Professional Documents

Culture Documents

Dokumen K3

Dokumen K3

Uploaded by

Ryan NdrowaaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dokumen K3

Dokumen K3

Uploaded by

Ryan NdrowaaCopyright:

Available Formats

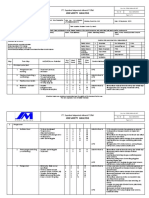

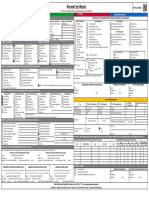

GA01.PRD.2406.HOWP.

52

HOT WORK PERMIT

REL

Seek an Alternative/ Safer Method If Possible!

This Hot Work Permit is for any operation involving open flame or producing heat and/or spark. This work includes, but is not limited to, welding, brazing, cutting, grinding, soldering, thawing pipe, torch-applied roofing,

or chemical welding. Take note that the permit may not require for hot work at designated area (ie. workshop) and shall not be authorised for hot work at restricted areas (ie. Ex-zone).

1 - Work Request

Permit Preparation Working at height equipment/tools

Date / Time Request : 22/06/2024 / 08:00 Type Quantity Condition Remark

Location of work/equipment : (GAI) Protective glasses 3 Y

PENAMBAHAN

PLATFOR

KATALIS Protective shoes 3 Y

Plant Supervisors :

Fire Extinguisher 3 Y

Head 3 Y

protection/helmet

Fire 3 Y

blankets/sacks

Emergency kit 3 Y

(stretches, first

aid kit)

Plant Supervisor Designation Work to Perform

PAK ASST. HEAD DEPARTMENT

Permit Number : GA01.PRD.2406.HOWP.52

PAK SUPERVISOR

Title : (GAI) PENAMBAHAN PLATFORM

PAK ASST. SUPERVISOR

PAK SAFETY OFFICER

Particulars of Requestor Job Description : (GAI) INSTALL BONGKAR SCAFOLDING

UNTUK PENAMBAHAN PLATFORM

Company Name : PT. Berkah Kawan Setya

Requestor Name : [alfiatus12] Alfiatus Solikhah Soldering Torch Cutting

Designation : Brazing Y Welding

Name of Workers Doing Hot Work (In Full) Y Grinding/ Abrasive work Other

Name Role

PAK SUCHAIMI SPV

PAK ARIFIN F1

PAK TEGUH F2

2 - How Work Preparation Step & Precautions

Job Safety & Environmental Analysis (JSEA) Isolations

Y JSEA reviewed and approved. Y Electrical & mechanical drives Instrumentation

Y Control measures implemented and verified by Permit Authoriser / Process lines Firefighting/ suppression system

EHS Officer

High Risk Activity – Hot Work Permit Checklist reviewed (attached) Services (Air/ Gas/ Water)

Initial Gas & Atmospheric Testing Hot work on enclosed equipment/ tank :

* Record additional readings on the HWP supplementary sheet

O2 (19.5-23.5%) 20.50 % Testing Frequency: The tank or vessel has been prepared in accordance with ‘Preparation for Hot

CO (<30ppm) 0.00 Continuously Work on Tanks Procedure’

H2S (<10ppm) 0.00

Y Periodically Additional PPE

LEL (0%) 0.00

Gas Tester Calibration Date: 20/06/2024 Y Safety glasses Y Welding head shield

Gas Tester Model SNDWAY Y Ear muff/plugs Y Welding gloves

Gas tester S/N# SN7500

Y Welding goggles Welding apron

Other

Additional Work Permits Required Fire Monitoring and Fire Watcher

Y Hot Work Permit Y Working at Height Permit Y Fire watcher trained in use of firefighting equipment and in sounding alarm

Cold Work Permit Electrical Work Permit Fire Watcher Names & Sign:

(Fire watchers are aware of their duties and won’t leave their post.)

