Professional Documents

Culture Documents

Procedure For Maintenance PDF Systems Theory Information Technology

Procedure For Maintenance PDF Systems Theory Information Technology

Uploaded by

nmctrr55b7Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Procedure For Maintenance PDF Systems Theory Information Technology

Procedure For Maintenance PDF Systems Theory Information Technology

Uploaded by

nmctrr55b7Copyright:

Available Formats

Procedure For

Maintenance

Uploaded by Anmol Chetri

0 ratings · 0 views · 2 pages

AI-enhanced title

Document Information

Original Title

UntitledDownload now

Copyright

© © All Rights Reserved Doc. No: PR-32

Rev. No.: 02

PROCEDURE FOR MAINTENANCE Date: 01.10.2021

Available Formats

Page: 1 of 2

1- PURPOSE : The purpose of this procedure is to develop a systematic process of maintenance of Machines & Equipments.

PDF, TXT or read online from Scribd

2- SCOPE : All the product & process related Machines & Equipment

3- RESPONSIBILITY: The overall responsibility lies with Incharge Production & Incharge Maintenance.

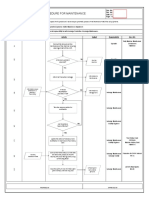

4- Process Flow

Share this document

S. No. Input Activity Output Responsibility Doc. Ref.

Daily Machine Maintenance

Conduct the daily preventive Operator Checksheet

1 maintenance of the machine including F/MNT/01

cleaning at start of the shift.

2 No Operator

Is there any problem Run the

observed? machine

Facebook Yes

Twitter

Machine Breakdown

Incharge Production Record

Information to

Inform to Production Incharge Incharge Maintenance F/MNT/03

Maintenance

3

4 Information About

Email

Breakdown in

Machine /

Tool/Utility

In-house

Rectification

possible or not?

YES

YES

NO Information to

Management Incharge Maintenance

Take the necessary action for

Incharge Maintenance

rectification

5

Did you find this document useful?

Incharge Maintenance

Are the actions NO Quality Engineer

6 taken effective?

YES

Tool History Card

Update the details of breakdown and

7 rectification in Machine and Tool History Incharge Maintenance F/PRD/04

Card Quality Engineer Machine History Card

F/MNT/11

Is this content inappropriate? Report this Document

Conduct the Pareto analysis on the data

Incharge Maintenance Procedure for CAPA Internal

Monthly and follow the procedure of CAPA

8 breakdown data

Incharge Quality PR-14

Internal (PR-14) for Raising CAPA on top

contributing factor.

List of Critical Spares

Critical Spare /

9 Keep the optimum level of critical spare Incharge Maintenance ML-06

Consumable

part inventory wherever required

parts list

PREPARED BY APPROVED BY

Doc. No: PR-32

Rev. No.: 01

PROCEDURE FOR MAINTENANCE Date: 01.10.2021

Page: 2 of 2

1- PURPOSE : The purpose of this procedure is to develop a systematic process of maintenance of Machines & Equipments.

2- SCOPE : All the product & process related Machines & Equipment

3- RESPONSIBILITY: The overall responsibility lies with Incharge Production & Incharge Maintenance.

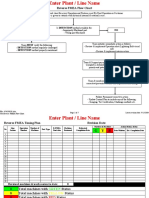

4- Process Flow

S. No. Input Activity Output Responsibility Doc. Ref.

List of all Incharge Machine Preventive

Prepare the annual preventive

machines and

10 maintenance plan Maintenance Maintenance Plan

utilities

F/MNT/02

Inform the outsourced party for Incharge

preventive maintenance for the Maintenance

machines which are outsourced for

11

preventive maintenance

FOr internal preventive maintenance,

plan for the required resources as per

the plan.

F/MNT/02

Monitor the preventive maintenance Machine Preventive

activities while performed by Incharge Maintenance Checksheet

outsourced vendor. Maintenance F/MNT/12

For internal preventive maintenance Or as per AMC gency

12

machines, perform the maintenance

as per the checksheet. First Piece Approval

FM/QA/30

Incharge

Run the machine & Take approval Quality

Maintenance

from quality Verification

13

Is approval NO

14 granted by Incharge Maintenance First Piece Approval

Quality? Incharge Quality FM/QA/30

YES

Machine History card

F/MNT/11

Update History card

15 Incharge Maintenance Tool History Card

F/PRD/04

PREPARED BY APPROVED BY

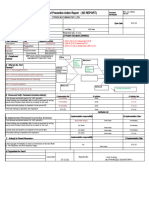

Revision History

Revision Date Rev. No. Revision Detail Approved By

03.07.2017 00 Initial Issue Mr. Dushyant

02.04.2018 01 Procedure revised Controls added Mr. Dushyant

01.10.2021 02 Action on machine breakdown and CAPA introduced for analysis. Controls and contents added. Mr. Dushyant

