Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

1 viewsLack Enclosure Documentation - V2

Lack Enclosure Documentation - V2

Uploaded by

João SantosCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Homemade Break-Barrel Shotgun Plans (Professor Parabellum)Document17 pagesHomemade Break-Barrel Shotgun Plans (Professor Parabellum)Leonardo Silva100% (1)

- Bug Baits Fortress InstructionsDocument9 pagesBug Baits Fortress InstructionsBenjamin Dunning86% (7)

- A Complete MDMA Synthesis For The First Time Chemist: Compilation and Editorial by Bright StarDocument14 pagesA Complete MDMA Synthesis For The First Time Chemist: Compilation and Editorial by Bright StarAdrien G. S. Wald100% (3)

- Practical Scrap Metal Small Arms Vol.14-Break-barrel Shotgun Plans TextDocument16 pagesPractical Scrap Metal Small Arms Vol.14-Break-barrel Shotgun Plans TextBenjamin Hobbs100% (1)

- UltimatearcadeII CabinetDocument23 pagesUltimatearcadeII CabinetFreddy IrarrazabalNo ratings yet

- Building The Osborne PlatterDocument9 pagesBuilding The Osborne PlatterHeman Lee50% (2)

- Wind TuerbineDocument23 pagesWind TuerbineGanesh Korore100% (1)

- Kreg Mini Jig Product ManualDocument2 pagesKreg Mini Jig Product ManualajaxleonNo ratings yet

- Open-Back Broadband Absorber Building Guide (Acoustic Panels) v1.5Document14 pagesOpen-Back Broadband Absorber Building Guide (Acoustic Panels) v1.5Churchil Meneer NaudéNo ratings yet

- Tango The Plywood Automata1Document25 pagesTango The Plywood Automata1Igor BettarelloNo ratings yet

- Pip Pie Trainer 01Document39 pagesPip Pie Trainer 01ebano.ttNo ratings yet

- Everyday Electronics 1974 10.CV01Document6 pagesEveryday Electronics 1974 10.CV01marcosscarato0% (1)

- Automotive Test Probe ConstructionDocument4 pagesAutomotive Test Probe ConstructionLy Fotoestudio DigitalcaNo ratings yet

- Read Me First!: Prefix Pro Series Preamp Installation GuideDocument2 pagesRead Me First!: Prefix Pro Series Preamp Installation GuideRoberto CastilloNo ratings yet

- Read Me First!: Prefix Series Preamp Installation GuideDocument2 pagesRead Me First!: Prefix Series Preamp Installation GuideRoberto CastilloNo ratings yet

- The Pippie Tender: Mike Waller Yacht Design PO Box 383 Morayfield Brisbane, QLD, AustraliaDocument0 pagesThe Pippie Tender: Mike Waller Yacht Design PO Box 383 Morayfield Brisbane, QLD, AustraliaacastromNo ratings yet

- Tray Template InstructionsDocument5 pagesTray Template InstructionsMohamed Mohiy El-DinNo ratings yet

- Router Table FenceDocument11 pagesRouter Table Fenceleo100% (2)

- Veritas Router Table Fence ManualDocument8 pagesVeritas Router Table Fence Manualsalvador LuqueNo ratings yet

- Bedding A Rifle With Matchgrade Bedding CompoundDocument24 pagesBedding A Rifle With Matchgrade Bedding CompoundDayle StuevenNo ratings yet

- Pippie8Tender PDFDocument32 pagesPippie8Tender PDFleonel montillaNo ratings yet

- Dovetail JigDocument12 pagesDovetail JigeducifueNo ratings yet

- Table Saw Sled - Taper Jig Accessory: Cut One or Many Tapers With Ease!Document8 pagesTable Saw Sled - Taper Jig Accessory: Cut One or Many Tapers With Ease!LinNo ratings yet

- Hadley Instructions v0 - 5Document78 pagesHadley Instructions v0 - 5mhudson46No ratings yet

- Building A Microphone and Amplifier - Watch Timing SystemDocument24 pagesBuilding A Microphone and Amplifier - Watch Timing Systemarp tiwNo ratings yet

