Professional Documents

Culture Documents

Dokumen K3

Dokumen K3

Uploaded by

Ryan NdrowaaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dokumen K3

Dokumen K3

Uploaded by

Ryan NdrowaaCopyright:

Available Formats

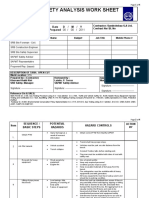

GA01.PRD.2406.WAHP.

51

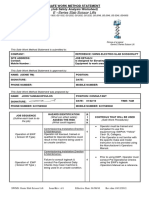

WORK AT HEIGHT PERMIT

REL

1 - Work Request

Permit Preparation Additional Work Permits Required

Date / Time Request : 22/06/2024 / 08:00

Y Hot Work Permit Y Working at Height Permit

Location of work/equipment : (GAI)

Cold Work Permit Electrical Work Permit

PENAMBAHAN

PLATFOR

KATALIS

Plant Supervisors : Lockout Tagout Permit Heavy Lifting Work Permit

Plant Supervisor Designation Confined Space Entry Permit Excavation Work Permit

PAK ASST. HEAD DEPARTMENT Working at height equipment/tools

PAK SAFETY OFFICER

PAK SUPERVISOR

Type Quantity Condition Remark

Full body harness 3 Y

Protective glasses 3 Y

Protective shoes 3 Y

Head 3 Y

protection/helmet

Particulars of Requestor Work to Perform

Company Name : PT. Berkah Kawan Setya Permit Number : GA01.PRD.2406.WAHP.51

Requestor Name : [alfiatus12] Alfiatus Solikhah Title : (GAI) INSTALL BONGKAR SCAFOLDING UNTUK

Designation : PENAMBAHAN PLATFORM

Job Description : (GAI) INSTALL BONGKAR SCAFOLDING

UNTUK PENAMBAHAN PLATFORM

Name of WAH Workers Working at Heights (In Full)

Name Role

PAK SUCHAIMI SPV

PAK ARIFIN F1

PAK TEGUH F2

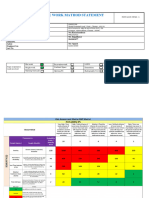

2 - WAH Preparation Step & Precautions

Job Safety & Environmental Analysis (JSEA) Erecting Scaffold or break-down

Y JSEA reviewed and approved. Scaffolding to be built under supervision or direction of a Qualified Scaffolder

Y Control measures implemented and verified by Permit Authoriser / Verify a firm foundation – Sole-boards & base plates

EHS Officer

High Risk Activity – WAH Permit Checklist reviewed (attached) Engineering sign off required? (Tick for YES)

Meeting related country regulations

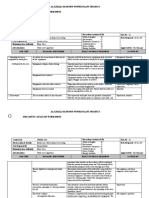

Hazard Identification Working from Scaffold

Y Falling objects Y Scaffold has a safety tag to identify status

Y Unprotected edges Y Scaffold decks fully planked ≤50mm gaps

Y Adverse weather (ie wind/ weather extremes) Y Service gap (between scaffold platform’s inside edge & the building facade)

spacing <225mm (when internal guardrails not required) or follow country

specified required dimension - whichever more stringent

Y Slope of surface Y Provide safe ladder/stairway access

Y Overhead electrical cables Y NO works on scaffold following severe weather until checked

Y Overhead pipes/ fixtures Workers to remain within the confines of the scaffold

Y Uneven floor surfaces Verify all guardrails and kick-boards are in place and secure

Fragile or brittle roofing NO modifications - unless by a qualified scaffolder

Vehicles operating in the area Mobile Scaffold - All castors must be lock-able

Overhead electrical cables Mobile Scaffold - Not to be moved with people on board

Hazardous substances/ materials Mobile Elevated Work Platform Use (MEWP)

Working alone or in isolation Machinery inspected and deemed fit for use (registration with cert. of fitness)

Log book checked and completed DAILY

Harness Use MEWP being operated within load limits: WLL:

Y Harness/equipment inspected and fit for use Kg

Y Harnesses being worn correctly Anchor points available (reject equipment if not available)

Confirm anchor point adequate for the load (>22kN) The area is safe to operate the MEWP

Ladder Use The ground is level and firm to support the weight of the MEWP.

Y The ladder is industrial rated and good working condition Controls tested/trial at the ground level.