Lockout Tagout Permit Heavy Lifting Work Permit

Name : [alfiatus12]Alfiatus Solikhah

Confined Space Entry Permit Excavation Work Permit Phone 087777968738

Department Maintenance

PROCEDURE FOR HOT WORK IN A CONFINED SPACE:

Air quality monitoring, ventilation, lockout, equipment isolation and rescue plan must be established prior to Confirmation 21/06/2024 16:48

hot work in confined space. A Confined Space Entry Permit must be issued and implemented in addition to a

Hot Work Permit before work commenced.

Emergency Equipment

Y Fire extinguisher (Type:powder) Water hose reel Fire blanket

3 - Authorisation & Acceptance

Parmit Valid From : Date : 22/06/2024 Hours Permit Requester Signature:

Maximum for one shift only From : 08:00 I agreed that all hot work precautions and instructions are adhered to

and I fully understand the nature and extend of works undertaken by

my workers and me.

To : 16:30

Permit Accepted by: (Permit Receiver – Wilmar supervisor/ technician/ engineer only/ Maintenance Manager)

I accept this Hot Work Permit and agree to abide by the conditions stipulated. I will instruct all workers on the Hazards and Risks and ensure all controls remain in place until the work is complete.

Permit Authorised by: (Plant/ Factory/ Project)

I certify that I have personally examined this application, the hot work risk assessment, the rescue plan, the work area, checked all precautions, tools and equipment and I am satisfied the controls

are in place and authorise hot work to commence.

1/2

You might also like

- Research 2023 Grade 11Document8 pagesResearch 2023 Grade 11noxolo dwane83% (18)

- Restore Power in Case of BlackoutDocument5 pagesRestore Power in Case of Blackoutadityasahay100% (2)

- R1937-JSA-004 Job Safety Analysis For Pipe PullDocument3 pagesR1937-JSA-004 Job Safety Analysis For Pipe PullVineet AgrawalNo ratings yet

- The Ultimate Healthy Grocery List PDFDocument1 pageThe Ultimate Healthy Grocery List PDFHazwan Ariff HakimiNo ratings yet

- Tanks Breathing CalculationDocument1 pageTanks Breathing CalculationRexx Mexx0% (1)

- Dokumen K3Document1 pageDokumen K3Ryan NdrowaaNo ratings yet

- Yanbu-Jiddah Pipeline Project: Automatic, Semi Automatic & Manual Welding of PipelineDocument3 pagesYanbu-Jiddah Pipeline Project: Automatic, Semi Automatic & Manual Welding of Pipelinesam mathewNo ratings yet

- Jsa CMMDocument7 pagesJsa CMMDeffous AbdelhadiNo ratings yet

- JSA - Cor Pilecap Darat (CV-104) - (Jsa No 009-Row No 30) TGL 050713Document3 pagesJSA - Cor Pilecap Darat (CV-104) - (Jsa No 009-Row No 30) TGL 050713Ita MonoarfaNo ratings yet

- TRA Renovation, Service For Building and Office Construction (Ex Telkom Building) Rev1Document8 pagesTRA Renovation, Service For Building and Office Construction (Ex Telkom Building) Rev1Dol29No ratings yet

- Job Safety Analysis: PT. Suprabari Mapanindo Mineral FORMDocument2 pagesJob Safety Analysis: PT. Suprabari Mapanindo Mineral FORMIta MonoarfaNo ratings yet

- Jsa Manual Excavation To Install New Fire Water Line & Fire Hydrant For New Ome Building 0000Document12 pagesJsa Manual Excavation To Install New Fire Water Line & Fire Hydrant For New Ome Building 0000thennarasuNo ratings yet

- TRA-GOR-0008 (Hydrotesting Piping System) Rev.4Document37 pagesTRA-GOR-0008 (Hydrotesting Piping System) Rev.4Alfyn Alkha RifhaiNo ratings yet

- SWMS No 6 Threaded Rod InstallingDocument6 pagesSWMS No 6 Threaded Rod InstallingMokka SamaiyalNo ratings yet

- Sepcoii II: Job Safety Analysis (J S A)Document8 pagesSepcoii II: Job Safety Analysis (J S A)Abdus SamadNo ratings yet

