Professional Documents

Culture Documents

TN62 Part 1

TN62 Part 1

Uploaded by

sadiaajmal09Copyright:

Available Formats

You might also like

- X30592Document16 pagesX30592CTN2010No ratings yet

- Manual de Torques CaterpillarDocument48 pagesManual de Torques CaterpillarJohn Calfuan Alfaro50% (2)

- TC450 Crown Block User ManualDocument11 pagesTC450 Crown Block User ManualHala Dawod100% (2)

- Cat General Torque Specifications PDFDocument48 pagesCat General Torque Specifications PDFAlaudin Awang Xwijaya0% (1)

- Model M ManualsDocument6 pagesModel M ManualsdiegoNo ratings yet

- Travers o V47Document32 pagesTravers o V47Jorge Espinoza100% (1)

- Skidmore Instructions Model MS ManualsDocument15 pagesSkidmore Instructions Model MS ManualsbwbrockNo ratings yet

- GMW16215 PDFDocument7 pagesGMW16215 PDFJuanPeriquitanNo ratings yet

- Assembly and Tensioning of High Strength Bolts and Nuts: Technical Note 62Document12 pagesAssembly and Tensioning of High Strength Bolts and Nuts: Technical Note 62rajuajiNo ratings yet

- Torque SpecificationsDocument50 pagesTorque SpecificationsNilton sergio gomes lins100% (1)

- Bolt Torque & Bolt Tap TestDocument20 pagesBolt Torque & Bolt Tap Testbudymood100% (4)

- 4.2 8.8/TF and 8.8/TB (Or 8.8/T When Referring To Both Types)Document1 page4.2 8.8/TF and 8.8/TB (Or 8.8/T When Referring To Both Types)mrmerajNo ratings yet

- ABTP and GL Wind Turbine Flange Bolt SquirtersDocument3 pagesABTP and GL Wind Turbine Flange Bolt SquirtersJonathanGagliardiNo ratings yet

- Torque SpecificationsDocument50 pagesTorque SpecificationsPiotr MościbrockiNo ratings yet

- Cut82hr Manual Parts (Cr9b-) 130712siDocument43 pagesCut82hr Manual Parts (Cr9b-) 130712si2222222222222-242735No ratings yet

- General InformationDocument7 pagesGeneral InformationRobert SantiagoNo ratings yet

- TX Dot RocapDocument9 pagesTX Dot RocapIFIdocsNo ratings yet

- 0620000008Document6 pages0620000008mahsaNo ratings yet

- Timing Chain: Service and Repair InstallationDocument3 pagesTiming Chain: Service and Repair InstallationDiego496No ratings yet

- Timing Chain: Service and Repair InstallationDocument3 pagesTiming Chain: Service and Repair InstallationDiego496No ratings yet

- Timing Chain: Service and Repair InstallationDocument3 pagesTiming Chain: Service and Repair InstallationDiego496No ratings yet

- Draft Spec No 0-41-00-04 (Rev 03) Oct 2011Document10 pagesDraft Spec No 0-41-00-04 (Rev 03) Oct 2011Thuong NguyenNo ratings yet

- Tighting Torque MethodDocument6 pagesTighting Torque Methodibrahim hegazyNo ratings yet

- General Information: Torque SpecificationsDocument3 pagesGeneral Information: Torque SpecificationsLuis TepezanoNo ratings yet

- Turn-Of-Nut Bolting MethodDocument12 pagesTurn-Of-Nut Bolting MethodbNo ratings yet

- TighteningofStructuralBolts 31-35Document5 pagesTighteningofStructuralBolts 31-35masaud akhtarNo ratings yet

- Juego de Valvulas C27Document4 pagesJuego de Valvulas C27gerardoNo ratings yet

- 70.00.00 Standard Practices - Maintenance ProceduresDocument21 pages70.00.00 Standard Practices - Maintenance ProceduresTimoteo Molina RomeroNo ratings yet

- HSFG Bolts British MetricDocument24 pagesHSFG Bolts British MetricAlastair BrownNo ratings yet

- Flowserve Seal - ISC2 - Install - LTRDocument8 pagesFlowserve Seal - ISC2 - Install - LTRjame11inNo ratings yet

- ETAG001 Part3Document13 pagesETAG001 Part3Serban RaduNo ratings yet

- Alignment: Torque vs. TensionDocument6 pagesAlignment: Torque vs. Tensionfrancesca_bonfanti_1No ratings yet

- Fis190 en A5Document8 pagesFis190 en A5andhucaosNo ratings yet

- Question & AnswerDocument12 pagesQuestion & AnswerbalamuruganNo ratings yet

- TCB Installation BookletDocument12 pagesTCB Installation BookletAsherNo ratings yet

- Bolt TensionDocument2 pagesBolt TensionJayaram GowdaNo ratings yet

- CB150 Operating Manual T2 (258126)Document13 pagesCB150 Operating Manual T2 (258126)Cesar VellorinNo ratings yet