- Wooden Puzzle Vault GIZSIP 327278258Document3 pagesWooden Puzzle Vault GIZSIP 327278258magoleija2010100% (1)

- Stables InstructionsDocument3 pagesStables InstructionsJavier Hidalgo SanchezNo ratings yet

- Book Case - Barrister 1Document6 pagesBook Case - Barrister 1Cris CondeNo ratings yet

- Freebird PDFDocument5 pagesFreebird PDFHHOLINo ratings yet

- Tutorial Magnum Spy PistolDocument6 pagesTutorial Magnum Spy PistolchopenNo ratings yet

- Professional Router Table PDFDocument17 pagesProfessional Router Table PDFhightecrebelNo ratings yet

- How To Build Your Own Effects Guitar Electronics Schematics PDFDocument9 pagesHow To Build Your Own Effects Guitar Electronics Schematics PDFCheryl ChuckNo ratings yet

- Bugbaits SMArmouryDocument10 pagesBugbaits SMArmouryMike Greenman100% (2)

- ENG - DNA HoldersDocument22 pagesENG - DNA HoldersTrikala2016No ratings yet

- Wood HingesDocument15 pagesWood HingesLuis Valens100% (1)

- Bara TelecoapeDocument11 pagesBara TelecoapeflorinakedNo ratings yet

- Entry Bench PlanDocument8 pagesEntry Bench PlancajemarNo ratings yet

- Notice Cellule KetkDocument2 pagesNotice Cellule KetkVIELMASNo ratings yet

- DIY BroadbandAbsorber by AaronYoungDocument2 pagesDIY BroadbandAbsorber by AaronYoungBryan AnthonyNo ratings yet

- Leg Tapering Jig: Project 14585EZDocument5 pagesLeg Tapering Jig: Project 14585EZBSulliNo ratings yet

- Making Your Own BladesDocument2 pagesMaking Your Own Bladesp6a4nduNo ratings yet

- "Slimline" Pen & Pencil Kit Assembly Instructions: Item #Pkpen and PK-PCLDocument2 pages"Slimline" Pen & Pencil Kit Assembly Instructions: Item #Pkpen and PK-PCLTamara MarreroNo ratings yet

- Polybatic Edge 540 Part1Document9 pagesPolybatic Edge 540 Part1dorimondNo ratings yet

- Sundial Instructions SY WebDocument12 pagesSundial Instructions SY WebNoah NashNo ratings yet

- Long Langstroth HiveDocument7 pagesLong Langstroth HiveWolfgangNo ratings yet

- Ornitoptero PDFDocument5 pagesOrnitoptero PDFninonunezNo ratings yet

- Read Me First!: Matrix Infinity VT Matrix Infinity Mic Blend Installation GuideDocument7 pagesRead Me First!: Matrix Infinity VT Matrix Infinity Mic Blend Installation GuideRofers Produções MusicaisNo ratings yet

- Wireless SpeakerDocument4 pagesWireless SpeakerGülbaharNo ratings yet

- Blog TH Kitchenette Upload Part 1Document4 pagesBlog TH Kitchenette Upload Part 1Antonio Aranda CabreraNo ratings yet

- RuterDocument7 pagesRuternokojNo ratings yet

- Instructions Kit Camera 6ledsDocument16 pagesInstructions Kit Camera 6ledsJacobite BondNo ratings yet

- Drill Press TableDocument11 pagesDrill Press TableWil NelsonNo ratings yet

- Arduino Minimal Drum KitDocument43 pagesArduino Minimal Drum KitmarioNo ratings yet

- A Dog Kennel: How To BuildDocument14 pagesA Dog Kennel: How To BuildRomeo MagdaNo ratings yet

- Tuffstar ManualV2.0Document6 pagesTuffstar ManualV2.0Isyna AriefNo ratings yet

- How To Build A Toy TheatreDocument20 pagesHow To Build A Toy TheatreJeremy VinesNo ratings yet

