Professional Documents

Culture Documents

Product Sheet - Explosion Vent ENG

Product Sheet - Explosion Vent ENG

Uploaded by

Sonia HuataOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Sheet - Explosion Vent ENG

Product Sheet - Explosion Vent ENG

Uploaded by

Sonia HuataCopyright:

Available Formats

Explosion Vents

DESCRIPTION

Damage to industrial equipment subjected to explosions can be

controlled through the use of explosion venting. Explosion venting as

a concept introduces a “weak element” in the pressure envelope of the

equipment, relieving the internal combustion pressure in case of an

explosion.

Fike’s high performance Sani-V-S™ explosion vents for Clean In

Place/Steam In Place applications were designed:

• With lightweight construction for simplifi ed handling and minimal risk

related to damage during installation

• To meet all applicable requirements of NFPA 68, and European

Standard for Explosion Venting Devices (EN14797)

© Camfil APC, Product Sheet /Explosion Vents /07-09-2019-1953 — External Use

• To satisfy the needs for clean production environments

SPECIFICATIONS

Applicable industries for Fike’s explosion vents include pharmaceutical,

• Materials of Construction (food grade quality):

- Membrane: stainless steel biotech, food and beverage, cosmetics, and many others.

- Seal: silicone

- Process Gasket: EPDM, up to 245°F FEATURES & BENEFITS

(120°C), Silicone, up to 460°F (240°C) • No crevices or openings where bacteriological hazards may exist.

• Complies with requirements of general food, beverage, and

• Maximum Operating Pressure/Maximum Vacuum

drug administrations.

Rating: up to 80% of the minimum stamped

• Unique seal offers long-term pressure seal under harsh operating

burst pressure.

conditions and acts as a bacteriological barrier.

• Provides instantaneous full opening of membrane, eliminating

• Burst Pressure Tolerance:

undetected small openings and unwanted risk of contamination.

± 15 mbarg for nominal bust pressures ≤

• No external mounting frame (for most popular burst pressures)

100 mbarg; ± 0.25 psig for nominal burst

• Vent pressure sealing area protected against mechnical damage

pressure < 1.5 psig

• Excellent service life (positive/vacuum pressures up to 80% of the

minimum burst pressure)

± 25 mbarg for nominal burst pressure ≤

• Provides 100% venting efficiency.

250 mbarg; ± 0.36 psig for burst pressure

• High mechanical integrity

≥ 1.5 and ≤ 3.6 psig

• Certified bust pressure

• Maintenance-free

± 50 mbarg for nominal burst pressure >

• Highest operating ratio

250 mbarg; ± 0.75 psig for burst pressure

• Up to full vacuum rating

> 3.6 psig

• Non-fragmenting

• Compliant with European ATEX-Directive 94/9/EC and

• Operating Temperature Range; -40 to 240°C /

NFPA 68 Guidelines

-40 to 460°F (continuous); up to 260°C / 500°F

intermittent

Camfil APC | Explosion Vents / 1

ww w.ca mf ila p c.co m

You might also like

- Sme56800a FM8900S PDFDocument264 pagesSme56800a FM8900S PDFArnold de VosNo ratings yet

- Business Plan For Goat FatteningDocument14 pagesBusiness Plan For Goat Fatteningbaguma83% (6)

- Medical Gas Terminal Units: For More Information Contact UsDocument4 pagesMedical Gas Terminal Units: For More Information Contact UsfaaaNo ratings yet

- High Performance Lubricants: Molykote HP-870 GreaseDocument2 pagesHigh Performance Lubricants: Molykote HP-870 GreaseBruno FranNo ratings yet

- Seeflex 040ASDocument1 pageSeeflex 040ASArstNo ratings yet

- Vegaswing 61: Contactless Electronic Switch Vibrating Level Switch For LiquidsDocument2 pagesVegaswing 61: Contactless Electronic Switch Vibrating Level Switch For LiquidsMohamed OmarNo ratings yet

- en Vegaswing 61 Relay (DPDT)Document2 pagesen Vegaswing 61 Relay (DPDT)Mel AwrNo ratings yet

- en Vegaswing 63 Relay (DPDT)Document2 pagesen Vegaswing 63 Relay (DPDT)MaxiwendelNo ratings yet