- Model MS ManualsDocument15 pagesModel MS ManualsbarrettshawnNo ratings yet

- Is 3063Document11 pagesIs 3063Sumit ShyamalNo ratings yet

- C4 4 CalibracionDocument5 pagesC4 4 CalibracionJaya Abadi100% (1)

- Northwest: Maintenance Manual DC9Document10 pagesNorthwest: Maintenance Manual DC9Erik Joan Quiroga RamirezNo ratings yet

- FW Murphy Level Maintainer ManualDocument14 pagesFW Murphy Level Maintainer ManualIRWIN_DSOUZANo ratings yet

- 009 - 000 - 000-2GD-FTV Engine Mechanical PDFDocument273 pages009 - 000 - 000-2GD-FTV Engine Mechanical PDFJosé Ignacio Quijada Rojas100% (1)

- John Deere 450CLC Excavator Service Repair Technical Manual (TM1925)Document14 pagesJohn Deere 450CLC Excavator Service Repair Technical Manual (TM1925)laopaodunNo ratings yet

- Overhead SetDocument6 pagesOverhead Setfathyelgaml770No ratings yet

- Catalog HRC Jaw CouplingsDocument8 pagesCatalog HRC Jaw CouplingsMadan Yadav100% (1)

- Pruebas y Ajustes C27 and C32 GeneratorDocument5 pagesPruebas y Ajustes C27 and C32 GeneratorMuhammad Ary safarta100% (1)

- wp1142II XMLDocument1 pagewp1142II XMLaugustinhodjNo ratings yet

- C-12 Industrial Engine BDL00001-UP (SEBP3252 - 59) - Reglages SoupapesDocument4 pagesC-12 Industrial Engine BDL00001-UP (SEBP3252 - 59) - Reglages SoupapesDamien LEGRANDNo ratings yet

- SI1129D Alternator Belt Tension, Methods of CheckingDocument2 pagesSI1129D Alternator Belt Tension, Methods of CheckingNickNo ratings yet

- DLD2 User ManualDocument10 pagesDLD2 User ManualTechnical OfficeNo ratings yet

- 4 - Structural Bolt Tightening Methods ChecklistDocument6 pages4 - Structural Bolt Tightening Methods ChecklistSharon MonicaNo ratings yet

- Connecting Rod - InspectDocument3 pagesConnecting Rod - InspectKopyuk Kopyuk Kopyuk KopyukNo ratings yet

- QA-MST-07-Method Statement of Bolt Tightening - R01Document8 pagesQA-MST-07-Method Statement of Bolt Tightening - R01Murat AcarNo ratings yet

- Rev00-Gasket Installation & Bolt Torquing ProcedureDocument24 pagesRev00-Gasket Installation & Bolt Torquing ProcedureHansel FrancisNo ratings yet

- Adjustment of The Compression BrakeDocument2 pagesAdjustment of The Compression BrakeCarlos Juarez ChungaNo ratings yet

- Paracaídas Instantáneo Dynatech/ Parachute Instantane DynatechDocument9 pagesParacaídas Instantáneo Dynatech/ Parachute Instantane DynatechJuan IribarrenNo ratings yet

- Sebf 8054 Обмеры и Правка КвDocument33 pagesSebf 8054 Обмеры и Правка КванджелаNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Corrosion EngineeringDocument9 pagesCorrosion EngineeringAli Imran MohamadNo ratings yet

- EN 9 - Arun SirDocument2 pagesEN 9 - Arun SirBrandon HaleNo ratings yet

- Esbc34 5005 AaDocument39 pagesEsbc34 5005 AaAlanevh AlanevhNo ratings yet

- Quotation List: Guangzhou Hundom Machinery Equipment Thchnology Co.,LtdDocument6 pagesQuotation List: Guangzhou Hundom Machinery Equipment Thchnology Co.,LtdPriyanka VaswaniNo ratings yet

- Jared Hazen: Work ExperienceDocument2 pagesJared Hazen: Work Experienceconfused597No ratings yet

- Scanner and Accessories - BIGPROBE PDFDocument39 pagesScanner and Accessories - BIGPROBE PDFTYO WIBOWONo ratings yet

- Gengard Gn7004: Description and UseDocument2 pagesGengard Gn7004: Description and Useengr.shahid041No ratings yet

- ElAgamy Company ProfileDocument28 pagesElAgamy Company ProfileHossamNo ratings yet

- Copy of General Cargo Feb 2023Document79 pagesCopy of General Cargo Feb 2023azadar.jaffri0323No ratings yet

- IBEF Metals-and-Mining-Feb-2023Document44 pagesIBEF Metals-and-Mining-Feb-2023Gurnam SinghNo ratings yet

- The Influence of HH Type Steel Microstructure On The Distortion Behavior of Grate Bar Part in The Indurating Machine of Pelletizing PlantDocument6 pagesThe Influence of HH Type Steel Microstructure On The Distortion Behavior of Grate Bar Part in The Indurating Machine of Pelletizing PlantkiddNo ratings yet

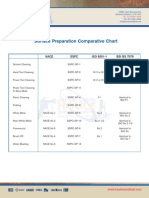

- Surface Preparation Comparative ChartDocument1 pageSurface Preparation Comparative Chartcmms88No ratings yet