- MCU AndalusDocument1 pageMCU AndalusMedical LafargeNo ratings yet

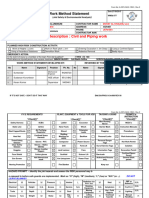

- Civil & Piping Work at Cast HouseDocument8 pagesCivil & Piping Work at Cast HouseVinayaga MoorthiNo ratings yet

- PTW Cold&hot All New YisuDocument4 pagesPTW Cold&hot All New YisuUD. Gunung JatiNo ratings yet

- Jsa For Inst. of TSF & Laydown AreaDocument23 pagesJsa For Inst. of TSF & Laydown AreaAshir RIZNo ratings yet

- 2 - JSA Hot WorkDocument9 pages2 - JSA Hot WorkAijaz AhmedNo ratings yet

- 001 - JSA For Back Filling - TCF AreaDocument5 pages001 - JSA For Back Filling - TCF AreaSalah Abd Eldayem100% (2)

- 01.20.ASP-JSA-04.06 (EN) - JSA For Fall Protection at Height WorkDocument5 pages01.20.ASP-JSA-04.06 (EN) - JSA For Fall Protection at Height WorkDNurul HudaNo ratings yet

- Job Safety Analysis Template - BatteryDocument3 pagesJob Safety Analysis Template - BatteryvenkateshbitraNo ratings yet

- Job Safety Analysis Work SheetDocument3 pagesJob Safety Analysis Work SheetHaleemUrRashidBangashNo ratings yet

- 7 - Dewatering of Rain Water From Compression Project AreaDocument4 pages7 - Dewatering of Rain Water From Compression Project AreaAijaz AhmedNo ratings yet

- Job Hazard Safety & Environment Analysis (JHSEA) WorksheetDocument3 pagesJob Hazard Safety & Environment Analysis (JHSEA) WorksheetGwen CondezNo ratings yet

- R1937-JSA-006 Job Safety Analysis For Material Transfer - RiggingDocument3 pagesR1937-JSA-006 Job Safety Analysis For Material Transfer - RiggingVineet AgrawalNo ratings yet

- JSA Declaration of Green Green Area For Gambat Compression ProjectDocument4 pagesJSA Declaration of Green Green Area For Gambat Compression ProjectAijaz AhmedNo ratings yet

- 01.20.ASP-JSA-04.05 (EN) - JSA For Moving and Material HandlingDocument15 pages01.20.ASP-JSA-04.05 (EN) - JSA For Moving and Material HandlingDNurul HudaNo ratings yet

- 8 - Manual Well Boring For Utility Water For Compression ProjectDocument4 pages8 - Manual Well Boring For Utility Water For Compression ProjectAijaz AhmedNo ratings yet

- Gas Cutting Work JsaDocument2 pagesGas Cutting Work JsaAKBAR ALINo ratings yet

- JSA For Station PipingDocument4 pagesJSA For Station PipingR Sahadeo ReddyNo ratings yet

- 1 - JSA Erectoin and Dismantling of ScaffoldingDocument5 pages1 - JSA Erectoin and Dismantling of ScaffoldingAijaz AhmedNo ratings yet

- Asphalt TitleDocument1 pageAsphalt TitleShahidNo ratings yet

- HIRARC-MFG-37 Aktiviti Mencuci Nozzle Water Spray Di CoolerDocument2 pagesHIRARC-MFG-37 Aktiviti Mencuci Nozzle Water Spray Di Coolerkhairul japriNo ratings yet

- PBSSFTJSA005-Work at HighDocument4 pagesPBSSFTJSA005-Work at HighHSE Pakubumi SemestaNo ratings yet

- Work Risk Assessment Wra Page 1 of Area: Wra Status Plant: GresikDocument10 pagesWork Risk Assessment Wra Page 1 of Area: Wra Status Plant: GresikcitraNo ratings yet

- Jsa EXCAVATIONDocument4 pagesJsa EXCAVATIONHSE Pakubumi SemestaNo ratings yet

- 3 - JSA Loading Off LoadingDocument5 pages3 - JSA Loading Off LoadingAijaz AhmedNo ratings yet