Share this document

You might also like

Document 5 pages

Repair and Maintenance

Procedure.docx

macky Panuelos

No ratings yet

Document 13 pages

Breakdown analysis

system

sherif mahmoud

No ratings yet

Document 2 pages

SOP -MT- 01

Maintenance.doc

Harits As Siddiq

No ratings yet

Magazines Podcasts

Sheet music

Document 4 pages

E_QMS_02_ENG

MAYMODERN STEEL

No ratings yet

Document 8 pages

fleet-management

Diana Lorena

No ratings yet

Document 172 pages

-Implementation

Strategies and[016-187]

Kenneth Quesada

No ratings yet

Document 7 pages

PM-Flow Chart.pptx

Sameer Bagalkot

No ratings yet

Document 7 pages

Pra-workshop Wpc & Serp

Gm

Erwin Raitz

No ratings yet

Document 97 pages

PM Training Doc

MAngesh Gade

No ratings yet

Document 2 pages

Preventive Maintenance

(BJ2)_ Process Diagrams

Naveen Reddy Kasarla

No ratings yet

Document 2 pages

1.1 SMP for Mechanical

Maintance of Airtube

PRANAV KUMAR GAUTAM

No ratings yet

Document 1 page

DOC-20191016-WA0001[1]

DhÓñ DóHútíá

No ratings yet

Show more

About Support

About Scribd Help / FAQ

Press Accessibility

Our blog Purchase help

Join our team! AdChoices

Contact us Publishers

Invite friends

Social

Gi!s

Scribd for enterprise Instagram

Twitter

Legal Facebook

Terms Pinterest

Privacy

Copyright

Cookie Preferences

Do not sell or share my

personal information

Get our free apps

Audiobooks • Books • Documents • Magazines •

Podcasts • Sheet music

Language: English

Copyright © 2023 Scribd Inc.

Download

You might also like

- Risk Assessment Asphalt WorksDocument7 pagesRisk Assessment Asphalt Workskannanjaduzz100% (1)

- Standard Operating Procedure For Engineering Breakdown MaintenanceDocument2 pagesStandard Operating Procedure For Engineering Breakdown MaintenanceMdrahaman Mithu100% (2)

- SOP For Machine Maintenance - For UpdateDocument3 pagesSOP For Machine Maintenance - For UpdatePeracha Engineering60% (5)

- VNSBN Om-3212401-0104Document606 pagesVNSBN Om-3212401-0104Hoàng Mạnh Linh100% (7)

- CPR Study Guide 2021: Online CPR Cheat SheetDocument14 pagesCPR Study Guide 2021: Online CPR Cheat SheetHenz Freeman0% (2)

- Dettol Project ReportDocument23 pagesDettol Project Reporturshila bhuyan60% (15)

- Terms of ReferenceDocument2 pagesTerms of ReferenceRahul VermaNo ratings yet

- Procedure For MaintenanceDocument2 pagesProcedure For MaintenanceAnmol ChetriNo ratings yet

- 20) Process For Machine Maintenance.Document4 pages20) Process For Machine Maintenance.Sagar DaundNo ratings yet

- Repair and Maintenance ProcedureDocument5 pagesRepair and Maintenance Proceduremacky PanuelosNo ratings yet

- 1.1 SMP For Mechanical Maintance of AirtubeDocument2 pages1.1 SMP For Mechanical Maintance of AirtubePRANAV KUMAR GAUTAMNo ratings yet

- QP MNT 01 Maintanance of Plant & Machinery NewDocument5 pagesQP MNT 01 Maintanance of Plant & Machinery NewMASU BRAKE PADS QANo ratings yet

- D10414410A CP Rev 00Document21 pagesD10414410A CP Rev 00Suraj RawatNo ratings yet

- Lifting EquipmentsDocument31 pagesLifting Equipmentsjrpatel18853No ratings yet

- SOP - MT - 01 MaintenanceDocument2 pagesSOP - MT - 01 MaintenanceHarits As SiddiqNo ratings yet

- Casting CPDocument2 pagesCasting CPSuraj RawatNo ratings yet

- Punyam Manufacturing INC: EngineeringDocument4 pagesPunyam Manufacturing INC: EngineeringMAYMODERN STEELNo ratings yet

- Breakdown Analysis SystemDocument13 pagesBreakdown Analysis Systemsherif mahmoudNo ratings yet

- Electrical Panel Manual Book 1 - 189Document6 pagesElectrical Panel Manual Book 1 - 189Harita Site KediukNo ratings yet

- R&D - Oi - 01 - Fmea P1Document7 pagesR&D - Oi - 01 - Fmea P1Abhinav SinghNo ratings yet