- Project Report: "Lintel Assembly"Document24 pagesProject Report: "Lintel Assembly"bharathmcx1No ratings yet

- Topdek PIR Installation Guide A5 Sept 2020Document12 pagesTopdek PIR Installation Guide A5 Sept 2020fahim007No ratings yet

- GFC Catalogue-JAN-2022Document20 pagesGFC Catalogue-JAN-2022eng.ahmadrihawiNo ratings yet

- SGRR Urology Hvac BoqDocument2 pagesSGRR Urology Hvac BoqEDUCATENo ratings yet

- Act 2 - M1Document1 pageAct 2 - M1Ralph A. PastranaNo ratings yet

- Tata Steel BasicDocument4 pagesTata Steel BasicChandra MouryaNo ratings yet

- Unit 3Document46 pagesUnit 3Sudarsan reddyNo ratings yet

- Common UK Standards For Joining and Surfacing - TWIDocument66 pagesCommon UK Standards For Joining and Surfacing - TWIarissaNo ratings yet

- Vacuum Jacketed Pipe Manual HHCNZ MWCDocument12 pagesVacuum Jacketed Pipe Manual HHCNZ MWCrodrigoperezsimoneNo ratings yet

- Qap of CondenserDocument1 pageQap of CondenserPrakash TiwariNo ratings yet

- Foundry Project Planning - Some Pit Falls Ziauddin Avinash JoshiDocument11 pagesFoundry Project Planning - Some Pit Falls Ziauddin Avinash Joshitushak mNo ratings yet

- Hose CatalogDocument26 pagesHose CatalogAshish ParasharNo ratings yet

- Page 4 PDFDocument1 pagePage 4 PDFqc_531040655No ratings yet

- Astm B 824Document6 pagesAstm B 824houk sukNo ratings yet

- Quotation 98664Document5 pagesQuotation 98664Reda IsmailNo ratings yet

- To Study About Pipe Earthing and Plate EarthingDocument4 pagesTo Study About Pipe Earthing and Plate EarthingApurva Christian100% (1)

- Educational Material: Pourbaix DiagramsDocument20 pagesEducational Material: Pourbaix DiagramsMakun SahooNo ratings yet

- Bolting B8 Class 1 and 2 UseDocument4 pagesBolting B8 Class 1 and 2 UseManish542No ratings yet

TN62 Part 1

TN62 Part 1

Uploaded by

sadiaajmal09Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TN62 Part 1

TN62 Part 1

Uploaded by

sadiaajmal09Copyright:

Available Formats

Technical Note 62

Assembly and Tensioning of High Strength Bolts and

Nuts - Part 1: Class 8.8

November 2015

Copyright

http://creativecommons.org/licenses/by/3.0/au/

© State of Queensland (Department of Transport and Main Roads) 2015

Feedback: Please send your feedback regarding this document to: tmr.techdocs@tmr.qld.gov.au

Technical Note, Transport and Main Roads, November 2015

TN62 Assembly and Tensioning of High Strength Bolts and Nuts - Part 1: Class 8.8

1 Clarification of bolt tensioning

The purpose of this technical note is to define the acceptable requirements for the assembly and

tensioning of High Strength Bolts for Department of Transport and Main Roads (TMR) projects.

2 Reference documents

A number of reference documents have been used to compile this technical note. The reference

documents are outlined below.

• Transport and Main Roads Technical Specification MRTS78 Fabrication of Structural

Steelwork

• Australian Standard AS 4100 – 1998

• Australian Standard AS 1252 – 1996.

3 Identification of conforming materials

All bolts and nuts shall be from tested batches. All bolts and nuts shall be tested in accordance with

MRTS78 Fabrication of Structural Steelwork.

The contractor shall only use bolts, nuts and washers complying with AS 1252. These bolts, nuts and

washers have identification marks embossed on the top of the bolt head, the top surface of the nut

and protrusions on the edges of the washers. Figure 3 shows the markings for the bolt, nut and

washer.

Figure 3 – Markings for structural assemblies

Inspection by the contractor of bolts, nuts and washers for damage to the threads and the galvanising

shall take place before fitting. The contractor shall discard any damaged bolts, nuts and washers.

4 Tensioning of bolts

There are three bolting categories defined in AS 4100-1998.

4.1 8.8/S

The bolts are installed and tensioned to “snug tight”. AS 4100 defines snug tight as, "The tightness

attained by a few impacts of an impact wrench or by the full effort of a person using a standard podger

spanner”, which brings the connecting parts into firm contact.

Technical Note, Transport and Main Roads, November 2015 1

TN62 Assembly and Tensioning of High Strength Bolts and Nuts - Part 1: Class 8.8

4.2 8.8/TF and 8.8/TB (or 8.8/T when referring to both types)

The bolts are installed and are fully tensioned in a controlled manner.

