Professional Documents

Culture Documents

Shaft Coupling

Shaft Coupling

Uploaded by

manojaparuchuri9990 ratings0% found this document useful (0 votes)

1 views37 pagesUntit 1 : shaft couplings,types

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentUntit 1 : shaft couplings,types

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

1 views37 pagesShaft Coupling

Shaft Coupling

Uploaded by

manojaparuchuri999Untit 1 : shaft couplings,types

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 37

Shaft Coupling

• Shafts are usually available up to 7 metres

length due to inconvenience in transport.

• It becomes necessary to join two or more

pieces of the shaft by means of a coupling.

• Two types of coupling

(a) Rigid Couplings (b) Flexible Couplings

Dr.Venkata Kiran Kumar.R

Shaft couplings are used in machinery for

several purposes, the most common of

which are the following

• To provide for the connection of shafts of units that are

manufactured separately such as a motor and

generator and to provide for disconnection for repairs

or alternations.

• To provide for misalignment of the shafts or to

introduce mechanical flexibility.

• To reduce the transmission of shock loads from one

shaft to another.

• To introduce protection against overloads.

• It should have no projecting parts.

Dr.Venkata Kiran Kumar.R

Requirements of a Good Shaft Coupling

1.It should be easy to connect or

disconnect.

2.It should transmit the full power from

one shaft to the other shaft without

losses.

3.It should hold the shafts in perfect

alignment.

4.It should reduce the transmission of

shock loads from one shaft to another

shaft.

5.It should have no projecting parts.

Dr.Venkata Kiran Kumar.R

Rigid coupling

It is used to connect two shafts which

are perfectly aligned.

(a) Sleeve or muff coupling.

(b) Clamp or split-muff or

compression coupling

(c) Flange coupling.

Dr.Venkata Kiran Kumar.R

Flexible coupling

It is used to connect two shafts

having both lateral and angular

misalignment

(a) Bushed pin type coupling,

(b) Universal coupling, and

(c) Oldham coupling.

Dr.Venkata Kiran Kumar.R

Sleeve or muff coupling

• Simplest type of rigid coupling, made of cast iron.

• It consists of a hollow cylinder whose inner

diameter is the same as that of the shaft.

• It is fitted over the ends of the two shafts by

means of a gib head key.

• The power is transmitted from one shaft to the

other shaft by means of a key and a sleeve.

• It is, therefore, necessary that all the elements

must be strong enough to transmit the torque.

Dr.Venkata Kiran Kumar.R

Dr.Venkata Kiran Kumar.R

Dr.Venkata Kiran Kumar.R

Clamp or Compression

Coupling

• It is also known as split muff coupling. In this

case, the muff or sleeve is made into two

halves and are bolted together. The halves of

the muff are made of cast iron.

• The shaft ends are made to abutt each other

and a single key is fitted directly in the

keyways of both the shafts.

Dr.Venkata Kiran Kumar.R

Dr.Venkata Kiran Kumar.R

Dr.Venkata Kiran Kumar.R

Dr.Venkata Kiran Kumar.R

Dr.Venkata Kiran Kumar.R

Dr.Venkata Kiran Kumar.R

Flange Coupling

• The flange coupling is adopted to heavy loads

and hence it is used on large shafting.

• A flange coupling usually applies to a coupling

having two separate cast iron flanges.

• Each flange is mounted on the shaft end and

keyed to it.

• The faces are turned up at right angle to the

axis of the shaft.

Dr.Venkata Kiran Kumar.R

• One of the flange has a projected portion and

the other flange has a corresponding recess.

• This helps to bring the shafts into line and to

maintain alignment.

• The two flanges are coupled together by

means of bolts and nuts.

Dr.Venkata Kiran Kumar.R

Unprotected type Flange coupling

• In an unprotected type flange coupling each

shaft is keyed to the boss of a flange with a

counter sunk key

• The flanges are coupled together by means of

bolts.

• Generally three, four or six bolts are used.

• The keys are staggered at right angle along the

circumference of the shafts in order to divide

the weakening effect caused by keyways.