- Job Description: StellenbeschreibungDocument5 pagesJob Description: StellenbeschreibungMireya RochaNo ratings yet

- Maint To Be FlowchartDocument2 pagesMaint To Be FlowchartArsalanNo ratings yet

- GM Casting CPDocument3 pagesGM Casting CPSuraj RawatNo ratings yet

- RVFS - Equipment Maintenance ScheduleDocument1 pageRVFS - Equipment Maintenance ScheduleRoy SumugatNo ratings yet

- General Maintenance: Who Will Do? Process FlowDocument7 pagesGeneral Maintenance: Who Will Do? Process FlowSameer BagalkotNo ratings yet

- Seminario de Vibraciones PrufftechnikDocument114 pagesSeminario de Vibraciones PrufftechnikOdlanier José MendozaNo ratings yet

- Control Plan: FG 260 As Per IS 210: 2009Document24 pagesControl Plan: FG 260 As Per IS 210: 2009Suraj RawatNo ratings yet

- Of Eeg It 002 Monthly Computer Maintanance ScheduleDocument1 pageOf Eeg It 002 Monthly Computer Maintanance ScheduleJoshua CooperNo ratings yet

- PPC Types of MaintenanceDocument4 pagesPPC Types of MaintenanceRajesh RoutrayNo ratings yet

- Job Description: StellenbeschreibungDocument7 pagesJob Description: StellenbeschreibungMireya RochaNo ratings yet

- Reverse FMEA ProcessDocument7 pagesReverse FMEA ProcessYayi MartinezNo ratings yet

- Procedure For ServicingDocument7 pagesProcedure For ServicingchahiNo ratings yet

- Defect History: Sr. No Typeof Defect Action StatusDocument22 pagesDefect History: Sr. No Typeof Defect Action StatusSameer SaxenaNo ratings yet

- Capa 8DDocument3 pagesCapa 8DVinod Kumar SharmaNo ratings yet

- Maintenance OrderDocument2 pagesMaintenance OrderFrancis DedumoNo ratings yet

- D10414410a Fmea MachiningDocument13 pagesD10414410a Fmea MachiningSuraj RawatNo ratings yet

- Złączenie Płukania Podgrzewaczy MGT12Document30 pagesZłączenie Płukania Podgrzewaczy MGT12kamil.wlodarczykNo ratings yet

- Machining Control PlannDocument18 pagesMachining Control PlannSuraj Rawat0% (1)

- Process Sheet: DescriptionDocument9 pagesProcess Sheet: Descriptionmohamed abdullahNo ratings yet

- Qsp-Maint - 01 Preventive MaintenanceDocument1 pageQsp-Maint - 01 Preventive MaintenanceDeepak KumarNo ratings yet

- Breakdown Service RecordDocument1 pageBreakdown Service RecordJayath BogahawatteNo ratings yet

- Process SheetDocument4 pagesProcess Sheetmohamedelshrpeni0No ratings yet

- Cat All 1000 035 TG 000 EngDocument9 pagesCat All 1000 035 TG 000 Engyeremia kristianNo ratings yet

- Wi-Tn-002 HIL Deferred Defect RectificationDocument6 pagesWi-Tn-002 HIL Deferred Defect RectificationIrfan FauziNo ratings yet

- Instr Procedure - 1y - PM - 28-K - 3112Document33 pagesInstr Procedure - 1y - PM - 28-K - 3112ofon OML102No ratings yet

- Preventive Maintenance (BJ2) - Process DiagramsDocument2 pagesPreventive Maintenance (BJ2) - Process DiagramsNaveen Reddy KasarlaNo ratings yet

- Cartoner Cdi 73Document22 pagesCartoner Cdi 73Ritche Lim BragaisNo ratings yet

- TCM-F-IMS-014 NCR - Pama - PC - Cleaning-MeiDocument2 pagesTCM-F-IMS-014 NCR - Pama - PC - Cleaning-Meiwahyu nurcahyoNo ratings yet

- Total Productive Maintenance (TPM)Document14 pagesTotal Productive Maintenance (TPM)Muhammad IrfanNo ratings yet

- Presentasi Wulan Rev.03Document12 pagesPresentasi Wulan Rev.03Amin RizkyNo ratings yet

- IT Coord: Job DescriptionDocument8 pagesIT Coord: Job DescriptionMireya RochaNo ratings yet

- Maintenance OrderDocument2 pagesMaintenance OrderFrancis DedumoNo ratings yet

- The Productivity of Your Factory Can Always Get Better!: Janets JT SimpleDocument7 pagesThe Productivity of Your Factory Can Always Get Better!: Janets JT SimplesentyNo ratings yet

- E-Field Service Report Inp (Rev)Document1 pageE-Field Service Report Inp (Rev)Marlini PasaribuNo ratings yet