- 6-R A For Handling, Storage and Use of Gas CylindersDocument4 pages6-R A For Handling, Storage and Use of Gas CylindersMohamedSaidNo ratings yet

- RA 002 - ExcavationDocument8 pagesRA 002 - Excavationsedat.cotNo ratings yet

- RA 003 - Sea Outfall Drainage Pipe InstallationDocument8 pagesRA 003 - Sea Outfall Drainage Pipe Installationsedat.cotNo ratings yet

- JSA Finishing Temporary FacilitiesDocument6 pagesJSA Finishing Temporary Facilitiesjet Louis Magallones100% (1)

- Job Safety Analysis (Jsa) : Helm Safety Boot Safety Glasses/Goggles Gloves - Cotton/leatherDocument3 pagesJob Safety Analysis (Jsa) : Helm Safety Boot Safety Glasses/Goggles Gloves - Cotton/leatherHANIF AKBARNo ratings yet

- Job Safety Analysis: JSA Basic DataDocument5 pagesJob Safety Analysis: JSA Basic DataPrabhu DivakaranNo ratings yet

- Hot JHADocument6 pagesHot JHAسيف علي عبد الحسن ANo ratings yet

- JSEA - Hydro Test - 2833Document13 pagesJSEA - Hydro Test - 2833Amit Sharma100% (1)

- JSA Sample 0Document13 pagesJSA Sample 0Razi KhanNo ratings yet

- Confined Space 05Document8 pagesConfined Space 05Royal RoyNo ratings yet

- RA 001 - Spun Pile DrivingDocument12 pagesRA 001 - Spun Pile Drivingsedat.cotNo ratings yet

- JOB SAFETY ANALYSIS RECORD SHEET-Off Cavern Jockey Pump Check Valve ReplacementDocument8 pagesJOB SAFETY ANALYSIS RECORD SHEET-Off Cavern Jockey Pump Check Valve ReplacementthennarasuNo ratings yet

- No Work Is So Urgent That We Cannot Take Time To Do It SafelyDocument2 pagesNo Work Is So Urgent That We Cannot Take Time To Do It SafelyAkmanezy AbdullahNo ratings yet

- RA 005 - Formwork, Reinforcement and Concrete Rev 01Document10 pagesRA 005 - Formwork, Reinforcement and Concrete Rev 01sedat.cotNo ratings yet

- Jsa Demolish of Existing Armor RockDocument2 pagesJsa Demolish of Existing Armor Rockabdan adly TNo ratings yet

- It CoverDocument1 pageIt CoverShahid BhattiNo ratings yet

- Electrical Metallic Tubes, Flexible Conduits, DB Panel, Juncation Box Installation, Electrical Wiring works&DB Panel TerminationDocument1 pageElectrical Metallic Tubes, Flexible Conduits, DB Panel, Juncation Box Installation, Electrical Wiring works&DB Panel TerminationRABIE EL MAGHWRY ABDELKHALEK ELGHAMRYNo ratings yet

- Man Lifter SWP BF#02Document14 pagesMan Lifter SWP BF#02Hari NairNo ratings yet

- PPM PAGA System 230522Document3 pagesPPM PAGA System 230522Idham ZawawiNo ratings yet

- SWMS No 11 Duct CuttingDocument5 pagesSWMS No 11 Duct CuttingMokka SamaiyalNo ratings yet

- JSA Box UpDocument7 pagesJSA Box Upimam dianiNo ratings yet

- Height Work.Document13 pagesHeight Work.Ashfaq Husain AnsariNo ratings yet

- Job Safety Analysis (Jsa) : Mast InspectionDocument1 pageJob Safety Analysis (Jsa) : Mast Inspectionmadjid bobNo ratings yet

- JSA - 20in Elbow Box-Up Near 03-SD-2Document4 pagesJSA - 20in Elbow Box-Up Near 03-SD-2Hashim BokhariNo ratings yet