Dr.Venkata Kiran Kumar.R

Dr.Venkata Kiran Kumar.R

Dr.Venkata Kiran Kumar.R

Dr.Venkata Kiran Kumar.R

PROTECTED TYPE FLANGE COUPLING

• Protruding bolts and nuts are protected by

flanges on the two halves of the coupling, in

order to avoid danger to the workman.

• The thickness of the protective

circumferential flange (tp) is taken as 0.25

d.

• The other proportions of the coupling are

same as for unprotected type flange

coupling

Dr.Venkata Kiran Kumar.R

Dr.Venkata Kiran Kumar.R

Dr.Venkata Kiran Kumar.R

Dr.Venkata Kiran Kumar.R

MARINE TYPE FLANGE COUPLING

• Flanges are forged integral with the shafts.

• The flanges are held together by means of

tapered headless bolts numbering from

four to twelve depending upon the

diameter of shaft.

Dr.Venkata Kiran Kumar.R

Dr.Venkata Kiran Kumar.R

Bushed-pin Flexible Coupling

Dr.Venkata Kiran Kumar.R

• A bushed-pin flexible coupling is a modification

of the rigid type of flange coupling.

• The coupling bolts are known as pins. The

rubber or leather bushes are used over the

pins.

• The two halves of the coupling are dissimilar in

construction. A clearance of 5 mm is left

between the face of the two halves of the

coupling.

• There is no rigid connection between them and

the drive takes place through the medium of

the compressible rubber or leather bushes.

Dr.Venkata Kiran Kumar.R

• In designing the bushed-pin flexible coupling,

the proportions of the rigid type flange coupling

are modified.

• The main modification is to reduce the bearing

pressure on the rubber or leather bushes.

• Bearing pressure should not exceed 0.5

N/mm2.

• In order to keep the low bearing pressure, the

pitch circle diameter and the pin size is

increased.

Dr.Venkata Kiran Kumar.R

Dr.Venkata Kiran Kumar.R

Dr.Venkata Kiran Kumar.R

Since the pin is subjected to bending and shear stresses

Dr.Venkata Kiran Kumar.R

Oldham Coupling

It is used to join two shafts which have lateral

misalignment.

It consists of two flanges A and B with slots and a central

floating part E with two tongues T1 and T2 at right angles

Dr.Venkata Kiran Kumar.R

•The central floating part is held by means of a pin passing

through the flanges and the floating part.

•T1 fits into the slot of flange A and allows for ‘to and fro’

relative motion of the shafts, while the tongue T2 fits into

the slot of the flange B and allows for vertical relative

motion of the parts.

•The resultant of these two components of motion will

accommodate lateral misalignment of the shaft as they

rotate.

Dr.Venkata Kiran Kumar.R

Universal (or Hooke’s) Coupling

• A universal or Hooke’s coupling is used to connect two shafts whose axes

intersect at a small angle.

• The inclination of the two shafts may be constant, but in actual practice, it

varies when the motion is transmitted from one shaft to another.

• The main application of the universal or Hooke’s coupling is found in the

transmission from the gear box to the differential or back axle of the

automobiles.

• In such a case, we use two Hooke’s coupling, one at each end of the

propeller shaft, connecting the gear box at one end and the differential on

the other end.

• A Hooke’s coupling is also used for transmission of power to different

spindles of multiple drilling machine. It is used as a knee joint in milling

machines.