- RustE11 BreakDownDocument6 pagesRustE11 BreakDownBilly DipperNo ratings yet

- Build Your Own Six-Seater Picnic Table: Using 2 x 4 (50 x 100 mm) Lumber, #1From EverandBuild Your Own Six-Seater Picnic Table: Using 2 x 4 (50 x 100 mm) Lumber, #1No ratings yet

- Safety Data Sheet: Paraplast X-TRA®Document7 pagesSafety Data Sheet: Paraplast X-TRA®meganingtyasNo ratings yet

- CPM (Critical Path Method)Document23 pagesCPM (Critical Path Method)sarprajkatreNo ratings yet

- PM1000 6000 PLSED310053EN - (Print)Document18 pagesPM1000 6000 PLSED310053EN - (Print)JoseVela82No ratings yet

- FunFarming@ @Document25 pagesFunFarming@ @aratan jrNo ratings yet

- Containers in Non-Cellular ShipsDocument7 pagesContainers in Non-Cellular ShipschildofheavenNo ratings yet

- Southern Cross - Iso Pump - Installation and Operating InstructionDocument4 pagesSouthern Cross - Iso Pump - Installation and Operating InstructionFerryNo ratings yet

- Systems Engineering Manager in Chicago IL Resume Daniel O'MalleyDocument2 pagesSystems Engineering Manager in Chicago IL Resume Daniel O'MalleyDanielOMalleyNo ratings yet

- 7RW80 Manual A4 V040300 UsDocument264 pages7RW80 Manual A4 V040300 UsvinodmpvNo ratings yet

- SunLink FTAMDocument118 pagesSunLink FTAMSaad AliNo ratings yet

- A A C C 5 5 - G GDocument2 pagesA A C C 5 5 - G GMelky LiwutNo ratings yet

- How To Claim Land and Not BuyDocument36 pagesHow To Claim Land and Not BuyJoshua Sygnal GutierrezNo ratings yet

- Rec PrechargeDocument3 pagesRec PrechargePrabha Karan.nNo ratings yet

- LashCon IMO - Rev 9.0 - tcm149-287975Document4 pagesLashCon IMO - Rev 9.0 - tcm149-287975Milind TambeNo ratings yet

- 7 Philip Hazel LCA2004.TalkDocument7 pages7 Philip Hazel LCA2004.Talkapi-3764104No ratings yet

- Design and Research On The LCL Filter in Three-Phase PV Grid-Connected InvertersDocument4 pagesDesign and Research On The LCL Filter in Three-Phase PV Grid-Connected InvertersJong Hee LeeNo ratings yet

- HDCE-30C User ManualDocument54 pagesHDCE-30C User ManualmazolasboNo ratings yet

- Telemecanique Altivar61 Manual 037 90kwDocument47 pagesTelemecanique Altivar61 Manual 037 90kwcuongNo ratings yet

- Goddstar Cb21t20s Pc-81aDocument19 pagesGoddstar Cb21t20s Pc-81aedisonic2000No ratings yet

- Family Member's Docs.Document2 pagesFamily Member's Docs.hishamNo ratings yet

- Ensuring Data QualityDocument16 pagesEnsuring Data QualityAlsayed AlgergawyNo ratings yet

- 04 - Management Tool (Quality Center)Document4 pages04 - Management Tool (Quality Center)Brahmanand DasreNo ratings yet

- Design and Fabrication of Angular DrillingDocument8 pagesDesign and Fabrication of Angular DrillingvasanthNo ratings yet

- MBA Project Report On 'Earn and Learn' Trainee Scheme at TATA YAZAKI AUTOCOMP LIMITEDDocument86 pagesMBA Project Report On 'Earn and Learn' Trainee Scheme at TATA YAZAKI AUTOCOMP LIMITEDAman BhattacharyaNo ratings yet

- Aux Relay NRDocument5 pagesAux Relay NRSibolis NaburjuNo ratings yet

- Outsourced New Product DevelopmentDocument5 pagesOutsourced New Product Developmentvinnakota5No ratings yet

- Masaood John Brown - Presentation - v1.1Document54 pagesMasaood John Brown - Presentation - v1.1Hanif Akbar100% (1)