There are four methods of tensioning the bolts:

1. The use of an adjustable and correctly calibrated impact wrench. The equipment required

is a load cell (similar to the Skidmore Willhelm Gauge) and an adjustable impact wrench. This

equipment is unavailable. Therefore, the contractor will be unable to use this method.

2. The use of the part turn method. Please note this method is not permitted as, there is a

variation in bolt tension using this approach.

3. The use of load indicator washers. This method would be acceptable, for when the bolt

head and load indicator washer can be clearly seen.

4. There is another method not in the Code. Some bolts/rivets requiring replacement have

their heads inside chord members. This would make checking the gap between the load

indicating washer and the underside of the head difficult. By using an adjustable impact

wrench, calibration of the system could occur by assembling a series of bolts, nuts and load

indicating washers in a simple joint in the workshop. Calibration of the wrench would be by

using load indicator washers to determine the appropriate wrench setting for field usage.

5 Non acceptable method of tensioning bolts

The reason the part turn method is not acceptable is outlined below.

A typical structural bolt, for example a M24 bolt will typically require a torque of approximately 800 Nm

in order to fully tension the bolt. A torque of 800 Nm is equivalent to applying a force of 81kg over a

1000 mm long spanner. The normal podge spanner is roughly 500 mm long, so assuming that the

force could only be applied at about 400 mm, you would need to apply a force of 204kg at this

distance.

In the past workers would place extensions on standard spanners in order to tension bolts, refer to

Figure 5. This process is both risky from a safety perspective and does not ensure a consistent

tension force is applied to all the bolts.

It is not practical to apply forces of this magnitude to a spanner particularly when working at heights.

Hence why manual tensioning of bolts is not permitted.

Figure 5 – Extension placed on the end of a ring spanner

Technical Note, Transport and Main Roads, November 2015 2

TN62 Assembly and Tensioning of High Strength Bolts and Nuts - Part 1: Class 8.8

6 Acceptable method for tensioning bolts

The accepted method for fully tensioning T/F and T/B bolts is as follows.

6.1 Load indicating washers

When the bolt head and nut are clearly visible at a bolted connection, the load indicating washers shall

be used. There are two types of load indicating washers.

Conventional load indicating washer - The first type of load indicating washer is the conventional

load indicating washer as outlined in AS/NZS 1252. After tensioning, the average gap needs to be

measured with a feeler gauge. For galvanised bolts, the minimum gap required between the head and

the load indicating washer is 0.25 mm.

Squirter DTI load indicating washers - The second type of load indicating washer is the “Squirter

DTI” supplied by Hobson Engineering. As the bolt is tensioned, a calibrated amount of orange silicone

appears from under the DTI’s squirt locations.

If the Squirter DTI load indicating washers are used. The bolting arrangement will need to be

calibrated for each batch of load indicating washers supplied for the project.

6.1.1 Squirter DTI calibration of load indicating washers

In a Skidmore – Insert a bolt, Squirter DTI, washer and nut into the Skidmore. Tighten the assembly

to about 10% to 20% over the minimum required tension as outlined in AS 4100, in the same manner

to be used to tension the bolt assembly. Once tightened, note the appearance of the flow volume and

the number of squirts emanating from under the DTI. If the DTI has five bumps there should be at

least four squirts from the DTI. The calibration process will need to be repeated a total of three times

to obtain a visual impression of how much squirt is necessary.

In Solid Steel – Insert a bolt, Squirter DTI, washer and nut into a steel section. Tighten the bolt

assembly until the DTI has sufficiently compressed so that a feeler gauge of the correct thickness

(0.13 mm (0.005") if the DTI is on the nut end, or 0.13 mm (0.005") if the DTI is under the head) will

not enter half of the available places right into the bolt shank. If it does, tighten the bolt a little more

and note the silicone squirt volume and appearance. The calibration process will need to be repeated

a total of four times to obtain a visual impression of how much squirt is necessary.

Note: For installation of Squirter DTI’s in old or reconditioned steelwork, it may be necessary to place

hardened flat washer against the steel surface and under the Squirter DTI’s so that the squirter feature

works reliably.

7 Acceptable method for tensioning bolts

The accepted method for fully tensioning T/F and T/B bolts is as follows. For the tensioning of the

Class 8.8 bolts, only a calibrated torque wrench can be used.

Technical Note, Transport and Main Roads, November 2015 3

TN62 Assembly and Tensioning of High Strength Bolts and Nuts - Part 1: Class 8.8

7.1 Types of tensioning equipment

Figure 7.1(a) – Electric torque wrench – Accuracy of +/- 4%

Figure 7.1(b) – Hydraulic torque wrench

Technical Note, Transport and Main Roads, November 2015 4

TN62 Assembly and Tensioning of High Strength Bolts and Nuts - Part 1: Class 8.8

Figure 7.1(c) – Pneumatic torque wrench

Technical Note, Transport and Main Roads, November 2015 5

TN62 Assembly and Tensioning of High Strength Bolts and Nuts - Part 1: Class 8.8

7.2 Calibrated impact wrench

This process is only permitted when the bolts already in stock are too short to accommodate the

washer, nut and load indicating washer. In order to ensure that the tension wrench is correctly

calibrated, there are two options available.