Y The ladder is on a secure footing & tied off to prevent sliding or a standby person Levelling devices functional and being used if required

holding secure

Y Workers facing the ladder, with 3 points of contact at all times

Non-conductive ladders to be used near electrical equipment

Crane – Man-cage “NON-Preferred Method”

Approval from Site Manager & Wilmar’s Personnel Lifting Standard/ Guideline

reviewed

The ground is safe to operate the crane – Service/ lift plan

Crane/equipment certificates verified and fit-for-purpose

1/2

You might also like

- C9.3 EngineDocument112 pagesC9.3 Enginedocumentossaf100% (10)

- Test Bank For Microbiology For The Healthcare Professional 2nd Edition Karin C Vanmeter Robert J HubertDocument21 pagesTest Bank For Microbiology For The Healthcare Professional 2nd Edition Karin C Vanmeter Robert J HubertTammyEricksonfitq98% (46)

- CH 42001Document110 pagesCH 42001马焜No ratings yet

- Jsa. Cable Laying and TerminationDocument10 pagesJsa. Cable Laying and TerminationMon Trang NguyễnNo ratings yet

- NBME Family Medicine Form 1Document8 pagesNBME Family Medicine Form 1Anna100% (1)

- W@H PermitDocument2 pagesW@H PermitJixtha SaintNo ratings yet

- PJHA Form - Compi (Ash Bin) Piling of CHBDocument3 pagesPJHA Form - Compi (Ash Bin) Piling of CHBPaul TamayoNo ratings yet

- JSA Painting Aut Tranformer Unit 3 OutageDocument7 pagesJSA Painting Aut Tranformer Unit 3 OutageMarhendraNo ratings yet

- WMS 168+Installation+of+Cable+Catenary+WireDocument6 pagesWMS 168+Installation+of+Cable+Catenary+Wireozer100% (1)

- ARK-JSA - Installation of Form Works, Rebars & Concrete PouringDocument7 pagesARK-JSA - Installation of Form Works, Rebars & Concrete PouringREMYA100% (3)

- Job Safety Analysis Work SheetDocument7 pagesJob Safety Analysis Work SheetTomNo ratings yet

- Acute Otitis Media PresentationDocument76 pagesAcute Otitis Media PresentationFarah NasyitahNo ratings yet

- Dokumen K3Document1 pageDokumen K3Ryan NdrowaaNo ratings yet

- Yanbu-Jiddah Pipeline Project: Automatic, Semi Automatic & Manual Welding of PipelineDocument3 pagesYanbu-Jiddah Pipeline Project: Automatic, Semi Automatic & Manual Welding of Pipelinesam mathewNo ratings yet

- WMS 155+Installation+of+Cable+Tray+Document6 pagesWMS 155+Installation+of+Cable+Tray+monik_atabaresNo ratings yet

- JOB SAFETY ANALYSIS RECORD SHEET-Off Cavern Jockey Pump Check Valve ReplacementDocument8 pagesJOB SAFETY ANALYSIS RECORD SHEET-Off Cavern Jockey Pump Check Valve ReplacementthennarasuNo ratings yet

- SICIM Form# JAPL GREEN-Confined Space Entry PermitDocument2 pagesSICIM Form# JAPL GREEN-Confined Space Entry PermitFarrukh IjazNo ratings yet

- SICIM Form # JAPL GREEN-Confined Space Entry Permit Rev. 01Document1 pageSICIM Form # JAPL GREEN-Confined Space Entry Permit Rev. 01Farrukh Ejaz100% (1)

- Working at HeightsDocument1 pageWorking at HeightsVictor Quijano JrNo ratings yet

- SICIM Form # JAPL BLUE-Cold Work Permit Rev. 01Document2 pagesSICIM Form # JAPL BLUE-Cold Work Permit Rev. 01Farrukh IjazNo ratings yet

- SICIM Form # JAPL BLUE-Cold Work Permit Rev. 01Document1 pageSICIM Form # JAPL BLUE-Cold Work Permit Rev. 01Farrukh EjazNo ratings yet

- Job Safety Analysis Work Sheet: Date Prepared D / M / YDocument4 pagesJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

- SICIM Form # JAPL - RED-Hot Work PermitDocument2 pagesSICIM Form # JAPL - RED-Hot Work PermitFarrukh Ijaz0% (1)

- Pre Job Hazard Assessment: Our Goal Is Injuries in The WorkplaceDocument1 pagePre Job Hazard Assessment: Our Goal Is Injuries in The WorkplaceNadya ShintaNo ratings yet

- Co2 Cylinder House-JesaDocument24 pagesCo2 Cylinder House-JesaResearcherNo ratings yet

- It CoverDocument1 pageIt CoverShahid BhattiNo ratings yet

- JSA-002-Diesel Refueling加油作业Document7 pagesJSA-002-Diesel Refueling加油作业caovanthien10121992No ratings yet

- SAR.JSA For Excavtion and backfillingDocument7 pagesSAR.JSA For Excavtion and backfillingRizwan KhanNo ratings yet

- SICIM Form # JAPL BLUE-Cold Work PermitDocument2 pagesSICIM Form # JAPL BLUE-Cold Work PermitFarrukh Ijaz0% (1)