- TdsDocument3 pagesTdsscribdme123No ratings yet

- Ceramic Capacitive OEM Pressure Sensor: Typical ApplicationsDocument2 pagesCeramic Capacitive OEM Pressure Sensor: Typical ApplicationsedilbertoNo ratings yet

- Product Information EDP PDFDocument2 pagesProduct Information EDP PDFpankaj mhatreNo ratings yet

- Anderson Greenwood POPRV Catalog - Series 200, 400, 500, 700 & 800Document64 pagesAnderson Greenwood POPRV Catalog - Series 200, 400, 500, 700 & 800Federico MoranNo ratings yet

- Dow Corning 785 Technical DatasheetDocument4 pagesDow Corning 785 Technical DatasheetShuvenduNo ratings yet

- Protect and Preserve The Integrity of Electronic Components: Gore Automotive Vents For Adhesive InstallationDocument4 pagesProtect and Preserve The Integrity of Electronic Components: Gore Automotive Vents For Adhesive InstallationBurak YILMAZNo ratings yet

- P611 Silicon Glass Fused Pressure TransmitterDocument2 pagesP611 Silicon Glass Fused Pressure TransmitterPrihartono Danan WingusNo ratings yet

- PDS Stopaq Insulwrap FR V1 enDocument1 pagePDS Stopaq Insulwrap FR V1 enAndyNo ratings yet

- PX419 - Series Pressure Sensor Data SheetDocument9 pagesPX419 - Series Pressure Sensor Data SheetDavid LaurenceNo ratings yet

- ProWear Plus BrochureDocument7 pagesProWear Plus BrochureJeff ThielNo ratings yet

- Product Information EDPDocument2 pagesProduct Information EDPkwanknNo ratings yet

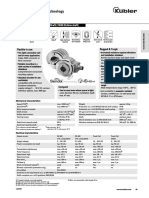

- Rotary Measuring Technology: Incremental EncodersDocument7 pagesRotary Measuring Technology: Incremental EncodersPassenger MedeamNo ratings yet

- Sps His Ppe Es Pro Wear Plus Bro en Final HighresDocument8 pagesSps His Ppe Es Pro Wear Plus Bro en Final HighresMartín AlonsoNo ratings yet

- Optimicron Pulse Filter Elements ON/PS / OH/PSDocument2 pagesOptimicron Pulse Filter Elements ON/PS / OH/PSSeyedAli TabatabaeeNo ratings yet

- Ip Transducers Series 500FCDocument2 pagesIp Transducers Series 500FCRajesh SirsathNo ratings yet

- En - Silcoset 158 TDS - 1Document1 pageEn - Silcoset 158 TDS - 1Андрей МошкинNo ratings yet

- Density Controller: GMDX95Document6 pagesDensity Controller: GMDX95Yasith Chinthaka50% (2)

- Tds Sikaflex250 PC CDocument2 pagesTds Sikaflex250 PC CNazar NazarNo ratings yet

- 5SL41047 Datasheet enDocument5 pages5SL41047 Datasheet enkavireeshgh_007No ratings yet

- Technicaldatasheet (TDS) 33mediumextremelowtemperaturegrease English 12062022Document2 pagesTechnicaldatasheet (TDS) 33mediumextremelowtemperaturegrease English 12062022pmf engineering limitedNo ratings yet

- Firetex FX5120 PDFDocument2 pagesFiretex FX5120 PDFArturo QuispeNo ratings yet

- DC 781 Acetoxy SealantDocument3 pagesDC 781 Acetoxy SealantL.S.No ratings yet

- Endress-Hauser Liquiphant M FTL50 ENDocument5 pagesEndress-Hauser Liquiphant M FTL50 ENtsarayuth1.2017No ratings yet

- 5SL41047RC Datasheet enDocument5 pages5SL41047RC Datasheet enDivakar Pullam ChettiNo ratings yet

- En - Silcoset 151 TDS - 1Document1 pageEn - Silcoset 151 TDS - 1Андрей МошкинNo ratings yet

- BsdcatalogDocument2 pagesBsdcatalogrickbolgerNo ratings yet

- Electrical ConnectorsDocument17 pagesElectrical Connectorsjohn garciaNo ratings yet

- Military Fuel HydrantDocument2 pagesMilitary Fuel HydrantJorge MuñizNo ratings yet