- Srs Airbag Control System: SectionDocument331 pagesSrs Airbag Control System: SectionMarcelo MendozaNo ratings yet

- Click125 PDFDocument112 pagesClick125 PDFCj Cruel0% (1)

- Rfa Monitoring - PGHDocument76 pagesRfa Monitoring - PGHRigelle DionisioNo ratings yet

Lack Enclosure Documentation - V2

Lack Enclosure Documentation - V2

Uploaded by

João Santos0 ratings0% found this document useful (0 votes)

1 views3 pagesOriginal Title

Lack enclosure documentation_V2

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

1 views3 pagesLack Enclosure Documentation - V2

Lack Enclosure Documentation - V2

Uploaded by

João SantosCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 3

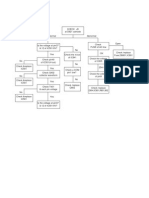

LACK ENCLOSURE - ELEGOO NEPTUNE 2

DESIGN INTENTS

- Our intent was to be able to print ABS with the Neptune

- Pop-able side panels for maintenance or printing PLA

- Top table including all panels and doors can be removed easily to allow working on the printer

- Modular panel brackets and door hinges to allow completely new configuration of panels and doors by other users

- PSU mounted outside the chamber and reusing OEM screws

- Spool mounted outside the chamber and reusing OEM screws and t-nuts

- Elegoo Neptune 2 fits perfectly inside including Min to Max Y movement

- Total height available inside = 510 mm (20")

BILL OF MATERIALS

Item Qty Notes

Ikea lack table 2

Side panels (443mm wide x 504mm high

3 Your choice of material and your size can vary slightly, measure first

x 3mm)

Front doors (223mm wide x 504mm high

2 Acrylic or equivalent if you want to see through…

x 3mm)

6mm x 3mm Neodymium magnets 20 Rare earth magnets if possible

For Door_Handles_Stopper. Use what you have on hand. Holes are

Button Head No 4 x 0.375" 4

4mm

Button Head No 6 x 0.5" 4 For Power supply_Horizontal bracket. Holes are 5mm

Or longer. For all 4 bottom corners to screw in table legs. Hole is

Hex head wood screw ¼" x 1" 4

7mm

PRINTED PARTS

- Qty to print for each is indicated in the filename (ex: Top corner rear_x2.stl print 2 of them)

- Orientation: All STL are already oriented correctly

- Support: none required

- Material: Your choice. I used PETG

- Infill: 20% Really, your choice here, but don't go too high. Some parts require lots of infill

- Approximate quantity of material: 550g @15% infill, 850g @40% infill

Lack enclosure documentation_V2.docx Page 1 of 3

PSU MOUNT

Drill 1" hole through

Cable will be long enough if

you position the PSU

approx like the image Re-use one original SHCS to

hold the PSU in place

DOORS AND HINGES

Use the ¼" wood screw to

attach to the bottom of the leg

Clip the "Hinge pin clip" first.

You might have to file some

material if your print is slightly Insert magnets everywhere

oversize there is a 6mm pocket

Make sure you check polarity

of magnet pairs

Parts were designed with 3mm

panels in mind. If you have

different width, you can

- Adjust the parts

- Remove back side and use

double-sided tape

- If panel is loose, I used

electrical tape to adjust

thickness of panels

Lack enclosure documentation_V2.docx Page 2 of 3

PANELS

Magnets is what keeps the top in place

You can also adjust to get a snug fit to

prevent the panel from vibrating while

printing

Bottom of panel is dropped in

the groove

SPOOL HOLDER

Use the OEM filament holder

Attach to base using the same

screws and t-nuts

Drill hole through and use

filament guide to protect

filament

Lack enclosure documentation_V2.docx Page 3 of 3

You might also like

- Homemade Break-Barrel Shotgun Plans (Professor Parabellum)Document17 pagesHomemade Break-Barrel Shotgun Plans (Professor Parabellum)Leonardo Silva100% (1)