Option 1

1. Place a bolt assembly in a Skidmore Willhelm Gauge with a Squirter DTI load indicating

washer Refer to Figure 7.2(a)

2. Tension the bolt with a tension wrench to the required tension as outlined in AS 4100 and

Table 7.2

3. Note the torque setting on the tension wrench to achieve the required tension force. Please

note that the torque setting is based on the constant application of force in a single movement

4. Once the torque wrench has been set for the specific bolt and nut, the torque wrench is placed

on a Norbar True Checker, refer to Figure 7.2(d). The True Checker will confirm the torque

setting for that specific bolt and nut combination.

Figure 7.2(a) – View of a skidmore

Table 7.2 –Minimum bolt tension

Nominal diameter of Minimum Bolt Max Upper Limit Bolt

bolt Tension kN Tension kN

M16 95 115

M20 145 185

M22 180 (Note 1) 230 (Note 1)

M24 210 265

M30 335 420

M36 490 610

Note 1: M22 tension capacity based on linear interpolation

Technical Note, Transport and Main Roads, November 2015 6

TN62 Assembly and Tensioning of High Strength Bolts and Nuts - Part 1: Class 8.8

Option 2

• Place a bolt, nut and washer assembly along with a Squirter DTI load indicating washer in a

solid steel section Refer to Figure 7.2(b).

• Ensure that the load indicating washer is installed in the correct orientation as shown in

Figure 7.2(c).

• Tension the bolt with a tension wrench until the DTI has sufficiently compressed so that a

feeler gauge of the correct thickness (0.13 mm if the DTI is on the nut end, or 0.13 mm if the

DTI is under the head) will not enter half of the available places right into the bolt shank. If it

does, tighten the bolt a little more and note the silicone squirt volume and appearance. The

calibration process will need to be repeated a total of three times to obtain a visual impression

of how much squirt is necessary.

• Note the torque setting on the tension wrench to achieve the required tension force. Please

note that the torque setting is based on the constant application of force in a single movement.

• Once the torque wrench has been set for the specific bolt and nut, the torque wrench is placed

on a Norbar True Checker, refer to Figure 7.2(d). The True Checker will confirm the torque

setting for that specific bolt and nut combination.

Figure 7.2(b) – Bolt placed in a tensioning plate

Figure 7.2(c) – Correct orientation for a load indicating washer

Technical Note, Transport and Main Roads, November 2015 7

TN62 Assembly and Tensioning of High Strength Bolts and Nuts - Part 1: Class 8.8

Figure 7.2(d) – View of the torque wrench on the True Checker

True Checker device is used to

outline the torque setting for a torque

wrench. Many wenches are set via

pressure and the true checker

determines the torque in the torque

wrench for a specific pressure. True

Checker can also be used to ensure

the torque in the torque wrench

correctly calibrated.

8 Installation of the bolts, nuts and washers

The nut must be able to run freely up and down the bolt. The correct way to clear a blockage is to run

the nut up and down the thread until the nut is free running. If the nut still will not run freely on the bolt

the contractor shall discard the nut and the bolt. This procedure must occur before taking bolts and

nuts to site.

The contractor shall draw together the two surfaces which require joining so they are in full contact.

This may involve the use of tacking bolts. Once the parts are in full contact, the contractor shall

replace any tacking bolts with high strength bolts one at a time.

The following requirements are to be satisfied:

• Driving of high strength bolts into the holes is unacceptable. In order to fit the bolts without

force, the contractor may ream or drift the holes.

• Washers are required under both the head of the bolt and the nut.

• Lubricate the bolt thread with “Stearin Wax” or “Relton Stick Wax” prior to installing the nut on

the bolt.

• There shall be a minimum of one full thread projecting above the top of the nut after assembly.

• If one full thread is not visible, then a longer bolt shall be used. If selecting a longer bolt, the

maximum amount of projection of the bolt end passed the nut shall be 15 mm. Packing with up

to three washers not exceeding 12 mm thickness is acceptable on the joint side not being

turned.

• Note: The reason a bolt cannot have to too much thread projection is due to the bolt not

having sufficient thread and when tightened the nut can run out of thread and will not be

tensioned correctly.

• Once all the bolts are assembled, the bolts shall be tensioned so they are snug tight and the

connecting surfaces are drawn together.

Technical Note, Transport and Main Roads, November 2015 8

TN62 Assembly and Tensioning of High Strength Bolts and Nuts - Part 1: Class 8.8

8.1 Acceptance criteria for bolt tensioning – Load indicating washers

When load indicating washers are used to validate that the bolt is correctly tensioned, the following

requirements must be followed.

A load indicating washer has locations available to place the feeler gauge in between the flat washer

and load indicator washer. Refer to Figure 8.1(a) and Figure 8.1(b).

Figure 8.1(a) – How to check a loading indicating washer

Figure 8.1(b) – How to check a loading indicating washer

A bolt is correctly tensioned once a correct thickness feeler gauge cannot be inserted up to the shank

of a bolt in half the available spaces. Table 8.1 outlines the acceptable criteria based on a load

indicating washer which has five available spaces to insert a feeler gauge.

