Professional Documents

Culture Documents

PC Spun Pile Dia 600 A1 fc52 - Standard 2019new-11-12

PC Spun Pile Dia 600 A1 fc52 - Standard 2019new-11-12

Uploaded by

kimvanhoang12388Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PC Spun Pile Dia 600 A1 fc52 - Standard 2019new-11-12

PC Spun Pile Dia 600 A1 fc52 - Standard 2019new-11-12

Uploaded by

kimvanhoang12388Copyright:

Available Formats

at service - 28 days after production (concrete strength min.

100% fc')

RL

Concrete weight : 3.85 kN/m

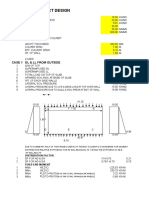

PILE ERECTION WITH ROLLING BLOCK Impact Load : 20%

4

RLL RLR Section Inertia : 5,105,088,062 mm

1.5m 1/3 L RR Modulus of Elasticity 33,892.18 N/mm2

a b at installation :

M allow handling at service = 124.50 kN.m

c

L f Vn = 106.24 kN

load factor DL = 1.00

handling at pile erection control :

Pile Flexural Moment (DL+I) Vu max Mallow/MDL+I Check fVn / Vu Shear

Length at : a at : b at : c 1.0(DL+I) Ratio Resume Ratio Capacity Resume

(m) (kN.m) (kN.m) (kN.m) (kN) Resume

6 -5.20 -4.54 1.70 11.88 23.9 under M.allow 8.94 sufficient shear cap. Comply Spec.

7 -5.20 -3.47 4.19 13.06 23.9 under M.allow 8.13 sufficient shear cap. Comply Spec.

8 -5.20 -1.95 7.54 14.31 16.5 under M.allow 7.42 sufficient shear cap. Comply Spec.

9 -5.20 0.00 11.70 15.60 10.6 under M.allow 6.81 sufficient shear cap. Comply Spec.

10 -5.20 2.38 16.63 16.91 7.5 under M.allow 6.28 sufficient shear cap. Comply Spec.

11 -5.20 5.18 22.33 18.23 5.6 under M.allow 5.83 sufficient shear cap. Comply Spec.

12 -5.20 8.39 28.78 19.57 4.3 under M.allow 5.43 sufficient shear cap. Comply Spec.

13 -5.20 12.02 35.98 20.92 3.5 under M.allow 5.08 sufficient shear cap. Comply Spec.

14 -5.20 16.07 43.93 22.27 2.8 under M.allow 4.77 sufficient shear cap. Comply Spec.

15 -5.20 20.53 52.63 23.63 2.4 under M.allow 4.50 sufficient shear cap. Comply Spec.

16 -5.20 25.41 62.07 24.99 2.0 under M.allow 4.25 sufficient shear cap. Comply Spec.

17 -5.20 30.69 72.25 26.36 1.7 under M.allow 4.03 sufficient shear cap. Comply Spec.

18 -5.20 36.39 83.18 27.73 1.5 under M.allow 3.83 sufficient shear cap. Comply Spec.

19 -5.20 42.50 94.84 29.61 1.3 under M.allow 3.59 sufficient shear cap. Comply Spec.

20 -5.20 49.02 107.25 31.48 1.2 under M.allow 3.37 sufficient shear cap. Comply Spec.

21 -5.20 55.96 120.40 33.36 1.0 under M.allow 3.18 sufficient shear cap. Comply Spec.

22 -5.20 63.30 134.29 35.23 0.9 Over M.allow 3.02 sufficient shear cap. Not Comply

23 -5.20 71.06 148.92 37.10 0.8 Over M.allow 2.86 sufficient shear cap. Not Comply

24 -5.20 79.23 164.29 38.97 0.8 Over M.allow 2.73 sufficient shear cap. Not Comply

25 -5.20 87.81 180.40 40.83 0.7 Over M.allow 2.60 sufficient shear cap. Not Comply

26 -5.20 96.80 197.25 42.70 0.6 Over M.allow 2.49 sufficient shear cap. Not Comply

27 -5.20 106.20 214.84 44.56 0.6 Over M.allow 2.38 sufficient shear cap. Not Comply