- Bug Baits Fortress InstructionsDocument9 pagesBug Baits Fortress InstructionsBenjamin Dunning86% (7)

- A Complete MDMA Synthesis For The First Time Chemist: Compilation and Editorial by Bright StarDocument14 pagesA Complete MDMA Synthesis For The First Time Chemist: Compilation and Editorial by Bright StarAdrien G. S. Wald100% (3)

- Practical Scrap Metal Small Arms Vol.14-Break-barrel Shotgun Plans TextDocument16 pagesPractical Scrap Metal Small Arms Vol.14-Break-barrel Shotgun Plans TextBenjamin Hobbs100% (1)

- UltimatearcadeII CabinetDocument23 pagesUltimatearcadeII CabinetFreddy IrarrazabalNo ratings yet

- Building The Osborne PlatterDocument9 pagesBuilding The Osborne PlatterHeman Lee50% (2)

- Wind TuerbineDocument23 pagesWind TuerbineGanesh Korore100% (1)

- Kreg Mini Jig Product ManualDocument2 pagesKreg Mini Jig Product ManualajaxleonNo ratings yet

- Open-Back Broadband Absorber Building Guide (Acoustic Panels) v1.5Document14 pagesOpen-Back Broadband Absorber Building Guide (Acoustic Panels) v1.5Churchil Meneer NaudéNo ratings yet

- Tango The Plywood Automata1Document25 pagesTango The Plywood Automata1Igor BettarelloNo ratings yet

- Pip Pie Trainer 01Document39 pagesPip Pie Trainer 01ebano.ttNo ratings yet

- Everyday Electronics 1974 10.CV01Document6 pagesEveryday Electronics 1974 10.CV01marcosscarato0% (1)

- Automotive Test Probe ConstructionDocument4 pagesAutomotive Test Probe ConstructionLy Fotoestudio DigitalcaNo ratings yet

- Read Me First!: Prefix Pro Series Preamp Installation GuideDocument2 pagesRead Me First!: Prefix Pro Series Preamp Installation GuideRoberto CastilloNo ratings yet

- Read Me First!: Prefix Series Preamp Installation GuideDocument2 pagesRead Me First!: Prefix Series Preamp Installation GuideRoberto CastilloNo ratings yet

- The Pippie Tender: Mike Waller Yacht Design PO Box 383 Morayfield Brisbane, QLD, AustraliaDocument0 pagesThe Pippie Tender: Mike Waller Yacht Design PO Box 383 Morayfield Brisbane, QLD, AustraliaacastromNo ratings yet

- Tray Template InstructionsDocument5 pagesTray Template InstructionsMohamed Mohiy El-DinNo ratings yet

- Router Table FenceDocument11 pagesRouter Table Fenceleo100% (2)

- Veritas Router Table Fence ManualDocument8 pagesVeritas Router Table Fence Manualsalvador LuqueNo ratings yet

- Bedding A Rifle With Matchgrade Bedding CompoundDocument24 pagesBedding A Rifle With Matchgrade Bedding CompoundDayle StuevenNo ratings yet

- Pippie8Tender PDFDocument32 pagesPippie8Tender PDFleonel montillaNo ratings yet

- Dovetail JigDocument12 pagesDovetail JigeducifueNo ratings yet

- Table Saw Sled - Taper Jig Accessory: Cut One or Many Tapers With Ease!Document8 pagesTable Saw Sled - Taper Jig Accessory: Cut One or Many Tapers With Ease!LinNo ratings yet

- Hadley Instructions v0 - 5Document78 pagesHadley Instructions v0 - 5mhudson46No ratings yet

- Building A Microphone and Amplifier - Watch Timing SystemDocument24 pagesBuilding A Microphone and Amplifier - Watch Timing Systemarp tiwNo ratings yet

- Wooden Puzzle Vault GIZSIP 327278258Document3 pagesWooden Puzzle Vault GIZSIP 327278258magoleija2010100% (1)

- Stables InstructionsDocument3 pagesStables InstructionsJavier Hidalgo SanchezNo ratings yet

- Book Case - Barrister 1Document6 pagesBook Case - Barrister 1Cris CondeNo ratings yet