- Jsa For Cable LayingDocument2 pagesJsa For Cable LayingSabari VtNo ratings yet

- Intra MHC JSA 006Document8 pagesIntra MHC JSA 006Clarence Jay GanirNo ratings yet

- Work at Height Permit FormDocument3 pagesWork at Height Permit FormEbenezer OpuniNo ratings yet

- Elevator Work Safety Checklist: (MR-Type)Document4 pagesElevator Work Safety Checklist: (MR-Type)BUKTI RANTAUNo ratings yet

- SAR.JSA FOR Geophysical studyDocument7 pagesSAR.JSA FOR Geophysical studyRizwan KhanNo ratings yet

- Switchgear Base Frame Installation PDFDocument39 pagesSwitchgear Base Frame Installation PDFArka Hati100% (1)

- Scaffolding JSADocument10 pagesScaffolding JSASubbu AbuNo ratings yet

- PTW in Working at HeightDocument1 pagePTW in Working at Heightbach.pham0932719192No ratings yet

- JSA-Scaffolding Erection & Dismantling Works RV-00Document2 pagesJSA-Scaffolding Erection & Dismantling Works RV-00abou bakarNo ratings yet

- Jsa For Site EstablishmentDocument8 pagesJsa For Site EstablishmentBenasher IbrahimNo ratings yet

- SICIM Form # JAPL RED-Hot Work Permit Rev. 01Document1 pageSICIM Form # JAPL RED-Hot Work Permit Rev. 01Farrukh EjazNo ratings yet

- Risk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityDocument2 pagesRisk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityJhundel FactorNo ratings yet

- Work Risk Assessment Wra Page 1 of Area: Wra Status Plant: GresikDocument10 pagesWork Risk Assessment Wra Page 1 of Area: Wra Status Plant: GresikcitraNo ratings yet

- JSA-005-Temporary and Permanent Electrical Work电工作业Document6 pagesJSA-005-Temporary and Permanent Electrical Work电工作业caovanthien10121992No ratings yet

- Sepcoii II: Job Safety Analysis (J S A)Document8 pagesSepcoii II: Job Safety Analysis (J S A)Abdus SamadNo ratings yet

- Manual Excavation For Identified Depth and Elevation of Existing PipelineDocument15 pagesManual Excavation For Identified Depth and Elevation of Existing PipelineshahbazchafekarNo ratings yet

- JSA TubingDocument9 pagesJSA TubingSubbu AbuNo ratings yet

- SWMS No 6 Threaded Rod InstallingDocument6 pagesSWMS No 6 Threaded Rod InstallingMokka SamaiyalNo ratings yet

- Appendix 6 - HR WAH REV 2-Restrict EditingDocument4 pagesAppendix 6 - HR WAH REV 2-Restrict Editingamri ashaariNo ratings yet

- 01 PTW For Work at Height (MEWP) - DailyDocument6 pages01 PTW For Work at Height (MEWP) - DailyIgnatius TanNo ratings yet

- Job Safety Analysis Work SheetDocument3 pagesJob Safety Analysis Work SheetHaleemUrRashidBangashNo ratings yet

- Job Safety Analysis (Jsa) : Mast InspectionDocument1 pageJob Safety Analysis (Jsa) : Mast Inspectionmadjid bobNo ratings yet

- STARRT CardDocument2 pagesSTARRT Cardsanny100% (1)

- Genie E Series Slab Scissor Lift OperationDocument11 pagesGenie E Series Slab Scissor Lift OperationSanket Arun MoreNo ratings yet

- Genie E Series Slab Scissor Lift Operation PDFDocument11 pagesGenie E Series Slab Scissor Lift Operation PDFRajesh gpNo ratings yet

- RECTIFICATION WORK FOR REVAMP 2.0- INSTALLATION OF WIRE ANODE-Document5 pagesRECTIFICATION WORK FOR REVAMP 2.0- INSTALLATION OF WIRE ANODE-borneocemerlangservicesNo ratings yet

- JSA-009-Shim Padding沃浆Document6 pagesJSA-009-Shim Padding沃浆caovanthien10121992No ratings yet

- Scaffolding Work Permit New FORMDocument1 pageScaffolding Work Permit New FORMRaka NusantaraNo ratings yet

- JSA For Cold Cutting J Hot Cutting J Loading and Unloading-Rev-00Document7 pagesJSA For Cold Cutting J Hot Cutting J Loading and Unloading-Rev-00DLPS HSENo ratings yet

- Electrical Metallic Tubes, Flexible Conduits, DB Panel, Juncation Box Installation, Electrical Wiring works&DB Panel TerminationDocument1 pageElectrical Metallic Tubes, Flexible Conduits, DB Panel, Juncation Box Installation, Electrical Wiring works&DB Panel TerminationRABIE EL MAGHWRY ABDELKHALEK ELGHAMRYNo ratings yet