28 -5.20 116.01 233.17 46.42 0.5 Over M.allow 2.29 sufficient shear cap. Not Comply

29 -5.20 126.24 252.24 48.28 0.5 Over M.allow 2.20 sufficient shear cap. Not Comply

* NOTE : MAXIMUM PILE LENGTH (m) = 21.00

VI. JOINT OF PILES

Welding layer

Groove 7-12mm Groove > 12mm

3

2a 3

2 >45◦C

1 >45◦C 1 2

b b b

Joint Plate Joint Plate Dimension for PC Pile 600 mm

Material = JIS 3101 SS400 or A36 a= 6.00 mm

Tensile strength = 400 MPa b= 12.00 mm

yield stress fy = 245.00 MPa Outer Dia. OD = 598.00 mm

Inner Dia. ID = 574.00 mm

ya = yb = 299.00 mm

Welding Welding section properties

2

Material = AWS A5.1 E6013 Area = 22,091.68 mm

4

Tensile strength = 60 Ksi Inertia = 948,671,949 mm

3

Tensile strength = 413 Mpa Section Inertia = 3,172,815.88 mm

2

Shear Area = 11,045.84 mm

Chek welding strength :

a. Due to cracking moment

Mjoint = s allow x Section inertia

Mjoint = (2/3) x fy joint plate x section inertia

Mjoint = 518.23 kN.m ID

Mjoint = 52.85 ton.m > Pile Cracking moment = 17.0 ton.m

b. Due to breaking moment

Mjoint = s yield x Section inertia

Mjoint = fy joint plate x section inertia

Mjoint = 777.34 kN.m OD

Mjoint = 79.27 ton.m > Breaking moment = 25.6 ton.m

Hak Cipta PT Wijaya Karya Beton

PC Spun Pile Dia 600 A1 fc52 - Standard 2019new Hal. : 11

c. Due to tension to decompression force

Pjoint = st x Section area

Mjoint = 0,7 x (2/3) x fy joint plate x section area

Mjoint = 2,525.82 kN

Mjoint = 257.58 ton > tension to decomp. = 68.5 ton.m

d. Due to ultimate tension

Pjoint = st x Section area

Mjoint = fy joint plate x section area

Mjoint = 5,412.46 kN

Mjoint = 551.95 ton > tension to decomp. = 104.3 ton

e. Due to ultimate shear

Vjoint = sh x Section area

Vjoint = 0,58 x fy joint plate x shear section area

Vjoint = 1,569.61 kN

Vjoint = 160.07 ton > ultimate shear. = 10.8 ton based on ACI Formula

40.6 ton based on BS formula

VII. Pile Interaction Diagram

PILE DIAGRAM INTERACTION

DIAMETER 600 Class A1 ( 18@PC Bar 7.1mm ) Mcrack 17t.m - fc'52Mpa, eff. Pts = 4.2 MPa

7000

0, Pn,o

0, 6650

0, fPn,o

5000 0, 4988

fM n,ot ; fPn,ot

235; 3977

AXIAL (kN)

0, l(fPn,o)

0; 3741 282; 3741 fM n; fPn

349; 3349

eot

Nominal

3000

e

2506

200; 2506 Factored

fM n,b; fPn,b

282; 1750 eb 447, 2076

1000 0.1 fc' Ag = 2573

226 251

0 200 400 600

w' max = 0.0606 mm << 0.2mm Mcrack 197.86

-1000

MOMENT (kN-m)

------ END OF CALCULATION ------

Hak Cipta PT Wijaya Karya Beton

PC Spun Pile Dia 600 A1 fc52 - Standard 2019new Hal. : 12

You might also like

- Resistance and PoweringDocument23 pagesResistance and Poweringjeesonantony3No ratings yet

- Examples On Design of Flexural Members: M KN X X MDocument9 pagesExamples On Design of Flexural Members: M KN X X MTesfa HunderaNo ratings yet

- Dew Point & Bubble Point ExcelDocument2 pagesDew Point & Bubble Point Excelayub100% (1)