- Freebird PDFDocument5 pagesFreebird PDFHHOLINo ratings yet

- Tutorial Magnum Spy PistolDocument6 pagesTutorial Magnum Spy PistolchopenNo ratings yet

- Professional Router Table PDFDocument17 pagesProfessional Router Table PDFhightecrebelNo ratings yet

- How To Build Your Own Effects Guitar Electronics Schematics PDFDocument9 pagesHow To Build Your Own Effects Guitar Electronics Schematics PDFCheryl ChuckNo ratings yet

- Bugbaits SMArmouryDocument10 pagesBugbaits SMArmouryMike Greenman100% (2)

- ENG - DNA HoldersDocument22 pagesENG - DNA HoldersTrikala2016No ratings yet

- Wood HingesDocument15 pagesWood HingesLuis Valens100% (1)

- Bara TelecoapeDocument11 pagesBara TelecoapeflorinakedNo ratings yet

- Entry Bench PlanDocument8 pagesEntry Bench PlancajemarNo ratings yet

- Notice Cellule KetkDocument2 pagesNotice Cellule KetkVIELMASNo ratings yet

- DIY BroadbandAbsorber by AaronYoungDocument2 pagesDIY BroadbandAbsorber by AaronYoungBryan AnthonyNo ratings yet

- Leg Tapering Jig: Project 14585EZDocument5 pagesLeg Tapering Jig: Project 14585EZBSulliNo ratings yet

- Making Your Own BladesDocument2 pagesMaking Your Own Bladesp6a4nduNo ratings yet

- "Slimline" Pen & Pencil Kit Assembly Instructions: Item #Pkpen and PK-PCLDocument2 pages"Slimline" Pen & Pencil Kit Assembly Instructions: Item #Pkpen and PK-PCLTamara MarreroNo ratings yet

- Polybatic Edge 540 Part1Document9 pagesPolybatic Edge 540 Part1dorimondNo ratings yet

- Sundial Instructions SY WebDocument12 pagesSundial Instructions SY WebNoah NashNo ratings yet

- Long Langstroth HiveDocument7 pagesLong Langstroth HiveWolfgangNo ratings yet

- Ornitoptero PDFDocument5 pagesOrnitoptero PDFninonunezNo ratings yet

- Read Me First!: Matrix Infinity VT Matrix Infinity Mic Blend Installation GuideDocument7 pagesRead Me First!: Matrix Infinity VT Matrix Infinity Mic Blend Installation GuideRofers Produções MusicaisNo ratings yet

- Wireless SpeakerDocument4 pagesWireless SpeakerGülbaharNo ratings yet

- Blog TH Kitchenette Upload Part 1Document4 pagesBlog TH Kitchenette Upload Part 1Antonio Aranda CabreraNo ratings yet

- RuterDocument7 pagesRuternokojNo ratings yet

- Instructions Kit Camera 6ledsDocument16 pagesInstructions Kit Camera 6ledsJacobite BondNo ratings yet

- Drill Press TableDocument11 pagesDrill Press TableWil NelsonNo ratings yet

- Arduino Minimal Drum KitDocument43 pagesArduino Minimal Drum KitmarioNo ratings yet

- A Dog Kennel: How To BuildDocument14 pagesA Dog Kennel: How To BuildRomeo MagdaNo ratings yet

- Tuffstar ManualV2.0Document6 pagesTuffstar ManualV2.0Isyna AriefNo ratings yet

- How To Build A Toy TheatreDocument20 pagesHow To Build A Toy TheatreJeremy VinesNo ratings yet

- RustE11 BreakDownDocument6 pagesRustE11 BreakDownBilly DipperNo ratings yet

- Build Your Own Six-Seater Picnic Table: Using 2 x 4 (50 x 100 mm) Lumber, #1From EverandBuild Your Own Six-Seater Picnic Table: Using 2 x 4 (50 x 100 mm) Lumber, #1No ratings yet

- Safety Data Sheet: Paraplast X-TRA®Document7 pagesSafety Data Sheet: Paraplast X-TRA®meganingtyasNo ratings yet

