitsuDocument1 pageMTO For Repair of Cooler - IdenmitsuQuy VoNo ratings yet

- Laboratory Analysis Report: No Action RequiredDocument2 pagesLaboratory Analysis Report: No Action RequiredjoseNo ratings yet

- Awc - Proton Ro Osmosis - Ecosac Pozo - 02 20240222032933Document5 pagesAwc - Proton Ro Osmosis - Ecosac Pozo - 02 20240222032933Raul GuevaraNo ratings yet

- KME CuNI Welding ProcedureDocument11 pagesKME CuNI Welding ProcedureJoaoNo ratings yet

- Discharge Vibrating Screen 322-SC-1001 DE Drive GearboxDocument7 pagesDischarge Vibrating Screen 322-SC-1001 DE Drive GearboxMishNo ratings yet

- Lube Oil Trend ReportDocument9 pagesLube Oil Trend ReportHoang LacNo ratings yet

- Raw Mix DesignDocument1 pageRaw Mix Designthangamuthu baskar100% (2)

- CIPW NormDocument1 pageCIPW NormEdin DivovićNo ratings yet

- Awc - Proton Ro Null Null 20230927041217Document6 pagesAwc - Proton Ro Null Null 20230927041217Daniel Ortiz GonzálezNo ratings yet

- Sharjah Standards of FE (STP)Document2 pagesSharjah Standards of FE (STP)hychauhan1No ratings yet

- CIPW Norm HollacherDocument2 pagesCIPW Norm HollacherAchmad Noviari AkbarNo ratings yet

- PKM 18Document2 pagesPKM 18Ranjith kumarNo ratings yet

- Astm A325Document1 pageAstm A325Alberto CárdenasNo ratings yet

- PKM 1Document2 pagesPKM 1Ranjith kumarNo ratings yet

- Hex 1201 FD LH 16112018Document2 pagesHex 1201 FD LH 16112018Tino FebriantoNo ratings yet

- Ejemplos Histogramas: D. Aburto M. 2014Document9 pagesEjemplos Histogramas: D. Aburto M. 2014Ismael Callasaya HernandezNo ratings yet

- Table 1 Chemical RequirementsDocument2 pagesTable 1 Chemical RequirementsmoodydoodyNo ratings yet

- CipwnormexcelDocument2 pagesCipwnormexcelHowel TurnerNo ratings yet

- Optimization of Desulphurization of Hot Metal and Liquid Steel For RAILDocument16 pagesOptimization of Desulphurization of Hot Metal and Liquid Steel For RAILratul_sarkarNo ratings yet

- Reverse Osmosis System Analysis For Filmtec™ Membranes Rosa 9.1 Configdb U399339 - 282 Project: Enerau - Hydro Case: 1 NP, MFT 10/25/2018Document3 pagesReverse Osmosis System Analysis For Filmtec™ Membranes Rosa 9.1 Configdb U399339 - 282 Project: Enerau - Hydro Case: 1 NP, MFT 10/25/2018unconformistNo ratings yet

- 150 m3d - 17000 PPM TDS - SWC5-LD - 35.0C - 3.0Y - 40.0R - AY10-22-2018Document3 pages150 m3d - 17000 PPM TDS - SWC5-LD - 35.0C - 3.0Y - 40.0R - AY10-22-2018Ashraf BayomiNo ratings yet

- Unitrac Results - R&DDocument10 pagesUnitrac Results - R&DKumar SubramanianNo ratings yet

- Komposisi Air Laut - Docx YuditDocument4 pagesKomposisi Air Laut - Docx YuditbickomcrNo ratings yet

- RD38 960E Wheel Transmission LH WheelDocument7 pagesRD38 960E Wheel Transmission LH WheelMishNo ratings yet

- DiagnosisDocument2 pagesDiagnosismd.rokonu ZzamanNo ratings yet

- Practica Calificada N°5 - Siderurgia NOMBRE: Magdalena Lucero Gómez Cabrera CODIGO: 20150203IDocument2 pagesPractica Calificada N°5 - Siderurgia NOMBRE: Magdalena Lucero Gómez Cabrera CODIGO: 20150203ILucero Gomez CabreraNo ratings yet

- Test Report: Equipment: Q4 TASMAN/ 214435Document1 pageTest Report: Equipment: Q4 TASMAN/ 214435test qtesNo ratings yet

- Aluminum LM5 As Manufactured - Gravity Die CastDocument1 pageAluminum LM5 As Manufactured - Gravity Die CastdolincastingNo ratings yet

- PT. Tekenomiks Indonesia: 05357110 PT - Kalimantan Prima Persada - SangattaDocument2 pagesPT. Tekenomiks Indonesia: 05357110 PT - Kalimantan Prima Persada - SangattaReksiNo ratings yet

- Batch No. 4.072 (F5) 3104GDocument1 pageBatch No. 4.072 (F5) 3104GAkhilesh Singh SinghNo ratings yet

- COA - Sulphuric AcidDocument2 pagesCOA - Sulphuric AcidMechem EurofinsNo ratings yet

- Tin Ingot AnalysisDocument1 pageTin Ingot AnalysisAreIf Cron BmxStreetNo ratings yet

- FabaDocument2 pagesFabaalwi sahabNo ratings yet

- Proyecto 1-ProcesosDocument2 pagesProyecto 1-ProcesosGUEVARA BERNARDO ARIANENo ratings yet

- Batch No. 4.090 (F5) 3104GDocument1 pageBatch No. 4.090 (F5) 3104GAkhilesh Singh SinghNo ratings yet

- PR_25.0C_0.0Y_50.0R_11-12-2023Document3 pagesPR_25.0C_0.0Y_50.0R_11-12-2023NetsolNo ratings yet