- Triple Point of T-Butanol ExperimentDocument20 pagesTriple Point of T-Butanol ExperimentmichaelheynenNo ratings yet

- Numerical Calculation of Psychrometric Properties On A CalculatorDocument5 pagesNumerical Calculation of Psychrometric Properties On A CalculatorBetoAdauta100% (1)

- Moist Air As Mixture of Ideal Gases: ME 306 Applied Thermodynamics 1Document33 pagesMoist Air As Mixture of Ideal Gases: ME 306 Applied Thermodynamics 1Harsh ChandakNo ratings yet

- PC Spun Pile Dia 600 A1 fc52 - Standard 2019new-09-10Document2 pagesPC Spun Pile Dia 600 A1 fc52 - Standard 2019new-09-10kimvanhoang12388No ratings yet

- Calculation - Loading PlatformDocument6 pagesCalculation - Loading PlatformDaniel SarmientoNo ratings yet

- Calculation - Loading PlatformDocument7 pagesCalculation - Loading PlatformDaniel SarmientoNo ratings yet

- 3.4 Buckling Length (L) : Sheet of Rev 3000 140 KN 70 KN 3000 3000Document7 pages3.4 Buckling Length (L) : Sheet of Rev 3000 140 KN 70 KN 3000 3000mn4webNo ratings yet

- Al Basti & Muktah (Villa) Calculation - 2.5m LedgerDocument3 pagesAl Basti & Muktah (Villa) Calculation - 2.5m LedgerDaniel SarmientoNo ratings yet

- Try M5 Beam-2Document21 pagesTry M5 Beam-2HHTNo ratings yet

- Design Annex Paundi KholaDocument19 pagesDesign Annex Paundi KholaBinod Thapa0% (1)

- Training Standard Regarding ShearDocument7 pagesTraining Standard Regarding ShearjologscresenciaNo ratings yet

- RCC Boundary Wall DetailDocument2 pagesRCC Boundary Wall DetailPallab DasNo ratings yet

- Belt Conveyor Capacity CalculatorDocument5 pagesBelt Conveyor Capacity CalculatorramsaiNo ratings yet

- Gantry ExampleDocument4 pagesGantry ExamplechrisNo ratings yet

- Design Calculation For Column 750Kn, 140Knm, 20Knm Parameter Unit Column Segment Oa Db1 AbDocument30 pagesDesign Calculation For Column 750Kn, 140Knm, 20Knm Parameter Unit Column Segment Oa Db1 AbJanaka KarunarathnaNo ratings yet

- One Way Spanning Slab Design To BS8110: Dead Load Live LoadDocument1 pageOne Way Spanning Slab Design To BS8110: Dead Load Live LoadNILRATAN SARKARNo ratings yet

- 1.5 QK Type B With LandingDocument1 page1.5 QK Type B With LandingDerek AngNo ratings yet

- 10T SWL Spreader Bar R2-Fos2.0Document8 pages10T SWL Spreader Bar R2-Fos2.0Snr Designer JayaNo ratings yet

- Cold Formed Sections DesignDocument17 pagesCold Formed Sections DesignSourabh Das100% (1)

- Strength Evaluation of Existing Structures: Mmax KN-M Vmax KN-M Dead Load MomentsDocument6 pagesStrength Evaluation of Existing Structures: Mmax KN-M Vmax KN-M Dead Load MomentsAbel MulugetaNo ratings yet

- Mk2+ Dual Wallform To Retaining Wall: Shade CorporationDocument15 pagesMk2+ Dual Wallform To Retaining Wall: Shade CorporationJuan Dela CruzNo ratings yet

- Mse WallDocument4 pagesMse WallEngr AtaUllahNo ratings yet

- 1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Document7 pages1-WAY SOLID CONCRETE SLAB DESIGN To BS 81101997 Table 3.12Tamer. ThekingNo ratings yet

- 5.3 Girder Design - 760mmDocument3 pages5.3 Girder Design - 760mmSantosh ZunjarNo ratings yet

- PLAXIS - 3D2018 Tutorial Lesson 09 PDFDocument14 pagesPLAXIS - 3D2018 Tutorial Lesson 09 PDFMarwan HMNo ratings yet