- CPM (Critical Path Method)Document23 pagesCPM (Critical Path Method)sarprajkatreNo ratings yet

- PM1000 6000 PLSED310053EN - (Print)Document18 pagesPM1000 6000 PLSED310053EN - (Print)JoseVela82No ratings yet

- FunFarming@ @Document25 pagesFunFarming@ @aratan jrNo ratings yet

- Containers in Non-Cellular ShipsDocument7 pagesContainers in Non-Cellular ShipschildofheavenNo ratings yet

- Southern Cross - Iso Pump - Installation and Operating InstructionDocument4 pagesSouthern Cross - Iso Pump - Installation and Operating InstructionFerryNo ratings yet

- Systems Engineering Manager in Chicago IL Resume Daniel O'MalleyDocument2 pagesSystems Engineering Manager in Chicago IL Resume Daniel O'MalleyDanielOMalleyNo ratings yet

- 7RW80 Manual A4 V040300 UsDocument264 pages7RW80 Manual A4 V040300 UsvinodmpvNo ratings yet

- SunLink FTAMDocument118 pagesSunLink FTAMSaad AliNo ratings yet

- A A C C 5 5 - G GDocument2 pagesA A C C 5 5 - G GMelky LiwutNo ratings yet

- How To Claim Land and Not BuyDocument36 pagesHow To Claim Land and Not BuyJoshua Sygnal GutierrezNo ratings yet

- Rec PrechargeDocument3 pagesRec PrechargePrabha Karan.nNo ratings yet

- LashCon IMO - Rev 9.0 - tcm149-287975Document4 pagesLashCon IMO - Rev 9.0 - tcm149-287975Milind TambeNo ratings yet

- 7 Philip Hazel LCA2004.TalkDocument7 pages7 Philip Hazel LCA2004.Talkapi-3764104No ratings yet

- Design and Research On The LCL Filter in Three-Phase PV Grid-Connected InvertersDocument4 pagesDesign and Research On The LCL Filter in Three-Phase PV Grid-Connected InvertersJong Hee LeeNo ratings yet

- HDCE-30C User ManualDocument54 pagesHDCE-30C User ManualmazolasboNo ratings yet

- Telemecanique Altivar61 Manual 037 90kwDocument47 pagesTelemecanique Altivar61 Manual 037 90kwcuongNo ratings yet

- Goddstar Cb21t20s Pc-81aDocument19 pagesGoddstar Cb21t20s Pc-81aedisonic2000No ratings yet

- Family Member's Docs.Document2 pagesFamily Member's Docs.hishamNo ratings yet

- Ensuring Data QualityDocument16 pagesEnsuring Data QualityAlsayed AlgergawyNo ratings yet

- 04 - Management Tool (Quality Center)Document4 pages04 - Management Tool (Quality Center)Brahmanand DasreNo ratings yet

- Design and Fabrication of Angular DrillingDocument8 pagesDesign and Fabrication of Angular DrillingvasanthNo ratings yet

- MBA Project Report On 'Earn and Learn' Trainee Scheme at TATA YAZAKI AUTOCOMP LIMITEDDocument86 pagesMBA Project Report On 'Earn and Learn' Trainee Scheme at TATA YAZAKI AUTOCOMP LIMITEDAman BhattacharyaNo ratings yet

- Aux Relay NRDocument5 pagesAux Relay NRSibolis NaburjuNo ratings yet

- Outsourced New Product DevelopmentDocument5 pagesOutsourced New Product Developmentvinnakota5No ratings yet

- Masaood John Brown - Presentation - v1.1Document54 pagesMasaood John Brown - Presentation - v1.1Hanif Akbar100% (1)

- Srs Airbag Control System: SectionDocument331 pagesSrs Airbag Control System: SectionMarcelo MendozaNo ratings yet

- Click125 PDFDocument112 pagesClick125 PDFCj Cruel0% (1)

- Rfa Monitoring - PGHDocument76 pagesRfa Monitoring - PGHRigelle DionisioNo ratings yet