Dr.Venkata Kiran Kumar.R

Dr.Venkata Kiran Kumar.R

Dr.Venkata Kiran Kumar.R

You might also like

- I-Shift, Design and FunctionDocument59 pagesI-Shift, Design and FunctionSherzad Chem94% (17)

- Power Transmission PDFDocument89 pagesPower Transmission PDFShubhang Charantimath50% (2)

- Carrier S.A. Liste de Pieces Spare Parts List: REF: 30HXC080-A-901 - EE - Standard Unit Date: 11/09/00Document1 pageCarrier S.A. Liste de Pieces Spare Parts List: REF: 30HXC080-A-901 - EE - Standard Unit Date: 11/09/00Luciano Lopes SimõesNo ratings yet

- Presentation ON: CouplingDocument32 pagesPresentation ON: CouplingJonnalyn ArcinasNo ratings yet

- Chapter Two Coupling Design at 2015 EDocument23 pagesChapter Two Coupling Design at 2015 EEyu KalebNo ratings yet

- Classifications of CouplingsDocument20 pagesClassifications of Couplingssyampnaidu100% (2)

- Coupling - A Breif StudyDocument39 pagesCoupling - A Breif StudyRenold ElsenNo ratings yet

- Machine Design II CouplingDocument27 pagesMachine Design II CouplingDangol RupeshNo ratings yet

- Coupling NotesDocument28 pagesCoupling NotesRose Mj80% (5)

- Coupling of Shafts MDDocument26 pagesCoupling of Shafts MDDev AgarwalNo ratings yet

- Chapter TwoDocument27 pagesChapter Twosena.mokoninNo ratings yet

- Shaft Coupling and TypesDocument8 pagesShaft Coupling and TypesBurhoneySonNo ratings yet

- Couplings in MechatronicsDocument23 pagesCouplings in MechatronicsRavindra MahadeokarNo ratings yet

- Typesofcoupling 180508042951Document22 pagesTypesofcoupling 180508042951Siva KulanjiNo ratings yet

- CouplingsDocument23 pagesCouplingsmalabadidd100% (4)

- COUPLINGDocument11 pagesCOUPLINGabduallah rabah100% (1)

- Shaft 141118092812 Conversion Gate02Document14 pagesShaft 141118092812 Conversion Gate02Aso SerwanNo ratings yet

- Coupling, Clutches, BrakesDocument36 pagesCoupling, Clutches, Brakeskeval patelNo ratings yet

- WelcomeDocument14 pagesWelcomeArsh 837No ratings yet

- Coupling: Type of CouplingsDocument10 pagesCoupling: Type of Couplingsdaya shanker shuklaNo ratings yet

- Shaft Couplings: Types, Working, Diagram, Advantages and ApplicationsDocument20 pagesShaft Couplings: Types, Working, Diagram, Advantages and Applicationsvj kumarNo ratings yet

- Couplings: RequirementsDocument5 pagesCouplings: RequirementsirshadNo ratings yet

- Couplings and ClutchesDocument14 pagesCouplings and ClutchesBhotka BhutkiNo ratings yet

- MEC 203 Lec 02Document15 pagesMEC 203 Lec 02Prince RajNo ratings yet

- 15ME3112 Design of Machine ElementsDocument29 pages15ME3112 Design of Machine Elementslikhith saiNo ratings yet

- Design of CouplingDocument75 pagesDesign of CouplingVatsal BhalaniNo ratings yet

- Prepared By: Suraj Kumar Chand Assistant Professor: 02-12-2017 Department of ME, GEC Raipur 1Document45 pagesPrepared By: Suraj Kumar Chand Assistant Professor: 02-12-2017 Department of ME, GEC Raipur 1ManojKumar MNo ratings yet

- Experiment 1Document22 pagesExperiment 1dhruvmistry300No ratings yet

- Shaft Couplings - Types, Working, Diag Etc.Document8 pagesShaft Couplings - Types, Working, Diag Etc.Maneesh BhartiNo ratings yet

- Unit 1 BMCDocument57 pagesUnit 1 BMCSagar ShindeNo ratings yet

- CouplingsDocument23 pagesCouplingszaib hassanNo ratings yet

- Emd Micro Project FinalDocument15 pagesEmd Micro Project Finalom pawarNo ratings yet

- Flat Belt Pulleys (Lec 2)Document7 pagesFlat Belt Pulleys (Lec 2)JeffersonTalanNo ratings yet

- Coupling, Clutch & Brake: Compiled By: Hardik Majiwala 1Document29 pagesCoupling, Clutch & Brake: Compiled By: Hardik Majiwala 1amrptl9010No ratings yet