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Document7 pages1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12bunheng lonNo ratings yet

- Design of Compresion MemberDocument11 pagesDesign of Compresion Memberp_ignatiusNo ratings yet

- Lecture 9 Design of Beams IIDocument27 pagesLecture 9 Design of Beams IIujjwalsingh8509No ratings yet

- Height of TankDocument2 pagesHeight of TankARSENo ratings yet

- TotalDocument2 pagesTotalSaurabh TiwariNo ratings yet

- PT Slab Bridge Deck 20 MDocument8 pagesPT Slab Bridge Deck 20 Msamirbendre1No ratings yet

- 4.3 Design Values of Bending Moments and Shear ForcesDocument7 pages4.3 Design Values of Bending Moments and Shear Forcesmn4webNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document5 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC298675No ratings yet

- Two-Way Solid Slabs - 1Document4 pagesTwo-Way Solid Slabs - 1rizwanjawaid.meenaNo ratings yet

- RCC95 Continuous Beams (Tables)Document8 pagesRCC95 Continuous Beams (Tables)Felicia GhicaNo ratings yet

- 1) Basic Data: Design of Cantilever Beam As Per IS 456-2000Document4 pages1) Basic Data: Design of Cantilever Beam As Per IS 456-2000khaniskhan03No ratings yet

- OF Capacity of 50x10 Plate: Document No. SheetDocument3 pagesOF Capacity of 50x10 Plate: Document No. SheetJemicah YumenaNo ratings yet

- OF Capacity of 50x10 Plate: Document No. SheetDocument3 pagesOF Capacity of 50x10 Plate: Document No. SheetJemicah YumenaNo ratings yet

- Box Culvert Design: Case 1 DL & LL From OutsideDocument8 pagesBox Culvert Design: Case 1 DL & LL From OutsideselvakumarNo ratings yet

- Cantilever Retaining Wall Design CalculationDocument29 pagesCantilever Retaining Wall Design CalculationFadhana A PutraNo ratings yet

- Spreadsheets To BS 8110: Single Column BaseDocument4 pagesSpreadsheets To BS 8110: Single Column BaseBobby A MathewNo ratings yet

- Design Data: Total Dead Load (Udl)Document13 pagesDesign Data: Total Dead Load (Udl)sachinthaNo ratings yet

- Design of R.C.C Column Footing: Input DetailsDocument15 pagesDesign of R.C.C Column Footing: Input DetailsAbilaash VelumaniNo ratings yet

- Foundation ADocument1 pageFoundation AMano HarNo ratings yet

- By: Engr Ata Ullah Shah Yousafzai: Data InputDocument5 pagesBy: Engr Ata Ullah Shah Yousafzai: Data InputEngr AtaUllahNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document5 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Murthy GunaNo ratings yet

- PDFProviderDocument56 pagesPDFProviderjitendra goyalNo ratings yet

- 35m Tower CheckDocument68 pages35m Tower CheckHarold Jackson MtyanaNo ratings yet

- Reinforced Concrete Tanks 4 Year Civil: Rectangular Tanks Continued By: Abdel Hamid ZaghwDocument33 pagesReinforced Concrete Tanks 4 Year Civil: Rectangular Tanks Continued By: Abdel Hamid ZaghwJumma AbualgasemNo ratings yet

- Eurocode Calculations For The Aluminium BridgeDocument23 pagesEurocode Calculations For The Aluminium Bridgestromek2006No ratings yet

- Double Girder Box Type EOT Crane DesignDocument24 pagesDouble Girder Box Type EOT Crane DesignA.K.M Shafiq MondolNo ratings yet

- Design of Beam (Steel)Document30 pagesDesign of Beam (Steel)jeyavaniNo ratings yet

- Pavement Slab Design For RTGDocument2 pagesPavement Slab Design For RTGBishal karki100% (1)

- Design of Gantry ShedsDocument4 pagesDesign of Gantry ShedsJulian TremontNo ratings yet

- RCC95 Continuous Beams (Tables)Document9 pagesRCC95 Continuous Beams (Tables)Murthy GunaNo ratings yet