Technical Note, Transport and Main Roads, November 2015 9

TN62 Assembly and Tensioning of High Strength Bolts and Nuts - Part 1: Class 8.8

Table 8.1 – Bolt tensioning acceptability

Number of

Available Accept or Reject Comment

Places

5 Reject Bolt is too loose. Keep tensioning

4 Reject Bolt is too loose. Keep tensioning

3 Reject Bolt is too loose. Keep tensioning

2 Accept

1 Accept

0 Reject Bolt is too tight. Bolt shall be replaced with a new bolt

9 Check of Torque and Re-Calibration

Once all the initial calibration of the torque wrench for each bolt and nut combination and has been

completed, it is important to ensure the torque wrench is operating at the correct settings.

9.1 Check of Torque Setting

During the course of a working shift the torque setting will need to be checked as per the requirement

outlined in Table 9.2, “Check of Torque Setting”. To check the torque the torque wrench is placed on

the True Checker and the torque wrench operated until it stops turning. The torque setting on the

display should match the settings recorded for that specific bolt and nut. If the torque value when

checked is slightly out, then torque wrench shall be adjusted so the correct torque is achieved.

Note: the tolerance on the torque setting shall not vary by more than +/- 10 Nm.

9.2 Re-Calibration

It is also important to ensure the torque wrench is correctly calibrated. The checking of the calibration

is dependent on how often the bolts are being tightened on a project. Table 9.2, “Torque Check and

Re-calibration Testing”, outlines the frequency at which the re-calibration should be performed.

To carry out the re-calibration Section 7.2 is followed using one bolt from the previously tested batch

of bolts.

Table 9.2 – Torque Check and Re -Calibration Testing

Time between Check of Torque Setting Recalibration

Last Bolt Requirement

Assembly

Tension bolts on a Start of Day Shift, 11am – 12pm and 2pm - 3pm On a monthly basis

daily basis or

Start of Night Shift, 11pm – 12am and 2am – 3am

Tension bolts on a Start of Day Shift, 11am – 12pm and 2pm - 3pm On a weekly basis

weekly basis or

Start of Night Shift, 11pm – 12am and 2am – 3am

Tension bolts on a Start of Day Shift, 11am – 12pm and 2pm - 3pm Before undertaking

monthly basis or or work on a bolted

longer joint

Start of Night Shift, 11pm – 12am and 2am – 3am

Technical Note, Transport and Main Roads, November 2015 10

TN62 Assembly and Tensioning of High Strength Bolts and Nuts - Part 1: Class 8.8

10 Marking of Tensioned Bolts

Once a bolt assembly has been tensioned, the bolt on the nut end shall be marked with a paint pen to

signify the bolt has been tensioned, refer to Figure 10.

Figure 10 – View of the marking of the bolt

Technical Note, Transport and Main Roads, November 2015 11

You might also like

- X30592Document16 pagesX30592CTN2010No ratings yet

- Manual de Torques CaterpillarDocument48 pagesManual de Torques CaterpillarJohn Calfuan Alfaro50% (2)

- TC450 Crown Block User ManualDocument11 pagesTC450 Crown Block User ManualHala Dawod100% (2)

- Cat General Torque Specifications PDFDocument48 pagesCat General Torque Specifications PDFAlaudin Awang Xwijaya0% (1)

- Model M ManualsDocument6 pagesModel M ManualsdiegoNo ratings yet

- Travers o V47Document32 pagesTravers o V47Jorge Espinoza100% (1)

- Skidmore Instructions Model MS ManualsDocument15 pagesSkidmore Instructions Model MS ManualsbwbrockNo ratings yet

- GMW16215 PDFDocument7 pagesGMW16215 PDFJuanPeriquitanNo ratings yet

- Assembly and Tensioning of High Strength Bolts and Nuts: Technical Note 62Document12 pagesAssembly and Tensioning of High Strength Bolts and Nuts: Technical Note 62rajuajiNo ratings yet

- Torque SpecificationsDocument50 pagesTorque SpecificationsNilton sergio gomes lins100% (1)

- Bolt Torque & Bolt Tap TestDocument20 pagesBolt Torque & Bolt Tap Testbudymood100% (4)

- 4.2 8.8/TF and 8.8/TB (Or 8.8/T When Referring To Both Types)Document1 page4.2 8.8/TF and 8.8/TB (Or 8.8/T When Referring To Both Types)mrmerajNo ratings yet

- ABTP and GL Wind Turbine Flange Bolt SquirtersDocument3 pagesABTP and GL Wind Turbine Flange Bolt SquirtersJonathanGagliardiNo ratings yet

- Torque SpecificationsDocument50 pagesTorque SpecificationsPiotr MościbrockiNo ratings yet

- Cut82hr Manual Parts (Cr9b-) 130712siDocument43 pagesCut82hr Manual Parts (Cr9b-) 130712si2222222222222-242735No ratings yet

- General InformationDocument7 pagesGeneral InformationRobert SantiagoNo ratings yet