- Diaphragm Pressure Switch, Flameproof Enclosure Ex D For The Process Industry Model MADocument11 pagesDiaphragm Pressure Switch, Flameproof Enclosure Ex D For The Process Industry Model MARida RoudiNo ratings yet

- Seeflex 040EDocument1 pageSeeflex 040EArstNo ratings yet

- PDS Stopaq High Impact Shield V5 enDocument2 pagesPDS Stopaq High Impact Shield V5 enAndyNo ratings yet

- VCTDS 00543 enDocument62 pagesVCTDS 00543 enguido algaranazNo ratings yet

- Watson Smith Type20425Document2 pagesWatson Smith Type20425ECO Green and BlueNo ratings yet

- 460 Stopaq - Product Data Sheet - Stopaq Outerwrap PVC - Version April 2009 (Uk)Document2 pages460 Stopaq - Product Data Sheet - Stopaq Outerwrap PVC - Version April 2009 (Uk)EngTamerNo ratings yet

- Pressure SwitchDocument11 pagesPressure Switchaswinpisharat1997No ratings yet

- Circle Seal Controls 500 Series Relief ValveDocument6 pagesCircle Seal Controls 500 Series Relief ValveJai BhandariNo ratings yet

- Dow Corning 791 Silicone Weatherproofing Sealant: Product InformationDocument4 pagesDow Corning 791 Silicone Weatherproofing Sealant: Product InformationРоман СередаNo ratings yet

- EN VEGASWING 66 RelayDocument2 pagesEN VEGASWING 66 Relayfm429vm7x2No ratings yet

- MOLYKOTE 3400A Anti-Friction Coating LF 80-3061C-01Document2 pagesMOLYKOTE 3400A Anti-Friction Coating LF 80-3061C-01MAHESH BELENo ratings yet

- Periflex PS r11Document2 pagesPeriflex PS r11OrshanetzNo ratings yet

- Data Sheets Series 200 400 500 700 800 Pilot Operated Relief Valves Anderson Greenwood en en 5198016Document64 pagesData Sheets Series 200 400 500 700 800 Pilot Operated Relief Valves Anderson Greenwood en en 5198016Bouzaida MaherNo ratings yet

- Moly KoteDocument2 pagesMoly KoteNagaraju PanguluriNo ratings yet

- HOERBIGER Explosion Relief Valves: Reliable Protection Against The Effects of Dust ExplosionsDocument4 pagesHOERBIGER Explosion Relief Valves: Reliable Protection Against The Effects of Dust ExplosionsAndy Kong KingNo ratings yet

- EagleBurgmann Statotherm HDPPro 9593 HDPPro enDocument1 pageEagleBurgmann Statotherm HDPPro 9593 HDPPro enkeyur1109No ratings yet

- Catalogo Transductores SwagelokDocument17 pagesCatalogo Transductores Swagelokjulio cesar medinaNo ratings yet

- Stopaq TensileDocument2 pagesStopaq Tensilearshi LerwickMNo ratings yet

- Nitoproof 600 Standard PDFDocument4 pagesNitoproof 600 Standard PDFManojKumawatRjNo ratings yet

- AVP700 SeriesDocument12 pagesAVP700 Seriesfaisal andreansyahNo ratings yet

- Instruction Manual Guide D'Utilisation Manual de InstruccionesDocument56 pagesInstruction Manual Guide D'Utilisation Manual de InstruccionesomarNo ratings yet

- Nano Ceramic Thermal Insulation CoatingDocument2 pagesNano Ceramic Thermal Insulation CoatingAli AlghanimNo ratings yet

- MS228 Insta Heat Press ManualDocument18 pagesMS228 Insta Heat Press ManualDamien OlverNo ratings yet

- Cissell Specifications HD 75 100 125 170 190Document4 pagesCissell Specifications HD 75 100 125 170 190mairimsp2003No ratings yet

- Cissell SpecificationsDocument4 pagesCissell Specificationsmairimsp2003No ratings yet

- Stepsmart Assignment July 30Document15 pagesStepsmart Assignment July 30MeconNo ratings yet

- A Guide To Using The 100 Home Based Businesses For Malaysians ManualDocument63 pagesA Guide To Using The 100 Home Based Businesses For Malaysians ManualMohd Afif Sukri100% (1)