- UNIT 2 Health & Lifestyle (Healthwatch Program)Document2 pagesUNIT 2 Health & Lifestyle (Healthwatch Program)Kone YüsufNo ratings yet

- Queen Creek Queen Creek Barber School: Enroll Now Full Time or Part Time!!!!Document4 pagesQueen Creek Queen Creek Barber School: Enroll Now Full Time or Part Time!!!!reneeclancyNo ratings yet

- Structure of A ChloroplastDocument2 pagesStructure of A ChloroplastsreenitthiNo ratings yet

- Issues N Chalenges in Health ManagementDocument133 pagesIssues N Chalenges in Health ManagementRachana Karki100% (1)

- BS en Iso Iec 80079-38-2016Document66 pagesBS en Iso Iec 80079-38-2016MstefNo ratings yet

- Environmental LeadershipDocument4 pagesEnvironmental LeadershipElpi FerrerNo ratings yet

- 1426kW BG Specs - Avus Biogas PDFDocument12 pages1426kW BG Specs - Avus Biogas PDFnavas1972100% (2)

- Test Bank Linux For Programmers and Users SolutionDocument4 pagesTest Bank Linux For Programmers and Users SolutionRichard1LauritsenNo ratings yet

- Essentials and Pre-Requisites of Medical ResearchDocument3 pagesEssentials and Pre-Requisites of Medical ResearchArchisman Mukherjee FAPSIANNo ratings yet

- Nitrogen and Its CompoundsDocument4 pagesNitrogen and Its Compoundssayma_akhter5074No ratings yet

- Surgical Rehabilitation of Deafness With Partially Implantable Hearing Aid Using Piezoelectric Ceramic Bimorpli Ossicular VibratorDocument8 pagesSurgical Rehabilitation of Deafness With Partially Implantable Hearing Aid Using Piezoelectric Ceramic Bimorpli Ossicular Vibratorİsmail KahramanNo ratings yet

- Neatecha 1Document20 pagesNeatecha 1cram retselNo ratings yet

- KRISHNAGIRIDocument13 pagesKRISHNAGIRItejas5No ratings yet

- Carcinoma of Prostate: Patho Ogy - Chapter &Document29 pagesCarcinoma of Prostate: Patho Ogy - Chapter &HAMIDNo ratings yet

- ASI4517 R3 V 06Document2 pagesASI4517 R3 V 06Дмитрий СпиридоновNo ratings yet

- Catalog DHF DSF enDocument2 pagesCatalog DHF DSF enRUTHNo ratings yet

- Food Service Top Class ComDocument70 pagesFood Service Top Class ComMaximo Alarcon SalvoNo ratings yet

- Lecture 5 Aditya SirDocument39 pagesLecture 5 Aditya Sirankur soniNo ratings yet

- Sandhya Vandhanam Argya Pradhanam: 1.om Achyuthaya Nama 2.om Ananthaya Nama 3.om Govindaya NamaDocument12 pagesSandhya Vandhanam Argya Pradhanam: 1.om Achyuthaya Nama 2.om Ananthaya Nama 3.om Govindaya Namaindyaone2003No ratings yet

- Fermenting Banana: Using The Alcohol (Anaerobic) FermentationDocument18 pagesFermenting Banana: Using The Alcohol (Anaerobic) FermentationSatria Aji0% (1)

- Lesson 1: PE and HealthDocument7 pagesLesson 1: PE and HealthCin DyNo ratings yet

- Hydrometallurgy: Jochen PetersenDocument7 pagesHydrometallurgy: Jochen PetersenAlex Paolo Paz AldayNo ratings yet

- Moon Sign Favorable Unfavorable: AriesDocument3 pagesMoon Sign Favorable Unfavorable: Ariesvheejay.vkhisti1070No ratings yet

- Proverbs and IdiomsDocument47 pagesProverbs and IdiomsMukilan MurugasanNo ratings yet

- Thesis OfwDocument3 pagesThesis Ofwyazi080% (1)

- 406 - Torts CAN - FeileyDocument17 pages406 - Torts CAN - FeileyGeeth MpNo ratings yet