- Calculo FertilizaciónDocument15 pagesCalculo FertilizaciónSERGIO PEREZ MATOSNo ratings yet

- OREAS 22f: Primary Quartz Blank (Grey Pigmented Quartz, Australia) Certified Reference MaterialDocument10 pagesOREAS 22f: Primary Quartz Blank (Grey Pigmented Quartz, Australia) Certified Reference MaterialsabisamoNo ratings yet

- Concentrate Recirculation: Saturations Raw Water Feed Water Concentrate LimitsDocument3 pagesConcentrate Recirculation: Saturations Raw Water Feed Water Concentrate Limitsjugal ranaNo ratings yet

- Extension of Stainless Steel Refining Complex by Twin Tank VOD UnitDocument6 pagesExtension of Stainless Steel Refining Complex by Twin Tank VOD UnitJJNo ratings yet

- Data Sheet For Hinged SystemsDocument6 pagesData Sheet For Hinged SystemsMohsin KhanNo ratings yet

- Chemical Composition NickelDocument3 pagesChemical Composition NickelGascod Holding SasNo ratings yet

- BSD-GL-HAL-HMS-100 - (Terms & Definitions)Document42 pagesBSD-GL-HAL-HMS-100 - (Terms & Definitions)Eduard GadzhievNo ratings yet

- Al55 66 Technical Manual v11 EngDocument60 pagesAl55 66 Technical Manual v11 EngProblem VelikiNo ratings yet

- Is-Cal01 Design Carbon Accounting On Site Rev.02Document6 pagesIs-Cal01 Design Carbon Accounting On Site Rev.02shoba9945No ratings yet

- Toro Homelite 3354-726Document8 pagesToro Homelite 3354-726Cameron ScottNo ratings yet

- Solution Manual For Fundamentals of Semiconductor Fabrication Gary S May Simon M Sze Isbn 0471232793 Isbn 978-0-471 23279 7 Isbn 9780471232797Document16 pagesSolution Manual For Fundamentals of Semiconductor Fabrication Gary S May Simon M Sze Isbn 0471232793 Isbn 978-0-471 23279 7 Isbn 9780471232797warepneumomxkhf100% (17)

- Practice Exam Linear Algebra PDFDocument2 pagesPractice Exam Linear Algebra PDFShela RamosNo ratings yet

- MGje 6 Fix GX PK Yp RBJ LBRDocument9 pagesMGje 6 Fix GX PK Yp RBJ LBRBANOTH KUMARNo ratings yet

- Omnivision Man lp06xx Rev0 0611Document18 pagesOmnivision Man lp06xx Rev0 0611ivan ramirezNo ratings yet

- Textbook Pediatric Behavioral Nutrition Factors Environment Education and Self Regulation 1St Edition Areej Hassan Ebook All Chapter PDFDocument39 pagesTextbook Pediatric Behavioral Nutrition Factors Environment Education and Self Regulation 1St Edition Areej Hassan Ebook All Chapter PDFjanet.galloway812100% (8)

- Contoh Form Rko Obat PRB Per ApotekDocument19 pagesContoh Form Rko Obat PRB Per ApoteksaddamNo ratings yet

- HT Billing System - May'2022Document2 pagesHT Billing System - May'2022V.Sampath RaoNo ratings yet

- Perdev Module 3Document13 pagesPerdev Module 3Renelyn JacoNo ratings yet

- Bristol Comp Catalog 4Document102 pagesBristol Comp Catalog 4Popica ClaudiuNo ratings yet

- Functional Specification For Deck CraneDocument31 pagesFunctional Specification For Deck Craneaiyubi20% (1)

- Exit Poll CedatosDocument1 pageExit Poll CedatosEcuadorenvivoNo ratings yet

- SCM and TQM: by Junaid ShaheedDocument8 pagesSCM and TQM: by Junaid ShaheedjunaidsNo ratings yet

- Describe Physical and Chemical Change OperationallyDocument2 pagesDescribe Physical and Chemical Change OperationallyMaria Anna GraciaNo ratings yet

- Lecture 7 - Synchronous Generators 7 PDFDocument28 pagesLecture 7 - Synchronous Generators 7 PDFDorwinNeroNo ratings yet

- As 1729-1994 Timber - Handles For ToolsDocument7 pagesAs 1729-1994 Timber - Handles For ToolsSAI Global - APACNo ratings yet

- A. Title of Experiment B. Date and Time of Experiment: Wednesday, 10Document15 pagesA. Title of Experiment B. Date and Time of Experiment: Wednesday, 10LichaNo ratings yet

- ProductSheet Iq200 Rackmount SatelliteModemDocument2 pagesProductSheet Iq200 Rackmount SatelliteModemAsim Penkar PenkarNo ratings yet

- TinyMobileRobots TinySurveyor FlyerDocument4 pagesTinyMobileRobots TinySurveyor FlyerfelipeNo ratings yet

- Visual Storytelling The Digital Video Documentary - Original PDFDocument44 pagesVisual Storytelling The Digital Video Documentary - Original PDFjparanoti100% (1)

- 9701 s02 ErDocument14 pages9701 s02 ErHubbak KhanNo ratings yet

- Tax System SriLankaDocument44 pagesTax System SriLankamandarak7146No ratings yet

- CR Unit 1 &11 (Part A &B)Document12 pagesCR Unit 1 &11 (Part A &B)durai muruganNo ratings yet

- Advanced Landscape DesignDocument10 pagesAdvanced Landscape DesignSomhita DasNo ratings yet

- Ag4q-212s KBDocument2 pagesAg4q-212s KBhtek.thunderainNo ratings yet

- Unit-6 Patterns of Industrialisation PDFDocument12 pagesUnit-6 Patterns of Industrialisation PDFNavdeep SinghNo ratings yet