- Floating Breakwater Brochure Supllement No Costs PDFDocument9 pagesFloating Breakwater Brochure Supllement No Costs PDFBo boNo ratings yet

- Chapter-Six: Object Oriented TestingDocument31 pagesChapter-Six: Object Oriented TestingBEKAN FAYERANo ratings yet

- Accreditation of CME Programme As Approved by Governing Body of U P Medical Council, Lucknow On 11 April 2012Document9 pagesAccreditation of CME Programme As Approved by Governing Body of U P Medical Council, Lucknow On 11 April 2012GauravChopraNo ratings yet

- Java Programming ExercisesDocument50 pagesJava Programming ExerciseskeitoumaNo ratings yet

- Shell Calculations NotesDocument35 pagesShell Calculations NotesRamakrishnan SrinivasanNo ratings yet

- Manual TransmissionDocument60 pagesManual Transmissionʞǝǝs Uǝ ƎpıɥNo ratings yet

- CG (Basics of Line Clipping) : BITS PilaniDocument9 pagesCG (Basics of Line Clipping) : BITS PilaniYash GuptaNo ratings yet

- Republic vs. Court of Appeals: Vol. 168, November 29, 1988 77Document6 pagesRepublic vs. Court of Appeals: Vol. 168, November 29, 1988 77Joanne CamacamNo ratings yet

- Metu-Mete-Phd Theses Since 1971 PDFDocument5 pagesMetu-Mete-Phd Theses Since 1971 PDFsiaeatoomNo ratings yet

- Mtoa TutorialsDocument214 pagesMtoa Tutorials123batutaNo ratings yet

- Combofix 1Document10 pagesCombofix 1Nur Faizah AzizanNo ratings yet

- Yat HarthDocument51 pagesYat HarthAnil BatraNo ratings yet

- Typical HVAC Report - 2Document34 pagesTypical HVAC Report - 2Maxmore KarumamupiyoNo ratings yet

- O Level Commerce 1Document393 pagesO Level Commerce 1TapiwanasheNo ratings yet

- JICA Guidelines For Procurement Under Japanese ODA Loans - April 2012 VersionDocument65 pagesJICA Guidelines For Procurement Under Japanese ODA Loans - April 2012 Versionkaztubu4830100% (1)

- Rainin Pipetting Handbook 17701066 ENDocument78 pagesRainin Pipetting Handbook 17701066 ENLaboratorio Detecto CaliNo ratings yet

- Mobile Voting MachineDocument11 pagesMobile Voting MachinegouravNo ratings yet

- Anikesh Srivastava Final ReportDocument35 pagesAnikesh Srivastava Final ReportamitNo ratings yet

- ErasmusPlus KA2 2021-2027 PartnershipsForCooperationAndExchangesOfPractices Projects Overview 2023-10-03Document1,217 pagesErasmusPlus KA2 2021-2027 PartnershipsForCooperationAndExchangesOfPractices Projects Overview 2023-10-03AyaNo ratings yet

- An Agent-Based Dynamic Occupancy Schedule Model For Prediction of HVAC Energy Demand in An Airport Terminal BuildingDocument10 pagesAn Agent-Based Dynamic Occupancy Schedule Model For Prediction of HVAC Energy Demand in An Airport Terminal BuildingKapil SinhaNo ratings yet

- Project On Query in Ms AccessDocument36 pagesProject On Query in Ms Accessmathews johnsonNo ratings yet

- Benefits of Binary MLM Plan For Network MarketingDocument4 pagesBenefits of Binary MLM Plan For Network MarketingSachin SinghNo ratings yet

- Lucy Zhang: Fluid and Deformable-Structure Interactions in Bio-Mechanical Systems and Micro-Air VehiclesDocument49 pagesLucy Zhang: Fluid and Deformable-Structure Interactions in Bio-Mechanical Systems and Micro-Air VehiclesMichelle MorrisonNo ratings yet

- Activities 1-5 - BoncalesDocument12 pagesActivities 1-5 - BoncalesBraille Boncales100% (1)

- C-40 Manual InglesDocument2 pagesC-40 Manual InglesAntuanet GPNo ratings yet

- Solar Energy Conversion System With Grid-Tied InverterDocument3 pagesSolar Energy Conversion System With Grid-Tied InverterIB JoeNo ratings yet