- TX Dot RocapDocument9 pagesTX Dot RocapIFIdocsNo ratings yet

- 0620000008Document6 pages0620000008mahsaNo ratings yet

- Timing Chain: Service and Repair InstallationDocument3 pagesTiming Chain: Service and Repair InstallationDiego496No ratings yet

- Timing Chain: Service and Repair InstallationDocument3 pagesTiming Chain: Service and Repair InstallationDiego496No ratings yet

- Timing Chain: Service and Repair InstallationDocument3 pagesTiming Chain: Service and Repair InstallationDiego496No ratings yet

- Draft Spec No 0-41-00-04 (Rev 03) Oct 2011Document10 pagesDraft Spec No 0-41-00-04 (Rev 03) Oct 2011Thuong NguyenNo ratings yet

- Tighting Torque MethodDocument6 pagesTighting Torque Methodibrahim hegazyNo ratings yet

- General Information: Torque SpecificationsDocument3 pagesGeneral Information: Torque SpecificationsLuis TepezanoNo ratings yet

- Turn-Of-Nut Bolting MethodDocument12 pagesTurn-Of-Nut Bolting MethodbNo ratings yet

- TighteningofStructuralBolts 31-35Document5 pagesTighteningofStructuralBolts 31-35masaud akhtarNo ratings yet

- Juego de Valvulas C27Document4 pagesJuego de Valvulas C27gerardoNo ratings yet

- 70.00.00 Standard Practices - Maintenance ProceduresDocument21 pages70.00.00 Standard Practices - Maintenance ProceduresTimoteo Molina RomeroNo ratings yet

- HSFG Bolts British MetricDocument24 pagesHSFG Bolts British MetricAlastair BrownNo ratings yet

- Flowserve Seal - ISC2 - Install - LTRDocument8 pagesFlowserve Seal - ISC2 - Install - LTRjame11inNo ratings yet

- ETAG001 Part3Document13 pagesETAG001 Part3Serban RaduNo ratings yet

- Alignment: Torque vs. TensionDocument6 pagesAlignment: Torque vs. Tensionfrancesca_bonfanti_1No ratings yet

- Fis190 en A5Document8 pagesFis190 en A5andhucaosNo ratings yet

- Question & AnswerDocument12 pagesQuestion & AnswerbalamuruganNo ratings yet

- TCB Installation BookletDocument12 pagesTCB Installation BookletAsherNo ratings yet

- Bolt TensionDocument2 pagesBolt TensionJayaram GowdaNo ratings yet

- CB150 Operating Manual T2 (258126)Document13 pagesCB150 Operating Manual T2 (258126)Cesar VellorinNo ratings yet

- Model MS ManualsDocument15 pagesModel MS ManualsbarrettshawnNo ratings yet

- Is 3063Document11 pagesIs 3063Sumit ShyamalNo ratings yet

- C4 4 CalibracionDocument5 pagesC4 4 CalibracionJaya Abadi100% (1)

- Northwest: Maintenance Manual DC9Document10 pagesNorthwest: Maintenance Manual DC9Erik Joan Quiroga RamirezNo ratings yet

- FW Murphy Level Maintainer ManualDocument14 pagesFW Murphy Level Maintainer ManualIRWIN_DSOUZANo ratings yet

- 009 - 000 - 000-2GD-FTV Engine Mechanical PDFDocument273 pages009 - 000 - 000-2GD-FTV Engine Mechanical PDFJosé Ignacio Quijada Rojas100% (1)

- John Deere 450CLC Excavator Service Repair Technical Manual (TM1925)Document14 pagesJohn Deere 450CLC Excavator Service Repair Technical Manual (TM1925)laopaodunNo ratings yet

- Overhead SetDocument6 pagesOverhead Setfathyelgaml770No ratings yet

- Catalog HRC Jaw CouplingsDocument8 pagesCatalog HRC Jaw CouplingsMadan Yadav100% (1)

- Pruebas y Ajustes C27 and C32 GeneratorDocument5 pagesPruebas y Ajustes C27 and C32 GeneratorMuhammad Ary safarta100% (1)

- wp1142II XMLDocument1 pagewp1142II XMLaugustinhodjNo ratings yet

- C-12 Industrial Engine BDL00001-UP (SEBP3252 - 59) - Reglages SoupapesDocument4 pagesC-12 Industrial Engine BDL00001-UP (SEBP3252 - 59) - Reglages SoupapesDamien LEGRANDNo ratings yet

- SI1129D Alternator Belt Tension, Methods of CheckingDocument2 pagesSI1129D Alternator Belt Tension, Methods of CheckingNickNo ratings yet

- DLD2 User ManualDocument10 pagesDLD2 User ManualTechnical OfficeNo ratings yet

- 4 - Structural Bolt Tightening Methods ChecklistDocument6 pages4 - Structural Bolt Tightening Methods ChecklistSharon MonicaNo ratings yet

- Connecting Rod - InspectDocument3 pagesConnecting Rod - InspectKopyuk Kopyuk Kopyuk KopyukNo ratings yet