- 2way Slab Output by RCCDocument4 pages2way Slab Output by RCCSherwin PonsNo ratings yet

- Shear - ULS-70m - LF 1.1Document6 pagesShear - ULS-70m - LF 1.1Sravanthi MeharNo ratings yet

- You Need To, The Torsion Constant Can Be Calculated by Adding BTDocument3 pagesYou Need To, The Torsion Constant Can Be Calculated by Adding BTThirojan JayabalasinghamNo ratings yet

- EOTxlsxDocument6 pagesEOTxlsxskpatilm23No ratings yet

- 2-Trim Stability BookletDocument16 pages2-Trim Stability BookletAung Htet Kyaw100% (1)

- Respuestas 235.Document4 pagesRespuestas 235.blancanestor76No ratings yet

- PDF Sample Problem1Document34 pagesPDF Sample Problem1ERVIN JAMES ABULOCNo ratings yet

- IS 1206 Part 2 2022Document12 pagesIS 1206 Part 2 2022Ajit P. SinghNo ratings yet

- Psych Rome TryDocument13 pagesPsych Rome TryAmira BagumbaranNo ratings yet

- What Is A Psychrometric Chart ?Document13 pagesWhat Is A Psychrometric Chart ?Genina Joy Atienza FusiNo ratings yet

- Calorimetry and Thermal Expansion PDFDocument54 pagesCalorimetry and Thermal Expansion PDFshyla100% (2)

- What Temperature Does Fahrenheit Equal CelsiusDocument4 pagesWhat Temperature Does Fahrenheit Equal CelsiusbhatovaisNo ratings yet

- q4 g9 Science Las-3 Marikina RTPDocument4 pagesq4 g9 Science Las-3 Marikina RTPMeyshia Vixen LavalleNo ratings yet

- Study Package - Physics 11Document378 pagesStudy Package - Physics 11rebeccasanjuNo ratings yet

- Kinetic TheoryDocument25 pagesKinetic TheorySultan ParvezNo ratings yet

- Helmholtz Free EnergyDocument6 pagesHelmholtz Free EnergyDuà Zàhrä RìzvîNo ratings yet

- Formula Sheet of SolutionsDocument2 pagesFormula Sheet of SolutionsSiddharth SharmaNo ratings yet

- Physical Sciences P2 Feb-March 2017 Memo Afr & EngDocument16 pagesPhysical Sciences P2 Feb-March 2017 Memo Afr & EngbuthelezikaybeeNo ratings yet

- Physics: Question-Answer BookDocument16 pagesPhysics: Question-Answer Bookjonas hoNo ratings yet

- Chnage of Standard Gibbs Free Energy For The Decomposition of Sodium Hydrogen CarbonateDocument8 pagesChnage of Standard Gibbs Free Energy For The Decomposition of Sodium Hydrogen CarbonateMay Lee50% (2)

- Chapter 3.2 - Energy Analysis of Closed SystemDocument31 pagesChapter 3.2 - Energy Analysis of Closed SystemKai Faha Lukum100% (1)

- AQA AS Physics Momentum 1QPDocument14 pagesAQA AS Physics Momentum 1QPdzniz.d10No ratings yet

- N4 Engineering Science August 2018Document10 pagesN4 Engineering Science August 2018marakalalampho0No ratings yet

- Thermodynamic Properties of Polystyrene and StyreneDocument9 pagesThermodynamic Properties of Polystyrene and StyreneGlebert Cañete DadolNo ratings yet

- Chemical Engineering ThermodynamicsDocument35 pagesChemical Engineering ThermodynamicsErik WeeksNo ratings yet

- Thermodynamics Properties of FluidsDocument70 pagesThermodynamics Properties of FluidsCesar BravoNo ratings yet

- Unit PressureDocument21 pagesUnit Pressureabandiola3819qcNo ratings yet

- Past QuestionDocument50 pagesPast QuestionNoisyboy GamingNo ratings yet

- Types of HVAC SystemsDocument6 pagesTypes of HVAC Systemsm2110100% (1)

- មេរៀនChapter3Document10 pagesមេរៀនChapter3Yves JuniorNo ratings yet