- REPORT5Document18 pagesREPORT5Kaleab EndaleNo ratings yet

- CouplingDocument9 pagesCouplingPrabir Kumar PatiNo ratings yet

- CH 1Document70 pagesCH 1Sagar ShindeNo ratings yet

- Mod 7.03b Tools SlideshowDocument79 pagesMod 7.03b Tools Slideshowzaidkadiri9No ratings yet

- Springs NotesDocument9 pagesSprings NotesP DargopatilNo ratings yet

- Coupling - WikipediaDocument40 pagesCoupling - WikipediaManojkumarNo ratings yet

- Synchronous GeneratorDocument15 pagesSynchronous Generatormanuvelbenny1No ratings yet

- 1Document4 pages1jimmy neutronNo ratings yet

- Control CablesDocument40 pagesControl CablesSeanRiniFernandoNo ratings yet

- Module 2 - CouplingsDocument18 pagesModule 2 - CouplingsthandonksNo ratings yet

- CH # 3 CouplingsDocument24 pagesCH # 3 CouplingsWaris Ali BozdarNo ratings yet

- Lecture - 39-40: Fasteners and JointsDocument17 pagesLecture - 39-40: Fasteners and JointsMuhammad Husnain AshrafNo ratings yet

- Lecture - 39-40: Fasteners and JointsDocument17 pagesLecture - 39-40: Fasteners and JointsMuhammad Husnain AshrafNo ratings yet

- Unit - Iii - Part - B - Shaft CouplingsDocument19 pagesUnit - Iii - Part - B - Shaft CouplingsPHANI RAJA RAONo ratings yet

- Power Transmission PDFDocument89 pagesPower Transmission PDFKumar Rajesh85% (54)

- Couplings 1Document19 pagesCouplings 1Aqib AliNo ratings yet

- Gear & Gear TrainDocument20 pagesGear & Gear Trainniaz kilamNo ratings yet

- Couplings: Machine Design 1Document45 pagesCouplings: Machine Design 1Edrian PentadoNo ratings yet

- Sanjivani K. B. P. Polytechnic Kopargaon: Department of MechatronicsDocument35 pagesSanjivani K. B. P. Polytechnic Kopargaon: Department of MechatronicsChaitanya YengeNo ratings yet

- Coupling Clutch BrakeDocument43 pagesCoupling Clutch BrakeSurjit Kumar Gandhi100% (1)

- MECHANICAL DRIVES & TRANSMISSION For TextileDocument62 pagesMECHANICAL DRIVES & TRANSMISSION For Textileumeshpatel100% (1)

- A PPT On Worm Gear: Presented byDocument19 pagesA PPT On Worm Gear: Presented byrip111176No ratings yet

- 21ELE23 Module 4Document27 pages21ELE23 Module 4A.Antony RozarioNo ratings yet

- Springs: Shammy Kumar Assistant Professor Department of Mechanical Engg. SRM University, CHENNAIDocument25 pagesSprings: Shammy Kumar Assistant Professor Department of Mechanical Engg. SRM University, CHENNAIAshish SinghNo ratings yet

- Unit 1 Shaft, Key, Splines, Couplings, Bearings, Clutch and BrakeDocument200 pagesUnit 1 Shaft, Key, Splines, Couplings, Bearings, Clutch and BrakeAbhijeet somawarNo ratings yet

- Coupling: Presented by - Kafil Ahmed & Rohan SalunkeDocument18 pagesCoupling: Presented by - Kafil Ahmed & Rohan SalunkeKafil KhanNo ratings yet

- Wood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingFrom EverandWood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingNo ratings yet

- Referncce Material 2Document87 pagesReferncce Material 2LohithaNo ratings yet

- Steering System PDFDocument7 pagesSteering System PDFallan lariosaNo ratings yet

- Gear Manufacturing ReportDocument10 pagesGear Manufacturing ReportSyedSalman AhmedNo ratings yet