- QA-MST-07-Method Statement of Bolt Tightening - R01Document8 pagesQA-MST-07-Method Statement of Bolt Tightening - R01Murat AcarNo ratings yet

- Rev00-Gasket Installation & Bolt Torquing ProcedureDocument24 pagesRev00-Gasket Installation & Bolt Torquing ProcedureHansel FrancisNo ratings yet

- Adjustment of The Compression BrakeDocument2 pagesAdjustment of The Compression BrakeCarlos Juarez ChungaNo ratings yet

- Paracaídas Instantáneo Dynatech/ Parachute Instantane DynatechDocument9 pagesParacaídas Instantáneo Dynatech/ Parachute Instantane DynatechJuan IribarrenNo ratings yet

- Sebf 8054 Обмеры и Правка КвDocument33 pagesSebf 8054 Обмеры и Правка КванджелаNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Corrosion EngineeringDocument9 pagesCorrosion EngineeringAli Imran MohamadNo ratings yet

- EN 9 - Arun SirDocument2 pagesEN 9 - Arun SirBrandon HaleNo ratings yet

- Esbc34 5005 AaDocument39 pagesEsbc34 5005 AaAlanevh AlanevhNo ratings yet

- Quotation List: Guangzhou Hundom Machinery Equipment Thchnology Co.,LtdDocument6 pagesQuotation List: Guangzhou Hundom Machinery Equipment Thchnology Co.,LtdPriyanka VaswaniNo ratings yet

- Jared Hazen: Work ExperienceDocument2 pagesJared Hazen: Work Experienceconfused597No ratings yet

- Scanner and Accessories - BIGPROBE PDFDocument39 pagesScanner and Accessories - BIGPROBE PDFTYO WIBOWONo ratings yet

- Gengard Gn7004: Description and UseDocument2 pagesGengard Gn7004: Description and Useengr.shahid041No ratings yet

- ElAgamy Company ProfileDocument28 pagesElAgamy Company ProfileHossamNo ratings yet

- Copy of General Cargo Feb 2023Document79 pagesCopy of General Cargo Feb 2023azadar.jaffri0323No ratings yet

- IBEF Metals-and-Mining-Feb-2023Document44 pagesIBEF Metals-and-Mining-Feb-2023Gurnam SinghNo ratings yet

- The Influence of HH Type Steel Microstructure On The Distortion Behavior of Grate Bar Part in The Indurating Machine of Pelletizing PlantDocument6 pagesThe Influence of HH Type Steel Microstructure On The Distortion Behavior of Grate Bar Part in The Indurating Machine of Pelletizing PlantkiddNo ratings yet

- Surface Preparation Comparative ChartDocument1 pageSurface Preparation Comparative Chartcmms88No ratings yet

- Project Report: "Lintel Assembly"Document24 pagesProject Report: "Lintel Assembly"bharathmcx1No ratings yet

- Topdek PIR Installation Guide A5 Sept 2020Document12 pagesTopdek PIR Installation Guide A5 Sept 2020fahim007No ratings yet

- GFC Catalogue-JAN-2022Document20 pagesGFC Catalogue-JAN-2022eng.ahmadrihawiNo ratings yet

- SGRR Urology Hvac BoqDocument2 pagesSGRR Urology Hvac BoqEDUCATENo ratings yet

- Act 2 - M1Document1 pageAct 2 - M1Ralph A. PastranaNo ratings yet

- Tata Steel BasicDocument4 pagesTata Steel BasicChandra MouryaNo ratings yet

- Unit 3Document46 pagesUnit 3Sudarsan reddyNo ratings yet

- Common UK Standards For Joining and Surfacing - TWIDocument66 pagesCommon UK Standards For Joining and Surfacing - TWIarissaNo ratings yet

- Vacuum Jacketed Pipe Manual HHCNZ MWCDocument12 pagesVacuum Jacketed Pipe Manual HHCNZ MWCrodrigoperezsimoneNo ratings yet

- Qap of CondenserDocument1 pageQap of CondenserPrakash TiwariNo ratings yet

- Foundry Project Planning - Some Pit Falls Ziauddin Avinash JoshiDocument11 pagesFoundry Project Planning - Some Pit Falls Ziauddin Avinash Joshitushak mNo ratings yet

- Hose CatalogDocument26 pagesHose CatalogAshish ParasharNo ratings yet

- Page 4 PDFDocument1 pagePage 4 PDFqc_531040655No ratings yet

- Astm B 824Document6 pagesAstm B 824houk sukNo ratings yet

- Quotation 98664Document5 pagesQuotation 98664Reda IsmailNo ratings yet

- To Study About Pipe Earthing and Plate EarthingDocument4 pagesTo Study About Pipe Earthing and Plate EarthingApurva Christian100% (1)

- Educational Material: Pourbaix DiagramsDocument20 pagesEducational Material: Pourbaix DiagramsMakun SahooNo ratings yet

- Bolting B8 Class 1 and 2 UseDocument4 pagesBolting B8 Class 1 and 2 UseManish542No ratings yet