- Ref: Work Permit No:: Honeywell International ME-HBS - Dubai Site-JBR-CCTV Upgrade Special Work PermitDocument6 pagesRef: Work Permit No:: Honeywell International ME-HBS - Dubai Site-JBR-CCTV Upgrade Special Work Permitdreamboy87No ratings yet

- Jesa FGDDocument26 pagesJesa FGDResearcherNo ratings yet

- OHS-PR-09-03-F07 (A) JSP No. 053 Installation of Fiber Optic Cable PanelDocument9 pagesOHS-PR-09-03-F07 (A) JSP No. 053 Installation of Fiber Optic Cable PanelEbrahsm ElshenawyNo ratings yet

- Al-Khalij 4X350 MW Power Plant Project Job Safety Analysis WorksheetDocument5 pagesAl-Khalij 4X350 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferNo ratings yet

- 4 Foundations To Help Trauma-Impacted YouthDocument4 pages4 Foundations To Help Trauma-Impacted YouthwaleskacrzNo ratings yet

- Soul Food JunkiesDocument7 pagesSoul Food JunkiesDennis GathuraNo ratings yet

- 04 - Issues of Collective BargainingDocument3 pages04 - Issues of Collective BargainingSurbhi SofatNo ratings yet

- The Denver Developmental Screening Test: August, 1967 The Journal o (PEDIATRICS 1 8 1Document11 pagesThe Denver Developmental Screening Test: August, 1967 The Journal o (PEDIATRICS 1 8 1Manju Kumari100% (1)

- Reflective Theories Writing AssignmentDocument7 pagesReflective Theories Writing Assignmentapi-582621575No ratings yet

- Buletin Farmasi 02/2013Document19 pagesBuletin Farmasi 02/2013afiq83No ratings yet

- Exercise Labels and Procedure TextDocument3 pagesExercise Labels and Procedure TextivhaNo ratings yet

- Chapter 3 14 Applied AnthropologyDocument26 pagesChapter 3 14 Applied AnthropologyMUJAHIDNo ratings yet

- Case History Sample 2 Case History Sample 2Document6 pagesCase History Sample 2 Case History Sample 2einsteinNo ratings yet

- Dansville CSD Reopening Plan 073120Document107 pagesDansville CSD Reopening Plan 073120News 8 WROCNo ratings yet

- Life Cycle Assessment of Defluoridation of Water Using Laterite Soil Based AdsorbentsDocument12 pagesLife Cycle Assessment of Defluoridation of Water Using Laterite Soil Based AdsorbentsVineet RathoreNo ratings yet

- A Comparative Study of Typhidot and Widal Test For Rapid Diagnosis of Typhoid FeverDocument5 pagesA Comparative Study of Typhidot and Widal Test For Rapid Diagnosis of Typhoid FeverArbusa86No ratings yet

- B.F SkinnerDocument11 pagesB.F SkinnerJoyceNo ratings yet

- Community Health Nursing WEEK-1-AND-2Document23 pagesCommunity Health Nursing WEEK-1-AND-2Don Maur ValeteNo ratings yet

- Slide Template HSE CTR Forum - JDCDocument20 pagesSlide Template HSE CTR Forum - JDCNebinsonNo ratings yet

- Noiseless PavementsDocument26 pagesNoiseless PavementsachsahNo ratings yet

- Chapter 5: Foundations of Sport PsychologyDocument13 pagesChapter 5: Foundations of Sport PsychologyyessodaNo ratings yet

- McGrath Video Laryngoscope Rev 0.1Document6 pagesMcGrath Video Laryngoscope Rev 0.1adevasenNo ratings yet

- MCU Based Drying System For Golden Rice Grains With Temperature and Humidity ModificationDocument4 pagesMCU Based Drying System For Golden Rice Grains With Temperature and Humidity ModificationJake Lester GatchalianNo ratings yet

- 1 s2.0 S2405452620300409 Main1Document8 pages1 s2.0 S2405452620300409 Main1Febria Rike ErlianaNo ratings yet

- Lesson 4 Health PDFDocument25 pagesLesson 4 Health PDFRomeo BalingaoNo ratings yet

- Research Jan ClarenzDocument6 pagesResearch Jan ClarenzBiboy De ungriaNo ratings yet

- Key To Being A Good ParentDocument15 pagesKey To Being A Good ParentJelena Preradovic100% (1)

- Driving Growth With Business Model Innovation - BCGDocument9 pagesDriving Growth With Business Model Innovation - BCGAndreeaChiricescu100% (1)

- SP 06 DR 01Document19 pagesSP 06 DR 01Miss'ElNo ratings yet