- Tag No.: Asset Id: Machine Name: Area: TanggalDocument8 pagesTag No.: Asset Id: Machine Name: Area: TanggaldioNo ratings yet

- Inspection at 150 Flight HoursDocument4 pagesInspection at 150 Flight HoursSiswadiNo ratings yet

- Fleet ManagementDocument8 pagesFleet ManagementDiana LorenaNo ratings yet

- Job Description: StellenbeschreibungDocument5 pagesJob Description: StellenbeschreibungMireya RochaNo ratings yet

- GM Machining CP REV 03Document17 pagesGM Machining CP REV 03Suraj RawatNo ratings yet

- Operate A Hand Drill Rev 2Document3 pagesOperate A Hand Drill Rev 2grantNo ratings yet

- Breakdown and Preventive MaintainanceDocument3 pagesBreakdown and Preventive MaintainanceSagar DaundNo ratings yet

- 13 Maintenance ProcedureDocument10 pages13 Maintenance ProcedureGourav SainiNo ratings yet

- Applsci 11 06953Document17 pagesApplsci 11 06953michealNo ratings yet

- Leon Cooperman's Letter To President To ObamaDocument3 pagesLeon Cooperman's Letter To President To ObamaLuis AhumadaNo ratings yet

- 10TMSS04R2Document32 pages10TMSS04R2mogbel1No ratings yet

- Gate Preparation Strategy: Reservoir EngineeringDocument1 pageGate Preparation Strategy: Reservoir EngineeringHemant SrivastavaNo ratings yet

- Buenavista Central Elementary SchoolDocument2 pagesBuenavista Central Elementary Schoolanon_108827268No ratings yet

- Openacc Online Course: Lecture 1: Introduction To OpenaccDocument47 pagesOpenacc Online Course: Lecture 1: Introduction To OpenaccQuant_GeekNo ratings yet

- 1.kim Hai Fob Price List 2019 (New)Document6 pages1.kim Hai Fob Price List 2019 (New)Khanh QuocNo ratings yet

- Carey MTD OrderDocument17 pagesCarey MTD OrderTHROnlineNo ratings yet

- FBI Mandalay Bay FOIA Production 2Document15 pagesFBI Mandalay Bay FOIA Production 2NoloContendere100% (4)

- ICFO Slides Part 2Document33 pagesICFO Slides Part 2Bhavesh ChauhanNo ratings yet

- Class002 - 201200394-201000327-201000542Document46 pagesClass002 - 201200394-201000327-201000542api-286690957No ratings yet

- 2193-Article Text-2779-1-10-20171231Document11 pages2193-Article Text-2779-1-10-20171231Roisya marzuqiNo ratings yet

- Recent Legislations - CabarlesDocument11 pagesRecent Legislations - CabarlesKarl CabarlesNo ratings yet

- Implementation and Monitoring:: Assessing Performance in Contract RelationshipsDocument49 pagesImplementation and Monitoring:: Assessing Performance in Contract RelationshipsReddy SumanthNo ratings yet

- CC 2Document43 pagesCC 2iamsabaalyNo ratings yet

- CompTIA Security+ (Student Edition) PDFDocument615 pagesCompTIA Security+ (Student Edition) PDFAd Hi Ie100% (1)

- Air Handling UnitDocument6 pagesAir Handling UnitAgung SetiajiNo ratings yet

- Siemense CNC 48SP2Document19 pagesSiemense CNC 48SP2Xaoc KabataNo ratings yet

- Philips Automatic Hand SanitaizerDocument24 pagesPhilips Automatic Hand SanitaizerAjith9410No ratings yet

- Crosley 1Document8 pagesCrosley 1ovidiu6767No ratings yet

- 1,000 Indie Posters PDFDocument325 pages1,000 Indie Posters PDFMauricio Mesa JaramilloNo ratings yet

- Monopoly Oligopoly Monopolistic Competition Perfect CompetitionDocument8 pagesMonopoly Oligopoly Monopolistic Competition Perfect CompetitionDerry Mipa SalamNo ratings yet

- Liebert CRV Row Based Cooling System User ManualDocument190 pagesLiebert CRV Row Based Cooling System User ManualAngel David Osorio RiveroNo ratings yet

- Nirma: UniversityDocument2 pagesNirma: UniversityBHENSDADIYA KEVIN PRABHULALNo ratings yet

- SOGA CH 2 - Transfer of Ownership Notes by Gyaani AcademyDocument5 pagesSOGA CH 2 - Transfer of Ownership Notes by Gyaani Academykjkapiljain510No ratings yet

- Poster RudiDocument1 pagePoster RudirudimakaleleNo ratings yet

- CAMEE Tool 7 2 Agreement MEP Client 2013Document15 pagesCAMEE Tool 7 2 Agreement MEP Client 2013SAID RGONo ratings yet