- PC200LC-8 S - N A90301-Up - K0930-01a0 Cab Travel PPC Valve Body (1 - 2) PDFDocument1 pagePC200LC-8 S - N A90301-Up - K0930-01a0 Cab Travel PPC Valve Body (1 - 2) PDFEider Arturo Garcia OsorioNo ratings yet

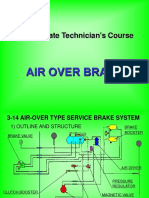

- Air Over BrakeDocument50 pagesAir Over Brakesidik purnomo100% (1)

- Gear ClassificationDocument13 pagesGear Classificationprkphani1984100% (1)

- NFPA 20 Standard For The Installation of Stationary Pumps For Fire ProtectionDocument19 pagesNFPA 20 Standard For The Installation of Stationary Pumps For Fire ProtectionMOHAMED ABD ELGHANYNo ratings yet

- BFV Tech DocDocument120 pagesBFV Tech DocLuis MozoNo ratings yet

- Manual Transmission / Transaxle: Service DataDocument3 pagesManual Transmission / Transaxle: Service DataMax K.No ratings yet

- Quick Exhaust Valve Sre PDFDocument80 pagesQuick Exhaust Valve Sre PDFAizzu ArrowNo ratings yet

- Spare Parts DC-PRO English 2012Document24 pagesSpare Parts DC-PRO English 2012Алексей КрижановскийNo ratings yet

- A-TRC, ABS, Brake Assist, Crawl, Downhill Assist Control, EBD, Hill-Start Assist Control, VSCDocument19 pagesA-TRC, ABS, Brake Assist, Crawl, Downhill Assist Control, EBD, Hill-Start Assist Control, VSCNguyễn TúNo ratings yet

- EKISUI Catalog-J EslonValveDocument100 pagesEKISUI Catalog-J EslonValveleonardo saul palaciosNo ratings yet

- H Type CouplerDocument10 pagesH Type CouplerSantosh Sharma50% (2)

- PT Rame Rekaguna Prakarsa: QuotationDocument1 pagePT Rame Rekaguna Prakarsa: Quotationtri_purwadiNo ratings yet

- Transmission SystemDocument3 pagesTransmission SystemRafiNo ratings yet

- Cigueñal y TransmisionDocument21 pagesCigueñal y Transmisionlau cv 97No ratings yet

- KSB ValvesDocument1 pageKSB ValvesRahul Das100% (1)

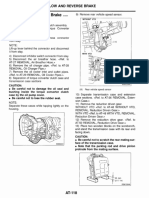

- Low and Reverse Brake: Automatic TransmissionDocument7 pagesLow and Reverse Brake: Automatic TransmissionAnton FortovNo ratings yet

- 4650 and 4850 Section 50Document100 pages4650 and 4850 Section 50josephmw0308No ratings yet

- Canrig Part Number Description: Component Literature: Top DriveDocument2 pagesCanrig Part Number Description: Component Literature: Top DriveAlex RamirezNo ratings yet

- KX91-3 (SN: 20000-29999) : VENDOR: Kubota Section: Engine Diagram: 050100 Water PumpDocument2 pagesKX91-3 (SN: 20000-29999) : VENDOR: Kubota Section: Engine Diagram: 050100 Water PumpMarkiyanNo ratings yet

- SM-XF-12T-IC Forklift-202012-EN-CEDocument126 pagesSM-XF-12T-IC Forklift-202012-EN-CEmirko coppiniNo ratings yet

- Clutch Booster Japanese Commercial VehiclesDocument12 pagesClutch Booster Japanese Commercial VehiclesferNo ratings yet

- 6 TransmissionDocument81 pages6 Transmissionalexis aguirre espejoNo ratings yet

- Hydraulics TrainingDocument47 pagesHydraulics Trainingmdhyderali100% (5)

- Hidraulicni Sistem-PodizaciDocument2 pagesHidraulicni Sistem-Podizacimohacsi1989No ratings yet

- 307 SchematicDocument2 pages307 Schematicthan zaw winNo ratings yet